5 minute read

Engineers of productivity Festo

ENGINEERS OF PRODUCTIVITY

Automation technology powerhouse Festo is a world leader in technical training and further education. The company’s goal: to maximise productivity and competitiveness for customers in factory and process automation.

Festo, named after its founders Albert Fezer and Gottlieb Stoll, is a multinational industrial control and automation company based in Esslingen am Neckar, Germany. The company produces and sells pneumatic and electrical control and drive technology for factory or process automation. Festo Didactic also offers industrial education and consultancy services and is one of the sponsors and partners of the WorldSkills Mechatronics Competitions.

The Festo Group can be found at 250 locations across the world with a total of 20,000 employees, and is a recognised innovator, with 8% of its annual turnover invested in research and development.

Pneumatic and electrical control

In the 1950s, Festo became the first company in Europe to use compressed air as a drive medium in automation. The company now offers over 30,000 products and system solutions for pneumatic and electrical automation technology which, thanks to a large variety of modular systems, can be tailored to specific customer applications in many different factory and process automation industry segments.

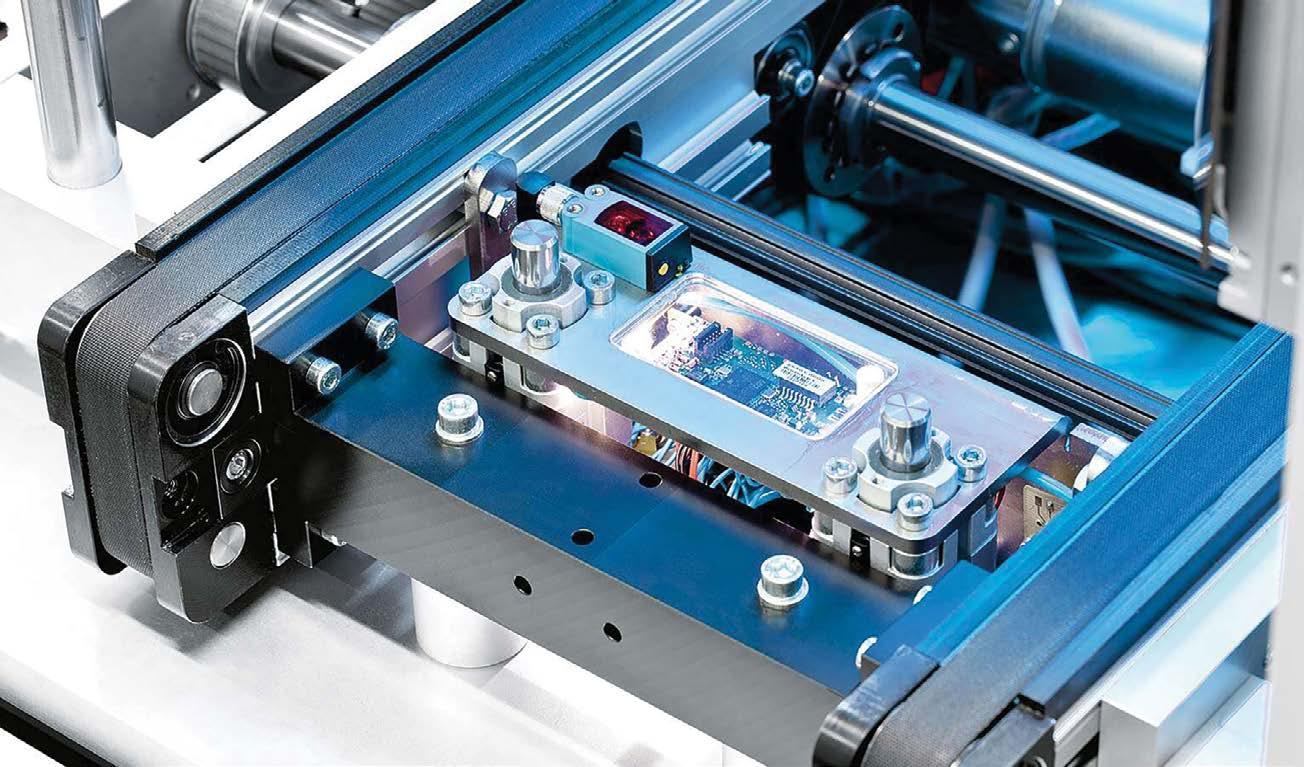

These include pneumatic and electric drives, valves, servo controllers, motion control, valve terminals, installation-saving connection technology, handling and assembly technology, air preparation equipment, fittings, vacuum technology, position and quality inspection, sensors and control technology.

The core product range comprises components from every phase of the pneumatic and electrical control chain, with which around 80% of all applications can be accomplished effortlessly and quickly. Festo also offers a wide range of modular systems solutions and standard handling systems.

Important industry segments are the automotive sector, the food and packing industries, electronics and assembly, biotech, pharmaceuticals and cosmetics, medical engineering and laboratory automation, chemicals and water treatment and, with growing importance, the medical technology and laboratory automation (LifeTech) segments, which have been in focus since the pandemic. Festo also supports all automated process steps in the field of electromobility, from battery production to the production of electric vehicles.

Digital transformation

Festo is advancing digitalisation in all its corporate divisions. To this end, the company is developing new future-oriented concepts founded on the triad of innovative and energy-efficient technologies, intuitive humanmachine collaboration, and education and further training.

As Industry 4.0 and the Internet of Things inspire original equipment manufacturers and end users alike, production and the digital world come together: factory automation is becoming more flexible and energy efficient, logistics processes are more closely interlinked, the value chain is optimised, and all of this in process automation as well.

Festo is playing a key role in shaping the move towards Industry 4.0 and promotes the development with an open automation architecture and a large product portfolio. Standardised software tools are also being developed: configurators for smart engineering, the Festo Automation Suite for easy commissioning and the digital maintenance manager Smartenance for reliable operation. Digitalised pneumatics such as the Festo Motion Terminal VTEM makes pneumatics more flexible than ever before. “The structural change in many sectors is clearly noticeable for us, from the electronics industry to electromobility and life tech. Electrification in the automotive industry is just gaining massive momentum. We are seeing strong demand for automation solutions for electric vehicle, in-vehicle electronics and battery production. In addition, there is a great demand for qualification in the entire spectrum of electrification. This offers us great growth opportunities over the next few years,” explained Chairman of the Management Board, Dr Oliver Jung.

Handling the challenge

Throughout 2020, the Festo Group coped with a 7.5% decline in turnover due to the pandemic. However, the was still able to close with a higher overall operating result above the previous year. After a strong first quarter, the company is expecting a catch-up year in 2021. With smart and intelligent products as well as digital learning platforms, Festo supports the structural changes happening in industry and society – from eMobility to vaccine production and laboratory diagnostics, to energy efficiency and climate-neutral production.

Festo’s products make an important contribution to the fight against Covid-19 - laboratory automation enables high throughput in virus testing, and automation plays a key role in vaccine development and production.

“Automation is the prerequisite for us to be able to supply and treat people worldwide quickly, safely and affordably with a high standard of medical quality – be it with medicines and vaccines, respirators or medical devices. We will therefore continue to strongly expand our LifeTech business in the coming years,” said Jung.

However, the pandemic is not the only challenge that the world is facing, he affirmed. “As a company and a society, we have to manage the balancing act in the pandemic by simultaneously finding ways out of the crisis while pivoting to focus our future activities on sustainability. Automation and technical education are key to this. We also have a social responsibility for sustainable development here. The goal is to gradually develop production in the direction of a circular economy.”

For 2021, like most companies, Festo expects to be playing catch-up. “We started the year well, with strong growth in the first quarter. Nevertheless, the end of the pandemic cannot yet be estimated. We are therefore continuing our savings course. At the same time, we continue to invest in our growth and innovation strategy,” Dr Jung concluded. n