7 minute read

MACHINERY

WATER AUTHORITY HAPPY WITH VENTURI-AERATOR

An Australian Water Authority has recently installed a Venturi-Aeration system from Hydro Innovations into a sludge storage tank to add dissolved oxygen, remove nutrients and mix the tank.

Advertisement

A Gorman-Rupp Super T Series pump was used with a 30kW motor to “drive” the Venturi-Aerator, and the unit was set up to discharge several metres below the surface.

All of the aeration equipment [pump and venturi unit] is located on the outside of the sludge tank, giving operators quick, safe and easy access to the equipment for monitoring. It is also convenient for operators to perform routine maintenance to ensure a long service life for the system.

The system works using Bernoulli’s principle, whereby a decrease in pressure is caused by increasing the speed of a fluid.

The Gorman-Rupp pumps draws fluid from the tank [or lagoon or basin] to be treated, then discharges it into the VenturiAerator, where a nozzle accelerates it up WITH EXAIR

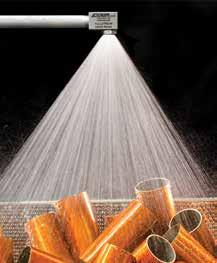

New from EXAIR, the ¼ NPT FullStream liquid atomising spray nozzle provides a full cone spray pattern for pressurised liquids. Whether you’re cooling, washing, cleaning, rinsing or even suppressing dust, the FullStream is the solution.

The tangential flow of the FullStream is vaneless, which creates wide-open internal features to resist clogging. Distribution is uniform in a round pattern with medium to large droplets, while the right-angle design is compact and can operate up to 100 PSIG liquid pressure.

FullStream cone nozzles are particularly effective with liquids containing particulate.

Liquid is supplied into the body of the nozzle, creating a swirling action within a vortex chamber. This vortex produces the spray pattern when the machined nozzle breaks the liquid surface tension as it exits the orifice and into a controlled spray angle.

The stainless steel construction of the liquid atomising nozzle adds to its durability and corrosion resistance. Available now from Compressed Air Australia, the FullStream range of nozzles to 16 metres per second.

This increase in velocity creates a low-pressure area within the Venturi unit, enabling atmospheric air to be drawn into the unit where water and air are mixed under pressure.

The effluent is then discharged, are CE compliant and available in a variety of flow rates.

The FullStream nozzles complement EXAIR’s large line of 1/8, ¼ and ½ NPT Air Atomising and No Drop Air Atomising spray nozzles, all of which come with EXAIR’s five-year built-to-last warranty. Compressed Air Australia 1300 787 688 www.caasafety.com.au saturated with dissolved oxygen. The venturi unit has no moving parts.

Venturi-Aerators are available in four sizes [50mm, 75mm, 100mm and 150mm], enabling the delivery of up to 30kg of dissolved oxygen per hour. Multiple units are used where more oxygen is required.

For large applications, larger single pumps can be used to pressurise multiple Venturi-aerators.

The Water Authority was very particular in specifying parameters for the system to meet, and rate the unit as delivering good performance, ensuring aerobic conditions are maintained.

Their average dissolved oxygen levels of up to 1.3mg/L are being maintained and ammonia nitrogen and phosphorus levels are less than 1.0mg/L.

Hydro Innovations 02 9898 1800

COOL, WASH AND RINSE

www.hydroinnovations.com.au

REDUCE MAINTENANCE COSTS ON OVERHEAD CRANES

LOAD LIMITERS ROPE AND CHAIN CRANES AND HOISTS • Helps reduce the risk of accidents • Protects against overloading of Crane and supporting structures • Quick and easy installation and available for all capacity cranes • Available preset or easily calibrated on site • Helps reduce maintenance costs • Minimizes down time • Automatic reset by reducing the load

CONDUCTOR BAR

Available in steel & copper Quickly and easily installed Supports required only every 1.5m Also available in a compact cluster range SIDE PULL PREVENTERS / ROPE GUIDE PROTECTOR

Prevents side pulling and protects rope guides and drums on most multi-fall cranes & hoist • Prevent dragging of loads • Easily fitted to any crane/hoist • Helps reduce down time

Liftco Industrial Supplies Pty Ltd (02) 9829 4411

sales@liftco.com.au www.liftco.com.au

AUSTAL ACCELERATES SHIPBUILDING WITH EATON SMART WIRING SYSTEM

Perth-based Austal is Australia’s global shipbuilder, defence prime contractor and maritime technology partner of choice, designing, constructing and sustaining cutting-edge defence and commercial vessels for the world’s leading operators.

Since 1988 it has designed and constructed more than 300 vessels for more than 100 customers in 54 countries, gaining an enviable reputation for innovative shipbuilding using advanced technologies and modern techniques.

The company operates shipyards in Australia, the USA the Philippines and Vietnam along with service centres around the world. It employs more than 6800 people and is listed on the Australian Stock Exchange (ASX: ASB).

Need for speed in shipbuilding

With a healthy order book for new vessels and tight delivery schedules Austal wanted to accelerate vessel design and construction.

Austal identified Eaton’s SmartWireDT wiring system as having the potential to significantly reduce the time taken to design and build electrical control panels for its vessels, and provide significant benefits to vessel operators.

Austal now has incorporated SmartWire-DT into multiple vessels including high-speed catamarans and trimarans built for customers around the world: Tahiti, Denmark, Trinidad and Tobago, and the Canary Islands.

The latest is Queen Beetle a next generation 83-metre trimaran ferry for JR Kyushu of Japan being readied for delivery in Austal’s shipyard in Henderson, Western Australia.

These vessels typically have up to 10 control panels fitted with multiple motor starters, switches and indicator lights to control and monitor the operation of electric motors that power pumps, fans and drives around the vessel

Traditionally these panels have been built using individual motor starters, door switches, relays and control wiring that was a labour-intensive task and could be prone to errors due to its manual nature.

A smarter way to wire control panels

In contrast, SmartWire-DT eliminates control wiring and speeds up the assembly process by easily plugging in function modules to each starter.

It uses a single flat eight-wire ribbon cable to connect all switches and indicator lights to motor control modules.

The cable is easily installed with clip-on function modules that pierce the insulation to connect each switch or lamp to the wire inside.

Keith Hudson, Control and Monitoring Manager at Austal, said SmartWire-DT had greatly reduced the time taken to design, build and test control panels, and these time savings had been a significant factor in Austal’s decision to use SmartWire-DT.

“The system we were using before needed about 45 minutes per circuit. That is for all the wiring associated with each motor starter and switches on the panel door. With SmartWire we were able to wire up an entire panel in 45 minutes.

“Plus we reduced the motor control circuit design to one page instead of 10 pages with the previous technology, significantly decreasing the design and assembly timeframe.”

Software enables real-time monitoring

Eaton’s Commercial Marketing Manager, Australia & New Zealand, Sanjay Kallianpur, said SmartWire-DT was complemented by Eaton’s SWD-Assist software that helps with panel design and facilitates testing of a panel during construction, as well as providing real-time monitoring for the customer once the system is in operation.

“SmartWire-DT is a structured wiring solution that, with SWD-Assist, delivers information on the status of the connected device: it makes dumb products into smart products,” he said.

“You can just plug components in and use SWD-Assist to get information out of the product for the customer. Other products on the market use a similar wiring bus but they need additional components to communicate.”

Keith Hudson added: “We receive diagnostic information through SWDAssist that we weren't able to get from our other system. Previously we would have needed another module and communications interface, doubling the cost of each motor starter.”

He said this feature, providing live maintenance data, had been a hit with customers. “That’s been a good selling point for us. Our customers can take the output from SWD-Assist into their maintenance packages and analyse the data over time.

Previously they would just run a motor until it tripped out on overload, or failed completely. But if they lose a sailing because of motor failure, the cost can easily run into the tens of thousands of dollars.”

Certified for marine applications

An additional, and essential, feature of SmartWire-DT for Austal was its certification by DNVGL the world’s leading classification society, for use in control panels for maritime applications.

“SmartWire has a number of certifications but the DNVGL certification is widely recognised and it’s the one required by Austal’s customers,” Mr Hudson said.

He concludes: “We have found SmartWire to be more than fit for purpose. That’s important for our customers as availability and through-life support are a big concern, with vessels in service for 20-plus years, and that is something we design for.”

Austal www.austal.com

Eaton www.eaton.com