5 minute read

FROM THE PUBLISHER

PUBLISHER SCOTT FILBY

Welcome aboard! New editor joins Industry Update

Advertisement

I would like to give a warm welcome to our new editor, Barry O’Hagan.

Barry brings a wealth of experience to the role, having worked as a media professional for more than 25 years.

His editorial guidance will help Industry Update reach even greater heights and build on its strong relationships with people and businesses in the manufacturing industry.

He has a proven record of finding innovative ways to share what’s new and what’s important. A former newspaper and magazine journalist, he has a passion for telling the stories of businesses and the people that work in them.

Most recently, Barry worked as a communications professional for IBM Australia and in a number of freelance roles in media production. Prior to that, he edited several trade and lifestyle magazines and served as deputy chief sub-editor on a daily newspaper in South Africa.

Since former editor Laurence Marchini retired in March 2020, Industry Update made an extensive search to find the right person – someone who shares a passion for the Australian manufacturing industry.

While COVID-19 has been a profound challenge for Australia and the world, we are seeing a silver lining with an incredible resurgence in parts of the Australian manufacturing industry.

Industry Update Manufacturing Magazine is also enjoying a significant growth period, and with the launch of the new Industry Update TV show expected in May 2021, the company will continue to grow and break new ground.

It’s a pleasure working with Barry, and I am unsurprised to see he has delivered a strong first issue with its focus on Australian Made.

With the inaugural Australian Made Week just around the corner in May, it’s timely to reflect on the importance of domestic manufacturing to the nation’s wellbeing.

Over 900,000 Australians depend on the manufacturing industry for their employment. That’s nearly four times the number of workers in mining, and over two and a half times the number in agriculture, forestry and fisheries.

Moreover, the country has a strategic interest in maintaining domestic manufacturing capability as Industry Update has long argued. In the past, some have waived away this truth as nothing more than the special pleading of vested interests. In the wake of COVID-19, not many are saying that now.

It’s important to think about these flowon effects when making our purchases.

In buying Australian Made, we not only support local manufacturers, growers and craftspeople, we benefit by purchasing products from a country with a reputation for quality.

It’s no surprise that research by Roy Morgan has found that most Aussies like to buy Australian.

With continued hard work by local manufacturers, good policy from government, and wise choices by local consumers, Australian manufacturing can look forward to a bright future. Thank you for reading Industry Update magazine, which is now in its 26th year of publication. You are among 76,968 readers who leaf through our publication to stay on top of what’s happening in both manufacturing and in industry in general. Industry Update is proud to be the go-to source for news and views. We aim to give our readers a better understanding of the issues of the day and inform them about the latest and greatest from Australian manufacturers and distributors.

There are few areas more topical at the moment than the return of manufacturing to our shores – a subject close to our hearts at Industry Update. You will find it is a recurring theme throughout the magazine. For example, on page 11 we have a story based on a survey of more than 500 senior manufacturing employees in Australia. It reveals that more than half of those who have offshored their operations intend to bring them back by 2023.

Starting on page 20, we also have 10 pages dedicated to Australian manufacturing, led by an in-depth look at the upcoming Australian Made Week being organised by the Australian Made Campaign. This campaign will run towards the end of May and should help draw attention to the myriad facets of local manufacturing. Our stories also explain everything there is to know about Australian Made, including how to register for a licence to use the iconic green and gold kangaroo logo.

Another important issue affecting many of us is the role of women in industry, and in particular in manufacturing. In the words of Dr Jens Goennemann (see page 14), the Managing Director of the Advanced Manufacturing Growth Centre: “Australian manufacturing is the engine room of advancement underpinning our moves from a lucky country to a smart country and women must play a bigger role. We also have commentary from former Federal Minister for Industry, Science and Technology, Karen Andrews and advice from several women who have excelled in their careers in manufacturing.

We again feature guest editorials from prominent politicians, although regular columnist Karen Andrews has moved on from her role and is now Minister for Home Affairs. Former Attorney-General Christian Porter has stepped in as Minister for Industry, Innovation and Science but was on leave at the time of going to press. We would like to welcome Ed Husic, Shadow Minister for Industry and Innovation as a columnist.

Also look out for our coverage of workplace health and safety, which focuses on mental health and Covid-19 vaccination scams, as well as a story about a company that makes automotive testing equipment alongside peanut butter machines. Our article on manufacturing success story PackServ (page 30), which makes manufacturing machinery, is also worth a read.

EDITOR BARRY O'HAGAN

Your Global Automation Partner

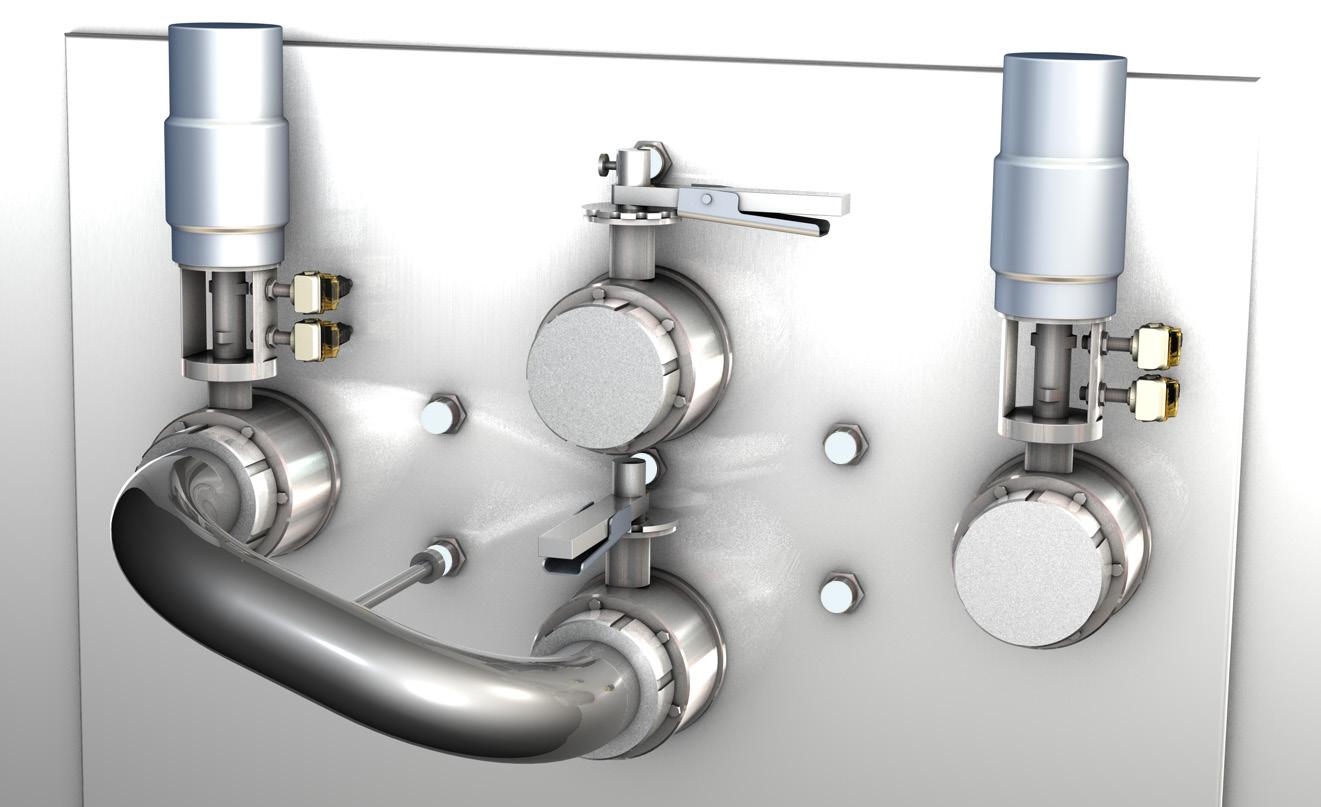

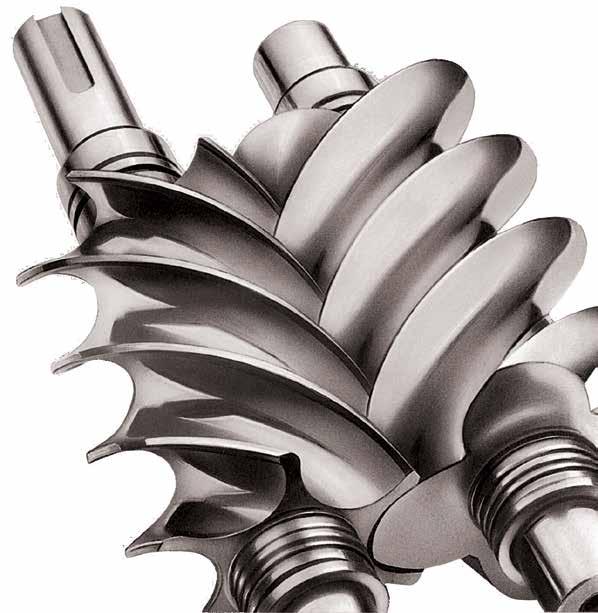

Get More Reliable Detection of Valves in Processing Applications

Choose rugged inductive sensors to more reliably monitor the position of valve handles on tanks and containers during processing applications. Actuated valves receive control signals from sensors and other devices to enable more efficient processing. With an assortment of potential mixtures, it is important to use sensors that are accurate, can optimize machine efficiency and stand up to harsh cleaning.

Wash-down rated Uprox Inductive sensors from Turck are ideal for liquid processing lines, in filling functions, or other types of food processing machinery to detect metal valves. Plus, IO-Link makes remote monitoring easy.