8 minute read

Industry News

How Circular Economy Can Transform

the Manufacturing Industry Continued from page 7.

Advertisement

manufacturing process from standard to a more sustainable method.

As a result, companies are now creating materials from previously discarded products, which diverts the waste from landfills and also reduces the cost of materials.

For instance, furniture manufacturing plants use disposed wood products. Such practices prevent the active cutting of trees and enrich the economy. The use of discarded wood products also reduces post-consumer waste in the immediate environment.

Expansion of Secondary Manufacturing Services

Circular economy continues to create demand for new essential services. The implementation of this model aims to reuse products for long periods. As a result, many service companies can continue to grow, including logistics, collection, refurbishment, remarketing and remanufacturing.

Such service companies promote the reusing and recycling of disposed of materials. They do so by channeling them back to manufacturing plants.

The manufacturing industry spends less money on purchasing raw materials and related logistics. The lower costs of production translate to increased profit margins. So, the manufacturing industry expands due to the implementation of circular economy.

Increases Business Satisfaction

Circular economy promotes an increase in business satisfaction through corporate social responsibility. As a result, increasing demand for sustainable products in the current market.

Businesses also must shift and adapt to new approaches to meet the demand, which must also take into account producing revenue. Circular economy is well-structured to help increase business satisfaction.

The model also ensures that materials and products stay in use. It does so through design in the manufacturing industry. Keeping materials in use for extended periods increases their value to various industries.

Combined with a circular economy model, corporate social responsibility does not attract ordinary employees, but ambitious employees who aim to change the manufacturing industry. Such employees promote the implementation of the model, which helps industries realise their set goals.

Moreover, circular economy has raised the business market value by approximately 6%. It has also raised employee productivity by approximately 13%.

Saves More Resources

In the linear approach, extraction is the common method of sourcing raw materials. However, since these raw materials decline, many manufacturing industries need to save resources. One way to do this is by implementing the circular economy approach.

Research shows that this economic model results in 70% material savings. Industries will continue scrambling for scarce raw materials with the growing population. Companies that have embraced circular economy are more likely to secure their viability.

Is the Circular Economy Model the Way To Go?

The circular economy model continues to take centre stage in the manufacturing industry. It redesigns waste.

Its aim of recycling and reusing waste as raw material is eye-opening. A lot of industries use and adapt the idea. It harbours many benefits. This is a concept that keeps improving with each dawn.

FAQs

Here are some commonly asked questions about circular economy:

What is the major drawback of circular economy? The circular economic model lacks strategic standardisation and guidelines. The principles of this model exclude the not-fully-recyclable materials. They do not provide proper guidelines on how to handle such materials, which is biased.

What is one way to improve circular economy? Like most models, circular economy can accept changes for the better. Encouraging less consumption of raw materials is one way to improve the model so that it focuses on the efficient use of raw materials. It does not focus on the industry consumption of materials.

Is circular economy sustainable? Circular economy is sustainable. The model promotes and designs reusable products that are viable to industries. It ensures such materials last for long. It aims to maintain the value of materials, making them sustainable.

EFFECT

DATA-DRIVEN SOFTWARE THAT DATA-DRIVEN SOFTWARE THAT SYNCHRONIZES PEOPLE, PROCESSES SYNCHRONISES PEOPLE, PROCESSES AND MACHINES AND MACHINES

PROCESSES _

MEET YOUR SPECIFIC INDUSTRY REQUIREMENTS. PEOPLE _ RIGHT PEOPLE WITH THE RIGHT EXPERTISE MAKE THE DIFFERENCE.

MACHINES _

RIGHT AUTOMATION MAXIMIZES MACHINES_RIGHT AUTOMATION MAXIMISES EFFICIENCY, FLEXIBILITY AND AGILITY. EFFICIENCY, FLEXIBILITY AND AGILITY.

2 Business, Finance & Accounting 9 Industry News 12 From the Publisher 16 FoodTech 24 Women in Manufacturing 26 Packaging & Labelling 30 ARBS 32 CeMAT 39 Materials Handling 44 Australian Made 48 Products 54 Events / Book Review 56 Machinery

OneCNC Makes Manufacturing Easy

52

automatic lubricator

simply superior! single point lubrication

NO batteries NO maintenance

Less maintenance downtime Increased productivity

www.dis.com.au

MANUFACTURING MAGAZINE

Industry Update Media Pty Ltd ABN 25 083 502 783 Suite 403, Level 4, 116-118 Christie Street, St. Leonards NSW 2065 +61 2 9439 1288 / sales@industryupdate.com.au Circulation 19,242 Readership 76,968 as at September 2018

All material in this publication is copyright to the publisher and/or its contributors. No material may be reproduced in part or in whole without the written consent from the Publisher. It is a condition of purchase or acceptance of this magazine that the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission on this publication or from the use of the information in this publication or from the use of the information and illustrations contained herein and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein. © Copyright Industry Update Media Pty Ltd 2022

Publisher

SCOTT FILBY

scott@industryupdate.com.au

Editor

EDITOR

editor@industryupdate.com.au

Sub-Editor

SYLWIA PRZYBYLA

subeditor@industryupdate.com.au

Advertising Sales Director

SCOTT FILBY

scott@industryupdate.com.au

Advertising Sales Manager

DOMINIC TUSA

dominic@industryupdate.com.au Marketing Manager

DUMI UDESHIKA

marketing@industryupdate.com.au

Creative Director

EDWIN KWONG

production@industryupdate.com.au

Production Manager

DUMI UDESHIKA

copy@industryupdate.com.au

Video Editor & Producer

CHARLIE LOUGHLIN

video@industryupdate.com.au

Office Manager

NICOLE CHARLES

nicole@industryupdate.com.au

Web Developer

JINI M R

Finance & Accounts

MICHELLE ALCOCK

michelle@industryupdate.com.au

Consultant

TRACY FILBY

tracy@industryupdate.com.au

Accounts Receivable

LYN SLIGAR

lyn@industryupdate.com.au

Subscription Assistant

SAM HICKS

info@industryupdate.com.au

Circulation Assistant

TAYLOR PARSONS

circ@industryupdate.com.au

Printer OVATO

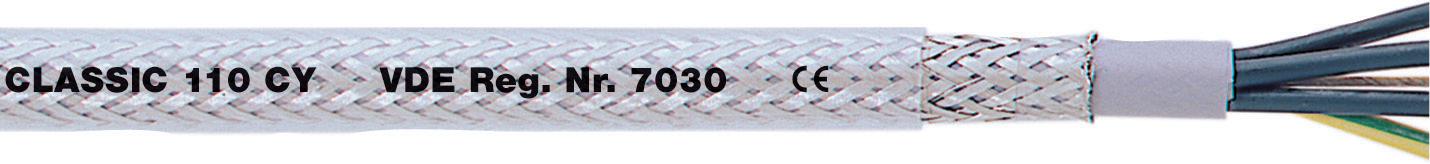

Treotham has all your VSD cable & glands needs covered

Treotham Automation supply an extensive range of high quality electrical exible cables and accessories from . The range is available from stock in Sydney, Melbourne, Brisbane & Perth. With a full range of industrial products, our technical engineers are able to provide fast and reliable service and custom-built solutions for special applications.

Hidden costs of battery replacements a thing of the past

Australian businesses can potentially save thousands of dollars annually and help them move closer to achieving their carbon emission targets with a simple battery switch, according to a leading battery manufacturer.

Procell, the professional batteries arm of leading global manufacturer Duracell, has developed a cost calculator, using Australian specific data, to help businesses identify hidden costs associated with battery replacement and its environmental impact.

It is estimated that sectors, such as hospitality, could save up to 44 percent in battery related costs by using the right battery, with the improved efficacies reducing battery replacements, labor costs and appliance downtime.

Duracell Asia B2B senior director Jane Lo, demonstrated the new cost savings calculator at Australia’s premier facilities management conference, Total Facilities 2022 held in Melbourne 10-12 May.

“In today’s highly automated, always-on business environment, there’s a heavy reliance on battery operated devices for companies to operate seamlessly. As a result, business expenditure on battery replacements has increased,” Lo explained.

“Batteries play an important role in the overall safety, performance, and reliability of many devices whether in a hospitality, security or medical setting. If it’s buying batteries for remote controls, smoke alarms, or sanitiser dispensers, we want to help businesses explore ways to increase efficiencies by replacing batteries less and save more.”

Different battery needs

High frequency, high drain devices (typically those operating a motor or mechanism such as electric door locks or blood pressure monitors) have different battery needs compared to intermittent low drain devices (such as remote controls or blood glucose meters).

“Taking into account device functionality when selecting batteries can achieve longer-lasting consistent performance, which in turn means fewer replacements and less expenditure,” Lo added.

She noted that saving time and labour replacing batteries is particularly critical in the current labour market, with chronic staffing pressure being felt in both healthcare and hospitality, two sectors that also have a high reliance on battery automation.”

Procell is a professional range of device specific alkaline batteries designed to minimise battery replacements and reduce the environmental impact of battery waste. It is the only range of high performing batteries with products tailored for both low drain and high drain devices.

Cost savings

The new cost calculator helps organisations determine the right Procell battery for each appliance across their business and identifies the potential cost savings, as well as environmental benefits of a reduction in battery turnover.

“We listened to the market and heard that businesses were looking for alternatives to the never-ending cycle of purchase-use-dispose-repeat when it comes to batteries,” Lo said.

Procell, and local importer Pental, are signatories of the Battery Stewardship Scheme (BSS) designed to encourage recycling and better waste management of end-of-life batteries. As accredited collectors, processors and recyclers of used batteries, they receive an import levy rebate further reducing the cost of the range.

Duracell Asia B2B senior director Jane Lo, said estimates indicate that some sectors could save up to 44 percent in battery related costs by using the right battery.

*Based on a 500 room hotel switching to Procell’s product portfolio. This is an estimated cost calculation based on specific makes` and models of devices versus relevant competition. The results will vary based on specific devices, usage habits, current batteries used, size of facilities, conditions and commercial maintenance schedules of devices including wages.