Also available in Sri Lanka, Malaysia, Singapore, Thailand, Taiwan, China & Hong Kong

EDITORIAL

On the makeover mode

A

s the Indian economy continues to surge at close to nine per cent per annum, and considering the dismal status of infrastructure in the country at present, it is not surprising to see the mega investments being planned towards it. Besides, the oil & gas sector has an ambitious target to achieve refining capacity of 302 MMTPA by 2017, as a part of ` 2.8-trillion investment for the 12th Plan period. Likewise, massive investments are in the pipeline towards greenfield/brownfield LNG terminals for meeting the rising LNG needs of consumers in energy and fertiliser sectors. Also, the Petroleum, Chemicals and Petrochemical Investment Region (PCPIR) policy, aimed at promoting integrated mega chemical clusters in the country, is expected to attract enormous investments. All these developments indicate the huge growth potential for the Engineering Procurement and Construction (EPC) activities in India. It is important to note here the changing dynamics in this arena as there is a growing trend towards appointing EPC contractors who would take single point responsibility for the entire project and be responsible for project management on a day-to-day basis. However, one of the key challenges facing the client today is ascertaining about the safety aspect of EPC contracting method. Some of the related issues include more complex and larger projects,

Business Insights Technologies Opportunities

Editor : Manas R Bastia Assistant Editor: Rakesh Rao Senior Features Writer: Prasenjit Chakraborty Features Writer: Mahua Roy Correspondent: Avani Jain (Ahmedabad) Copy Editor: Marcilin Madathil Edit Associate - Products: Paskaline Sebastian Assistant Art Director: Varuna Naik Chief Photographer: Mexy Xavier Photographer: Neha Mithbawkar, Joshua Navalkar Design: Mahendra Varpe Production: Vikas Bobhate, Pravin Koyande, Dnyaneshwar Goythale, Ravikumar Potdar, Ravi Salian, Sanjay Shelar, Lovey Fernandes, Pukha Dhawan, Varsha Nawathe, Akshata Rane, Abhay Borkar Marketing & Branding: Jagruti Shah, Ganesh Mahale CEO-Publishing: Sandeep Khosla Associate Vice President: Sudhanva Jategaonkar Subscription: Sunil Nair, Distribution Head Email: sunil.nair@network18online.com, customercare@infomedia18.in Tel: 91-22-3003 4631/4633

higher risk exposure, delay in the finalisation of contracts due to lengthy negotiations/budget issues, etc. Given this scenario, the Lump Sum Turnkey mode of execution seems to be having an edge in terms of client preference, primarily because of transfer of almost all associated risks to the EPC contractor by virtue of assigning single point responsibility towards quality, price and timely delivery. Turn to ‘Sector Watch’ and ‘Market Scope’ to track some of the latest practices as well as future prospects in the EPC segment, with a special focus on India. Now, let us look at the field of effluent treatment, where a significant shift has occurred in the recent times. Thanks to the advent of new technologies such as reverse osmosis, nanofiltration, membrane bioreactors, etc, effluent treatment is not only controlling water pollution but also helping to conserve the resources as well as energy. ‘Industry Update’ offers several insights as to how biotechnology can offer a cheaper and cleaner alternative to conventional effluent treatment processes that utilise chemicals.

Editorial Advisory Board Pothen Paul Executive Chairman, Aker Powergas Pvt Ltd D P Misra Director, TCE Consulting Engineers Ltd and Former Director General, ICC P D Samudra Executive Director (Sales) & Member of the Board, Uhde India Ltd

Manas R Bastia Editor manas@infomedia18.in

Editorial & Business Office Infomedia 18 Ltd, Special Interest Publications Division, ‘A’ Wing, Ruby House, J. K. Sawant Marg, Dadar (W), Mumbai 400 028 Tel: 91-22-3024 5000/3003 4672, Fax: 91-22-3003 4499 Email: chemedit@infomedia18.in

New Delhi (Mukesh/Surendra): Tel: 011-6630 3278 Fax: 011-2332 7884 Email: sipd.delhi@infomedia18.in

Other Business Offices Ahmedabad (Shashin): Tel: 079-3982 6432 Fax: 079-3982 6464 Email: sipdahmedabad@infomedia18.in

Surat (Sunil): Tel: 0261-263 0181 Fax: 0261-263 0974 Email: surat@infomedia18.in

Mumbai : Tel: 022-3003 4640 Fax: 022-3003 4499 Email: spmktg@infomedia18.in

Pune (Rohit): Tel: 020-3322 3309 Fax: 020-3322 3322 Email: sipd.pune@infomedia18.in

Bangalore (Mahadev B): Tel: 080-3001 0900 Fax: 080-3001 0999 Email: sipd.bang@infomedia18.in

Vadodara (Samarth): Tel: 0265-392 6500/1 Fax: 0265-235 6013 Email: vadodara@infomedia18.in

Chennai (Hari): Tel: 044-3986 4200 Fax: 044-3986 4250 Email: sipd.chennai@infomedia18.in

Jaipur (Durgesh): Tel: 0141-300 7414; 300 7411 Fax: 0141-221 3728 Email: sipd.rajasthan@infomedia18.in

Ringier Trade Media Ltd Overseas Contacts China: Tel: +86 21 6289 5533 Ext. 368; Fax: +86 21 6247 4855 Email: craig@ringier.com.hk Hong Kong: Tel: +852 2369 8788 Ext. 21; Fax: +852 2869 5919 Email: octavia@ringier.com.hk Taiwan: Tel: +886 4 2329 7318 Ext. 16; Fax: +886 4 2310 7167 Email: sydneylai@ringier.com.hk Singapore: Tel: +65 9625 7863; Fax: +65 6841 5273 Email: annie@janianmedia.com Germany, Austria, Switzerland: Tel: +41 44 734 0472 Fax: +41 44 734 0680 Email: info@islerannoncen.ch

Kolkata (Deb Ranjan): Tel: 033-2265 8637/38 Fax: 033-2265 2964 Email: sipd.kol@infomedia18.in

B2B Portales: Tel: +1 305 4486227 Email : tbeirne@b2bportales.com

Ludhiana (Inder): Tel: 0161-302 6198/99, 302 6200 Fax: 0161-302 6198 Email: ludhiana@infomedia18.in

Issue Price: ` 100

Cochin (Robin): Tel: 0484-4054 380/90 Fax: 0484-405 4370 Email: kochi@infomedia18.in Coimbatore (Prakash): Tel: 0422-309 2600 628 Fax: 0422-309 2666 Email: coimbatore@infomedia18.in Hyderabad (Rahul): Tel: 040-3064 7600 Fax: 040-3064 7676 Email: sipd.hyderabad@infomedia18.in Indore (Ameya): Tel: 0731-307 4876 Fax: 0731-307 4882 Email: sipd.indore@infomedia18.in

Annual Subscription: ` 799

Printed by Mohan Gajria and published by Lakshmi Narasimhan on behalf of Infomedia 18 Limited and printed at Infomedia 18 Ltd, Plot no.3, Sector 7, off Sion-Panvel Road, Nerul, Navi Mumbai 400 706, and published at Infomedia 18 Ltd, ‘A’ Wing, Ruby House, J.K.Sawant Marg, Dadar (W), Mumbai - 400 028. Chemical World is registered with the Registrar of Newspapers of India under No. 14798/2005. Views and opinions expressed in this publication are not necessarily those of Infomedia 18 Limited. Infomedia 18 Limited reserves the right to use the information published herein in any manner whatsoever. While every effort has been made to ensure accuracy of the information published in this edition, neither Infomedia 18 Ltd nor any of its employees accept any responsibility for any errors or omission. Further, Infomedia 18 Ltd does not take any responsibility for loss or damage incurred or suffered by any subscriber of this magazine as a result of his/her accepting any invitation/offer published in this edition. No part of this publication may be reproduced in any form without the written permission of the publisher. All rights reserved. Editor: Manas R Bastia

June 2011 | Chemical World

7

CONTENTS

19

LEADERS SPEAK 19

“The chemical industry needs to set its house in order” ...says Prasad Chandran, Chairman, BASF Companies in India, & Head - South Asia

ROUNDTABLE 22

Effluent treatment systems: Imperative to make them more effective

FACILITY VISIT 26

IKA India: Aiding R&D, empowering innovation

SECTOR WATCH 30

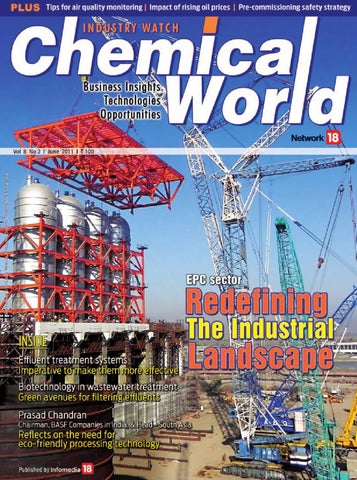

EPC sector: Redefining the industrial landscape

22

MARKET SCOPE 36

Engineering and contracting: Ready for the global leap? Pothen Paul, Chairman and India Country Manager, Aker Powergas Pvt Ltd

INDUSTRY UPDATE 39

Biotechnology in wastewater treatment: Green avenues for filtering effluents

QUALITY MONITOR 42

Ambient air quality monitoring: Curbing unsafe atmospheric elements Samir Bhandarkar, Divisional Manager, Forbes Marshall, Pune

COATINGS CORNER 47

Rising oil prices: A challenge for supply chain Dr Mosongo Moukwa, Vice President - Technology, Asian Paints Ltd

30

SAFETY ZONE 50

Plant pre-commissioning: Getting set for the next level K N K Murthy, Consultant

TREND ANALYSIS 52

Exhaust air purification: Blowing the winds of change Varun Gupta, Senior Sales Manager - EES, Durr India Pvt Ltd

CASE STUDY 54

Efficient ERP: Saving resources with enterprise-wide collaboration Courtesy: SAP Cover photo courtesy: Essar Projects (India) Ltd

R EG U L A R S EC TI O N S

39

47

Editorial ...................................................... 7 National News ......................................... 10 National News - Report .......................... 16 World News............................................. 17 Events Calendar ....................................... 60 Product Update........................................ 66 Product Index........................................... 71 Advertisers’ List ....................................... 72

Highlights of Next Edition Sector Watch

: Logistics & Supply Chain Management

Industry Update : Petrochemicals Note: ` stands for Indian rupee, $ stands for US dollar and £ stands for UK pound, unless mentioned otherwise

8

Chemical World | June 2011

Details on page no. 27-28, 56-59, 60, 70

NATIONAL NEWS

INVESTMENT

CSR EFFORTS

BASF launches major ‘Water Education’ project in Mangalore BASF in partnership with UNHABITAT recently announced a new project to promote water education in Mangalore. The project aims to promote water education in schools and improve water quality monitoring in Mangalore. The Energy and Resources Institute L-R: Pronab Dasgupta, Andre Dzikus, (TERI) will implement the project Prasad Chandran and Dr Hartmut Unger over the next two years. As a symbolic commitment to the project objectives, Prasad Chandran, Chairman, BASF Companies in India, and Head - South Asia; Dr Hartmut Unger, Head – BASF Social Foundation; Andre Dzikus, Chief – Water and Sanitation Section II, UN-HABITAT; and Pronab Dasgupta, Senior Advisor and Director, TERI, signed a statement of purpose. In his address, Chandran said, “BASF is committed to conducting business sustainably. We are also committed to choosing social projects that will have a positive impact on the communities in which we operate.” The ‘Water Education’ project will encompass 5,000 students from 25 schools in Mangalore. Provision of access to safe drinking water will be provided to students in these schools as well as communities in the vicinity of these schools. Out of the 25 schools, 8 will be equipped with ‘water laboratories’ to facilitate water quality monitoring and 2 will have ‘water classrooms’ to educate students on water cycle and water conservation methods. In addition, water quality testing kits will be provided to select schools for field analysis benefitting communities living around the schools.

IFFCO inks pact with IFC and EIB to raise ` 1,500 crore Fertiliser major IFFCO recently announced that it has signed a financing agreement with International Finance Corporation (IFC) and European Investment Bank (EIB) to raise debt of ` 1,500 crore for its joint venture phosphoric acid project in Jordan. The co-operative IFFCO and Jordan Phosphates Mines Company (JPMC) had formed a joint venture Jordan India Fertiliser Company (JIFCO) in 2008 to set up phosphoric acid plant at an investment of $ 625 million. In the JV firm, IFFCO holds 52 per cent equity, while JPMC holds 48 per cent. The annual capacity of plant is 4.75 lakh tonne. IFFCO will purchase a minimum 70 per cent of the production of phosphoric acid under a long-term agreement for domestic consumption, while JPMC will buy the balance. The foundation stone for the project was laid in October 2009, and commercial production is expected to start by mid 2013. JPMC will supply the required quantity of rock phosphate under a longterm supply agreement. “This joint venture project will provide assured supply of phosphate fertilisers to Indian farmers for sustenance in food grains production,” said U S Awasthi, Managing Director, IFFCO.

FILAMENT WINDING

CPP announces commissioning of plant Chemical Process Piping (CPP) recently announced the commissioning of its new Continuous Filament Winding (CFW) Plant, in Vadodara. The CFW plant will produce Glass Reinforced Plastic (GRP) pipes and sleeves from sizes 300-2600 mm diameter. The plant has the ability to manufacture cross-country piping for conveying potable water, sea water and wastewater. Initially, the company is aiming to target the Indian market and later, South East Asian markets. Rated capacity of the unit is 18,000 MT of GRP per year. CPP is estimated to cross ` 100 crore in year 2011-12 and achieve a turnover of ` 500 crore by 2015.

10

Chemical World | June 2011

Vijay Rajpurohit, Managing Director, CPP, said, “We are looking forward to foray into the water industry. With rapid increase in population, there is scarcity of water on one hand and increased need for electricity on the other. These problems can be solved by implementing desalination projects and setting up power plants. In both cases, large amounts of GRP piping would be required.” In fact, in Maharashtra itself, the state government has set up a high powered committee to make a feasibility report, which will enable the government to set up two desalination plants in Mumbai

Vijay Rajpurohit addressing the audience

to tackle the overdependence of the city on rain water. With the commissioning of these plants, CPP foresees a huge demand for GRP pipes that are low on maintenance, highly resistant to soil corrosion and sea water, do not need special linings on the exterior and are available at a competitive price.

NATIONAL NEWS

NEW FACILITY

RCF mulls over superphosphate unit Rashtriya Chemicals & Fertilisers (RCF) may set up a single superphosphate (SSP) unit at a cost of ` 3 billion at its Thal plant, as per Gautam Sen, Director - Finance, RCF. “Demand for complex fertilisers is growing and it has better margins. Hence, we are considering a plant for SSP,” Sen said. The state-run company also plans to expand urea manufacturing capacity at its Thal plant, Maharashtra, and at Talcher, Orissa, at a total investment of ` 120 billion. “Each of the expansion projects would raise our urea capacity by 1.15 million tonne per year,” said R G Rajan, Chairman and Managing Director, RCF. Both units are expected to start commercial production over a period of three to five years, he said adding state-run GAIL India and Coal India were joint venture partners for the Talcher expansion. RCF expects sales to rise by 20-25 per cent to about ` 70 billion in FY12 on higher imports, said a company official. “Last year, our domestic production and sales did increase but the imports were lower. This year, we expect sales to grow on imported products,” added Rajan.

INNOVATION

Clariant showcases new dimensions in textile processing The textile chemicals business of Clariant Chemicals (India) Ltd showcased its ecoefficient Pad/Sizing-Ox denim processes, one of the groundbreaking innovations developed under Clariant’s Advanced Denim concept, at the Kingpins India Denim Show, New Delhi. The key talking point was Clariant’s focus on more colours, performance and sustainability that will help take denim to a new dimension altogether. Clariant’s Advanced Denim concept sets a new benchmark in denim production that unites technological and ecological advances with new fashion effects. Effectively, Advanced Denim combines the advantages of Peter unprecedented fashion flexibility with more sustainable, ecoefficient manufacture to create a win-win situation for producers and consumers alike, claimed the company. The result of an ongoing development and innovation process, Clariant’s new sulfur dye-based concept combines the advantages of high performance with an ecological profile that complies fully with the latest environmental requirements. As per the company, the new Clariant specialty Diresul RDT Indicolor dyes enhance denim’s look and feel, add a vast range of new shades and wash-down effects, and create finishes

that leave indigo-based denims trailing behind. Denim-Ox, another Advanced Denim innovation, is a compact, versatile dyeing process that can be adapted to any equipment and mechanical conditions. In this process, the dye is fixed using oxidation/fixation and requires no previous washing. The process fixes the dye firmly and saves significant quantities of water. P Rajasekaran, Head of Textile Chemicals Business of Clariant, India, explained, “Clariant India is committed to the denim segment and would like to have a more active role. The Kingpins Denim Show has been a platform for that objective.” Palm Peter Palm, ViceChairman & Managing Director - Clariant Chemicals (India) Ltd, explained, “Globally, Clariant has begun reaping the benefits of its continuous restructuring, undertaken since the past two years, and succeeded in building a solid platform for profitable growth. The primary focus in 2010 continued to be on ‘Project Clariant’, which was launched in 2008 with the aim of generating cash, reducing costs and streamlining processes to reduce complexities.” Clariant is now looking towards improving profitability across all its business units, as well as increasing value, he added.

EPC PROJECT

Coromandel International appoints Uhde India to build NPK DAP plant

Coromandel International, among the leading manufacturers of phosphatic fertilisers in the country, has appointed Uhde India to design and construct a 65 tonne per hour urea grade NPK plant at the former’s fertiliser complex in Kakinada, Andhra Pradesh. The plant,

12

Chemical World | June 2011

which has a completion period of 20 months, will be built by Uhde India on Lump Sum Turnkey (LSTK) basis. The technology for the plant will be provided by Incro (Spain), whose proven state-of-the-art pipe reactor technology is at work in a number of plants in India, including plants executed by Uhde India for several leading fertiliser majors. When completed, the complex will boost Coromandel International’s combined phosphatic fertiliser capacity to 3 MMTPA from its facilities

at Kakinada and Visakhapatnam, where Uhde India has also successfully implemented a NPK plant at Coromandel’s Visakhapatnam facility in the year 2000. Coromandel International has been associated with Uhde India from the nineties for fertiliser projects as well as for low temperature cryogenic storage facilities at their Kakinada, Visakhapatnam and Chennai facilities. Uhde India has executed a number of projects for DAP-NPK fertiliser plants in India and abroad.

NATIONAL NEWS

INVESTMENT

HPL to invest ` 4,000 crore in WB Haldia Petrochemicals (HPL) is planning to invest about ` 4,000 crore in eight projects in West Bengal. “The change of guard in the state is allowing us to think about many new things. A fresh hope is there in terms of our dealing with the state, the new government wants to take actions quickly. We are planning to invest ` 4,000 crore in eight different projects over a period of three to three-and-a-half years once it gets started,” said Purnendu Chatterjee, Chairman and ViceChairman, HPL. The projects include ethylene propylene diene monomer (EPDM), styrenebutadiene rubber (SBR) and maleic anhydride.

14

Chemical World | June 2011

INSTITUTE RANKING

ICT ranked 4th in research standards Institute of Chemical Technology (ICT), Mumbai has been ranked fourth in the world by a recent survey on the research standards of engineering and technology institutes. “Prof Jude Sommerfeld of Georgia Institute of Technology, USA has been publishing annual surveys on research standards of engineering and technology institutes in the world. His survey published this year shows that the ICT stands number one in India and number four in the world,” said Prof G D Yadav, Director and Vice Chancellor, ICT. Dr G D Yadav The institute has on its roll 537 full-time PhD students with full fellowships and 319 Masters students, which is a record. It also publishes more than three international peer reviewed papers per faculty, he said. ICT’s impact per dollar spent has been the highest in the world. The institute has published papers in all leading journals in the world and has citations of more than 33,000 with very high h-index, Yadav said. The 79-year-old institute, earlier called University Department of Chemical Technology, has produced many industrialists, academics, bureaucrats, Padma awardees, secretaries to Government Departments, directors of CSIR labs and over 500 first generation entrepreneurs.

NATIONAL NEWS

SOFTWARE BUSINESS

Persistent in pact with Agilent to buy its French software unit Persistent Systems Ltd (PSL) has signed an agreement to acquire Agilent Technologies’ software marketing and development business unit based in Grenoble, France. The acquisition is expected to be final by August 1, after which the unit will be called Persistent Systems, France. Dr Anand Deshpande, Chairman and Managing Director, PSL, said the acquisition will contribute to Persistent’s thrust in the life sciences and healthcare markets and also give it a presence in Europe. The Agilent business is now focussed on supplying data acquisition and control software for scientific instruments to the life sciences, environmental, energy, applied research and other markets. Currently, PSL’s life sciences business contributes 10-12 per cent to its topline and was worth $ 20 million in FY 2011. The team here includes over 40 domain experts and more than 500 software professionals working on services supporting laboratory instrumentation, bioinformatics and chemical informatics projects for leading companies. To leverage the life sciences business, Persistent plans to set up a Life Sciences Centre of Excellence in Grenoble to expand into the European market. While bringing in new solutions and services to these, the centre will also provide it a platform to leverage its corporate technology position in areas such as cloud, analytics, mobility and collaboration. FERTILISERS

Coromandel International acquires 42.2 per cent in Sabero Organics Coromandel International has acquired 42.2 per cent stake in Sabero Organics at ` 160 per share. The acquisition is expected to help CIL to enhance its offerings on pesticides. This complements its strategy of evolving as a focussed agri input player with less dependence on subsidies from the government, rather than just a fertiliser company. Coromandel International plans to expand its fertiliser manufacturing capacity in Andhra Pradesh at an investment of ` 350 crore. “We will complete the expansion in second quarter of this financial year. The plan is to raise capacity to 2.2 million tonne from 1.7 million tonne,” said Kapil Mehan, Managing Director, Coromandel International. The company has earmarked ` 500 crore for its capital expansion plans. While majority of it will be used for Kakinada plant expansion, the rest will be for maintenance and strengthening of its existing operations. Secunderabad-based Coromandel is a leading producer of phosphatic fertilisers. The company has fertiliser manufacturing facilities in Visakhapatnam, Ennore and Ranipet besides Kakinada. The company also produces specialty nutrients and organic fertilisers, besides crop protection products.

June 2011 | Chemical World

15

NATIONAL NEWS Report

Energy-efficient facility

Rockwool inaugurates ‘green’ insulation material plant in Gujarat The company’s first manufacturing plant in Asia located at Dahej will produce stone wool insulation material having the potential to save energy and reduce CO2 emissions. Avani Jain

I

per cent per annum. We have entered India at the right time.”

n a bid to cater to India’s growing needs of insulation material in the process industries, the Material advantage Denmark-based Roxul Rockwool has opened Effective insulation practices are common in the a greenfield factory at Dahej, Gujarat, for the building sector; however, the process industry production of stone wool insulation material, a has not yet adopted standardised and/or natural material spun into wool from volcanic specified energy-efficiency requirements. If one diabase rock. The new factory has the capacity to was able to insulate hot processes with the same produce 30,000 tonne per annum of high-quality drive as new buildings, the benefits would be insulation material, which is biodegradable and can phenomenal. Thus, the usage of the insulation material becomes extremely important in the easily be used for land filling. While Europe is still chemical industry. Ian Russel, Business the strongest region Director UK & Export, for Rockwool, sales and Rockwool technical production activities are insulation, explained, “At growing significantly in every chemical facility, Asia, especially in India, something is heated every year. Through this to either generate facility, Rockwool aims steam, or materials to cater to the Indian L-R: Eelco Van Heel, CEO, Rockwool Group; Peter are blended through market as well as export Hoedemaker; Narendra Modi, CM, Gujarat and chemical reaction. These to Europe, Middle East Freddy Svane, Danish Ambassador, inaugurating materials are mostly and other parts of Asia. the new facility at Dahej kept in tanks & boilers Narendra Modi, Chief Minister, Gujarat, while inaugurating the and are sent for further processing in pipes. Thus, new facility, said, “The world is recognising the better the insulation on the pipes and boilers, less efficiency and growth-oriented policy-making energy will be needed to transport the steam or hot process of the Gujarat Government. Factors like chemicals around the factory. Moreover, the stone transparent administration, vibrant economy, wool insulation material is non-combustible and fire zero man-hour loss, best infrastructure, farsighted resistant. It is designed for operating temperatures planning have paid off, and companies like up to 650ºC, withstanding the heat of flames up to 1,177ºC without melting.” Rockwool are welcome.” On the cost front, Frank Jacobs, Managing Peter Hoedemaker, Chairman, Kaefer Isoliertechnik, with whom Rockwool has entered Director, Rockwool Technical Insulation, said, into a joint venture for the Dahej plant, observed, “The durability of our product is much higher and “There is huge demand for insulation materials the maintenance cost is minimum. The average in power plants, ships, refineries and chemical lifespan of our product is between 25 to 50 years, industries. In India, this demand is increasing at 20 but it depends on its usage.”

16

Chemical World | June 2011

WORLD NEWS

STRATEGIC ALLIANCE

POLYSILICON BUSINESS

Wacker begins construction of polysilicon plant in the US Wacker Chemie AG officially started construction work on a fully integrated polysilicon production site in the US. In December 2010, the company announced the plans to start construction for its integrated production site with an annual capacity of 15,000 metric tonne. The new facility is scheduled for completion in late 2013 and represents WACKER’s intention to continue investment in the growing photovoltaic and solar energy industries. The plant will meet the increasing demand for hyperpure polycrystalline silicon used by industry in the manufacture of solar panels and photovoltaic devices. It will be WACKER’s first plant of its kind outside Europe. The cost of the project will be $ 1.5 billion and the plant will be spread over an area of 550 acre greenfield site.

EPC CONTRACT

TransGas begins construction of coal-to-gasoline complex TransGas Development Systems, LLC, has begun construction of America’s largest coal-to-gasoline complex, the Adams Fork Energy plant in Mingo County, West Virginia. The plant will convert regional coal into 18,000 barrels per day of premium grade, ultra clean gasoline. The facility was permitted by the State of West Virginia, and is based on Uhde’s PRENFLO PDQ gasification technology provided by Uhde Corporation of America, which belongs to the ThyssenKrupp Group. Uhde Corporation of America is business partner of Uhde, which is one

of the world’s leading companies in coal gasification. Due to the current energy market situation, Uhde sees a significant increase in the demand for coal-based, alternative energy projects. Gasification offers a number of upstream and downstream advantages in an environment of record oil & gas prices and dwindling energy reserves worldwide. Coal gasification plants provide higher efficiency, and particularly lower emissions than conventional coal conversion plants, and allow the utilisation of low-grade feedstocks for a variety of products.

BASF and INEOS sign joint venture contract for Styrolution BASF SE and INEOS Industries Holdings Ltd have recently signed a contract, which regulates the formation of the joint venture (JV) company, Styrolution. The establishment of the JV is subject to approval by the appropriate antitrust authorities. BASF and INEOS plan to combine their global business activities in styrene monomers (SM), polystyrene (PS), acrylonitrile butadiene styrene (ABS), styrene-butadiene block copolymers (SBC) and other styrene-based copolymers (SAN, AMSAN, ASA, MABS) as well as copolymer blends into the new JV, Styrolution. The business with expandable polystyrene is not part of the transaction. BASF and INEOS will retain their respective businesses. It is a 50:50 JV by BASF and INEOS. BASF will receive cash consideration following the completion of the transaction. Dr Martin Brudermüller, Vice Chairman, Board of Executive Directors, BASF SE and responsible for the plastics segment, said, “The signing of the joint venture contract is an important milestone. With the signing, we have built a strong foundation to establish Syrolution, the leading global company for styrenics, before the end of the year, subject to regulatory approval. Styrolution will deliver better service, a fast and secure supply as well as excellent product quality to its customers around the globe.”

APPOINTMENT

TECHNOLOGY

Sir William is the new President of IChemE

New Malvern video highlights versatility of Parsum in-line particle probe

Sir William Wakeham, former Vice Chancellor of Southampton University, UK, has been appointed as the President of the Institution of Chemical Engineers (IChemE) in place of Desmond King. During his presidential address, he highlighted the impact that an increasingly diverse membership base will have on the future of IChemE. Sir William explained that as the location, industry sector and education background of the membership changes, the institution must evolve. “IChemE is a global organisation with members in 120 countries. But those members are working in a wider range of sectors than ever before and not all of them have what might be called a ‘traditional chemical engineering’ background,” he said.

The UK-based Malvern Instruments has launched a new 3-minute video highlighting the versatility of the Parsum IPP 70 (In-line Particle Probe) which is now available on its website. Designed to continuously measure the size, size distribution and velocity of granular particles, directly in the process, the Parsum IPP is a valuable tool for process development and automated production. It has applications in many sectors including food, chemicals and pharmaceuticals.

June 2011 | Chemical World

17

WORLD NEWS

RESIN BUSINESS

LANXESS showcases novel resins at IWEX As part of Sustainabilitylive! 2011, LANXESS presented ion exchange resins from its proven Lewatit range at the recently held Industrial Water Expo (IWEX) in Birmingham, the UK. The mixed event Sustainabilitylive!, which takes place every four years, combines the UK’s five leading environmental exhibitions: BEX (Brownfield Expo), ET (Environmental Technology), NEMEX (National Energy Management Exhibition), SB (Sustainable Business) and IWEX. PERFORMANCE CHEMICALS

Rhodia launches new solutions Aroma Performance Enterprise, part of the Rhodia consumer chemical cluster, has introduced two new solutions: Ethyl DiFluoroAcetate (DFAE) for agrochemical & pharmaceutical markets and new LiTFSI (Lithium salt) applications for electronics. Rhodia Aroma Performance offers one of the world’s largest and strongest portfolios in fluoroaliphatics and diphenol intermediates, two product lines based on core integrated technologies and a high number of patented processes.

BUSINESS DELEGATION

Belgium offers attractive business opportunities for Indian chemical companies The Consulate General of Belgium in Mumbai recently announced the ‘Flanders, Belgium Invest Roadshow 2011’ – a tailor-made opportunity for Indian companies in Flanders, Belgium. The roadshow comprised a high-level Belgian delegation headed by Jean-Joel Schittecatte, Consul-general, Belgium in Mumbai. It shared valuable insights on opportunities in Flanders, Tom Vermeulen, Trade and Investment Commissioner of Belgium, and showcased it as an ideal and Flanders (seated extreme right) attractive destination for Indian companies to and Jean-Joel Schittecatte invest. Flanders, already rated as India’s 3rd (standing extreme left) are flanked by other dignitaries most preferred trade partner in the European Union (EU) and top-destination for Indian FDI, has a lot more to offer to Indian exporters and investors. The Belgian officials shared information on setting up companies, visa formalities, market trends, fiscal incentives, financial assistance, etc for Indian companies looking to expand into Europe or expand existing European operations. The strong sectors in the Flanders economy include chemicals and plastics, automotive, life sciences, logistics and food. Flanders offers companies one of the most highly developed chemical clusters in the world. In sector terms, the chemical industry is a major player, generating more than 20 per cent of total Belgian exports and 17 per cent of European exports of chemical products. The region of Flanders is home to the lion’s share of the chemical industry with about 1,500 companies. The industry accounts for 1,60,000 direct and indirect jobs and an annual turnover amounting to around Euro 33 billion.

LAB EQUIPMENT

POLYMER CHEMISTRY

Agilent Technologies introduces Cary 60 UV-Vis

Elevance Renewable Sciences and Royal DSM to collaborate for bio-based materials

Agilent Technologies Inc has introduced Cary 60 UV-Vis, which uses xenon flash lamp technology, with improved performance, ease-ofuse and sample handling. Supporting a multitude of applications, the new UV-Vis is designed to improve workflow in a wide variety of settings, including chemical, industrial, and pharmaceutical/biotech laboratories. With its unique, proven design, Cary 60 UV-Vis provides a robust solution at the lowest cost of ownership of any instrument of its kind – the lamp typically lasts 10 years. High-quality fibre-optics capabilities allow for remote sampling of everything from bulk solutions to

18

Chemical World | June 2011

cold biological samples. This minimises sample handling, eliminates the need for expensive cuvettes and increases the speed of analysis without compromising data quality. “Cary 60 UV-Vis builds on more than 60 years of optical design excellence from the Cary brand and is backed by Agilent’s commitment to quality and support,” said Phil Binns, VP - Spectroscopy Division, Agilent.

Elevance Renewable Sciences Inc and Royal DSM NV have signed a letter of intent for a collaboration to evaluate Elevance’s unique monomers for production of specialty bio-based high performance thermoplastic materials, for DSM’s engineering plastics portfolio. Commenting on the development, Roelof Westerbeek, President, DSM Engineering Plastics, said, “Partnering with Elevance enables DSM to further broaden our portfolio of products that provide improved performance over existing polymer solutions.” Elevance will provide natural monomers produced from plant oils along with its proprietary metathesis technology to enable the production of various polymers.

LEADERS SPEAK

“The chemical industry needs to set its house in order” …believes Prasad Chandran, Chairman, BASF Companies in India, & Head - South Asia. He is a member of the Task Force on Chemicals set up by the Government of India. Chandran is also actively involved with the National Action Plan on Climate Change through TERI. He holds a Masters in Chemistry as well as Business Administration from the US, the UK and Japan. Reflecting his passion for chemistry and sustainability, he informs Mahua Roy about the responsible image of BASF and the green route to be adopted by the chemical industry in India.

June 2011 | Chemical World

19

LEADERS SPEAK

Sustainability is an important pre-requisite for business success in today’s world. Companies that conduct business sustainably and act responsibly will be more successful than their competitors in the long run. Chemical companies need to respect the ecology and society within which they function. Pioneering innovations at BASF

Emphasis on sustainability in today’s world

BASF has a long history of many significant innovations. Our research innovations play an important role in improving the quality of life as well as environmental and resource conservation. A few examples of chemical innovations from BASF include engineering plastics for lightweight cars, insulation systems and concrete admixtures for energyefficient housing, biodegradable packaging materials and environmentfriendly paint ingredients.

Sustainability is an important prerequisite for business success in today’s world. Companies that conduct business sustainably and act responsibly will be more successful than their competitors in the long run. At BASF, economic considerations do not take priority over environment, health and safety (EHS) issues. Sustainable development enables to enhance our existing business, create new business opportunities and minimise risks. BASF has been included in the world’s most important sustainability index, the Dow Jones Sustainability World Index, for the tenth year in succession.

On the competitive product pipeline The innovative chemistry of BASF is the driving force for many industries and provides an important impetus for new products, technologies and processes. Our approach helps us to find answers to global challenges such as climate change, resource conservation, health & nutrition and housing & mobility. This is our contribution towards a better future for the present as well as coming generations. As we like to say, we do not just create chemicals, we create chemistry. In 2010, BASF had more than 9,600 employees dedicated to R&D worldwide and around 1,900 collaborative partnerships with universities, institutes, start-up companies and industry partners. During the same year, we invested nearly Euro 1.5 billion in R&D projects. In India, BASF has two R&D Centres – in Mumbai and Mangalore, working in close collaboration with BASF’s Global Technology Platform.

20

Chemical World | June 2011

On negative image of the chemical industry Many chemical manufacturing processes create waste products that can be harmful to the environment and human health when not properly handled. If chemical companies do not follow safe manufacturing and effluent discharge methods, they can cause significant risks to human life and environment. Industrial accidents and environmental pollution related to the chemical industry is a major reason for the negative image of the chemical industry. Another reason for the negative image, is lack of awareness. The chemical industry is an intermediate industry; most of its products do not come in the form of end-products for consumers. That is why innovations in the chemical industry go unnoticed,

since consumers are not aware of what goes into the making of the final product.

Strategies to portray the industry in a positive light A change in perception cannot be brought immediately. It has to be gradual. First and foremost, the chemical industry needs to set its house in order. Only then it can focus on changing its image. Safe manufacturing practices in line with international safety guidelines have to be adopted at chemical manufacturing sites. Chemical companies need to respect the ecology and society within which they function. Some initiatives that can change the negative perception include: R Adoption of stringent EHS norms and make it part of the business plan R Discharge of effluents responsibly after treatment R Have effective disaster management plans in place R Involve local communities and society through Corporate Social Responsibility (CSR) programmes R Conduct regular surveys to assess public opinion about the chemical industry R Industry self-regulation to ensure that best practices are followed by every company, big or small R Education to create awareness about the role of chemistry R Highlight innovations by chemical companies and how they have aided other industries to come up with innovative products. For eg, Bt Cotton (which has led to a double digit increase in cotton production) and low-cost water purifiers from Tata were made possible by the chemical industry

Future outlook for the chemical industry The Indian chemical industry is the 12 th largest in the world and 3 rd largest in Asia, in terms of volume. It

LEADERS SPEAK

accounts for about 17.6 per cent of the output of India’s manufacturing sector and about 3 per cent of the GDP. The industry output is estimated at $ 35 billion, with a total investment of approximately $ 60 billion. India’s current per capita consumption of chemicals is just 1/10 th of the world’s average, indicating the tremendous scope for the industry’s growth in the country.

BASF’s mantra for sustainable growth For BASF, sustainable development means combining economic success with environmental and social responsibility. A company’s commitment to sustainability can only make a difference when all its people have fully integrated this way of thinking as part of their daily responsibilities At BASF we take sustainability aspects into account in the

development of our business strategies. At all our sites in India, we use various systems to monitor EHS standards in line with BASF’s global standards. With sustainable products & services, we have created competitive advantages for both BASF and our customers. To ensure sustainable development, BASF is committed to partnering with the society, in which we operate through various CSR projects that benefit the local communities. Also, the Eco-Efficiency Analysis developed by BASF, is an internal tool to consider the two major dimensions of sustainability: environment and cost. This analysis considers the entire lifecycle of a product ‘from cradle to grave’, ie starting from the extraction of the raw material from the earth, production, usage behaviour of the final consumers, through recycling or other various possibilities for reuse and disposal. Since 1996,

the Eco-Efficiency Analysis has been helping BASF and its customers to identify areas of potential economic or environmental improvement for products and processes.

Business opportunities in India BASF is continuously scanning and monitoring the business environment for opportunities in India. It is aiming to grow both organically and through possible acquisitions in this market. In 2010, BASF India Ltd completed the acquisition of Ciba India Ltd. This was after the global acquisition of Ciba Holding AG by BASF SE. With this acquisition, BASF in India has been able to expand its portfolio in the specialty chemicals segment with product offerings ranging from paper chemicals, UV stabilisers, antioxidants, to coating effects and care chemicals.

June 2011 | Chemical World

21

ROUNDTABLE

Effluent treatment systems

Imperative to make them more effective Environmental and health risks due to variety of effluents generated from chemical industries have become a matter of concern in the country. The attitude of the industry towards waste management is being questioned and SMEs are seen as the major culprit. It seems that even the existing regulatory norms and the effluent treatment plants (ETPs) are not adequate enough to deal with the massive discharges and need to be revisited. In conversation with some industry experts, Avani Jain finds out why the improvisation of ETPs is imperative and how it can be achieved.

Ravi Kapoor, Managing Director, Heubach Colurs The present regulatory norms are more than adequate for the current and, for that matter, the future discharges. The problem is the lack of compliance on the part of the industry and its attitude towards waste management & sustainable development. Moreover, the mixed effluent does not have an individual identity, which adds to the problem. The Common Effluent Treatment Plants (CETPs) can offer limited treatment as the mix of all effluents from different industries make the task more difficult. It has been observed that segregation of effluents is often helpful in the treatment process. SMEs need to treat effluents, created at their end, to the maximum extent possible, and for this, better facilities should be provided by industrial bodies and the government. Hence, it will require a joint effort.

22

Chemical World | June 2011

Once the correct attitude is adopted, the implementation of suitable technology will follow. If a level-playing field is provided and the focus is directed towards zero tolerance and implementation of norms, without compromise, throughout the industry, then the effluent-related risks can be abated to a large extent. The golden rule should be maximum treatment of all waste generated by individual industry through the use of latest technologies, irrespective of size as environment protection matters for one and all. The next level of treatment can be done in CETPs. In addition, certain types of products should not be manufactured unless the waste treatment methods are clearly in place and demonstrated. The other areas of improvement should revolve around process optimisation and sustainable development by way of recycling and reuse of by-products by undertaking innovative methods.

ROUNDTABLE

Dr Rajeev Singh, Director General, Indian Chamber of Commerce Within the chemical industry, dyes and organic chemicals pose high health and environmental risks, as compared to the other segments, more so, because the problems are still not properly mitigated in a systemic organised framework, like in the petrochemical sector. The industry needs to redefine its regulatory framework in sync with the latest international standards and must also take into account the fact that the lion’s share of the pollution caused by chemical sectors come from the low resourcebased, fragmented, traditional SMEs, who on their own are incapable of conforming to the set standards. In view of the above, the collective responsibility action solution promoted by CETP is ideal for issues like cost optimisation and gaining access to premier technology bases, both globally and domestically. However, CETP does not warranty zero costs for the SMEs and the abatement costs have to be borne initially until the benefits of pollution mitigation flows in. Within each CETP, the members can adopt a tradable emission permit scheme for effective effluent abatement. In a liberalised market framework, government subsidies should be extended to protect the labour-intensive, resource-constrained SMEs under CETP, to meet their compliance needs. Moreover,

the industry, at large, should also invest in cost-effective, efficient and environment-friendly production technologies & implement product recycling practices. Government assistance in technology development and MSME training, through targeted subventions can be helpful. In addition, India has recently launched the National Clean Energy Fund towards reducing its carbon footprint. Moreover, India has a host of environment control acts and is a signatory to international conventions like the Stockholm Convention on Persistent Organic Pollutants; the Chemical Weapons Convention; the Montreal Protocol on Ozone Depleting Substances; the Kyoto Protocol on Global Warming; and the Basel Convention on Trans-boundary Movement of Hazardous Waste. But the grey area is monitoring and enforcement. Cases of non-compliance should be dealt with strictly in a time-bound manner. India needs to gear up its domestic production machinery to meet the global standards and a supportive domestic regulatory framework can become the right catalyst in propelling the future growth of the chemical industry.

Omkar P Herlekar, Whole Time Director, Omkar Speciality Chemicals Ltd Discharges from industries pollute land, sea, rivers and other water resources and have resulted into destruction of marine livestock, agricultural produce, etc. Whenever the issue of water pollution is raised, the governments issue notices or penalties on the errant industries. Giving an undertaking, bank guarantee or paying the fine to the government finally settles the issue, but the real problem remains unsolved. The case is different outside India. In European countries, only those products are manufactured that are economically feasible and curb pollution, as they are conscious about the safety, environment & health of their people, and hence import those products (that are prone to result in high levels of pollution) from other countries. However, in India neither the industry nor the government is striving to resolve this issue proactively. In genuine cases, where the implementation of all the control measures is not that easy for certain industries, the government needs to play a supporting role. It should form an advisory committee of technical experts from reputed institutions like IIT and ICT to study material balance, water balance, waste balance, etc, generated during the chemical process, and monitor the process to verify the effectiveness of control measures.

The purpose should not be restricted only to monitoring the process, collecting samples of effluents and taking disciplinary action or serving closure notices, but also give importance to understanding the problem and recommending proper solutions to overcome them. On another front, industries should also realise their responsibilities and any chemical manufacturing facility, whether small- or large-scale, must implement effluent treatment measures in totality, not limited only to primary treatment. For small-scale industries, government should provide adequate subsidies and raw materials required for effluent treatment. The industries should strictly implement all the required measures for effluent treatment, failing which they should be liable for disciplinary actions. The government needs to encourage effluent treatment processes, such as, zero discharge effluent with total recycling of wastewater; recovery of solvents from waste; recovery of solids from waste; generation of energy/bio-gas from waste; and development/use of innovative equipment & processes in ETP.

June 2011 | Chemical World

23

ROUNDTABLE

K R Desai, CEO, Narmada Clean Tech Ltd The qualitative norms given for treating effluent in No-Objection Certificate (NOC) by Pollution Control Board (PCB) are adequate, but some parameters need to be stringent. Certain norms should be project-specific and based on mode of discharge whether it is, to deep sea, to CETP or to natural creeks, etc. Thus, they should be rationally reviewed looking at its ultimate effect on environment, may it be in long term. For example, value of Chemical Oxygen demand (COD) is one of the stringent norms (particularly for marine discharge). Refractory COD and COD contributed by chloride/sulphates (inorganics) are to be viewed differently and rationally when compared to COD contributed by biodegradable organic matter. The latter should be strictly regulated. When it comes to industries, they should also adopt the most suitable and well-proven advanced technologies with precise process

control devices. The industry should take steps to treat the waste through effective means like water recycling and ensure close monitoring of process, quality and inventory control. To minimise the impact of effluent discharge on the environment, the first and foremost requirement is to control pollution at source. It is the prime responsibility of industry to control effluent at generation stage, as it is the most technically feasible and economically viable solution. It can be observed that micro & small-scale industries have their own constraints and limitations. CETP is the practical remedy, provided it is developed with right approach since conceptual phase. It can offer solutions, but there are challenges also. Irrespective of the scale of industry, ETP is being viewed as cost centre and not as a profit centre. One should understand and accept that better recovery of material and less waste always pay better. Also many-a-time, the top authorities are not aware of what is happening at the floor of ETP as it is highly ignored area. Thus, a lot needs to be done in this area.

Kirit C Mehta, Past President, Chemical and Alkali Merchants’ Association The effluent discharge is in three forms - solid, liquid and gaseous. PCB should consider each separately and set the guidelines like the height of the chimney or the ways to separate the three effluents so that they do not mix with each other. Basically, it is the responsibility of the government to keep a check on this. If the authorities, ie PCB become strict and formulate stringent norms and confer immediate punishments on the guilty, then the industry will have no other option but to

follow the rules. When it comes to industries, then it depends on how the issue is looked upon. They are by far taking good steps in this regard but as one can see, there are always exceptions. They have set up CETPs for effluent treatment and are doing their best. Moreover, cost and availability of technology & resources is a big deciding factor. If the government provides subsidies on the cost of machinery and raw material to be used in the ETPs, then the industries would not mind setting up ETPs. Thus, all this boils down to the efficiency of the concerned authorities.

Dr Y R Singh, Executive Director, Alkali Manufacturers’ Association of India The existing norms are more than adequate to take care of the massive effluent discharge from the chemical industries. There are various acts in this area like the Water (Prevention and Control of Pollution) Act 1974, the Air (Prevention and Control of Pollution) Act, 1981, and acts related to solid waste

24

Chemical World | June 2011

management, among others. The industry on its part should voluntarily come forward and realise its responsibilities towards environment by adopting zero discharge policy. Often it is seen that the large-scale industries have their separate ETPs, but the problem is with the small-scale industries where there is lack of funds and resources to establish the ETPs. Thus, some steps should be taken toward this end.

FACILITY VISIT

IKA India

Aiding R&D, empowering innovation IKA, a 100-year old German organisation, which has been operating in India since 10 years, established its first assembling unit in the country in 2009. The Bengaluru facility is one of IKA’s six assembling units in the world, and is equipped with a global R&D, marketing and application centre.

The assembly line

Mahua Roy

I

KA has been an established name in laboratory, analytical and process equipment market worldwide. The parent company was founded in Germany in 1910 as a supplier for pharmacies and hospitals. In 1942, during the Second World War, the company left bombed-out Cologne for Staufen in Breisgau. It soon became one of the leading companies for laboratory technology as well as dispersing, stirring and kneading machines.

The Indian journey IKA started out in India as a liaison office with few people. “Since we sold only through channel partners, we concentrated more on facilitating sales, co-ordination, order processing and expediting of deliveries. In 2008, the business

26

Chemical World | June 2011

Testing of electronic contact thermometer ETS-D5

had grown and in order to serve this vast market, it was decided to set up a manufacturing base here. Now, assembling is carried out through this facility for catering to the demands of the global market, with 70 per cent of the products being exported,” says Suren Dixit, Managing Director, IKA India. Due to its extensive expertise and

Product portfolio Lab equipment R Magnetic stirrer R Overhead stirrer R Homogeniser R Bomb calorimeter R Hot-plate R Heating bath R Disperser

R R R

Shaker Rotary evaporator Laboratory reactors

Process equipment R Process pilot R Labour pilot R Magic Lab

CW_June _2011_ Engg Expo_Tab-1_27

CW_June _2011_ Engg Expo_Tab-1_28

FACILITY VISIT

Packaging in progress

Orbital shaker

experience, the company’s presence is felt in the pharmaceutical, chemical, petrochemical & food industries as well as CSIR labs and various educational institutes.

Each and every step is in line with German standard operating procedures. The total employee strength in this facility is now up to 80 and is expected to reach 100 by December 2011.

The facility landscape

Application laboratory

The Bengaluru facility is equipped with state-of-the-art manufacturing machinery and follows stringent standards. “We simply model the standards of our German facility to the smallest detail. Our sourcing is entirely centralised with global vendors, who supply to IKA units worldwide, thus enabling us to maintain the same quality standards,” asserts Dixit. The facility spans around 35,000 square feet and is still undergoing expansion. Assembling of the flagship products of IKA, ie magnetic stirrers, overhead stirrers and homogenisers, is undertaken at this facility, along with other products. The entire process is streamlined with high process efficiency and expertise.

To enhance its engagement with customer processes and to customise solutions, IKA India has developed an application laboratory at this facility. The customers can undertake various studies regarding the suitability, efficacy, efficiency, tests and trials of the products being offered to them. IKA is also increasing its training programmes to channel partners, customers as well as developing a robust after-sales support team. The company is now beginning to market process equipment in India. “We foresee a huge market for these products in India. We aim to make the transition from R&D to pilot to production, much smoother,” says

Dixit. As a result of this foresight, the company plans expansion of this unit to set up an application laboratory for process equipment as well.

R&D activities

The engineers in our R&D lab are working on global projects. In the long run, we aim to attain the goal of bringing all benefits of global knowledge to India, by designing customised products for domestic markets, thus providing smaller, smarter, faster and more elegant products in the future. Suren Dixit Managing Director

The force behind being one of the most reputable names in the industry is the vigorous R&D backbone. The Bengaluru centre is equipped with excellent facilities for research and innovation. It is one of the hubs, which undertakes various projects aimed for global launches. “Our R&D centre today employs 10 scientists and we plan to take the figure to 25, as India has a rich pool of scientific talent. The mechanical, electrical, electronic and computer science engineers in the R&D lab are working on global projects. In the long run, we aim to attain the goal of bringing all benefits of global knowledge to India, by designing customised products for domestic markets,” explains Dixit. Extensive R&D efforts are required in this sector. The R&D breakthrough of IKA resulted in the development of its magnetic stirrer, which utilises 25 per cent less energy. Dixit opines that similar coherent efforts are the need of the hour for gaining an edge even in the coming years. “We aim to provide smaller, smarter, faster and more elegant products in the future,” he concludes. (Photo by: Shrikanth S Y)

June 2011 | Chemical World

29

SECTOR WATCH

Engineering, Procurement and Construction (EPC) is relatively a new concept in India, which is picking up pace. Huge investments in chemical, petrochemical, oil & gas sectors in the country have made the prospects brighter for EPC companies. However, Indian EPC sector is still at a nascent stage and it needs to adopt modern practices to track progress of all projects to ensure timely completion within the budgeted cost.

Courtesy: Essar Projects (India) Ltd

30

Chemical World | June 2011

SECTOR WATCH

Prasenjit Chakraborty

E

PC sector in India is making a steady progress across industries since the last few years. There is a high demand worldwide for new and refurbished infrastructure of all kinds – roads, bridges, mass transit systems, water treatment facilities, power, chemical, petrochemical plants, healthcare facilities – the list is virtually endless. Against the backdrop of increasing focus on India as the manufacturing hub of Asia, the construction activities in different sectors have accelerated. This has fuelled the growth of EPC as a whole.

Growth propellers The emphasis on infrastructure development is one of the major growth drivers for the EPC sector. “Infrastructure has to be spruced up at all levels across India to support the burgeoning economy, which is projected to grow consistently at 9 per cent per annum in the 12th Plan period (201217). To meet the growing demand, the Indian companies – from both public and private sector – are seeking EPC firms having the expertise to deliver complex mega projects, which are being envisaged for oil & gas, power, steel, pipelines, marine, offshore, civil & building sectors in India,” points out Ravindran Kayarat, CEO – Hydrocarbon, Essar Projects (India) Ltd (EPL). A closer look says that it is a winwin situation for both the companies (clients of EPC) and the EPC contractor, since they get to concentrate on their core business strengths. The client needs to build a quality asset at a competitive cost within schedule, while effectively transferring major risk factors. The EPC contractor’s role in such a case is to take up single point responsibility to deliver a project utilising the excellent project management skills, dedicated vendor base, and the ability to engineer & visualise the project as per client requirements. “We have delivered projects worth $ 15 billion across key segments

Hydrocarbon sector with its major expansion plans in refineries, fertilisers, LNG terminals, etc, will provide ample scope for EPC companies in the years to come. The huge growth plans in various industries will have a cascading effect on associated EPC sector for the next three years. Ravindran Kayarat CEO – Hydrocarbon, Essar Projects (India) Ltd like oil & gas, power, steel, pipelines, marine, offshore, civil & building. EPL brings an unparalleled advantage of providing an owner’s perspective to the client as the EPC sector in India gathers momentum,” says Kayarat. As infrastructure segment is making rapid strides, this is bound to fuel the growth of EPC sector. “The government proposed an investment worth ` 20,56,150 crore in infrastructure during the 11th Plan. During the period 2011-2012, the aim has been to attain sustainable growth of 9 per cent, with emphasis on growth and quality of life. But it is also clear that infrastructure inadequacies will act as a constraint in achieving this growth. To overcome this challenge, the government is also emphasising on the PPP model,” says Sanjeev Nakhasi, Corporate Vice President - Operations, Synefra E&C Ltd. Besides the infrastructure aspect, there are few important leverage points for which companies are roping in EPC contractors. Today, customers’ mindsets have changed. They do not want to be responsible for project management on a day-to-day basis and prefer to appoint an EPC contractor, who takes single point responsibility for the entire project. While elaborating on this scenario, Nakhasi explains, “This helps the client to save time for project execution, and system integration has also become easier. There is one contractor who can be contacted for all issues involving the project, and the client needs to maintain only a skeletal staff for project monitoring. This trend has also led to the emergence of SMEs in EPC sector, thus leading to entrepreneurial and employment opportunities.”

Despite the growing demand for EPC activities, the question remains as to whether EPC contracting is a complete safe method or not. There are many issues associated with EPC as well. Higher risk exposures and global competition are driving owners & EPC contractors to dwell upon alternative ways to mitigate & control risks. EPC projects today are getting more complex and realisation of larger projects are getting uncertain; at the same time projects are being broken up into phases for cost benefits. Timing of project awards is becoming more unpredictable than ever and it is reflected in delay in the finalisation of contracts by way of lengthy negotiations/budget issues. Service providers are on the frontline of cuts, but opinions differ on the impact. Taking everything into consideration EPC Lump Sum Turnkey (LSTK) mode of execution appears to be the most preferred method. “The EPC LSTK method of project delivery still remains the preferred choice, since it generates substantial benefit for project owners,

What India offers for EPC sector R Creating infrastructure for all

sectors is a priority R PCPIR policy aims at promoting

huge investments in the chemicals sector in the country and making it a prominent hub for both domestic and international players R Oil & gas sector in India is poised for tremendous growth with major expansions planned in refineries (302 MMTPA by 2017)

June 2011 | Chemical World

31

SECTOR WATCH

In EPC projects, estimating the cost and tendering requires efficient skillsets to ensure that we do not run into a financial loss in executing a project. The availability of vast pool of personnel with specialised technical knowledge makes India one of the best manpower providers in the international market. Sanjeev Nakhasi Corporate Vice President - Operations, Synefra E&C Ltd largely due to transfer of all associated risks to EPC contractor vide assignment of single point responsibility towards quality, price and timely delivery,” says Sathiamoorthy G, Managing Director, Tecnimont ICB (TICB) Pvt Ltd.

Refining & petrochemical projects In India, the oil & gas sector is a lucrative one for EPC, as it is poised for tremendous growth, with major expansions planned in refineries (302 MMTPA by 2017) as a part of ` 2.8 trillion investment for the 12th Plan period. The progressive steps like price deregulation in petroleum products should ensure that the oil & gas majors are on track for the expansion of projects. “After introduction of nutrient-based subsidy for fertiliser industry, there is now incentive for the dormant companies to finally carry on with the planned investments. With obvious advantages of the single point responsibility EPC LSTK contracts, the clients trust only those EPC contractors with experience of having effectively delivered complex mega projects,” asserts Kayarat. Huge investments are also being planned to establish/expand LNG terminals by public and private sector

companies for catering to LNG demand by consumers in power and fertiliser sectors. The Petroleum, Chemicals & Petrochemical Investment Region (PCPIR) policy, aimed at promoting huge investments in the chemicals sector in the country and making it a prominent hub for both domestic & international players, is expected to attract investments to the tune of ` 2-3 trillion to each notified PCPIR. The PCPIRs approved by the Centre are brownfield Bharuch (Gujarat), Visakhapatnam (AP), Haldia (West Bengal) and greenfield Paradeep (Orissa). The one proposed at Cuddalore in Tamil Nadu is in advanced stages of approvals while the Mangalore (Karnataka) project is under the planning stage. There are few projects either completed or soon to be completed through EPC method in the country. Take the example of Gujarat’s Vadinar Refinery – a 20-MMTPA project, out of which 14 MMTPA has already been completed by Essar Projects (India). IOCL Paradip Refinery (15 MMTPALSTK package A-ongoing-within Paradip PCPIR) is also an ongoing project for Essar Projects (India). “We bring an owner’s perspective into all projects we deliver. This results in cost-effective solutions, in-house expertise in hydrocarbon sector;

Each EPC company will have to develop its own strategy for optimal profitability and success. Leadership in use of information technology will be most important in winning future EPC LSTK work, and knowledge management systems may become a mandatory EPC offering in the near future. Sathiamoorthy G Managing Director, Tecnimont ICB (TICB) Pvt Ltd

32

Chemical World | June 2011

faster mobilisation of equipment and manpower,” claims Kayarat. Similarly, TICB (an integral part of Maire Tecnimont Group) is a 52-year old company and among the few engineering & construction companies in India that have the capability and experience to supply plants to petrochemicals/chemical/oil & gas sectors on EPC LSTK basis. “Our strength can be attributed to strong orientation to technology, engineering and advanced skills in vendor development, project management and control to deliver complex projects,” claims Sathiamoorthy.

The issues The construction industry has been expanding rapidly over the last few decades. Along with this, the nature of main contracts has also dramatically changed. Contracts are of increasingly complex types – EPC, turnkey, BOOT, PPP, etc. With the opening of different sectors to privatisation and international investment & competition, projects (even in private sector) in areas like roads & bridges, complete townships, SEZs, airports, power plants, industrial plants, etc, are expected to increase manifolds. To cater to all these sectors, companies should possess high level of skillsets. It is implied that these companies should have an in-house capacity to undertake projects and also deal with eventualities. Project delivery calls for multiple skillsets and involves high risk, owing to the size & complexity of certain projects. “In EPC projects, estimating the cost and tendering requires efficient skillsets to ensure that we do not run into a financial loss in executing a project, and at the same time, stay competitive in winning contracts,” points out Nakhasi. Project management is critical in executing complex projects. The contractor must have the knowledge of using modern programming tools integrated to track progress of all projects to ensure timely completion within budgeted costs. Site management

SECTOR WATCH

India has world-class expertise and the cost of engineering, procurement and construction services is comparatively low. In an increasingly global market, it is only a matter of time before companies start to focus on India for high-quality, low-cost technical and professional services. Jean Beaudoin Executive Vice-President, Chemicals and Petroleum, SNC-Lavalin is another critical factor. Having skilled and experienced manpower is also another factor that is considered while selecting a contractor. According to Sathiamoorthy, the main risks for contract implementation in India are those associated with vendor deliveries, interface management and external issues such as taxation procedures, state and central level legalities, etc. “Besides, we cannot ignore the infrastructure constraint, which puts a strain on the logistics planning and extent of supervision,” he says. Another aspect worth mentioning is the availability (or may be lack) of qualified vendors and their commitment on cost of supplies/services & deliveries. This remains a major challenge for the EPC contractors triggered by the volatile market conditions. Furthermore, lack of availability of skilled/unskilled labourers is also heavily impacting the construction schedule.

Where India stands? In India, the concept of EPC is at a nascent stage. The owner is not yet

convinced that vendors can procure high value material on their own. This is mainly because the owner does not rely on the competencies of vendor, the quality control techniques, the capital expense involved, etc. “Actually giving the entire project to an EPC company has distinct advantages. EPC gives the owner single point responsibility and other advantages,” asserts Nakhasi. It is important for the EPC sector to disseminate information about the advantages of EPC contracting. And at the same time, EPC companies need to equip themselves to meet any difficult situation while executing a project. Jean Beaudoin, Executive VicePresident, Chemicals and Petroleum, SNC-Lavalin, strongly feels that India has world-class expertise and the cost of engineering, procurement and construction services is comparatively low. “In an increasingly global market, it is only a matter of time before companies start to focus on India for high-quality, low-cost technical and professional services,” he says.

Aerial view of Essar’s Vadinar refinery (Gujarat) Courtesy: Essar Projects (India) Ltd

34

Chemical World | June 2011

Scaling new heights With the advent of technological expertise, strategic alliance and worldclass standards, the EPC sector is increasingly adapting to faster and efficient methods. Indian EPC majors are not restricting themselves to national shores but are also looking across the borders. India has a definite edge over other countries due to low cost, fast execution and availability of resources. “The availability of vast pool of personnel with specialised technical knowledge makes India one of the best manpower providers in the international market. This trend is expected to substantially increase over the next few years,” observes Nakhasi. India as a country has tremendous growth potential in the infrastructure segment mainly in development of roads and bridges, among others. The scope for the public and private sector is also increasing as the demand is huge and the complexity of projects is increasing. EPC sector is envisaged to play a huge role in the infrastructure story of India. Kayarat is quite optimistic about hydrocarbon sector in India. “Hydrocarbon sector with its major expansion plans in refineries, fertilisers, LNG terminals, etc, will provide ample scope for EPC companies in the years to come,” he says. Besides hydrocarbon, power, ports and road sectors will provide tremendous scope for EPC to grow. “The huge growth plans in the above sectors will have a cascading effect on associated EPC sector for the next three years,” opines Kayarat. It is all about the survival of the fittest. Looking at the ongoing activities, the future of EPC sector is expected to be bright, yet challenging. “Each EPC company will have to develop its own strategy for optimal profitability and success. Leadership in use of information technology will be most important in winning future EPC LSTK work, and knowledge management systems may become a mandatory EPC offering in the near future,” concludes Sathiamoorthy.

MARKET SCOPE

Engineering and contracting

Ready for the global leap? With the growing focus on the development of infrastructure in India, engineering and contracting sector can look at cashing in on the emerging opportunities, besides making inroads into the global market. And to pave the successful path, it needs to eliminate the roadblocks on its way.

Pothen Paul

A

fairly longstanding problem of the manufacturing sector in India has been its inability to be a contributor of consequence to the country’s service sector-driven growth story of recent years. Because of this, its participation in the GDP too has stagnated at a paltry 16 per cent, prompting the Finance Minister to propose a set of measures in the Union Budget 2011 for gradually improving the sector’s contribution to 25 per cent. A much better performing manufacturing sector is a crucial prerequisite for the generation of employment opportunities, especially for blue collar workers, and for faster growth of exports & consequently better foreign trade balance.

facilitator towards this end. In addition, a steady increase of financial participation by the private sector via PPP schemes, etc, which has expanded to 35 per cent plus of the annual infrastructure spend, is also a positive development. An analysis of the project loans of $ 53.5 billion sanctioned by banks and overseas lenders in 2010 shows that power projects bagged close to 50 per cent of it, followed by the telecom and road & transportation sectors with 21 per cent and 14 per cent respectively. However, the collective share of industry sector including oil & gas and petrochemical projects was just a paltry 16 per cent. This is not a true reflection of the weightages of sector-wise investments, because many of these projects are internally funded, to a large extent, by their promoters. However, the good news is today, power and transportation infrastructure projects are in the limelight.

Infrastructure projects Fortunately in case of the infrastructure sector, the decades of neglect, which made power cuts and transportation bottlenecks a way of life and imposed serious constraints on the manufacturing sector, is currently being tackled on a priority basis at an annual expenditure equivalent to 8 per cent of the GDP. A budget allocation of ` 2.14 trillion, an increase of 23 per cent over the previous year, is acting as a

36

Chemical World | June 2011

Investment scenario It is an undisputed fact that for a country of India’s dimensions and location in the centre of the Asia and Middle East growth regions, the per capita production, consumption and exports of chemicals, petrochemicals and products derived from them remain modest. It is also true that India is yet to attract significant investments from key global players in domestic manufacturing

MARKET SCOPE