The is much easier to get excited about than the

Past

E d i t o r ’ s N o t e

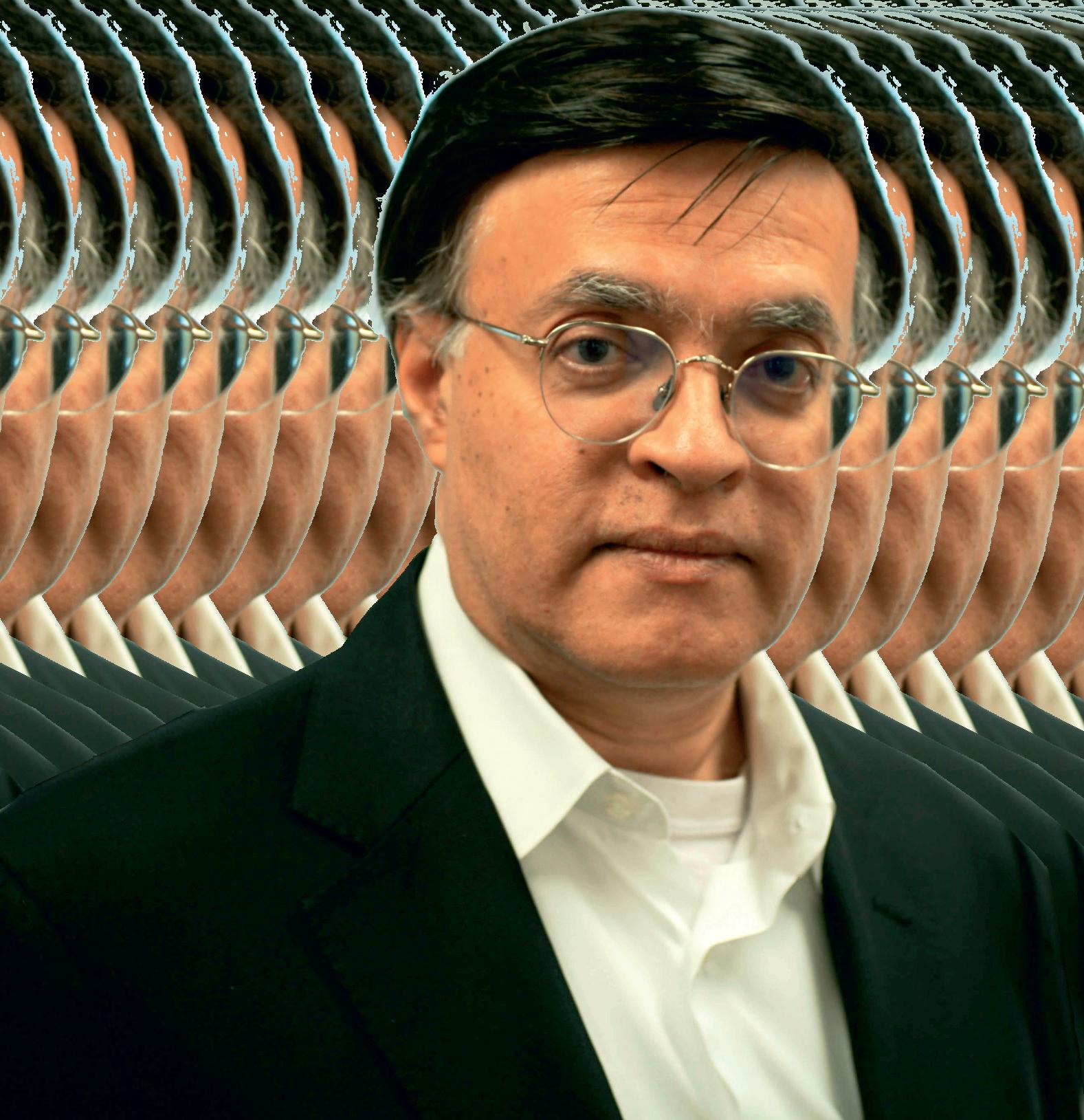

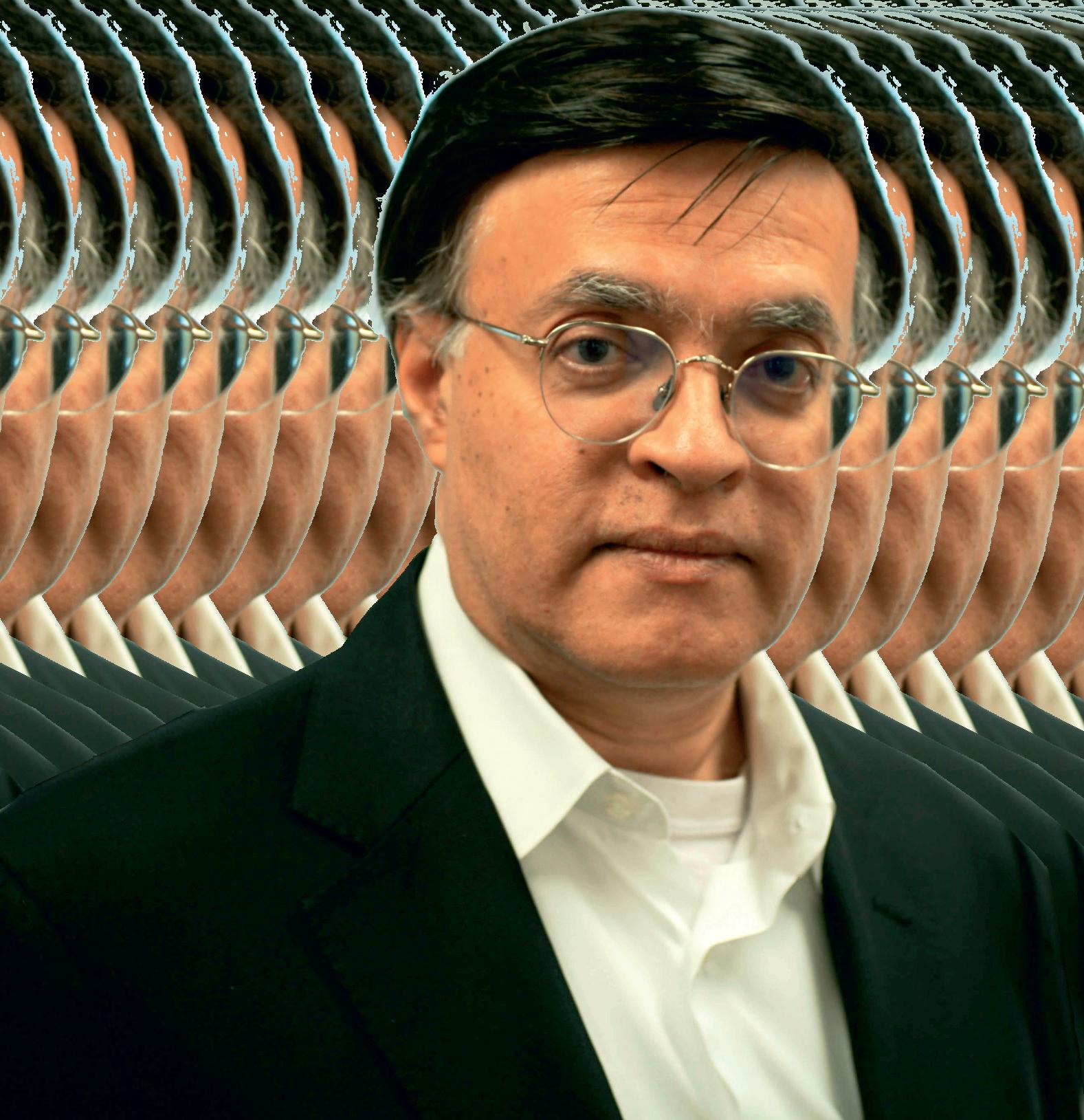

Inanerawheretechnologicalinnovationisreshapingindustries,visionary

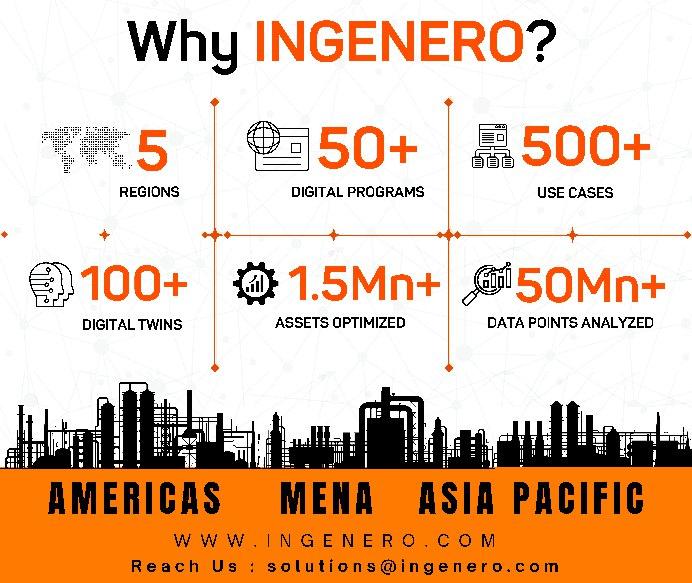

leaderswhopushtheboundariesofengineeringandsustainabilityare settingthepaceforthefuture.OnesuchtrailblazerisDr.PratapNair,a pioneeringfigureinglobalchemicalprocessengineering.AstheFounder, President,andCEOofIngenero,Dr.Nairistransforminghowindustries approachprocessengineering,optimization,andsustainabilitythroughcuttingedgedigitalsolutions.

Withasteadfastcommitmenttoinnovation,Dr.Nairhasrevolutionized chemicalandprocessengineeringbyintegratingadvanceddigitaltwin technology,AI-drivenanalytics,andreal-timemonitoring.Hisworkhas empoweredindustriestoenhanceoperationalefficiency,reduceenvironmental impact,anddrivesustainablegrowth.HisleadershipatIngenerohasnotonlyset newbenchmarksinprocessoptimizationbuthasalsodemonstratedtheimmense potentialofdigitaltransformationintraditionalindustries.

Beyondhistechnicalexpertise,Dr.Nair’sinfluenceextendstomentoringfuture leadersandadvocatingforsustainableindustrialpractices.Hisdedicationto advancingefficiency,safety,andenvironmentalresponsibilityhasearnedhim widespreadrecognitionasathoughtleaderandinnovator.

Aswemoveinto2025,Dr.PratapNairstandsasoneoftheMostImpactful PersonalitiestoFollow,inspiringprofessionalsandorganizationstoembrace technologicaladvancementsforasmarter,greener,andmoreefficientfuture. CIOLookrecognizesDr.PratapNairforhisoutstandingcontributionsto revolutionizingchemicalprocessengineeringandsettingnewstandardsfor globalindustrialtransformation.

Hisvision,expertise,andcommitmenttoinnovationmakehimabeaconof progress,provingthattechnologyandsustainabilitycangohandinhandto shapeabetterworld.

C O V E R S T O R Y

Pooja M Bansal Editor-in-Chief

Managing

Art

Associate

Senior

Customer

Technical

SEO

Dr. Pratap Nair Founder, President & CEO Ingenero

Revolutionizing Global Chemical Process Engineering with Ingenero

Dr. Nair, a visionary in advanced analytics and process engineering, describes a three-pronged approach to sustainability that leverages digital innovation and creative engineering.

Yesterday’smagicistoday’sreality.Today’s enchantingandimpossibilitieswillbetomorrow’s realism.That’showeverythingischangingata pacewhichmightfeelsupersonictoapersonfromthe19th centuryifthatpersonisnotDr.PratapNair,the legendary Founder,President&CEOof Ingenero

Asinatimethatsawthebirthofworld’stechmarvelinthe formofinternet,or‘the logical point where it all started,’ inDr.Nair’swords,thatis,inthe1980s,hegotabasic chemicalengineeringdegreefromIITBombay

InceptionofIngeneroinIngenuity

Dr.Nair’sjourneytofoundingIngeneroisrootedinadeep passionforchemicalengineeringandanunwavering entrepreneurialspirit.“The foundation for Ingenero was laid through years of hands-on experience in chemical engineering and a pioneering approach to process manufacturing,”heexplains.Withastrongacademicgrounding fromIITBombayandadoctorateinchemicalengineering fromRiceUniversity,Dr.Nair'searlycareerwasdefinedby innovation.Hisfirstjobinvolveddevelopingsimulation softwareforChemShare,acompanyrenownedforits processsimulationsolutions.“Even in the late '80s, we were building and deploying the first online optimizers, linking remotely to plants despite the technological challenges of the time,”herecalls,markingthisasa

“

Dr. Nair expanded his expertise, delving into process consulting, business development, and operational management in the pharmaceutical and specialty chemicals sectors. “

formativeperiodthatsparkedhisvisionforrevolutionizing theindustry.

Overtheyears,Dr.Nairexpandedhisexpertise,delving intoprocessconsulting,businessdevelopment,and operationalmanagementinthepharmaceuticaland specialtychemicalssectors.Theserolesprovidedhimwith a360-degreeviewoftheindustry’sneedsandgaps.

“Working both in the U.S. and India gave me a wellrounded perspective on what this industry lacked and how it could evolve,”heshares.Thisexperience,combinedwith hisentrepreneurialspirit,setthestagefortheinceptionof Ingenero.

“

Dr. Nair's journey with Ingenero has been driven by a deep understanding of the chemical industry’s challenges and the transformative potential of innovative solutions. “

Despiteskepticslabelingtheideaasaheadofitstime,Dr Nairestablishedthecompanywithseedfundingfrom Boston-basedventurecapitalistsandabusinesspartner Ingenero’smissionwasclear:tosupportglobalprocess manufacturingcompaniesbyleveragingIndia’stechnologicalexpertise.“It was a bold step, but I knew the industry needed a fresh approach. We bootstrapped our way forward, driven by the belief that we could make a difference,”headds.

Today,IngenerostandsasatestamenttoDr.Nair’svision andresilience.Bycombiningfoundationalknowledge, globalexposure,andacommitmenttoinnovation,healong withhisbusinesspartnersandstrongteam,hasbuilta companythatbridgescontinentsandtransformstheprocess manufacturinglandscape.

Dr.Nair'sjourneywithIngenerohasbeendrivenbyadeep understandingofthechemicalindustry’schallengesandthe transformativepotentialofinnovativesolutions.Reflecting onthecompany’sinception,heshares,“When we started, I saw a gap—particularly in the Western world—where the process industry was facing a ‘grandpa boom.’Experienced professionals were retiring, and fewer chemical engineers were entering the field. Meanwhile, in India, the industry was blooming with talent and potential.”Thisunique juxtapositionofchallengesandopportunitiesinspiredthe foundationofIngenero.

Initsearlydays,Ingenerofocusedonbridgingthisgapby leveragingIndia’sexpertiseinchemicalengineeringand couplingitwithadvancedtraininginsimulationtechniques andanalytics.Thecompanybeganprovidingremote supporttoprocessmanufacturingfacilities,analyzing operationaldataliketemperatures,pressures,compositions andflowrates.Dr.Nairdescribestheprocess:“Much like the medical field uses diagnostics to understand the human body, we used chemical engineering fundamentals to interpret plant operations and provide actionable insights.” ThisapproachenabledIngenerotopredictissuessuchas leaksandinefficiencies,preventingsafetyandreliability concernsbeforetheyescalated. Italsoservedasaneutral capabilitycenterenablingexperimentationwithprocess modificationsandoperatingchanges,utilizingsimulation anddigitaltwins,withouttheriskofonlineexperimentation.

Asthecompanyevolved,sodiditsservices.Ingenero expandedintodesignengineeringattherequestofits clients,creatingagroupdedicatedtoengineeringsolutions. In2014,thecompanytookasignificantleapbyintegrating appliedAItoolstoautomateitsremotesupportoperations, birthingtheDigitalSolutionsGroup.“This group was an evolution of our initial support services, leveraging AI to enhance decision-making and operational efficiency,”Dr Nairexplains.Today,thisgroupleadsthecompany’sefforts indigitaltransformation,deliveringcutting-edgedigital solutionstoclientsglobally

Ingenerohasalsodiversifieditsexpertise,establishinga safetypracticetoreviewfacilityoperationalsafetyanda nascentsustainabilitygroupfocusedongreenerindustrial processes.Dr.Nairemphasizesthecompany’smultifaceted mission:“We’ve grown from being a remote plant life cycle support service to a comprehensive provider of engineering expertise and digital transformation. Our goal is to help plants improve productivity, efficiency, and safety while embracing sustainability.”

Throughitsinnovativeapproach,Ingenerohasbecomea vitalpartnerfortheprocessofmanufacturingindustries.It blendsoperationalanalytics,engineeringexcellence,and digitaltransformationtoreshapethechemicalindustry’s future.

IncorporatingArtificialIntelligence(AI)intochemical processengineeringhasrevolutionizedhowindustries

operate,analyze,andoptimizetheirprocesses.Dr.Nair, reflectingonIngenero’sjourney,sharesinsightsintohow thecompanyhasimplementedAItodelivertransformative results.“Our approach to AI is what we call applied AI—tailored specifically for process manufacturing. It’s about leveraging AI and co-enabling tools within a framework of deep domain expertise to create meaningful value.”

Thejourneybeganin2014whenapivotalinteractionwith theCEOofaleadingmidstreamcompanyintheU.S. highlightedacriticalgap.Despiteinvestingheavilyin digitizationandcreatingcentralizeddatavisibilityacross60 facilities,theCEOadmitted,“I’m seeing the data presented beautifully, but I’m not able to get any value out of it.”This revelationspurredIngenerotocombineAIwiththeir domainknowledgetodevelopdigitaltwinsforthefacilities,enablingactionableinsights. In the first year alone, these implementations resulted in tangible benefits exceeding $25 million.

However,thepathtosuccesswasn’twithoutitschallenges. Initially,theteamgrappledwithintegratingdatascience intoadomain-specificcontext.Dr.Nairrecalls,“We tried hiring data scientists to apply their skills directly to our vertical, but it didn’t work well. Instead, we found greater success training our domain experts in data science, to work better with data science teams, enabling them to bridge the gap effectively.”Thisstrategybecamea cornerstoneofIngenero’sapproach,ensuringaseamless blendofprocessengineeringexpertiseandadvanced analytics.

Dr. Nair’s leadership philosophy revolves around recognizing the diverse abilities within his teams. “

OneofthekeydifferentiatorsinIngenero’sAI-driven solutionsistheirfocusondeliveringvaluethrough integrationandusability.Beyonddeployingalgorithms,the teamemphasizescreatinginteractivedashboards,employingaugmentedandvirtualreality(AR/VR),andintegrating solutionsintoclients’workflows.Dr.Nairexplains,“It’s not just about presenting data but telling a story and ensuring that the final action is taken to improve operations.”

Fastforwardtotoday,Ingenero’sAI-enabledsolutionshave beenimplementedacrossnumerousfacilitiesworldwide, deliveringunparalleledvalueandoperationalexcellence. Theirsuccessunderscorestheimportanceofhybridizing domainexpertisewithcutting-edgetechnology AsDr.Nair putsit,“The secret sauce lies in marrying deep domain knowledge with AI, data science, and IT to extract the value that pure data science alone cannot deliver.”

Throughtheseinnovations,Ingenerohasnotonlyenhanced chemicalprocessengineeringbutalsosetabenchmarkfor howAIcanbeeffectivelyutilizedinspecializedindustrial verticals,provingthattargeted,domain-specificapplicationsofAIholdthekeytotransformativesuccess.

Establishingrobustsuccessmetricsisvitalforensuring measurableimpactinchemicalprocessengineering, particularlywhenimplementingAIsolutions.Dr.Nair providesvaluableinsightsintohowthecompanyevaluates success,emphasizingthemultifacetednatureofbenefits beyondmonetarysavings.“Success for us is not just about millions saved—it’s about enhancing efficiency, improving safety, and ensuring the long-term reliability of our clients’ operations.”

AtthecoreofIngenero’sapproachliesanunderstandingof industry-specificmetricshonedthroughyearsofremote supportforprocessmanufacturing.Thesemetricsinclude efficiency,energyuse,emissions,andsafety AIbroughta transformativecapabilitytoanalyzevastdatasets,uncover patterns,andidentifyleadingindicatorsthatthehuman mind—orevenlargeteams—couldoverlook.Dr.Nair explains,“AI doesn’t just do the same thing faster; it opens up entirely new possibilities by covering a breadth of data that was previously unimaginable.”

OneofthekeybenefitsofAIliesinitspredictive capabilities.Forinstance,itenablesoperatorstodetect potentialequipmentfailuresmonthsinadvance,reducing theriskofunplannedshutdownsandcostlydowntime.This earlywarningsystemsignificantlyenhancesreliability.Dr Nairshares,“Looking at leading indicators and getting months of advance notice allows operators to address issues proactively rather than reactively. That’s where AI transforms operations.”

However,implementingthesesolutionsisn’twithout challenges.AcommonmisconceptionisthatAIisaplugand-playsolution,butasDr.Nairnotes,“AI implementations demand extensive model training, testing, and domain expertise based knowledge infusion to ensure the results are credible and actionable.”Thefailureofearlyadoptersin theindustryoftenstemmedfromunrealisticexpectations andinadequateintegration,leadingtoskepticismaboutAI’s potential.

Byfocusingonbuildingcredibilityfromtheoutsetand integratingdomainexpertisewithAIcapabilities,Ingenero hasestablisheditselfasaleaderindeliveringresultsthat matter.Theseresultsnotonlymitigaterisksinhigh-stakes manufacturingenvironmentsbutalsofostertrustandlongtermclientsuccess.Thus,thecompany’ssuccessmetrics extendbeyondquantifiablesavingstoincludeoperational resilienceandstrategicreliability,whichultimatelydefine thevalueofitsservices.

Fosteringinnovationinanorganizationrequiresaleadershipstylethatemphasizescollaboration,empowerment,and adaptability.Dr.PratapNairofIngeneroshareshisinsights intocreatingaculturethatprioritizesinnovation,particularlyinthedemandingfieldofadvancedanalytics.

“Innovation cannot rely on one person—it thrives when multiple minds come together, sharing ideas and driving creative solutions.”

Dr.Nair’sleadershipphilosophyrevolvesaroundrecognizingthediverseabilitieswithinhisteams.Heacknowledges thatwhilesomeindividualsexcelinstructuredenvironmentsandperformwellwithcleardirectives,others flourishwhengrantedautonomy.Thekeytofostering innovation,heexplains,isempoweringthesecreative minds.“Once people feel empowered, they take ownership of their work and start thinking beyond the immediate tasks, which is when true innovation begins.”

Tocreateanenvironmentconducivetoinnovation, Ingeneroadoptedaflatorganizationalstructurethat minimizeshierarchicalconstraints.Thisapproachencouragesopencommunicationandallowsteammembersatall levelstocontributeideas.“We’ve intentionally avoided a highly hierarchical setup because innovation requires creative thought to flow freely across the organization,” saysDr.Nair.Bybalancingtheneedfortechnicalexpertise withcreativeproblem-solving,thecompanyensuresthat innovationalignswiththepracticalitiesofprojectexecution anddelivery

AnothercornerstoneofDr.Nair’sleadershipstyleis adaptability Asthebusinesslandscapeevolves,heemphasizestheimportanceofstayingattunedtomarkettrendsand beingwillingtopivotwhennecessary.Steeringthe organizationinnewdirectionsrequiresengagingtheteam, encouragingdiverseperspectives,andcollaboratively decidingthebestcourseofaction.“When you have an idea, it’s important to bring everyone on board, listen to their perspectives, and collectively decide the way forward,”he explains.

ThisleadershipstylehasnotonlyhelpedIngenerostay aheadofindustrytrendsbutalsocultivatedaculturewhere innovationisasharedresponsibility.Byfosteringasenseof ownershipandencouragingcreativity,theorganization continuestothriveinadynamicandcompetitiveenvironment,settingabenchmarkforwholesomeleadership innovation.

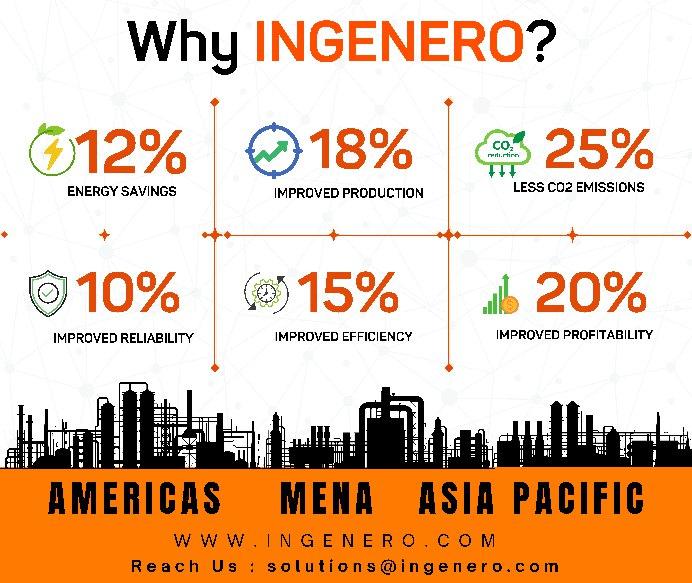

Sustainablemanufacturingisevolvingrapidly,with solutionsemergingacrossshort-,medium-,andlong-term horizons.Dr.Nair,avisionaryinadvancedanalyticsand processengineering,describesathree-prongedapproachto actionablesustainabilitythatleveragesdigitalinnovation andcreativeengineering.“In the short term, digital solutions allow us to track, measure, and optimize operations in real-time, helping reduce emissions and energy usage while improving resource efficiency,”heexplains. Theseimmediateactionsoffertangiblebenefitsandlaythe foundationforamoresustainablefuture.

Formedium-termgoals,Dr.Nairemphasizestheimportanceofadaptingandscalingemergingtechnologies.This includesincorporatingbio-basedfeedstocks,transitioning energysources,andimplementingadvancedrecovery systems.“We excel at bridging the gap between lab-based innovations and industrial applications, ensuring that

groundbreaking process technologies are scalable and effective in real-world settings,”henotes.Byworking closelywithtechnologyvendors,Ingeneroacceleratesthe adoptionofsustainablepracticeswithinthemanufacturing sector.

Long-termsustainabilityeffortsfocusongroundbreaking innovationslikecarboncaptureandutilization(CCU). Theseprojectsaimtoconvertcapturedcarbonintovaluable chemicalsratherthanmerelystoringitunderground.“We are partnering with institutes and early-stage companies to develop and industrialize transformative technologies, ensuring their readiness for large-scale implementation in the decades ahead,”saysDr.Nair.Byinvestinginand collaboratingwiththesepioneers,Ingeneroactively contributestoshapingasustainablemanufacturingfuture.

Dr.Nair’sholisticapproachreflectsacommitmentto addressingsustainabilityateverylevel—short-term efficiency,medium-termprocessinnovation,andlong-term technologicalbreakthroughs.Thisstrategynotonlyaligns withglobalsustainabilitygoalsbutalsopositionsIngenero asaleaderindrivingtransformativechangeinthemanufacturingindustry

Greenchemistryisascienceofdesigningchemicalproducts

andprocessesthatminimizeoreliminatetheuseand generationofhazardoussubstances.Itisanapproachapplied throughtheentirelifecycleofachemicalproductfromitscreationto itsmanufacturing,application,anddisposal.Chemicalsandprocesses shouldaimtoensurethattheybecomecheaperandsafer,but performancewillbeatasimilarlevelcomparedtotheirpolluting counterparts;thepollutionitminimizeswouldcomefromthesource. Diminishingwaste,maintainingrawmaterials,andminimizingallsorts ofnegativeeffectsforhumanhealthandtheenvironmenthavemuchto dowithgreenchemistry.

Greenchemistryleadstocleanerairandwatersinceitreducesthe emissionofhazardouschemicals.Thismeanslessdamagetopeople's lungsandcleanwaterfordrinkingandrecreation.Italsomakes workplacesinthechemicalindustrysaferbyreducingtheuseoftoxic materialsandtheriskofaccidents.Theoutcomeofgreenchemistryis saferconsumerproducts,includingdrugs,pesticides,andcleaning agentsmadeinlesserconcentrationsofchemicalsthatcancauseharm andwithlesswaste.Italsomeanssaferfoodsinceiteliminates persistenttoxicchemicalsthatcanfindtheirwayintothefoodchain.

FortheEnvironmentManychemicalsarereleasedthroughdeliberate emissions,accidentalreleaseintheproductionsite,orintothe environmentduringdisposal.Greenchemicalsdecomposeinto harmlessproductsorgetrecycledforfurtheruseandhenceplantsand animalsareexposedtofewertoxicchemicals.Greenchemistryalso decreasesthechancesofglobalwarming,depletionoftheozonelayer, andformationofsmogandchemicaldisruptionofecosystems.Italso reducestheextentoflandfills,particularlythatofhazardouswastes.

Intermsofgreenchemistry,itimplieshavinghigheryieldsofchemical reactionsthatmeanlowerinputofrawmaterialstodeliverasimilar

outputofproduct.Usually,therewouldbelessrequirement forsyntheticsteps,acceleratingmanufacture,boostingplant capacity,andsavingonenergyandwaterresources.

Withthiswastereductionapproach,expensivecleanup, toxicwastesdisposal,andend-of-pipetreatmentis eliminated.Greenchemistryalsoallowscompaniesto replacepurchasedrawmaterialswithwasteproductsand improveproductperformancesothatlessproductis needed.Italsoreducestheuseofpetroleumproducts, whichslowsdowntheirdepletionandavoidsprice fluctuations.Greenchemistrycanevenreducethesizeof manufacturingplantsbecauseofincreasedproduction. Finally,itcanincreasesalesbyallowingcompaniesto makeuseofsafer-productlabels.

Greenchemistrybasesitsdesignofchemicalproductsas wellashowtoimplementitonanumberofprinciples whichguidethesystem.Theseinclude:

• Prevention:Itisbettertopreventwastethanitistotry tocleanuportreatitafteritisformed.

• AtomEconomy:Syntheticmethodsshouldbesuchthat theyavoidtheuseofallavailablematerialsinthe processinthemostburiedform.

• LessHazardousChemicalSyntheses:Wherever practicable,syntheticmethodsshouldbedesignedto workwithmaterialsthatofferlittleornotoxicityto humanhealthandtheenvironment.

• DesigningSaferChemicals:Chemicalproductsshould bedesignedtosupporttheirintendedfunctionwhile reducingtheirtoxicity.

• SaferSolventsandAuxiliaries:Theuseofauxiliary materials,suchassolvents,separationagents,etc., shouldbeavoidedwhereverpracticableandharmless whenused.

• DesignforEnergyEfficiency:Allchemicalprocesses mustbeassessedintermsoftheirenergydemandsso thatboththeirecologicalandtheireconomic consequencescouldbeassessedandminimized.Where feasible,syntheticroutesshouldbeperformedat ambienttemperatureandpressure.

• UseofRenewableFeedstocks:Afeedstockorstarting materialmustberenewableratherthanadepleter wherevertechnicallyandeconomicallyfeasible.

• Derivatives:Inprinciple,avoidallunnecessary derivatizationsteps:blockinggroups,protection/ deprotection,temporarymodificationof physical/chemicalprocesses;thismeansextrareagents

areinvolvedandwasteswillbegenerated.

• Catalysis:Catalyticreagents-asselectiveaspossiblearesuperiortostoichiometricreagents.

• DesignforDegradation:Chemicalproductsshallbe designedsuchthat,whentheyhavecompletedtheir function,theydegradeintoharmlessproductsanddo notpersistintheenvironment.

• Real-timeanalysisforPollutionPrevention:Analytical methodsneedtobedevelopedfurtherinorderto facilitatereal-timemonitoringandcontrolpriortothe generationofhazardousproducts.

• InherentlySaferChemistryforAccidentPrevention: Thesubstanceandformofasubstanceusedina chemicalprocessshallbeselectedsuchthatchemical accidentssuchasrelease,explosion,andfirecanbe minimized.

Greenchemistryisappliedinmanyindustriesfor developingproductsormanufacturingprocesses.Someof theseare:

• Developingnew,saferpesticidesthataretoxiconlyto specificpestsandthatbreakdownquicklyafteruse.

• Designingnew,moreenergy-efficientmanufacturing processesthatreducewasteandemissions.

• Creatingnew,biodegradableplasticsthatcanreplace traditionalplasticsmadefrompetroleum.

• Usingrenewableresourcessuchasbiomasstoproduce chemicalsandfuels.

• Designingsaferchemicalsthatarelesstoxictohuman healthandtheenvironment.

Greenchemistryisvitalforthepreservationofhuman healthandtheenvironment.Greenchemistryisa developingfield,henceprovidingsolutionstoproblems suchasclimatechange;itsprinciplesarethusnecessaryfor futuregenerationstoacknowledge.Thisisbecause sustainabledevelopmentsingreensynthesis,energyefficientproductionprocesses,andtheuseofrecyclableand reusablematerialsplayaverysignificantrole.

Themajorgoalsofgreenchemistryaredesigningmore resource-efficient,intrinsicallysafermolecules,materials, products,andprocesses.Greenchemistryisapathway throughwhichwecanshiftfromcircumstance-driven solutionsformoreintrinsiconessolvingtheproblemof environmentalitselfatthesource.

Inchemicalprocessmanufacturing,safetyprotocolsarethemost

importantthing.Chemicalprocessesandproductsareavitalpart ofmodernlifeandplayaveryimportantroleinpharmaceuticals, petrochemicals,andfoodindustries.

However,improperhandlingoruseofchemicalsmaycausesevere accidents,injuries,andevenfatalities.Thus,safetyinchemical processesandproductsisofutmostimportancetoprotectworkers,the environment,andthepublic.

Processsafetyisunderstandinghazardsandrisks,managingrisks throughtheprovisionofappropriatelayersofprotectiontominimize thefrequencyandseverityofincidents,andlearningfromincidents whentheyoccur.Itinvolvesidentifyingandunderstandingpotential hazards,assessingconsequences,safeguards,andrisks,andthenadding layersofprotectiontopreventormitigateincidents.Thesesafeguards protectstudents,staff,faculty,thepublic,theenvironment,and property

AgoodsolidSafetyManagementSystem(SMS)istheplatformofsafe productionofchemicals.AgoodandeffectiveSMSneedshazard identificationorriskassessmentincludingtheimplementationof controlmeasuresatappropriatestagestopreventaccidentsregularly AsassertedbyOSHA,theHazardsIdentificationorRiskAssessment successfullyimplementedwilllikelyreduceinjuriesoftheemployees whileworkingatsitesbyupto25%.

Thereareseveralkeyelementstoensurethatchemicalmanufacturing processsafetyisundertaken,includingHazardIdentificationandRisk Assessment(HIRA).Thisidentifiesandassessestheriskoftenenough andpreventsaccidents;andawell-implementedHIRAcanremarkably reduceworkplaceinjuries.Startwithidentifyingpotentialhazardsthat couldariseduringthechemicalprocessorproductdevelopment, includingchemicalreactionsandfires,explosions,andexposureto hazardoussubstances.

Assessthelikelihoodandseverityofeachhazard,taking intoaccounttheamountandconcentrationofchemicals used,thetemperatureandpressureoftheprocess,andthe possibilityofhumanerror.Identifywhomightbeharmed byeachhazard,includingworkersinvolvedintheprocess, nearbyresidentsorcommunities,ortheenvironment.

• SOPs:Specific,detailedSOPsensureauniformityin operationsandalsosafetypractices.SOPsshallbe reviewedforperiodicupdateswherethereare variationsinprocessesorregulations.

• EngineeringControls:Suchcontrolsinvolve engineeringchangestoanyequipmentortheprocess thatisdonetocontroloreliminateanyhazard. AdministrativecontrolsorevenPPEnormallyarenot nearlyasreliableasthesecontrols.Examplesinclude ventilationsystems,whichgreatlyreducethe concentrationofairbornecontaminants,and containmentandisolationmethods,whichavoid exposure.TheEuropeanAgencyforSafetyandHealth atWork(EU-OSHA)saysthatpropercontainmentcan cutdownexposuretodangerouschemicalsbyasmuch as73%.Automatedsystemsalsocanminimizehuman exposuretohazardousprocesses.

• AdministrativeControls:Theadministrativecontrols consistofsafelabprocedures,chemicalhygieneplans, jobsafetyanalysis,managementofchange,andsafe workpractices.

• BehavioralControls:Thebehavioralcontrolsconsistof personalprotectiveequipment(PPE),righttools,useof stop-workauthority,andfollowinglabprocedures.

• PersonalProtectiveEquipment:Theprovisionof appropriatesafetyequipmentisessentialinprotecting employees.Thismaybepersonalprotectiveequipment suchasgloves,goggles,respirators,andprotective clothing.Ensuretheemployeesknowhowtouseand maintaintheequipmentproperly

• EmergencyPreparednessandResponse:Emergency preparednessiscrucialinreducingtheeffectsofa chemicalaccident.Aneffectiveresponsetoan emergencysaveslivesandminimizesdamage.Key aspectsofemergencypreparednessincludeelaborative plansstatingwhattodoincaseofachemicalspill,fire, orexplosion.

Forchemicalprocessesandproductstoremainsafe, implementationandmaintenanceofsafetystandardswith respecttostoringandusingchemicalsareessential, involvingthefollowingsteps:

• ControlandMitigationMeasures:Developingcontrols andmeasurestomitigatethesehazardsbasedontheir likelihoodandseverity.Inmostcases,thesecontrols involveengineeringcontrolsoradministrativecontrols while,incertainsituations,usingpersonalprotective equipmentmaybeindispensable.

• ImplementtheControlsandMitigationMeasures: Oncethecontrolsandmitigationmeasureshavebeen developed,theyshouldbeimplementedinthechemical processorproductdevelopment.Thiswillinvolve changingequipmentorproceduresorproviding employeeswithappropriatepersonalprotective equipment.

• TrainEmployeesAllemployeeswhomaycomeinto contactwithchemicalprocessesorchemicalproduct shouldbegiventheappropriateeducationaboutsafety practicesandprocedures.Suchtrainingincludes teachingemployeesontheuseofpersonalprotective equipment,howtoreactinanemergency,andproper handlingofhazardousmaterials.

• RegularReviewandUpdateofSafetyProtocols:The safetyprotocolsandcontrolsshouldberegularly reviewedandupdatedtoensuretheyremaineffective andrelevant.Thismayinvolveconductingperiodic auditsorinspectionsoftheprocesstoidentifyany potentialissues.

• Documenttheoutcomeoftheriskassessment, indicatinghazardsidentified,thelikelihoodofthe hazardhappening,andseverityincaseofthehazard.It alsogivesdetailsonthecontrolsandmeasuresthat havebeentakentominimizetheriskinvolvedwiththe injury

• ReviewandUpdatetheRiskAssessmentRegularly: Reviewandupdatetheriskassessmentregularlyto ensureitremainsrelevantandeffectiveasconditions change,suchaschangesinchemicalsusedor modificationstotheprocess.

ProcessSafetyManagementSystemaimsforexcellenceby wayofcontinuousimprovementandemployeeinvolvement inthesafeoperationofplants.Implementingappropriate safetyprotocolsandcontrolshelpsminimizeharmto employees,thenearbycommunity,andtheenvironment. Beingup-to-dateandimplementingbestpracticesand constantimprovementsinsafetywillmakeaplacesaferto workin.