SMaLL

Pushing the limits of nanofabrication into the third dimension

By Mary SpIro

W

Tetherless thermobiochemically actuated microgrippers Gracias Lab/JHU

18 | Johns Hopkins NanoBio Magazine

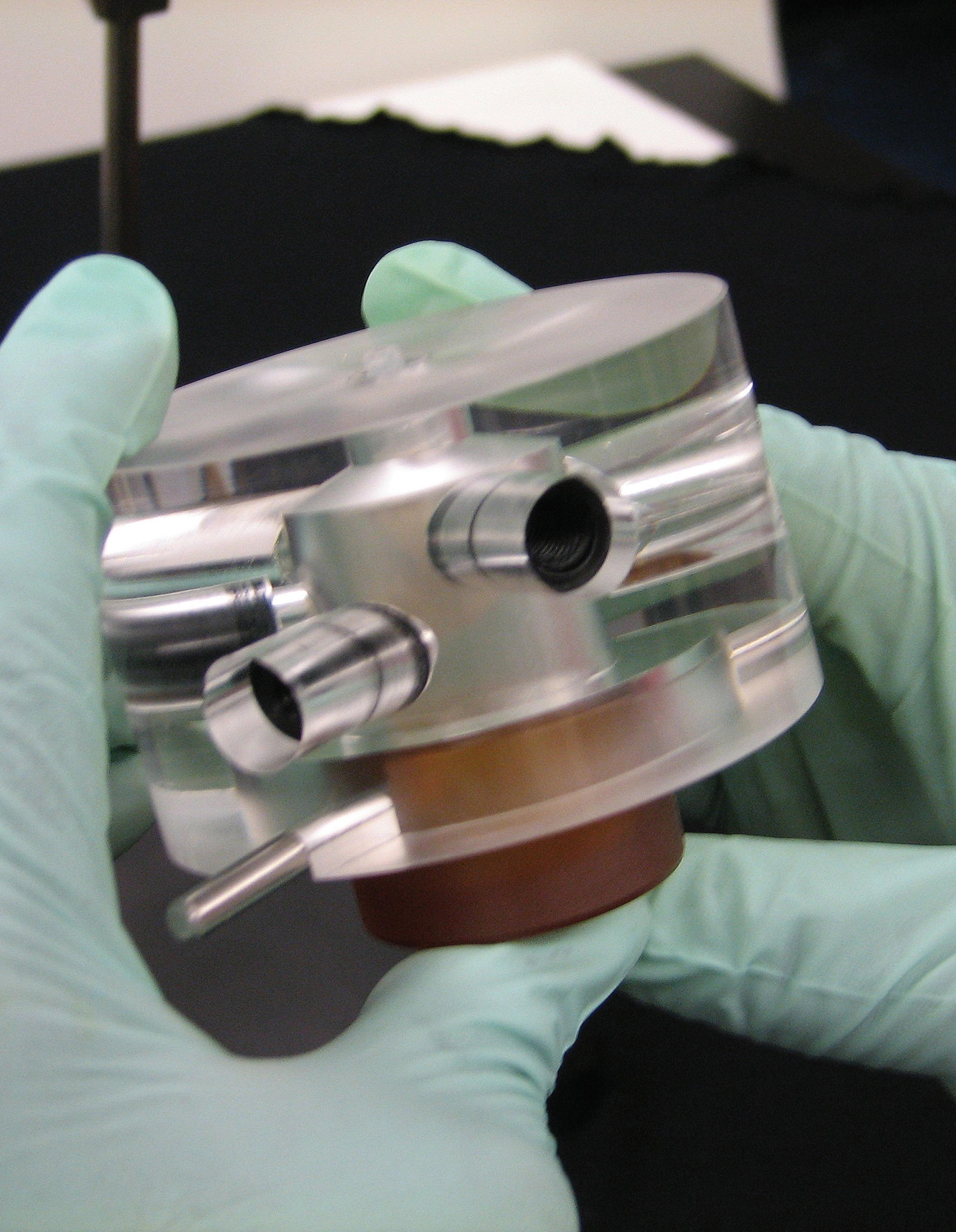

hen Johns Hopkins University engineer David Gracias started building self-assembling structures that were millimeters to tens of microns in size, he knew he’d developed something with staggering potential. Self-loading micro-containers developed by members of his lab might one day carry life-saving drugs or protect transplanted cells from the immune response. Gracias, an associate professor of chemical and biomolecular engineering and a member of the Johns Hopkins Institute for NanoBioTechnology (INBT), wondered how small he could make these objects. How far could one push the limits of nanofabrication, especially into the third dimension? It turns out that the answer to that question is pretty darn small. Gracias and his colleagues recently constructed a 100 nanometer cubic container with precisely patterned surfaces. One nanometer is one-billionth of a meter in length or about 1/100,000th the width of a human hair. “These cubes are about 15 times smaller than anything we’ve constructed. They are ten times smaller than a bacterium and are the typical size of viruses or small organelles within eukaryotic cells. Previously, no one has been able to sculpt a 3D nanoparticle with precisely patterned surfaces, so this is a big leap in human engineering,” Gracias said.