4 minute read

International Efforts Delivers N95 Masks, Face Shields for Johns Hopkins Health System

By Amy Weldon Honggang Cui watched with concern early this year as his hometown in China’s Henan province locked down to prevent the spread of the novel coronavirus, quickly spreading from Wuhan to neighboring Hubei province. Cui knew from media coverage that medical supplies, including the PPE used by frontline healthcare workers, became scarce during the height of the pandemic. So, when COVID-19 began to spread in the United States in late February, the associate professor of chemical and biomolecular engineering at the Whiting School wanted to do something to help. “My hometown was hit very hard and was on lock down,” said Cui, a member of the Institute for NanoBioTechnology. “I knew how bad it would be, so I wanted to try and find PPE supplies in China and have them sent to our healthcare workers here at the Johns Hopkins Health System.” Cui began asking friends and family back in China to help him with this project, but quickly learned that other JHU faculty, including fellow professor and INBT Associate Director Hai-Quan Mao, students of Chinese heritage, and their parents all had the same idea. Connecting at first as strangers via the internet, they joined forces, leveraged their resources and succeeded in coordinating the delivery of 10,000 face shields and N95 masks from all over China to the Health System in mid-April. Diana Yin, the parent of computer science third-year student William Li, was one of those spearheading the effort. Yin, a Florida resident, said she was inspired to give back after friends, acquaintances, and strangers from around the world came together to support her while her oldest son, away at graduate school on the West Coast, was seriously ill with what they now think may have been COVID-19. After she mentioned on a JHU parent WeChat group her plans to buy and send 1,000 face shields from China to the U.S., Cui and others expressed their willingness to do the same. In the end, contributions from more than 40 people, including JHU faculty and parents, helped that order grow to 10,000.

“I was overwhelmed by all the help we received,” said Yin. “In just 24 hours, we got all of this done, and friends of mine in China helped us negotiate fair prices for the face shields, so we could order as many as possible.” These efforts by members of the WSE community are among several similar projects across Johns Hopkins, including the School of Medicine and Krieger School of Arts and Sciences, and amassing nearly 10,000 pieces of PPE equipment. With China and Chinese heritage as their common denominator, those involved expressed that they were motivated to help healthcare workers facing the challenges of caring for patients during this global pandemic.

Advertisement

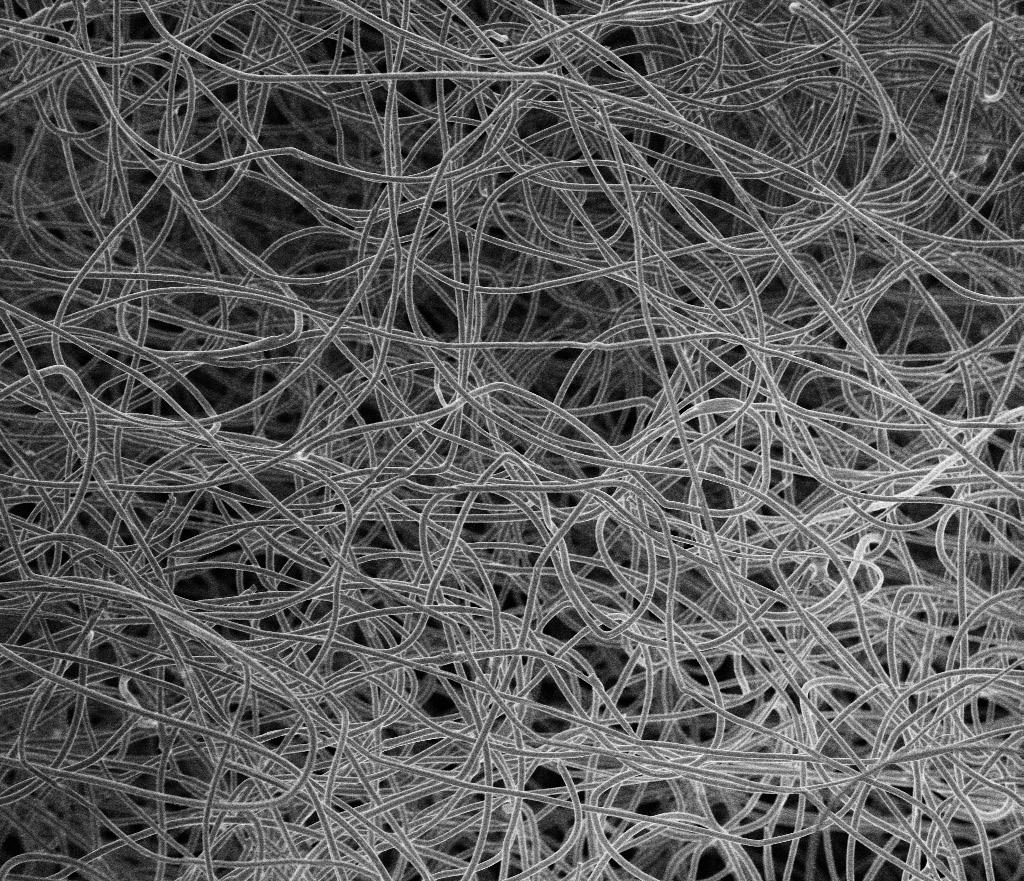

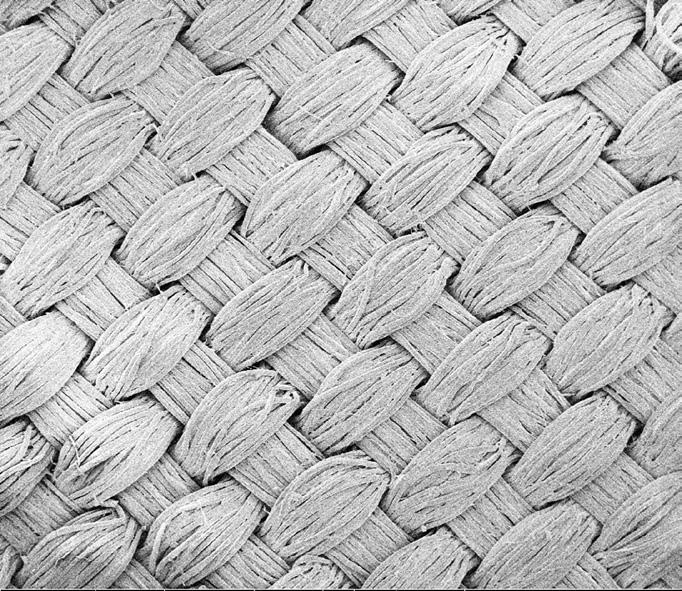

Microscopy image of a polypropylene (PP) filter from a N95/K-N95 mask (left). A sample of the woven polyester fabric filter created by students (right).

“No matter if you are Chinese or American, this virus is spreading around the world and we, as humans, have a fundamental motivation to help others,” said Yin.

Around the same time Cui and company were making plans to ship PPE from China, a group of undergraduate students were embarking on a project to help another hard-hit country to develop and manufacture masks for its population.

Biomedical engineering students Michael Lan (’21), Anson Zhou (’23), Jerry Yan (’19), and materials science & engineering major Bruce Enzman (’22) were approached by Hai-Quan Mao to work with Junaid Abdul Razzak of the JHU School of Medicine, and a clothing manufacturer in Pakistan to help tackle the shortage of surgical masks there.

“At the beginning of the pandemic, there were something like 15,000 masks available for the healthcare workers in all of Pakistan,” said Zhou. “We have worked with electrospinning, which is a technique that creates nanofibers and that’s why Dr. Mao reached out.” The student group met virtually with Pakistan healthcare and textile workers to assess what materials and manufacturing technology was immediately available and began designing filters and the processes for making them. After researching the textiles available, the group decided to go with a woven polyester fabric because of its availability and structural stability.

By the end of summer, their cohorts in Pakistan had begun the testing phase for the polyester fabric filters and the students shifted their focus to product design and that’s when they connected with Leslie Speer of the Maryland Institute College of Art (MICA). Together, along with Speer’s product development course students, they began designing the masks that would house the new filters.

The engineering students found the thought processes of the art students to be wildly different from their own, but together the JHU and MICA students developed a design that is now in the prototype phase and approaching completion.

If anything, 2020 has been a year of unlikely connections, network-building, interdisciplinary cooperation, and innovation. We are proud to have INBT students on the frontlines.