International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

Sunny Patel, Shubham Jogani, Dip Chaklashiya, Dharmik Chodvadiya, Miten Naliyadhara,Vaibhav Monpara

Abstract - Water injection systems represent a transformative approach to enhancing internal combustion engine performance. These systems utilize water’s thermodynamic properties to reduce intake temperatures, increaseair density,andoptimizeenginecombustion, leading to improved horsepower and efficiency. The BMW M4 GTS, a high-performance sports car, exemplifies the practical applicationofthistechnology. Thispaperprovidesanin-depth explorationoftheprinciples, design, andadvantagesofwater injection systems, with a detailed examination of their implementation in the BMW M4 GTS. Additionally, advanced mathematical analyses illustrate the quantitative impact on air density, temperature, and power output.

Key Words: Water Injection Technology, Engine Performance, Air Density Enhancement, Knock Prevention, High-Performance Engines

1.INTRODUCTION

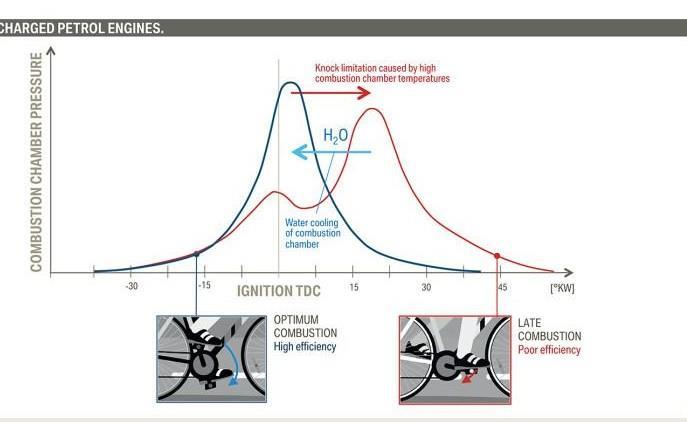

The relentless pursuit of enhanced performance in automotive engineering has spurred the development of innovativetechnologiesdesignedtoboostengineefficiency, reliability,andpower.Waterinjectionsystemsstandoutasa revolutionary advancement, offering a unique method to addresscriticalchallengessuchasknocking,thermalstress, andfuelinefficiency.Byinjectingafinemistofwater,often combinedwithmethanol,intotheintakeairorcombustion chamber, these systems achieve significant cooling, increasing air density and reducing the likelihood of prematurecombustion.Thisenablesenginestooperateat higher boost pressures and advanced ignition timings, resulting in substantial gains in power and efficiency. A primeexampleofthisinnovationistheBMWM4GTS,which employswaterinjectiontodeliverexceptionalperformance without sacrificing reliability. This paper explores the foundational principles of water injection, its technical application in the BMW M4 GTS, and the theoretical and mathematicalinsightsintoitsbenefits,includingincreased airdensity,improvedcombustion,andreducedemissions. Beyondhigh-performancevehicles,thebroaderpotentialof water injection extends to hybrid systems, heavy-duty engines,andapplicationsinsectorslikeaviationandmarine propulsion.Astheautomotiveindustryincreasinglyfocuses onsustainabilityandefficiency,waterinjectionemergesasa promisingsolutionwithvastpotential forglobal adoption andfuturedevelopment.

Techblog.com)

Water injection operates on the concept of evaporative cooling. By injecting atomized water into the intake manifold, the system reduces intake air temperatures throughheatabsorptionduringthephasechangefromliquid tovapor.Thisleadstodenserairenteringthecombustion chamber,enhancingtheengine’sperformancepotential.

Key Benefits:

Knock Mitigation: Lowering peak combustion temperatures reduces the risk of engine knock, allowinghighercompressionratios.

Improved Efficiency: Cooler, denser air enables more complete combustion, optimizing thermal efficiency.

IncreasedPowerOutput: Enhancedchargecooling permitshigherturbochargerboostpressures.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

reddit.com)

TheRoleofWaterInjectioninMassAirflow

Waterinjectionplays a crucial roleinincreasingthe mass airflowintotheenginebyreducingintaketemperatures.As wealreadyknow,coolerairisdenser,anddenserairallows more oxygen to enter the engine. Water injection lowers intake temperatures, which increases air density. This increaseinairdensityisaresultoftheincreaseinpressure theenginecansafelyhandlewithoutknocking.

EffectonAirDensityandBoostPressure:

Water injection enables the engine to run at higher boost pressures. This is critical because as boost pressure increases,themassofairenteringtheenginealsoincreases. Asairdensityincreases,moreairandoxygenareavailable forcombustion.

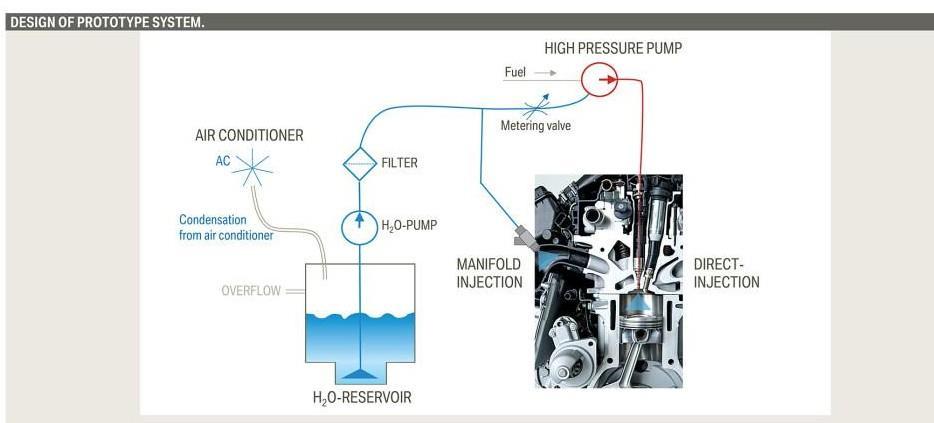

The BMW M4 GTS integrates an advanced water injection systemdevelopedincollaborationwithBosch.Thesystemis designedtooptimizetheperformanceoftheS55engine,a 3.0Ltwin-turboinline-6powerhouse.

Key Components:

Water Tank: A 5-liter tank located in the trunk provides waterforinjection.

Pump: Pressurizeswatertoensureprecisedelivery.

Nozzles: Atomize the water for even distribution into the intakemanifold.

Process Description The water injection process in the BMWM4GTSfollowsthesesteps:

1. Water Storage: Water is stored in a 5-liter tank located in the trunk. The tank is insulated to maintain the water’s temperature and prevent contamination.

2. Water Delivery: Ahigh-pressurepumpdeliversthe waterfromthetanktotheenginebaythroughheatresistanttubing.

3. Water Atomization: At the intake manifold, precision nozzles atomize the water into fine droplets,ensuringuniformmixingwiththeintake air.

4. Cooling Effect: As the atomized water enters the intakemanifold,itevaporates,absorbingsignificant heatfromtheair.Thisreducestheair’stemperature andincreasesitsdensity.

5. Combustion: Thecooledanddenserairentersthe combustion chamber, enabling higher boost pressures and improved combustion efficiency withouttheriskofknocking.

6. System Monitoring: Sensorscontinuouslymonitor the system’s performance, including water levels, injection pressure, and air intake temperatures, ensuringoptimaloperation.

Technical Specifications: -

EngineConfiguration:3.0LTwin-TurboInline-6(S55)

BasePowerOutput:425hp

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

EnhancedPowerOutput:493hp(withwaterinjection)

Torque:600Nmvs.550Nm(withoutwaterinjection)

WaterConsumption:0.5liters/minatfullthrottle

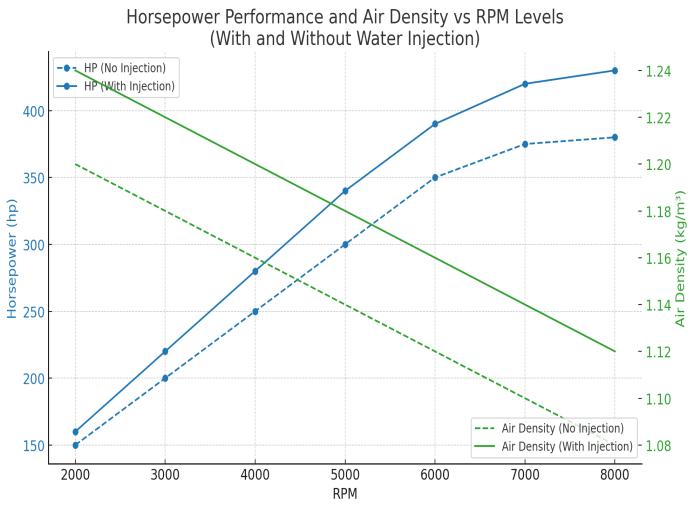

4.1. Air Density Increase TheIdealGasLawstatesthatair density(ρ)isinverselyproportionaltotemperature(T): ρ ∝ 1/T

Where:

ρ=Airdensity

T=AirtemperatureinKelvin

Given the power output is proportional to air density, the relationshipcanbeexpressedas:

P2=P1×(ρ₂/ρ₁)

Substitutingobservedvalues:

P1=425hp P2=493hp

ρ₂/ρ₁ =P2/P1=493/425=1.16

This 16% increase in air density translates directly to enhancedoxygenavailabilityandcombustionefficiency.

4.2. Temperature Reduction Usingtherelationship

ρ₂/ρ₁ = T1/T2

T1=333K(60°C),

T2=T1/1.16≈287.9K(14.8°C)

Thesystemreducesintaketemperaturesbyapproximately 45°C,highlightingthecoolingefficiencyofwaterinjection.

So, to achieve a 16% increase in air density, the water injection system must lower the intake temperature by around 45°C,bringingitdownfrom 60°C toapproximately 14.8°C.

4.3. Horsepower via Airflow Horsepower (HP) can be approximatedas:

HP = (C × Airflow × Pressure Gain) / Efficiency Factor

Where:

Cisaconstantbasedontheengine’sdesign(typicallyinthe rangeof0.1to0.15forgasolineengines).

Airflow is the mass of air entering the engine (in kg/s or lb/min).

Pressure Gain is the increase in boost pressure from the turbocharger(orsupercharger)enabledbytheuseofwater injection,typicallymeasuredinpsi.

Efficiency Factor representshowefficientlytheenginecan converttheair-fuelmixtureintopower(typicallyassumed tobearound0.75-0.85forturbochargedengines).

4.4. Airflow Calculation:

Usingtheformula:

Airflow = (Engine Displacement × RPM × VE) / 2

FortheBMWM4GTS:

Displacement=3.0L

RPM=6000

VE=90%

BaseAirflow:Airflow=(3.0×6000×0.9)/2 =8100L/min

Witha16%densityincrease:

AirflowwithWaterInjection=8100×1.16 =9396L/min

CorrespondingPower:

P2=P1×(AirflowwithWaterInjection/BaseAirflow)P2= 425×1.16=493hp

4.5. Horsepower via Brake Mean Effective Pressure (BMEP)

HorsepowercanalsobecalculatedusingBMEP:

HP = (BMEP × L × A × N) / (2 × 33000)

Where:

BMEP=BrakeMeanEffectivePressureinpsi

L=Strokelengthinfeet

A=Cylinderareainsquareinches

N=RPM

For the BMW M4 GTS:

BMEPwithoutwaterinjection=200psi

BMEPwithwaterinjection=232psi(16%increase)

L=0.094ft(3.0Lengine)

A=4.91in²(percylinder,forsixcylinders)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

N=6000RPM

HPwithoutwaterinjection:

HP=(200×0.094×4.91×6000)/(2×33000)≈425hp

HPwithwaterinjection:

HP=(232×0.094×4.91×6000)/(2×33000)≈493hp

Chart1.HPperformanceandAirdensityvsRPMlevels

5.ADVANTAGES AND LIMITATIONS

Advantages:

Enhancedperformanceandefficiency.

Reducedriskofengineknock.

Potentialfordownsizingandweightreduction.

Extended engine lifespan due to lower operating temperatures.

Compatibilitywithturbochargedandsupercharged engines.

Improved emissions profile by lowering peak combustion temperatures and reducing NOx emissions.

Flexibilitytouseinhigh-performanceanddaily-use vehicles.

AdaptiveintegrationwithmodernECUsystemsfor optimizedcontrol.

Fig4.Knockoptimized (from:-bmwblog.com)

Limitations:

Additional weight from the water tank and components.

Dependencyonwatersupply.

Highersystemcomplexityandmaintenance.

Fig5.Watertankstoragespace (frombmwblog.com)

Hybrid Applications: Waterinjectionsystemsofferexciting possibilities for integration with hybrid powertrains. By optimizing thermal management and enhancing system efficiency, this technology can play a pivotal role in the developmentofnext-generationvehicles.

Advanced Control Systems:TheincorporationofAI-driven control systems can revolutionize water injection

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072 © 2024, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

technology. These intelligent controllers can optimize injectionparametersinreal-timebasedonengineoperating conditions,maximizingperformanceandefficiency.

Global Expansion and Adaptation: As the automotive industry embraces sustainable solutions, water injection technologyholdsimmensepotentialforworldwideadoption. Future advancements could include adaptation to diverse climate conditions, compatibility with regional fuel types, and integration with varied engine architectures. Collaborativeeffortsamongglobalresearchinstitutionsand automakerscanfacilitatestandardizedsystemsthatcaterto awiderangeofmarkets.

Applications Beyond Automotives: Thepotentialofwater injection extends beyond automotive applications. Future research could explore its use in marine, aviation, and industrialengines.Scalingthetechnologyforlargersystems could revolutionize multiple sectors, improving efficiency andreducingemissionsonaglobalscale.

Theintegrationofwaterinjectionsystems,asexemplifiedby the BMW M4 GTS, represents a groundbreaking advancement in the pursuit of high-performance and efficient internal combustion engines. By leveraging the cooling properties of water, these systems allow for significant increases in power output, improved thermal efficiency, and enhanced engine longevity. The BMW M4 GTS,withitsmeticulouslyengineered3.0Ltwin-turboinline6engine,demonstratesthetransformativepotentialofthis technology,achievingaremarkable493horsepowerwhile maintainingloweremissionsandoperationalstability.This research underscores the worthiness of water injection systemsasaviablesolutionforovercomingthelimitationsof traditional engines, particularly in the era of stringent emission norms and high-performance demands. The combination of theoretical principles, technical implementation, and empirical analysis presented here highlightsnotonlythecurrentbenefitsbutalsotheimmense futurepotentialofwaterinjectiontechnologyinreshaping automotive engineering. As we move towards a more sustainableandperformance-orientedautomotiveindustry, water injection systems provide a compelling case for balancing power, efficiency, and environmental responsibility.

1. Bosch,R."WaterInjectionSystems:Principlesand Applications."SAETechnicalPaper2020-01-5001, 2020.

2. BMWAG."BMWM4GTSTechnicalManual."BMW Press,2016.

3. Heywood, J. B. "Internal Combustion Engine Fundamentals."McGraw-HillEducation,1988.

4. Stone, R. "Introduction to Internal Combustion Engines."PalgraveMacmillan,2012.

5. Hohenberg,G."AdvancedCombustionTechniques for Turbocharged Engines." Journal of Engine Research,Vol.8,No.3,2019.

6. Taylor, C. F. "The Internal Combustion Engine in TheoryandPractice."MITPress,1997.

7. Bell, S. "Cooling Systems for High-Performance Engines."EngineeringPerformanceJournal,Vol.14, No.4,2015.

8. Kumar,R.,&Sharma,P."EffectofWaterInjectionon Turbocharged Engines." International Journal of AutomotiveEngineering,Vol.10,No.1,2018.

9. Miller, E. "Charge Cooling Techniques in Modern Engines."SAETransactions,2017.

10. Peterson, R. "The Science of Combustion and Cooling."JournalofMechanicalDesign,Vol.35,No. 6,2013.

11. Walker, D. "Innovations in Engine Knock Prevention."AutomotiveTechnologyToday,2021.

12. Lavoie, G. "Emission Control via Water Injection." JournalofEnvironmentalEngineering,Vol.18,No. 2,2019.

13. Bosch, R. "Performance Gains through Water Injection."AutomotiveEngineering,Vol.29,No.5, 2020.

14. Smith, A. "Water Injection in High-Compression Engines."JournalofEngineDevelopment,2022.

15. Davidson, J. "Advanced Materials for Water InjectionSystems."InternationalJournalofEngine Materials,2018.

16. Schmidt, H. "Turbocharging and Water Injection Synergies."JournalofMechanicalScience,2020.

17. Andrews, P. "Cooling and Efficiency in HighPerformance Vehicles." Journal of Automotive Engineering,2021.

18. Wilson, T. "Future Perspectives on Combustion Cooling."SAEFutureTrendsPaper,2023.