1 minute read

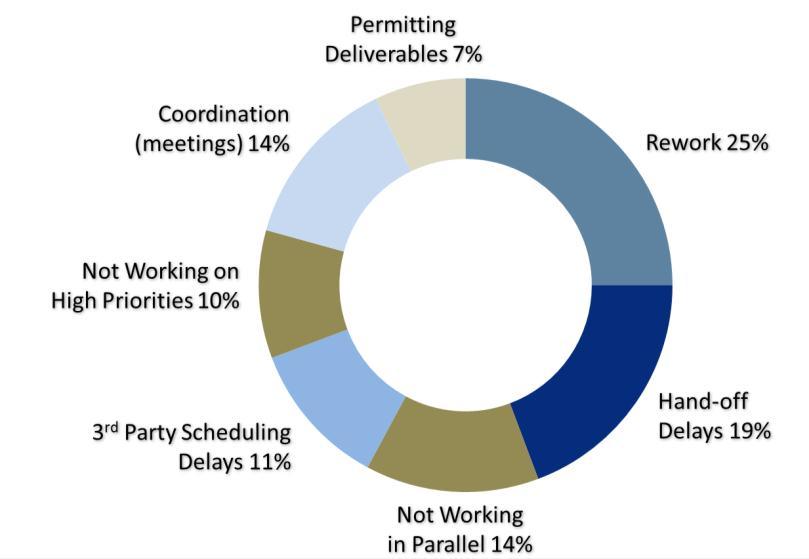

What do you believe are your top well permitting problems?

Executive Overview

The Acme Energy paper presents the challenges and benefits, from four different experiences of process improvement in Oil and Gas exploration and production, and integrates them into a single Business Guide. These real-world examples can easily be adapted to the content of each organization interested in the value of the template-based WPM solution. This is the only Well Process Management system that can be configured entirely through templates created by business users, and is also the only WPM solution that delivers an end-to-end E&P scheduling capability natively built into the product.

Advertisement

Goals and Challenges

Acme Energy identified three strategic challenges within their Field Development Planning and Exploration process that are holding them back from achieving their goals.

Challenge Addressed $ Benefit Operational Benefit

Concept to Permit- Increased from 100 to 200 permit applications per year$4,000,000Approval without adding resources. Enabled 3 additional wells to be drilled per rig, per year. Maximize Rig Drilling Time $30,000,000 (3 free wells per year.)

Drilling to Tie-in $57,000,000 Reduced working capital by reducing work-in-progress inventory by 30 wells. In addition, accelerated revenues by 35 days.

Goal: Double Exploration, without hiring additional resources

Challenge 1 -

‘Concept to Permit-Approval, Process Efficiency’ . Hand-off delays, habitual rework loops, sequential processing, and inefficient scheduling were more than doubling the effort required to take a well from Concept through Permit-Approval. Result: Leveraging template-based process management and obtaining scheduling transparency enabled Acme to increase the number of ready to drill wells from 100 to 200.

Goal: Improve Drilling Efficiency to enable 3 additional wells, per rig, per year

Challenge 2 –‘Maximize Rig Drilling Time.

’ A time study revealed that on average rigs are only drilling 42% of the time. The low percentage is due to longer than expected rig moves, unscheduled maintenance, shortage of permitted wells, sub-surface conflict with completions, and inefficient transparency into ‘no-drilling’ stipulations and permit expiration.