Portfolio

Jesper Cassiman

Jesper Cassiman

Preface

In this portfolio I discuss my skills and competences as a 3rd year Product Design student. I present work of which I am proud. At the same time, these projects illustrate my learning journey throughout these years. I hope you enjoy this journey as much as I have and for further information or questions don’t hesitate to contact me.

About me

My name is Jesper Cassiman, I’m a twenty year old Product Design student at the university of Antwerp. I was born and raised in Barcelona and after eighteen years I decided to pursue my creative side and started studying in Belgium. In my free time I’m very active, I spend a lot of time doing sports, listening to music, spending time with loved ones or exploring on my own. People close to me would describe me as composed, hardworking and loyal.

Hard skills

SolidWorks CAD

Photoshop

InDesign

Illustrator

Sketching

Soft skills

Motivation

Leadership & teamwork

Communication

Self drive

Problem solving

My design interests

When it comes to design I tend to focus on two issues: usability and form. The interesting part about usability is the engineering behind it, understanding how everything really works. I am fascinated about how modern designers integrate engineering in their projects, making problem solving a key feature in my designs.

Second but no less important, form giving and expression are critical elements in my design process. We know that for a product to be successful it has to be beautiful in meaning and shape.

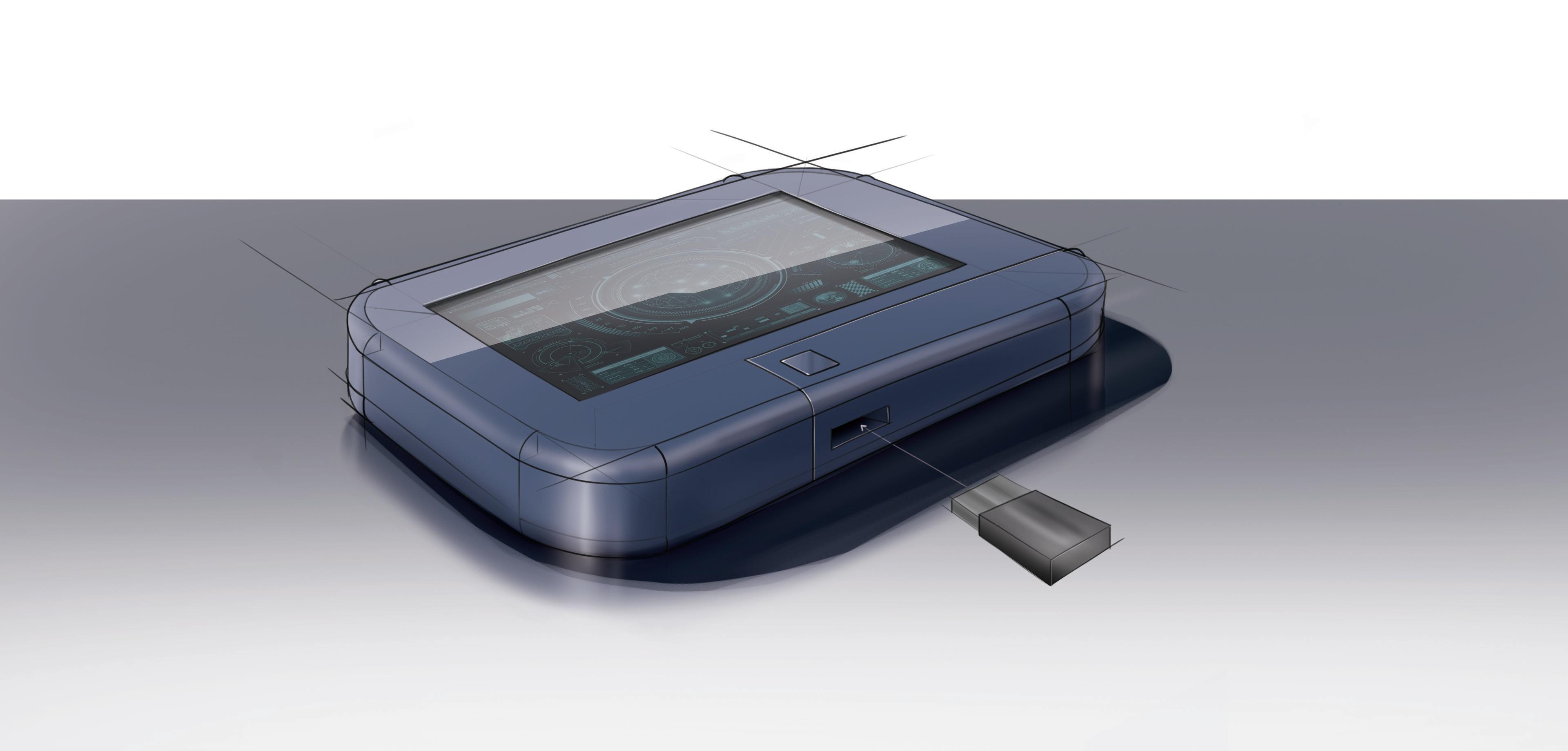

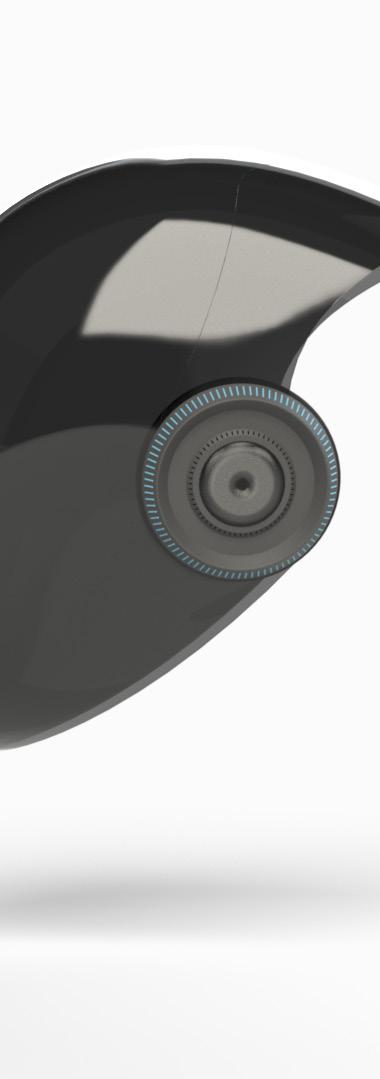

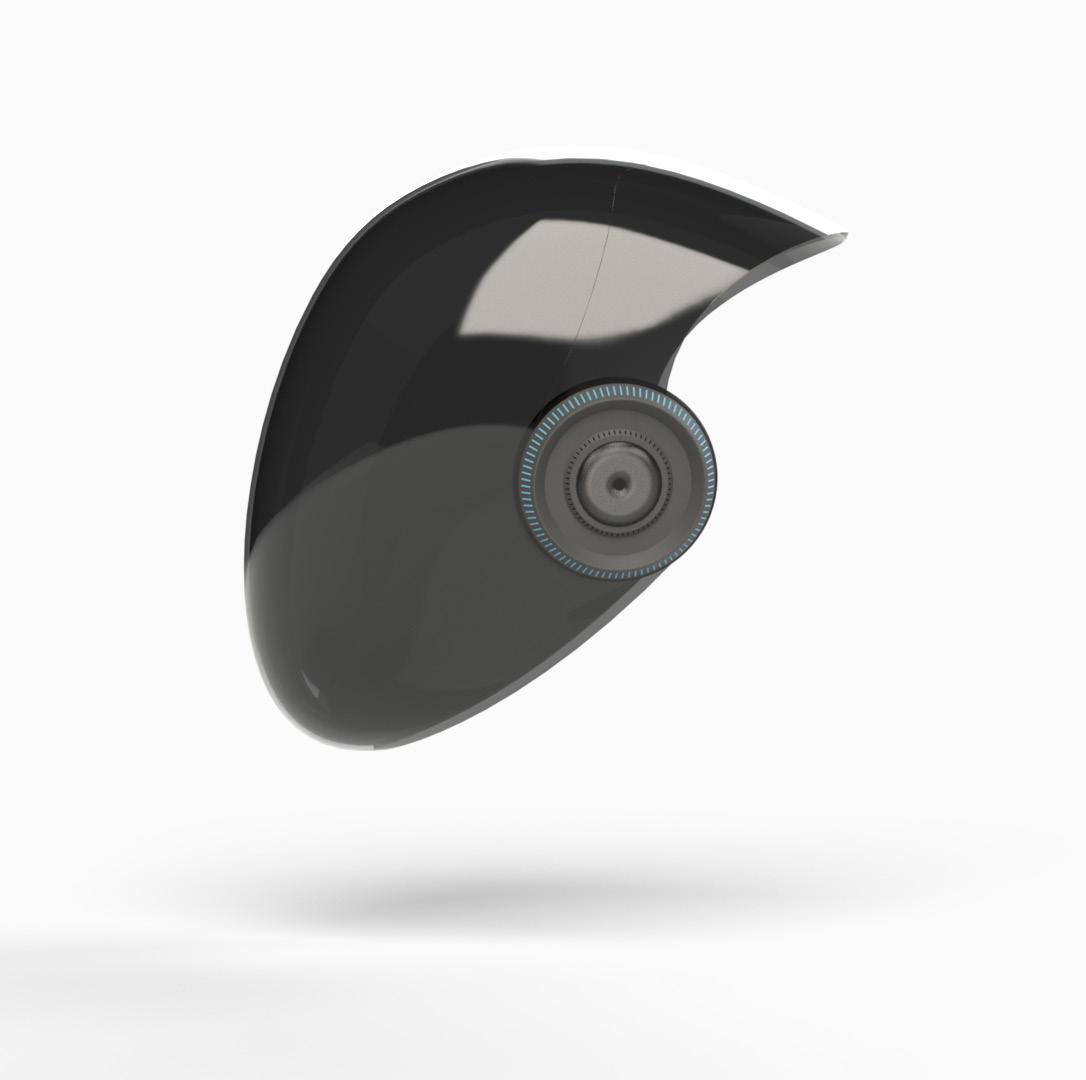

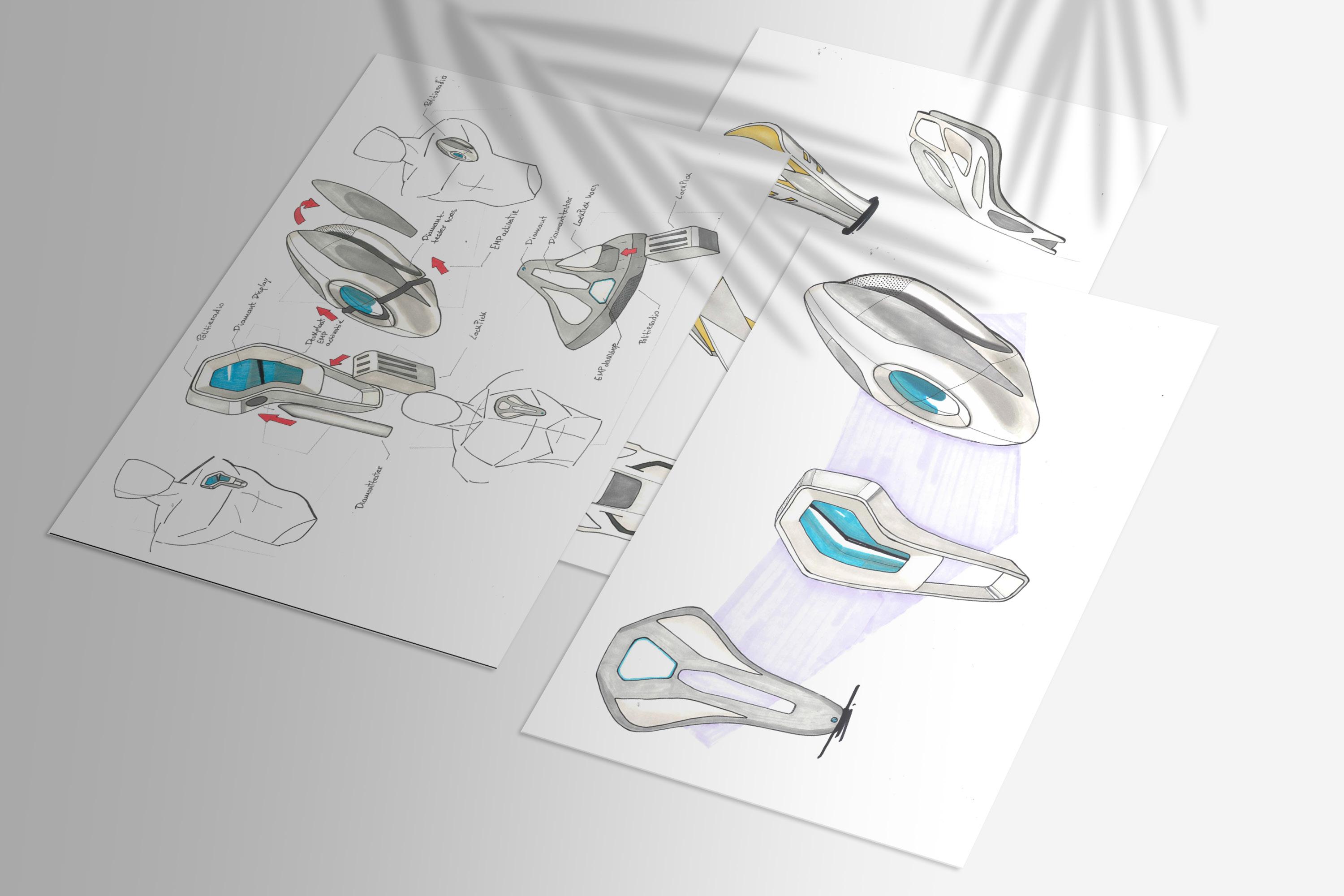

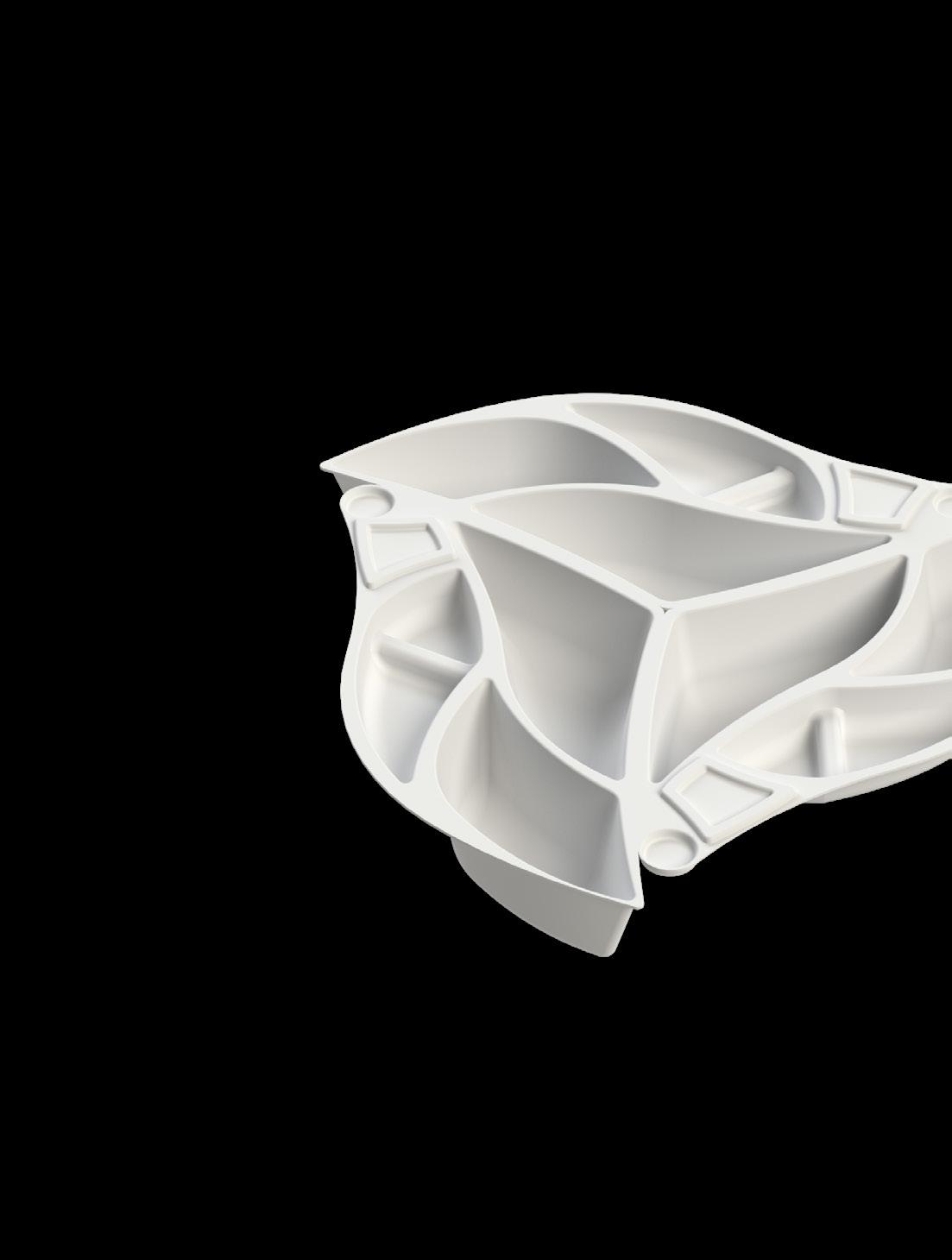

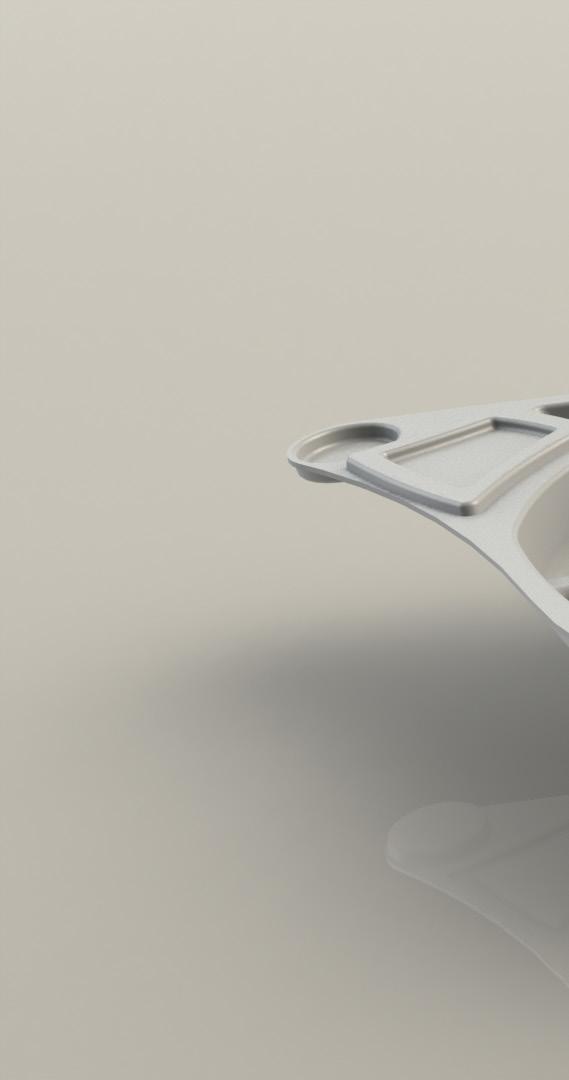

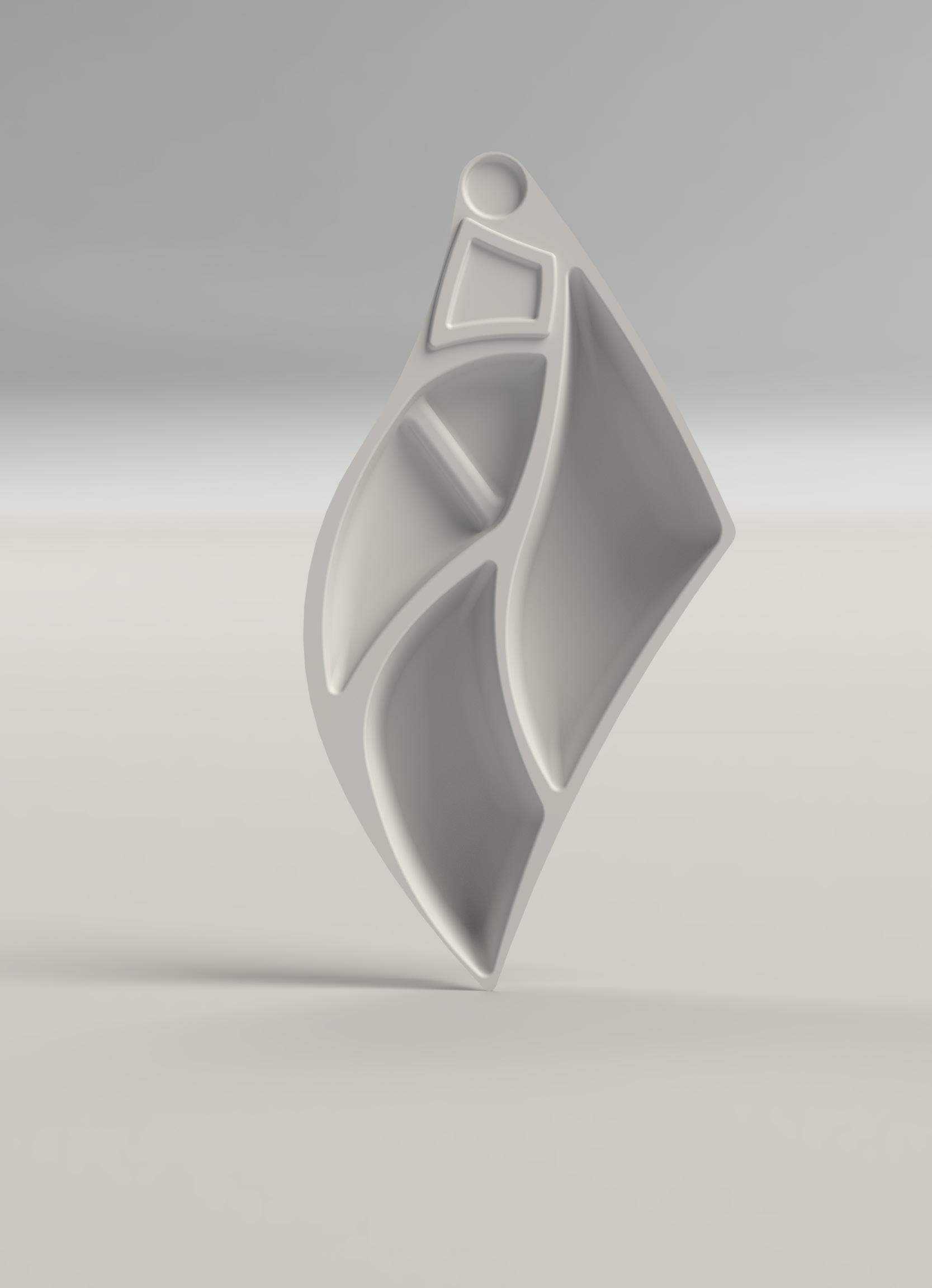

The project

The objective of this project was to design a personal container for a predetermined persona. A persona that we created from scratch. The personal container is an object that has to store three items and has to execute two functions. Our persona is called Piérre Caillou, a thief who specializes in diamonds. The personal container stores a diamond tester, a lock picker (both especially designed for him and his container), and his first stolen jewel (a very sentimental object for our persona). It also has a built-in police radio and EMP-“bomb” so that he’s always one step ahead of the authorities.

In order to design the perfect container we had to explore this persona, his likes and dislikes, how he lives and what he does. We had to understand his style by sketching recurring shapes and forms and by drawing inspiration from his surroundings. Afterwards we presented three possible containers and chose one to further develop and optimize, creating the perfect personal container for Piérre Caillou.

Furthermore, we had to think about the perfect combination between on-body positioning and how it interacted with our persona, and about the materials and the colours that we were going to use.

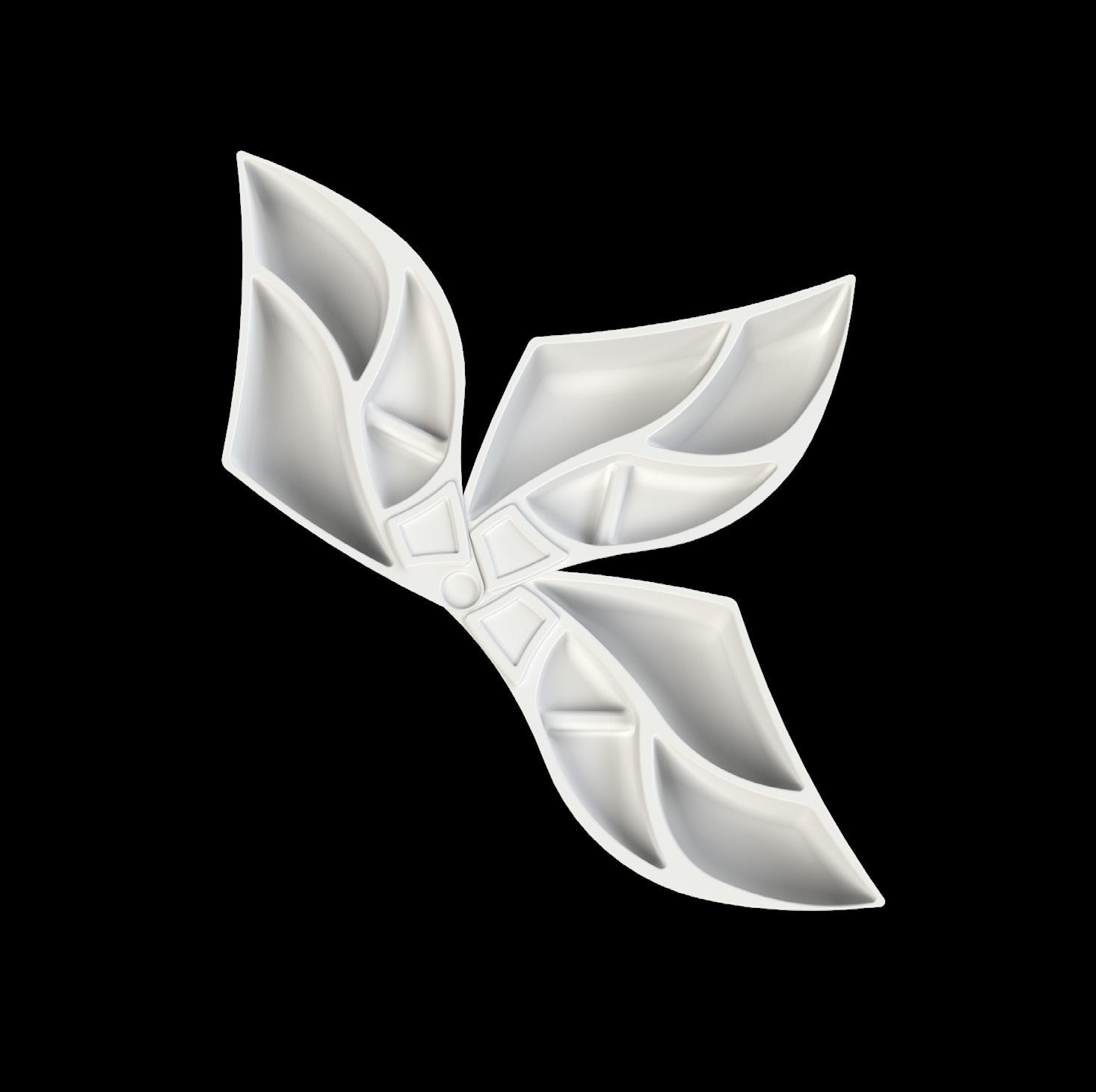

Ola Mediterránea

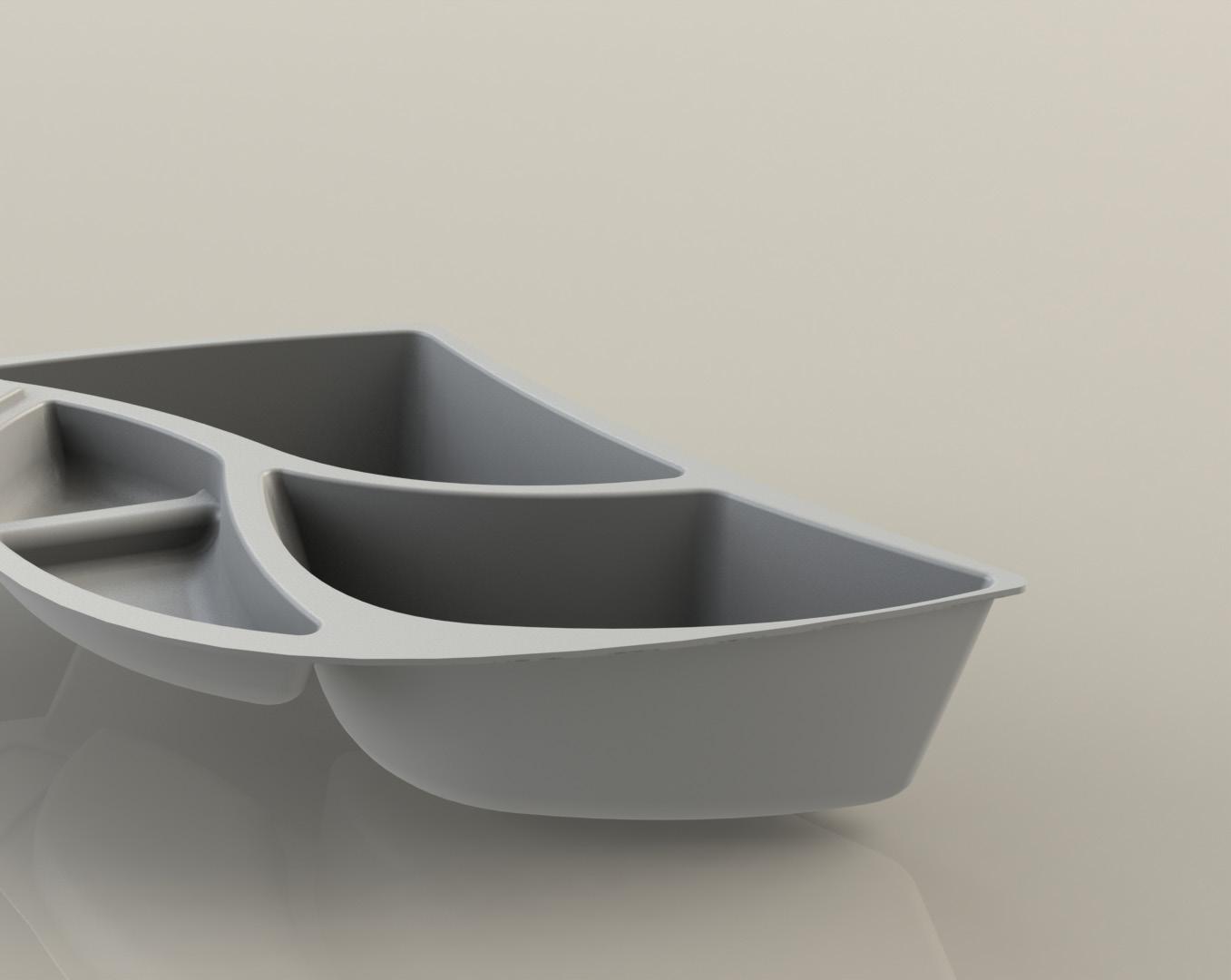

The objective of this project was to design a foodtray for a predetermined situation (Spanish tapas in a food truck convention). The process started by making quick designs. It was important to keep in mind what, and for whom I was designing. Not only were the looks important but the food-tray also had some functions to fulfil. The food-trays had to be able to be carried in groups of three and had to form a whole when set on the table together. Afterwards, the food-tray would be made in a vacuum forming machine so there were some specifications to be followed. I worked out the model in CAD Solidworks and made quick prototypes out of cardboard so I could get a sense of how the food-tray would really feel. After some further optimization, I made the “Ola Mediterránea” in CAD ready for production.

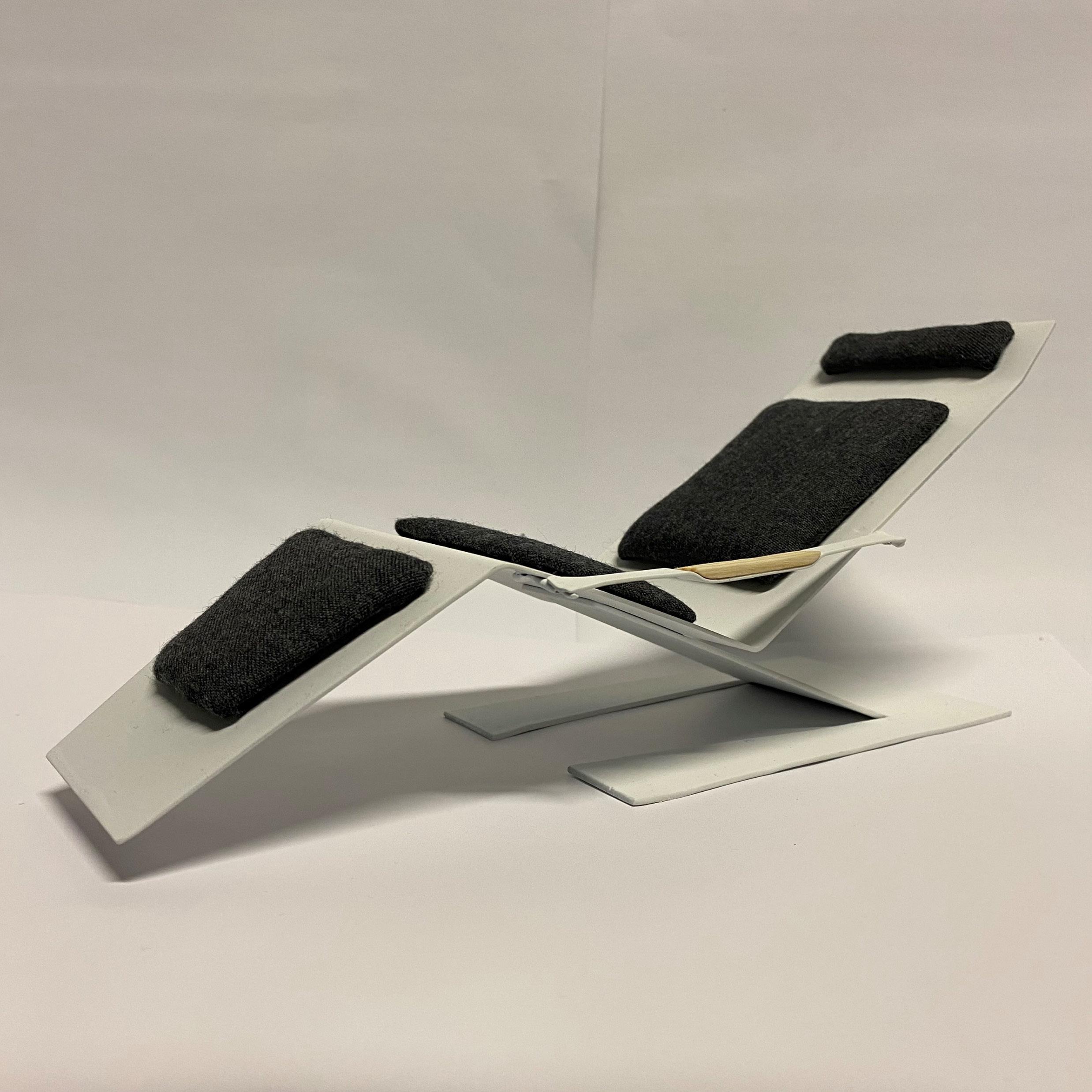

Zero gravity

During my third year I participated in an exchange program and I studied the first semester in Rovaniemi, Finland. At the university of Lapland (Lapin Yliopisto) I was faced with different challenges. Furniture design was something that I always wanted to try, and it did not disappoint.

The goal of this project was to find inspiration in the work of young Finnish designers, design a piece of furniture and make a scale model of it. I decided to be inspired by Harri Koskinen and his design of the Valovoima (lamp). Thereon out I started sketching potential designs. Once I decided on a design I started making prototypes and testing out the final materials. Finally the scale model of the final design was made. With extra detail to ergonomics the Zero Gravity lounge chair was designed for comfort. By laying in the lounge chair your body lays in the so called zero gravity position which is the optimal position for resting and relaxing.

Throughout the process I acquired a lot of new skills, mainly working in a metal workshop. The university of Lapland has a lot to offer, working and testing all kind of machinery and materials really made me advance in the field of prototyping.

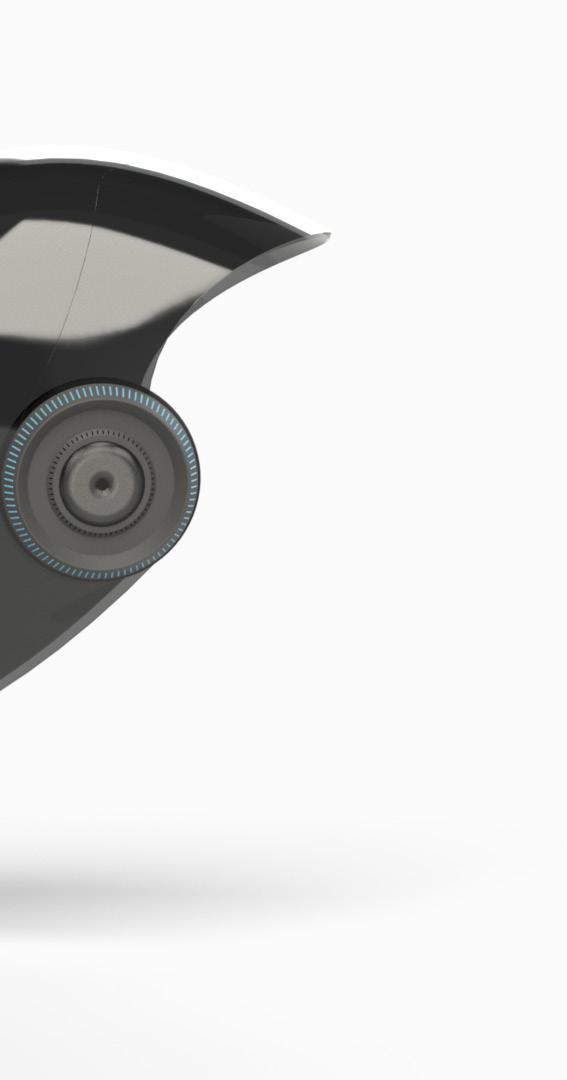

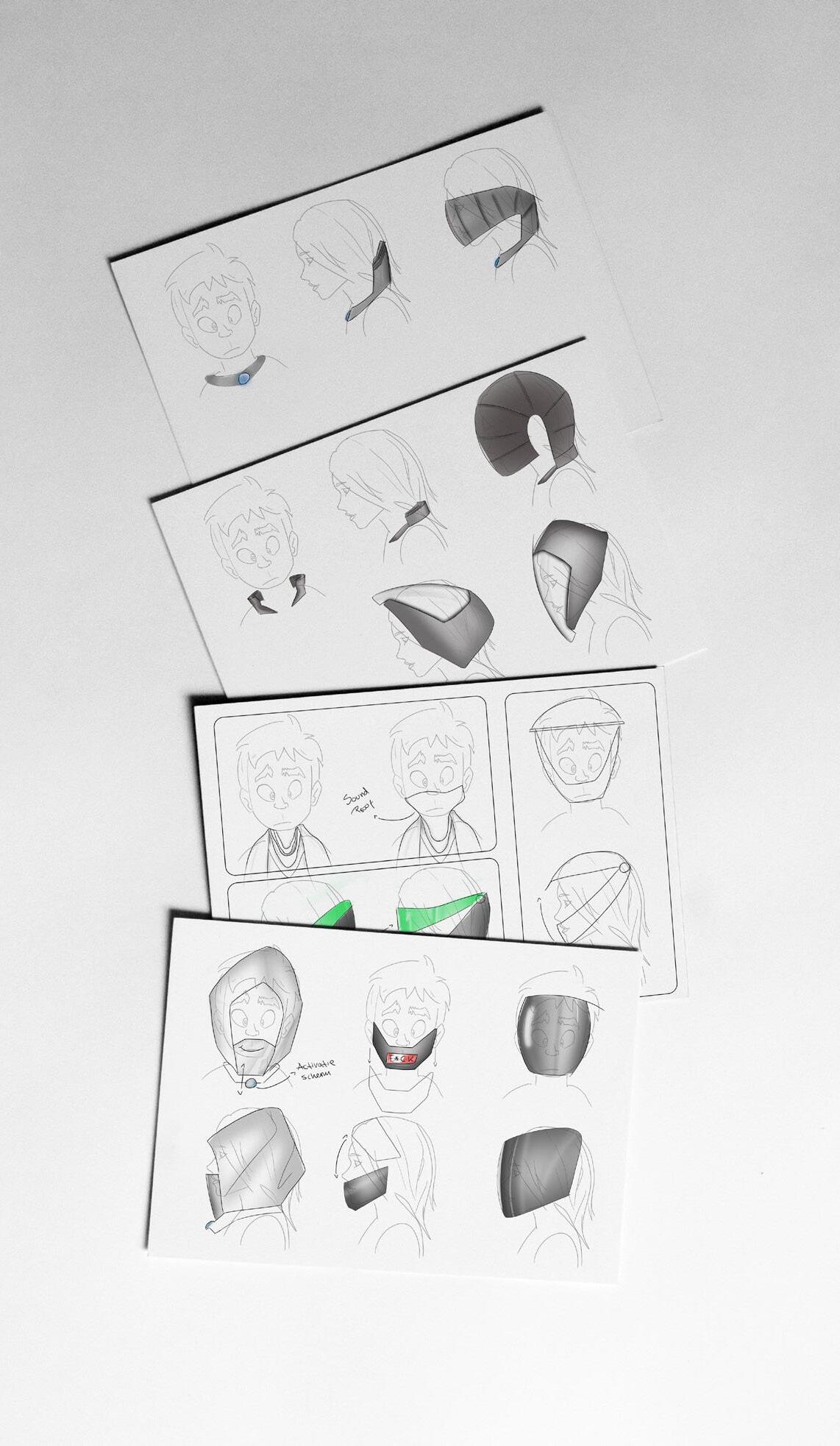

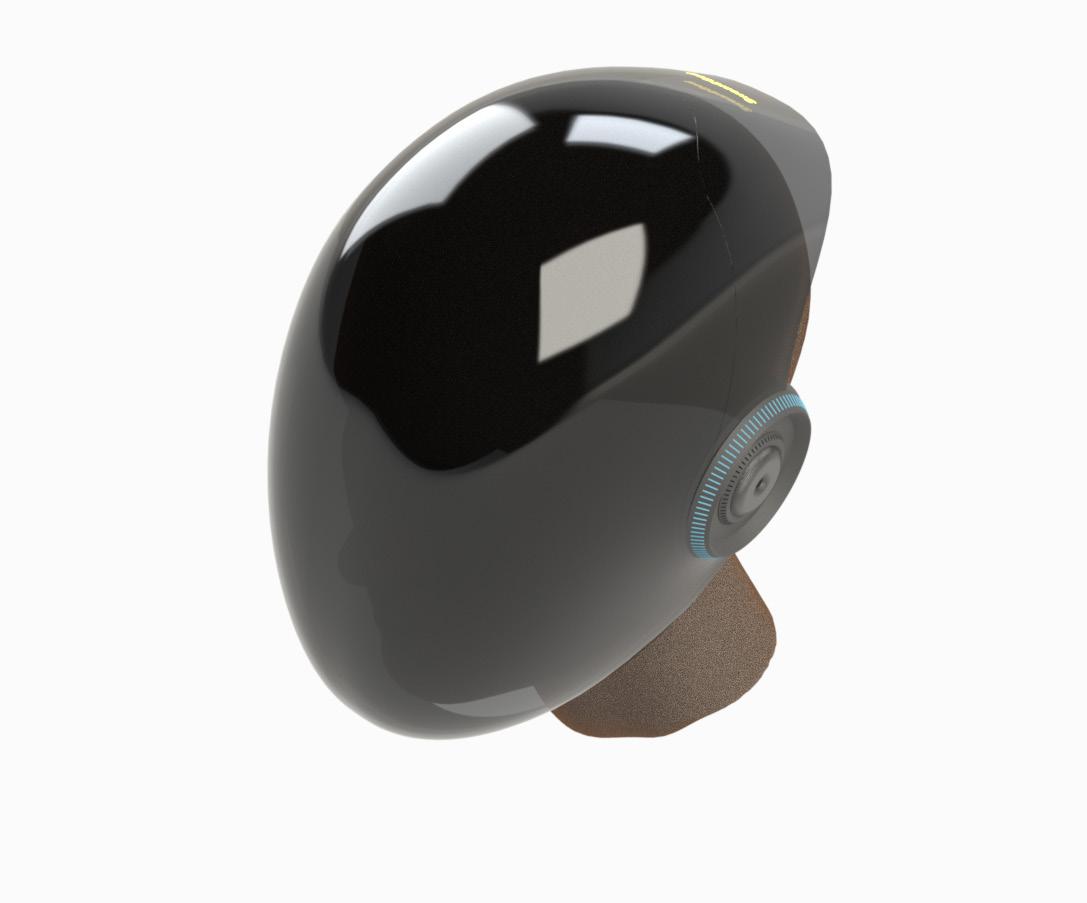

The fight against Tourette’s

We chose to investigate the world of people suffering from Tourette’s syndrome, understand their problems and design a wearable to help children suffering from this syndrome lead a better daily life. The Swear2God is a conceptual exercise with the intention of taking the first step into the world of wearable design against Tourette syndrome.

The main idea behind our design was to create something that kids would want to wear. Something cool and maybe even something other kids would be jealous of. But of course it had to be something that would help kids cope with Tourette’s syndrome, and maybe even get some friends involved.

Kids that suffer from this disability are often seen as misbehaved, different or “not normal”. Our intention was to design something that would make them look differently but in a positive way. Now they are not seen as someone with a disability, but rather as a hero who flies through life.

The project

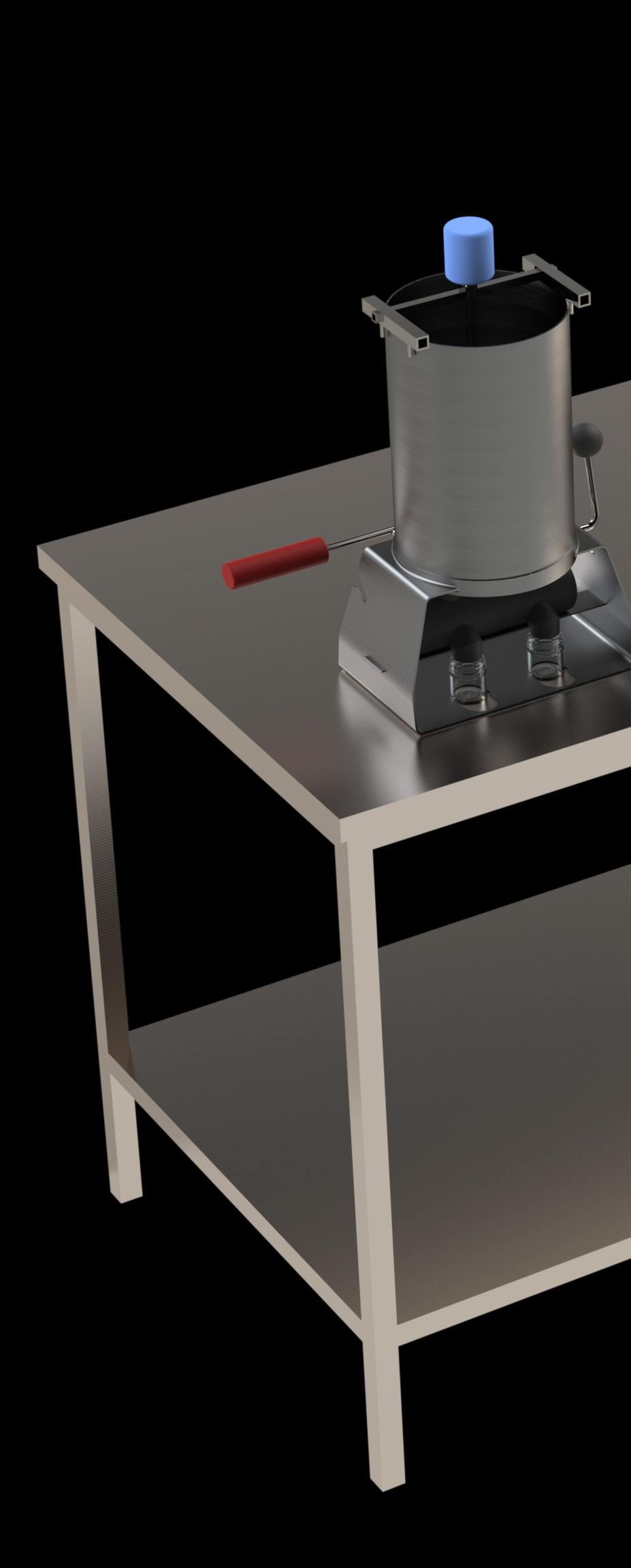

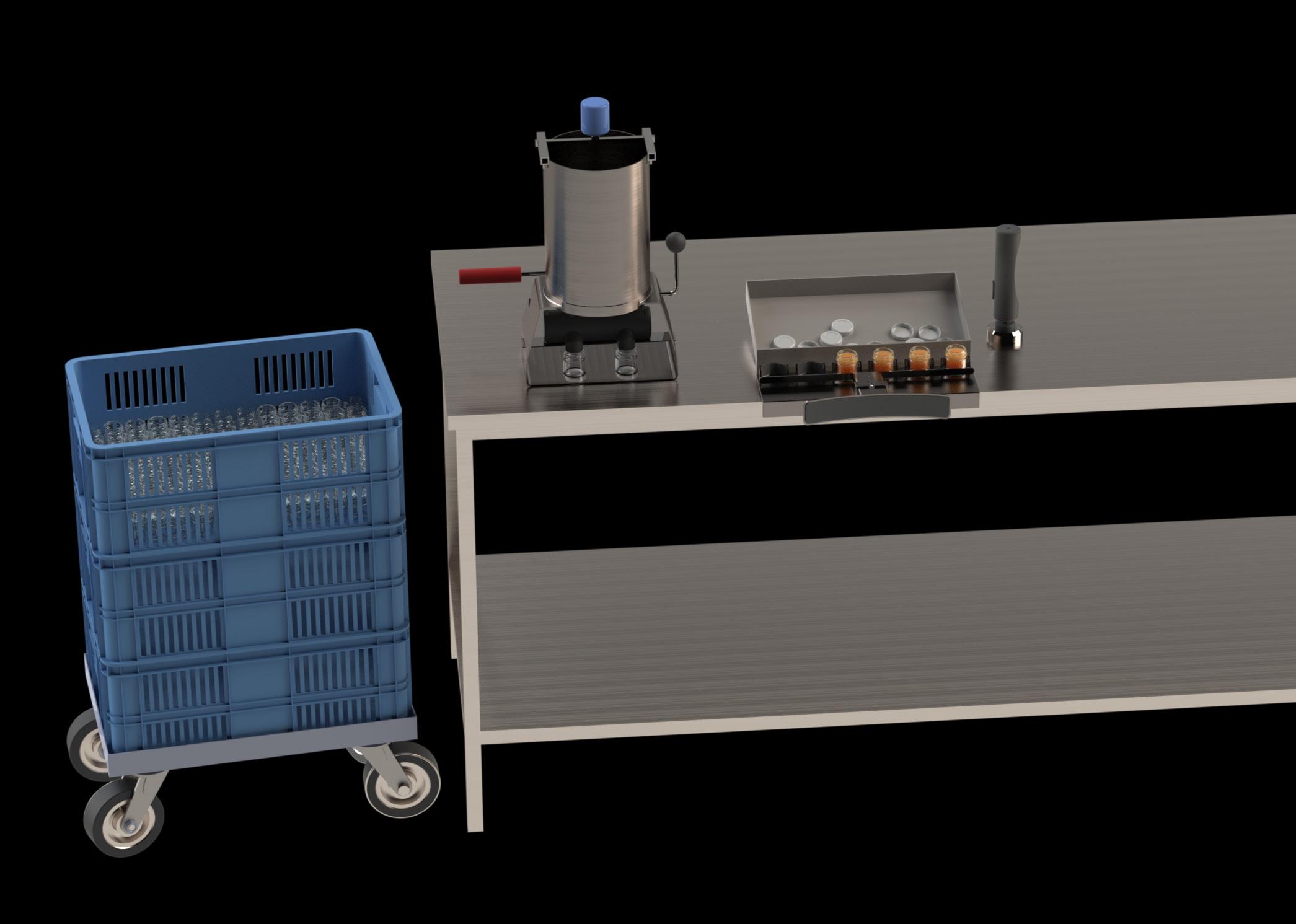

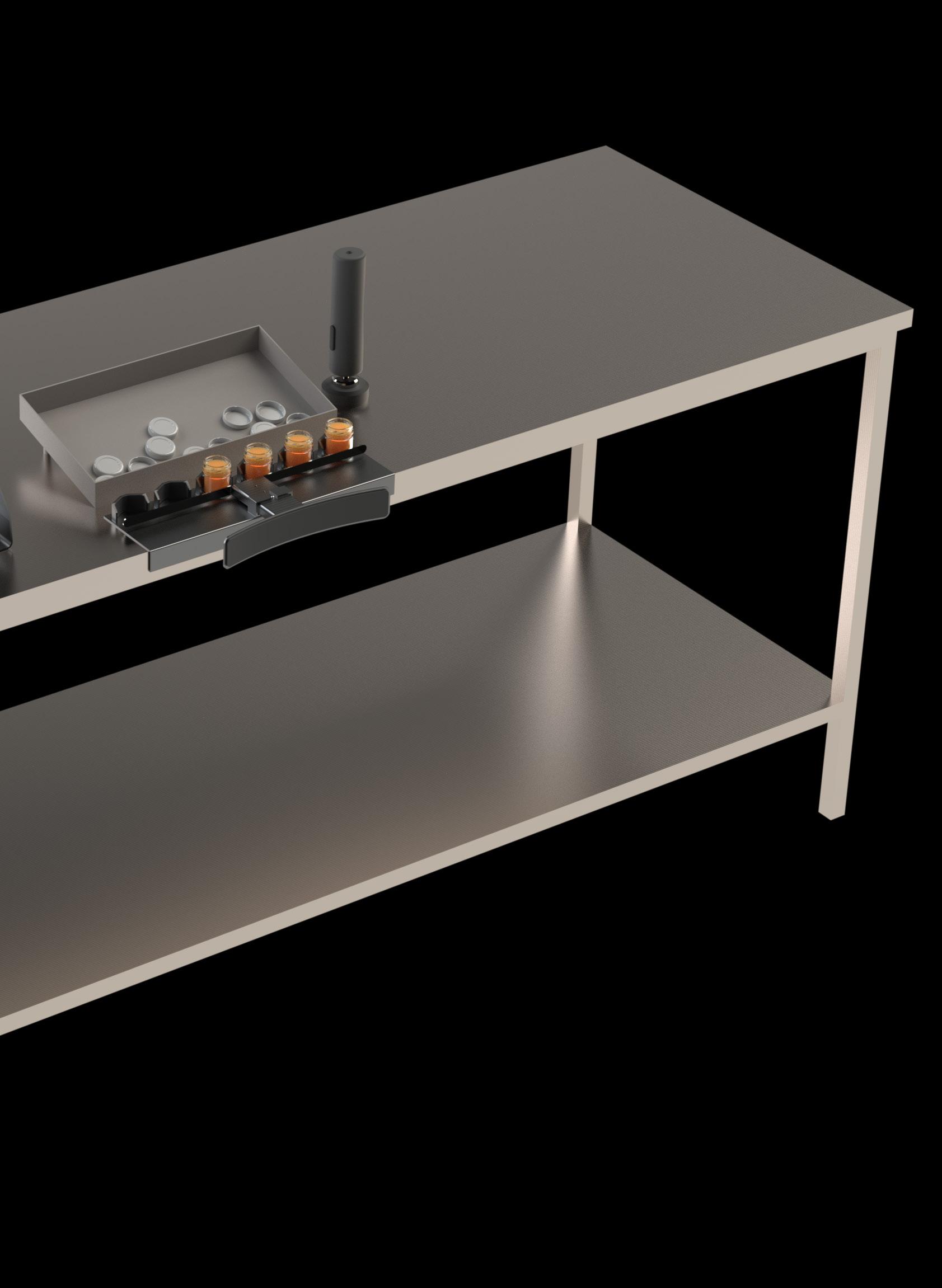

My bachelor thesis was in collaboration with Van Camp’s, a Belgian company that specializes in mustard, pickles and various pickled vegetables. They work with a variety of jar sizes and they really struggle with filling and capping their smallest jars. It was my job to find a solution and make their lives easier.

The workflow

The project was focused on improving the entire workflow. Efficiency, exactness and cleanliness were key points when looking for a solution. I redesigned their workflow introducing two new machines, one for easy and clean filling and one for efficient capping. The current workflow was able to fill and put a lid on 200 jars in one hour and forty minutes, with the redesigned workflow it is possible to do it in just under 20 minutes.

In order to come up with a real solution I did extensive research, 1 on 1 scale models, 3D printed models for testing, ergonomic testing… Once the final design was ready it was also necessary to choose the right materials and processing techniques for the job. I contacted businesses that specialized in such matters in order to make sure my design met the regulatory requirements (especially food grade) and that it was indeed possible to make.