graduate architecture

Email: john@raridon.org | Phone: (515)661-2867

University of Nebraska-Lincoln

Master of Architecture

Projected Graduation - August 2023

Bachelors in Science of Business Administration

Graduated May 2020

Nebraska Innovation Studio | Shop Intern | Fall 2022

• Achieved expert level understanding of fabrication software and equipment.

• Led trainings on wood shop equipment and gained understanding of shop safety.

• Learned organizational skills per regular maintenance of shop equipment.

Main Built Custom Homes | Home Design Intern | Summer 2022

• Application of design process with responsibilities as a home designer.

• Acquired valuable people experience through weekly client meetings.

• Gained knowledge of construction process with frequent on site experience.

Nebraska Football | Student Athlete | Fall 2016 - Spring 2020

• Acquired Leadership and team building skills.

• Learned to perform under physically and mentally challenging circumstances.

• Implemented time management strategies on a daily basis.

Stille & Domann Youth Football Camp | Coach | Summer 2020

• Worked with Lincoln Youth to help better them selves as athletes and people.

Nebraska Football Community Outreach | Player | Fall 2016 - Spring 2020

• Participated in various community outreach events during my time as a player.

West Des Moines Youth Football League | Coach | Fall 2019

• Coached and mentored West Des Moines youth football players.

Mark Main | Main Built Custom Homes

Email: markmain@mac.com Phone: (515)689-9882

Jerry Reif | Nebraska Innovation Studio

Email: jreif@unl.edu Phone: (402)499-9462

Dennis Leblanc | Nebraska Athletic Department

Email: dleblanc@unl.edu Phone: (402)540-1140

Jeff Day | Professor of Architecture at UNL

Email: jday@unl.edu Phone: (402)415-5551

FABRICATION EQUIPMENT

• CNC router

• Laser cutter

• 3D printer

• Vacuum bag clamp

• Table saw

• Miter saw

• Band saw

• Scroll saw

• Planer

• Jointer

• Domino jointer

• Various hand tools

• Various sanders

• Metal bender

• Fiber laser

• Plasma cutter

• Bench grinder

• Screen printing press

FABRICATION SOFTWARE

• VCarve

• Easel

• ShopBot

• Fabcreator

• Ultimaker

DESIGN SOFTWARE

• AutoCad

• Rhinoceros

• Revit (minimal)

• Adobe Illustrator

• Adobe Photoshop

• Adobe InDesign

• Adobe Lightroom

**Extensive experience with Microsoft Excel and Microsoft word

Table Of Contents

01a 02 03 04

The U-Chair........ The U-Factory..... The Art Table....... The Bourough......

01b Misc. Projects......

05 The Main House..

pg. 6 pg. 12 pg. 18 pg. 28 pg. 36 pg. 46

noun mutual trust and friendship amongst individuals who share a common goal.

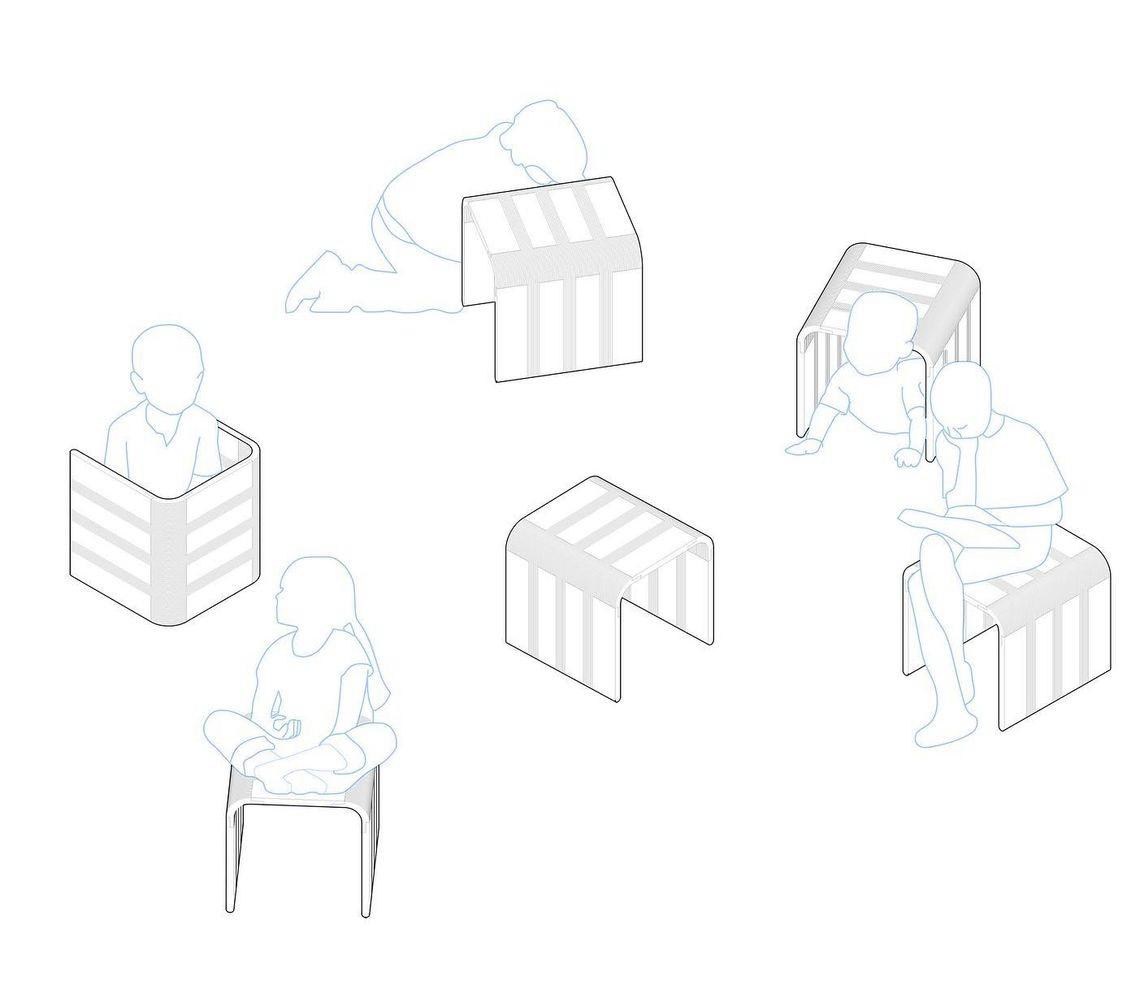

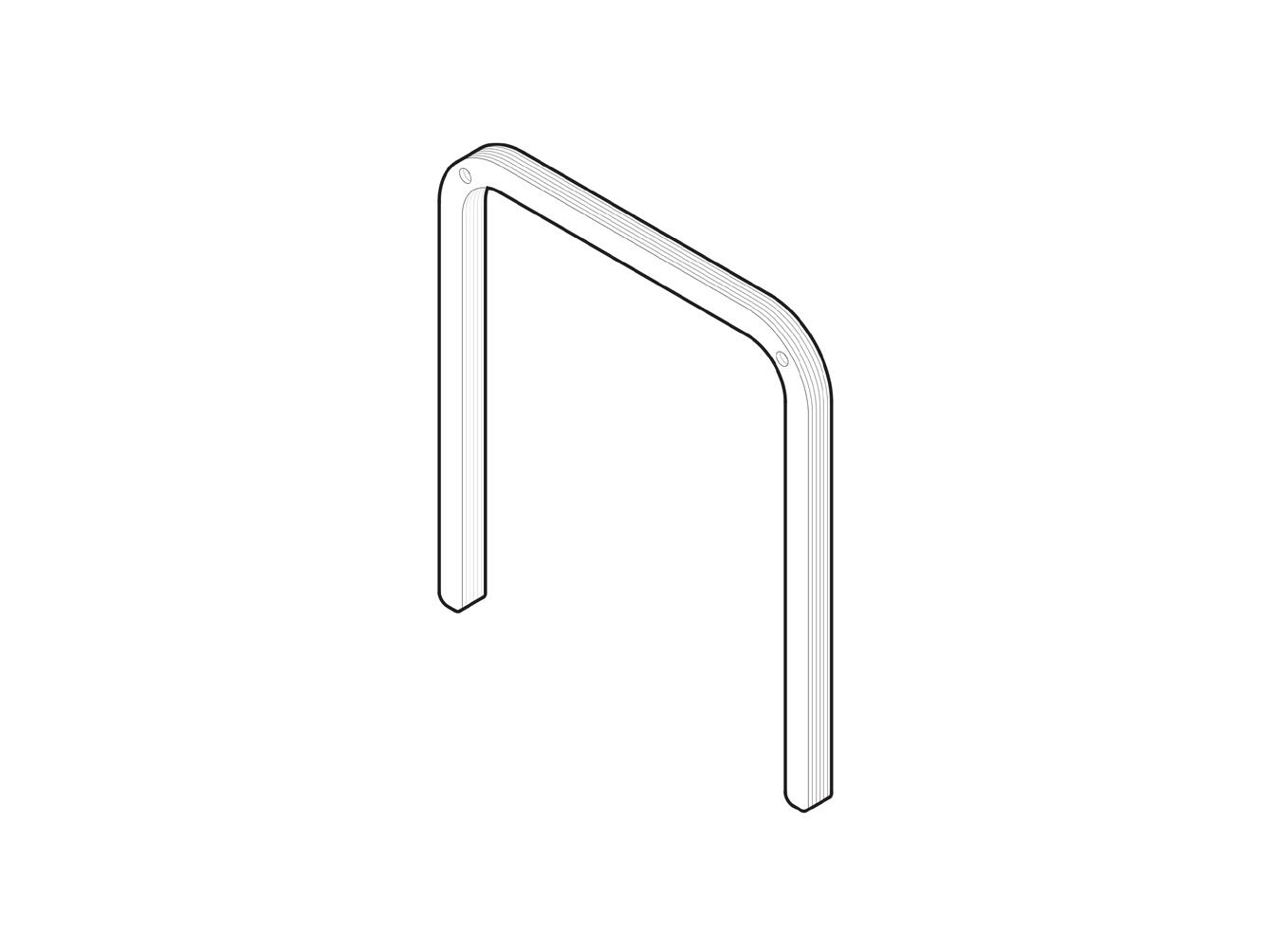

The U Chairs were created as modular stools for a non-profit organization called “Our Village Collective”. The organization specializes in connecting trauma-afflicted children with positive learning experiences. Danae Peterson, founder of Our Village Collective, expressed a need for chairs the children could use for various activities throughout the day. Danae further expressed that she was not interested in you average school chairs. Instead these chairs needed to be modular, tactile, something that could spark imaginative play. We believe the simple form of the U-Chair was a successful response to our clients requests.

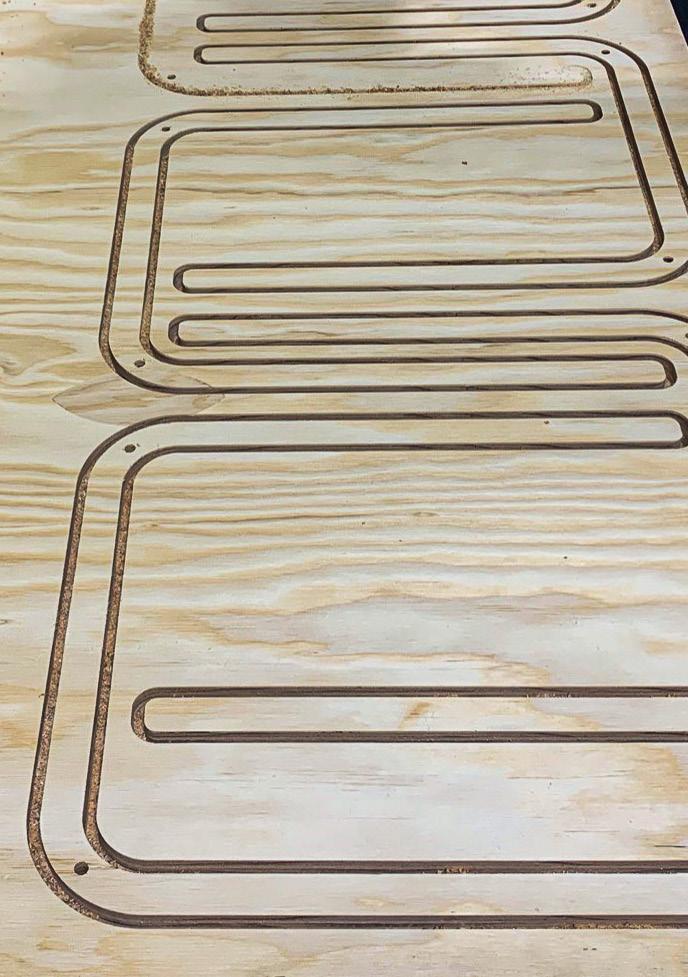

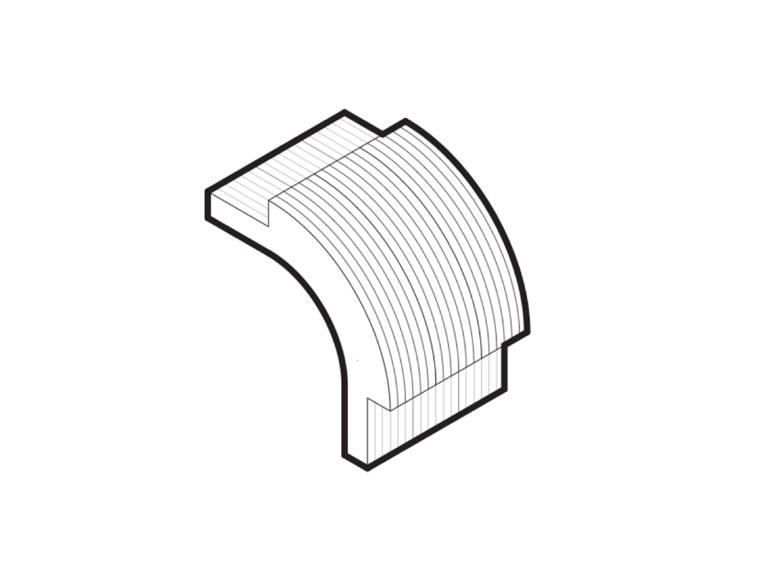

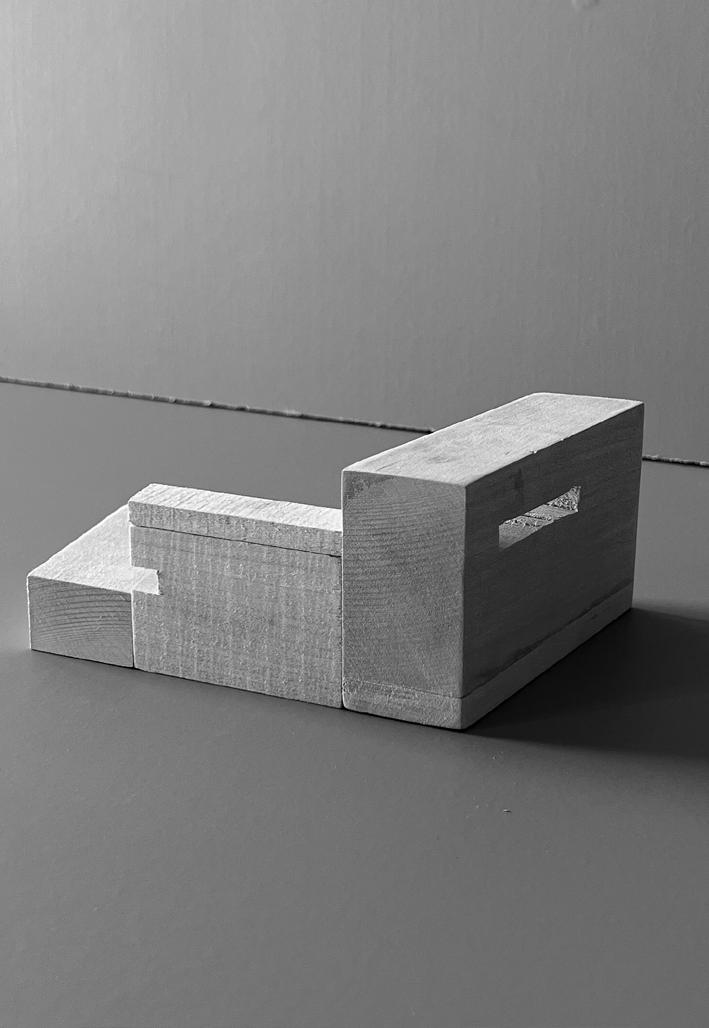

During the design phase of The U-Chairs we realized we had a potential issue with actually making them... It takes 74 individual parts, glue laminated to make just one chair. Thats 518 parts to fill our clients order of 7 chairs. Drawing upon experience I knew that these chairs would not be possible to assemble unless we had a very specific jig and an organized process. Knowing we had access to a ShopBot CNC machine, I gathered up all the required clamps and materials needed, took thorough measurements, and made the tool paths that allowed us to fabricate The U-Factory.

Encouraging learning through play and creativity

The Art Table was designed and built for a larger interior renovation project for a non-profit art center called, The Art Chapel. My group was responsible for the design and fabrication of the furniture that would inhabit the space. Our client spoke of different art classes as well as sewing classes that could take place in this space. After many more meetings with our client we determined that she could use a very versatile, durable, and aesthetically pleasing utility table. Our response was a rolling-stainless-steel top table with a glue-laminated BCX plywood frame, 4 drawers, and 8 outlets connected to one power source.

“make nothing”

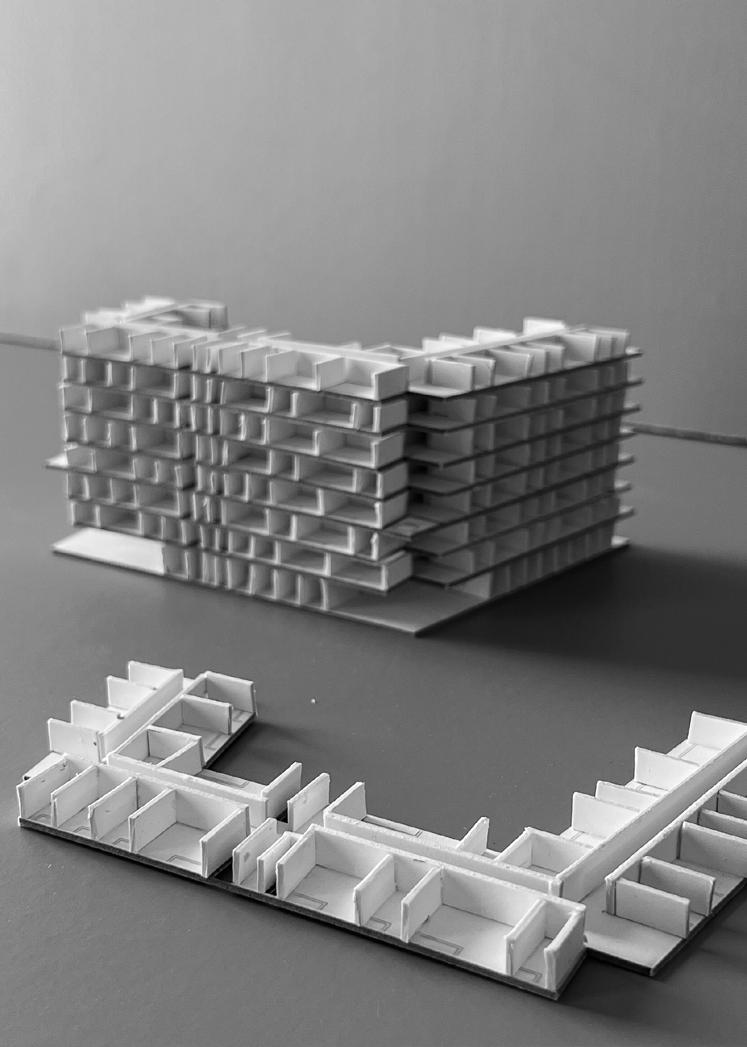

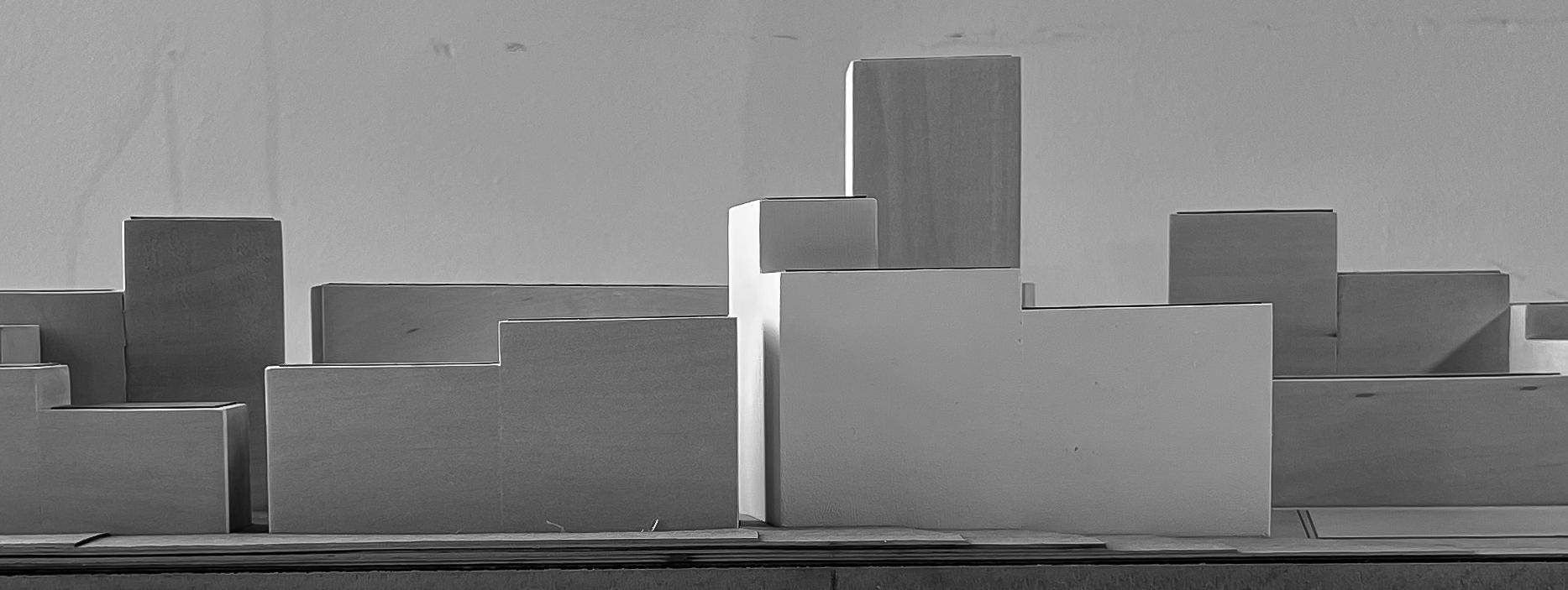

The Borough was my design for an affordable housing complex as part of a hypothetical proposal for the redevelopment of an existing shopping mall. I implemented 4 apartment types; family town homes on the ground level then1 bedroom, 2 bedroom and studio above The Borough is specifically suited for new families and single workforce inhabitants. To simultaneously serve the needs of our occupants and the development at large, 9,500 sqft. of retail and 4,200 sqft. of daycare were added to the ground-level. At The Borough, our tenants can also enjoy the outdoors via a large public courtyard as well as a 26,000 sqft semi-private rooftop garden.

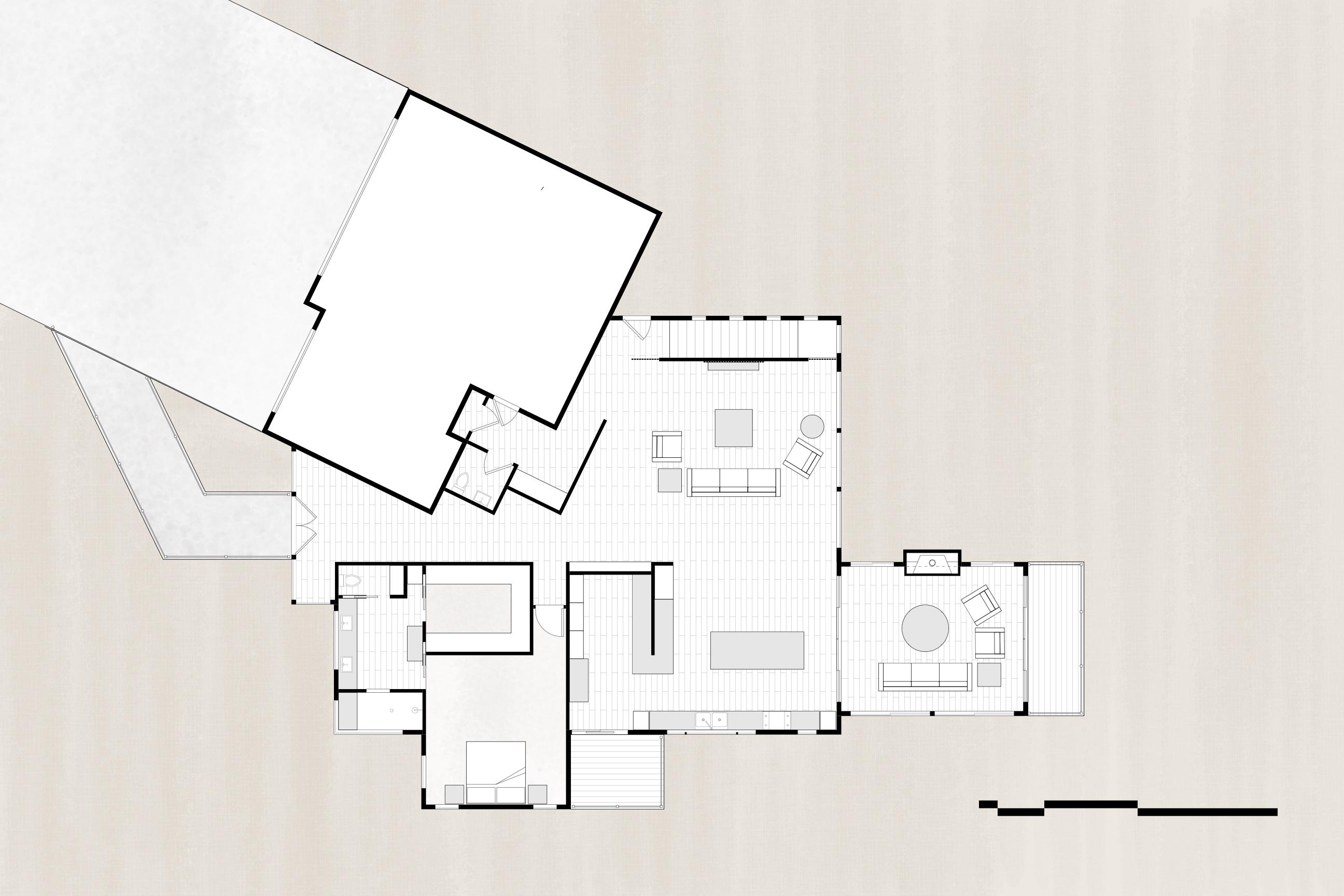

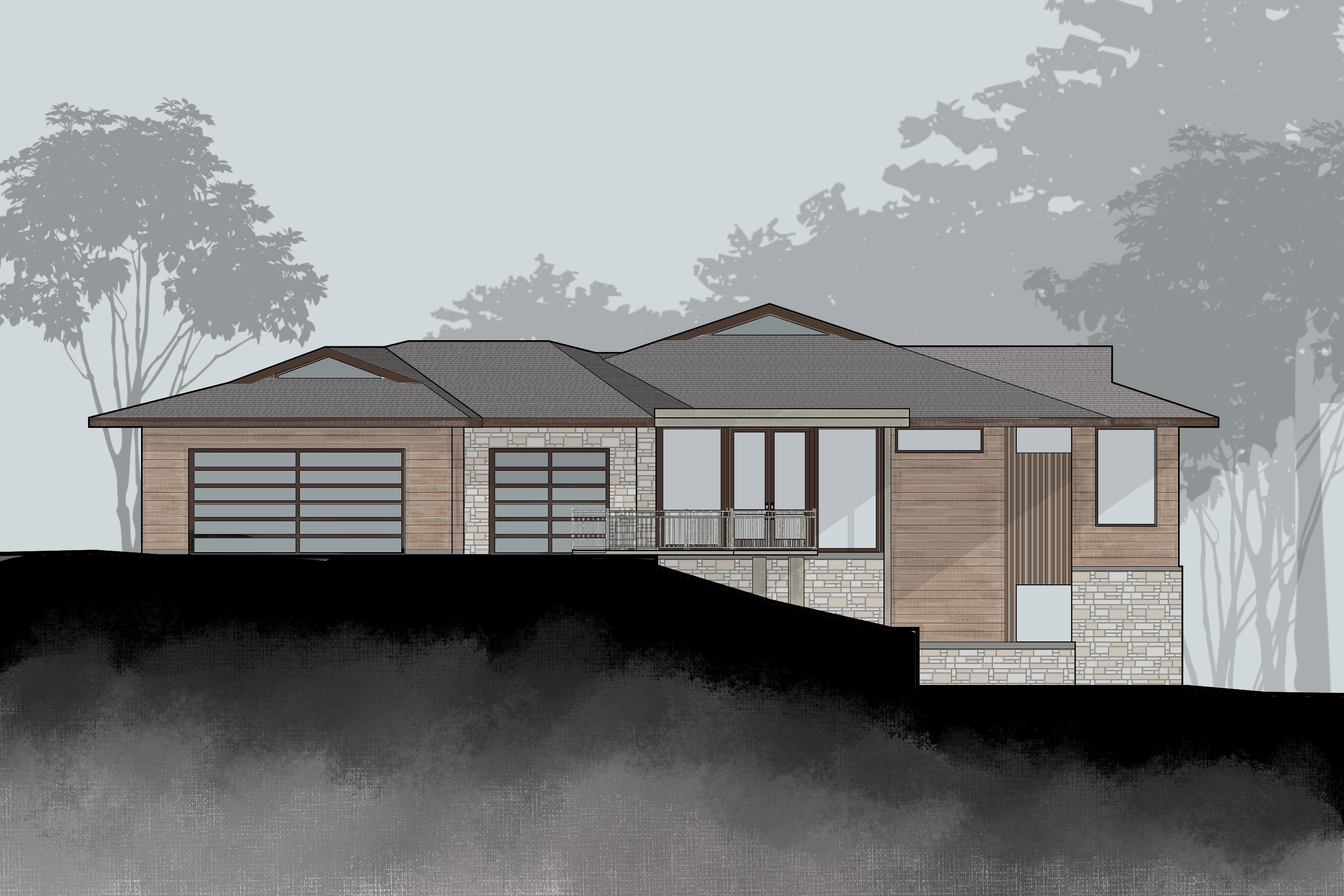

The Main House was the result of my summer internship with Main Built Custom Homes in Clive, Iowa. When I arrived at Mainbuilt, my boss, Mark Main and his wife were looking to build a home on Lake Panorama. Mark had the idea of having me try to generate a design as an exercise to apply what I was learning through my daily site visits and meetings with clients and contractors. As the design progressed Mark really liked what I was producing and had me present the Idea to his wife. She loved the idea as well, so mark and I spent the rest of the summer refining my work. The project is set to break ground this summer.