MEDIA KIT

MAXIMIZE YOUR REACH WITH THE ULTIMATE ADVERTISING EXPERIENCE

LEADING THE PROFESSIONAL CHARGE

MAXIMIZE YOUR REACH WITH THE ULTIMATE ADVERTISING EXPERIENCE

LEADING THE PROFESSIONAL CHARGE

GOLD: OUR MOST POPULAR OPTION – AND WITH GOOD REASON. PREMIUM SPACE AT AN EXCEPTIONAL VALUE.

Maximise your exposure with an entire page for the key visuals, ensuring every single reader takes note of your placement.

What’s more, with an adjacent 500 words of editorial text, this package is the perfect balance of both showing your capabilities and explaining them too.

FULL PAGE - WIDTH 194MM X HEIGHT 274MM

WIDTH 194MM

HEIGHT 274MM

ASK YOUR SEPARATION SPECIALIST

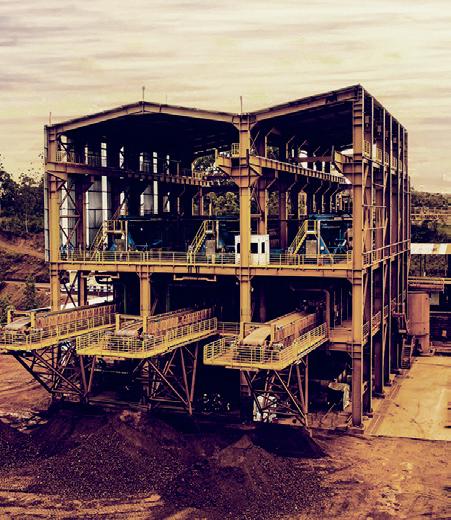

Increasing throughput while preserving product quality, minimizing energy consumption and operating costs or increasing water recovery: Efficient separation technology backed by innovative automation and digitalization is a crucial competitive advantage.

ANDRITZ‘ current portfolio covers the full solid/liquid separation process

separation@andritz.com / andritz.com/separation

from sedimentation and dewatering to drying, and ensures excellent throughput of high-quality products –all with low operating costs and maximum reliability.

The variety of technologies combined with the opportunity to analyze your processing requirements and conduct tests in a state-of-the-art laboratory means,

that you get the right equipment or individualized line solution for your specific need.

Did you know?

ANDRITZ offers an extensive selection of thickening, dewatering and drying solutions, catering to the precise processing needs of critical minerals necessary for expansion of e-mobility.

INCLUDE 3MM BLEED. INCLUDE CROP MARKS DO NOT USE TEXT CLOSER THAN 10MM TO THE EDGE

ASK YOUR SEPARATION SPECIALIST

Increasing throughput while preserving product quality, minimizing energy consumption and operating costs or increasing water recovery: Efficient separation technology backed by innovative automation and digitalization is a crucial competitive advantage.

ANDRITZ‘ current portfolio covers the full solid/liquid separation process

separation@andritz.com / andritz.com/separation

from sedimentation and dewatering to drying, and ensures excellent throughput of high-quality products –all with low operating costs and maximum reliability.

The variety of technologies combined with the opportunity to analyze your processing requirements and conduct tests in a state-of-the-art laboratory means,

that you get the right equipment or individualized line solution for your specific need.

ANDRITZ offers an extensive selection of thickening, dewatering and drying solutions, catering to the precise processing needs of critical minerals necessary for expansion of e-mobility.

ANDRITZ Separation provides mechanical and thermal technologies as well as services and the related automation solutions for solid/liquid separation, serving the chemical, environmental, food, and the mining and minerals industries The customized, innovative solutions focus on minimizing the use of resources and achieving highest process efficiency, thus making a substantial contribution towards sustainable environmental protection.

A PARTNER WITH THE EXPERTISE TO TACKLE TOMORROW’S CHALLENGES

Increasing throughput while preserving product quality, minimising energy consumption and operating costs or increasing water recovery: efficient separation is a crucial competitive advantage in the mining and minerals business Having mastered these challenges for more than a century, we at ANDRITZ know how to tailor our complete range of state-of-the-art technologies to meet your needs and to find the best processing solutions And, by exploring innovative new ways to automate and monitor remote facilities, we ensure that you are ready for the future as well

AUTOMATING PROCESSES, CUTTING COSTS: ONE STEP AHEAD IN DIGITALISATION

Digital innovation is bringing a variety of benefits to industrial operations, and the mining and minerals sector is no exception ANDRITZ has combined the power of smart sensors, big data analytics, and virtual and augmented reality to develop Metris, a portfolio of digital industrial solutions Within this portfolio, Metris addIQ control systems offer cutting-edge machine and process control for solid/liquid separation equipment and systems To ensure safe, trouble-free operations, ANDRITZ automation solutions range from upgrades to individual systems, including electrics, control equipment and instrumentation, to full automation of entire processes and plants

Because of the boom in the battery industry, the demand for lithium is currently exceeding global production At the same time, the evolution of battery content also indicates future increases in the demand for cobalt, aluminum, magnesium, nickel, and other by-products ANDRITZ provides support throughout the whole life cycle of these batteries: With full debrining and drying solutions at major lithium producers to secure more than half the world’s battery-grade lithium production, aluminum battery casing manufacturing lines, and separation solutions for battery recycling Batch and continuously operating filtration centrifuges as well as full dewatering and drying solutions, including centrifuges, filter presses, filters, thickeners, and dryers, deliver superior purity, the right moisture content, and energy efficiency In the meantime, battery minerals processing and battery recycling solutions are offered to meet the demands of a changing market and provide solutions for recovery of the black mass

ANDRITZ’s current portfolio covers the full solid/liquid separation process from sedimentation and dewatering to drying and ensures excellent throughput of high-quality products – all with low operating costs and maximum reliability The variety of different thickening, dewatering, and drying technologies, ranging from thickeners to decanter or pusher centrifuges, heavy-duty belt presses or hyperbaric disc filters to closed-cycle contact dryers means that we are able to configure a processing line tailored to fit your specific needs

www andritz com/separation