6 minute read

Experts in EMS Share Insights on Monitoring Medication and Blood Temperatures

In late 2020, Temptime sponsored a special webinar – “Top Tips for EMS Professionals: Monitoring Jeff Gutkind Medication and Blood Product Temperatures for Better Patient Care and CAAS Accreditation” – that brought leaders in the field together to discuss the why and how of medication monitoring for EMS professionals. Panelists discussed a range of topics including the changing role of EMS crews in the field, the differences between manual and electronic temperature monitoring and how the benefits of automated processes can help save time and money.

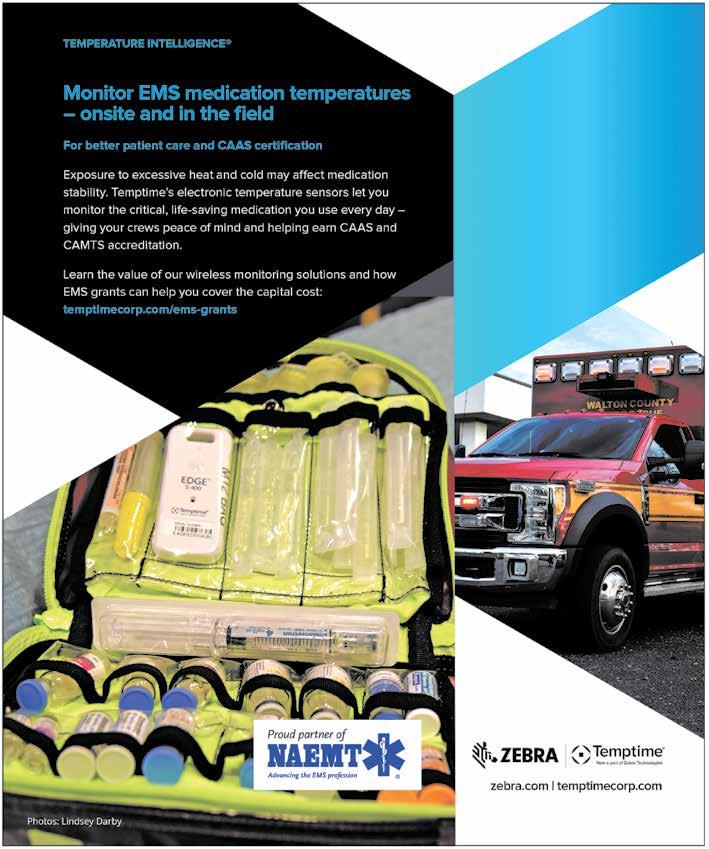

For EMS operations, everything comes down to ensuring the best patient outcomes. Several factors go into achieving this such as welltrained staff and access to the most current technology and equipment among them. Keeping medication and IV fluids carried on-board EMS vehicles and held in storage in the proper temperature range is also essential. So important, in fact, many accreditation agencies such as CAAS and CAMTS require that applicants have some sort of policy in place for maintaining proper temperatures. This can be as simple as having crews recording temperatures manually at regular intervals. However, Chief Tim Turner, EMS Training Division Chief for Walton County EMS in Florida, says that process can be cumbersome and just means extra work for crews. That’s why Walton County turned to automated, electronic temperature monitoring solutions when they began working toward CAAS accreditation.

Advertisement

The Evolving Role of EMS Crews

In many cases, EMS crews are also taking on greater responsibility in the field. Some have been involved in conducting COVID-19 tests, for example. Others may be called on to help administer vaccines once they are available, says Director Tim Grice, National Registered Paramedic and Shift Supervisor for Jackson County EMS in Georgia. “Several of these vaccines have very specific temperature profiles.”

Jackson County EMS is also involved in a pre-hospital transfusion plasma study. “In Georgia, EMS personnel are not allowed to transfuse blood products,” says Lissa Shirley, Supervisor of the Blood Bank at Northeast Georgia Medical Center Blood. “Our trauma administrators went before the Georgia Board to request permission to conduct this pilot study. Our goal is to prove that not only is transfusion in the field safe, but it can also greatly benefit patients.” Blood products need to be stored at 1º to 6º celsius, she says. If they go outside that range, they need to be carefully evaluated to ensure they won’t cause any harm to the recipient.

Manual Versus Electronic Temperature Monitoring

“Monitoring the temperature of medication is not a standard in the EMS industry,” says Chief Turner. “Most ambulances today are equipped with a power source, which allows them to plug in from their stations. That’s how we’ve always maintained temperatures in the patient compartment.” It wasn’t until Walton County EMS started the application process for CAAS accreditation that they began looking for alternatives to recording temperatures manually.

Director Grice agrees, saying that temperature monitoring was not really on Jackson County EMS’s radar until they partnered with the medical center for the prehospital plasma pilot program. “Blood products have very strict temperature requirements, so trying to operationalize a manual temperature check from a thermometer that’s placed in a refrigerator or drug drawer would just not be practical.” Ms. Shirley adds that blood product storage temperatures require continuous monitoring and results must be documented regularly. “I don’t think there are many EMS services that would be able to do that manually — so electronic monitoring is the way to go.”

How Electronic Temperature Monitoring Works

Wireless sensors are placed in each vehicle, refrigerated compartment or StatPackTM carrying medication or blood product. Users can set parameters for checking temperatures in various intervals — from every 30 seconds to once an hour.

“We record temperatures every minute,” explains Chief Turner. “In addition to following USP guidelines as CAAS suggests, we also consider manufacturer recommendations, which are more specific about how long medications can be exposed to extreme temperatures.” Recording temperatures in short intervals gives them a good idea of how long medication may have been out of range, helping make informed decisions about whether or not it needs to be discarded.

Temperatures are logged and saved on the sensor. Data can then be uploaded to the cloud, which can be done manually using a mobile app. Walton County EMS and Jackson County EMS, however, both opted to install wireless gateways in their bays. When a sensor comes within range and connects to the gateway, data is uploaded automatically. Users can access data on the mobile app for each individual sensor. A webbased dashboard gives a broader view with a comprehensive sideby-side snapshot of data for all sensors. This, says Ms. Shirley, makes it much easier to look back and spot trends or track what might have happened in a particular situation. In addition to the overview of temperature data, the dashboard allows users to run reports, set high or low temperature limits and set alarms to notify administrators when temperatures go outside limits. Both organizations have already benefitted from these notifications. “We had an incident where a plasma storage unit went out of range, and we got an alert,” says Director Grice. “We returned the bags to the blood bank, and it was decided to take them out of circulation just to be safe.” In the past, he says, there were other instances where their refrigerated drug drawers on ambulances malfunctioned. “We weren’t monitoring temperatures at the time, so we ended up losing medication because we didn’t know how long the contents had been exposed to excessive heat.”

The Value of Electronic Temperature Monitoring

Of course, there’s a cost to the technology behind electronic temperature monitoring — but many have found the benefits outweigh the initial investment. “I would definitely recommend electronic monitoring with automated data uploads, especially for those seeking some sort of accreditation,” says Chief Turner. “It takes a burden off crews — giving them more time for training and all the things they are supposed to be doing every day.” Added to this is the potential of saving medication, which can be as much as $1000 to $1500 depending on what crews are carrying. On average, blood products can cost $200 to $300 per bag. That’s why both Chief Turner and Director Grice advise not letting finances be a deterrent to implementing electronic monitoring. “The solutions are relatively affordable, and there are both national and local grants EMS organization can apply for to cover the costs,” says Chief Turner.

Director Grice agrees, saying if there’s anything an EMS provider can do to increase the quality and capacity of their service, they should look seriously at pursuing it.

Assistance for Grant Applications

Recognizing the financial barriers some EMS organizations may face in implementing this type of critical temperature monitoring technology, Temptime has partnered with EMSGrantsHelp.com. This valueadd service from Temptime gives you access to the most extensive database for local, federal, state, foundation and corporate grants available. Designed to help fund capital investments for technology and equipment like our electronic temperature sensors and software, the database is updated regularly so there are always new opportunities. EMSGrantsHelp.com (emsgrantshelp.com/temptimegrant-assistance/)can even provide assistance in completing grant requests. You can learn more on our website at temptimecorp. com/ems-grants/. You can also gain access to the full webinar at temptimecorp.com/ems-webinar/.

ResourcesTo learn more about CAAS and CAMTS accreditation requirements: www.caas.org and www.camts.org.

Jeffrey Gutkind is a Senior Business Development Manager for Temptime Corporation. He has extensive experience in helping a wide range of organizations choose and implement temperature monitoring solutions for pharmaceuticals, medical devices, blood products and other sensitive biologics.