Uma Vempati

Kimley-Horn Associates Ph: 612-209-1912 uma.mnawwa@gmail.com

Rob Isabel CDM Smith Ph: 651-252-3716 isabelrs@cdmsmith.com

Chris Voeltz

City of Saint Peter Ph: 507-934-0670 chrisv@saintpetermn.gov

Eric Volk

City of New Brighton Ph: 651-638-2110 eric.volk@newbrightonmn.gov

Jim Hauth

City of Columbia Heights Ph: 763-706-3711

jhauth@columbiaheightsmn.gov

Miles Jensen

SEH, Inc. Ph: 651-490-2000 mjensen@sehinc.com

The ideas, opinions, concepts, procedures, etc. expressed in this publication are those of the individual authors and not necessarily those of the MNAWWA section, its officers, general membership, or the editor. The mention of trade names for commercial products does not represent or imply the approval or endorsement of AWWA. This magazine is presented solely for informational purposes

Breeze Magazine is published by Ph: 866-985-9780 Fax: 866-985-9799 www.kelmanonline.com

Managing Editor - Julia Waterer

Design/Layout - Tracy Toutant

Marketing Manager - Jeff Kutny jeff@kelman.ca

Minnesota Water Research Fund: The First Five Years

PFAS Substances: Protecting Ourselves and Our Drinking Water

Message from the Chair

Message from the Director

News

Save the Date

AWWA Membership Application

Advertiser Product & Service Center

©2022 Craig Kelman & Associates. All rights reserved. The contents of this publication may not be reproduced in whole or in part without the express consent of the publisher.

Advertising Co-ordinator - Stefanie Hagidiakow Content Manager

Tricia Christensen Black & Veatch

Ph: 952-896-0844

christensenp@bv.com

This

at

As I sit here writing my final Message from the Chair column, my immediate thought is: where did the year go? It seems like just yesterday I took the reins as the Section Chair. The old adage “time flies when you are having fun” definitely applies here. During our Annual Conference (September 13–16), I will be handing the chair’s gavel to Rob Isabel. Congratulations and good luck, Rob; it will fly by!

Looking back through this past year, there have been some very memorable events and accomplishments by the section, such as the Board Member Retreat and Training, hosting AWWA’s Regional Meeting of Section Officers (RMSO) in Bloomington, the AWWA Water Matters! Fly-In, participating in ACE competitions by our section members, and the AWWA Summer Leadership Workshop. These events not only gave our volunteers a chance to collaborate with other sections, but also to represent our section at the national level. A very special thank you goes to all the board members and the volunteers that participated in these events and made them successful.

Our Minnesota Section AWWA continues to have financial strength, with thanks due to our strong leadership from the board members. I am honored to have had the opportunity to lead the section this year. The professionalism and spirit of co-operation that exists within the board and among the volunteers and staff was made clear to me time and again. Everyone involved in making the section a success believes in our mission to serve the water industry.

I would like to thank all of the members for their hard work and many volunteer hours this past year. The dedicated members in our districts, councils, and committees are what makes this section so productive – for the section itself and the entire water industry. I also would like to thank Mona Cavalcoli for making the Minnesota Section run so efficiently every day.

In reviewing the year, I am confident in the direction and course that the section is taking. It is important to note that this course and direction is set by you, the member, and your needs. The most important and valuable asset to our organization is you. Without members, there is no Minnesota Section AWWA. There are no councils, districts, or committees on which to serve. There is no board of directors, or executive committee, no section chairs, and certainly, no parent association or association presidents. It is YOUR Organization. You, the member, own this one and make it better. The one thing that I ask you is to please volunteer and contribute.

Uma Vempati“I would like to thank all of the members for their hard work and many volunteer hours this past year. The dedicated members in our districts, councils, and committees are what makes this section so productive – for the section itself and the entire water industry.”

In closing, I am forever grateful for the opportunity to serve the membership as Section Chair. The experience has been rewarding, both personally and professionally, and I will be looking back on it often throughout my life. The lessons learned and the friendships made will last a lifetime. •

Our team has extensive experience providing water planning, design, and construction engineering services for more than 150 water treatment facilities in the past 10 years, along with numerous water distribution, supply, and storage facilities.

Bolton-Menk.com

Bolton-Menk.com

Itis easy for people to take for granted some of the important things afforded to us by living in such a great country.

A country where we have laws mandating that we must have access to safe reliable drinking water. At the same time, it is also hard to fathom that one in three people in the world do not have access to safe drinking water. How is that possible in today’s world?

As a profession, we ensure that our residents and business owners are supplied with safe water to consume and use, day in and day out. One of our biggest customers in each community are the school districts. We work hard to ensure that the young minds of our future are not drinking water filled with lead and copper.

Students around the world are not so fortunate. Worldwide, schools are only able to supply three out of ten students with clean water while they are in classes.

Many of us who work in the water industry also pull double duty in the wastewater industry. We do an equally amazing job of providing sound sanitary sewer services so our customers can safely convey the wastewater from their homes and businesses to wastewater treatment plants serving their community. Surprisingly, over 50% of people on the planet do not have access to adequate toilet facilities.

With all the great work we do, our job still isn’t done. There are an estimated two million people in the United States

that still do not have access to complete plumbing facilities, and we still have two million souls that we must take care of. We seek to do this with pride, and without question.

So, when we are participating in the philanthropic events throughout the year, remember that your donations are going to Water For People and Water Equation. Both of these amazing organizations are working hard to provide safe drinking water and adequate facilities for people in our country and around the world. They also promote our workforce in training, career advancement, and overall collaborative efforts, which helps our mission tenfold. Thank you for your commitment to our industry and remember to take pride in the legacy. •

minds

with lead and copper.”

A recent release by the U.S. Environmental Protection Agency (EPA) of guidance related to lead service line inventories is a timely reminder that October 16, 2024 is coming. That’s the compliance date for the Lead and Copper Rule Revisions (LCRR).

The new lead service line inventory guidance, which was announced in an August 4th press release, describes what EPA expects water systems to do in preparing lead service line inventories, and best practices which water systems can employ to improve those inventories over time. The guidance includes case studies and messaging about prioritizing inventory development in disadvantaged communities and areas where children live and play.

In December 2021, EPA announced that the LCRR would go into effect. EPA currently is developing a new proposed rule to further strengthen the LCRR, called Lead and Copper Rule Improvements (LCRI). EPA anticipates proposing the LCRI in early 2023 and finalizing sometime in 2024, prior to the current LCRR compliance date.

“The standard of care that EPA incorporated into the LCRR will be challenging to meet,” said Steve Via, AWWA’s federal relations director. “Given the public health and political significance of lead, water systems must do more than simply comply with the letter of the law.”

Utilities must take steps now to complete the following actions by October 16, 2024: • Build and share a credible service line inventory. This should include both the water system’s portion of a service line and the portion owned by the customer, as well as galvanized service lines that are or may have been preceded by lead pipe. It also should list service lines of lead status with unknown materials.

• Expand customer service contact programs. Water systems need dependable processes in place to rapidly notify their customers about lead sampling results, engage them in lead service line replacement, rapidly distribute pitcher filters and conduct samples at schools and childcare facilities.

• Update utility communications plans and practices. Water systems must proactively and regularly communicate with their communities and distribute required public notifications. Resources such as AWWA’s Trending in an Instant: A Risk Communication Guide for Water Utilities and the Lead Communications site are helpful. Note: AWWA is developing an updated guide that will assist utilities in communicating about lead leading up to the new rule’s implementation. Expect initial materials to be available this fall.

• Review and adapt current lead and copper monitoring protocols and sample plans. These must be in place to meet LCRR deadlines.

• Understand current corrosion control practices and track data These can help facilitate evaluation of ongoing operations and potential changes in treatment, analysis of new supplies, and response to observed high lead levels. AWWA has developed a new series of e-learning corrosion control classes.

Initial estimates are that 40% of larger water systems with lead service lines will be required to conduct mandatory lead service line replacement and revise their corrosion control practice. It is better to prepare than to rush into these efforts because that can lead to very challenging implementation circumstances and substantial loss of public confidences.

More resources for managing lead in drinking water are available on AWWA’s website.

All sizes of U.S. water utilities are ramping up for monitoring activities required in the Fifth Unregulated Contaminant Monitoring Rule (UCMR 5) that was finalized by the U.S. EPA in December 2021.UCMR is a recurring national water quality monitoring program required by the Safe Drinking Water Act (SDWA). It requires EPA to identify up to 30 unregulated contaminants for inclusion in the monitoring program to help provide information for future regulatory decisions on drinking water standards.The UCMR 5 monitoring activities will be implemented from Jan. 1, 2023, through Dec. 31, 2025, and could potentially include twice the number of U.S. water systems than required in previous UCMR rules.

“As with previous UCMRs, all systems serving more than 10,000 people will participate, and UCMR 5 will add 800 systems serving fewer than 3,300 people,” said Chris Moody, regulatory technical manager with the American Water Works Association’s (AWWA) government affairs office. “A notable

change with UCMR 5 is that all systems serving between 3,300 and 10,000 people are expected to be required to participate,” Moody added. “Although the final number is dependent on how much funding EPA receives from Congress, EPA anticipates that enough funding will be available for all of these systems, bringing the total number of systems participating in UCMR 5 to more than 10,000.”

EPA has already notified the largest systems and a portion of the small systems required to participate. The agency will notify small systems six months in advance of the respective year in which they will be monitored. Samples will be collected and analyzed for a total of 29 per- and polyfluoroalkyl substances (PFAS) and lithium. Water systems will also need to provide information about facilities, including information about previous PFAS and lithium testing and treatment in addition to identifying potential current/historical sources of PFAS affecting each facility’s water supply. •

Since 1913, HR Green has provided solutions that build communities and improve lives.

u ST. PAULu

Despite the global COVID-19 pandemic and a series of extreme weather events, AWWA members and water sector partners indicated their highest level of optimism about the health of the water sector in 17 years in a recent survey.

AWWA’s State of the Water Industry survey, conducted between September and November 2020, asked utility and nonutility participants from the United States and Canada to rate the current health of the water industry on a 1-7 scale, with 1 being “not at all sound” and 7 “very sound.” Responses averaged 5.24, the fourth consecutive increase and most optimistic response since a low of 4.34 in 2017.Complete survey results are available in the newly-released 2021 AWWA State of the Water Industry Report and accompanying Executive Summary,

As water professionals persevered through the past year’s unprecedented challenges, they maintained their commitment to deliver safe, reliable water and sanitation services to the public through problem solving and innovation.

“The pandemic and the response to natural disasters in many regions inspired us to shake off the ‘we have always done it that way’ mentality,” said Melissa Elliott, AWWA’s immediate past president. “In some ways, we’ve leapt 10 years ahead of where we might have been.We’ve always been resilient, but what the last year reinforced is that we are adaptable too, and that’s a pretty unbeatable combination.”

For example, early in the pandemic, Des Moines Water Works implemented round-the-clock response planning and execution to maintain full capacity operations, said Ted Corrigan, CEO and general manager of the utility. “This included being one of the country’s first utilities to sequester personnel in campers on-site to ensure their health and the continued flow of drinking water to the public,” he said. “We updated our plan daily in response to new science and unforeseen challenges.”

David LaFrance, AWWA CEO, said he attributes the annual survey’s continuing upward trend in optimism to the water sector’s ability to “accumulate knowledge and experience to solve modern-day water challenges.”

“This year’s continuing upward trend –especially during a pandemic – reinforces this theory and demonstrates the growing confidence in our ability to work together on solutions,” he added. “We know we can support a better world through better water.” •

“In some ways, we’ve leapt 10 years ahead of where we might have been. We’ve always been resilient, but what the last year reinforced is that we are adaptable too, and that’s a pretty unbeatable combination.”

“Virtual

lets

help you

in the

and get what truly works for

Seibert, ead BIM/Revit Specialist

Author: Tricia Christensen is a MWRF Advisory Committee member. She has spent her 20 plus year career in water and is currently the Upper Midwest Planning and Asset Management Lead at Black & Veatch. She can be contacted at christensenp@bv.com.

By providing sustained water research funding and partnerships with outside stakeholders, UMN CEGE can develop innovative research to improve water treatment technologies and water quality in the environment and to enhance public health, while also attracting more water research experts to the University.

Bernie Bullert (Chair)

BCE 1968, MBA 1977, UMN SL-serco

Michelle Stockness (Vice Chair)

BSCiE 2001, Univ. of Missouri-Columbia Barr Engineering

David Allen

BA Mass Comm. 1993, UMN SL-serco

Lisa Cerney

BCE 1999, UMN Hennepin County

Tricia Christensen BSCE 2001, South Dakota State Univ. Black & Veatch

Bo Johnston MSCE 2005, UMN Black & Veatch

Andrew Ohrt

MSCE 2005, UMN West Yost

Naeem Qureshi

MSCE 1985, UMN

Sambatek

Karl Streed BCE 1972, UMN

Stew Thornley

BS Bus. Administration 1981, UMN MN Department of Health

Shannon Wolkerstorfer

UMN External Relations

hat can be done in five years?

A lot, according to water research champion Bernie Bullert. Five years ago, Bullert embarked on a journey to create a water research fund at the University of Minnesota (UMN). Today the Minnesota Water Research Fund (MWRF) is thriving and making an impact in Minnesota and beyond.

The MWRF had humble beginnings, just like founder Bernie Bullert, who grew up on a Minnesota dairy farm and was the first in his family to graduate from college. In 1968 he earned a Bachelor’s of Civil Engineering and later in 1977, a Master’s in Business Administration, both from UMN. Following college, Bullert got a job with Saint Paul Regional Water Resources, where he spent 35 years climbing the ranks to general manager, a position he held for 12 years. He later became director of water treatment

and distribution services for the City of Minneapolis, and he now consults part time. Bullert has a passion for sustainable water systems, is a natural leader, and no stranger to hard work. It comes as no surprise that he has big plans for MWRF.

Bullert established the MWRF Advisory Committee and continues to inspire the team to work toward the vision of enabling UMN to be a national leader in innovative water research, to improve public health, and protect Minnesota’s water resources. The Advisory Committee is composed of UMN alumni and industry professionals who have an interest in supporting water research in Minnesota. Many of the committee members started volunteering because of their deep commitment to Bullert and now are personally committed to MWRF’s mission and goals.

“Water is vital to everyone’s health and to business and industry. Water resources are impacted by human activity, which changes the amount and quality of water available for all water needs on the planet. These impacts on water need to be researched so we will continue to have adequate supplies of quality water.”

– Bernie Bullert

W

Fundraising, research, communication, and education are all fundamental components of MWRF.

The fund’s short-term goal is to provide annual research grants for faculty and students working in water treatment and water resource management.

MWRF’s long-term goal is to raise $2 million to create an endowed chair to support a UMN faculty member who is an international leader in the field.

The largest fundraising event supporting MWRF is Give to the Max Day, which is November 17, 2022. This is a day when Minnesotans come together to donate to nonprofits and schools across the state. In addition to seeking individual donations, the advisory council is working hard to identify partnership models to cultivate industry support. MWRF is actively seeking fellow visionaries to make the dream of longterm, ongoing water research a reality for Minnesota.

MWRF’s mission is to provide sustained funding for innovative UMN water research which will improve water treatment technologies and water quality in the environment. MWRF also aims to improve public health, protect water resources, and ensure the next generation of water industry leaders will make decisions grounded in solid research.

So far, MWRF has been making annual distributions in the range of $5,000 – $10,000, which have funded 8 projects and one significant research equipment purchase. The Advisory Committee reviews project requests each year and recommends one to two projects for funding. True to Bullert’s roots, many of the funded research projects address problems

unique to Minnesota’s rural areas. The Advisory Committee also aims to support emerging research, providing seed funding for projects that do not yet have other funding sources. MWRF has positively impacted multiple UMN professors, graduate students, and undergraduate students who work on the research projects.

• 2022: Phosphorus Retention in Stormwater Ponds: Professor Emeritus John Gulliver with PhD candidate Vinicius Taguchi

• 2022: Quarternary Ammonium Compounds in MN Waters – Effects of the COVID-19 Pandemic: Professor William Arnold

• 2021: Impacts of Vegetation on Surface Water/Groundwater Interactions: Assistant Professor Judy Yang

• 2021: Purchase of ISCO Automated Water Sampling Devices for Use in Water Research and Teaching CEGE Students

• 2020: Optimization of Water Quality Monitoring in Streams: Adjunct Associate Professor Paul Capel

• 2019: Water-Conscious Cultivar Selection for Protecting Minnesota Groundwater: Assistant Professor Xue Feng with PhD candidate Brandon Sloan

• 2018: Integrated Biocatalysis and Reactor Design for Clean Water and Energy from Waste: Professor Paige Novak

• 2018: N-nitrosodimethylamine Precursors in the Upper Mississippi River: Professor Raymond Hozalski

• 2017: Innovative Nitrogen Removal: Graduate student Anndee Huff working with Professor Paige Novak

MWRF is also a proponent of industry education, hosting regular virtual events for students and professionals interested in the state of water. Last year’s educational event highlighted the UMN Water Council, a new interdisciplinary team bringing UMN scholars and resources together to tackle the pressing concern of access to clean water in the 21st Century.

MWRF started five years ago as the vision of one man. Today, MWRF can boast that it has provided funding for several projects, educated many students and water professionals, raised funds toward its long-term goal of an endowed chair at UMN, and positively impacted students, researchers, water professionals and their communities.

There is no doubt that water research plays an essential role in the future of our cities, states, and nation. MWRF is committed to ongoing water research that will enhance Minnesota’s economy and the health of Minnesota citizens, now and for future generations.

To support the MWRF or become a thought partner, please contact Bernie Bullert at bernie.bullert@sl-serco.com or another member of the Advisory Committee. More information about the MWRF can be found online at cse.umn.edu/cege/minnesota-waterresearch-fund.

This article is one of a four-part series that will be published in the Breeze Next quarter’s article will highlight the importance of water research in Minnesota. Future articles will focus on the impact MWRF has on students, faculty, and the university.

The MWRF will have a booth near the registration table at the MN AWWA Conference in Duluth. Many of the MWRF Advisory Committee members are active participants in MN AWWA. Bernie Bullert, Michelle Stockness, Tricia Christensen, Bo Johnston, Andrew Ohrt, and Naeem Qureshi will all be attending the conference this year. Please stop by the MWRF Booth to visit or catch them at the social and technical events. •

Safe. Reliable. Affordable.

Committed to our communities , treating every drop of water like our own.

Design with community in mind stantec.com/water

If it involves water, MSA Professional Services has the expertise to address it. Big or small, we do whatever it takes to meet each need, working to make Minnesota municipalities stronger in the process.

When you partner with MSA, it’s more than a project. It’s a commitment.

DULUTH | ST.PAUL www.msa-ps.com

PIPE THAT STANDS THE TEST OF TIME. The Romans designed everything to last. When it comes to moving your water, we do the same. With the added protection of zinc coating and V-Bio wrap, we engineer pipe to last for a very long time, doing the job generations from now. That means higher confidence as well as lower life-cycle costs. Ask us about the official pipe for long-term thinkers everywhere.

From water systems to industrial pumping applications, from storm water to metering,

experienced and ready to make your job easier. Our crew specializes in combining experience and innovation to offer you solutions for your challenging projects. Contact us today to learn more about how DSG can help you.

On June 15, 2022, the EPA released drinking water health advisories for four PFAS. Health advisories provide states and water utilities with a reference point as they evaluate potential contamination and appropriate responses to assure the safety of drinking water. The PFOA and PFOS advisory levels are extremely low and do not reflect the draft recommendations of EPA’s own expert Science Advisory Board review. The health advisory levels at parts per quadrillion, undetectable by modern laboratory methods.

AWWA is committed to both the protection of public health and decision-making based on the best available science. As a community of water professionals, we share EPA’s desire to keep harmful levels of PFAS out of the nation’s drinking water. We support setting national drinking water standards for PFAS that protect all consumers, including the most sensitive populations. We also stand for strong source water protection to prevent PFAS contamination and increased investment in PFAS research.

At the national level, EPA is already in the process of setting maximum contaminant levels for PFAS within the scientifically rigorous framework of the Safe Drinking Water Act (SDWA). A proposal is expected in the fall. Through the SDWA regulatory process, many utilities are sampling for PFOA, PFOS and other PFAS to better understand where they occur and at what levels. They are sharing that information with their communities. It’s important that EPA complete this rulemaking process so that states, utilities and consumers have a clear and consistent path forward for managing harmful levels of PFAS in drinking water.

These four health advisories reflect potential risk assuming 70 years of exposure. EPA’s support materials appropriately point consumers toward opportunities to reduce PFAS exposure in their daily lives, be it exposure through drinking water, food, dust, or other routes.

AWWA’s members are working diligently to manage the risk posed by PFAS in drinking water. At the low levels set in the health advisories, protecting source water from PFAS contamination is critical. AWWA urges Congress and other decision-makers to implement policies that keep harmful PFAS out of our communities, especially the nation’s drinking water supply.

As part of a government-wide effort to confront PFAS pollution, EPA is making available $1 billion in grant funding through the new Bipartisan Infrastructure Law to help communities that are on the frontlines of PFAS contamination to reduce PFAS in drinking water in communities facing disproportionate impacts. EPA is making $1 billion available in the fiscal year 2022 and a total of $5 billion for fiscal years 2022–2026.

The goal of the Emerging Contaminants in Small or Disadvantaged Communities grant program is to have states, territories and tribes prioritize grant funding in small or disadvantaged communities to focus exclusively on addressing emerging contaminants in drinking water, including PFAS, pharmaceuticals and personal care products, and unregulated contaminants such as manganese, perchlorate and 1,4 dioxane. Funding will be provided to participating states and territories to benefit small or disadvantaged communities in scoping, planning, testing and remediating emerging contaminants in drinking and source water.

There are likely thousands of PFAS that are currently present in the United States. Each of these chemicals has different properties and may be used for different purposes or may simply be present as unintended by-products of certain manufacturing or other processes. The toxicity of the chemicals varies, and people may be exposed to each chemical in different ways, in varying amounts and with different mixtures.

Robust information about PFAS is needed to better understand the risks they pose and to be able to take effective actions to protect human health and the environment. EPA’s research is helping to deepen our understanding of these chemicals so that we can take steps to continue reducing the risks posed by PFAS and provide certainty to state, local and tribal partners and the public. That is why EPA has placed a strong emphasis on research and why this work is vital to addressing PFAS in the environment.

EPA researchers continue to evaluate different drinking water treatment technologies that can remove certain PFAS from drinking water systems. They are evaluating systems across the nation currently treating PFAS and gathering data on cost and performance. Researchers are also testing

modifications needed to improve treatment. This research is being conducted in cooperation with drinking water utilities and with other federal agencies.

Researchers will generate performance and cost data with collaborators to develop models and provide tools to enable local communities to determine optimal treatment choices based on their specific needs and circumstances.

This work is incorporated into the Drinking Water Treatability Database, which helps drinking water utilities, communities, states, academics and more identify effective treatment

EPA researchers are developing methods for characterizing PFAS releases and movement in soil, water and sediments at contaminated sites, so that site managers can understand the

“EPA researchers are measuring PFAS in air, drinking water and soils to understand how and to what degree people might be exposed to PFAS.”Ess Brothers & Sons, Inc. – Construction Specialists for 153 Years!

of different sources and pathways for PFAS. This will help states, tribes and local communities to assess potential risks and to choose the most effective methods for protecting public health.

PFAS can be present in our water, soil, air and food as well as in materials found in our homes or workplaces, including:

• Drinking water – in public drinking water systems and private drinking water wells.

• Soil and water at or near waste sites – at landfills, disposal sites and hazardous waste sites such as those that fall under the federal Superfund and Resource Conservation and Recovery Act programs.

• Fire extinguishing foam – in aqueous film-forming foams (or AFFFs) used to extinguish flammable liquid-based fires. Such foams are used in training and emergency response events at airports, shipyards, military bases, firefighting training facilities, chemical plants and refineries.

• Manufacturing or chemical production facilities that produce or use PFAS – for example, at chrome plating, electronics and certain textile and paper manufacturers.

• Food – for example, in fish caught from water contaminated by PFAS and dairy products from livestock exposed to PFAS.

• Food packaging – for example, in grease-resistant paper, fast food containers/wrappers, microwave popcorn bags, pizza boxes and candy wrappers.

• Household products and dust – for example, in stain and water-repellent used on carpets, upholstery, clothing and other fabrics; cleaning products, non-stick cookware, paints, varnishes and sealants.

• Personal care products – for example, in certain shampoos, dental floss and cosmetics.

• Biosolids – for example, fertilizer from wastewater treatment plants that is used on agricultural lands can affect ground and surface water, as well as the animals that graze on the land.

Information obtained from awwa.org and www.epa.gov/pfas •

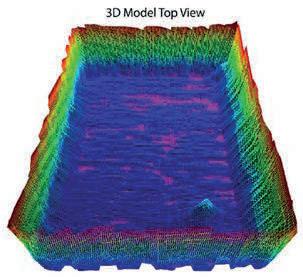

For over a century, conventional granular media downflow filters have provided reliable, economic water and wastewater treatment. Even today, this type of filtration system provides proven treatment capabilities and long-term maintenance benefits. Though the process of granular media filtration is relatively well-understood, the long-term success of a filter may ultimately depend more on the filter underdrain design.

The filtration operation for conventional filters is comprised of two distinct phases: filtration and cleaning (backwashing). The filtration phase to remove particulate material is accomplished by passing the water downward through a filter bed comprised of one or more granular medias (e.g., sand, anthracite, GAC), with or without chemical addition. The solids removal process is accomplished by several removal mechanisms such as straining, sedimentation, impaction, interception, adhesion, and adsorption. The filtration phase must end once the suspended solids in the effluent increase to an unacceptable concentration or when a limiting headloss occurs across the filter bed. Backwashing cleans the filter media by reversing the flow through the media to send the solids-laden wash water for treatment elsewhere. Air is often used in addition to water, either sequentially or simultaneously, to provide enhanced media scouring.

All granular downflow filters must contain media and an underdrain that: 1) supports the granular media;

2) withstands maximum filtering headloss; 3) uniformly allows percolation of the filtrate across the media bed; 4) uniformly distributes backwash water across the entire bed at varying flowrates;

5) uniformly distributes the scouring air either separately or simultaneously with the backwash water;

6) withstands the upthrust created at the maximum rates of backwash and scouring air; and 7) resists corrosion.

Filter underdrains are principally comprised by one of the following: (a) suspended concrete slab or steel plate with integral filtration nozzles and plenum below; or (b) set of round-, triangular-, or blockshaped parallel pipes (laterals) containing holes, slots or nozzles and that connect into a main header pipe or duct (flume).

Suspended underdrains utilize an elevated floor, supported on columns or between dwarf walls, creating a plenum underneath. The plenum space, with at least 6" to more than 30" of vertical height, advantageously provides for inspection and service through an access hatch. Floors are constructed using steel plate (for small filters), from precast slabs, or by pouring a monolithic concrete slab on top of base form panels. Monolithic slabs minimize grouting (i.e., potential leakage points) and include reinforcement bars linked to the tank structure to create a robust design that withstands very high vertical forces. Nozzles sleeves are cast into the concrete floor, and once curing is finished, nozzles are quickly installed. Unlike nozzle-less lateral underdrains, suspended floors may be pressure-tested to ensure structural capability by inserting blanking plugs into the nozzle sleeves.

Lateral underdrains consist of a main header pipe or flume with several parallel laterals branched perpendicularly off one or both sides of the header or flume. The headloss in each lateral includes entry, friction, and discharge losses, the sum of which vary water and air

flowrates considerably under different operating conditions. Lateral underdrains are often fixed in place by grout or anchor bolts and buried in gravel to support and retain media and improve backwash performance.

Except in specific cases, filter underdrains must be level for uniform filtration across the bed and to evenly distribute the water and air fed during backwashing in a two-dimensional horizontal plane. Uneven, shallower parts of the media bed will create undesirable and increased filtering, backwash, and separate air scour flowrates. For simultaneous air-water cleaning, a zone of lower water flow may receive a higher proportion of air due to reduced water flow back pressure.

Filter underdrains must either have a fine straining method to hold back the media or have graded gravel to prevent media migration and loss. For underdrains requiring gravel, packing layers must remain stationary during backwash –if disrupted, the gravel must be re-laid.

Backwashing, particularly at increased rates, will not regrade the material, and instead will likely cause spouting through the media. Air scour and simultaneous air/water washing make problems from

gravel layer undulations much worse. Suspended underdrains with large slot opening nozzles and gravel permit horizontal short circuiting, convergence of flow from several nozzles, and formation of a spout through the packing layer. Fine slot nozzles to retain media directly above the suspended underdrain eliminate horizontal short circuiting and also provide the advantage of a lower hydraulic filter profile.

Lateral systems (triangular or block with slots, round pipes with nozzles) that have openings fine enough to retain the media can block up if backwash water is not entirely free of grit. In contrast, because suspended underdrain velocities are relatively low, nozzles with very fine slots may be used without concern as grit particles in backwash water may settle in the plenum.

Critical to a filter is the ability for its media to be effectively cleaned. With proper backwashing, conventional filters have many significant advantages over other filter types, to include much longer filter runs with smaller overall backwash volumes; however, not all conventional filter backwash capabilities are “created equal.”

Velocities under a suspended underdrain are relatively low, which reliably leads to good backwash and air scour distribution. The large plenum area buffers changes and provides uniform water and air flowrates across the filter floor. Comparatively, underdrains with laterals produce higher velocities, friction loss, and the Bernoulli effect, resulting in limits of effective lateral length, additional filter design concerns, and increased maldistribution. The flow pattern down the length of a lateral forms an asymmetric “U” shape and changes significantly according to flowrate, leading to operational challenges and structural design concerns. When the air/water interface is created during air scour, without a sufficient lateral cross-section for the air to pass down the lateral length, waves are created that produce intermittent discharge and damage. As inferred previously, nozzle-less lateral systems cannot be pressure-tested following installation, introducing doubt

of installed structural capability during these conditions.

Air is distributed through laterals using the orifices or slots located in the crown of a round pipe or triangular lateral, near the top of the primary duct of a block-shaped lateral, or through slotted nozzles mounted on a round pipe lateral. For triangular and nozzle-less round laterals, orifices must be engineered only for a specific set of flowrate conditions, which unquestionably change during backwash and air scour operation and lead to poor performance and orifice blockage.

Air is distributed through a suspended floor through precision-engineered nozzles/strainers. A nozzle has three main components – the strainer to retain media, a water control orifice, and a stem with air orifices. Nozzle stems include a top air bleed hole and lower air metering hole or slots. As scour air is supplied, air collects at the plenum top and depresses the plenum water to form a uniform air/ water divide line across all filter stems. The air bleed hole triggers the flow of air and the resulting headloss causes depression of the plenum water interface. Once the air metering hole or slots are exposed, this larger orifice area stabilizes the water level; however, when air and water flows simultaneously, the driving head increases, forcing air into the stem, which raises the plenum water level. By correct selection of the stem bore and of the size and location of the orifices, a range of air/ water interface level may be beneficially maintained under both air-only and simultaneous conditions. After air scour has ended, the air bleed hole allows venting of air from the underdrain.

Though nozzle-based underdrains predominate the international municipal market, block-shaped lateral systems are prevalent in the United States. The molded block contains a triangular or semi-circular primary manifold that distributes into an outer pair of secondary ducts, which in turn feed an upper face (or cap). Multiple lengths of blocks are laid side-by-side and grout is placed between these laterals. Originally (late 1970s), the cap contained large perforations requiring gravel; however,

to avoid the packing layer in the early 1990s, sintered polyethylene bead slabs were screwed onto the block top. Due to the numerous amounts of floor uplift events, resulting mostly from slab plugging, biological fouling, and grout leakage, manufacturers are currently discontinuing the beaded slabs, reverting to slotted caps, and providing a significant amount of supplementary hardware to hold down the blocks.

In response to the prevalent floor failures, stainless steel triangular laterals have recently increased in usage. Though having a low hydraulic filtering profile, maldistribution of triangular lateral systems is significantly higher than that of block or nozzle-based monolithic floors. Undesired outcomes resulted in poor media agitation and cleaning, shorter filter runs, increased backwash rates and volumes, and a reduction in filter capacity. Adding the recent increased cost of stainless steel, the life cycle benefit of triangular lateral systems over that of block style is questionable.

To fully capture the treatment capabilities and long-term maintenance benefits of conventional filters, prudent municipal filter design must include consideration of suspended monolithic floors. This type of nozzlebased underdrain system eliminates gravel, has excellent filter and backwash distribution characteristics, and is structurally superior to lateral systems. At end-of-life cycle, in contrast to a complete lateral underdrain overhaul, nozzles are simply replaced as the monolithic floor remains part of the civil structure. One monolithic underdrain manufacturer, Orthos Liquid Systems, boasts 200 installed filters, some with over 20 years of operation, without a filter underdrain failure. Lateral systems manufacturers with significant experience can make no such claim. •

1. Stevenson, D.G. ‘Water Treatment Unit Processes.’ London: Imperial College Press. 1997.

2. Tchobanoglous, G. & Burton, F.L. ‘Wastewater Engineering: Treatment, Disposal and Reuse.’ New York: McGraw Hill. 1991.

When you look through most of the textbooks and papers that are written to train technicians in the water industry, one can very quickly identify that the lens through which most of these are written is one where water ‘usage’ is the prevailing theme. To a certain extent, this usage lens is/was understandable. It was measurable and trackable. You could also tie roles and incentives to this measurable metric in the water space. But that lens is now too cloudy. We need a new more intelligent lens from which we view, design, and run our water systems. We need a more biological lens. And by biology I mean a lens that focuses on quality. Yes, I know that the industry currently works to ensure that the water coming out of taps is clean and drinkable (for the drinking water side of the industry which we at Varuna focus on). But we have definitely not used this as the lens for the development of most of the new approaches and technologies

in the industry. We live in a world where we have at least 30,000 new chemicals developed over the last 20 years and we do not know the effects of these chemicals on our drinking water. We do not know because we haven’t even developed tests to check whether our water is contaminated with these new chemicals. So we carry on focusing on the obvious problems we can address: non-revenue water losses.

We need to redesign our water systems towards more intelligence in detecting, managing, and running our systems to prevent biological issues. And by biological I mean quality. Because biology is what customers experience from their water utility. Most of us cannot agree on the right quantity of water for a consumer to drink. But I have yet to meet a person who does not want to drink clean water. If that, clean drinking water, is the metric that we all agree on, why aren’t we designing our water systems and running them with that as the most central factor? It’s time we did that.

I’ll stretch the biology analogy a step further and talk about the cell towers in the telecoms industry. Cell towers were designed to work like biological cells with the optimal ‘cell design,’ the spacing and structure between towers, selected to ensure the best quality signal for customers. Biology being used to define design and consequently provide the best user experience. Water lags telecoms, in terms of adoption of technologies and approaches, by ~10 years and it is time for us to start borrowing from that industry a lot more than we currently do. Because what is innovation if not taking ideas and approaches from one place and applying them in another? We need to look to biology to design intelligent water systems. What does this look like?

Intelligent systems are organizations that optimally use human intelligence with technology-enabled insights to make smart decisions, especially in the face of uncertainty and complexity. The water industry has typically focused decisionmaking based on the silo of information that is readily available. The distribution system information silo, different from the plant system information silo, separate from the water quality database populated with physical sample data, all further hindered by the

asynchronous nature of the data feeds and no connections between them. Integrating all these streams of information and knowledge is the only way for the water industry to survive an increasingly complex world where weather/climate change/ consumer expectations are all putting a strain on water systems –especially the small to medium water systems. Integrating the water data/info silos for decision-making enables a water system from a state where we’re making good decisions 40% of the time to making good decisions 80% of the time. That’s a full 100% increase in the number of times we are right about an operational or a financial decision! Just because we move towards removing silos and becoming more advanced tech/human-centric businesses. According to some MIT research (Building A More Intelligent Enterprise, 2017) there are five steps towards an intelligent (water) system.

Find the strategic edge: This will require looking at the past organization decisions and situations to hone in on areas that can be improved. This will require a first step of actually digitizing all the historic data that the water system has to then model/simulate past scenarios based on these.

Run prediction tournaments: Discover the best methods of decision-making across the organization. The beauty of having combined the data in the first step is that you can run these competitions across many data sets and not just yours. This can be achieved using anonymized data from other water systems. Varuna’s Delta product enables this.

Model the experts in your midst (within and without):

Simulating decisions and scenarios. This is also akin to developing resilience plans against contaminant shock and asset shocks.

This modeling and scenario planning is done using artificial intelligence. And then you move to the final step, #5.

Changing the way the organization operates towards a more exploratory and predictive approach to decisionmaking using human/machine intelligence. We need to move our water systems to these intelligent approaches of decision-making. The overarching goal is to make sure that water systems can deliver clean water consistently. We need to move the industry towards an approach of removing silos to improve decision-making. Going back to our ‘cell’ analogy, we need the cells/departments to be permeable so that information can be shared across the cells to improve decision-making in the whole organism, the corporation. We need a formation of cells, all coming together to give the whole organism system views, built or designed to optimize each cell while optimizing the whole system towards ensuring safe delivery of water consistently. We need self-healing, continuous learning intelligent organizations, and more intelligent water systems. •

Commercial / MunicipalCommercial / Municipal Water SystemsWater Systems

As we continue to deliver valuable information through the pages of this magazine, in a printed format that is appealing, reader-friendly and not lost in the proliferation of electronic messages that are bombarding our senses, we are also well aware of the need to be respectful of our environment. That is why we are committed to publishing the magazine in the most environmentally-friendly process possible.

This publication is printed on Forest Stewardship Council® (FSC ®) certified paper with vegetable oil-based inks. Please do your part for the environment by reusing and recycling.

Today’s forest industry is working hard to become one of the greenest industries on earth. Paper is an essential part of human civilization. While we all use and depend upon electronic communications, it is easy to ignore that it comes at an environmental cost. Worldwide spam email traffic creates greenhouse gases equivalent to burning two billion gallons of gasoline yearly, with numbers rising. More than $55 billion in toxic e-waste material is thrown away every year in the US alone, with a recycling rate of only 20% compared to 64.7% for paper. No industry is perfect. But the paper industry has made, and continues to make, huge investments in environmental responsibility. Specifying and buying paper from certified sources ensures the continuation and growth of carbonabsorbing forests. Using paper with appropriate amounts of recycled fibre helps preserve forests, conserve energy, and maximize fibre usage through paper lifecycles.

Brought to you by Craig Kelman & Associates Ltd. publisher of this magazine and

Brought to you by Craig Kelman & Associates Ltd. publisher of this magazine and

With so many components on an elevated legged tank, it can be easy to overlook windage rods. These are rods that provide bracing and stability to a water tower. They are not nearly as large or eye-catching as the tank shell – the part where a city’s logo is often emblazoned. They are also not the sturdy legs that are fixed in concrete and easy to see.

A fresh coat of paint helps prevent corrosion, which weakens steel’s integrity. Rusted windage rods are more likely to bend or break.

Windage rods should appear taut and without any sag or sway. If a windage rod is curved too much, that’s a telltale sign that it is too slack. If an inspector can grab a windage rod from the ground and it then wiggles or shakes – it’s too loose and needs to be tightened.

Windage rods can be judged on three points of observation:

A visual inspection can be performed to determine if windage rods are showing any signs of sagging, bowing, or movement that would indicate the rods are loose.

You can shake, knock or push on the rods to observe how much sway they have, and thus judge the rods’ tightness. If the rod moves easily, it means the rods are loose and need adjustment.

Inspectors use a tool to knock on the windage rods and listen to their reverberations. Similar to a guitar string, the looser the windage rods, the deeper and longer the sound will reverberate. The tighter the windage rods, the higher and shorter the sound will be.

When a tank is being professionally inspected, it’s best to use all three points of observation because one or two points might not provide the whole picture. Also, each method builds on the previous inspection check. However, if a rod passes the visual test, there’s typically no need to move on to the next observation point.

Visual inspections can be conducted from the ground or off the tower access ladder. However, if a rod appears loose, then a closer inspection is needed.

There’s no set timetable for when windage rods should be adjusted. There are several factors to consider. Did a strong windstorm, tornado, or hurricane recently hit the water tower? High winds can damage windage rods and other components, so the tank should be inspected immediately. If a severe storm struck the water tower, it’s very likely the windage rods need to be adjusted.

Saltwater is highly corrosive to metal. Storage tanks located along coastal areas typically begin showing rust much quicker than their landlocked counterparts. Elevated tanks along coastal areas will also likely need their windage rods inspected and recoated more regularly.

A fresh coat of paint helps prevent corrosion, which weakens steel’s integrity. Rusted windage rods are more likely to bend or break.

Otherwise, it’s not uncommon to see the need arise after a few inspection cycles – which is typically three to five years –depending on whether the tank has cathodic protection or not.

An elevated tank is designed to handle most natural disasters. Engineers factor strong wind speeds into the design and make it so the structures can withstand most high winds.

Of course, there are exceptions. An EF4 tornado with winds just shy of 200 mph (which would have made it EF5) barreled into an elevated legged tank in Mayfield, KY, and reduced it to rubble

in December 2021. The tank was built in the early 1950s but had undergone significant maintenance work in the past five years. That still wasn’t strong enough to withstand a historic tornado.

But there have also been elevated tanks that have withstood direct hits from hurricanes with little to no damage. Regardless of whether you can see damage or not, it’s always best to have your tank professionally inspected after a natural disaster. After all, smaller elements or ones lofted higher in the air like a windage rod are easy to overlook.

Birds and insects have a knack for finding a way into places they shouldn’t be. Birds, insects, snakes, and some animals can squeeze themselves into the smallest openings. Openings in and around water towers and tanks should be sealed off to prevent unwanted critters from entering.

The American Water Works Association recommends that tanks be inspected every three years. In between

professional inspections, tank owners should make a point to visually inspect their storage tank weekly. That could be as simple as taking a few minutes to walk around the tank and make sure there are no breaks in screens or holes.

Be mindful of other openings too. Cathodic protection holes should be fitted with covers to block access. If a tank’s rusted through, it’s susceptible to holes. Aside from being at greater

risk for structure failure, a holy tank is open to contaminants and animals.

Ideally, a tank should have properly designed and fitted screens or patches covering any potential openings. Improperly designed or installed roof hatches and vents are entry points for birds and bees.

If a screen is improperly fitted, it can be difficult to get off. That may cause inspection or repair delays and could even result in remobilization costs if work is supposed to be done but cannot be performed because the contractors can’t access the tank.

Overflow pipes should be covered with a coarse, corrosionresistant screen and a flap valve, according to AWWA D100-11. Vents should be designed to prevent birds, insects, and animals from entering a tank, according to AWWA D100-11. The codes recommend installing a pressure-vacuum screened vent or a separate pressure-vacuum relief mechanism that works if the screen frosts over or clogs. Similarly, NFPA also calls for screens on vents and overflows to prevent animals from gaining entry.

Stub overflows are more likely to be infiltrated by critters because it’s easier to access. Extending an overflow down to grade and adding a flapper valve and screen helps prevent unwanted intrusions.

Hornets, wasps, and bees are drawn to cool and dry places like overflow pipes or inside the concrete shaft of a composite tank. Enter an area where hornets and wasps like to nest at your own risk.

Don’t kick the hornet’s nest is an idiom that means, don’t start trouble in a hazardous situation. If you literally kick a hornet’s nest, you might expect angry hornets to fly out at you, ready to sting.

However, sometimes you need to kick the hornet’s nest. That’s what inspectors do when they hit an overflow pipe to see if wasps or hornets have taken residence. It’s more like knocking to gauge the threat level. If there are hornets or wasps, the inspectors might not be able to finish their inspection until the pests are removed.

Snakes can also crawl up pipes, though they are more likely to be found in valve pits. During a routine inspection in rural New York, an inspector came across hundreds of snakes at the bottom of a dark valve pit. He was unaware that the snakes were present until halfway down the ladder. By then, a few of the snakes were already slithering toward him. The inspection was not completed that day.

Birds like to make nests up high – away from predators. Water towers are naturally an attractive home for birds. If there are birds around a water source, there’s a greater chance that bird droppings or feathers, or even the whole bird might find itself inside the tank. To deter birds from nesting, tank owners might try putting up stuffed vultures, stuffed owls, or tube men –the flappy inflatables most often spotted at car dealerships.

It would be ill-advised to shoot birds because any pellets or bullets that miss could puncture the water tank or surrounding structures. Besides, many birds are protected by federal laws, so they can’t be harmed.

During one inspection, dozens of large turkey vultures circled an old tinman-style tank on a college campus. A college maintenance official knew just the trick to make the birds scatter –use a fishing pole to float a black helium balloon toward the birds.

Bird droppings have been known to contaminate water supplies. A 1993 incident in a small Midwestern town resulted in seven deaths and multiple hospitalizations for gastroenteritis. The town’s water tower had an improper roof vent and an uncovered hatch – allowing birds, bird droppings, and other contaminants to foul up the water.

It’s not uncommon to find dead birds in or around water tanks. If a screen is missing or broken or there’s a hole big enough for birds to fly through, a bird will likely become caught in the tank and eventually die. Once inside a tank, animals have a difficult time finding their way out. Tanks are confined spaces, and above the water line can hold toxic gases, fatal to humans and animals if there’s prolonged exposure.

Dead birds were found in a pair of Ohio water tanks five years after city officials received a report that the tanks needed repairs due to metal corrosion and evidence of animal intrusion, according to a Cincinnati ABC affiliate. Residents didn’t find out until the Ohio EPA temporarily shut down the tanks after finding issues.

Inspect tanks regularly to check for any unwanted visitors. If any problem areas crop up, it’s better to address them early on before there’s an even bigger issue with contaminated water. •

Water towers are naturally an attractive home for birds. If there are birds around a water source, there’s a greater chance that bird droppings or feathers, or even the whole bird might find itself inside the tank.

By Dave White and Adam T. Carpenter

By Dave White and Adam T. Carpenter

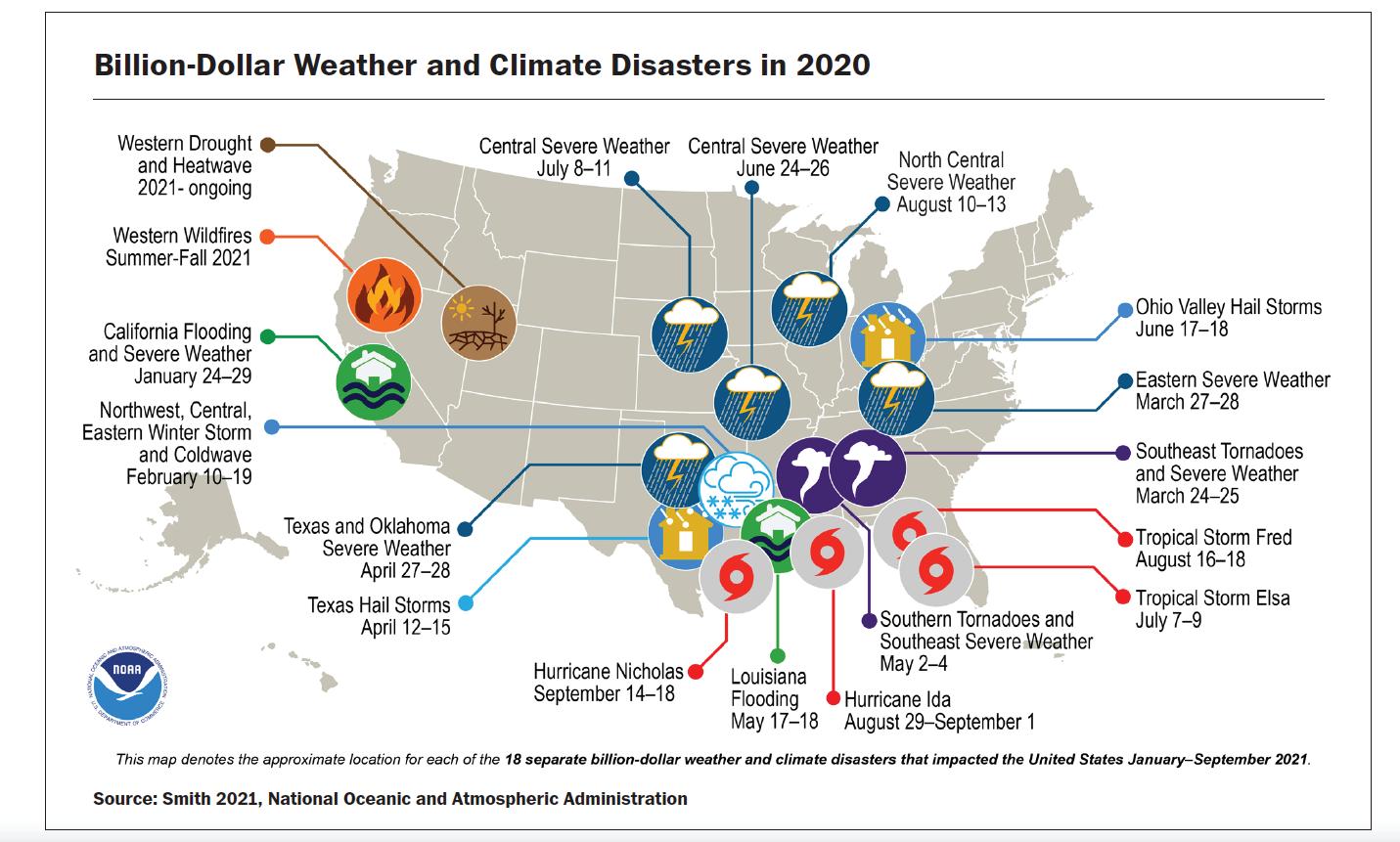

From the environment to our forests, to agriculture, and the water we drink, climate change continues to adversely affect many sectors of our lives. Once rare and extreme weather events are becoming commonplace. The National Oceanic and Atmospheric Administration (NOAA) tracks natural disasters, and since 1980 the United States has experienced 291 weather and climate disasters that each exceeded $1 billion (NOAA NCEI 2021). The cumulative cost is staggering: more than 14,000 lives lost and in excess of $1.9 trillion to pay for disaster relief. Between 2016 and 2020, there were 81 severe disasters that caused nearly 4,000 deaths and whose total cost was more than $600 billion. Figure 1 shows the billion-dollar disasters that occurred just in 2020.

In the western United States, wildfires are happening with increasing frequency and severity as well. The National Association of State Foresters documents that the fire season today is 78 days longer than it was in the 1970s and projects that fire seasons will become hotter, more unpredictable, and more expensive (NASF n.d.). The amount dedicated to fire suppression in the Forest Service budget has grown from 20% of the total to more than 50%, and in 2018 the US government spent more than $3 billion fighting wildfires.

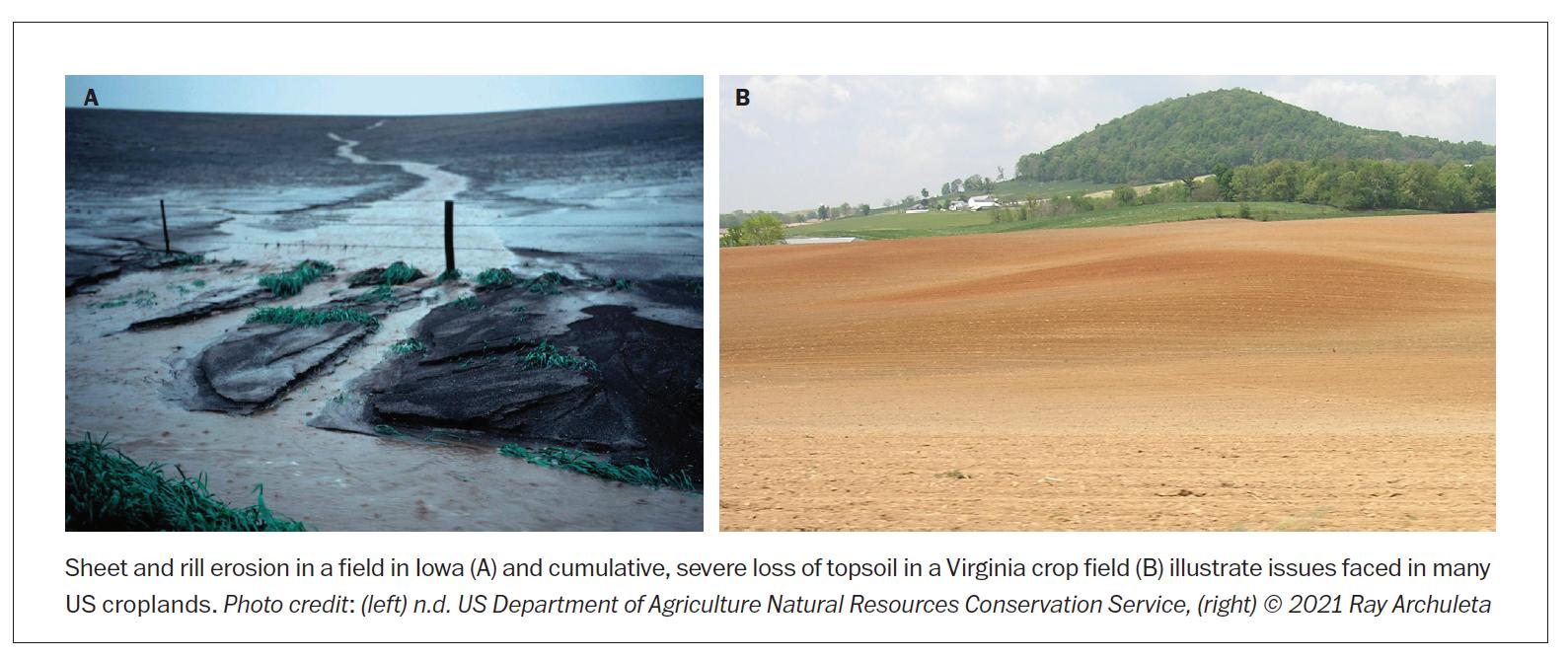

In addition to these many challenges is the uneven increase in world population. The United Nations projects that there will be 9.7 billion humans on Earth by 2050, many of whom will be in water-poor areas (UN DESA 2019). To feed this many people, worldwide food production will need to substantially increase. In 2012, the World Wildlife Fund’s 2050 Criteria report stated that in the next 40 years, humanity would have to produce more food than we have in the last 8,000 years combined (WWF 2012). At the same time, agricultural issues increasingly affect drinking water. A 2021 study published in Proceedings of the National Academy of Sciences (Thaler et al. 2021) found that over the years, some one-third of the cropland in the US Corn Belt has lost its carbon-rich topsoil to erosion (Figure 2). While farm production has kept up with the loss of topsoil through advanced genetics and additional fertilizer, agricultural runoff has accelerated water quality problems in many US lakes and waterways. For example, the City of Toledo had to issue a “do not drink” order for three days in 2014 because of a harmful algal bloom in Lake Erie caused by phosphorus runoff, primarily from agricultural lands. Today, harmful algal blooms commonly occur around the world, and excessive nutrients and chemicals often increase costs to water utilities to ensure safe drinking water for their customers. The challenge is clear – the world must find a way to work together to increase food production to

Originally published in the March 2022 Journal AWWA

Figure 1: Billion-Dollar Weather and Climate Disasters on 2020

Figure 1: Billion-Dollar Weather and Climate Disasters on 2020

meet all human needs while also safeguarding our environment, addressing climate change, and ensuring overall economic vitality. And we must do that in the face of increasingly erratic weather patterns.

There are 1.9 billion acres of land in the United States (excluding Alaska), and some 1.4 billion acres of those are classified as nonfederal rural land. In the lower 48 states, approximately 70% of the land is privately owned, and about 88% of all surface water falls on private lands before reaching lakes, streams, and groundwater aquifers.

Agriculture accounts for the vast majority of private lands in the United States, and because of this mammoth footprint, it’s

clear that the quality of our environment is determined by the countless decisions that farmers make every day. It’s equally clear that working with agriculture is an effective way for utilities to help address climate change and ensure the protection and viability of their surface water and groundwater sources. It’s estimated that agriculture contributes approximately 10.5% of the US emission of greenhouse gases. Primary GHGs associated with agriculture are carbon dioxide (CO2), nitrous oxide (N2O), and methane (CH4). In 2018, US agriculture emitted an estimated 698 million metric tons of carbon dioxide equivalent: 12.3% as CO2, 36.2% as CH4, and 51.4% as N2O. The US Environmental Protection Agency estimates that N2O contributes 6% of the total US load of GHGs, and the vast bulk comes from agriculture. It’s worth noting that nitrous oxide and methane are much more

Figure 2: Sheet and rill erosion in a field in Iowa (A) and cumulative, severe loss of topsoil in a Virginia crop field (B) illustrate issues faced in many US croplands.

Photo credit: (left)n.d. US Department of Agriculture Natural Resources Conservation Service, (right) © 2021 Ray Archuleta

Figure 2: Sheet and rill erosion in a field in Iowa (A) and cumulative, severe loss of topsoil in a Virginia crop field (B) illustrate issues faced in many US croplands.

Photo credit: (left)n.d. US Department of Agriculture Natural Resources Conservation Service, (right) © 2021 Ray Archuleta

powerful GHGs than carbon dioxide – nitrous oxide is 298 times and methane 84 times more potent than CO2. In other words, every pound of N2O kept out of the environment is the equivalent of 298 pounds of carbon dioxide reduction; every pound of methane reduced equals 84 pounds of CO2. Climate change is widely acknowledged to adversely affect agriculture, and there is keen interest to ensure everyone has a reliable food supply. As far back as 2015, the US Department of Agriculture (USDA) projected that climate change would negatively affect many of the nation’s primary crops, including corn, soybeans, rice, and cotton. However, agriculture can also be a carbon sink, and by using regenerative practices that sequester carbon in the soil, trees, or grasslands, agriculture has the unique ability not only to offset its own carbon footprint but also to help mitigate the worst effects of climate change.

The USDA Natural Resources Conservation Service (NRCS) has more than 150 different science-based conservation practices, and many of them protect source waters and are also climate friendly. Ranging from contour buffer strips to no-till farming, to cover crops, to windbreaks, and shelterbelts, these conservation practices solve resource issues while they also sequester carbon. Additionally, edge-of-field structural practices such as drainage water management, saturated buffers, and denitrifying bioreactors help reduce nutrient loss to waterways (and the subsequent conversion of nitrogen into N2O), which reduces costs to produce potable water. Other livestock-related practices such as using digesters reduce methane emissions while keeping manure out of water bodies. Taken together and working as conservation systems, these relatively inexpensive practices not only help utilities protect their source waters – they can also mitigate climate change and help agricultural producers become more resilient to maintain their long-term economic viability. The bottom line is, working with agriculture can provide water utilities with some of the most cost-effective and reliable conservation practices to reduce GHG emissions, build resilience and sustainability on farms and in communities, and protect drinking water sources.

Working with local and regional partners is a frugal way to leverage limited finances to fund source water protection. In the United States, USDA operates several voluntary, incentivebased conservation programs for agricultural producers –farmers, ranchers, and woodland owners – and most of them are managed by NRCS. When it comes to stretching money, of key interest to US water utilities is the Regional Conservation Partnership Program (RCPP). Under this program, NRCS co-invests with both public and private partners to implement environmentally beneficial projects. NRCS will pay 50% of

a project, with project partners making up the balance, and noncash, in-kind contributions are allowed. There is no question that utilities in the United States can participate. AWWA worked with Congress to ensure water utilities are specifically mentioned in law as being eligible partners. Further, Congress has directed NRCS to spend at least 10% of its conservation funding on source water protection projects. The RCPP is unique in that the local partners get to select the geographic area they want to work in, choose the natural resource problem they want to focus on, and select and prioritize the practices they want to use. This means that if a utility knows the issues affecting its source waters –whether it’s from cropland, grassland, or forestland – they can work to design a project that will address that need. While all land uses are eligible, the carbon sequestration potential of sound forest management and reforestation is particularly clear. NRCS has about $300 million annually to invest in RCPP projects and publicly announces its funding opportunities. NRCS is focused on agriculture, so water utilities interested in the program need to work with local agricultural and conservation partners to develop and submit applications tailored to their specific issues.

“

Working with agriculture can provide water utilities with some of the most cost-effective and reliable conservation practices to reduce GHG emissions, build resilience and sustainability on farms and in communities, and protect drinking water sources.

AWWA worked with the House and Senate Agriculture Committees and USDA during the development of the 2018 Farm Bill to secure the ability of water utilities to participate in USDA conservation programs and to ensure at least 10% of the funding goes to source water funding. But the legislative achievements didn’t just happen; they were the result of a deliberate relationship-building effort on the part of AWWA that began in 2016. When the effort first started, neither the Agriculture Committees nor USDA had any idea who AWWA was, so AWWA spent two years developing relationships on Capitol Hill and within USDA. Those relationship-building efforts paid off, and AWWA became viewed as a new – and welcome – nontraditional voice in the development of the agricultural act. AWWA became a trusted source that added greatly to informing the final outcome of the Farm Bill. For water utilities, the principle is the same: the first task is to establish local and state relationships with USDA (particularly NRCS) and with local agricultural and conservation groups. Put bluntly, they need to know and trust you and your utility’s aims before they will collaborate with your team. Start by contacting your local NRCS field office – there is generally one in every county or parish across the country, and a complete listing of all the USDA offices can be found at offices.usda.gov. The goal is to get to know the people who work there on a first-name basis. At the state level, the

NRCS state conservationist represents the first stop. The state conservationist is responsible for all the agency’s statewide operations. In many states, someone is dedicated to working with potential and current partners to help them navigate the various programs and funding opportunities. AWWA published Working with the NRCS for Source Water Protection, which serves as a handy guide on whom and how to contact. As utilities survey their source water protection efforts, they are encouraged to reach out to their local NRCS office – let them know who you are, whom you represent, and that you are interested in opportunities to work with NRCS to protect source water in your service area. Inquire about the RCPP and offer to meet with NRCS staff. It takes time to build relationships and trust, but the payoff can be significant. By taking the approach described here, utilities can work with their communities to develop effective collaborations that protect source waters while working against further climate change.

About the Authors: Dave White is the former chief of the Natural Resources Conservation Service and advised AWWA on its efforts to amend and implement the Farm Bill to recognize and fund source water protection for potable water; he can be contacted at dwhite@9bgroup.com.

Adam T. Carpenter is the manager of energy and environmental policy in AWWA’s Government Affairs Office in Washington, D.C. •

:B" .( .#$*+*($*= .# "+ (*+-.#; .# $B* ;97, $3 <+29. 60--7" B5%6 .+29 +--7%96 2$ 259 ;.62 "9+. $3 494:9.65%"#F> NHE424/O

! = > * 9 $ #0" +;?3. )0 +0; # 9 $ #01* &@A

C#> "?*+%$."#( %#= %=).#.($+%$.-* ($%GG I*F": $B* ('?*+-.("+> F*-*F %$ % '$.F.$> :.$B )"+* $B%# /@222 (*+-.&* &"##*&$."#( C#> ($%GG )*)I*+ %$ % '$.F.$> :.$B G*:*+ $B%# /@222 (*+-.&* &"##*&$."#( N25O

! B#2.*+# &5<

C =*;+** (**R.#; .#=.-.='%F %$$*#=.#; %# %&&+*=.$*= *='&%$."#%F .#($.$'$."# *#+"FF*= .# $B* #')I*+ "G B"'+( +*['.+*= I> $B* .#($.$'$."# G"+ B%FG $.)* "+ G'FF $.)* ($%$'( N/8O

% &' ( )*+&'* * #, $+-+$ . ( '* $ /'*, 0+( '* .%) 0 , %12# &. 3

56'#*' , "' , 7 % &6 . %

6 ; B +) 8 C" *$ & 4 ; . . + 0 D *)+) * 0 A ; /) 8). "++ 0 F G / $ 2

H 6 ; B +) 8 C" *$ & 4 ; . . + 0 D *)+) * 0 :/7$ 3 *- & F G / $ 2

, I -7$ & / # $ / * J $ 2 $ & "+ K 4 * " *$K L - 8 "+

% , - /3;+ *)/ @ J )& #

= , - / * & " 8 *- &

J 6 & ) 7" *$ :/ 2;3 * & )"+ 4 0 3 *$ # - & C" *$ & C < -+ $ 3 "+ $ &

I A"/; ?" 8 * ; & $ & -? = M;). # $ / * N 4 ; . . +) $ 3 O )/ 8 +; 2)/ @ & $ . & $ 3 $ / * " *) 7$ 3P

! Q %)3 * & )B ; *- & -? = M;). # $ / * N 4 ; . . +) $ 3 O )/ 8 +; 2)/ @ & $ . & $ 3 $ / * " *) 7$ 3P

! : = 2; 8 " *)- /"+ :/3 *) * ; *)- /3 O?" 8 ;+ * 0 N 3 * ; 2 $ / * 3PK L )B & "& ) $ 3 "/ 2 - * < $ & & $ +" *$ 2 - & @ "/)R " *)- /3

! S J;++ 0 >$ *)& $ 2

! T >$ 3 $ "& 8 < L "B

! 2 3 4 5 & " -667 & + 4( 4 5 & 8 & 6 + 9 : 6 & -$ & $: & ;7 * '<

! "#$ % &' ( #$' )%* + , '- $ .'-( */, '- +%0 * ( %12# &+ 3- 4 ' 5 . -' * 6' . 7

2 0+& ,+2#6 #, $+-+$ . 3 4 56'#*' , "' , 7 % &6 . % &'8

! V H - * < C" *$ & 4 ; . . + 0 N C"3 *$ G" *$ &

! W C" *$ & 4 ; . . + 0 F /+ 0

! X C"3 *$ G" *$ & F /+ 0

! Y F * < $ &

C <" * - / $ 8 " *$ @ - & 0 B $ 3 * 2 $ 3 8 & )B $ 3 0- ; & Z- B *) *+ $[ O 6 + $ "3 $ 8 < $ 8 \ - /+ 0 - / $P

! 1 = ]$ 8 ; *) 7$ OI $ / $ & "+ A"/"@ $ &K , - # #)3 3)- / $ &K H - "& 2 A $ # B $ &K ,) * 0 A"/"@ $ &K A ; /) 8). "+ 4 ; . * K A"0- &K 6 & $ 3)2 $ / * K ^ ) 8 $ 6 & $ 3)2 $ / * K F G / $ &K 6 "& * / $ &K %)& $ 8 *- &K $ *8 P

! H A"/"@ $ # $ / * 5 ! - / = / @)/ $ $ & )/ @ O %) 7 )3)- / Q $ "2 K 4 $ 8 *)- / Q $ "2 K A"/"@ $ &K % $ . * Q $ "2 K , - # . * &-++ $ &K $ *8 P

! , % $ 3)@ / "/ 2 = / @)/ $ $ & )/ @ 5 H - * < A"/"@ $ & )"+ "/ 2 ! - / A"/"@ $ & )"+ O, <) $ ? = / @)/ $ $ &K ,) 7 )+ = / @)/ $ $ &K A $ 8 <"/) 8 "+ = / @)/ $ $ &K = + $ 8 * = / @)/ $ $ &K = /7 )&- / # $ / * "+ = / @)/ $ $ &K 6 +"/ /)/ @ A"/"@ $ &K J ) $ + 2 = / @)/ $ $ &K 4 0 3 *$ # % $ 3)@ / $ &K $ *8 P

! % = ;7 & . 47 8 ; > ? ( . !-.-A & " 7-6 9B 5 & 07$ 4 C D7(6 ( A7$ 4 C D7( : 5' $7 ;7$ 4 C E& $ & -" ; 5 & "C 1 /"+ 0 3 * K $ *8 P

! = 6 ; & 8 <"3)/ @ O

built with quality, not only as a core design feature, but a brand

With

certification, an array of standard

no wonder it’s been the

brand

and the ability to be extensively

for over 100 years.

Breeze is made possible by the companies below who convey their important messages on our pages. We thank them for their support of The Minnesota Section of the American Water Works Association (MN AWWA) and its publication and encourage you to contact them when making your purchasing decisions. To make it easier to contact these companies, we have included the page number of their advertisement, their phone number, and, where applicable, their website.

Company

Page Phone Number Web Address

AE2S 14 701-364-9111 www.ae2s.com

American Ductile Iron Pipe 18 205-325-7701 www.american-usa.com

Apex Engineering Group 35 701-373-7980 www.apexenggroup.com

Barr Engineering Company 26 952-832-2619 www.barr.com

Bergerson Caswell 30 763-479-3121 www.bergersoncaswell.com

Bolton & Menk, Inc. 8 507-625-4171 www.bolton-menk.com

Brown and Caldwell 26 800-727-2224 www.brownandcaldwell.com

Core & Main 4 952-937-9666 www.coreandmain.com

Dakota Supply Group 18 800-328-3976 www.dakotasupplygroup.com

E.H. Renner & Sons, Inc. 21 763-427-6100 www.ehrenner.com

Electric Pump, Inc. 16 800-211-6432 www.electricpump.com

ESS Brothers & Sons, Inc. 20 763-478-2027 www.essbrothers.com

Ferguson Waterworks 3 www.ferguson.com/waterworks

General Repair Service 2 800-767-5151 www.generalrepair.com

Hawkins Water Treatment Group 10 800-328-5460 www.hawkinsinc.com

HR Green, Inc. 12 800-728-7805 www.hrgreen.com

Integra – Vita-D-Chlor Company 36 253-479-7000 www.vita-d-chlor.com ISG 26 507-387-6651 www.isginc.com

Janssen Machine Co. 31 218-493-4470 www.janssenmachine.com

M.E. Simpson Co.Inc. 17 800-255-1521 www.mesimpson.com

Master Electric 22 855-99TESTT www.testtcompany.com

Metering and Technology Solutions 9 877-398-0450 www.metertechsolutions.com

Mid America Meter, Inc. 13 800-324-0365 www.midamericameter.com

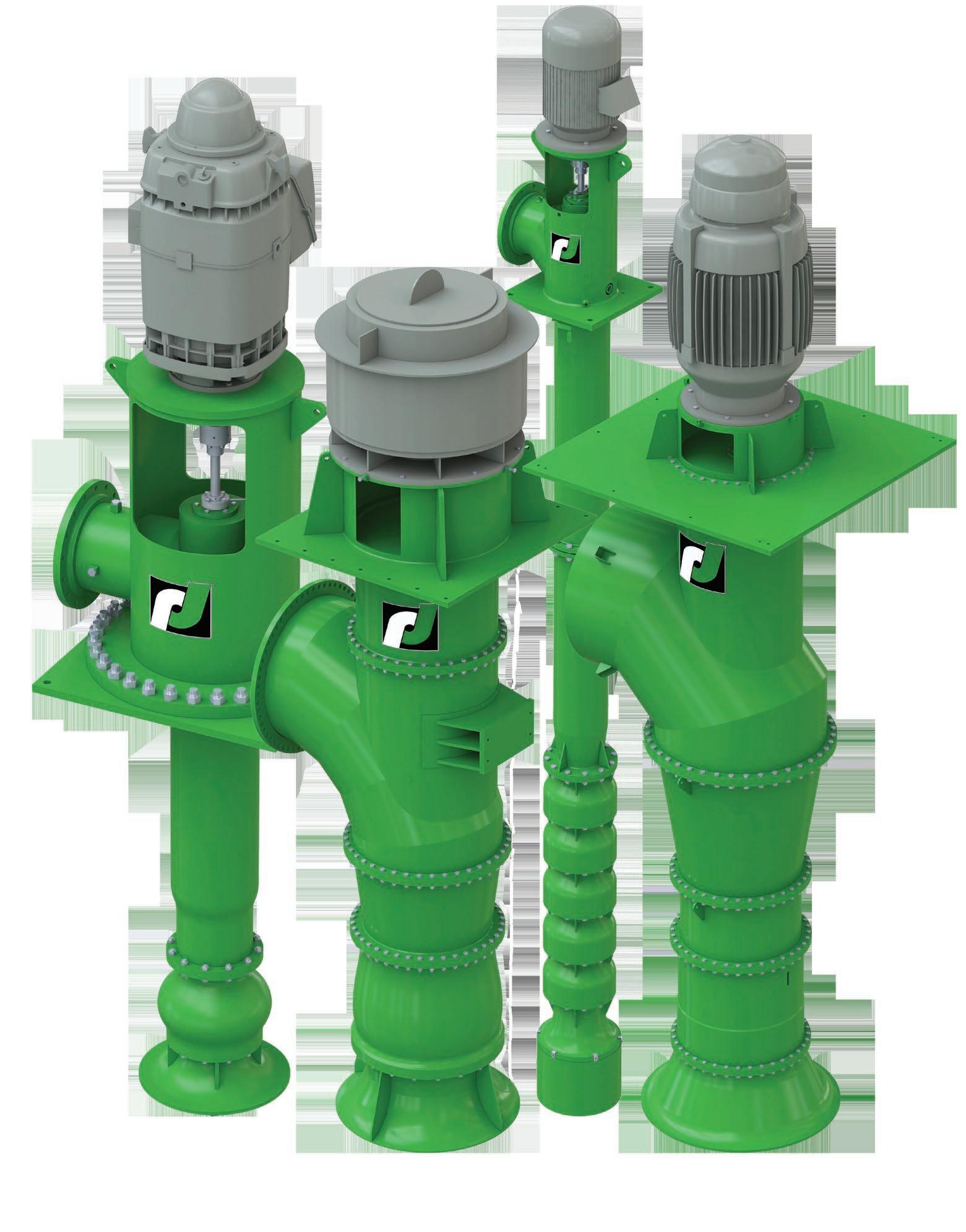

Minnesota Pump Works 45 877-645-8004 https://minnesotapumpworks.com

Moore Engineering, Inc. 14 701-282-4692 www.mooreengineeringinc.com

MSA Professional Services, Inc. 17 800-362-4505 www.msa-ps.com

Northern Dewatering, Inc. 37 763-428-2616 www.northerndewatering.com

Northwestern Power Equipment Company 48 651-628-0683 www.nwpeco.com

Pittsburg Tank & Tower Maintenance Co. Inc. 36 270-826-9000 www.pttg.com

SEH 10 651-490-2000 www.sehinc.com

Stantec 17 651-604-4706 www.stantec.com

Team Laboratory Chemical Corp. 28 800-522-8326 www.teamlab.net

Thompson 7 866-258-8462 www.thompsonknows.com

TKDA 21 651-292-4621 www.tkda.com

Vessco 6, 47 952-941-2678 www.vessco.com

WW Goetsch Associates, Inc. 42 952-831-4340 info@wwgoetsch.com

Water Conservation Services, Inc. 42 612-600-8716 www.watermainleaklocator.com Widseth 21 218-829-5117 www.widseth.com

WSB 12 763-541-4800 www.wsbeng.com

Ziegler Cat 41 952-885-8218 www.zieglercat.com

To reach water professionals through Breeze magazine and its targeted readership, contact Jeff at your earliest convenience to discuss your company’s promotional plans for 2022/23.