Gorman-Rupp for

in the industry. But even the

can’t

Effective wastewater handling requires lift stations with valves, controls, pipes and pumps that all work together to meet your sewage handling needs. If any one of these components fails, it can put your operation–and your investment–at risk.

Gorman-Rupp created the ReliaSource® line of packaged, fully customizable, above- and below-ground lift stations to eliminate costly service interruptions caused by inferior parts.

Every component of a ReliaSource lift station–from the pumps, to the NEMA-rated controls, to the corrosion- and weather-resistant

fiberglass enclosures–is 100% Gorman-Rupp custom-engineered, manufactured and assembled. With Gorman-Rupp quality inside and out, ReliaSource lift stations outlast and outperform any other lift station on the market, delivering trouble-free performance you can rely on. Guaranteed.

Valve Package (ASVP)

Uma Vempati

Kimley-Horn Associates Ph: 612-209-1912 uma.mnawwa@gmail.com

Rob Isabel CDM Smith Ph: 651-252-3716 isabelrs@cdmsmith.com

Chris Voeltz

City of Saint Peter Ph: 507-934-0670 chrisv@saintpetermn.gov

Eric Volk

City of New Brighton Ph: 651-638-2110

eric.volk@newbrightonmn.gov

Jim Hauth

City of Columbia Heights Ph: 763-706-3711 jhauth@columbiaheightsmn.gov

Miles Jensen

SEH, Inc. Ph: 651-490-2000 mjensen@sehinc.com

The ideas, opinions, concepts, procedures, etc. expressed in this publication are those of the individual authors and not necessarily those of the MNAWWA section, its officers, general membership, or the editor. The mention of trade names for commercial products does not represent or imply the approval or endorsement of AWWA. This magazine is presented solely for informational purposes

Breeze Magazine is published by Ph: 866-985-9780 Fax: 866-985-9799 www.kelmanonline.com

Managing Editor - Tammy Marlowe Johnson Design/Layout - Tabitha Robin

Marketing Manager - Jeff Kutny jeff@kelman.ca

©2022 Craig Kelman & Associates. All rights reserved. The contents of this publication may not be reproduced in whole or in part without the express consent of the publisher.

Advertising Co-ordinator - Stefanie Hagidiakow Content Manager

Tricia Christensen Black & Veatch

Ph: 952-896-0844 christensenp@bv.com

Finally, the winter season this year is behind us and spring has officially sprung. In addition to experiencing the winter in the natural world, I feel like we experienced winter season in our professional and personal lives as well. COVID-19 and its impacts on our professional and personal lives slowed things down and made us feel stagnant or stuck. In our water sector, we had to come up with creative and innovative strategies to protect our key resource: professional operators from getting exposed to COVID-19 so we can continue to provide water supply to our customers. Conversely, many conferences and operator schools were cancelled or turned to virtual, which took away the opportunities for water sector professionals to interact and learn from fellow professionals. It appears to me that most of those difficult times are behind us.

We are going to capitalize on what we learned over winter and move into the spring season with a renewed sense of energy and drive to bring better experiences to our Minnesota AWWA members. For instance, MN AWWA hosted an AWWA regional meeting in Minneapolis on April 1 and 2, which was originally scheduled to be held in 2020.

We, in association with AWWA, were able to host section leaders from Wisconsin, South Dakota, North Dakota, Iowa, Illinois, and Minnesota to discuss some important topics impacting the water sector, AWWA, and our sections. These topics revolved around succession planning, workforce issues, and regulatory issues (such as PFAS, lead and copper, and source water protection). It is always invigorating to get perspectives from other leaders in the region.

We are back with the in-person District Operator Schools this year –the first time since 2019. The philanthropic fundraising events, such as the Spring Golf event supporting Water Equation scholarships, are happening in May. Our Conference Council is evaluating some

Uma Vempatichanges at our annual conference which are going to provide even better experiences and learning opportunities to the attendees.

The Minnesota AWWA Board is excited about the future and feels the energy to come up with creative ideas and make them happen, especially after the slowness in the past couple of years. We are ready to jump back in with both feet and start planting seeds for providing new educational opportunities for our membership. I look forward to seeing you in-person at the upcoming events and hearing about your experiences regarding the various additions at our events. Be safe and be well!! •

“We are going to capitalize on what we learned over winter and move into the spring season with a renewed sense of energy and drive.”

Iknow you have all heard about what you get for your membership: the discounted schools and publications, the access to standards, and great volunteering and networking opportunities. What you may not know is that there are a couple of groups out there that are always looking out for you on the regulatory and technical side.

There is an entire team of full-time employees that work in Washington, DC, that are always working with legislators on legislation that will affect our industry. Lately, they have been putting tons of time into more than a few different regulations that you may be, or may not be aware of.

Just some of the issues they are working on include the Lead and Copper Rule Revision, the Farm Bill, Cybersecurity Measures, and the Infrastructure Investment and Jobs Act of 2021. If you ever want to know what the DC team is working on The Hill, you can visit their page on the American Water Works Association under the Policy and Advocacy tab.

Another team you may not be aware of is the Standards Council. The Standards Council is comprised of 24 volunteers, 72 committees, and 1,600 volunteer subject matter experts. The Standards Council is 102 years old and has produced 189 AWWA Standards and the Standards Committees have produced 16 of AWWA’s Manuals of Practice.

If you are interested in the current list of standards, the council and committees

are working on you can visit their page under the Publications tab on the American Water Works Association page.

So, when you are considering whether or not to renew your membership, or to add another member of your organization to the AWWA ranks, remember that your membership reaches further than you think. We are strong in Minnesota, we are strong across the country, and we are strong around the world.

Safe. Reliable. Affordable.

Committed to our communities , treating every drop of water like our own.

Design with community in mind stantec.com/water

“Your membership reaches further than you think. We are strong in Minnesota, we are strong across the country, and we are strong around the world.”

Bolton & Menk has provided professional design and construction engineering services for approximately 80 water towers and reservoirs. There is no such thing as a one-size-fits-all solution. We recognize that every project and client are unique and we treat them that way.

Bolton-Menk.com

Bolton-Menk.com

The American Membrane Technology Association (AMTA) and the American Water Works Association (AWWA) announced awardees at the 2022 Membrane Technology Conference and Exposition (MTC) in Las Vegas.

Brian Ward of the City of Fargo Water Treatment Plant in Fargo, ND, was presented with this year’s Robert O. Vernon Operator of the Year Award. The award recognizes outstanding contributions by a plant operator working at a membrane filtration, desalination or water reuse facility that resulted in significant, long-term improvement in water production and/or water reuse.

The Robert W. Sokoll Joint Venture Surface Water Treatment Plant, which provides drinking water and rural farm use water for about 50,000 customers in Waxahachie, TX, was presented with this year’s Membrane Facility of the Year Award. The award recognizes an

outstanding water/wastewater facility that uses membrane technology with high efficiency in an environmentally friendly approach.

Rodrigo A. Tackaert, senior engineer at Trussell Technologies, won the Austin F. McCormack, Jr. Award, which recognizes and honors membrane related contributions made by a young professional to the water or public health community.

Managing and Treating Per- and Polyfluoroalkyl Substances (PFAS) in Membrane Concentrates (by Emily W. Tow, Mahmut Selim Ersan, Soyoon Kum, Tae Lee, Thomas F. Speth, Christine Owen, Christopher Bellona, Mallikarjuna N. Nadagouda, Anne M. Mikelonis, Paul Westerhoff, Chandra Mysore, Val S. Frenkel, Viraj deSilva, W. Shane Walker, Andrew K. Safulko and David A. Ladner) was presented with the Membrane Treatment Best Paper Award.

Additional award recipients include:

• Avista Technologies, Inc., was awarded best exhibit.

• Closed Circuit High-Pressure Membrane Systems for the Separation of Per- and Poly fluoroalkyl Substances by Andrew Safulko was awarded Best Paper.

• Retrofit of Hollow Fiber MBR with Submerged Ceramic Membranes for Fats, Oils and Hy drocarbon Management in Industrial Reuse Plant by Stanton Smith and Abdurrehman Rashid was awarded Best Poster.

• Flux and Antifouling Performance of Bioinspired Liquid Infused Membranes by Rushabh Shah was awarded Best Student Paper.

• Urea Recovery and Fouling Mitigation of Fresh Human Urine Using Cross-flow Re verse Osmosis and Nanofiltration by Lucas Crane was awarded Best Student Poster. •

Health Educator, Drinking Water Protection

Health Educator, Drinking Water Protection

T he west-central Minnesota city of Courtland recently replaced its water tower – an event commemorated by some scenic photos: one by Mathew D. Sparlin Photography of New Ulm, and the one by Tiffany Hoffmann of the City of Courtland.

Another notable tower, which once held more than 24,000 gallons of water, has been spruced up in recent years. It was the namesake for Tower View Estate, the home of Alexander Pierce Anderson on US Highway 61 in Burnside Township, which was annexed by Red Wing in the 1970s. Anderson is best remembered as the creator of the process for puffing cereal grains.

In 1901, Anderson was able to heat corn starch to a temperature high enough to cause it to explode, thus turning the expanded starch granules into a porous puffed mass. He started the Anderson Puffed Rice Company and eventually received 25 patents for the puffing process and the machinery used to manufacture it.

Anderson was self-sufficient (or, in today’s lingo, ‘off the grid’) on his estate, which contained his home, a farm, a research center, and the water tower. Anderson died in 1943, and the property has gone through different owners. It became the home of Central Research Laboratories in the 1940s and later a campus for Red Wing Vocational Technical College, which established an energy education center on the grounds.

In 1995, the site became the Anderson Center for Interdisciplinary Studies at Tower View, a center that supports artists through residency programs.

“It’s for arts and ideas and how they intersect with other disciplines, such as science,” said Stephanie Rogers, the center’s executive director, who added that its objectives line up with AP Anderson’s values.

The tower, which hasn’t held water since the 1970s, is one of eight buildings on the estate listed on the National Register of Historic Places. In need

of repairs, the tower underwent a five-year restoration project that began in 2016. The work – which included replacing concrete, rebuilding the circular balcony, and repainting – had to follow historic specifications. Another challenge was dealing with a 115-foot-high structure.

“When working that high,” notes Rogers, “everything becomes more complicated.”

The balcony serves as an observation deck and surrounds the Tea Room, which is used for special events and as a studio for artists in residence. The restoration work was partially funded by the Minnesota Historical Society through the 2008 Minnesota Clean Water, Land, and Legacy Amendment.

Reprinted with permission from the MN Department of Health Waterline •

The tower, which hasn’t held water since the 1970s, is one of eight buildings on the estate listed on the National Register of Historic Places.Photo by Tiffany Hoffmann of the City of Courtland. Photo by Mathew D. Sparlin. Photography of New Ulm.

Xue Feng, Assistant Professor, Department of Civil, Environmental, and Geo-Engineering, recently received a National Science Foundation (NSF) Career Award. The awards are given to outstanding junior faculty who exemplify the role of teacher-scholar – excelling at and integrating both research and education. The competitive award comes with a federal five-year grant for research and education activities.

Feng’s research has two main goals: to discover new ways that water shapes the ecosystem response to climate change, and to use that new knowledge to advance modeling of Earth systems and climate predictions.

Global water, carbon, and energy cycles are affected by plants.

Plants use water and carbon dioxide (CO2) to photosynthesize and grow. CO2 enters plants through stomata, small openings on leaves. Water enters plants through roots and is transported to leaves through the vascular systems.

How efficiently the stomata and vascular systems supply water and CO2 to the plant – through a process called plant hydraulic regulation – depends on a range of environmental conditions (for example, dryness in the soil and in the air) and plant characteristics.

Feng’s project will use mathematical optimization of plant performance to understand how hydraulic regulation impacts stomata (at the leaf scale), carbon use and storage (at the wholeplant scale), and spatial distribution of plant types (at the ecosystem scale) over different timescales of environmental change.

New insights into how plants cope with changes in environmental conditions will be used to incorporate plant hydraulic regulation into models to bring about more accurate predictions of global water, carbon, and energy cycles.

Feng’s project also includes educational aspects: an interactive makerspace exhibit and a summer camp module for middle school students at the Bell Museum, plus new course modules for undergraduate and graduate students to understand the problem of plant water use in changing environments.

The Minnesota Water Research Fund (MWRF) was an early supporter of Assistant Professor Feng, funding her research project, Water-Conscious Cultivar Selection for Protecting Minnesota Groundwater, in 2019.

The MWRF provides research support for faculty and students of the UMN Department of Civil, Environmental, and Geo- Engineering working in water resource management and water treatment.

Visit www.cse.umn.edu/cege/minnesota-water-research-fund to support MWRF and learn more.

•

Feng’s research has two main goals: to discover new ways that water shapes the ecosystem response to climate change, and to use that new knowledge to advance modeling of Earth systems and climate predictions.

Breeze magazine is the official publication of our Minnesota Section of AWWA. Distributed in print to all of our members and industry stakeholders as well as online in a mobile-friendly digital edition, our industry-specific magazine will be instrumental in helping water professionals across our great state stay informed and current on the industry’s latest trends, techniques and important news.

We are looking for topical, timely and informative articles provided by operators, managers, engineers, consultants, environmentalists, etc. who are willing to share their knowledge and expertise by contributing an article to the Breeze magazine. It is an ideal way to:

✓ enhance the knowledge of your colleagues ✓ advance the water profession throughout Minnesota ✓ gain exposure and recognition with your peers

* Note: We will provide additional details and any assistance you require to ensure a smooth and efficient contribution process.

If you are interested in being published in a future issue of Breeze magazine and contributing significantly to the advancement of our profession, please contact: Tammy Marlowe Johnson, Managing Editor • tammy@kelman.ca • 1-844-985-9717

Keynote Speaker John Kriesel

Keynote Speaker John Kriesel

The Metro Water Operators School was back after a two-year absence because of COVID-19, taking place April 5 to 7 at the Earle Brown Heritage Center in Brooklyn Center.

The keynote speaker the opening morning was John Kriesel – a former member of the Minnesota House of Representatives and currently a motivational speaker, author, and part-time personality on KFAN Radio.

In 2006, Kriesel lost his legs in Iraq when an improvised explosive device detonated. He was at Walter Reed Army Medical Center for nine months and shared his stories and lessons with the water operators on Tuesday. He is the

author of the book Still Standing: The Story of SSG John Kriesel. The 2022 Metro Water Operators School was a success, with classes covering half-day sessions on distribution, treatment, leadership, regulatory issues, operations, and emerging technologies.

The breakfast and lunch on Wednesday included speakers on the topics of an update on commercial driver’s licenses and on diversity and inclusion.

A study class for those taking the exams for Class C and D licenses took place Wednesday with exams for all classes on Thursday.

Participants also visited the annual vendor exposition Thursday morning, along with mini-sessions and Gimmicks and Gadgets and a special session for supervisors and superintendents.

We look forward to this event happening again next year. •

The Metro Water Operators School was back after a two-year absence.

you set the bar at

how do you

Water distribution systems needing a modest-sized elevated tank will often select a traditional steel multi-column or perhaps a single-pedestal tank. But for an owner desiring a more maintenancefree, lower life-cycle-cost option that also offers speed of construction, a new option has arrived on the market.

Pittsburg Tank & Tower Group (PTTG) has pioneered a composite elevated water tower for tank capacities ranging from 50,000 to 250,000 gallons, with plans for larger sizes. The support shaft for the tower employs stackable pre-cast concrete segments.

Over the previous 40 years, CETs had become popular for large tanks of 250,000 to three million gallons or so, but they weren’t cost-effective for smaller tanks.

Concrete for each circular segment can be poured at ground level – either on-site or off-site, depending on location and size of structure – which greatly reduces the amount of construction work at elevated heights to enhance safety and quality. The pre-cast segments are then raised by crane and locked into place, resulting in less build time.

The concrete support shafts range from 8’0” to 16’0” outside diameter and typically are 8’0” in height, and comply with AWWA D100, D103 and D107 standards, as applicable.

A patent is pending for this product, which PTTG President Ben Johnston and his engineering staff developed for making composite elevated tanks (CET) practical and cost-effective for smaller applications.

These Precast CETs offers several advantages, including:

• Safety is enhanced by fewer manhours worked at elevated heights.

Over the previous 40 years, CETs had become popular for large tanks of 250,000 to three million gallons or so, but they weren’t cost-effective for smaller tanks.

• Quality is improved by constructing at ground level.

• Greater security against vandalism and less exposure to attractive-nuisance liabilities.

• Use of local concrete.

• Readily available to be raised, lowered or even relocated.

• Lower carbon footprint than an all-steel structure.

To further reduce future maintenance, these precast CETs offer several options for tanks that don’t require initial or future painting, including glass-fused-tosteel Aquastore-brand tanks, as well as welded stainless, bolted stainless, or bolted galvanized steel tanks.

Protecting the reliability, quality, and availability of your community’s water supply.

MANY THINGS will keep water suppliers up at night – supply chain issues, COVID-19 illnesses of staff, family and friends, approaching severe weather and cybersecurity breaches. There are numerous resources to assist water suppliers with unraveling the complicated web of how someone can attack the IT of a water system. But the key is to begin to take steps now to protect our infrastructure and to continue to provide safe drinking water.

WHY: Water systems have been attacked and this will very likely happen again. It is important to minimize impacts in the event of a successful attack. Impacts to a utility may include, but are not limited to: interruption of treatment, distribution or conveyance processes from opening and closing valves, overriding alarms or disabling pumps or other equipment; theft of customers’ personal data such as credit card information or Social Security numbers stored in online billing systems; loss of use of industrial control systems (e.g., SCADA system) for remote monitoring of automated treatment and distribution processes, encrypted data files and more. Any of these impacts can erode public confidence in water supply safety.

WHAT: According to IBM, cybersecurity is the practice of protecting critical

systems and sensitive information from digital attacks. Also known as information technology (IT) security, cybersecurity measures are designed to combat threats against networked systems and applications, whether those threats originate from inside or outside of an organization. In 2020, the average cost of a data breach was $3.86 million globally, and $8.64 million in the United States.

WHO: All water utilities need to understand the problem and be proactive in addressing it. State primacy agencies need to address the status of cybersecurity programs during site visits such as sanitary surveys and share resources for improvements with water suppliers. EPA will develop guidance and conduct training for sanitary survey inspectors and water suppliers. It is anticipated that the Department of Homeland Security DHS, will issue cybersecurity performance goals for critical infrastructure control systems.

WHEN: NOW! Don’t be overwhelmed by the myriad of ways you could be attacked, or the tremendous number of resources that exist to assist you. Think of spring as the time to spring into action to protect your IT system.

If you have completed your risk and resilience assessment (RRA) and have

updated your emergency response plan (ERP) as required under the America’s Water Infrastructure Act, but failed to include addressing cybersecurity events, do this now. The RRA should cover electronic, computer, or other automated systems and the security of such systems. An ERP should include strategies and resources to improve the resilience of the system, including physical security and cybersecurity of the water system. In addition, the ERP should include plans to address malevolent acts, which is what a cyber-attack is considered.

Here are some ideas to get you started, but this is not an exhaustive list:

Follow the recommendations in EPA’s Cyber Incident Action Checklist to prepare, respond and recovery from an attack. www.epa.gov/ sites/default/files/2017-11/documents/

• Develop a cybersecurity culture by training staff and establishing and enforcing policies.

• Be suspicious of emails. Curb your curiosity to open all emails and click on links. Don’t trust anyone unless you know them and yet, you still need to be cautious and leery of anything that does not look or feel right.

• Require changing of passwords every 90 days and do not allow sharing of passwords.

• Use multi-factor authentication: what you have and what you know (similar to how most banks require you to log into your account by sending you a text with a code to your cell phone or email).

• Revoke/inactivate credentials of former employees.

• Keep software up to date and install patches when available.

• Limit remote access and allow only for those with a verified operational need.

• Practice shifting to manual operations to be more familiar if or when the need arises.

• Back up data and store offline, allowing for easier restoration if data is lost, stolen, or encrypted.

• Keep servers in a secure room, lock the door and limit access.

• Keep billing IT separate from SCADA IT.

• Consider cybersecurity when undertaking other projects so it isn’t an add-on or an afterthought.

• Sign up for a FREE, confidential, cybersecurity assessment and technical assistance offered by EPA’s contractors at www.horsleywitten. com/cybersecurityutilities.

WHERE: Numerous resources exist and advisories are shared by CISA, EPA, AWWA, and WaterISAC, to name a few. Many are free and without membership subscriptions. Sign up for these and stay on top of updating software.

EPA: www.epa.gov/ waterriskassessment/epacybersecurity-best-practiceswater-sector CISA Advisories: www.cisa.gov/ uscert/ncas/alerts; subscribe at the link at the bottom of their page.

WaterISAC: www.waterisac.org/ fundamentals

AWWA: www.awwa.org/resourcestools/resource-topics/risk-resilience/ cybersecurity-guidance

WHO (again): Consider reporting events to WaterISAC, which compiles water sector incident information to share with the sector. This assists other water suppliers with knowing what events are occurring across the sector. Information shared is done anonymously. www.waterisac.org/report-incident Capture response assistance contacts, such as the Critical Infrastructure Security Agency (CISA) per the Cyber Incident Reporting: A Unified Message for Reporting

to the Federal Government (www.dhs.gov/ publication/cyber-incident-reporting-unifiedmessage-reporting-federal-government), which explains when, what, and how to report a cyber incident to the federal government. Key contact information is: Cybersecurity and Infrastructure Security Agency (CISA) www.cisa.gov

To report incidents, phishing, malware, or vulnerabilities: Online forms: www.cisa.gov/ uscert/report

Email: CISA Service Desk: cisaservicedesk@cisa.dhs.gov

Phone: 888-282-0870

Federal Bureau of Investigation (FBI) www.fbi.gov

Finally, remember to capture your planned response and recovery actions in emergency response plans and Continuity of Operation Plans and exercise these plans at least annually. If an event has occurred, be sure to conduct an after-action review, capture ideas for improvements in your plans, and provide additional staff training.

Taking steps now to further protect your water system will help you sleep at night – at least until the next storm is headed your way. •

Ess Brothers & Sons, Inc. – Construction Specialists for 153 Years!

Ess Brothers & Sons, Inc. – Construction Specialists for 153 Years!

Understanding the potential impacts of the Lead and Copper Rule Revisions (LCRR) and having an effective compliance and funding strategy to address the impacts of the rule are critical to meeting the rule requirements. The federal government is currently negotiating a US infrastructure plan and as details emerge, funding for lead service line replacement remains a priority of any future bill. While the details continue to evolve, Drinking Water State Revolving Funds (DWSRF), Water Infrastructure Finance and Innovation Act (WIFIA) and federal earmarks are likely vehicles for funding to water systems. As such it is important to understand how those programs work and what it will take to apply for and administer funds received under those programs to support LCRR compliance.

PART I of this article appeared in the Winter 2021-22 Issue of Breeze. This PART II concludes the piece.

Sample site selection under the LCRR will be based on a new set of tiering criteria (Table 1) that prioritize structures served by an LSL. For Tier 1 and 2 sites, a first liter and a fifth liter must be collected and analyzed. The first liter will be analyzed for copper and the fifth liter for lead. For all other sites, a first draw one-liter sample will be collected and analyzed for lead and copper.

The prioritization of sampling at sites served by an LSL could result in significant increases in the statistics used to determine LCRR compliance. Figure 1 compares lead statistics for a system that collects 100 samples twice per year under the current LCR (i.e. minimum of 50% single family structure served by an LSL and 50% sSFS served by a copper service line, with lead solder installed prior to 1982) and LCRR (SFSs served by LSLs only).

The results show significant increases in lead statistics when only homes served by an LSL are considered. Under the LCR or current sampling protocol (columns labeled ‘50:50’), the 90th percentile lead concentration is well below the AL and appears to be comfortably below the TL. However, exclusion of the copper service line sites (columns labeled

Table 1. LCRR sample site tiering criteria.

Tier 1 SFSs served by LSLs.

Tier 2 Buildings, including multi-family residences served by LSLs.

Tier 3 SFS served by galvanized service lines that are/were downstream of an LSL.

Tier 4 SFS service by copper service line with lead solder.

Tier 5 Representative sites.

SFS = Single Family Structure

‘LSL only’) results in a 90th percentile lead concentration that exceeds the TL in each of the first two years evaluated and approaches the TL in the third year.

When additional LSL sites are added (i.e. new LSL sites are substituted for the copper service line sites), this system may be at even more risk of exceeding the TL, and perhaps the AL.

(For LCR sampling, data from a mix of 50% LSL sites and 50 percent copper with lead solder sites are indicated by ‘50:50.’ For LCRR sampling, data from only single-family structures served by an LSL indicated by ‘LSL only.’)

Figure 1 only considers the impacts of the change in sampling location. The potential impact on lead concentrations due to the fifth liter sample in homes with LSLs can be seen in Figure 2

In this instance, the increase in total lead concentration was not significant, maybe 20% to 30%, but it was sufficient to push the value at this home over the TL.

When considered together, the focus on locations with LSLs and the shift to a fifth-liter sample could significantly impact a water system’s compliance status resulting in the need to optimize or study corrosion control treatment and/or initiate LSL replacement.

Funding Strategies: How do I pay for LSLR Planning and LSL Replacement?

USEPA estimates the average cost to replace a single LSL is approximately $4,700 (2019). However, costs can vary significantly from system to system and could be as high as $10,000 to $15,000 or more per LSL when all costs (site restoration, public outreach,

Figure 2. Typical water quality profile for a home with a lead service line comparing first and fifth liter samples.

Figure 1. Comparison of lead statistics under current and LCRR monitoring protocols.

Figure 1. Comparison of lead statistics under current and LCRR monitoring protocols.

household filters, etc.) are considered. For those communities with a significant number of LSLs, the financial burden of replacement could be quite significant. Further, disadvantaged homeowners may be unable to afford LSL replacement if the water system is unable to pay for the full cost of replacement.

Fortunately, there are a number of existing grant and loan programs available and a number of agencies which may fund LSL replacement, including: the Drinking Water State Revolving Fund (DWSRF), Water Infrastructure Finance and Innovation Act (WIFIA), United States Department of Housing and Urban Development (HUD), Federal Emergency Management Agency (FEMA), and the United States Department of Agriculture (USDA) Rural Development, as well as state and federal earmarks and other programs.

The federal government is currently negotiating a US infrastructure plan. Though the details continue to emerge, one priority remains a focus of any future bill – funding for lead service line replacement.

In addition, the federal government is currently negotiating a US infrastructure plan. Though the details continue

to emerge, one priority remains a focus of any future bill – funding for LSL replacement.

While the details regarding funding evolve, the most recent Senate bill includes $15 billion in DWSRF specifically for LSL replacement, as well as an additional $11.7 billion for DWSRF which the White House has indicated can be used for LSL replacement. WIFIA and federal earmarks may also be used to provide funding to water systems.

It is important to understand how these programs work and what it will take to apply for and administer funds received under those programs. For example, securing DWSRF funds typically requires submission of a Facility Plan (i.e. an LSLR Plan) and other commitments by a water system.

Similarly, the first gate for WIFIA funding is the submission of a letter of interest, and although there is no deposit required with the submission of the letter of interest, the water system will need to provide a deposit with the application approximately one year after submitting the letter.

In addition, the utility will be charged a financing fee for each successfully funded project, though that may be waived by

USEPA if conditions warrant. WIFIA may also require the water system to fund 50% or more of the replacement as a condition for award.

If and how DWSRF or WIFIA requirements may change when it comes to funding LSL replacement is unclear, but water systems should begin developing a strategy to apply for and administer funds for LSL replacement. Understanding current DWSRF and WIFIA requirements is an important first step to determining which funding model is best suited for a particular water system.

For example, DWSRF might be a better option for small systems due to the priority given to small systems with the greatest funding needs. Once made available, there will be deadlines to apply for and, perhaps more importantly, use funds to replace LSLs. Having an answer to the question, ‘How and what will it take for my system to replace every LSL as quickly as possible?’ will be key to preparing your LSLR Plan and determining the most appropriate funding strategy for your system.

The LCRR are the most significant drinking water regulation in the US in more than a decade. Water systems will be required to meet the requirements of the LCRR by October 2024. Figure 3 provides a suggested timeline to guide systems to meet the LCRR requirements by the compliance deadline and have a funding strategy in place for LSL replacement.

A few key elements of the proposed timeline:

Begin reviewing historical data now to determine how changes in monitoring requirements could impact future compliance. In the absence of fifth liter samples at homes with an LSL, collect some samples to approximate the impacts of fifth liter sampling on compliance status.

Meet with your state or primacy agency as soon as possible to understand their expectations for the inventory and

what they will require for designation of non-lead status.

Begin preparation of your inventory and have a plan for implementation of the public interfaces.

Review current funding program requirements (e.g. DWSRF or WIFIA) and identify which program is best suited to your system. Monitor federal legislation to understand how funding for LSL replacements will be distributed to water systems and what the associated administration and utility-provided funding commitments will be.

Assess funding program eligibility to cover the cost of the inventory and LSLR Plan preparation. For example, DWSRF can be used for engineering design fees after submittal of the Facilities Plan.

Preparing the Facilities Plan in such a way that it identifies how the LSLR Plan will be developed, including field verification and additional testing, may make those costs eligible for funding.

Similarly, the WIFIA funding may be used for ‘development phase activities, including planning, preliminary engineering, design, environmental review, revenue forecasting, and other pre-construction activities.’ WIFIA funds can be used to reimburse the cost of these activities if the activities were carried out under federal guidelines.

Prepare funding applications and other required program documents in 2022 (e.g. DWSRF Facilities Plan or WIFIA letter of interest).

Use the time available between now and December 2024 to collect additional data to assess the potential impacts of changes in monitoring on your system. You want to avoid surprises when the first round of new compliance data is gathered in 2025.

Use the time between now and December 2024 to verify service line materials in accordance with state or primacy agency expectations and reduce the number of lead status unknown service lines in your system.

Verify service lines of unknown status now. The requirements for non-lead sites and systems are substantially less than those with LSLs or lead status unknowns. Use the time between now and December 2024 to verify service line materials and reduce the number of lead status unknown service lines in your system.

This can have significant financial impact on a water system. For example, if a system has 1000 known LSLs and 4000 unknowns and is required to implement LSL replacement, the required 3% per year is 150 LSLs. The number of required replacements could be reduced significantly by verifying those unknown status services are non-lead.

Understand the new monitoring and public education requirements for schools and childcare facilities (though not discussed at length in this article). Review data from previous sampling efforts at these facilities, if available. Water systems should initiate discussions with

school districts and childcare facilities in their service areas as soon as possible.

It is important that schools and childcare facilities not be caught off guard by the rule requirements and have a plan to communicate with their customers about the risks of lead in drinking water.

The LCRR will be challenging for many water systems for a variety of reasons. Understanding how the rule might impact your water system and developing an effective funding strategy for LSL replacement will be key to achieving compliance with the new rule.

Water systems should begin an evaluation of their compliance and potential financial risk and exposure and formulate a strategy to address those risks immediately. The suggestions in this article can serve as a road map to initiate that assessment.

Christopher Hill is AECOM’s Drinking Water Market Sector Leader. He has nearly 30 years of experience helping water systems throughout the US develop and implement effective lead and copper corrosion control strategies.

Quirien Muylwyk is AECOM’s Water Quality Technical Director. She has more than 25 years of experience helping water systems throughout the world effectively manage distribution system water quality and is currently working with some of the largest water systems to develop and execute their LSL replacement programs.

John Konkus is AECOM’s Senior Manager of Government Affairs. He has over 20 years of experience in government affairs and strategic planning and has helped his clients secure more than $250 million in state and federal funds since joining the firm in 2019.

Tom Loto is AECOM’s Regional Municipal Market Sector Leader for Northeast Water including New England and Upstate New York. He has over 28 years of experience in managing water and wastewater projects throughout the Northeast and New York.

As we continue to deliver valuable information through the pages of this magazine, in a printed format that is appealing, reader-friendly and not lost in the proliferation of electronic messages that are bombarding our senses, we are also well aware of the need to be respectful of our environment. That is why we are committed to publishing the magazine in the most environmentally-friendly process possible.

• We use lighter publication stock that consists of recycled paper. This paper has been certified to meet the environmental and social standards of the Forest Stewardship Council® (FSC®) and comes from responsibly managed forests, and verified recycled sources making this a RENEWABLE and SUSTAINABLE resource.

• Our computer-to-plate technology reduces the amount of chemistry required to create plates for the printing process. The resulting chemistry is neutralized to the extent that it can be safely discharged to the drain.

• We use vegetable oil-based inks to print the magazine. This means that we are not using resource-depleting petroleum-based ink products and that the subsequent recycling of the paper in this magazine is much more environment friendly.

• During the printing process, we use a solvent recycling system that separates the water from the recovered solvents and leaves only about 5% residue. This results in reduced solvent usage, handling and hazardous hauling.

• We ensure that an efficient recycling program is used for all printing plates and all waste paper.

• Within the pages of each issue, we actively encourage our readers to REUSE and RECYCLE.

• In order to reduce our carbon footprint on the planet, we utilize a carbon offset program in conjunction with any air travel we undertake related to our publishing responsibilities for the magazine.

So enjoy this magazine... and keep thinking green.

These are permanent standing committees that analyze issues within their areas of jurisdiction and make recommendations to the board. These committees also monitor and evaluate the performance of the whole organization in relation to its responsibility.

To be responsible for coordinating all aspects of planning and logistics for the Minnesota Section Annual Fall Conference.

To actively reach out and understand what members and potential members need to feel included and welcomed into the water industry so that they want to be actively involved as members in our Section.

To publicly position MN AWWA and be an advocate for the Minnesota drinking water community and profession.

To enhance information, education, and training for Section members and Minnesota public.

To advise the Executive Board on issues of interest to the Section’s associate members; for encouraging membership and active participation in MN AWWA by representatives of the manufacturing, engineering, and manufacturer’s representative industries; and to work to identify, develop, maintain, and enhance partnerships with others to leverage the resources of the MN Section.

To develop action programs to initiate, evaluate, respond and comment, within the framework of Section and Association policies, on legislative, regulatory and other matters which directly affect water utilities and to encourage provision of better water service to the consuming public.

San Antonio, Texas, USA June 12—15, 2022

Breeze is made possible by the companies below who convey their important messages on our pages. We thank them for their support of The Minnesota Section of the American Water Works Association (MN AWWA) and its publication and encourage you to contact them when making your purchasing decisions. To make it easier to contact these companies, we have included the page number of their advertisement, their phone number, and, where applicable, their website.

Company

Page Phone Number Web Address

AE2S 27 701-364-9111 www.ae2s.com

Apex Engineering Group 22 701-373-7980 www.apexenggroup.com

Barr Engineering Company 32 952-832-2619 www.barr.com

Bergerson Caswell 32 763-479-3121 www.bergersoncaswell.com

Bolton & Menk, Inc. 10 507-625-4171 www.bolton-menk.com

Brown and Caldwell 36 800-727-2224 www.brownandcaldwell.com

Core & Main 4 952-937-9666 www.coreandmain.com

Dakota Supply Group 34 800-328-3976 www.dakotasupplygroup.com

E.H. Renner & Sons, Inc. 17 763-427-6100 www.ehrenner.com

Electric Pump, Inc. 26 800-211-6432 www.electricpump.com

ESS Brothers & Sons, Inc. 27 763-478-2027 www.essbrothers.com

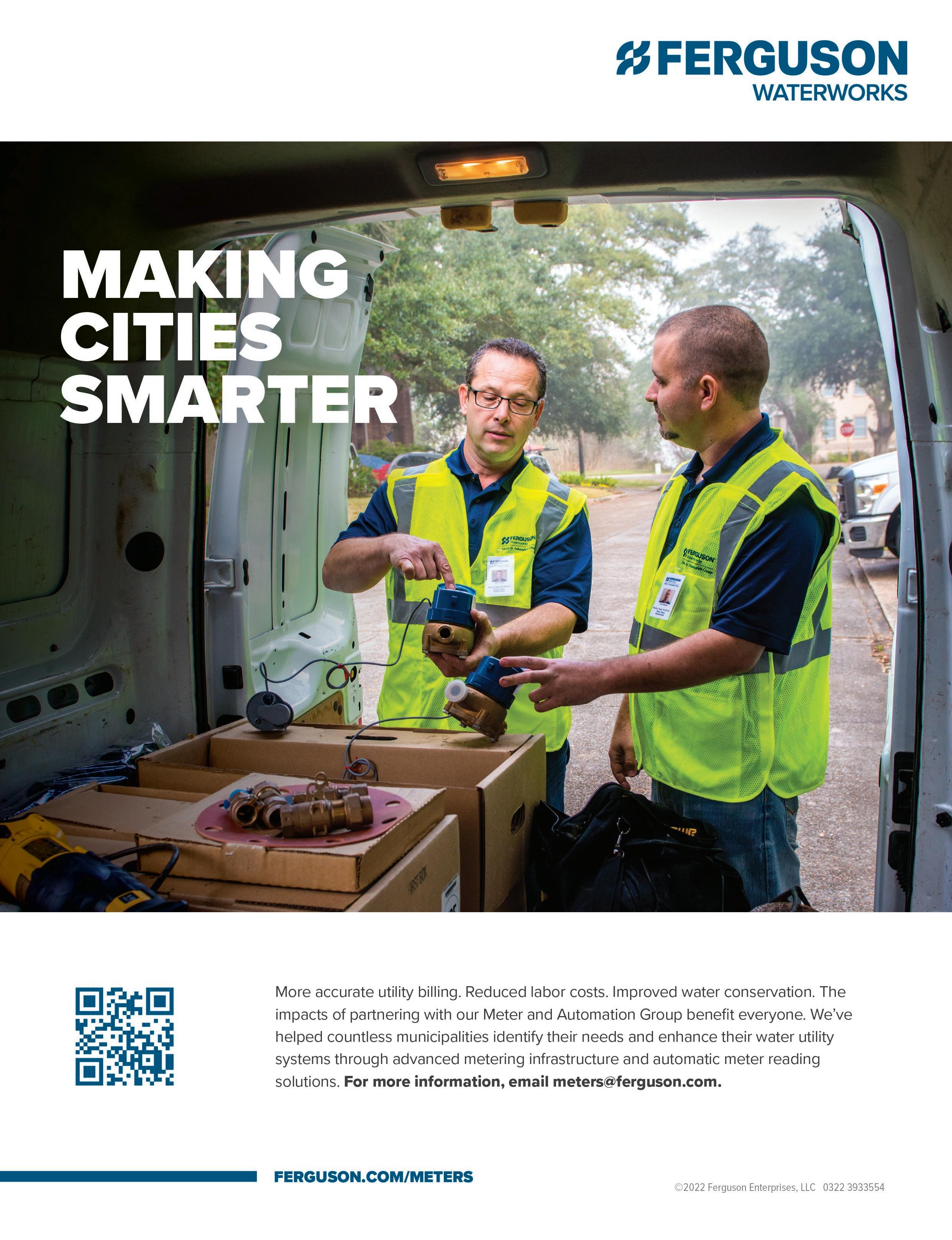

Ferguson Waterworks 6 www.ferguson.com/waterworks

General Repair Service 2 800-767-5151 www.generalrepair.com

Hawkins Water Treatment Group 12 800-328-5460 www.hawkinsinc.com

Hi-E-Drystore.com/Alden Pool 7 877-242-7156 www.hi-e-drystore.com

HR Green, Inc. 16 800-728-7805 www.hrgreen.com

Integra – Vita-D-Chlor Company 13 253-479-7000 www.vita-d-chlor.com

ISG 24 507-387-6651 www.isginc.com

Janssen Machine Co. 24 218-493-4470 www.janssenmachine.com

KLM Engineering, Inc. 22 888-959-5111 www.klmengineering.com

M.E. Simpson Co., Inc. 30 800-255-1521 www.mesimpson.com

Metering and Technology Solutions 21 877-398-0450 www.metertechsolutions.com

Mid America Meter, Inc. 7 800-324-0365 www.midamericameter.com

Minnesota Pump Works 3 877-645-8004 www.minnesotapumpworks.com

Northern Dewatering, Inc. 20 763-428-2616 www.northerndewatering.com

Northwestern Power Equipment Company 40 651-628-0683 www.nwpeco.com

Pittsburg Tank & Tower Maintenance Co., Inc. 36 270-826-9000 www.pttg.com

Preload, LLC 12 631-231-8100 www.preload.com

SEH 34 651-490-2000 www.sehinc.com

Stantec 9 651-604-4706 www.stantec.com

Team Laboratory Chemical Corp. 39 800-522-8326 www.teamlab.net

Thompson 16 866-258-8462 www.thompsonknows.com

TKDA 36 651-292-4621 www.tkda.com

Treatment Resources, Inc. 32 651-702-2692 www.treatmentresources.com

Vessco 8, 18 952-941-2678 www.vessco.com

WW Goetsch Associates, Inc. 16 952-831-4340 info@wwgoetsch.com

Water Conservation Services, Inc. 16 612-600-8716 www.watermainleaklocator.com

Widseth 36 218-829-5117 www.widseth.com

WSB 13 763-541-4800 www.wsbeng.com

Ziegler Cat 32 952-885-8218 www.zieglercat.com