7 minute read

11 Earned Value Analysis

Emerging Managers

Ms. Garima Soni MBA, Batch 2020-2022, IBS Hyderabad, India.

Advertisement

Earned Value Analysis

Earned Value analysis is a method of performance measurement. Earned Value is a program management technique that uses “work in progress” to point what is going to happen to f igure within the f uture.

Earned Value is an enhancement over traditional accounting progress measures. Traditional methods f ocus on planned expenditure and actual costs. Earned Value goes one step f urther and examines actual accomplishment. This gives managers greater insight into potential risk areas. With a clearer picture, managers can create risk mitigation plans supported by the actual cost, schedule, and technical progress of the work. It is an “early warning” project management tool that permits managers to spot and control problems bef ore they become insurmountable.

It allows projects to be managed better – on time, on budget. Earned Value Management System isn't a selected system or toolset, but rather, a group of guidelines that guide a company’s management control system. In the case of cost over run, the project management team may execute a value engineering program for cost reduction either reducing scope and quality in some sections of the project or providing an additional budget to cover overrun cost. Similarly, f or time overrun cases, they may plan some programs like f ast-tracking or time crashing f or time reduction.

Parameters

EVA uses cost because of the common measure of project cost and schedule performance. It allows the measurement of cost in currency, hours, workerdays, or the other similar quantity which will be used as a standard measurement of the values associated with project work. EVA uses the subsequent project parameters to evaluate project perf ormance:

Budget at Completion (BAC)

The original budget of the project.

Planned Value (PV)

Planned Value describes how f ar along project work is meant to be at any given point within the project schedule and price estimate. Cost and Schedule baseline ref ers to the physical work scheduled and the approved budget to accomplish the scheduled work. Planned Value (PV) is decided by the value and schedule baseline. PV= Planned % Complete x BAC

Actual Value (AC)

Actual Cost (AC), also called actual expenditures, is that the incurred f or executing work on a project. Current AC is the actual costs of activities perf ormed during a given period. Actual Cost (AC) is decided by the actual cost incurred on the project.

Earned Value (EV)

To report the accomplishments of the project, Earned Value (EV) is applied to the f igures and calculations in the project. EV is that the quantification of the “worth” of the work done so f ar. EV tells you, in physical terms, what the project has accomplished. As with PV and AC, EV re of ten presented in a Cumulative and Current f ashion. Cumulative EV is that the sum of the allow the activities accomplished so f ar. Current EV is the sum of the budget f or the activities accomplished during a given period. Earned Value is additionally called the Budgeted Cost of Work Perf ormed (BCWP). Earned Value (EV) tells you, in physical terms, what the project accomplished. EV is the amount of money worth of work you actually did on the project. EV= Actual % Complete x BAC

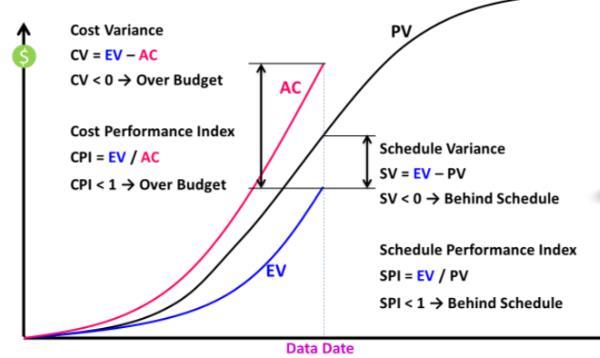

Schedule variance (SV)

Schedule Variance status does indicate the dollar value dif f erence between work that is ahead or behind the plan and reflects a given measurement method.

Schedule Variance status does not address the impact of work sequence, address the importance of work, ref lect critical path assessment, indicate the amount of time it will slip, identif y the source (labor & material) of dif f erence, indicate the time ahead/behind (or regain) schedule, nor indicate the value needed to regain schedule. The f ormula utilized to express schedule variance is project earned value minus the project planned value as of the date of examination. If the variance is equal to 0, the project is on schedule. If a negative variance is decided, the project is not on time and if the variance is positive the project is ahead of schedule.

SV = EV – PV

Cost Variance (CV)

The cost variance is defined as the “difference between earned value and actual costs.” Sometimes this f ormula is expressed because of the dif ference between the budgeted cost of work perf ormed and the actual cost of work perf ormed. If the variance is equal to 0, the project is on budget. If a negative variance is determined, the project is over budget and if the variance is positive the project is under budget.

CV = EV – AC

Schedule Performance Index (SPI)

The SPI is defined as “a measure of schedule ef f iciency on a project. It is the ratio of earned value (EV) to planned value (PV).

The SPI is equal to earned value divided by planned value. An SPI equal to or greater than one indicates a positive condition and a worth of less than one indicates an unf avourable condition.”

SPI = EV/PV

Cost Performance Index (CPI)

The CPI is defined as a “measure of cost efficiency on a project. It is the ratio of earned value (EV) to actual costs (AC). The CPI is equal to the earned value divided by the actual costs.” A CPI equal to or greater than one indicates a f avourable condition and a value of less than one indicates an unf avourable condition.

CPI = EV/AC

Estimate to Completion (ETC)

Forecasting the amount that will be needed to complete the current project based on the current perf ormance.

ETC = EAC - AC

Variance at Completion (VAC)

The dif f erence between the original budget and the new f orecasted budget. This value should be positive f or projects that may end at or under budget

VAC = BAC - EAC

To-Complete Performance Index (TCPI)

The perf ormance that must be met to end the project within the budget.

TCPI = (BAC – EV) / (BAC – AC)

Implementation Challenges

For organizations implementing Earned Value Management, the challenge lies not just in the mechanics of the method, but more of ten in the cultural change required to underpin an EV based project control system. Additionally, when most organizations f irst attempt to use EVM, they typically f ind that it highlights weaknesses or gaps in the project planning and control processes and capabilities. For example: ● A robust baseline needs to be developed as soon as possible af ter contract award – this task alone challenges many organizations – and then it must be maintained ● The planning process must identif y all major project deliverables clearly, not just the f unctional ef f ort assumed to be required to deliver a project ● Objective measures of physical progress must be assessed routinely ● Business systems and processes need to provide data in a timely manner (e.g. costs) and need to be structurally compatible with the needs of the EVM system.

ABOUT US

The word “Kaizen”, where “Kai” = change “Zen” = good, simply means “change for better”. In English Kaizen is typically applied to measures f or implementing continuous improvement. It is an approach to activity organisation based on common sense, self -discipline, order and economy and is a strong contributor and f undamental part of a lean production process model in lean manufacturing.

Kaizen- The Of f icial Operations Club of IBS Hyderabad believes in relishing in the essence of "Constant Change and Evolvement" and hence we, as an organization work willingly f or the betterment of the student community.

KORE- Kaizen’s Operations and Research Entity, one of our primary wings which flaps to cater to the needs of students and motivate them to soar high by polishing their technical competencies. KORE’s area of expertise includes Case Based Research, Consultancy, Live Projects and Workshops. LAKSHYA, an initiative taken by KORE primarily f ocuses on the concepts of operations management and various articles based on the day to day operations and logistics of an organisation.

NISHU KUMARI KEJRIWAL EDITOR IN CHIEF - KORE Kaizen – IBS Hyderabad Batch 2019-21

LAKSHYA is an academic print and is not for any commercial sale. Reliability and Responsibility, for sources of data for the article vests with the respective authors. Please feel free to drop in your suggestions at kaizenclub.ibs@gmail.com

KORE: Kaizen’s Operations & Research Entity. Kaizen – The Official Operations Club of IBS Hyderabad

All Rights Reserved

Designed by