K KRISTOFF FINK

PORTFOLIO FALL 2023

PORTFOLIO FALL 2023

KRISTOFFFINK.COM

(417) - 719 - 3461

KRISTOFF.FINK@GMAIL.COM

© Allrightsreserved.Nopartofthisbookmaybe reproducedorusedinanymannerwithoutwritten permissionofthecopyrightownerexceptforthe useofquotationinabookreview.

Interested in advanced film and compositing techniques, Kristoff not only explores the realm of architectural design but also nurtures a genuine passion for sharing knowledge. Having completed his comprehensive 5-year B.Arch degree from Rensselaer Polytechnic Institute in upstate New York, his journey led him to SCI-Arc, where he further sharpened his skills and passion.

During his time at SCI-Arc, Kristoff completed an Advanced Masters of Architecture II, focusing on amplifying and refining his technical expertise, modeling proficiency, and design methodology. His goal of crafting works that resonate profoundly at the juncture of art, architecture, technology, and culture remains unwavering.

Kristoff seeks opportunities to impart his expertise, fostering a culture of learning and exploration within the academic community. This multifaceted journey stands as a testament to his dedication to contributing impactful narratives to the realm of architectural innovation while simultaneously nurturing the growth of aspiring minds.

IN COLLABORATION WITH

FELIX REYES

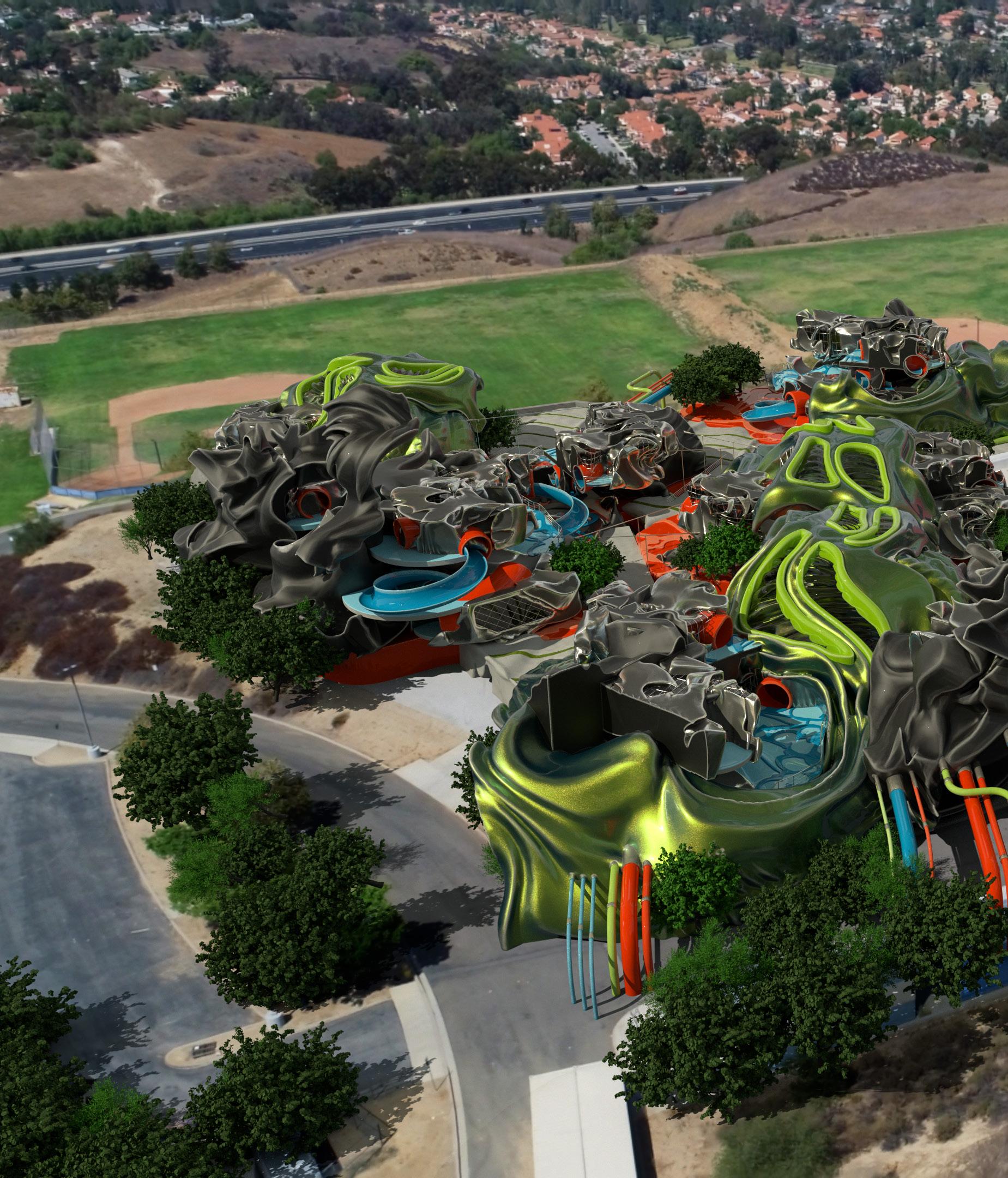

Before there was life, there was dust. The small unbiased matter from which all life is created. Latent with potential for growth, dust creates the ticking clock which gives purpose to all natural life. These clocks tick differently for every living being but one thing is always certain; when the clockwork turns the last time there will be an inevitable return to the dust.

Bergson describes that “ it’s the actualization of the durée that rids man’s soul of the obsession with time.” The durée or duration of life and specifically the realization or actualization of that duration is what takes our focus from the ticking away of seconds and diverts it to collecting as many seconds as possible. Why else would you envelope yourself in the study of life if not in the pursuit of understanding, augmentation, and innovation to extend the duration. Forging the latest life saving discovery further that will further changes us and differentiate us from the natural orders of life. The agent seeks refuge in the symbiotic conglomeration and safety of the whole.

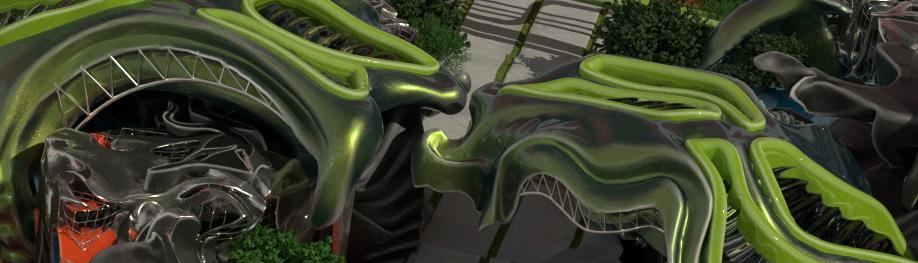

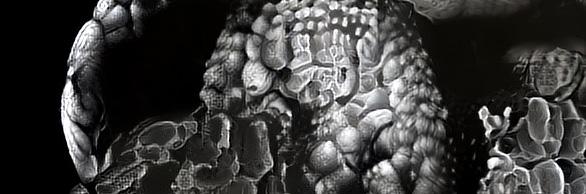

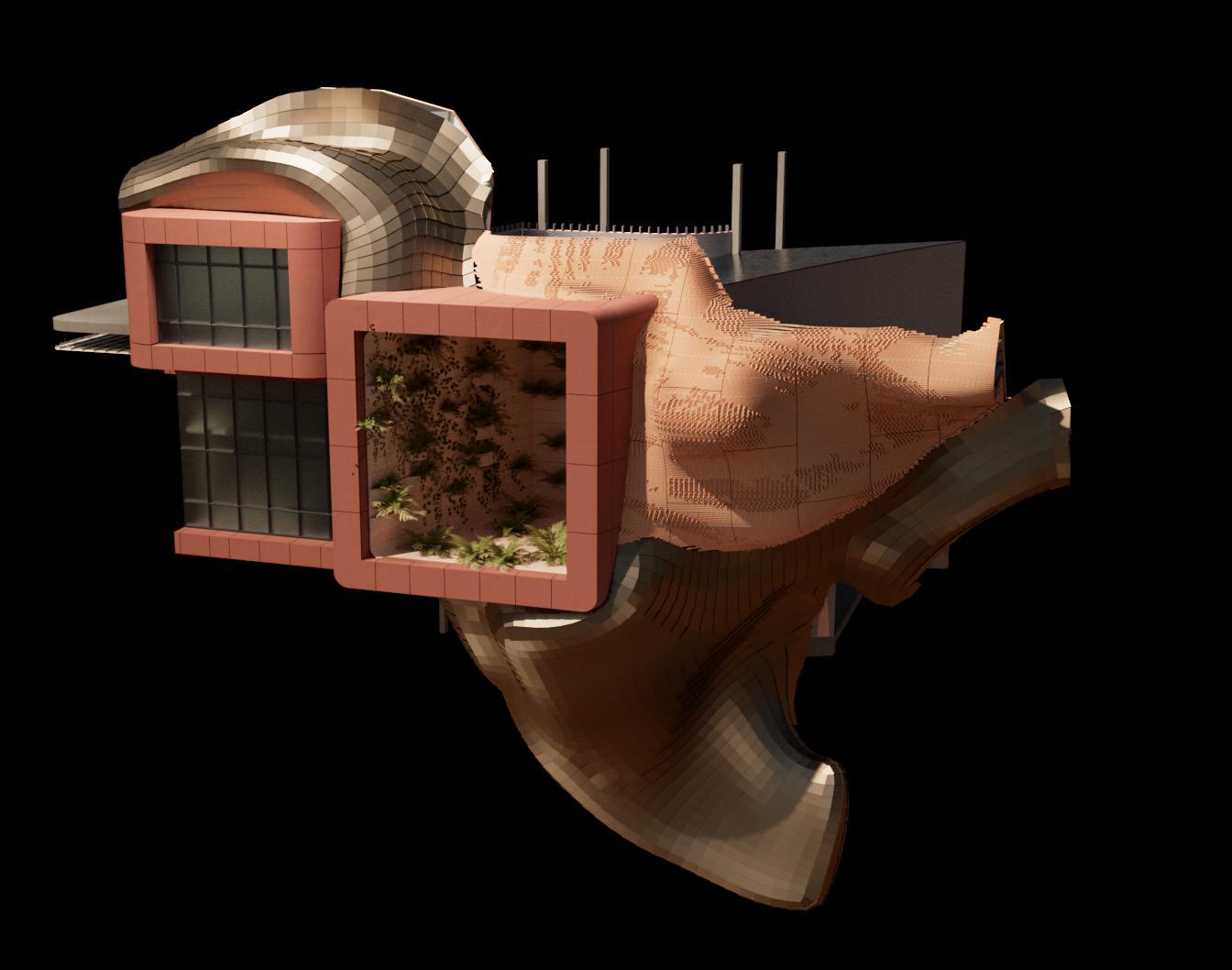

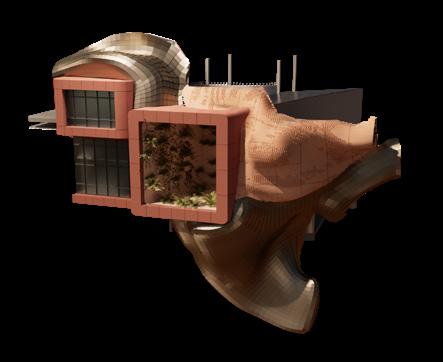

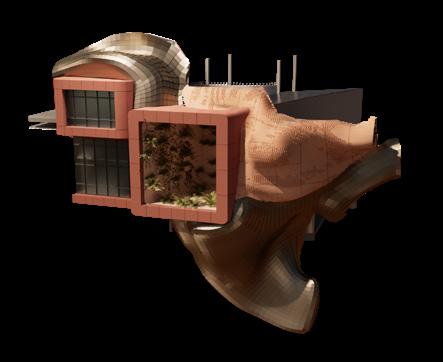

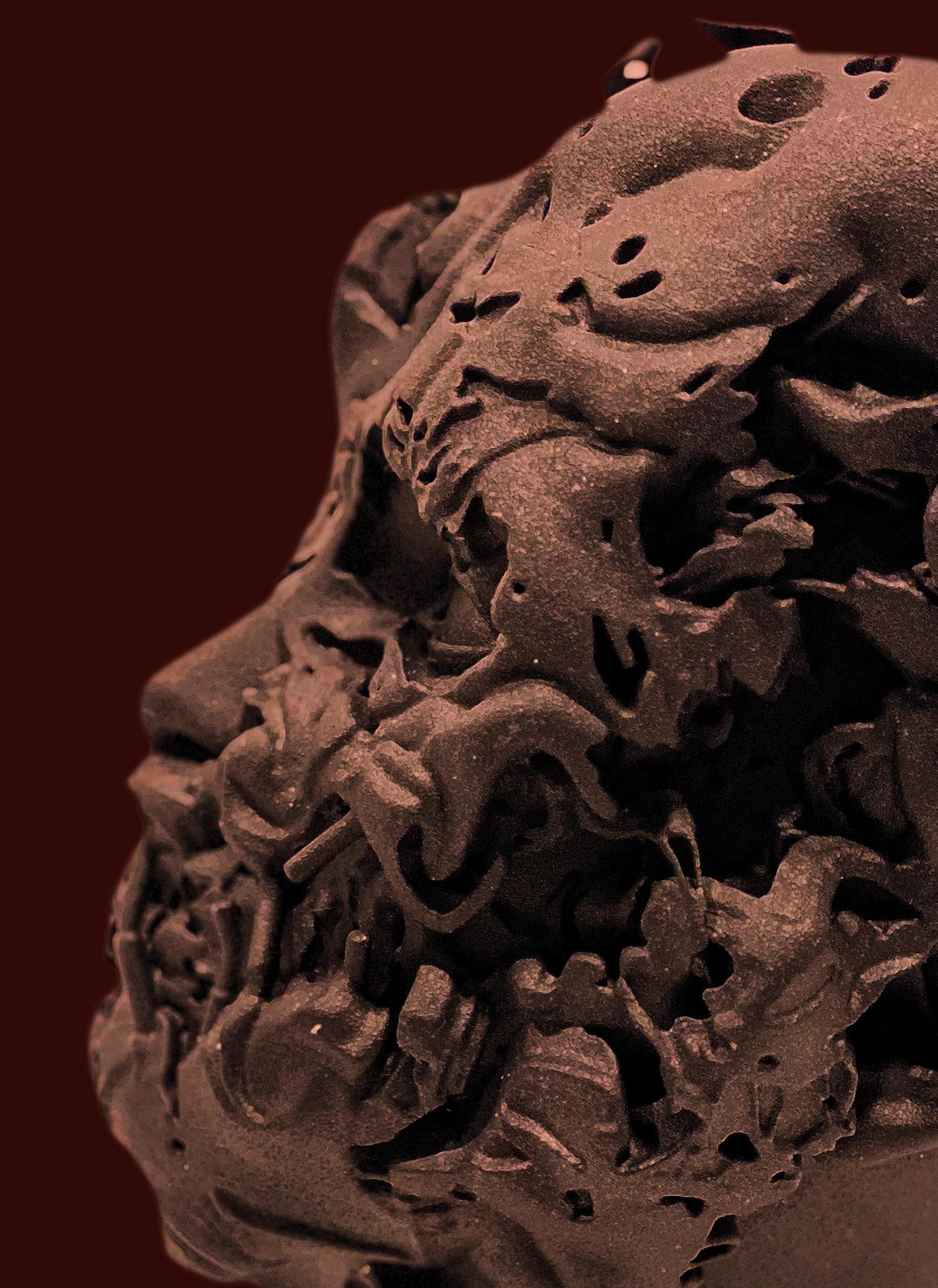

As the formal gestures of the generated images emerged, we understood the relationships between soft form, ribbed structure, and contouring as strategies for developing these images into plyable 3D form.

Sculpted from the inspired images forms like this one became the genetic code for us to begin splicing and parsing formwork together to develop the formal expression of the biotech facility.

SPLICED FORM

Similar to the splicing and parsing of genetic code, the building exists as a physical manifestation of spliced form and rigid skeletal lattice structures that imprint vertical contours on the exterior of the building.

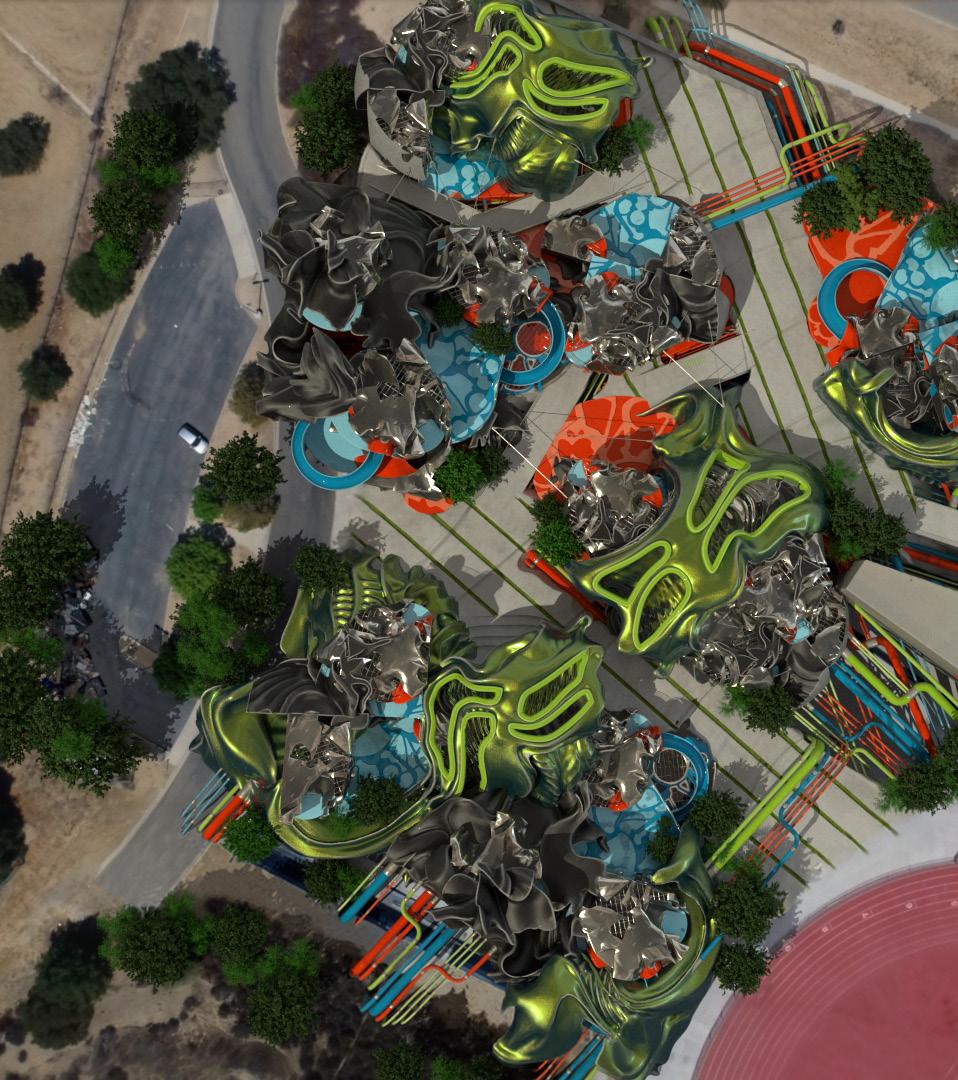

Like a living organism, the building breathes, hums with mechanical exuberance, and exchanges heat to achieve a climactic homeostasis internally. From mounds of earth littered with beds of Athanasia flowers, mysterious pipes sprout emitting a cocktail of pheromones and vapors, attracting local non-human entities to act as specimens for extraction.

The detrimental effects of the climate crisis, species extinction, as well as drought and famine in the year 2080, have led to drastic shifts in the biopolitics and technological infrastructures dictating human survival and inevitable extinction.

With limited prospects of longevity, humans have turned to CRISPR technology as a means of genetically modifying human and non-human entities in an effort to extend the duration of human life on Earth.

With a looming crisis on the horizon, CRISPR has now been implemented globally in several experimental biotech facilities, under the corporate conglomerate Athanasia, which conducts extensive research into species modification. District 14, formally known as the city of El Segundo, houses the site for a new Athanasia biotech facility responsible for serving the state of California. The conglomerates’ namesake derives from a yellow flower of the same name that resists against traditional conventions in nature as it never loses its leaves.

The mythical allure surrounding the Athanasia flower alludes and inspires notions of immortality which coincide with an underlying human need for self preservation and longevity.

The Dexterity Incubator tests and qualifies the fitness of generational species which have been modified and manufactured within other parts of the building. These emulated ecosystems expose new generational prototypes to the existing regional environments within the state of California.

Through the glass. Scientists observe, analyze, and qualify each prototype summarizing each as a transcribed data set useful for later debate and discussion within the conclave chamber..

Through the emulation of regional or local enviroments to each Athanasia biotech facility, generations of modified species are exposed to a qide variety of conditions to qualify each generation against the overall goal of the facility.

THE CONTENT: 02 ATHANASIA DESIGN DEV

IN COLLABORATION WITH

FELIX REYES

SHUANG CHU

MICHAEL WEBB

FANG SHU

PIYUSH PANCHAL

JOY CHEN

MAN SHU

AMIN MARANDI

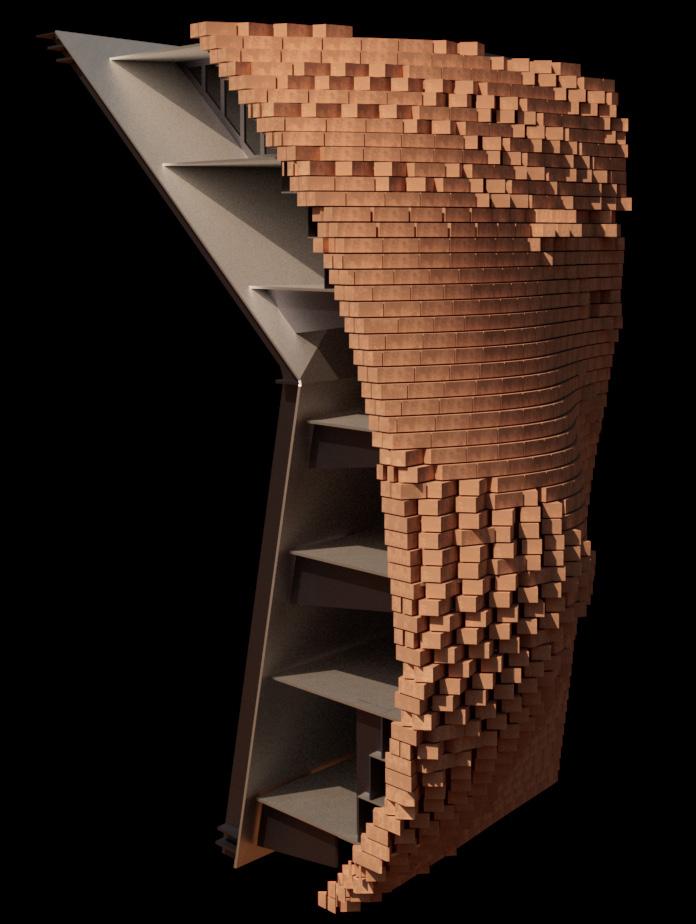

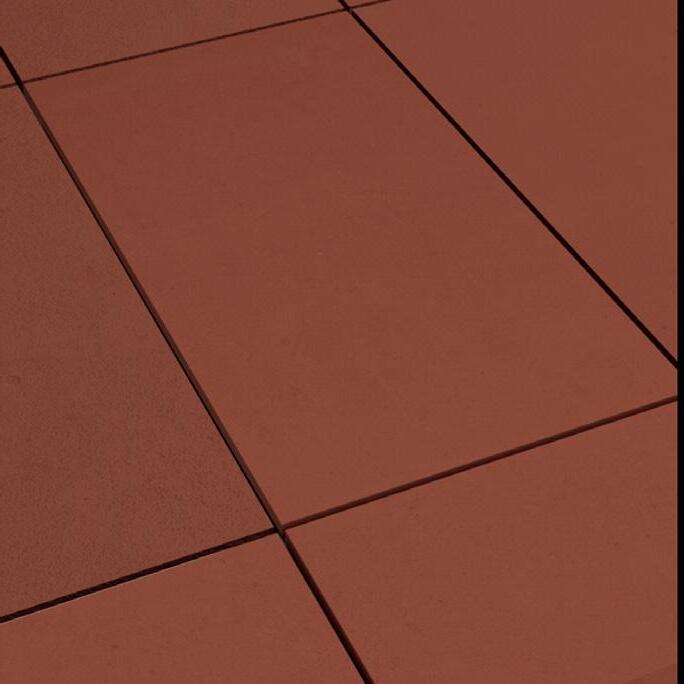

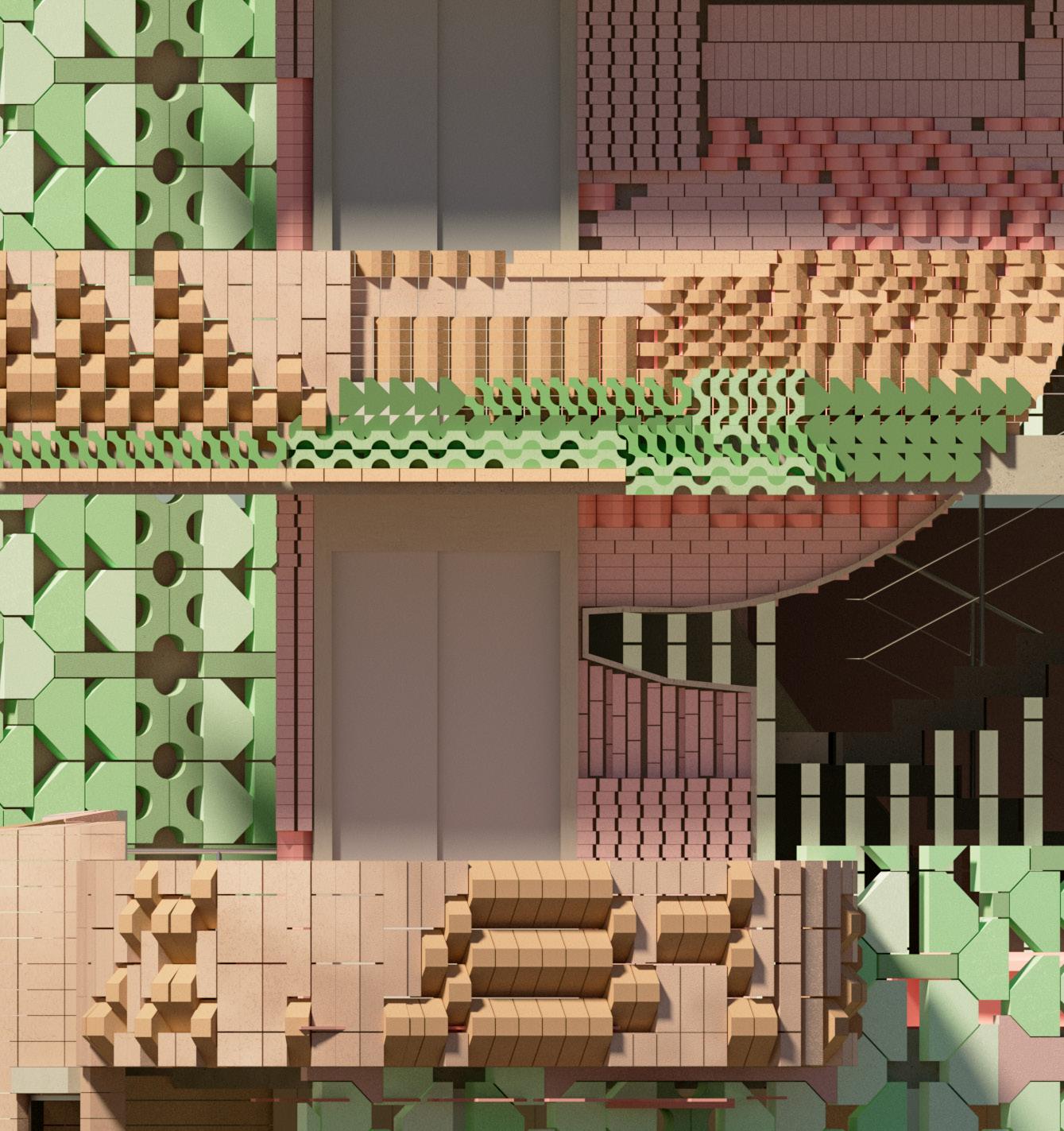

Panelized brick facade system that is prefabricated off site and assembled in large panels. The custom brick system tracks how extreme the corbel becomes and adapts its shelving system to how the angle of the facade changes

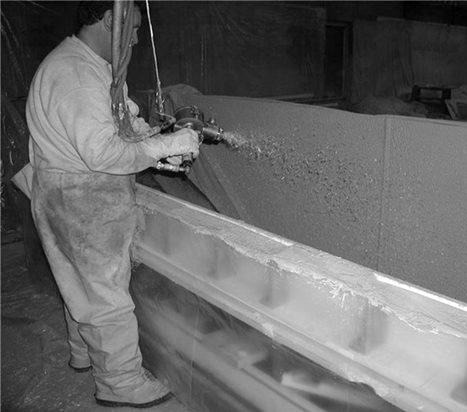

Cast in a shop these GFRC panels are reinforced with fiber glass to create very thin but resilient concrete panels. These panels can take the shape of whatever formwork they’re poured and sprayed into.

x 2’ single curved copper panel system mounted on brackets that can angle and adapt to the condition of the form. The panels overlap to hide the seams and present as a monolithic copper facade system.

THE CONTENT: 02 ATHANASIA DESIGN DEV

THE CONTENT: 02 ATHANASIA DESIGN DEV

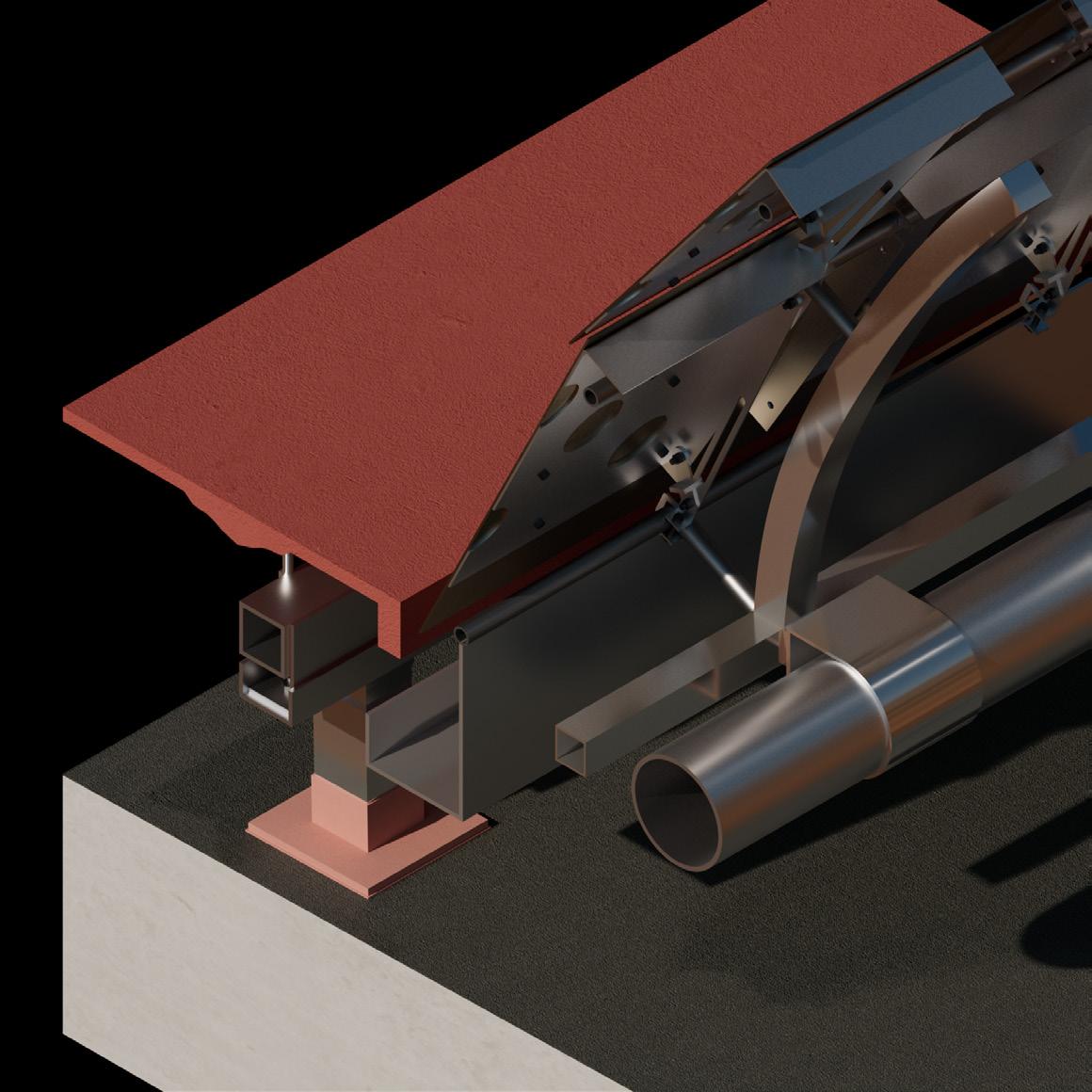

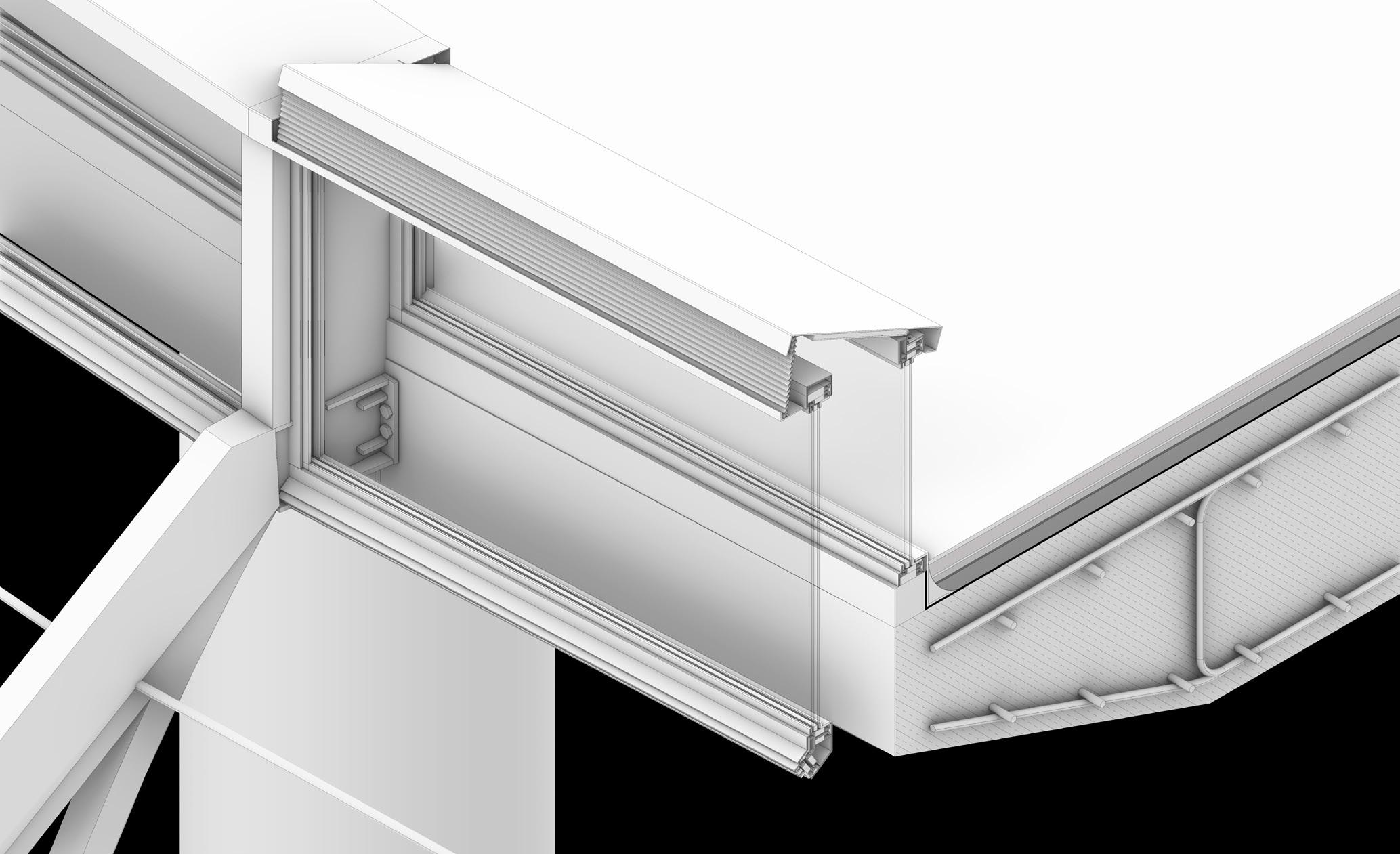

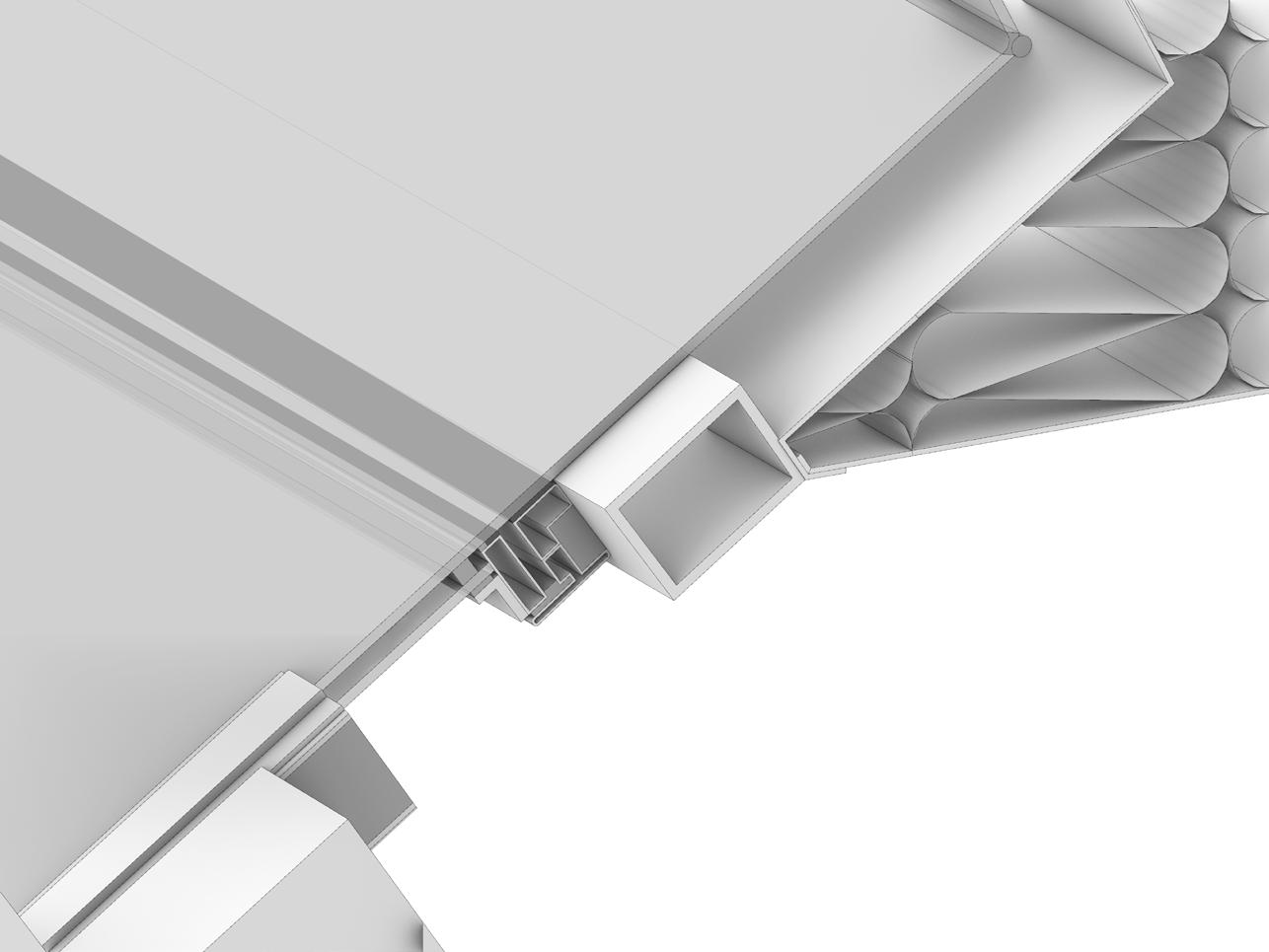

This details shows the transition between the copper panel system and the GFRC panels system of the grotto aperatures and labs. It hides an internal gutter for drainage utilizing the copper panel system for mounting.

The brick to copper panel transition happens at a major steel shelf that is welded and mounted off from the egg crate. This allows for water behind the bricks to be drained via a weep hole at the base of the bricks and the copper panel system to neatly tuck up into the brick shelf creating a clean line between the two materials.

A detail that shows the waterproofing and insulation continuity between the GFRC panel system that wraps around the concrete grotto and labs spaces and the IGU glazing that allows for natural light to the interior.

This detail highlights the typical copper panel condition. A primary facade tube structure is mounted off from the egg crate and the panelized copper panel frame which was prefabricated off site is mounted to the tube structure. The panels themselves are mounted to brackets with adjustable screws to define the angle of the copper panel as it moves across the facade.

Cast in a shop these GFRC panels are reinforced with fiber glass to create very thin but resilient concrete panels. These panels can take the shape of whatever formwork they’re poured and sprayed into.

Within the grotto cement tiles line each surface. Every so often a planter with irrigation behind is mounted in a panel slot and then vegetation is planted to create green space throughout the interior.

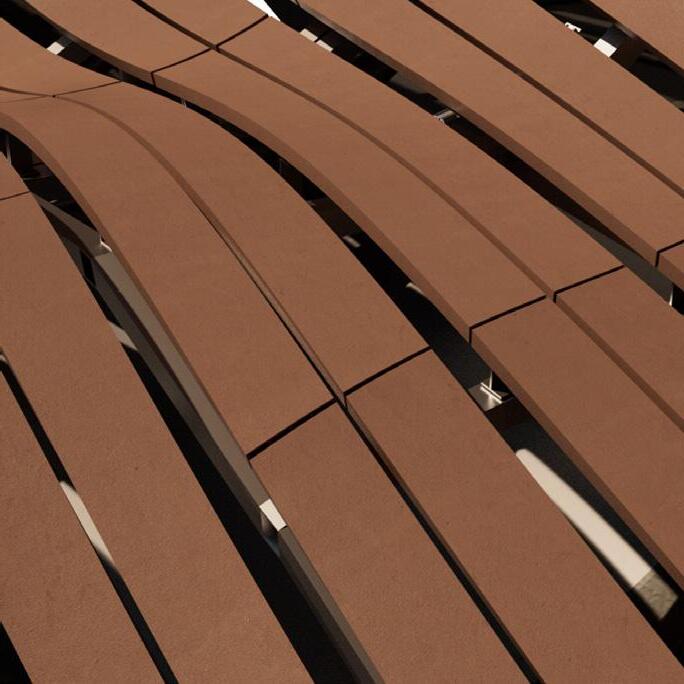

SLUMPED TERRACOTTA

Prefab terracotta panels constructed from box steel frames with mounting fixtures to hold slumped and fired terracotta ribs.

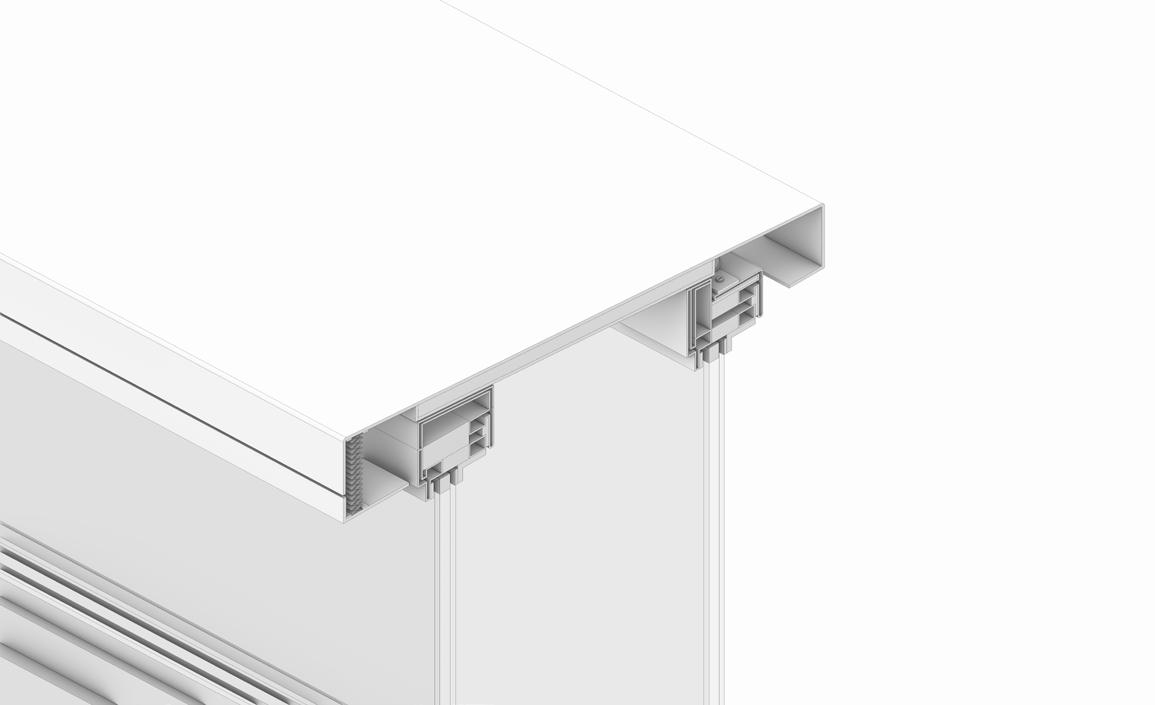

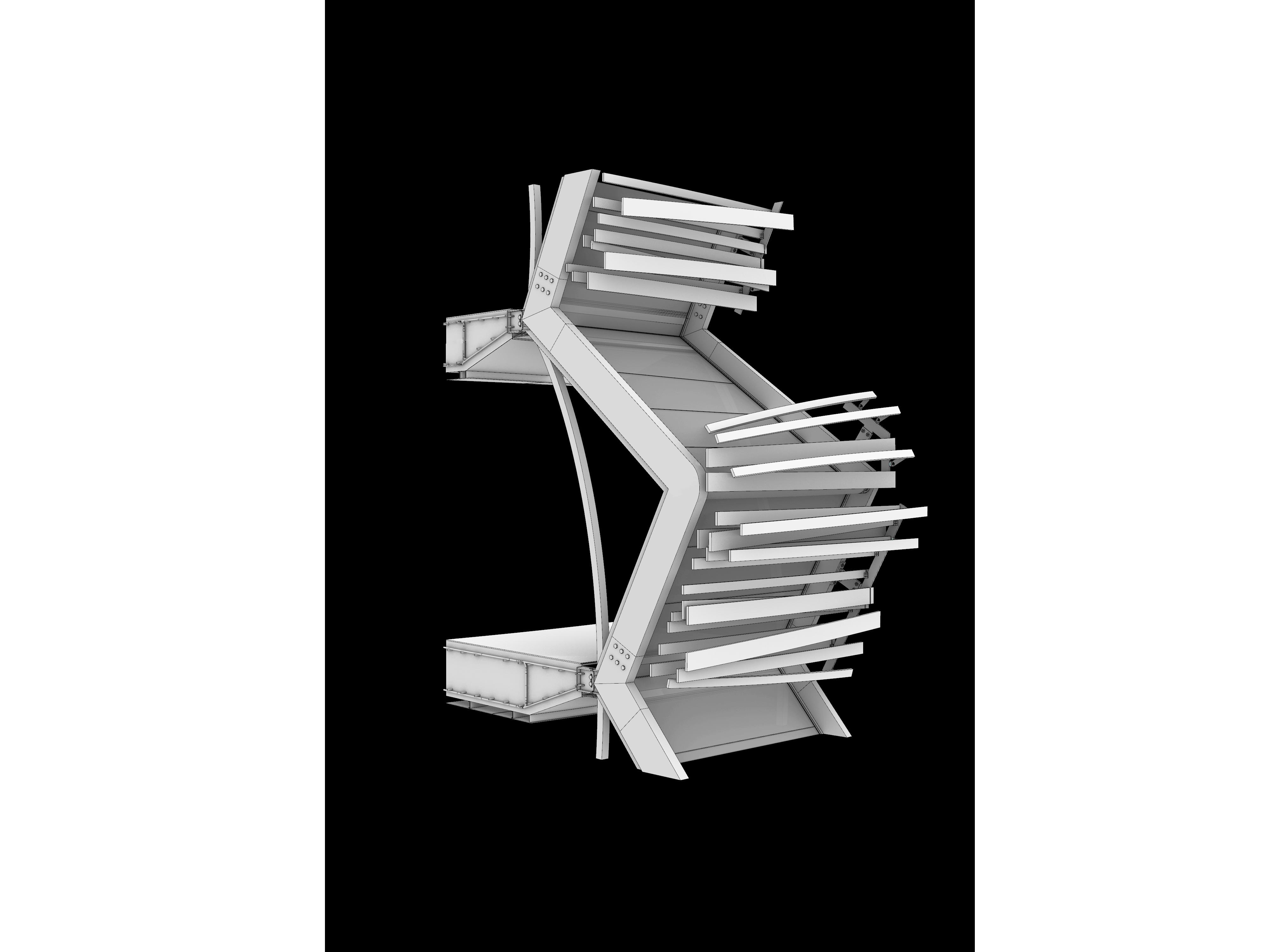

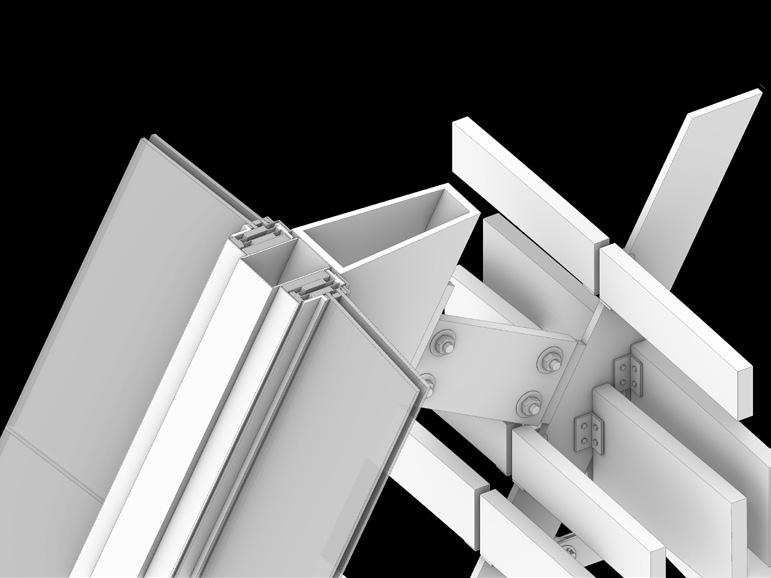

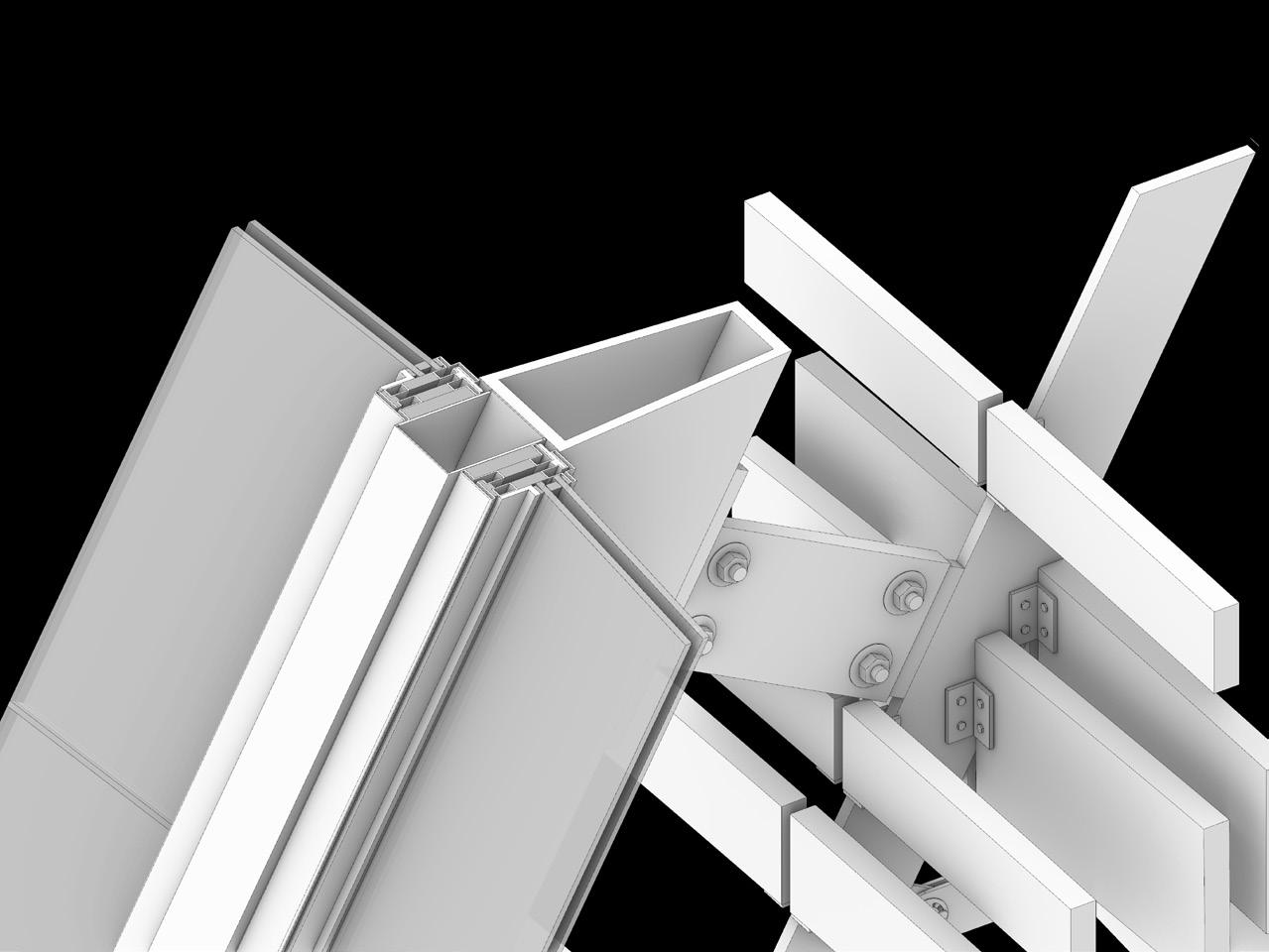

Rendered axons of the drawn detail.

Above: Macro system highlighted from exterior to interior.

Below: close up of the terracotta bolt through connection

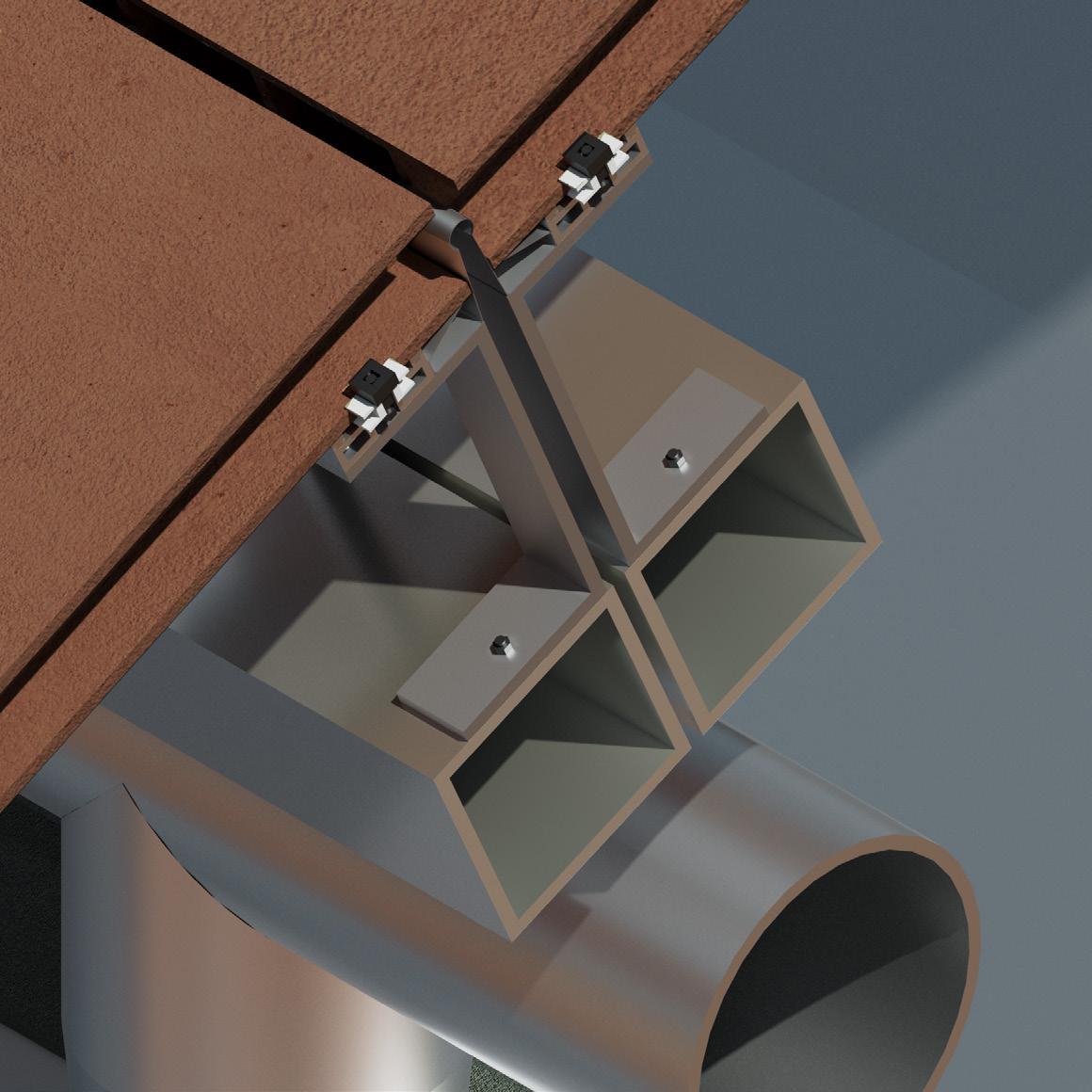

This detail shows the system in place for mounting the slumped terracotta ribs to a steel C channel via through hole bolts and gasket. That C channel is then mounted to a 4x4” steel tube picture frame that becomes the composite prefab panel brough to site. The panel is then mounted on site to a macro steel tube facade structure and that tube structure is then mounted back to the egg crate facade system.

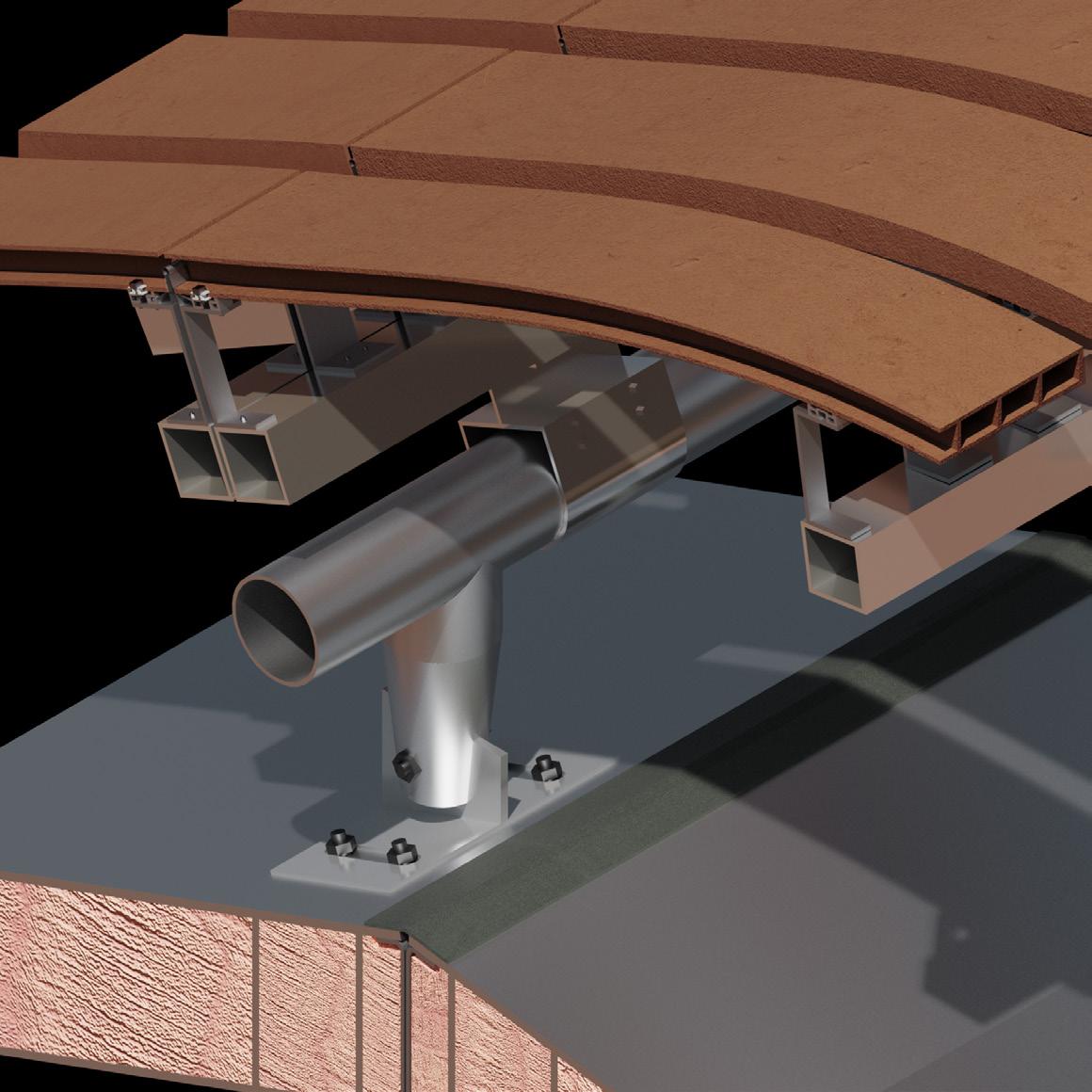

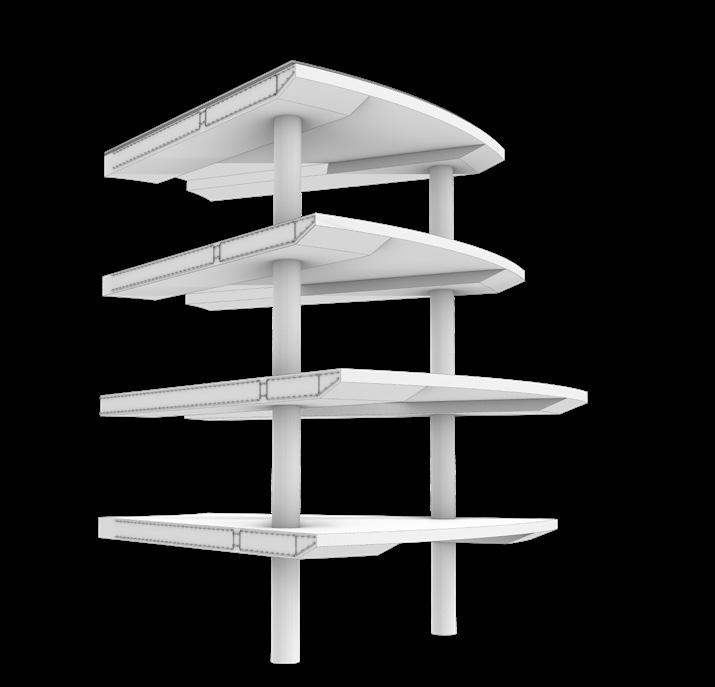

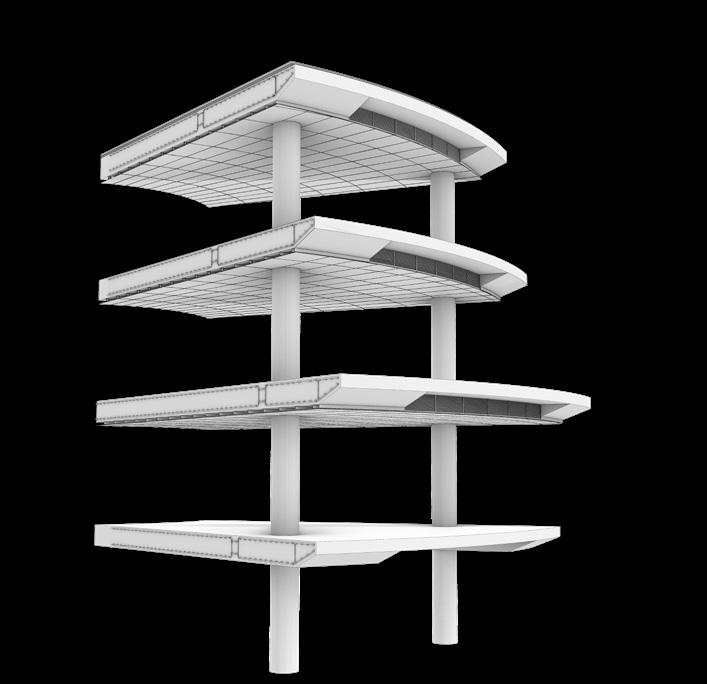

The Darling Exchange is a mixed use development in Sydney Australia designed by Kengo Kuma. The ground floor is an extension of the plaza level serving as an open market hall. The Mezzanine has space for retail and lounging. As we move up the building the next two floors contain a “21st century library and IQ hub” open for public consumption. The final two floors house child care and kindergarten classes servicing the urban blocks surrounding the building. The roof terrace has a restaurant and bar with views of the Darling Harbor to the north and of the Darling Square to the south. The building sits amongst newly developed housing and retail blocks and crowns the Darling square as the main public space in the area.

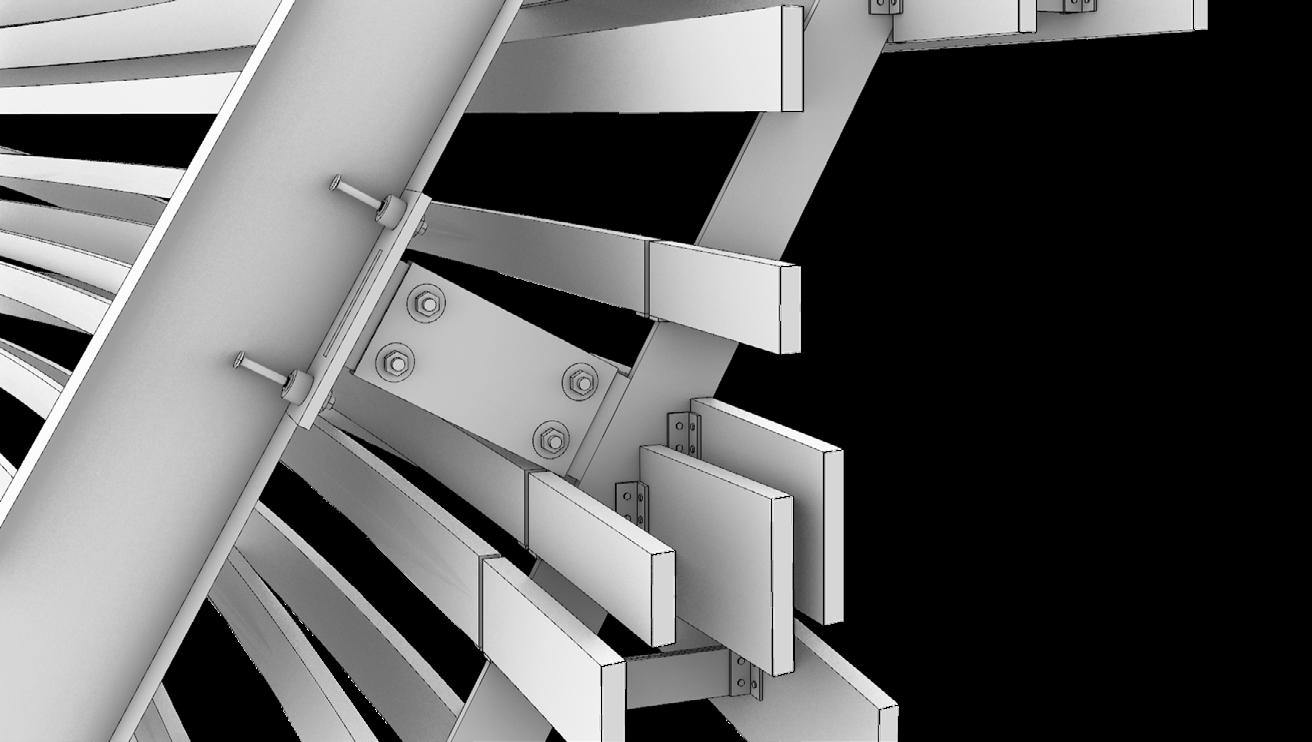

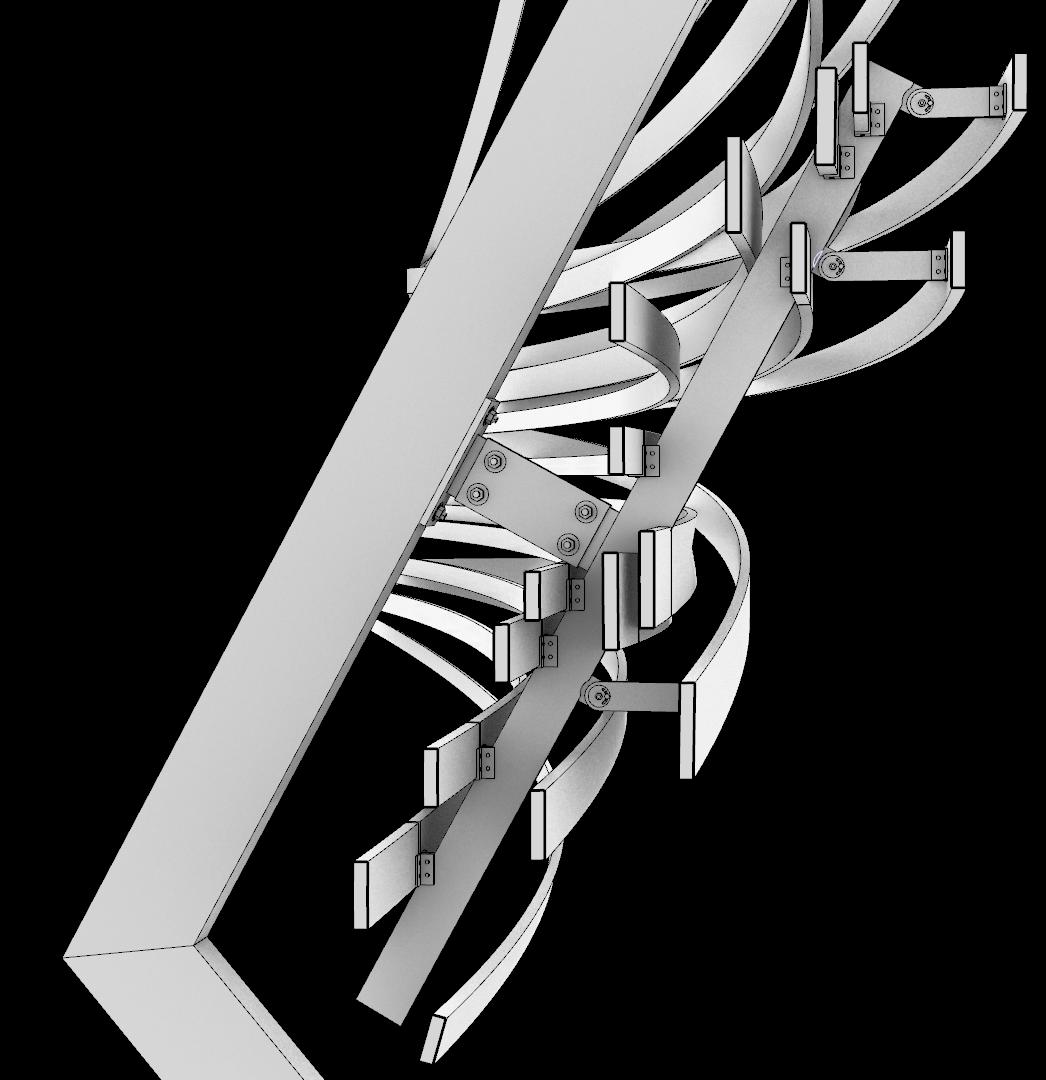

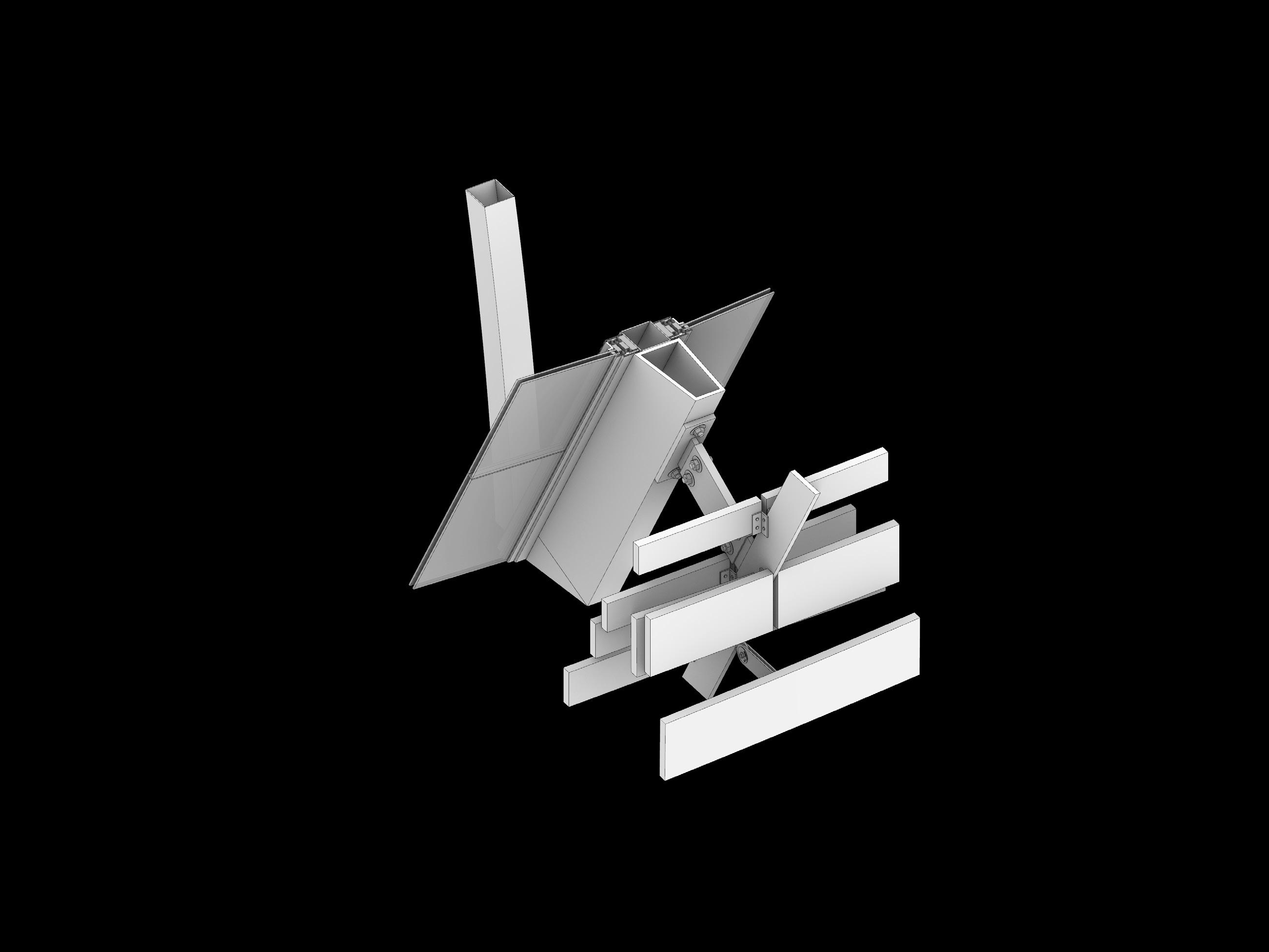

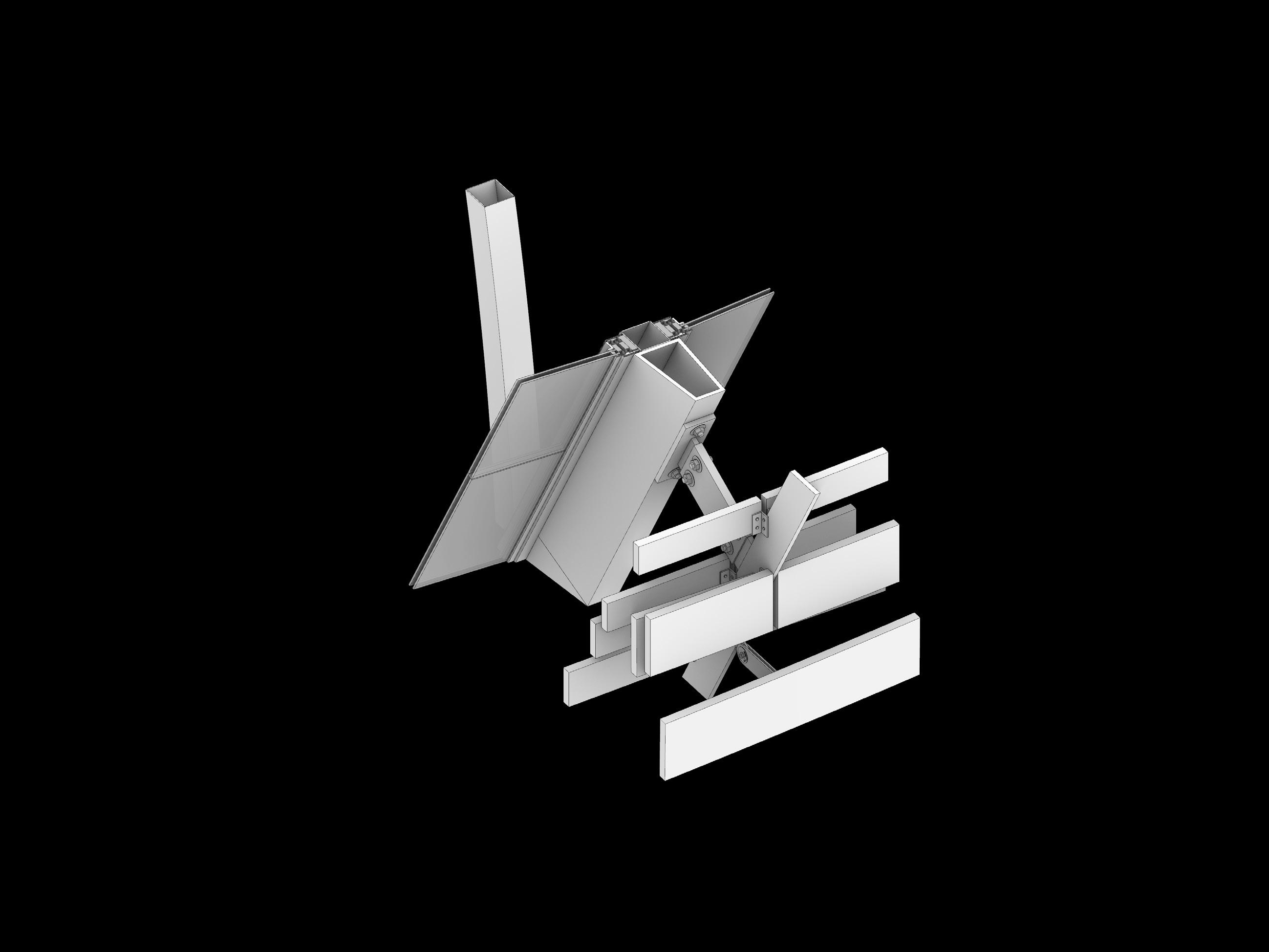

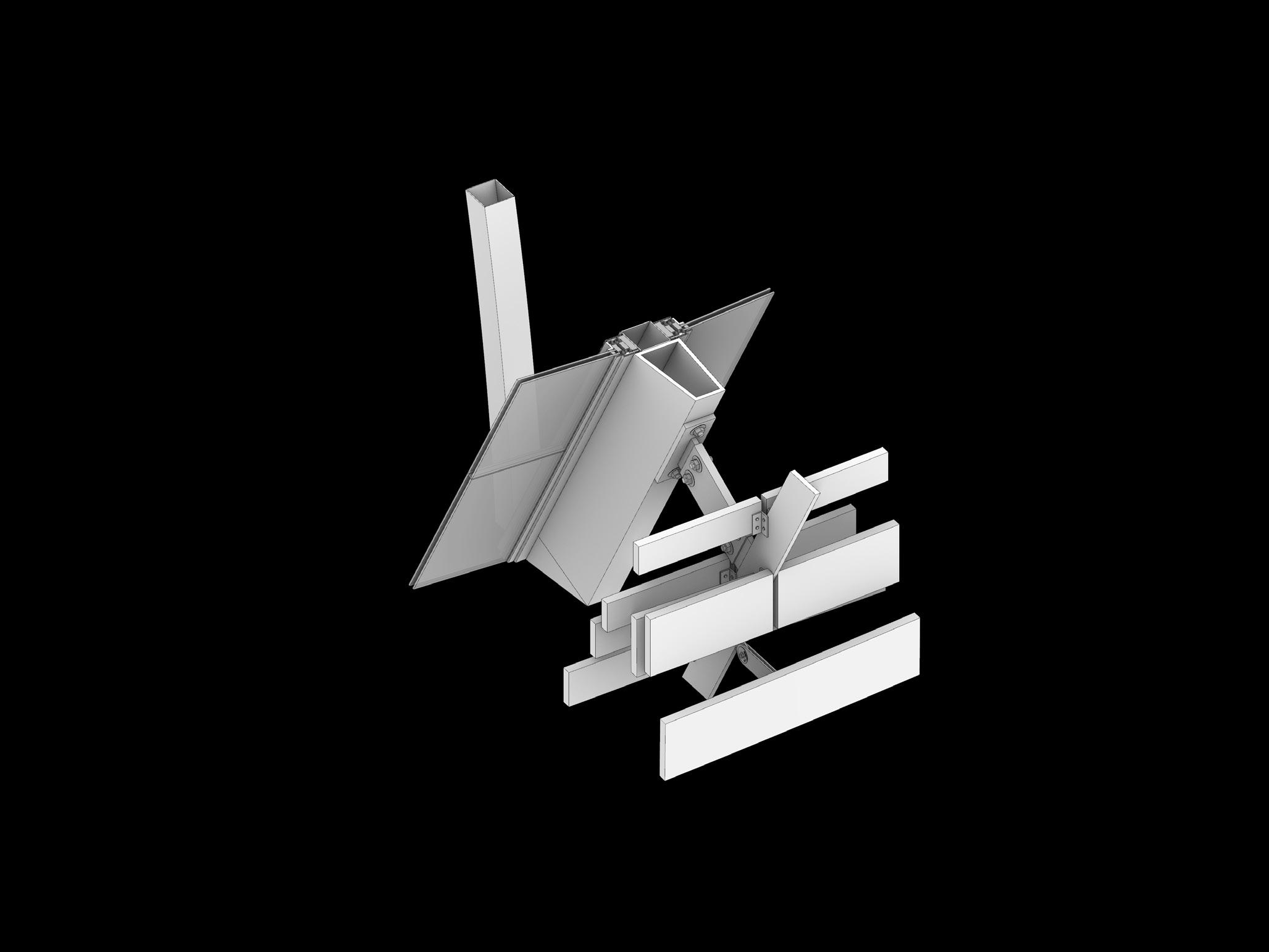

This tectonic analysis of the Darling Exchange is focused on the construction and performative aspects of the facade. This chunk analysis describes the tectonic make up of the building from the point of enclosure all the way to the slab edge where the nest like wood wrapping is captured by steel hangers.

01. 15” Reinforced Floor Slab

02. 30” Thickened Structural Slab

03. Radially Arrayed 3’ Structural Columns

04. Glass Panel Canopy With Spider Joint Connectors

05. 3’ Glass Railing With 1/2” Steel Plate Uprights

01. 5’ Wide IGU Panel Unit Marking Primary Enclosure

02. Accoya Wood Canopy Wrapping

03. Light-Gauge Steel Drop Ceiling Framing

04. Radially Arrayed 2.5’ Wide Panels

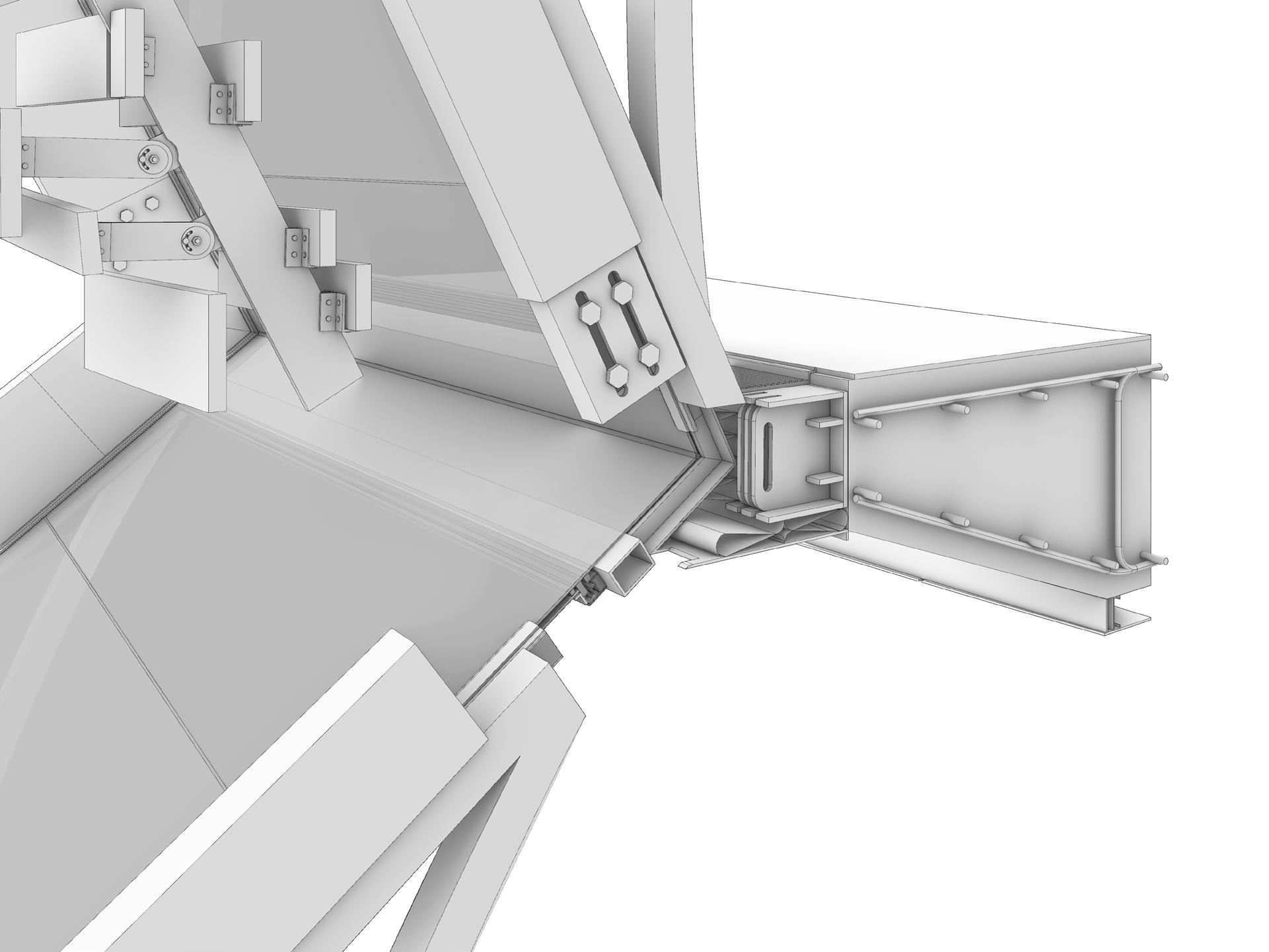

We modified the design of the Darling Exchange by attempting to move the point of enclosure to the facade itself. We created a monolithic expression of the nested wood wrapping and created variation on the facade through the mountain and valley folds of the primary tapered steel members. We designed the joints and connection with the construction of the facade in mind. The facade is tied back to the original geometry of the slab edge. The IGU wall sits inset from the steel structure establishing the point of enclosure at the facade differing from the original Darling Exchange. As the facade reaches the green roof a double IGU parapet detail is employed to provide the supplemental natural ventilation. The clear parapet is utilized to maintain consistent transparency behind the accoya wood wrapping. This creates a monolithic impression of “nesting” bands which hug and bind the building all the way around.

THE CONTENT: 03 DARLING EXCHANGE

01. 1/2” Adjustable Steel Bracket

02. Bracket for Wood Lap Joint

03. Bracket for Wood Overlap Joint

04. Bracket for Wood Joint 05.

C1

01. 4” x 4” Interior Glass Mounting Brace

02. Secondary Vertical Structure Slotted End

03. Floor Grate Cap

04. Embedded Facade Mounting Bracket

05. Spandrel Aluminum Capping Plate

06. Batt Insulation

07. Spandrel Glass Mullion (Refer to D2)

C2

08. Wood Bracket Sleeve Connection

09. Accoya Wood Panel

10. Secondary Vertical Structure

11. 8” Diameter Tube Bracing

12. Outer Corner Glass Mullion (Refer to D3)

13. Glass IGU 30” x 120”

C3

14. Secondary Vertical Facade Structure

15. Adjustable Slotted Connection

16. Vertical Structure Connector Component

17. Embedded Facade Mounting Bracket

18. Vertical Structure Welded Edge

C1 FLOOR EDGE SPANDREL DETAIL

C1 FLOOR EDGE SPANDREL DETAIL

D2 IGU MULLION AT VERTICAL TAPERED STRUCTURE

01. 4” x 4” Interior Glass Mounting Brace

02. Glass IGU 30” x 120”

03. Secondary Vertical Structure

04. Wood Bracket Slotted Connection

05. Glass Mullion

06. Accoya Wood Panel

07. Wood Bracket with Adjustable Angle

D1

08. Secondary Vertical Structure

09. 4” x 4” Interior Glass Mounting Brace

10. Glass Mullion

11. Glass IGU 30” x 120”

12. Wood Bracket Slotted Connection

D2

13. Glass IGU 30” x 120”

14. Glass Mullion Exterior Cap

15. Secondary Vertical Structure

16. Extrude Aluminum Mullion

17. 8” Diameter Tube Bracing

D3 IGU MULLION AT 8” STRUCTURAL TUBE BRACING

D3

18. Batt Insulation

19. Spandrel Aluminum Capping Plate

20. Extended Single Glass Pane

21. Steel Rectangular Tube

22. Structural Glazing Adhesive

23. Extrude Aluminum Mullion

24. Glass IGU 30” x 120”

The structure of the class was organized into several ‘Chapters’, each one of them being a particular procedure of work. At every step, techniques were developed that advanced the final project. The four chapters also followed the fabrication process of the model. Students began working on the model the first day of class, by selecting the brick format and mold, all the way up to midterm review. Students constructed the model during this period. After the midterm review, students focused on the large section drawing. No model was required for the final review, as the midterm model was presented alongside the drawings.

The aim of the studio was to develop a consistent design process, where research, fabrication and design were folded into a working method. This gave students a clear method of design where every component was an intrinsic part, all geared towards the design of an architectural project that was conceptually driven. The project challenged known architectural paradigms yet was engrained in the discourse of architecture.

We studied brick construction yet challenged the argument defined by Lewerentz in the above quote who rejected the notion of treating the brick “aesthetically” as he believed that it should be manipulated in an “ethical” manner. We moved away from dialectical contrasts and more toward conceptual hybrids, where aesthetics and ethics were interwoven. Our brick construction was both beautiful and functional at once.

The class was organized in varied formats, from conceptual lectures and required readings, to software tutorials, and digital pin-ups. The feedback from all those forms of academic research concluded in the design of a model and a large section drawing. It was recommended that students work in teams in order to distribute the workload.

The Brick is a fragment of architecture that carried such a rich and profound history and therefore represents a powerful potential for space, material, and landscape.

THE CONTENT: 05 THE MASK WE WEAR

IN COLLABORATION WITH FELIX REYES

“We wear the mask that grins and lies, It hides our cheeks and shades our eyes,—This debt we pay to human guile; With torn and bleeding hearts we smile, And mouth with myriad subtleties.”- We Wear the Mask by Paul

Laurence Dunbar

Laurence Dunbar

We stretch a smile across our face to restrain inner traumas, conflict, and bubbling pain. This smile serves as a means of censorship, where the succession of teeth present as cell bars constraining the volatile truths that are deemed unsavory by societal standards. This artificial mask stands as a hardened wall, resolute to the influences of the world. But no fortress is perpetually impenetrable and absolute. This mask staves back the violent eruption of the these constraints and a subsequent oozing of the dark matter that lies behind the walls. As the grin comes across the face you begin to see the mask tear open, the bars come free, and the fiery expression of individual identity is released. The tear symbolizes freedom, but not without its own troubles. Breaking the structure of the mask till it fails leaving us naked to the world.

The bars come free, and the fiery expression of individual identity is released. The tear symbolizes freedom, but not without its own troubles. Breaking the structure of the mask till it fails leaving us naked to the world.

This artificial mask stands as a hardened wall, resolute to the influences of the world. But no fortress is perpetually impenetrable and absolute.

Strapped and bound to the body the mask exists as an outward facing facade. Built from convention, expectation, and ambition the mask represents an assemblage of trauma, scar tissue, and resilience.

Leather straps wrap the head firmly securing the mask to the fragile and impressionable soul beneath. The heat of expression illuminates the bars crossing the mouth and eyes with a red hot glow. The scars and hardening of the surface of the mask symbolize the survival and reaction to storms of the past.

The back of the head simplifies to a single leather strap holding tight to its base. The thin fastening of the mask implies the voluntary nature by which it is worn. The major tear along the left side of the mask exposes the ripped edge of one of these leather straps. The structural integrity of the mask is being jeopardized and the eventual failure of the mask appears inevitable.

The overall impression of the mask is always outward focused. As the wearer awakens to the reality of their identity the mask fails. It’s structure and protection is a reflection on the naive and attention seeking nature they exist within as judgment is passed.

The tectonic and ergonomic nature of furniture creates many opportunities within design to break the mold.

Furniture which can’t be stacked or organized in a controlled and equal manner but rather pieces that demand their own space and expression. Furniture which can be altered and painted to reflect the individual identity of the students occupying them.

The Desk is a piece of furniture based on the proportions of the typical desk teachers occupy. Playful and ergonomic while catered to the physicality and proportions of an adult. Large and imposing within the space the hierarchy of the teacher student relationship remains evident despite a more intricate and detailed approach to the formal language.

The Chair is designed as an intricate piece for the students themselves to style and evoke their own personal identity. The detailed formal approach to the chair is a step away from the mundane and universally utilized furniture which students are accustomed to.

Utilizing the found metal structure from chairs and desks that already exist in production around the world to serve as the underlying structure for a new monolithic formal gesture of heirarchy.

As multiple materials interface with eachother in an embrace of bent metal and sculpture, the desk presents itself as a monolithic proposal for how an educator engages with the classroom

Reflecting on time spent in elementary school we realized that the spaces that were meant to be nurturing and creative only actually existed as a simple cork board plastered in construction paper. We sat in a grid of desks and chairs designed resulting in a student experience that was monotonized and averaged. The idea that as labor is reduced to its most generic form devoid of any specific duty, education adopts a typical plan that is simple, flexible, and reproducible. Our genuine ability to express ourselves in these spaces was not only stunted but discouraged by efficient design.

Our project means to activate space for students by encouraging them as young authors of their own personal experience. To create a new plan for education dedicated to self directed learning. A classroom where the perception of right and wrong are less defined. Our architectural approach to the classroom suggests a more playful and unbalanced way of approaching the learning environment. Formal modification, coloration, and organization define a new approach to expression beyond the desk.

Idealized and equalized design dominates the modern day classroom. By ignoring the grid we establish a layout tailored to individual experience and need.

The standardization of student experience has established the need for a ‘typical plan’ within the education system that attempts to serve all equally but in the end serves no one.

“This class will look in detail at the movie ‘Powers of 10’, by Ray and Charles Eames, a Film from 1977 that presented a cinematic shift in scale, from the micro to the macro, on a linear path. This notion of scalar change will be the focus of this class, from small items at the scale of furniture, to large scale work on the context and site in the city. The studio will fully develop a project in detail, in a cinematic manner, by looking at design spatially rather than in orthographic format, as a way to be immersed in architecture.”

The classroom animation takes the form of a top view ‘Powers of 10’ sequence. At its closest the frame shows the details of the classroom furniture and the tools that the students might use to express their individuality. As the camera pulls out you begin to see the classroom grow. The way you circulate between spaces highlighed in a bright red. At the widest angle you can see the full view of the classroom. The stage like presentation platform at the front. Multiple levels of student space and a ball pit to the back of the classroom for recess.