8 minute read

Climate change resources — decarbonising the supply chain

To meet the aims of the Paris Agreement and achieve net zero carbon emissions by 2050, we will need to remove almost all carbon from our supply chain. Claire Thirlwall looks at the prevalence of fossil-fuel derived elements in the materials we specify, and the issues we need to be able to resolve as we move towards zero carbon landscapes. Illustrations by Anna Gibb.

Despite a post-pandemic reduction in the overall demand for oil, petrochemical production is predicted to continue to grow in the medium term1. Bans on single use plastics and nonrecycled packaging have had only moderate impact on overall plastic consumption and the demand for plastic products continues to increase. The products created by this sector have revolutionised the modern world, allowing innovation in medicine, agriculture, transport and construction. The wipeable vinyl paint on our walls, the inexpensive synthetic carpet on the floor and the lightweight pipes that bring water to our homes –they all begin with crude oil.

The petrochemical sector, an industry worth an estimated $460.7 billion globally in 2021, is reliant on the extraction of fossil fuels2. However, to meet climate change targets our reliance on fossil fuels, not only for our energy needs but also the materials we use day to day, will need to reduce. For landscape architects one of the first steps in this process is to understand the prevalence of fossilfuel derived ingredients in the products we specify.

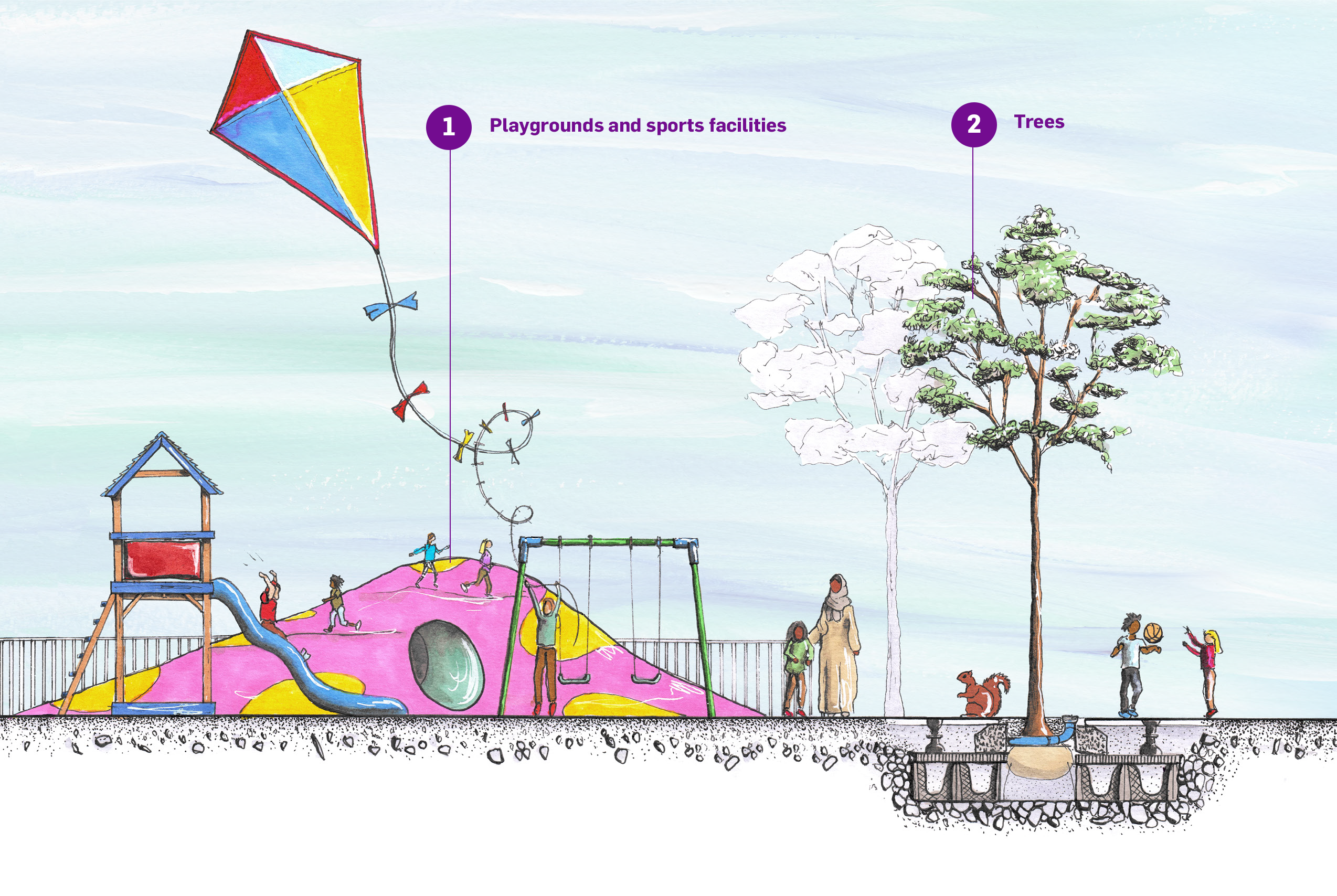

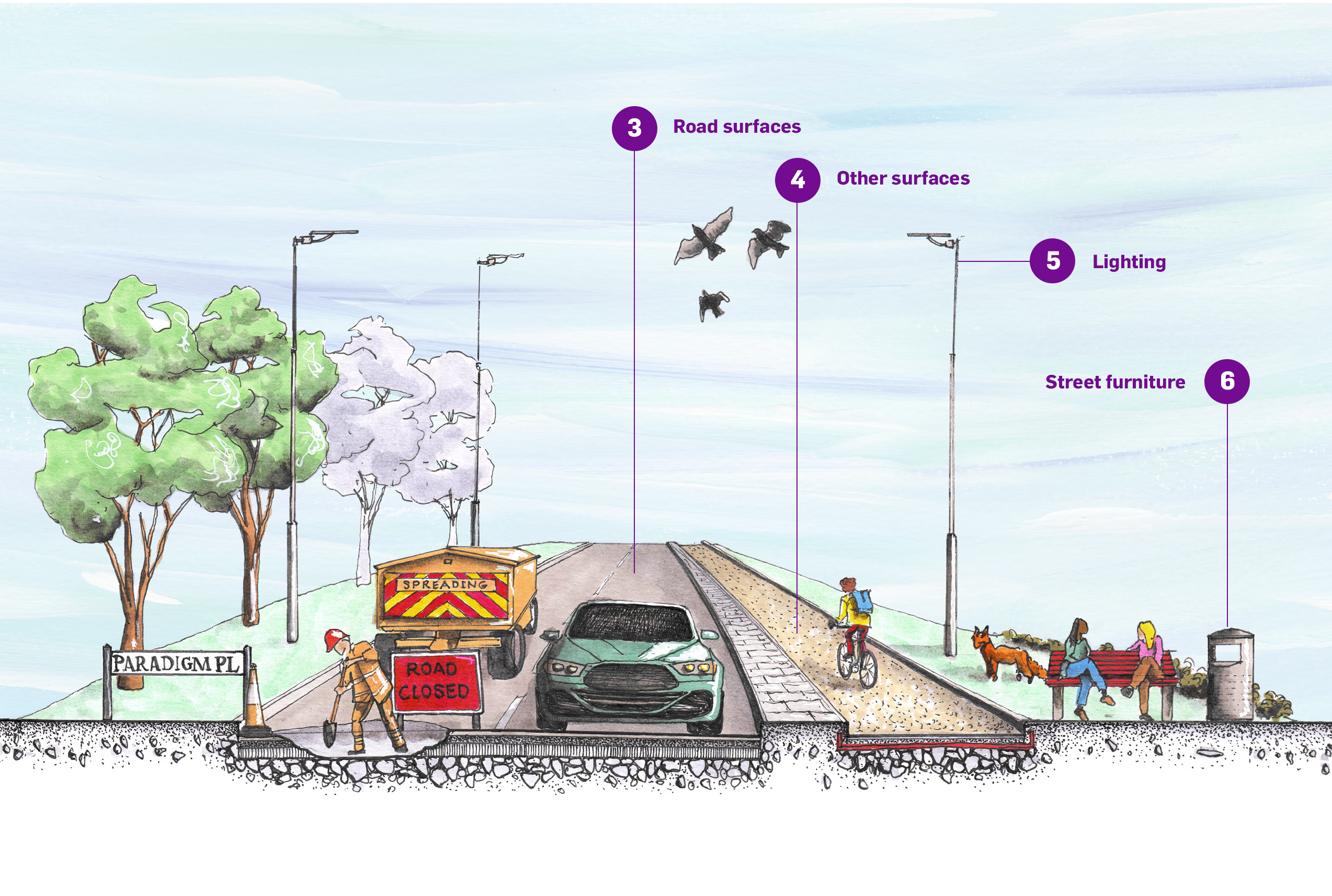

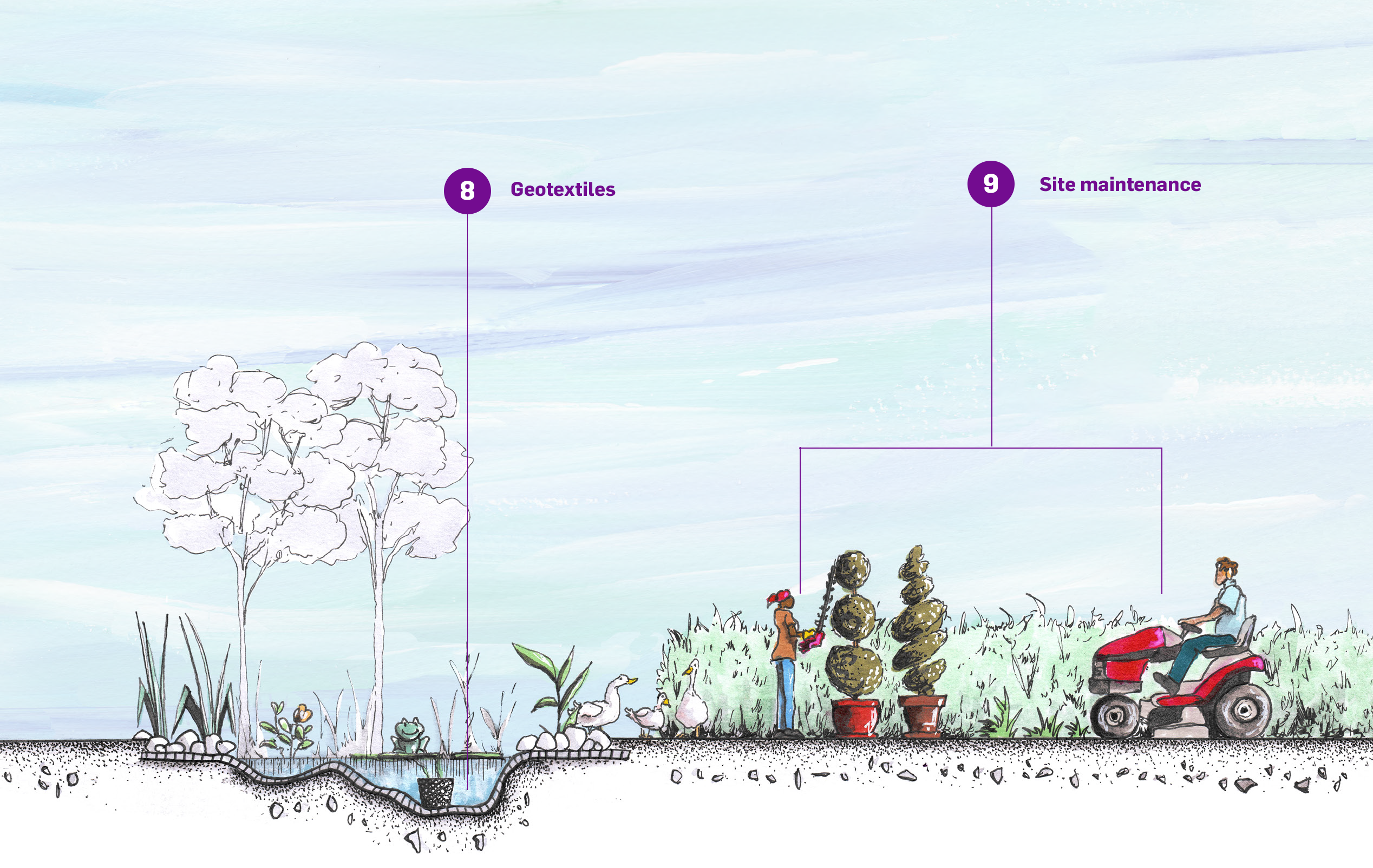

Walking along a typical street it is hard to find components that are not derived from fossil fuels. Our imaginary road shows just how prevalent they are.

1. The colourful playgrounds and sports facilities that we design would not exist without fossil fuels. The plastic seats on swings or hand-holds on climbing walls are easy to identify, but there are also petrochemical derived materials in less obvious elements. The brightly coloured waterproof panels on climbing frames are often made of High-Pressure Laminates (HPL), which include resins derived from methane and petroleum derived benzene.

Often described as rubber surfacing, the wet-pour surfacing used in play areas is not made of natural rubber but is typically made up of Styrene Butadiene Rubber

(SBR) and a polyurethane binder. According to ROSPA more sustainable options such as sand, wood chip and shingle achieve high levels of impact attenuation but are not widely used in the UK.³

2. Tree planting is central to the UK Government’s plan to combat climate change and to achieve net zero carbon emissions by 2050.⁴ However, there are fossil-fuel derived elements in products used in urban and rural tree planting. The soil cells used to allow root space for urban trees are made from polypropylene,⁵ tree ties are made of polycarbonate,⁶ and typically tree guards are made from polypropylene.⁷

Alternatives to plastic tree guards are available, made of material including cardboard and wool, but the majority of schemes use degradable polypropylene which breaks down and releases micro-plastics into the environment. Recent research by the Woodland Trust and the National Trust found that, based on a Life Cycle Assessment (LCA), planting without tree shelters is “the most preferable option across most environmental impact categories.” However, the report also found that survival rates with tree shelters were 85% and 50% without, and that the carbon emissions of tree guards “are negligible when compared to the amount of carbon sequestered by a tree in 25 years.”⁸ This one example shows the level of complexity for landscape architects when comparing the available options – should we opt for higher planting densities to compensate for trees lost to browsing animals, plant older trees that are more resilient or stick with plastic tree tubes and ensure they are recycled at end of life?

3. Tarmacadam, bitmac and asphalt

The creation of these inexpensive, flexible materials for roads, footways, cycleways and playgrounds has transformed the our world. Without surfaced roads travellers face deeply rutted roads impassable in heavy rain and choked with dust in the summer.

As countries become more wealthy, surfaced roads are often part of their plan for prosperity and mobility.

Great Britain has 247,800 miles of surfaced road, all of which includes bitumen, most commonly sourced from the distillation of petroleum. National Highways, the agency responsible for England’s motorways and major A roads, is one of the UK’s largest buyers of construction materials. The Agency has set out a road map for zero carbon concrete, asphalt and steel by 2040. To date, innovations have included updating standards to require lower temperature asphalt, asphalt recycling and the use of recycled plastics in surfacing but their reports include no mention of carbon-free processes. The intention is to aim for zero carbon construction but with hard-todecarbonise materials such as asphalt there appears to be an acceptance that carbon capture and storage will be part of the solution⁹ – for such a ubiquitous product the work to offset the impact will be significant and is a useful reminder that reaching zero emissions is not yet a viable option.

4. Other surfaces that we specify as landscape architects, such as resinbound surfacing also include fossil fuels. Whilst the main component is aggregate, the durability is provided by polyurethane resins and highdensity polyethylene.

5. As well as the surfacing we specify we also need to look at street furniture. The main components, such as timber and steel, are fossil-fuel free, though the production of steel is a high-energy process. However, the coatings and paint finishes used often contain polymers.

6. Changing to LED street lighting provides significant energy savings, and using existing technologies it is possible to decarbonise the energy supply. However, the components inside the lamp, such as the wire casings, and any polymer coating, are all reliant on fossil fuels.

7. The tree and shrub stock we specify utilises substantial amounts of plastic during the growing process and whilst being transported to site. The horticultural sector uses plastic plant pots, plant labels, tree tags, tree ties and polytunnels, and plastic wrap is used to protect plant stock during transport. The sector is looking at alternatives to plastic, especially for the hard to recycle black plastic pots, but suitable replacements are yet to become commonplace.

Another type of fossil fuel is peatthough used in landscape as a growing medium rather than an energy source, it is a non-renewable product which releases carbon when extracted. Peat bogs are an important store of carbon, and metre for metre they store more carbon than any other terrestrial ecosystem.10 The UK Government plans to ban the sale of peat in England and Wales by 2024 but only for retail use.

8. Another hidden aspect of our work is the geotextiles and geogrids used to line ponds, stabilise paths and create access routes. Both products are made of polymers, such as polypropylene, polyethylene or polyester.

9. One final point for consideration is the carbon cost of site maintenance. For areas of lawn the initial carbon impact is low, but if they are managed as close mown grass and mown with a petrol mower, the lifetime impact can be significant. The choice of grass seed mix can impact on how often the site needs to be cut, and machinery can be run via rechargeable batteries or biofuels.

As our first steps towards net zero landscapes, we need to ask manufacturers to list the materials and processes they use in production and maintenance. Some manufacturers provide Environmental Product Declarations (EPDs)11 which include information about the materials and processes used, including the use of fossil fuels, but these can be difficult to understand.

We also need to understand that we are aiming for net zero, not zero – future unknown technologies may resolve this, but for now there is an acceptance that not all issues will be resolved, that some processes are hard to decarbonise and that carbon capture will be needed to mitigate these processes.

However, once we understand the elements in the materials we specify we can begin work to phase out all unsustainable products from the landscape supply chain.

Claire Thirlwall

A director of Oxfordshire based landscape practice Thirlwall Associates. Her book “From Idea to Site: a project guide to creating better landscapes” is published by RIBA Books.

Anna Gibb

An architect and illustrator. Her hand drawings have been exhibited both in the UK and internationally, including at the 2012 Venice Biennale.

References:

1 International Energy Agency, Oil 2021.

2 Petrochemicals Market | Global Industry Report, 2031 https://www.transparencymarketresearch.com

3 ‘Play area surfacing - RoSPA’, <https://www.rospa.com/play-safety/advice/surfacing> [accessed 22 November 2022].

4 ‘Tree planting - Environment, Food and Rural Affairs Committee’, <https://publications.parliament.uk/pa/ cm5802/cmselect/cmenvfru/356/report.html#footnote-291-backlink> [accessed 29 November 2022].

5 ‘Pavement Support System - RootSpace®’, in GreenBlue Urban, <https://greenblue.com/gb/products/ rootspace/> [accessed 23 November 2022].

6 ‘Rainbow Buckle Tree Tie - Tree Ties & Support | Green-tech’, <https://www.green-tech.co.uk/tree-plantingproducts/tree-ties-and-support/rainbow-buckle-tree-tie> [accessed 23 November 2022].

7 ‘Vigilis Tree Shelters’, <https://www.sure-green.com/standard-tree-shelters.html? msclkid=caec8fc9ccd91c527fbcecb7810c0114> [accessed 23 November 2022].

8 C Chau et al., ‘The environmental performance of protecting seedlings with plastic tree shelters for afforestation in temperate oceanic regions: A UK case study’, in Science of The Total Environment, vol. 791, 2021, 148239.

9 N Highways, ‘Net zero highways - National Highways’, National Highways, 2021, , p. 18, , Worldwide <https://nationalhighways.co.uk/our-work/environment/net-zero-highways/> [accessed 28 November 2022].

10 BJM Robroek et al., ‘Taxonomic and functional turnover are decoupled in European peat bogs’, in Nature Communications, vol. 8, 2017, 1161.

11 ‘Environmental Product Declaration (EPD) EN 15804 | BRE Group’, , 2018, <https://bregroup.com/ services/testing-certification-verification/en-15804-environmental-product-declarations/> [accessed 22 November 2022].