3 minute read

Demag® CC 3800-1 lattice boom crawler crane

A challenging job at a power plant work site in the United Arab Emirates. As part of a power plant expansion, one of the jobs for Al Faris was to install 16 double-wall heat recovery steam generators, which will be used to recover the gas power plant’s waste heat and improve its efficiency.

The company used its own Demag® CC 3800-1 lattice boom crawler crane as the main crane for the job. “After considering the load weights and the required performance characteristics, it became clear that only a crane in the 650-ton class would be able to get the job done. And the reason we ended up deciding on the Demag CC 3800-1 was that it met every single requirement better than all other machines, not to mention that we’re very familiar with its high reliability and incredible capabilities,” Al Faris founder and Managing Director Hilary Pinto explains. It took a seven-person setup team made up of a crane operator, a supervisor, and five assembly technicians 20 hours to set up the crane with an SSL resp. SWSL configuration. “That really was a pretty amazing feat by our people. After all, the 66-meter-long boom couldn’t be assembled on the ground due to the SSL configuration and the limited space available, so they had to do it at height,” Hilary Pinto says while praising his team. The project took a total of six months and consisted of transporting and setting up various power plant components, such as condensers, boilers, HRSG modules, generators, and tanks. To take care of this, Al Faris used a whole armada of special-purpose vehicles, including hydraulic trailers and various all-terrain and crawler cranes.

Main lifts with SWSL configuration

The heaviest and most challenging lifts by far involved the 28-meterlong heat recovery steam generators, which weighed up to 80 tons. These HRSG units had to be brought to a height of just under 60 meters at a radius of 40 meters so that they could be installed. To do this, the Al Faris team used an SWSL configuration with a 48-meter main boom, a 36-meter fly jib, a Superlift counterweight of 165 tons with a radius of eleven meters. For the 16 lifts, the Demag CC 38001 was assisted by a 250-ton crawler crane from Al Faris’ fleet: The latter

picked up the heat recovery steam generators from one end so that the CC 3800-1 would be able to bring them to a vertical position. After this, the 250-ton crane “unhanded” the load so that the CC 3800-1 would be able to travel under load with the corresponding HRSG unit and place it into the desired position.

A job well done

The Demag CC 3800-1 took about two months at the worksite to complete these 16 lifts, as well as all other lifts, with an SWSL configuration. “And in hindsight, the biggest challenge was the tight space conditions during setup, conversion, and disassembly. Handling the long boom components in particular really demanded a great deal of our team, but they were able to take care of that smoothly, and not in small part thanks to the crane’s ease of assembly,” Hilary Pinto says while praising both his team and machine.

Tandano,

Damien.Bizjak@tadano.com, www.tadanofaun.de/en/

YEARS

1981-2021

ANNIVERSARY

Management system certified in accordance with the requirements of ISO 9001 - ISO 14001 - OHSAS 18001

WAKE UP! GET BACK TO REALITY

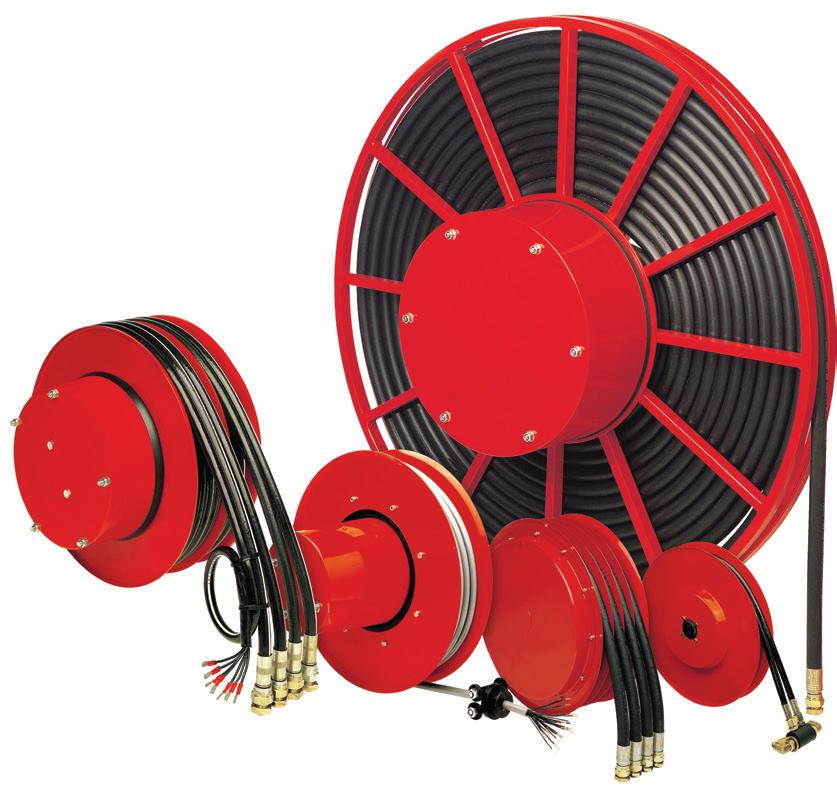

Dreams are not reel, it can be real.

DEMAC S.R.L. | MAGENTA (MI) - ITALY | +39 02 9784488 | INFO@DEMAC.IT | WWW.DEMAC.IT