The official magazine

LEEASA

MAY/JUN 2023 South Africa’s LMI shortage is impacting the lifting sector, raising concerns

for

(Lifting Equipment Engineering Association of SA)

Lifting Africa

Managing Editor: Surita Marx

Tel: +27 (0) 87 700 9834

Cell: +27 (0) 83 281 5761

Email: surita@liftingafrica.co.za

Web: www.liftingafrica.co.za

Editor: Xane Roestroff

Email: adverts@liftingafrica.co.za

LEEASA Editor: Kyle Graham

Email: kyle@leeasa.co.za

Sales: Lusana Merckel

Email: lusana@liftingafrica.co.za

Cell: +27 (0) 65 704 0003

Sales Assistant: sales@liftingafrica.co.za

Advertisers

and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication.

Lifting Africa - May/Jun 2023 3 Contents

Disclaimer: Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers LEEASA. The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility

Combilift, press@combilift.com,

Acrow CS Bell Equipment IFC BMG 39 Combilift OFC Cooper & Cooper Group 37 Demac 43 Foam and Upholstery Centre 21 Giovenzana 27 Golf day of the year invitation 41 HP Cranes Consulting 33 Igus 15 J Express 23 Kempston Controls 17 Kite 19 LEEASA OBC Liebherr Africa 13 LiftEx IBC Lifting Equipment Conference 7 Lifting Placements 11, 46 TVH Parts 35 Yale Lifting 29 New Combilift product launched 4 From the Chairman’s Table 6 2023 LEEASA Individual Members & Company Members in Good Standing 8 South Africa’s LMI shortage is impacting the lifting sector, raising concerns 10 Lifting and rigging solutions for lifting and moving wildlife 14 Safety is no accident 16 Delta-Q Technologies Commences Full Production of its 3.3 kW Battery Charger 18 How can you ensure your overhead lifts are safe? 20 Adapting and innovating in a changing market CS Enerpac JS-250 for Aertssen Cranes bridge deck installation 26 Borg Havn modernises port with all-electric LPS 420 E 28 At Certus Engineering Africa’s booming oil, gas and mining industries are good news 30 Cargotec and SSAB partner to bring new zero-emission recycled steel to the cargo and load handling industry 32 Steinmüller Africa expands its plant and equipment hire services 34 What is a mechanical load brake, and why does it matter to me? 36 Modulift’s new CMOD spreader frame now lighter, stronger and half the price 38 Niftylift’s new HeightRider 17 All-Electric (HR17E) has won Product of the Year at the Hire Awards of Excellence 2023 39 Becker Mining South Africa and Verope Mining team up to supply mine winding ropes 40 How approaches to wire rope lubrication are shifting in South Africa 42 BUYERS GUIDE 44

www.combilift.com

New Combilift product launched

As leading forklift manufacturer Combilift continues its 25 years in business celebrations, this week saw the launch of another new model truck, this time at Ligna, the international timber and woodworking show.

The new Combi-CB70E is a further addition to Combilift’s ever growing range of electric models which offers powerful performance, extensive battery life and unrivalled ergonomics.

This model, in the vibrant Combigreen livery first seen on the recently launched Combi-CUBE product, boasts the distinction of being the shortest 7t capacity counterbalance truck on the market whilst also benefitting from multidirectional ability, enabling the versatile space saving handling of both long and bulky loads.

Design features incorporated into the high-capacity Combi-CB70E such as its large super-elastic tyres and compact wheelbase make it ideally suited for the operational demands of the timber industry. With a 7,000kg/15,500lb lift capacity, this model benefits from an impressively small footprint as well as exceptional manoeuvrability meaning that it can easily move bulky loads of timber around in confined spaces. Occupational health and safety requirements

mean that the welfare of the workforce has become ever more important over the years. Drivers of industrial vehicles, who are often required to spend extensive periods in their workstations, quite rightly expect the highest levels of comfort and safety. Combilift’s designers have therefore gone to great lengths to ensure that the latest generation of models are kitted out with top quality components that ensure sophisticated ergonomics for a stress-free in-cab environment. Features in the spacious cab include generous glazing for excellent allround visibility, the tilting steering column, hydraulic steering and the Grammer MSG65 seat.

What sets the Combi-CB70E apart from other forklifts is its gas strut suspension cab, which uses components such as those found in large scale industrial machinery with cab suspension.

Combined with the super-elastic tyres this guarantees the smoothest of rides over uneven or less than perfect ground conditions such as those typically experienced in

lumber yards. Combilift’s newly developed Auto Swivel Seat was also premiered at the Ligna show. This optional feature automatically engages and swivels the seat and armrest 15° to the right or left to accord with the direction of travel selected by the operatorreducing driver strain, particularly when travelling in reverse. (Patent Pending Application No. 2305983.5)

The truck also features Combilift’s internationally patented and Red Dot awarded independent electric traction which provides all front and rear drive wheels with 100% traction control. This negates the need for differential lock on slippery surfaces and significantly reduces long load momentum twisting when travelling sideways. Each electric drive incorporates parking and regenerative dynamic braking for power efficiency. Roll-out access for major electrical components also simplifies maintenance tasks. This mix of next-gen performance, extensive battery life and exceptional ergonomics combined with all the advantages of the Combi-CB range, makes this the most powerful compact electric multidirectional forklift to date.

Combilift CEO and Co-Founder Martin McVicar said: “The increased capacities that we are offering in our electric range will answer the demand for ever more powerful products which at the same time help companies to achieve their aims for more sustainable operations.

We chose Ligna as the platform for launching the Combi-CB70E due to its innate suitability for customers in the timber sector, but we are confident that this model will be a popular addition to our portfolio for many other industry applications.”

Combilift, press@combilift.com, www.combilift.com

4 Lifting Africa - May/Jun 2023

COVER STORY 4 Lifting Africa - May/Jun 2023

CHAIRMAN’S TABLE

From the Chairman’s Table

As the year is flying by and we are already planning for 2024, I thought the below quote from Michael Altshuler is quite applicable: “The Bad news is that time flies. The good news is you’re the pilot.” That being said, we as LEEASA are reaching new heights.

We are excited to share that things at LEEASA are taking shape and that we are gaining momentum in various areas.

The new board of directors are hard at work to realise goals & expectations set in the beginning of the year in conjunction with a few new initiatives.

In the coming months LEEASA is looking to issue a few technical clarification guidelines & “one pagers” to its members and the lifting industry with the aim of standardisation & clarification.

These will include (but are not limited to):

• Testing & inspection of monorail beams

• Testing & inspection of Overhead Cranes & Hoists

• “What to do when there are discrepancies between regulations & standards”

• Relationships & collaboration channels between LEEASA, DEL, ECSA, SABS & other organisations

In addition, LEEASA aims to provide a regular “Safety Bulletin” on any significant events or occurrences within the lifting industry in the form of a short document that summaries key learnings, insights, and relevant recommendations.

The purpose of the above documents/guides are in line with LEEASA’s goal, i.e. to provide perspective, uplift and provide fast and accurate feedback to the lifting industry, for swift and relevant action.

In so doing, LEEASA aims to create a positive and value adding atmosphere for all stakeholders to share knowledge and insights.

Other events and activities to look out for and where you will meet the team include:

• The Big 5 Construct Expo, 27 - 29 June 2023

• Kwazulu-Natal Industrial Technology Exhibition - KITE, 18 - 20 July 2023

• LEEASA Confrence, 19 July 2023

• Annual Lifting Africa golf day, 15 September 2023

• Availability of new LEEASA sheave- fork wear gauges (July 2023)

• LEEASA Johannesburg Seminar, 4-5 October 2023

As always, we appeal to everyone who would like to reach out to any of the board members if you have anything to share, any suggestions or if you want to bring anything to our attention, as we strive to improve all lifting practices and the industry at large.

Feel free to reach out to the board members if the need requires.

Chairman: Ashley Davis | ashley@leeasa.co.za

Vice Chair: Andries Agenbag | andries@leeasa.co.za

Treasurer: Surita Marx | surita@leeasa.co.za

Ordinary Members: Kyle Graham | kyle@leeasa.co.za

Sandra Hurlimann | sandra@leeasa.co.za

Francois Weideman | francoisw@leeasa.co.za

Administration: Desiré Davis | admin@leeasa.co.za

Marketing: Xane Roestroff | production @leeasa.co.za

Yours in SAFE LIFTING, Francois Weideman and the rest of the LEEASA team

6 Lifting Africa - May/Jun 2023

Lifting Equipment conference Durban Exhibition Centre 19 July 2023 LEEASA is hosting a Lifting Equipment conference and ECSA members will receive 1 CPD point +27 (0) 79 658 5602 | admin@leeasa.co.za www.leeasa.co.za Invest in your business, visit KwaZulu-Natal’s Premier Trade show

2023 LEEASA Individual Members in Good Standing

Mr. Aaldrik Graham Kiewiet

Mr. Alan Victor Botha

Mr. Albert Anthony Freeme

Mr. Albert Olof Jansen Van Vuuren

Mr. Amogelang Gilbert Mmusi

Mr. Amos Tulela

Mr. Ananias Zhou

Mr. Andre van der Merwe

Mr. Andries Aucamp

Mr. Andries Gordon

Mr. Andries Josias Agenbag

Mr. Hendrick Rapule Mahuma

Mr. Hendrik de Jong

Mr. Hendrik Prinsloo

Mr. Henry Oswald Kerr

Mr. Hermanus Barend Dahms

Mr. Ian O’Hara

Mr. Imraan Moolla

Mr. Irvin Charles Murrish

Mr. Isidro Ernesto Fernando

Mr. Israel Mooketsi

Mr. Jacobus (Jacques) Mare

Mr. Nelson Chaita Moyane

Mr. Nicolaas Benjamin Smit

Mr. Nicolaas Theunissen Wynant

Mr. Nkosinathi Perfect Mbatha

Mr. Nkosinathi Richard Mavimbela

Mr. Noel Nyamukoho

Mr. Octovias Lebakang Mabelane

Mr. Pastor Noosi

Mr. Paulo Jorge de Freitas Marques

Mr. Paulus Stephanus Marais

Mr. Peter Abraham du Toit

Mr. George Cornelius Krafft

Mr. George Khehla Kuhlase

Mr. Gerhardus Jacobus Oosthuizen

Mr. Gert Vos

Mr. Given Nyathi

Mr. Glenton William Rebello

Mr. Graham Roy Twaddle

Mr. Happy Tafara Tati

Mr. Harris Naidoo

Mr. Michael Lionel Roberts

Mr. Milton Mhlanga

Mr. Mogakolodi Gregory Thamage

Mr. Mohamed Hoosen Dawood

Mr. Mthandeni Kunene

Mr. Mzinhle Leonard Sibenya

Mr. Napo Michael Noosi

Mr. Nathaniel Happy Sambo

Mr. Neil Naude

Mr. William Charles Palvie

Mr. William Henry Pepler

Mr. Wynand Byleveldt

Mr. Yogandren (Donny) Soobramoney

Mr. Zaheer Shameer Khan

Mr. Zenzele Siphamandla Ntshakala

Mrs. Ruwaida Mahomed

Mrs. Sandile Wyeth Mzimela

Mrs. Surita Marx

Ms. Lynda Lake

Lifting Africa - May/Jun 2023 9 2023 LEEASA Company Members in Good Standing “These records are up to date at the time of going to print” LEEASA: +27 (0) 79 658 5602 | admin@leeasa.co.za www.leeasa.co.za

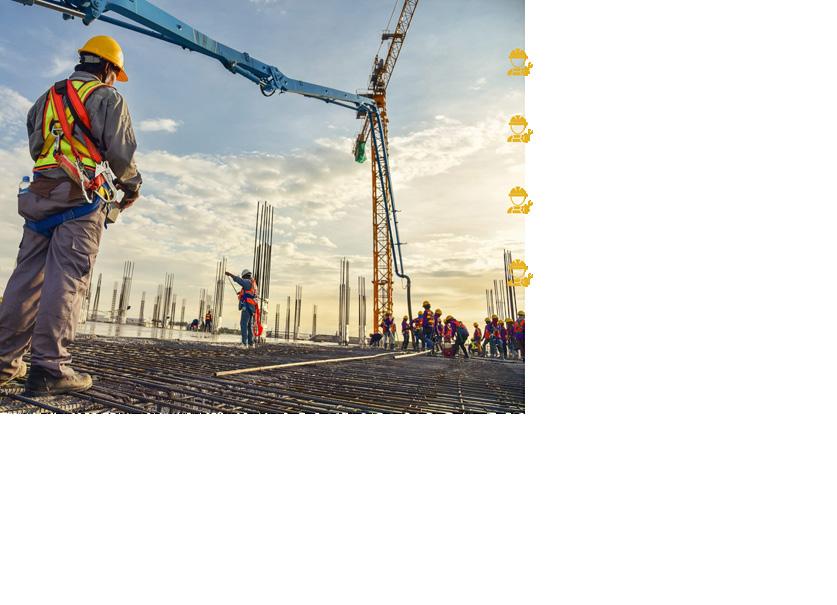

South Africa’s LMI shortage is impacting the lifting sector, raising concerns

Lifting Placements, the leading recruitment agency for Lifting Machine Inspectors (LMIs), recognises the pressing concern in the lifting industry caused by the scarcity of qualified and active LMIs across the country, emphasising the critical need for skilled professionals to ensure safety and compliance.

The Lifting Machinery Inspectors (LMIs) shortage is fast becoming a critical issue in South Africa, causing significant disruptions in the lifting sector and raising concerns about safety standards. LMIs are crucial in ensuring the proper functioning and safety compliance of lifting equipment, including cranes, hoists, and forklifts. The scarcity of these skilled professionals has created a challenging situation with potentially farreaching consequences. According to Surita Marx, the scarcity of LMIs is primarily attributed to a combination of factors, including an increasing demand for their services, a lack of qualified individuals, and limited training opportunities. As the South African economy expands, the construction and industrial sectors have witnessed a surge in lifting equipment usage. The need for LMIs to conduct regular inspections, certify machinery safety, and issue permits has skyrocketed.

“Unfortunately, the country’s capacity to produce and train LMIs has not kept pace with this growing demand,” explains Marx. “The rigorous certification

process and specialised training required to become an LMI restrict the influx of new professionals. Additionally, the lack of awareness about career prospects and limited incentives to pursue this profession further exacerbate the shortage.”

The impact of the LMI shortage is being acutely felt in the lifting sector, says Marx. “Construction projects, industrial operations, and logistics companies heavily rely on lifting equipment to perform essential tasks. Without timely inspections and certifications from LMIs, such equipment becomes risky, potentially compromising worker safety and causing costly delays. Construction sites have reported project setbacks and increased downtime due to the unavailability of LMIs, leading to financial losses for both companies and individuals.” Placing LMIs with companies has become increasingly difficult. “We are inundated with requests for LMI placements and simply cannot meet the demand.

10 Lifting Africa - May/Jun 2023

RECRUITMENT

10 Lifting Africa - May/Jun 2023

We must change the situation and drastically increase the number of LMIs in the country.”

Marx highlights the challenging landscape in LMI placement, attributing the scarcity of professionals to the rising difficulty in recruiting and employing LMIs. With limited supply and high demand, these specialists wield the power to negotiate their salaries, making them a costly but necessary investment for organisations in need of their expertise. “We are finding that many LMIs are calling their salaries and there is not much companies can do but accommodate these very high wages. This makes it extremely difficult for companies that cannot necessarily afford these very high and expensive professionals.”

A concerning consequence arises when companies, unable to afford the inflated salaries demanded by LMIs, are compelled to compromise by hiring individuals who may not possess adequate training or qualifications, ultimately risking compromised safety standards and potentially hazardous work environments.

The increasing demand for qualified professionals in the lifting equipment industry places significant pressure on recruitment services like Lifting Placements. However, as a trusted provider of specialised recruitment services exclusively for the lifting sector, Lifting Placements remains steadfast in its commitment to connecting employers with top-quality placements, ensuring the industry’s continued growth and success. “Our comprehensive and integrated approach focuses on matching talented professionals with rewarding career opportunities in various roles such as Lifting Machine Inspectors, Lifting Tackle Inspectors, Crane Technicians, Sales Managers, Technical Sales Engineers, and other essential positions that support the lifting sector,” says Marx.

Dealing with the challenges

Several industry experts that Lifting Africa spoke to highlighted the concerns raised by Lifting Placements. Most prefer not to be named for fear of retribution by authorities.

“The shortage of LMIs is particularly worrisome as the average age of these professionals is significantly higher than that of other trades in South Africa,” says one source. “This raises concerns about transferring valuable knowledge from experienced LMIs to the younger generation before they retire. Without proper knowledge transfer, the industry risks losing valuable expertise, which may harm safety standards.”

Adding to the challenges, many LMIs currently need to be in better standing with the Engineering Council of South Africa. Please uphold registration fees and participate in Continuous Professional Development (CPD) activities, required every five

years, which has compromised their status. This further exacerbates the shortage and limits the available pool of qualified LMIs. “While it is difficult to calculate the exact number of LMIs required to ensure legal compliance within South Africa due to the vast amount of lifting machines, the unconfirmed total of ECSA registered, active paid up LMI is 150 members with various categories,” says another source.

The industry highlights numerous challenges, from the need for dedicated plans evident from DoEL for the LMIs of the future to the lack of clear and concise guidelines and future development of LMIs.

There is also uncertainty around the process of LMI ECSA registration with regards to RPL versus existing National Qualification. “Currently, the process only provides the Recognition of Prior Learning (RPL). However, National

Certificate: Lifting Machinery Inspection (58496) is the following National Qualification there is. However, no ownership for the national mentioned above certificate and no recognition is given to this under the Merseta,” says another source. Following the Occupational Health and Safety Act 85 of 1993, Driven Machinery Regulation 18 (DMR 18), it is legally required to perform visual inspections and performance tests on all lifting tackle and lifting machines.

Trends that are overwhelming the industry are that “candidate” unregistered employees are doing the testing work and that this is being signed off by registered LMIs in the company that are acting as mentors. Some companies do this very well, following strict protocols, but in many instances, even untrained or poorly trained inspectors are sent out to do the work on behalf of the short-staffed LMIs.

Other employers are reaching out to try and train their future LMIs, but this is costly.

Dealing with the consequences

The ramifications are significant, says Andries Agenbag, LEEASA Vice Chairperson. The organisation has been working closely with the authorities and industry to address some challenges.

He says it is critical to highlight and increase awareness of possible career opportunities for LMIs in the industry. An in-depth interaction between DoEL, ECSA and LEEASA is also required to correct the current activity and bring the fierce registration and development plan into control.

ECSA is the registration body, but DoEL and LEEASA must form a solid alliance to change the process and ensure legal compliance and individual upliftment.

Many in the industry are also calling for a candidacy programme to be implemented to allow the beginner or less experienced group of practitioners to gain sufficient knowledge and experience to enable them to qualify or register as LMIs and, in that way, start their development program.

Lifting Placements, +27 (0) 87 700 9834, info@liftingplacements.co.za, www.liftingplacements.co.za,

12 Lifting Africa - May/Jun 2023

RECRUITMENT

Long, powerful and versatile!

The LTM 1230-5.1

The first crane with where the multi-award-winning VarioBase® support technology was combined with an asymmetrical support base – creating VarioBase® Plus. Allowing particularly high lifting capacities, especially at the rear working area, over the supports – calculated in real-time by the LICCON. Featuring an extremely long telescopic boom, this 5-axle crane sets new standards in terms of lifting capacity. Ideal for working with the boom fully raised and at large hook heights.

www.liebherr.com

Mobile and crawler cranes

Liebherr-Africa (Pty.) Limited Vlakfontein Road, Springs 1560 Phone: +27 11 365 2000 E-mail: info.laf@liebherr.com www.facebook.com/LiebherrConstruction www.liebherr.com

Lifting and rigging solutions for lifting and moving wildlife

BMG’s dedicated Lifting and Rigging division has been involved in important projects recently, including the lifting and moving of wildlife.

“A challenging task for the team was assisting a game farmer relocate three young giraffes from a game reserve in Nylstroom, to Kuwait,” explains Tanita RouselBrett, Tools & Equipment Lifting and Rigging, BMG.

“To make the move as comfortable as possible for the animals, we constructed a robust sling especially

for the project, using high-strength McKinnon chain, to load the crate holding the giraffes safely onto a truck. “Another project involved the design and manufacture of a sling to lift and move wildebeest from one enclosure to another.”

“Our team of specialists works together to provide solutions for any lifting or rigging challenge.

BMG’s broad range of quality branded equipment is enhanced by a technical advisory and support service, that ensures simplified, efficient and safe procedures in every application.”

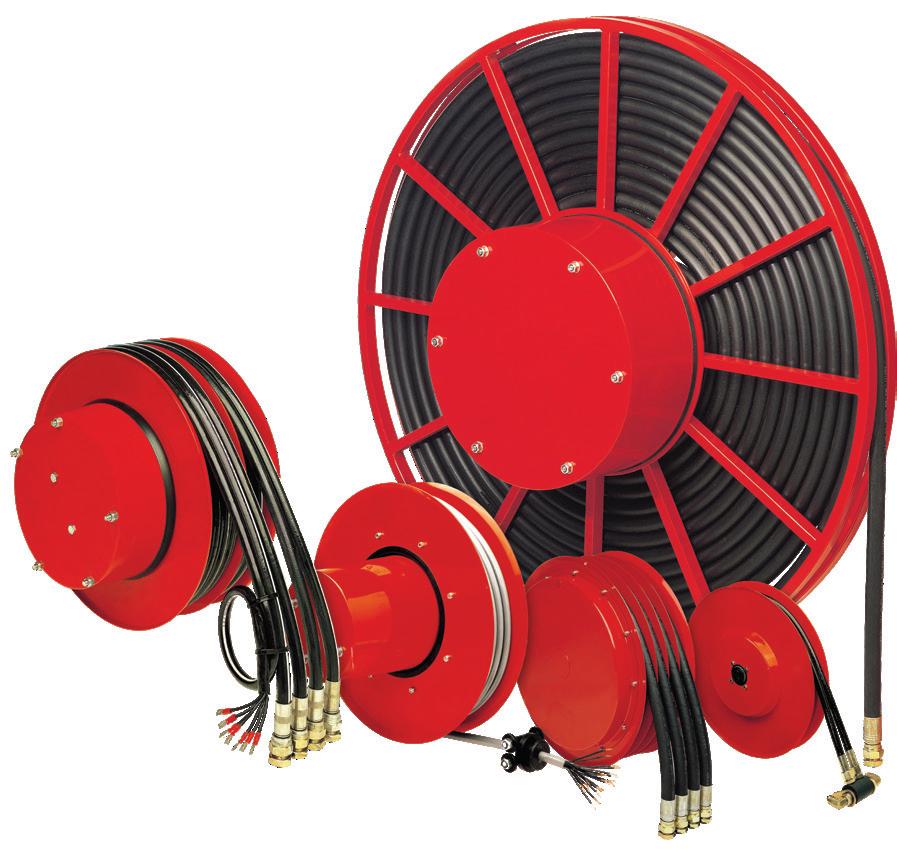

Included in BMG’s extensive range of tools, lifting and rigging equipment are electric, chain and lever hoists, geared and plain crawls, chain, wire and webbing slings and hydraulic, pneumatic hoists and winches, as well as manual Tirfor winches and ropes.

The range also comprises high-pressure hydraulic tools, mechanical ratchet jacks, jib cranes and eye bolts.

BMG complies fully with the requirements of the lifting machine and lifting tackle regulations of the Occupational Health and Safety Act (OHSA) Act 85 of 1993.

The company’s Lifting Machinery Inspector (LMI) is certified in terms of the Engineering Profession Act 2000 (Act no46 of 2000) and is a registered member of the Engineering Council of South Africa (ECSA).

BMG has approval from The Department of Labour in terms of

14 Lifting Africa - May/Jun 2023 LIFTING & RIGGING SOLUTIONS

the driven machinery regulations 18 (5) of the occupational and safety Act 1993, for examining and testing of lifting machines and lifting tackle. The company has a fully equipped trailer and is able to offer an onsite load testing service for customer convenience and peace of mind.

BMG specialists consider the safe operation of lifting and rigging equipment, as one of the most critical aspects in materials handling and recommended that customers’ equipment is independently load tested annually, or as per urgent requirements and inspected every three months.

BMG’s Tools & Equipment Lifting team offers a specialist service to diverse sectors throughout Africa, including automotive and tyre manufacturing, paper and pulp, sugar, forestry and agriculture, as well as marine and mining.

BMG, +27 (0) 11 620 7467, tanitar@bmgworld.net, www.bmgworld.net

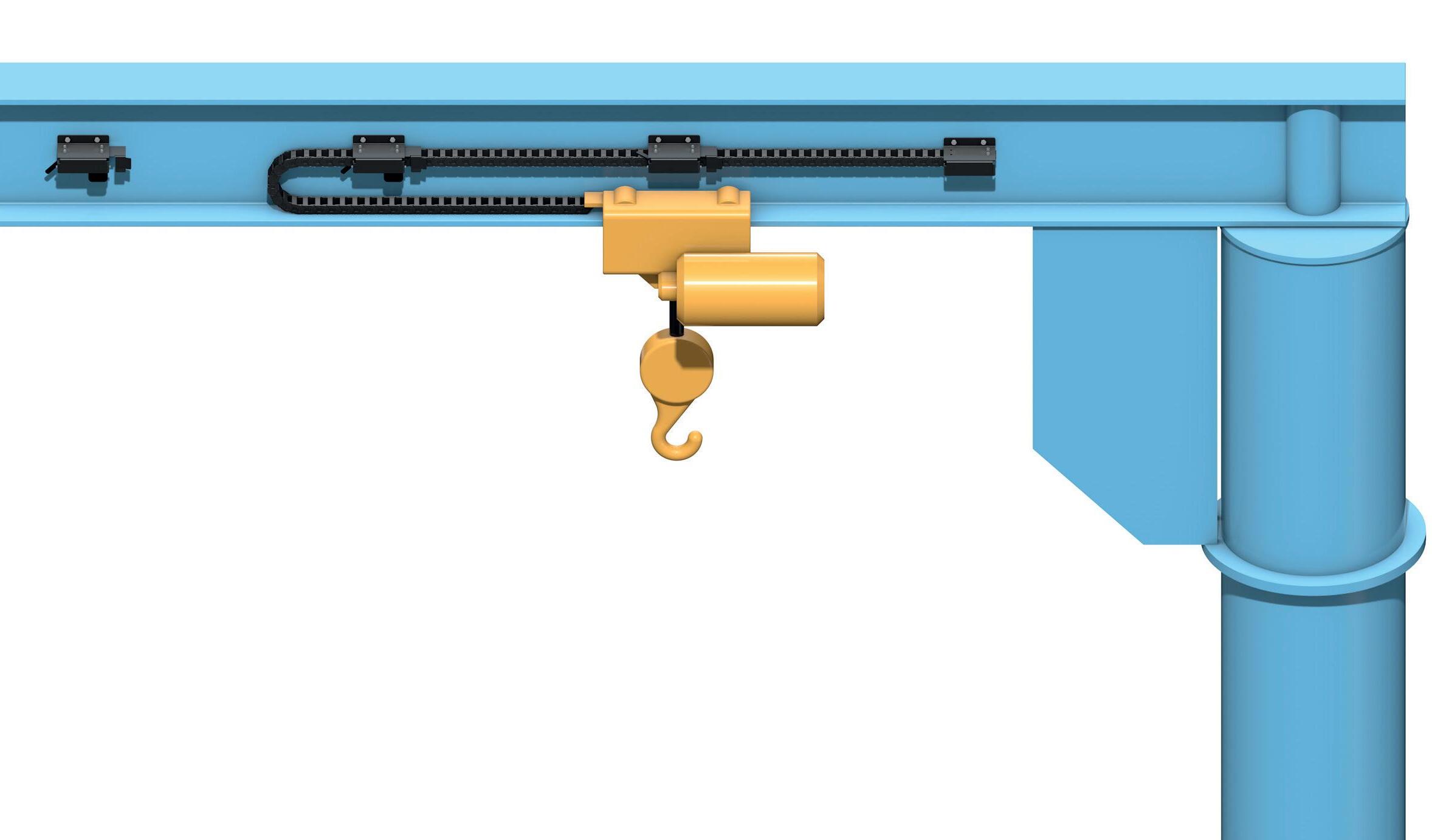

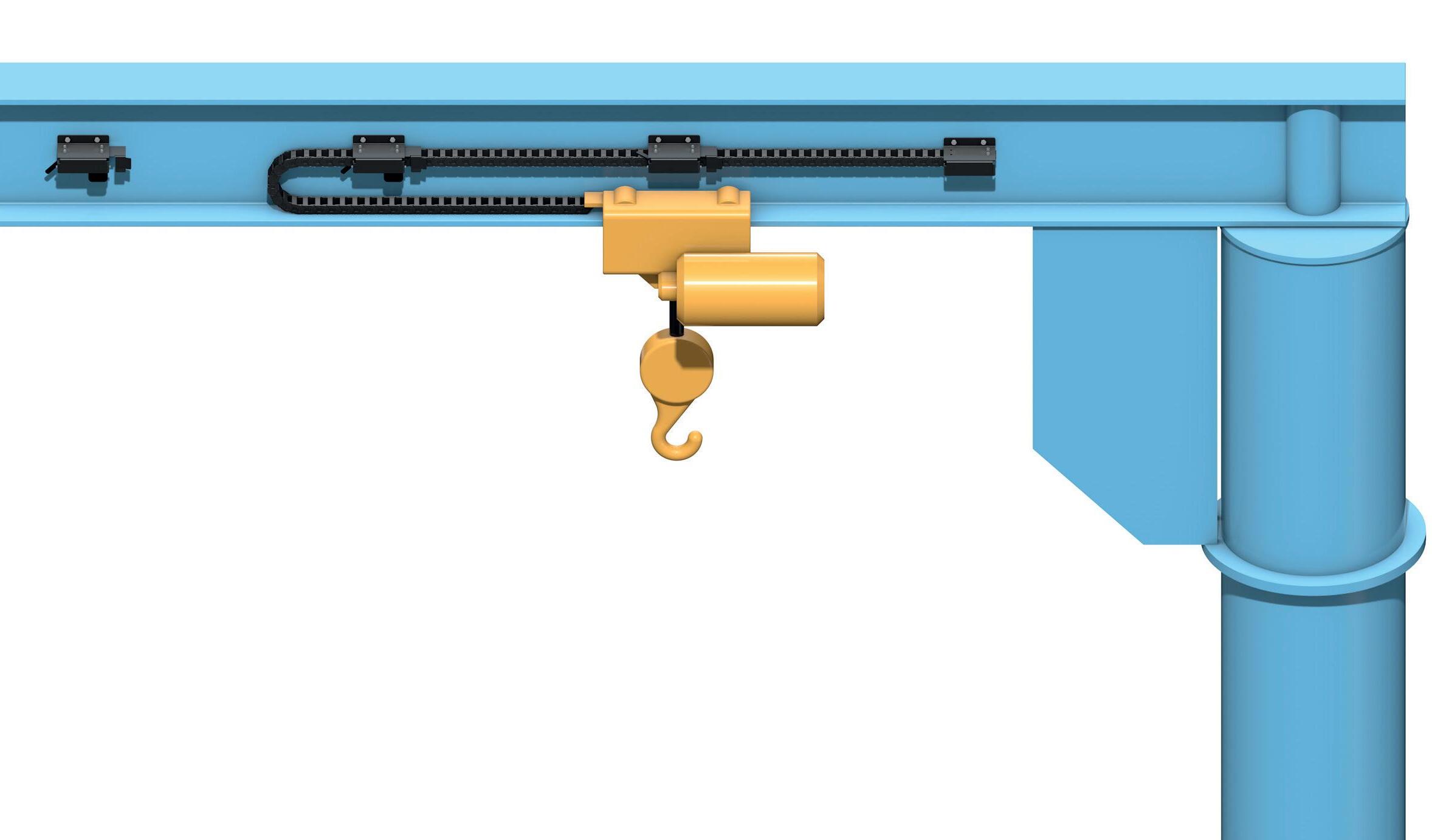

The cable carrier guidelok swing GLO.S increases the safety in the operation of swing cranes. The cost-effective alternative to cable loops reliably protects the cables and thus prevents them from getting tangled and tearing off. The space-saving system thus ensures increased system availability and reduces downtime costs.

Lifting Africa - May/Jun 2023 15

of festooning Secure energy supply for slewing cranes up to 10 metres travels. No more cable loops motion plastics® ... improve what moves Tel. +27-113121848 za-sales@igus.net

Fast assembly instead

LIFTING & RIGGING SOLUTIONS

Safety is no accident

Occupational health and safety in the material handling industry is critical, with the safe operation of forklift trucks being integral to its success. Regardless of its costs, it must become an industry standard.

The goal - zero harm

According to Dawn Van Dyk, SHEQ Manager at CFAO Equipment SA, the majority of accidents are due to a lack of proper training, licensing, and human behaviors.

“Material handling equipment predominantly operates in reverse, resulting in reduced visibility for the operator. Coupled with this, many warehouse and logistics spaces do not have demarcated areas for pedestrians to walk, with many having to walk between machinery and racks. This increases their potential risk for injury, with the majority of accidents the result of collisions between forklifts and pedestrians.”

In addition, operators are often incentivised to increase their productivity. With this comes working at speed, which can result in them picking up bad habits, including driving outside

of designated routes, not wearing seatbelts, not remaining in the cage when accidents occur, turning while the load is still in the air and trying to take sharp turns at speed. These can lead to the tipping of the forklift, racking being hit, the potential damaging of equipment and goods, and increased risk of injury to the operator and those nearby.

Setting high safety standards

As part of the greater CFAO Group, CFAO Equipment SA abides by Toyota’s After Sales Service Evaluation and Certification (ASEC) standards - a program that ensures its dealers offer the best service in the industry, with an emphasis on safe working conditions.

From a technician's point-of-view, safety always comes first, with ASEC-certified technicians required to complete a compulsory risk assessment before beginning any job.

Their mobile mechanic system prompts the technicians on whether they have the correct PPE to perform the task, and if the area they are working in is level and

clear of obstructions. This ensures the technician is aware of the safe working procedures to do the job correctly, as well as highlighting the risks involved before starting the job. The company is passionate about operator training and has developed a fully certified operator training course to ensure that the operators at its customer’s sites have the relevant licenses and the best theoretical and practical knowledge to do their jobs efficiently and safely.

A new benchmark in forklift safety

As the distributor of Toyota Material Handling's diverse range of material handling equipment, CFAO Equipment SA believes the brand’s product offerings encompass all safety requirements for customers to efficiently and safely drive their businesses forward.

“Toyota Material Handling develops its products with safety first. The new 8FBE range of forklifts proves its worth as one of the safest and most productive on the market. Boasting a host of innovative technological advancements, the 8FBE comes equipped with

16 Lifting Africa - May/Jun 2023 FORKLIFTS

With the majority of accidents in the material handling industry attributable to collisions between forklifts and pedestrians, more needs to be done to reduce injuries and potential fatalities.

several safety features that bolster safety, performance, efficiency and productivity,” says Van Dyk.

Featuring the industry-first SEnS+ operator assistance system, the AI-powered camera system distinguishes between pedestrians and objects behind the forklift and notifies the operator with a buzzer and lights when a pedestrian is nearby. The system also automatically controls the travelling speed of the truck and prevents it from moving backwards.

While similar products exist, many require pedestrians to wear tags for the forklift to identify them, which is often not practical.

Unlike tag-dependant systems, the SEnS+ system can detect unspecified obstacles and pedestrians, making them particularly useful at logistics sites, which have unspecified movement constraints. Its exclusive System of Active Stability (SASe) - a system that monitors forklift operations - detects instances of instability, where the automated vehicle speed control and the turning speed control can actively adjust forklift speeds to reduce the chance of lateral tip-over.

“Adding to this, the Active Mast Function Controller senses and reacts to instability by limiting mast angle and speed according to the load's height and weight, while the Active Steering Synchroniser ensures that the angle of the steering wheel corresponds to the angle of the rear steered wheels,” she comments.

By partnering with CFAO Equipment SA and its diverse range of Toyota Material Handling products, customers have the performance and agility they need to adapt to the ever-changing industry.

The future of forklift safety

“We are seeing large multinationals become increasingly safety conscious and we anticipate they will lead the charge in acquiring technological innovations that will help them achieve their safety goals,” remarks Van Dyk.

“Operator monitoring will become increasingly important, where the industry could harness technologies such as in-cab cameras like those used in the trucking industry to monitor operator fatigue, amongst others.”

Safety is a measure of success in

the material handling industry and one which CFAO Equipment SA regularly promote during on-site customer workshops. Highlighting the implications of not promoting safety and understanding how it can affect businesses and their employees, will be the deciding factor in ensuring that more industry stakeholders make the necessary changes to their operations. Prevention is better than a cure, and in the material handling industry, it can truly mean the difference between life and death. And this is why CFAO Equipment SA is committed to the safety-first principle of Anzen.

CFAO Equipment SA, +27 (0) 11 395 0600, info@cfaoequipment.co.za, www.cfaoequipment.co.za

Lifting Africa - May/Jun 2023 17 CHI Improved Service, Communication and Pricing ...and much more. Hunting Tooth Limit Switches Speed Responsive Switches Heavy Duty Switches Relays & Contactors Cam Switches Brakes T: +44 (0)1407 762888 E: holyhead@kempstoncontrols.co.uk

Manufacturing FORKLIFTS

The Legacy Lives On With Kempston Controls

Delta-Q Technologies Commences Full Production of its 3.3 kW Battery Charger

The XV3300 battery charger is a 3-in-1 on-board charging system offering stellar performance and features, suited for non-road mobile machinery

Delta-Q Technologies (Delta-Q), a leader in battery charging solutions for electric vehicles and industrial equipment, has announced that its innovative mid-power charger, the XV3300, is now in full-scale production. With its unique 3-in-1 design, this highly efficient charging system integrates a 3.3 kW battery charger, a 500 W DC-DC converter to power the vehicles’ auxiliary loads, and an EV charging station interface.

These key features, encased in a ruggedized IP67 design, provide OEMs with an attractive package for simplifying electrification of their off-road applications.

“No other 3.3 kW charger on the market also includes a DC/DC converter for auxiliary DC loads and an EVSE charging interface in such a compact size,” said Mourad Chergui, Senior Product Manager with Delta-Q. “As we start fullscale production, we can begin to fulfill the substantial demand we received since we first announced the initial development.” The 3.3 kW charging solution is available in

58.8, 65, and 120-volt DC models and is scalable, allowing OEMs to stack up to three chargers for power levels up to 10 kW. The XV3300 uses complex algorithms to deliver a precise charge to batteries of various chemistries and voltages, maximizing battery life and optimizing charge time.

Key features and benefits of the XV3300 charger include:

• High Reliability: The XV3300 battery charger is compact, rugged, and IP67-rated. It is tested for automotive-grade shock and vibration. Its fully sealed aluminum die-cast enclosure protects the charger from dust, liquids, and the effects of immersion in up to one meter of water.

• Enhanced Protection: The XV3300 is a low-voltage charger that optimally charges all battery chemistries and nominal voltages between 48 V to 120 V. It is also protected against short circuits, over-voltage, and over-temperature to ensure safe operation.

• Flexible Power Options: The XV3300 is scalable and can be

paralleled to provide between 3.3 kW to 10 kW of power for fastercharging options. The charger is also available as an on-board and off-board charger, providing OEMs with additional flexibility.

• Integrated DC-DC converter: It provides auxiliary power to operate vehicle accessories such as air-conditioners, controllers, lights, turn signals, navigation, and communication devices. It also eliminates the need for an external DC-DC converter, saving OEMs and equipment operators space and cost.

• EV Charging Station Interface: The XV3300 complies with SAE J1772 (levels 1 and 2) and IEC 61851 (modes 2 and 3) to charge from standard EVSE AC charging stations across North America and Europe. This feature provides end-users more charging options and greater vehicle flexibility.

TVH Parts, +27 (0) 11 281 2700, sales@tvh.com, www.tvh.com

18 Lifting Africa - May/Jun 2023 BATTERY CHARGER

How can you ensure your overhead lifts are safe?

From choosing the correct pick points for an off-center load to using the right rigging gear to protect both the load being lifted and those making the pick, there are many factors to consider before a lift.

What are some of the common causes for accidents and injuries when using cranes?

It’s usually one of two major problems that cause accidents and injuries:

• Arrogance • Improper connection

By arrogance, that means people think they know what they’re lifting, and what lifting specialists have found is many people do not.

For example, they may think a load weighs 20,000 lbs., and it turns out to weigh almost 30,000 lbs. Not knowing what they’re lifting is a hazard. You’re going to overload your crane, and potentially, cause damage to product and people.

Using a load cell or dynamometer is all about knowing how much you’re going to pick up.

The load cell will indicate how much weight you have on your hook. Strain gauge technology measures the microscopic strain on the body of the load cell.

Then, the results are converted into a pound, kilogram, kilonewton,

or metric ton reading. In terms of connection, that refers to how the load is attached to the crane. Using the wrong lifting devices or rigging hardware could have disastrous results.

Other issues

The length of a crane’s boom presents safety issues to everyone on a jobsite.

If you have an extremely high or long boom length, you’ve got extremely large loads and very little visibility. It’s very hard to know what’s happening. It’s very easy to make a mistake without the right technology.

How has technology advanced in recent years to improve crane safety?

For load cells, Crosby used to have mechanical systems that looked like a dial.

Think of a clock that’s gone from analog to digital. In the last 10 years, they’ve advanced to a wireless system that runs on 916.5 megahertz.

With their StraightPoint products, Crosby has gone to a 2.4 gigahertz system, which is extremely reliable and will transmit up to over a halfmile line of sight.

A load cell looks like a block of steel. It has strain gauges on the

inside with some electronics, and is powered by batteries. It’s basically a load cell, but in this industry, it’s called a dynamometer or a crane scale. The government calls it a LID, which stands for Lifting Indicating Device. In larger and newer cranes, load cells are built into the machines themselves.

What’s the advantage of having a separate load cell for larger cranes? Typically, an onboard load cell in a crane system is a pressure transducer mounted at a dead end.

It’s not nearly as accurate as putting a dynamometer below the hook because that’s going to give you your best:

• Accuracy • Repeatability

When you put a load cell below the hook, there are several questions that need to be answered:

• How do you know the onboard weighing system load cell is accurate?

• When was it last checked?

• What’s the accuracy?

In addition to its typical use, a dynamometer can be used to conduct load or proof tests with a crane.

Crosby has seen their load cells used for load testing or proof testing of:

• Hoists • Cranes • Slings • Ropes

20 Lifting Africa - May/Jun 2023

OVERHEAD

CRANES

• Custom fixtures • Spreader beams What Other Technological Improvements Have Been Made to Enhance Safety on Cranes?

BlokCam

Crosby’s BlokCam system is a sophisticated camera you can mount on a crane block to give the operator a full line of sight below the hook.

It looks at the load as it’s being connected. Also, instead of making blind lifts, operators have a bird’s eye view at the hook level of what’s going on below it.

In recent months, Crosby has developed a B6 battery, which is more powerful than the previous five versions. The newest B6 battery is lithium-ion based. It’s a fastcharging, longer-lasting battery. Typically, the battery’s going to last 10 to 12 hours now because of the lithium-ion upgrade.

Additionally, Crosby is looking at ways to improve the radio frequency signal. The BlokCam operates a 5.2 gigahertz radio frequency.

In the field, BlokCam has been added to blade tools in wind turbine construction. When crane operators are going to pick up a blade, they actually can see the pick.

The blades are marked, or they’re going to start to be marked again, where the lifting points are. Without these pick-point marks, there has been a lot of damage to blades during lifts. Unfortunately, blades have snapped when not picked up in the correct position.

Because of this, Crosby has started trials with some of the OEMs (original equipment manufacturers) to put a BlokCam on the blade tools, and also, for tower lifting. When operators lift a tower section onshore, there’s always someone in the tower underneath the load. Now, with a BlokCam system, the crane operator can make sure there is nobody directly under the load before lowering sections of the tower.

StraightPoint

With StraightPoint load cells, some of the additional features are in the accessories.

Crosby has a wireless light and alarm that can be used to let operators know if they’re overloading the crane. Also, there is an analog output system that’s wireless. Crane operators can take that analog output signal and have the results sent into a computer to help prevent overloads. There’s

a base station that has a built-in relay designed to prevent a crane overload.

This feature can work on any type of crane that has an electrical cutout.

How Can You Ensure Your Cranes are Used Safely and within Safety Regulations?

Any company that’s proactive on the safety side would actually encourage their people to have load cells. You want to know how much you’re lifting and help prevent any overload. If you don’t, you’ll likely wear out your equipment at an accelerated rate, including:

• Ropes • Sheaves

If you don’t know what they’re lifting, how do you know you’re not overloading it? In the overhead lifting world, you typically have a 5:1 safety factor.

If equipment is breaking, you’re exceeding the working load limit.

FOAM AND UPHOLSTERY CENTRE W e b b i n g a n d R a t c h e t S t r a p s C a m B u c k l e S t r a p s T r u c k , B a k k i e a n d C a r a v a n M a t t r e s s e s D o g L e a s h e s M a n u f a c t u r e d t o c u s t o m e r r e q u i r e m e n t s M o t o r T r i m m e r s U p h o l s t e r e r s

OVERHEAD CRANES

By using a load cell, you can see everything that’s happening, make any needed changes to improve your operations and prevent equipment wear.

Training courses are another way you can improve safety on your jobsites.

Properly training your employees is paramount to having a safe working environment. Companies doing training are proactive instead of reactive. As a result, they’re seeing significantly fewer accidents if you have a good training program, whether that’s something you do internally or they bring in outside companies to train their people. Additionally, you want to have a risk management analysis, too. Always understanding what risks are present and what can be done proactively to avoid those things will help keep people safe.

Unfortunately, however, lifting specialists have seen most of the decision-making is based on mistakes and issues, which is reactive instead of proactive. Remember, you can’t put a dollar amount on the ability to prevent injuries and / or fatalities.

How can companies become more proactive?

In the opinion of some lifting experts, using the content produced by manufacturers and distributors is one way to be more proactive.

A lot of people want to work safely, and product awareness often is the biggest challenge. Information

being available to consumers is the key. Crosby has dealt with operators with years of experience in the lifting and rigging industry, and they will ask, “Hey, how long have these products been around?”

Sometimes, people are genuinely shocked because they just weren’t aware the technology was out there. As more people are made aware of failed lifts, there’s going to be a push to avoid similar instances. What do Crosby and Mazzella do increased communication

Being able to see the load has helped communication increase. In addition to the camera, there is a microphone on the unit. If communication is down below the hook with the rigging crew, the crane operator still can be part of the conversation.

Remember, BlokCam is NOT meant to replace any of the existing communication or signaling processes. Hand signals still are critical in the crane world, and so are two-way radios. BlokCam is another tool the operator has to be able to operate safer. Think of it like the backup camera in a car. You can use it to help you view what’s behind the car, but you still have to use your mirrors to check other blind spots. Crosby has seen the same type of actions need to be taken by crane operators.

Field demos

In recent years, Crosby has been bringing BlokCam onto jobsites. With permission from operators,

Crosby has put BlokCam on their customers’ crane blocks, and then, let them use it. On more than one occasion, Crosby has put the BlokCam system on a customer’s crane and let them try it for a week. When going back to pick up the BlokCam after the trial period, Crosby has been told by operators, “No, don’t take that off. I need that because it does help provide additional information.”

What is the future of safety Technology?

As lifts become more complex, companies will continue to make advances in safety for the lifting and rigging industry.

Since The Crosby Group purchased StraightPoint and BlokCam, it has been considering different avenues to incorporate multiple levels of technology. That could include pairing a camera with a load cell and an alert system. Crosby has been asked by customers, “If a block’s coming down, can we add a laser? Then, it would actually count down 50’, 40’, 30’, 20’.” Obviously, that would help the operator obtain additional information instead of relying on a call-out signal.

Additionally, in order to provide a safer lift for specific applications, Crosby has been involved on projects, where it’s required:

• Product customization

• Combining the technologies of different products

Wind turbine work

In recent years, Crosby personnel in the United Kingdom did work with BlokCam on wind turbine construction. There were special applications involved which required a combination of technologies to maximize safety. Based in Spain, Crosby | airpes developed custom lifters and lifting devices for the wind industry. They make custom blade lifters, and Crosby incorporated a completely customized BlokCam to fit on the airpes blade lifter. It helped crane operators to combine those two technologies because they were able to see the load while installing the wind turbines. Before this unique solution, crane operators never had that capability.

22 Lifting Africa - May/Jun 2023

OVERHEAD CRANES

Canadian oil refinery

In 2022, Crosby had a “unique and exciting” opportunity in Canada, as operators were picking up an oil refinery module. They needed a custom fixture, and added 12 load cells so they could monitor the load at each pick point. Because the software was able to monitor up to 128 load cells at the same time, the operators saw all 12 load cells live. The engineer loved it because he was able to tweak each individual pick point so it had the correct load distribution.

This technology is so far advanced from where a lot of the industry was only a few years ago. It may take more time to get operators to adapt to using this equipment in the field. However, through case studies and marketing of real-life use, operators will see the value in new technology.

Verton EVEREST SpinPod

The Verton EVEREST SpinPod 7.5 is a load-orientation solution that allows you to have 360° control of the load under the spreader bar.

The Verton Everest SpinPod 7.5 (SP7.5) attaches to a spreader bar and applies torque moving the suspended load on its axis. The unit is battery powered and uses gyroscopic principles to transfer energy generated from the spinning flywheels into torque to orient the suspended load.

The flywheels (gyroscopes) can spin up to 3,000 rpm (revolutions per minute), generating enough torque to move loads between 25 and 35 tons (depending on the orientation and area of the load).

With the SP7.5, riggers can control the suspended load from a safe distance (up to 200 m), making lifting operations hands-free. This technology has been developed with the intention of removing operators from the danger zone. With the ability to control loads from a remote control, riggers are no longer required to be near suspended loads to push or pull a tagline.

Removing riggers from the vicinity of suspended loads is a significant improvement in safety in these very challenging and dangerous operations. Because they have a lot of technology, the SpinPod units are very expensive. However, Crosby is developing rental units and how they can test it in realworld applications with low costs to consumers.

Hardware

We offer one of the largest and

most complete inventories of rigging and lifting products in the country from some of the largest manufacturers in the world. Some of the products we stock are:

• Shackles—all types, sizes, and finishes from ¼ ton to over 1,000 tons

• Hoist rings—standard and metric

• Eyebolts—forged, metric, and stainless steel

• Hooks—swivel, eye, choker, selflocking, and weld-on

• Master rings / links—all sizes, types and finishes

• Turnbuckles and swivels

Tyler Henley, Mazzella’s national account manager for specialty ropes, and Wayne Wille and Denny Davis, The Crosby Group‘s business development managers.

marketing@mazzellacompanies.com, www.mazzellacompanies.com

Lifting Africa - May/Jun 2023 23

OVERHEAD CRNES

Adapting and innovating in a changing market

In the ever-evolving world of storage solutions, Acrow has emerged as a resilient and forward-thinking player, navigating the challenges of the market with agility and innovation. Lifting Africa sat down with Enrico Moya to learn more about the company's latest developments.

With an expanded product line and a consistent trajectory of growth in the dynamic South African market, Acrow repeatedly showcases its adaptability. The company's success in South Africa is a testament to its resilience and strategic foresight.

Last year proved to be a record-breaking year for Acrow, reflecting its solid performance amidst a potentially disastrous business landscape. While some companies struggled, Acrow's approach to being adaptable and flexible has served them well. By focusing on their community and taking care of their clients, the company has weathered the storms of the past few years and come out on top.

"We have always opted to take a proactive approach to challenges," says Moya. "There is no denying some serious challenges in the South African business environment, but for us, these offer opportunities to do things differently and better."

This approach has enabled the business to navigate through obstacles and emerge as a thriving entity.

"We continue to prioritise our customer-centric approach," explains Moya. "Whilst this has always been important in our line of business, it is critical in the current cost-saving and streamlining environment. We have also established ourselves as a reliable and trustworthy partner in the industry."

Product line investment

According to Moya, continuous efforts are underway to increase the product line. "In the current economic environment, the importance of companies like ours expanding and diversifying product lines cannot be overstated. With rapid technological advancements, changing consumer preferences, and increasing competition, we must stay ahead to remain relevant and thrive in the market."

Moya says by expanding their product lines, businesses can tap into new revenue streams, reach a broader customer base, and mitigate risks associated with relying heavily on a single product or service. "A diversified product portfolio also enables us to adapt to changing market dynamics, cater to evolving customer needs, and capitalise on emerging trends. Moreover, it also enhances brand loyalty, customer retention, and overall market competitiveness."

The retail sector, in particular, has been a significant source of ongoing and new business for the company. Acrow has been able to fulfil its customers' wildest imaginations by providing excellent consultation services and leveraging its advanced facilities.

"We have developed an interesting new cantilever for one of our clients, for example, that has gone down well in the market. For us, however, it is not about

STORAGE SOLUTIONS 24 Lifting Africa - May/Jun 2023

developing one product but finding the best solution to meet a company's needs. If that requires the development of a new product, then that is what we do. It is about a complete solution, however, and not just a product," he says. "A combination of factors determines success for us. Firstly, our excellent consultation service, our facilities, and, of course, a strong after-sales service. These are the differentiating factors."

Keeping up with market trends

The logistics industry has seen significant changes since the global pandemic in 2020. Nowadays, near-shoring has become an increasing topic of discussion, while the efficacy of the just-in-time approach has also been a much-talked-about phenomenon. "We are seeing an ongoing change in the logistics sector, which impacts storage and racking solutions," explains Moya. "Keeping minimal stock and outsourcing to third-party logistics providers, for example, seems to be an approach that is no longer favoured. This has boosted demand for more racking and shelving solutions as more demand in warehouses now holds more stock."

Moya says Acrow has always invested in technical capability and state-of-the-art equipment. "Our products have been developed over years while at the same time, we have ongoing investment in research and development to ensure we meet the changing environment and deliver the necessary products that our clients require." According to Moya, automation is one trend in South Africa that is gaining traction slower than the rest of the world. "In Europe, it is the current buzz force and a driving force in the manufacturing sector. In Africa, there are forms of automation happening, but it is not yet as large-scale as in the rest of the world." He says there are various reasons for this, including the challenges around electricity supply. "Infrastructure is by far the biggest challenge for our industry in Africa. When the power is cut for 12 hours a day, it becomes challenging to remain competitive with the rest of the world." But, says Moya, more and more companies are finding solutions to these infrastructural challenges, a testament to the resilience and agility of companies.

"One of Acrow's core values is to provide our customers exactly what they need no matter how challenging the environment we have to deliver that in. This approach has worked for us in the past and will remain our objective. We don't operate with just a standard price list for products. We bend backwards to meet our customer's needs."

Acrow, +27 (0) 11 824 1527, info@acrow.co.za, www.acrow.co.za

STORAGE SOLUTIONS Lifting Africa - May/Jun 2023 25

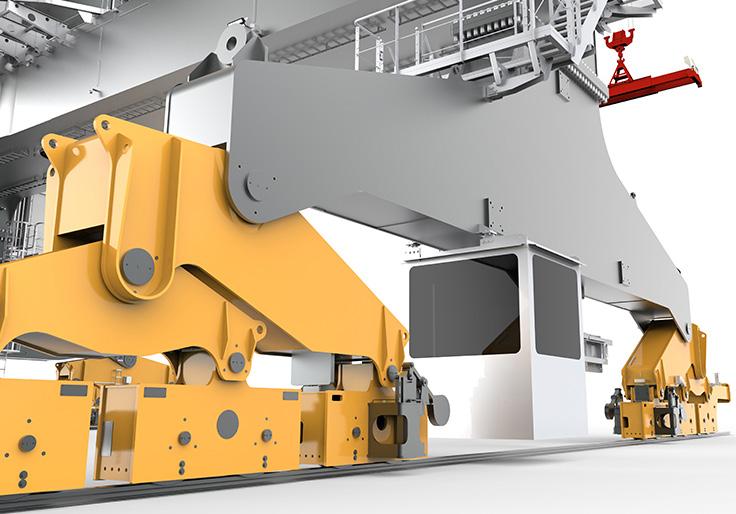

Enerpac JS-250 for Aertssen Cranes bridge deck installation

Antwerp based, Aertssen Cranes has completed the installation a new railway bridge for Eiffage Génie Civil in Laudun L'Ardoise near Avignon, France, using an Enerpac JS-250 jack-up system to raise the 220-tonne bridge deck for SPMT installation.

The stability of the jack-up lifting system enabled bridge installation preparations to continue uninterrupted even during high winds.

Measuring 24.80 meters long and 4.80 meters wide, the bridge deck was assembled on site resting on two header beams.

Working at ground level rather than at height ensured a safer working environment.

Aertssen Cranes was tasked with first positioning two abutments, each weighing 350 tons, and then installing the bridge deck, over a weekend.

The tight timing and compact construction site made the JS-250 jack-up system the most efficient lifting system.

The two JS-250 lifting beams were connected to the header beams supporting the bridge deck by round synthetic rope slings. It was then raised to 10m, raising

up the bridge deck to 7.8m.

A SPMT equipped with climbing jacks was positioned under the bridge deck. After lowering onto the SPMT, the deck was transported and installed on the abutments.

“The JS-250 jack-up system's small footprint makes it advantageous for use in a confined construction site like we had here,” said Manuel Aertssen, business development manager, Aertssen Group.

“At the request of the main contractor we needed to execute a test lift of all our equipment 48 hours before the final installation with SPMTs. Due to high winds, we were able to lower the bridge deck to a safer height without losing valuable time during the final installation preparations.”

The stability of the JS-250 jackup lifting system enabled bridge installation preparations to continue uninterrupted even during high winds that would not be acceptable, and cause delays, when

using traditional lifting methods with cranes.

JS-Series multi-point lifting system

The Enerpac JS-Series jack-up system is a multi-point lifting system comprising four jack-up towers, one positioned under each corner of a load.

The lifting frame of each jack-up tower contains four hydraulic cylinders, which lift and stack steel barrels.

The load is lifted in increments as barrels are inserted via an automated system and stacked, forming the lifting towers.

Managed by a single operator, each tower’s lifting and lowering operations occur simultaneously, while the jack-up’s synchronous technology maintains the balance of the load.

Enerpac, +27 (0) 12 940 0656, africa@enerpac.com, www.enerpac.com

26 Lifting Africa - May/Jun 2023 CRANE BRIDGE

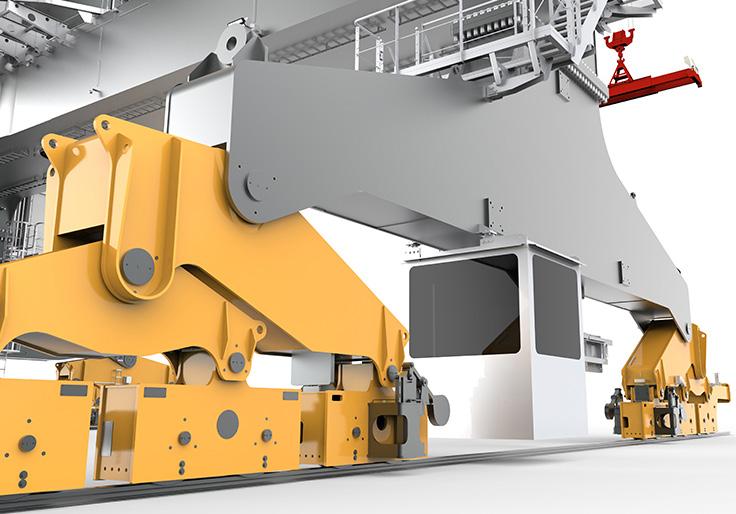

Borg Havn modernises port with all-electric LPS 420 E

To help meet its climate goals while offering multipurpose cargo handling options, Borg Havn has chosen the Liebherr LPS 420 E. The port’s investment in an electric infrastructure is the ideal foundation through which the crane will operate. The crane will be delivered fully erected by ship and mounted on the quay at Øra in Fredrikstad.

Borg Havn is investing in a new allelectric harbour crane. The Liebherr portal slewing crane will be the first of its kind delivered in Norway and exceeds the average turnover of comparable electric driven cranes in the market. All crane movements

like luffing, hoisting, slewing and travelling are done by electric motors. The LPS 420 E can be supplied with high or low voltage, depending on the transformer requirements. This ensures that Borg Havn can fulfil its logistical

operations while greatly reducing its environmental footprint. Paving the way for reduced emissions, benefitting from years of industry know-how

Borg Havn is a multi-purpose port which handles all types of cargo like containers, bulk, general cargo, and heavy lift. It’s the third biggest container port in Norway, with 67,249 TEUs in 2021, which is an increase of 14% from 2020.The LPS 420 E will be used for all types of operation and is the first Liebherr crane at the port.

The contract for the new crane was entered into in March 2022. “This is a large investment for Borg Havn,” says Port Director Tore Lundestad. “Renewing and modernizing our crane fleet in line with harbour activity is crucial to us. Among the main reasons for our investment in the LPS 420 E is its more environmentally friendly profile, which allows us to greatly reduce emissions and noise in the

28 Lifting Africa - May/Jun 2023

HARBOUR CRANE

area.” It is estimated that as much as 7% of greenhouse gas emissions from shipping occur while the vessels are completely stationary in the harbour. Life on board also needs electricity when the vessel is docked. The ships therefore have the auxiliary engines running to keep the systems running. Whether it’s light and heat or loading and unloading. The investment in shore power at the Port of Borg is an important measure to cut emissions and a contribution to reaching Fredrikstad’s ambitious climate goals. Borg Havn produces its own energy from solar cells which are connected to an internal grid.

The maximum output is 2 MW, which on sunny days powers all five cranes in the port with their own power in addition to shore power.

Based on the modernized electric infrastructure of the port, the LPS 420 E is equipped to provide optimal and safe operations. Thanks to the Liebherr active-front-end frequency converter, deviations in the voltage supply can be compensated easily for safe and stable operation. To accommodate potentially limited space and any

harsh environmental conditions, a liquid-cooled and highly efficient performance capacitor system was implemented. This Liebherr-built component, known as LiCaTronic, has proven itself in Liebherr ship-to-shore gantry cranes and material handlers. “We are proud to welcome to our Liebherr family such a new customer as Port of Borg. With our innovative LPS 420 E and outstanding customer service, we will support an ambitious target of Port of Borg and develop a new partnership for the future,” says Roman Chopyk, Area Manager for Liebherr mobile harbour cranes.

Top bulk turnover and container handling capabilities

The LPS 420 E raises the bar in terms of electrical driven bulk handling performance. A turnover of up to 1 ,200 tonnes per hour allows the new Liebherr electric crane to exceed the average turnover of comparable all-electric cranes in the market. With up to 30 cycles per hour, the LPS 420 E is the perfect solution when it comes to container handling performance. The crane can be fitted with various types of fixed or telescopic

spreaders on a 60-tonne load chart for twin-lift container operation. A maximum outreach of up to 48 metres allows for ships up to Panamax class size to be served. This makes the crane the ideal electrical driven solution for bulk handling – local emission-free.

The main components of the E-drive are liquid cooled and the heat is dissipated by heat exchangers.The fully closed liquid cooling system in combination with the heat exchanger are installed on top of the slewing platform.

According to this, no overpressure unit is necessary to prevent dust coming inside the machinery house, which is a big benefit for cranes working in a dusty environment. It is this overall combination of dynamic operation and environmental benefits that has made the LPS 420 E a suitable fit for Borg Havn.

Liebherr Africa, +27 (0) 11 365 2000, info.laf@liebherr.com, www.liebherr.com

Lifting Africa - May/Jun 2023 29

HARBOUR CRANE ASSET

ON-SITE

ENGINEERED

& INSPECTION MANAGEMENT SOLUTIONS

SERVICE & EXPERT TRAINING

PRODUCTS & SERVICES

t 011 794 2910 | e info@yalelift.co.za (general) | crm@yalelift.co.za (sales) | www.yale.co.za INDUSTRIAL

EQUIPMENT

Technology leaders in the development and production of innovative lifting and material handling solutions

HOISTING

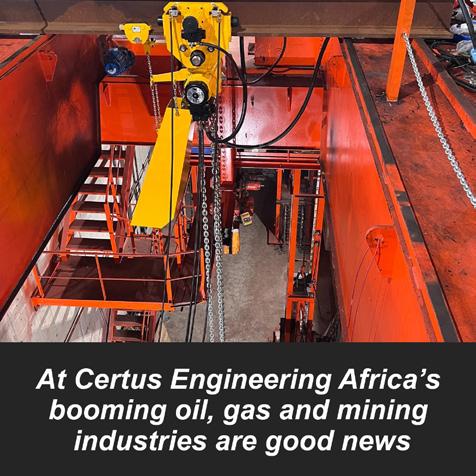

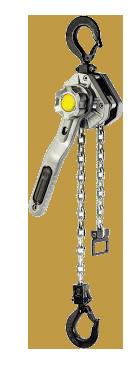

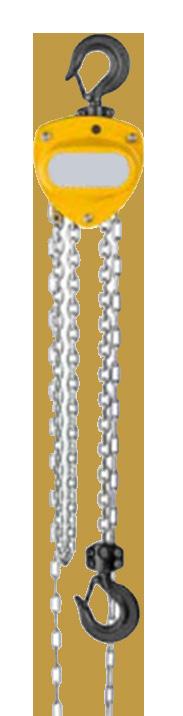

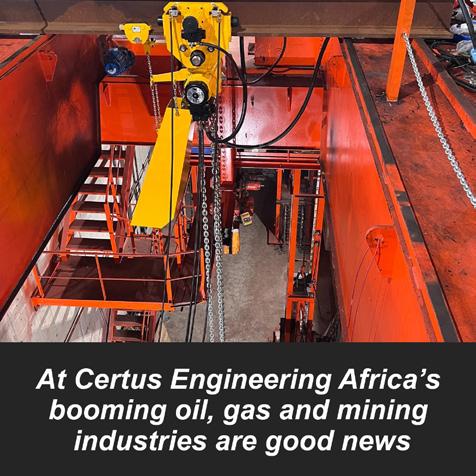

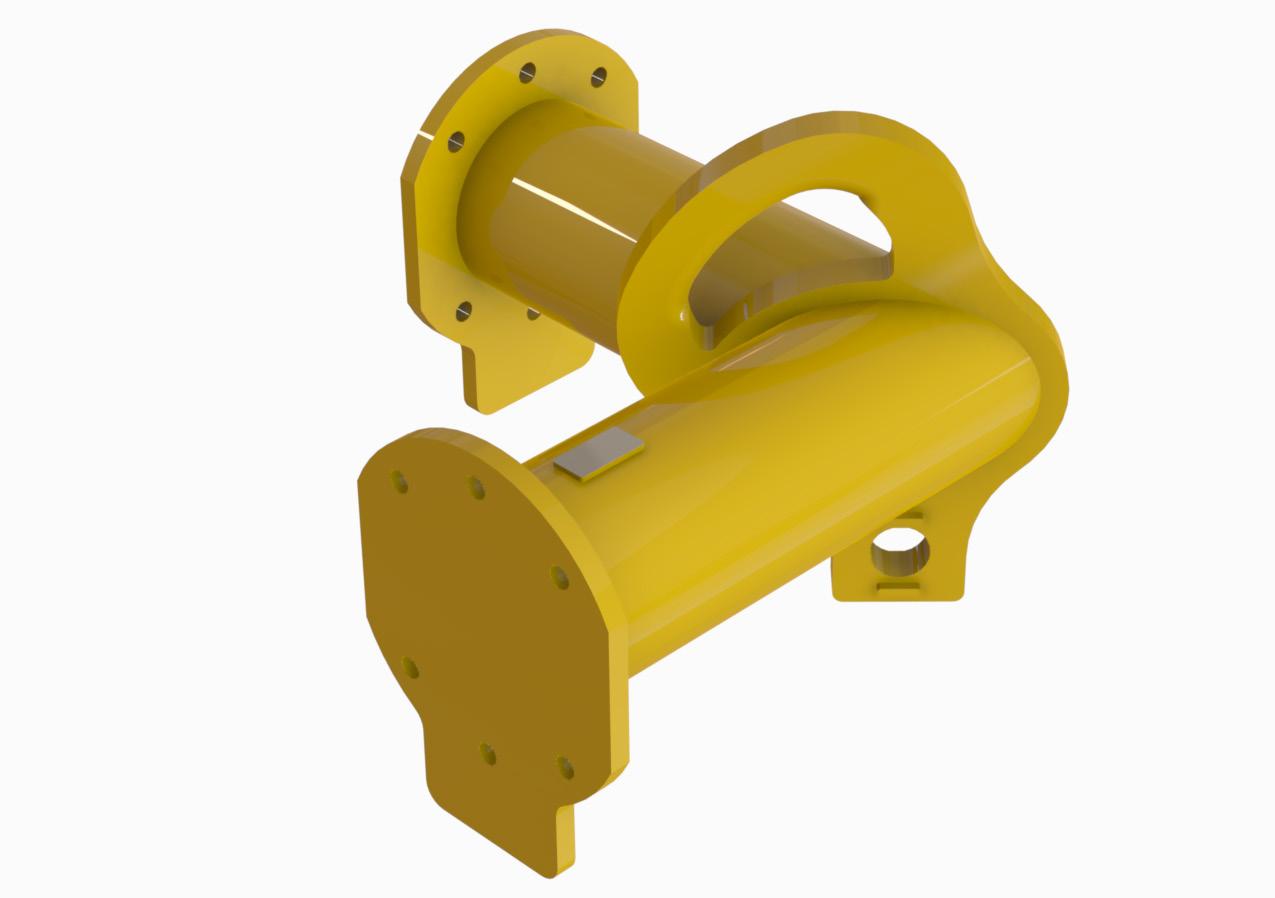

At Certus Engineering Africa’s booming oil, gas and mining industries are good news

Recent oil and gas discoveries in Africa, coupled with regulatory changes and fast-growing energy demand from markets around the world offer significant opportunities for the continent. Add in the booming mining sector and the picture is even brighter, especially for the lifting sector. Lifting Africa finds out more.

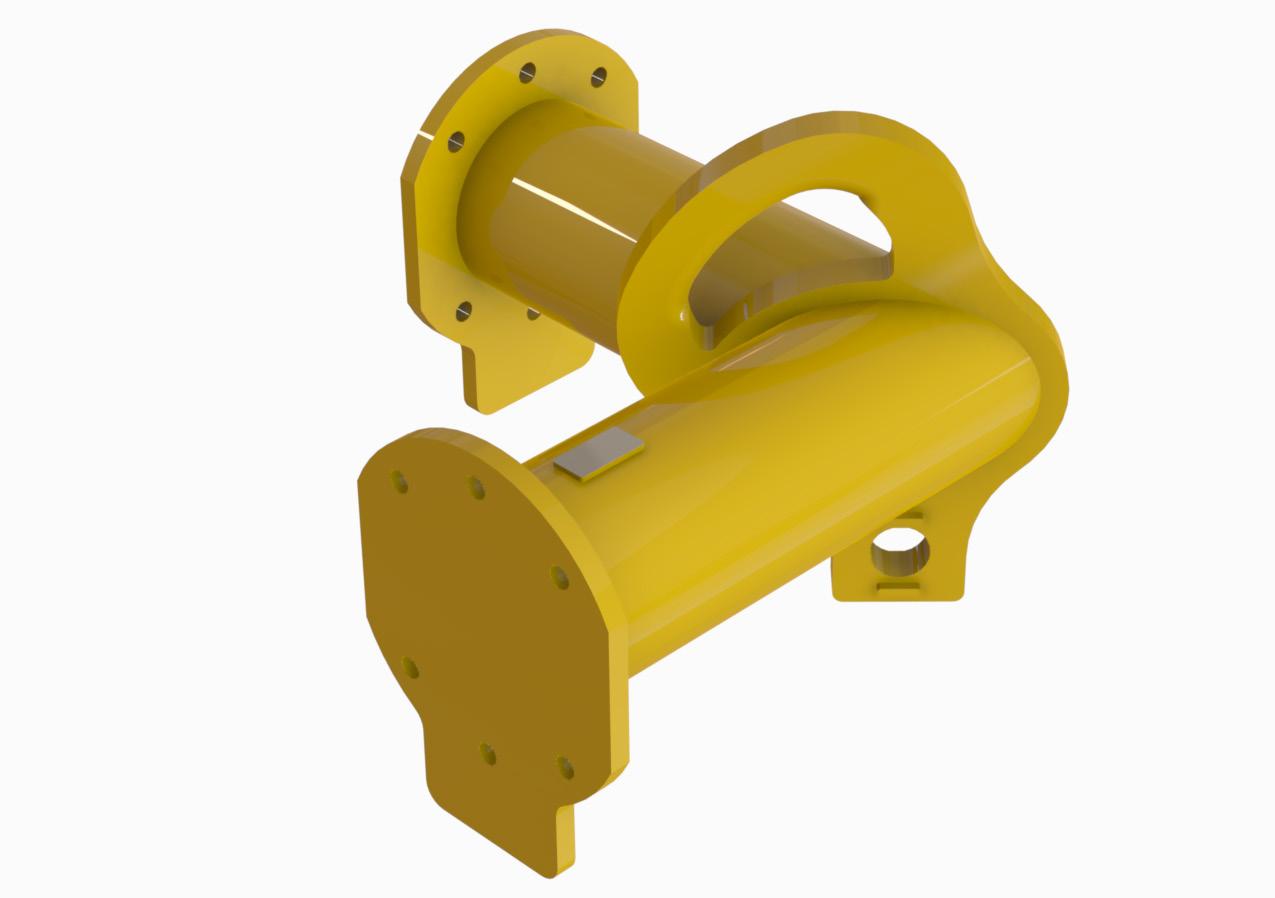

At Certus Engineering Africa’s booming oil, gas and mining industries are good news. This metal engineering company has been involved in the design and manufacturing of different lifting products since 2008.

“We offer a complete engineering service to solve lifting requirements,” explains Les Faber, who heads up Business Development at the company.

“We analyse and advise on rigging, planning and the design of custom-

made equipment. Certus-certified lifting products are manufactured to the latest international design standards and we meet country and industry-specific safety standards as well.”

The company is also an agent for hoist manufacturer Cheng Day which is headquartered in Taiwan. This company has been in the manufacturing business since 1971 and offers the Black Bear, U-Mega and Yong Sheng product ranges while also known for specializing in custom-designed bespoke manufactured products.

According to Faber, Cheng Day’s pneumatic chain hoists are particularly gaining popularity. Considered the best choice for hazardous areas particularly the growing oil and gas sector is being targeted.

More recently, the company has seen keen interest in pneumatic hoists from the mining sector.

“The air chain hoist generates power by using air instead of electricity which is different from traditional hoists,” explains Faber.

“The compressed air does not generate sparks and it is

30 Lifting Africa - May/Jun 2023

CHAIN HOIST

explosion proof, making it ideal for operations where chemical powder, inflammable or volatilizable material is involved.”

Covering Africa

Faber says the hoists are popular across Africa. Most recently, a pneumatic chain hoist was delivered to the Sukari Gold Mine in Egypt. With a lifting capacity of 16 tons and a lift of 20 meters.

“The hoist is ideal for operation in a harsh environment such as the case of a mine. Not only is it very robust, but also easy to use and maintain. The products are also extremely competitively priced.”

The capacity of the hoist is particularly significant, says Faber, as it is set to do some serious heavy lifting at its new site in the Egyptian desert. Sukari is Egypt’s first large-scale modern mine situated about 25km from the

Red Sea in the Eastern Desert. The landscape and climate are unforgiving and much are expected of equipment.

According to Faber, the hoist that is run off an I-beam was also fitted with Cheng Day’s unique balance trolley.

“This is to support the chain bucket so that the hoist can hang perfectly vertical when the bucket is empty and the hook at its slowest or when the chain bucket is full.”

The chain hoist trolleys can be adjusted to fit different beam sizes by simple relocation of the spacing washers to the inside or the outside of the frame. The drop-forged steel trolley wheels are also heat-treated and have precision bearings to provide smooth and easy travel. Considered to be extremely userfriendly the hoist is moved left to right or up and down with a

pendant control button. The hoist’s load chain is manufactured out of 16mm alloy steel and weighs nearly 6kg per meter bringing the weight of the chain alone to 342kg, says Faber.

The hoists are also manufactured to be impervious to contaminants such as dust – another benefit for the desert operating environment.

“Pneumatic hoists are also optimal to use in more remote environments because they are dependent on electricity,” he says. “With fewer moving parts they are considered to be of an extremely robust design which can lower some of the maintenance costs.”

Future outlook

Faber is bullish about the outlook for the lifting sector in Africa saying strong growth is considered. As demand for copper continues to rise the African mining sector is poised to see a considerate increase in demand. “In Mozambique, we are keeping a firm eye on the developments in the north where gas projects are expected to pick up again in early 2023.”

In 2021 Total Energies were forced to declare force majeure on their LNG project in Mozambique after attacks by insurgents linked to Isis. According to Faber, companies such as Certus are ideally positioned to service this growing market.

“We have the experience and capability to meet the lifting requirements of these industries whether they require customengineered lifting solutions or are looking for an internationally certified lifting tackle.”

He says the developments in southern Africa, including Mozambique and the southern DRC, boded well for South African manufacturers and agents. “We are very positive and believe that demand for air hoists will continue to grow especially in Africa’s growing oil and gas sector. Also, the mining sector continues to hold potential.”

Lifting Africa - May/Jun 2023 31 Certus Engineering, +27 (0) 11 316 6549, info@certus.co.za, www.certus.co.za CHAIN HOIST

Cargotec and SSAB partner to bring new zero-emission recycled steel to the cargo and load handling industry

Cargotec and SSAB are taking their partnership to the next level by introducing SSAB Zero™, a fossil carbon emission-free recycled steel, to the cargo and load handling industry. Cargotec plans to gradually start using this steel in its products this year.

The collaboration on SSAB Zero™ is a natural next step where Cargotec and SSAB continue their work together to reduce impact on climate in cargo and load handling solutions. The partnership has already resulted in the introduction of the world’s first load-handling equipment, a MULTILIFT hooklift, made with fossil-free steel. A prototype of this hooklift was unveiled by Hiab, part of Cargotec, in September 2022.

Approximately 26 percent of Cargotec’s total greenhouse gas emissions came from purchased goods in 2022. Decarbonising Cargotec’s supply chain is an important step in achieving the company’s ambitious sciencebased climate target, which is to reduce value chain emissions by 50 percent by 2030. SSAB Zero™ and, eventually, fossil-free steel will be key factors in this mission. “As a provider of cargo

and load handling equipment and solutions we are a major user of steel. Whenever possible, we give preference to materials with a smaller carbon footprint than traditional alternatives, and SSAB Zero™ provides a zeroemission and circular solution,” says Päivi Koivisto, Vice President Sustainability at Cargotec. “This is an important step on the journey towards fossil-free steel, and a great opportunity for Cargotec to grow its low and zero-emission offering.”

“We´re happy to welcome Cargotec as a partner also for SSAB Zero™ and look forward to continuing our joint efforts to reduce carbon footprints in the value chain,” says Thomas Hörnfeldt, Head of Sustainable Business at SSAB. “Demand for zero-emission steel keeps increasing, and SSAB Zero™ enables us to deliver more steel of this kind to our customers already

this year.” SSAB Zero™ has zero fossil carbon emissions (less than 0.05 kg CO2e emissions per kg steel in scope 1 and 2) in operations, including purchased energy and transportation. SSAB practises market-based emission factors for the electricity used and may secure fossil-free electricity through electricity guarantees of origin. Fossil fuels remain in the ground as SSAB has implemented a system to manage and ensure the correct source and use of alternatives connected to the production of SSAB Zero™.

Only recycled steel is used as a raw material, which means SSAB Zero™ supports the circular economy. Neither Cargotec nor SSAB engage in carbon emission offsetting activities.

Hiab, +27 (0) 11 865 1425, sales@hiup.co.za, www.hiup.co.za

32 Lifting Africa - May/Jun 2023 LOAD HANDLING

Tel: +27 (0) 11 740-9725/28/33

Email: donavon@hpcranes.co.za

Web: www.hpcranes.co.za

PRODUCTS & SERVICES :

Manufacturing and Modification of Cranes

Erection, Servicing & Load Testing of Cranes

Sling Inspection

Designing of Electrical Panels

Factory Maintenance

Supply, Installation of Standard & Specialized

Radio Control Systems

Hiring of Mobile Cranes and Load Test Weights

WE COMMIT OURSELVES TO:

A Service That Meets The Requirements of Our Clients

Provide Well Managed, Trained and Motivated Personnel

Meeting any Regulatory and Statutory Requirements

Applicable to Our Business

The Development and Maintenance of a QUALITY SYSTEM

Designed to Ensure Continuous Improvement and Meeting

The Requirements of SABS ISO 9001 : 2015

POWEREDBYFAITHINJESUS

CERTIFICATES AVAILABLE ON REQUEST :

: 2015

AGENTS FOR :

THE FOUNDER OF H.P

HENRY SPAMERS,

WITH HIS SON DONAVON SPAMERS WORKSDIRECTOR

CRANES

CEO

Henry And Debbie Spamers @craneshp @Hp_Cranes

HP Cranes

9001

Steinmüller Africa expands its plant and equipment hire services

Already a force to be reckoned with in the African power generation sector, Steinmüller Africa has taken its service delivery offering to the next level with its plant and equipment hire services.

Through its Middelburg Depot, the company has expanded its plant and equipment hire services, now offering a pool of over 24 000 items for clients in the power generation, petrochemical, chemical, mining, renewable energy, pulp and paper and general Industrial sectors.

To date the Middelburg Depot has handled plant projects in Sasolburg, Rustenburg, Newcastle, Richards Bay and Eskom power stations in Mpumalanga.

The plant hire division boasts a comprehensive range of equipment consisting of cranes, trailers, tractors, welding machines, generators, rigging, grinding and drilling equipment. “Through this depot, we are showing our commitment to supply our clients the best equipment for their project requirements, With this hire solution, they can get their projects up and running quicker while mitigating equipment ownership costs,” said Mpho Muvhango, Corporate Communications Specialist at Steinmüller Africa. Muvhango added that the company also offers expert advice to their clients on equipment selection

“We are committed to giving our clients the best quality customer service and ensuring that our high standards are upheld in all that we offer. Our team assesses our clients’ projects and their intended outcomes to provide them with a comprehensive solution,” she said.

One-stop-shop for plant and equipment hire services

Muvhango noted that, as a South African pioneer in the steam generation industry, Steinmüller Africa is a trusted turnkey partner to its clients. As such, this offering of plant and equipment hire further extends our one-stop-shop commitment to our clients. The division's offerings complement the company's overall customer centric approach.

All machinery hired from Steinmüller Africa complies with national safety standards and is issued with relevant safety certificates.

“We also have a dedicated Lifting Machine Inspector (LMI), responsible for all machines and lifting equipment which leaves the depot,” Muvhango points out.

Expansion of fleet to meet rising demand

The company has also simplified its equipment hire process. Muvhango pointed out that its equipment hire agreements are tailor-made to each client’s requirements, but are subject to availability. To deal with rising demand, the fleet of equipment stored at the Middelburg Depot was expanded to include several cranes ranging from 5 to 400 tons, as well as a wide range of trailers, tractors, welding machines, generators, rigging equipment and other construction tools.

Steinmüller Africa provides highly competent solutions and services for every phase of a power plant‘s life-cycle. In addition to the planning, maintenance and repair of complete power generation plants, the company also designs and manufactures power plant components, at its workshop in Pretoria.

Steinmüller Africa, +27 (0) 11 806 3321, mpho.muvhango@bilfinger.com, www.steinmuller.bilfinger.com

34 Lifting Africa - May/Jun 2023

HIRE

EQUIPMENT

CONTACT US KEEPS YOU GOING. TVH PARTS SOUTH AFRICA (PTY) LTD • HEAD OFFICE JOHANNESBURG 90 Electron Avenue • Isando • Kempton Park 1600 • South Africa • GPS S -26.130318, E 28.214541 T +27 11 281 2700 • F +27 11 392 3599 / +27 11 974 9845 • sales.southafrica@tvh.com • www.tvh.com DURBAN 17 Kyalami Road Westmead Pinetown 3600 T +27 31 100 0760 F +27 31 700 6191 LICHTENBURG Shop 1 103 Scholtz Street Lichtenburg 2740 T +27 18 632 6192/6092 F +27 18 632 6108 PORT ELIZABETH 220 Commercial Road Sidwell Port Elizabeth 6001 T +27 41 453 1404/8 F +27 41 453 1409 RICHARDS BAY Unit 3 Ferro Park 1 Ferro Gang Road • Alton Richards Bay 3900 T +27 35 751 1001 F +27 86 530 3145 CAPE TOWN 4 Buchan Street Stikland Industrial Bellville, Cape Town 7530 T +27 21 988 2432 F +27 21 988 9127 T +27 11 281 2700 sales.southafrica@tvh.com www.tvh.com F4 FULL ELECTRIC PALLET TRUCK AVAILABLE NOW

What is a mechanical load brake, and why does it matter to me?

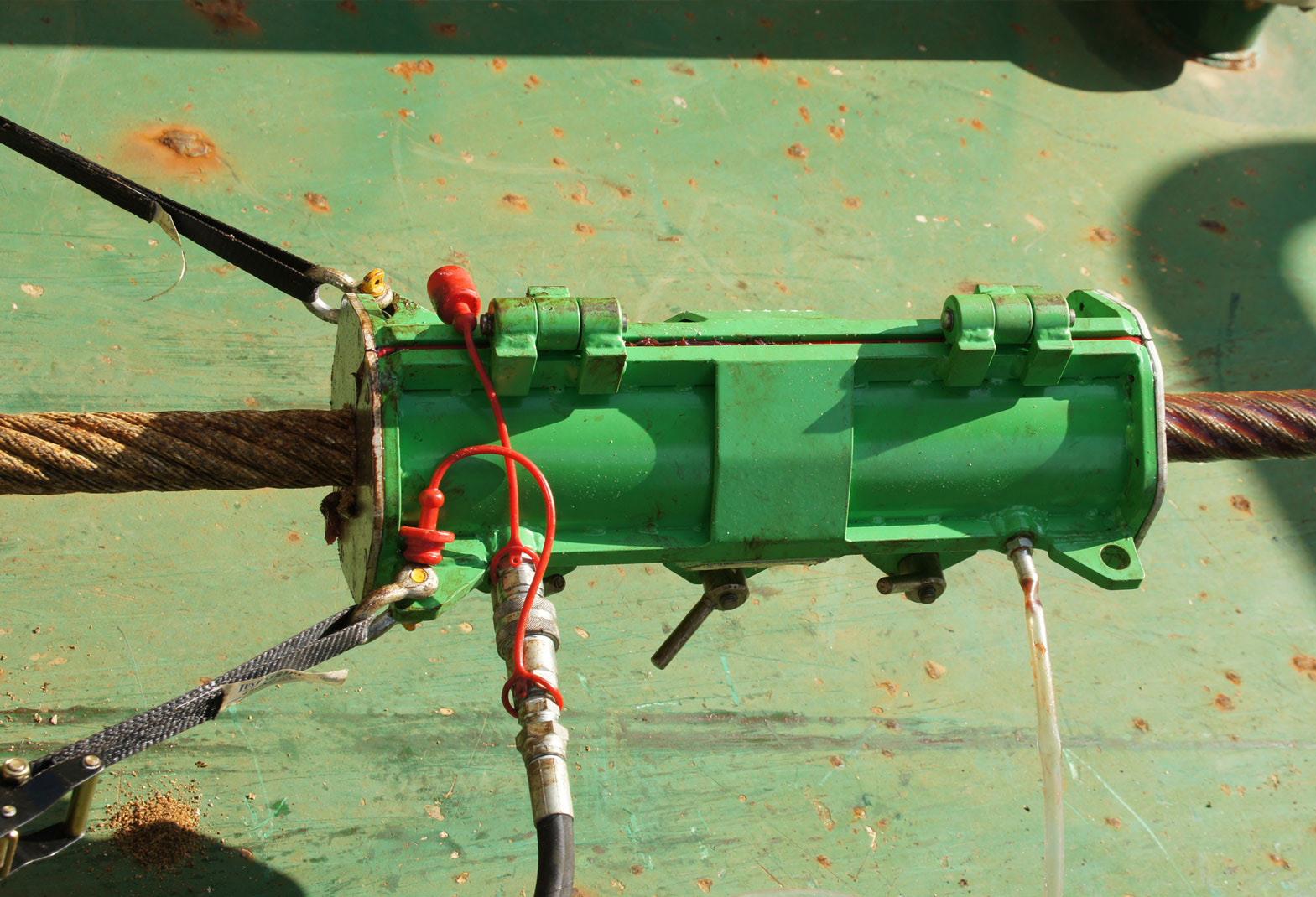

The mechanical load brake is a key component of crane safety. It serves as a secondary braking mechanism of the crane hoist, controlling the lowering speeds of rated loads and preventing loads from free falling. As an alternative, some cranes have an electrical load brake, which serves the same function.

In addition, the mechanical load brake is designed to assist the motor holding brake to hold the load in place when the hoist motor stops running, but if the holding brake should not set the mechanical load brake will stop and hold the load or at least allow the load to slowly descend at a controlled rate of speed.

All of the torque of a hoist motor is applied to lifting loads. In the lowering phase, however, gravity takes over, and the mechanical load brake is in place to counteract the gravitational pull for a safe, controlled descent of the load. As a secondary brake, the role of the mechanical load brake is limited, but is still essential for the safety of operators as well as the equipment. For this reason, regular inspections and maintenance are critical.

Maintaining load brakes

The best piece of advice for maintaining load brakes is to follow original equipment manufacturer (OEM) specifications. Maintenance guidelines vary from one OEM to another. Some require a teardown of the gearbox to permit a thorough inspection. Others call for an annual load test to check the functionality of the load brake – in some cases specifying a test at 25 percent of the rated capacity and others recommending at least an 80 percent load. I have also conducted near-rated-capacity load tests in

which the load is lifted just a few inches off the floor. With the load in this position, the holding brake – a disc brake or shoe brake – is manually released to see if the mechanical load brake holds the load or at least keeps the descent at a safe, controlled rate.

However, if the load freefalls, we know the brake is under capacity and will require a rebuild or a good cleaning.

Not following OEM recommendations can result in premature wear of your load brake. It is especially important to follow OEM instructions for changing the gearbox oil. Some say every six months, while others say annually. Some recommend using automatic transmission fluid. Others say 3040 or 80-90 weight gear oil. And some even require using extreme pressure (EP) additives.

Konecranes, +27 (0) 11 568 1701, Parts.ZA@konecranes.com, www.konecranes.com

36 Lifting Africa - May/Jun 2023

LOAD BRAKE

WE HAVE SOME THRILLING NEWS TO SHARE WITH YOU!

At Cooper & Cooper, we believe in pushing boundaries and redefining excellence