ENDORSED BY SAPMA, SAPSDA, SAVAMA AND VAMCOSA

MAR/APR 2021

Mine pump acceptance testing from the comfort of an armchair

If its not INVAL, it’s not Invincible

2

Pipes, Pumps and Valves Africa - Mar/Apr 2021

CONTENT COVER STORY Bray/McCannalok Valves improve safety and productivity in sugar mill evaporator

4

PIPES Plan and strategise with the experts

6

PUMPS Amid the uncertainty created around the world following the outbreak of COVID-19

8

KSB commits further investment into Namibia

10

Vesconite deflector protects 30% of pump value

12

COVID-19: Solutions that pump with value in the fight to flatten the curve

13

Bearings that solve NGL pump problems

14

Mine pump acceptance testing from the comfort of an armchair

16

VALVES Dynamic Fluid Control sees future in own valve designs AFS specialises in the design and manufacturing of slurry related valves

18

On the cover

20

Bray, +27 (0) 10 007 3222, stephen.leatherbarrow@bray.com, www.bray.com

Slurry valve specialists

22

Drop tight for decades – delivering quality valves for Africa

24

BEARINGS 10 Hydraulics tips you need to know

26

WATER “What water means to us” – Xylem’s shared mission to solve water

30

Skills, collaboration needed to overcome growing water challenges

34

Motheo saves a landmark billion litres of water in 24 months

36

PRODUCTS & SERVICES AF-E 400: new ultra-compact flowmeter for utilities and industrial automation

37

INDUSTRY NEWS Japan hands over water training centre to SA NuWater who we are?

38 40

Enerpac split-flow pump kits expand heavy lifting capabilities

42

BUYERS GUIDE

43

Pumps & Valves Africa

Managing Editor: Surita Marx Tel: +27 (0) 87 153-1217 Cell: +27 (0) 83 281-5761 Email: info@pumpsandvalves.co.za Web: www.pumpsandvalves.co.za Sales: Elma Heuer Email: Elma@pumpsandvalves.co.za Production Manager: Xane Roestroff Email: adverts@pumpsandvalves.co.za

Advertisers

Air & Vacuum Technologies 7 Billfinger 39 Bray OFC,35 Fluid Power Valve Technologies 23 IFAT Africa 33 Industrial Valve Summit IBC Invincible Valves IFC KSB 29,OBC Mine Track & Tools 21 Stelkon 11 Stewarts & Lloyds 15 Vega Controls 41 Verder Pumps 13 Xylem 17

Disclaimer:

Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers SAPMA or VAMCOSA The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication.

Pipes, Pumps and Valves Africa - Mar/Apr 2021

3

COVER STORY

Bray/McCannalok Valves improve safety and productivity in sugar mill evaporator Block valves for evaporators at one of the largest sugar mills in Colombia. Colombia is one of few countries where sugar production takes place throughout the entire year. This customer was investing in an Energy Saving Project for its evaporators, to block vegetable gases towards the warmup equipment. A total of twentyone replacement valves was needed to complete the project. Bray/McCannalok Valves significantly improved safety, protecting the lives of operation & maintenance personnel. Eliminating valve steam leaks resulted in reducing downtime and lower operating costs which resulted into reducing maintenance costs by more than 70 %. Saving space and weight with each valve leads to general plant improvements and worker mobility. Continous service is critical to the profitability of the plant — demanding reliable valve operation during the entire production cycle. Challenge Maintenance and cleaning procedures for evaporators require zero leakage sealing to prevent accidents. This sugar mill was using angle valves, which were presenting serious safety concerns and operational challenges. The angular valve design,

For over 30 years the reliability of the Bray/McCannalok has been conclusively proven, both in lab tests and thousands of field applications.

with three axes, allowed frequent steam leakage to the environment — endangering operator’s lives and causing significant profit losses. Leak repairs required stopping steam production, which was only possible twice a year — meaning known leaks could continue un-repaired for months. Other drawbacks of the angle valves include: • No indication of valve position, increasing the possibility of over/under travel. • Up to 3 mechanical operators were used per valve, requiring extra space and weight. • Specialized external service staff was required for annual maintenance. Solution The main objective of the sugar mill was to guarantee the safety and integrity of operations & maintenance personnel, without halting the steam production process. As cleaning and maintenance procedures were done every 15 days, high-quality, reliable valves with zero leakage were required.

Bray recommended the Bray/McCannalok Series 41R high-performance butterfly valve, which was designed specifically for the sugar industry. Key valve features for this application include: • Designed to handle steam applications, such as evaporators. • Lightweight & cost-effective. • Guaranteed zero leakage shutoff through more than 100,000 cycles. • Simplified field maintenance — requiring no specialized external staff. • Shared components with standard Series 41 valves reduced the need for special repair inventory. • Simple rotary automation, with minimal components required. Results

Double offset stem and disc design Offset from the Center of the Stem to the Center of the Pipe

Offset from the Center of the Stem to the Center of the Seat

The customer installed twenty-one Bray/McCannalok S41R valves in varying sizes, and to date, they have demonstrated excellent performance. During more than five years of operation, only one valve has required inline maintenance. Benefits of the Bray/McCannalok S41R valves over previously installed valves include: • Eliminated steam leaks. • Required only one gear operator, instead of the pevious three. • Space and weight savings simplified installation and maintenance. • Eliminated external staff requirements for maintenance procedures. The results have greatly improved plant operations, including: • Significantly improved safety — protecting the lives of operation & maintenance personnel. • Eliminated valve steam leaks — resulting in reduced downtime and lower operating costs. • Reduced maintenance costs by more than 70%. Saved space and weight with each valve — resulting in general plant improvements and worker mobility.

Bray Controls Africa (Pty) Ltd, +27 (0) 10 007 3222, www.bray.com

Plan and strategise with the experts A robust water management system is essential to build resilience against increasing demand on limited resources and the effects of climate change on the frequency and severity of droughts and floods. The Covid-19 pandemic has further weakened many water, sanitation and health (WASH) systems.

PIPES

The issue of water in Africa is a precarious one. The statistics are sobering. At least one in three people don’t have access to clean or safe water on the continent. It is estimated 115 people in Sub-Saharan Africa die every hour from diseases linked to poor sanitation, poor hygiene and contaminated water. About 66% of Africa is arid or semi-arid and more than 300 of the 800 million people in sub-Saharan Africa live in a water-scarce environment – meaning that they have less than 1,000 m3 per capita per year. In many African countries, more than 50% of the people are without access to a basic water supply which is a barrier to hand washing and hygiene, while the lack of clean water contributes to high rates of disease and death in both mothers and newborns. Every minute a child dies from a water-related disease. More than 315 000 children die annually from diseases

6

Pipes, Pumps and Valves Africa - Mar/Apr 2021

caused by unsafe water and poor sanitation. Even just finding water in Africa is a challenge. It is estimated people walk an average of 6km per day just to find water carrying heavy loads of 18kg and more home to sustain their families. According to SRK Consulting principal scientist, Avril Owens never before has effective water management been quite as necessary as at present. A tailored water management plan, with pragmatic actions to address current on-the-ground challenges and develop and sustain the system, was needed particularly in African countries where drought has affected the already precarious state impacting more than 45 million people’s access to food in 14 countries. It was also not taking into account the impact of climate change that in itself was presenting new challenges while disasters such as landslides and coastal flooding were becoming

all more frequent. “This plan must, in turn, be based on validated information, as well as sufficient human and financial resources, so that it can be implemented and kept relevant.” More so, she said, we lived in a world where one could ill afford the system not to work indicating that a significant amount of water was lost every year due to deteriorating infrastructure and leaks. In Kenia, it is estimated some 40% of potable water is lost through leaking. South Africa is not far behind at around 37%. Pollution and the contamination of groundwater not to mention poor stormwater and groundwater management collectively added a constraint to the system placing huge economic pressure on countries.

“Taking a strategic perspective on planning firstly helps to achieve water management goals regardless of the scale you are operating at, whether it is a high-level crossboundary catchment area or at the project-specific level.” She advises countries to align their strategic thinking to the African Union (AU) Agenda 2063 that takes into account the legal obligations to international conventions and bilateral agreements as well as the United Nations (UN) sustainable development goals that all inform and influence how water management issues should be approached. “The AU Agenda 63, in particular, is a framework for action to finding the desired water future for Africa. It calls for national, regional and local structures to be put in place working towards this goal.” A robust water management system, says Owens, is essential to build resilience against increasing demand on limited resources and the effects of climate change on the frequency and severity of droughts and floods. The Covid-19 pandemic has further weakened many water, sanitation and health (WASH) systems. A successful water management plan must align with the greater policy and strategy objectives. Once the overall strategy has been defined it is essential to develop actions and targets based on modelling, data analysis and results followed by the assigning of a responsibility and

Stakeholder involvement According to Ismail Mahomed, a hydrogeologist at SRK Consulting, one of the aspects not often considered in detailed planning is the role of pump and drilling contractors. “These people are often called in long after the strategy and plan has been drawn up and without any of their input in the detailed planning required for the water project,” he says. Their services are procured long after the strategy and plans have been drawn up and the expectation is that they simply install boreholes and pumps to the required design existing within the strategy or planning documents.

PIPES

Responding to the crisis According to Owens, governments must address water management challenges by adopting a clear strategy and integrated approach that is linked to systematic planning.

timeframes. “It is important to formulate a monitoring programme to determine the plan effectiveness,” says Owens. “During the monitoring and reviewing it is essential to collect and review available documentation on the projects, develop a checklist to ensure all is on track and engage with key stakeholders regularly. Site investigations are critical to report on findings, progress, challenges and to identify opportunities for improvement.”

“If one considers, however, where some of these projects are and the lack of infrastructure that exists and the numerous challenges that have to be overcome in water projects it is clear that the pump specialists must be part of the upfront discussions right at the beginning,” he says. “In my opinion, the pump service providers and the installers along with the drilling experts all need to be part of the discussion around the aim, objective and requirement of the project and then also around the logistics. If we can already troubleshoot at these meetings plans can be improved significantly alongside contractors.” Mahomed says it is essential that even in the strategizing of water management limitations and opportunities are discussed. To do this pump experts who are au fait with what is possible in the field need to be involved in the discussions. Without a clear understanding of the engineering and pumping constraints from the getgo, projects are doomed to fail regardless. “In the water pumping environment, it can sometimes even be the simplest of things that gets a project stuck. One can never over-plan, but having working relationships and key stakeholders on board from the beginning will bring about far more successful water projects.”

Authorized Distributor of

Sole ARO® distributor for Mpumalanga and Limpopo provinces. ARO® is an Ingersoll Rand brand, specialising in air operated diaphragm pumps, air driven centrifugal pumps & air operated piston pumps for pumping, moving or transferring liquids, powders and greases. Commonly used in mining dewatering applications, chemical, food and beverage industries.

SALES, SPARES AND REPAIRS

instrupump2@vactech.co.za 082 575 6339 www.vactech.co.za Pipes, Pumps and Valves Africa - Mar/Apr 2021

7

Amid the uncertainty created around the world following the outbreak of COVID-19

PUMPS

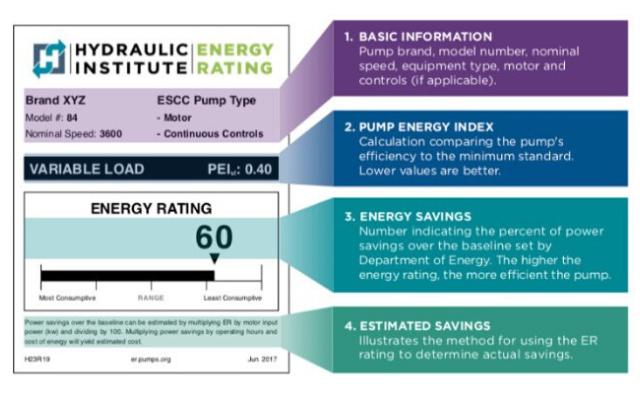

It can feel like sustainability initiatives have taken a back seat. However, energy efficiency and cost savings are often intrinsically linked. The Hydraulic Institute, the global authority on pumps and pumping systems, maintain that utilities in countries remain uniquely positioned to gain energy efficiencies in their operations while launching incentive programs that encourage other companies to seek more energy-efficient clean water pump systems. Pumps, says Edgar Suarez, manager of technical programmes at the Hydraulic Institute (HI), are a good and cost-effective (and proven) measure to help one fill out commercial and industrial programme portfolios. To support energy-efficient pump incentive programs, the HI launched a collection of tools and educational materials that can drive the development and implementation of incentive programs that advance pump system energy savings. Such programs, says Suarez, can help utilities meet regulatory goals and provide other value-adds to customers. HI’s utility resources build upon the Energy Rating Programme the organisation launched earlier which underpins incentive programs by streamlining the way pump manufacturers and distributors communicate energy efficiency. Pump systems may account for 40% of industrial energy usage, but they don’t have to. Paving the way towards more energy-efficient and reliable

pumping systems starts with training, says Suarez. The HI advocate that training is a top priority as it is critical for teaching first and foremost pump system fundamentals, but also system optimisation and assessment. It also instituted a certification programme for a certification program for Pump Systems Assessment Professionals (PSAP). This program sets the standard for the discipline of pump systems assessment and the use of pump system optimization techniques. Following these developments, the organisation implemented its Lab approval programme to ensure higher efficiency and compliance to test standards. Delivered through a third-party audit it provides pump test labs with the opportunity to demonstrate compliance to their established quality programme, procedures, instrument calibration to ISO 17025 and pump testing to HI 40.6 methods for rotodynamic pump efficiency testing that is referenced to the US Department of Energy requirements. Most recently it launched its energy rating programme – a metric, label, database and utility resources that advance the use of energy-efficient pumps. According to Suarez, while energy and cost savings will vary depending on a variety of factors for different settings, the reality is that by properly selecting pumps and ensuring they have an HI Energy Rating Label savings can be

1. BASIC INFORMATION Pump brand, model number, nominal speed, equipment type, motor and controls (if applicable). Brand XYZ

ESCC Pump Type

Model #: 84

- Motor

Nominal Speed: 3600

- Continuous Controls

VARIABLE LOAD

PEl vt: 0.40

ENERGY RATING

3. ENERGY SAVINGS Number indicating the percent of power savings over the baseline set by Department of Energy. The higher the energy rating, the more efficient the pump.

60

Most Consumptive

RANGE

Least Consumptive

Power savings over baseline can be estimated by multiplying ER by motor input power (kw) and dividing by 100. Multiplying power savings by operating hours and cost of energy will yield estimated cost.

H23R19

8

er.pumps.org

2. PUMP ENERGY INDEX Calculation comparing the pump’s efficiency to the minimum standard. Lower values are better.

Jun 2017

Pipes, Pumps and Valves Africa - Mar/Apr 2021

4. ESTIMATED SAVINGS Illustrates the method for using the ER rating to determine actual savings.

increased. “The HI Energy Rating (ER) Label is designed to indicate the power savings obtained from pump system upgrades and changes,” he explains.

“With the HI Energy Rating, energy-efficiency program administrators have a new way to encourage adoption of more efficient technology. Through incentives to distributors or rebates to equipment purchasers, programs can encourage commercial and industrial facilities to install more efficient pumps,” says Suarez. “This programme quantifies real savings ultimately paving the way paving the way for pump end-users to be better informed as they purchase pumps and pump systems.” According to Suarez for the process of identifying, understanding and cost-effectively eliminating unnecessary losses while reducing energy consumption and improving reliability in pumping systems, while meeting process requirements, minimizes the cost of ownership over the economic life of the pumping systems, requires one to first see the bigger picture. That means pumps must be selected to meet system requirements. Assessment is another important step as it provides the necessary information required to either further optimize the system or address issues identified. Suarez argues that energy efficiency should be built into the cost assessment. “With the HI Energy Rating, it is possible to capture additional savings when a more efficient motor and/or controls are added to a pump after it has left the manufacturer’s facility,” he explains. This label and certificate respond to the need to identify products that perform more than a representative

PUMPS

Energy Rating The HI Energy Rating (ER) Label programme is aimed at helping manufacturers differentiate their higher efficiency products and provide ways for commercial and industrial customers to save energy. The rating label identifies energy-efficient pumps and provides a tool for the developers of energy efficiency programs, electric utilities, distributors, and customers to identify energy-saving products. The pumps with the higher ER rating will provide greater energy savings than similar pumps with lower ratings.

baseline so that prescriptive incentive programmes can be developed. These programmes will accelerate the adoption of more efficient products into the marketplace and contribute towards broad-based energy savings. Industrial businesses can and do save big over time by implementing these solutions, maintains the HI. Its research has shown that if an industrial plant using 40 pumps operating at an average of 15-hp switched or modified its pumps to achieve an energy rating of 50, that business would save 1.3 million kWh per year which roughly equals R1,7 million ($117 000) in annual savings, more than R18 million ($1,3 million0 in cost savings over an estimate 11-year lifetime of the pump and 114% internal rate of return. Hydraulic Institute, training@pumps.org, www.pumps.org

FOLLOW US ON :

Pipes, Pumps and Valves Africa - Mar/Apr 2021

9

KSB commits further investment into Namibia

PUMPS

The newly appointed managing director of KSB Pumps and Valves (Namibia) (Pty) Ltd, DeWet van Wyk will head-up the recently established KSB Pumps and Valves Namibia, a company formed out of a long history of service to Namibia’s people by one of the world’s leading pump manufacturers – KSB. The evolution from a sales office of the South African operation to a fully-fledged company comes at a time when soaring demand for pumps and services necessitates a move to bigger premises with a fully stocked distribution warehouse, service and repair facilities to meet future growth requirements. DeWet, who is a veteran of the Namibian pumping industry, has been involved in many pumping projects around the country ranging from the procurement and installation of KSB pumps and valves at the country's major water utilities to large-scale mining and agricultural projects, as well as a myriad of smaller projects that have commanded equal attention through the years. Established company “We are fortunate that KSB has been one of the preferred pump suppliers in Namibia for decades and with our vast footprint in Namibia and the Namibian government pushing for more local content the decision was made to establish a fully-fledged Namibian company. “Situated in the Northern Industrial area of Windhoek, the company’s new premises consist of nine offices, two boardrooms, reception and a fully equipped workshop area. The office block is 370m², while the workshop adds a further 420m² to the facility.”

The workshop has 2 big roller doors for deliveries and collections that make access in and out easy. The location has easy access to the highway and we are fortunate that most of our key customers and suppliers are in the same area. “Additionally, we will have a workshop and a field service team to provide maintenance, services and repairs and enough spares to cater for our footprint in Namibia. This will give us a more dedicated focus on our clients and further improve service and reliability of our supply chains. What is more, we now provide local content to the Namibian market and will not need to constantly import equipment from South Africa, which unnecessarily lengthens delivery waiting periods,” says DeWet. Growing strong The history of success has been contributed largely by Klaus Streit and that of KSB operating in Namibia for more than 31 years teaming up with Fenner in 1990 and Hydroweld two years later when Fenner changed its strategy and necessitated the move. The move to Hydroweld gave the team the room and resources to greatly expand operations in Namibia and laid the path for future business while building long-lasting relationships with the people of Namibia. This growing success led to the operation becoming a KSB Sales Office for KSB Pumps and Valves South Africa in 2014 and effectively laid the foundation for the establishment of the new business. “The opening of the doors of the new business and new premises on 1 January 2021 marks a new milestone for KSB Pumps and Valves Namibia to grow and expand our business to all corners of the country,” concludes DeWet. KSB Pumps and Valves South Africa, +27 (0) 822 1746, Annett.Kriel@ksb.com, dewet.vanwyk@ksb.com, www.ksb.com

10

Pipes, Pumps and Valves Africa - Mar/Apr 2021

NON-RETURN VALVE SPECIALISTS SINCE 1969

NEW 4TH GENERATION LONG LIFE VALVES AND FOOT VALVES REMAIN DROPTIGHT FOR DECADES Applications

• Slurries, mine drainage, clean water, acids, Alkalines, etc • Pressure ranges: 1mm H2O up to 120 bar • River water, leaves, stones, twiggs, mine bilge water etc ok • No high density fibre: sewage, paper pulp

Features

• Durable diaphragm 20mm thick: the only moving and wearing part • Replace on site – minimum production downtime • Unlimited 24 month guarantee – expect 20 to 30 years to first maintenance • Market segment: users who want to purchase once in a lifetime

100% MANUFACTURED IN NORTHERN CAPE

+27 84 606 0425 / stelkon@heckroodt.co.za

Vesconite deflector protects 30% of pump value

PUMPS

A starch and glucose producer in South Africa fitted Vesconite wear-resistant deflectors to its centrifugal pumps in 2019, and substantial maintenance, component and capital-cost savings resulted. Deflectors are cylindrical rings placed at either end of the bearing assembly around the shaft. In this application, they fit at the end of oil lip seals to prevent the ingress of water and dust. The producer had previously not used deflectors but in the food environment, in which the pumps are hosed down as part of hygiene practises, it was noted that the life of

ADVERTISE WITH US TODAY !!

The type of pump used by the starch and glucose producer, which experienced substantial maintenance, component and capital-cost savings when it fitted Vesconite wear-resistant deflectors to its centrifugal pumps bearings could be improved with deflectors being installed. Pump solutions provider SAM Engineering proposed deflectors and a cost-effective material that would protect the bearing assembly against dust and water was sought. On most (sites/ process plants), fitting of deflectors are generally overlooked, as lip seals serve the purpose of retaining lubricant in the bearing housing and prevent water and dust ingress; however, installing deflectors provide added protection. SAM Engineering reports that the Vesconite deflector is likely to improve the life of bearings and decrease the likelihood of mechanical seal replacement and, most importantly, protect the bearing assembly, the cost of which can be considerable.

+ 27 (0) 83 281 5761 info@pumpsandvalves.co.za www.pipespumpsandvalves.co.za 12

Pipes, Pumps and Valves Africa - Mar/Apr 2021

The bearing assembly totals 30% of the cost of this chemical-process pump, so the Vesconite deflectors could be said to protect 30% of pump value, the pump solution company states. Vesconite Bearings, +27 11 616 1111, vesconite@vesconite.com, www.vesconite.com

COVID-19: Solutions that pump with value in the fight to flatten the curve

There is no denying that the global novel Coronavirus (COVID-19) pandemic has introduced unprecedented challenges. However, as nations scrambled to come to grips with the changing context – particularly in the early stages of the lockdowns - efforts to combatting the impacts of the pandemic have also lead to some of the fastest innovations that markets have seen in decades. If we look at testing and pharmaceutical laboratories, for example, certainly these facilities across the globe have been under immense pressure to meet the duality of demands; to ramp up on people screening test requirements and keeping up with research and development in the race to find a vaccine, or at least the right mix of antibody-based COVID-19 drugs, that can be rolled out at speed and scale. Amidst the chaos of these pressures, these working environments demand extremely hygienic conditions. There is no room for error, as even the slightest contamination can render a screening test or drug sample batch inconclusive and/or unusable, which could set research back and this poses a knock-on risk to societies ability to recover. And having the right equipment in place in the labour for the production of pharmaceutical products is missioncritical. Taking this a step further, and at the heart of maintaining the highest levels of hygiene standards means having fit-for-purpose pumping solutions that have been designed and built to eliminate any risk of contaminants

during production. In laboratory and pharmaceutical environments, processes must be reliable, repeatable and error-free. To maintain this sustainably – and with the ability to adapt and quickly ramp up production when necessary – technicians need high-quality equipment and machinery that is reliable and meet the highest hygiene standards and accuracy rates 100% of the time, to ensure the quality of their product is always of the highest standard!

PUMPS

The Packo 3A certified pharmaceutical process pumps of the PHP2 series are used for the most demanding sterile applications in the pharmaceutical, biotech and semiconductor industry. These perfectly cleanable pumps have stainless steel 316L pump casings constructed in thick cold-rolled plate, 100% non-porous and extremely smooth.

As a global leader in advanced industrial and niche market pump solutions and laboratory equipment, we understand that navigating the technical obstacles of selecting the right pumping solutions for specific scientific and/or processing applications can be complex. Especially when the application requires a solution that offers the best fit and cleanability, as well as certified quality that is compliant with hygiene and safety standards. This is why we provide a one-stop offering of advanced, cost-effective, efficient and long-lasting solutions. Our hygienic pumps for the production of pharmaceutical products solve all challenges: from extremely high or low viscosity to shear sensitivity liquids and of course abrasive fluids. Our solutions are also comprehensively certified, available in different surface qualities and offer the best cleaning and self-draining capability. Verder Pumps, +27 (0) 11 704 7500, info@verder.co.za, www.verderliquids.com

A COMPLETE RANGE OF PUMPS FROM ONE MANUFACTURER

VERDER

A pump solution for every application FIND OUT MORE

Adv_180x65mm_Pharma_SA.indd 1

16-03-2021 19:49

Pipes, Pumps and Valves Africa - Mar/Apr 2021

13

Bearings that solve NGL pump problems There has been a dramatically increased use of natural gas liquids (NGL) pumps in North America. These pumps are generally smaller diameter horizontal multistage pumps that are vertical turbines turned on end.

PUMPS

The pumps are part of an HPS (horizontal pumping system) and usually have between 70 & 100 stages, developing high head and low flow. Problem: As described above, these pumps have a high head pressure thus developing a high thrust load in the axial direction opposite that of the flow. Each pump is fitted with a specially designed thrust chamber that sits between the pump and the electric motor. This thrust chamber can only handle thrust in one direction axially. In this application, the customer was experiencing thrust in both directions. This situation was due to a design problem within the terminal. These kinds of problems are occurring all too often in these plants as they are designing and building them as fast as they can. The pumps were failing in as little as 1 week of service. Graphalloy solution: This OEM has been using GRAPHALLOY® bushings exclusively in these types of pumps for years because it can handle the low viscosity liquids being pumped. The engineer contacted us for help in designing a solution that would allow the GRAPHALLOY® material to also handle

14

Pipes, Pumps and Valves Africa - Mar/Apr 2021

the inherent axial thrust loads. Working with Yonkers engineering, we designed a flanged bearing that would handle the loads and allow the unit to operate under normal conditions. Babbitt-grade Graphalloy was chosen as the bearing material and the customer has been using that Graphalloy grade for several years. Results: The Graphalloy flanged bushings were installed in some test pumps and were successful. The pumps in the field were upgraded to Graphalloy and have been in service for several years now. The customer is happy that they have a solution for those situations that require additional protection against the possibility of load in the “wrong” direction. Graphalloy is the standard for many HPS pumps pumping low lubricity fluids and gases and is included as the OEM bushing in the brochure of a major pump manufacturer. Graphalloy, sales@graphalloy.com, www.graphalloy.com

Mine pump acceptance testing from the comfort of an armchair

PUMPS

Local pump manufacturer, KSB Pumps and Valves has launched an innovative online acceptance test procedure that no longer requires customers nor their engineering teams to be present when acceptance testing takes place. The service was initially implemented to curb expenses that are usually incurred through travel and accommodation to test centres. The remote pump acceptance testing has also allowed business to continue as usual during the ongoing Covid-19 pandemic. According to KSB Pumps and Valves technical manager, Friedrich Görgens, acceptance tests and final inspection are an essential proof of compliance when purchasing pumps and equipment to ensure the guaranteed values are met. In the past, customers always had to travel to the test facility to witness their purchased pump being tested. Improved convenience “Online acceptance testing is KSB’s answer to improve the ease and convenience of acceptance testing. They are transmitted live via the internet and are encrypted to be accessible only to required users. It allows the customer to see a live camera view of the pump in the test facility as well as the characteristic curve being generated live from readings taken and displayed during testing. “In addition to pressure and flow data, the test software records all further performance data required for a measurement to inspection/testing standard DIN EN ISO 9906, enabling the derivation and assessment of the pump’s efficiency. Additional measurement and recording of bearing temperature and vibration is available.

These are displayed live in parallel to the performance and incorporated in the final test report. “We provide the customer with organisational information, order data sheets and a precise description of the acceptance testing prior to the acceptance test. This includes details on the measuring instruments used including the corresponding calibration certificates. After the acceptance test KSB display the results for comment and then e-mails the customer with the certificates within minutes, says Friedrich. Testing centres Online acceptance testing is available at KSB Pumps and Valves South Africa’s test centre in Germiston and the facilities can accommodate pump sets with a drive rating of up to 550kW and flow rates of up to 3000m³/h and discharge pressures up to 60 bar. String tests with the customer’s original motors, transformers and frequency inverters can also be performed. A YouTube video is available on https://www.youtube. com/watch?v=2tHxYJGjT_s that shows the online tests in operation. KSB Pumps and Valves South Africa, +27 (0) 11 876 5600, Annett.Kriel@ksb.com, www.ksb.com

KSB Pumps and Valves recently introduced remote acceptance testing for live testing of pumps and hydraulics via the internet.

16

Pipes, Pumps and Valves Africa - Mar/Apr 2021

The new SCUBA compact close-coupled submersible pump from Xylem brings a new level of reliability and flexibility to primary water supply options for wells, tanks or reservoirs, sprinkler irrigation systems, and pressure boosting. SCUBA quiet, compact multistage pumps are high performance and corrosion resistant, and designed to help people solve mainly domestic, light commercial and agricultural water challenges

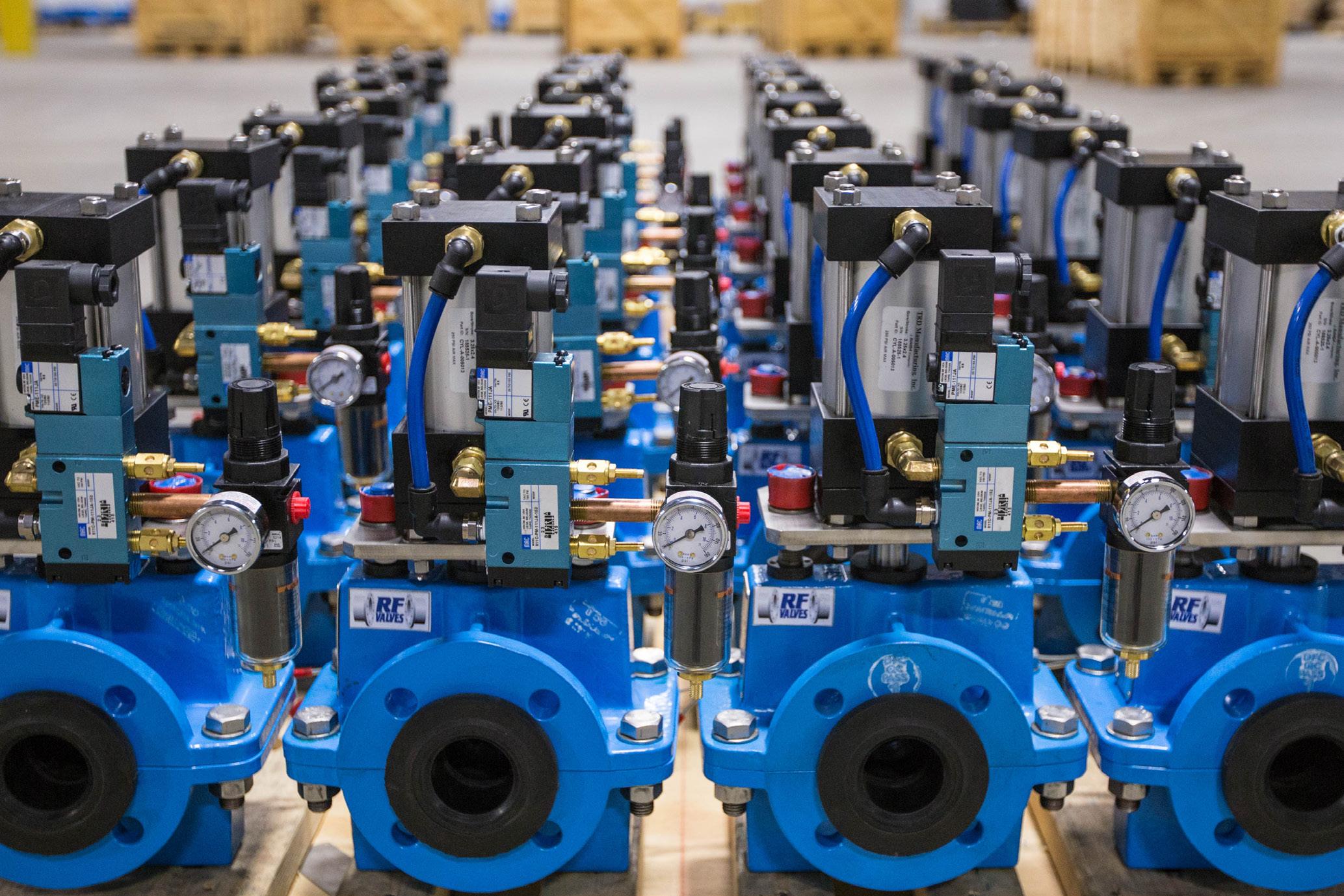

Dynamic Fluid Control sees future in own valve designs Dynamic Fluid Control, a 100% black-owned and managed manufacturer of valves for the water, effluent and mineral processing industries is urging water utilities to seek out public-private partnerships to modernise and expand their water and sanitation infrastructure and improve the efficiency of water systems.

VALVES

The Benoni based manufacturer employs over 300 staff and currently exports products to 129 countries.

18

While water covers 70% of the surface of the planet, only 3% of this is suitable for human consumption and irrigation. Of this, two-thirds is effectively unavailable and mostly locked in frozen glaciers. Of the remainder that gets piped to homes globally, some 35% - 60% is lost to leaks. In South Africa, 1.1 million litres of expensive treated water is lost annually, some of it to leaks on the country’s 290,000 km of underground infrastructure.

was drought-related, the burden of making sure it doesn't happen again largely depends on the Government's ability to cut down on water losses and promote responsible usage. “DFC is open to sharing its expertise with Government and other role-players in water and collaborating on developing technologies tailored to driving distribution efficiencies. The main priority is to get water utilities to audit their systems and install and upgrade valves where needed. Valves on the network don’t get much credit,” adds Tsehlo.

“Leaks are a great equaliser and it is not just a third world problem. Observances like the National Water Week and the World Water Day are a good platform for development actors to come together to advance strategies to minimise water losses, build efficiencies in the distribution systems as well as improve existing technologies,” says Tumi Tsehlo, CEO, DFC.

Managing water pressure in one of the most cost-effective leakage management strategies. The higher the pressure, the more water lost through bursts or leakages. Most pipe bursts occur not only because of high pressure but rather due to ongoing pressure fluctuations forcing the pipes to continuously expand and contract, resulting in stress fractures.

The issue is becoming more acute, mainly because many take water for granted. Before Covid-19 took over SA's collective psyche, the country experienced a catastrophe of its own in Cape Town, when the city almost became the first in the world to run completely dry. Even though it

Valves play a critical role in water distribution systems for flow or pressure control and subsystem isolation. Subsystem isolation is key to the repair and rehabilitation of broken sections of the network and can be done by shutting off valves. The efficient placement of valves

Pipes, Pumps and Valves Africa - Mar/Apr 2021

VALVES

improves the reliability of water distribution systems and can limit the loss of non-revenue water (NRW). NRW is not used or paid for, affecting local economies as well as local resources. Some of DFC’s critical valves installed on SA’s water distribution infrastructure have proven their reliability and continue to deliver a return on investment

even after more than 20 years. “We are not satisfied being a manufacturer of world class products. We believe strong design can be at the heart of both disruptive and sustained commercial success and will be the focus of our investments over the next few years,” says Tsehlo. “With over 70 years of experience in manufacturing valves we understand the needs of the water sector. Our design team is currently engineering valves that can limit water losses while upholding the best conditions for the network, provide state of the art water control and is homegrown offering compelling competition to imported alternatives that neither contribute to the local economy or job creation.” Following years of despair, the outlook for manufacturing in South Africa is looking more optimistic. Global supply chain disruptions due to Covid-19 accelerated the trend toward increased domestic manufacturing. ABSA’s latest Purchasing Managers’ Index (PMI) rose to 53.0 points in February from 50.9 points in January, remaining above the 50-point mark signalling an expansion of manufacturing activity in the country. “While the uptick in manufacturing output is welcome, we need manufacturing to also favour South African ingenuity. At DFC we are fundamentally relooking at the way our products are designed, putting a premium on innovation and training workers to move up the value chain,” says Tsehlo in conclusion. Dynamic Fluid Control, +27 (0) 10 300 4900, dfc@dfc.co.za, www.dfc.co.za Pipes, Pumps and Valves Africa - Mar/Apr 2021

19

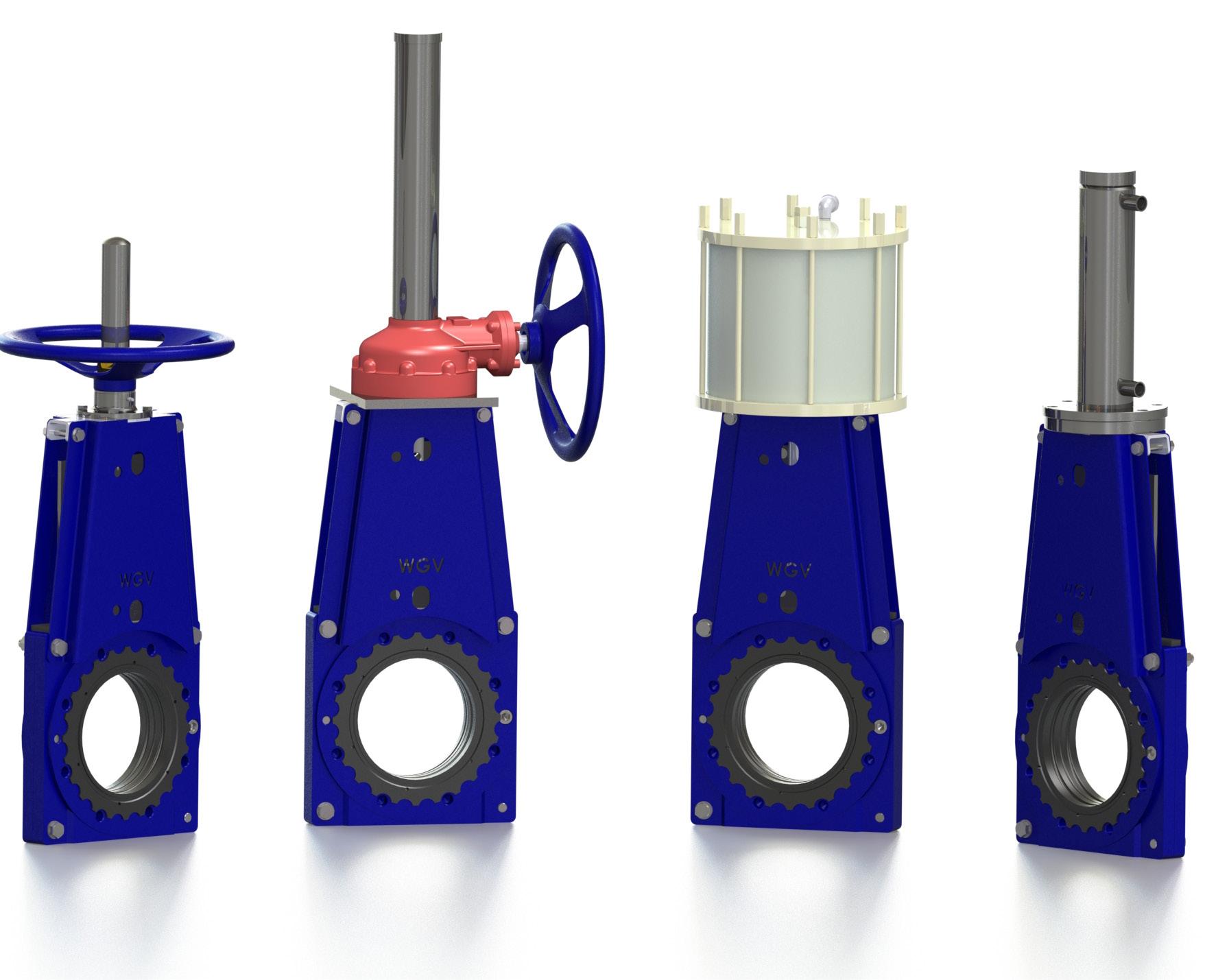

AFS specialises in the design and manufacturing of slurry related valves

VALVES

Engineering Solutions Group (ESG) part of Invicta Holding Limited, has established a new company – Abrasive Flow Solutions (AFS). “ESG’s strategy to further expand its fluid technology services, through the launch of an in-house manufacturing facility, strengthens the group’s position in the valves sector on the African continent. The establishment of AFS also expands specialist valves services to a broader customer base and provides new market and application opportunities,” says Willie Lamprecht, business unit manager, Low Pressure, Fluid Technology division, BMG. “The AFS team has extensive experience in slurry related valves, including Klep diaphragm and wedge gate valves. Our specialists have set their first challenge: to improve the quality of diaphragm valves, by extending service life and reducing the maintenance requirements of this range. This will be achieved through the implementation of the latest developments in design technologies, materials and coatings. “At the helm of AFS is MD Donald Morrison, who has many years’ experience in the severe slurry service valve market, for which BMG is an official distributor.” The AFS manufacturing plant in Benoni, which is equipped with the latest equipment, complies with stringent quality

20

Pipes, Pumps and Valves Africa - Mar/Apr 2021

and safety standards. This facility is supported by technical specialists who offer dependable technical support to ensure optimum safety, efficiency and extended service life of every system, even for those used in corrosive environments and arduous conditions. The team can specify the correct valves needed for every application and also assists customers in solving the problems of difficult installations and applications. Through BMG's broad branch and distributor network, the industry has easy access to a comprehensive portfolio of locally manufactured and imported valves. This range includes AFS Klep diaphragm valves and wedge gate valves, AFS FPV non-return valves, pinch valves and knife gate valves, plus many other valves. This range is particularly well-suited for use in harsh conditions in diverse industries, including mining, chemical and petrochemical, water and wastewater, energy production and agri-food industries. Abrasive Flow Solutions (AFS), +27 (0) 11 955 1119 , monicag@abrasiveflowsolutions.com , www.abrasiveflowsolutions.com

Mine single most most influential influential valve valve company companyto tothe themines minesthat that Mine Track Track & & Tools Tools serves serves as as the the single mine running through through the the Witwatersrand WitwatersrandBasin. Basin. mine the the Great Great Gold Gold Reef Reef running

CONTACT

Vincent Mulder +27 79 517-4489 vincent@minetrack.co.za vincent@minetrack.co.za

info@minetrack.co.za info@minetrack.co.za +27 +27 11 11 412-4536 412-4536 www.minetrack.co.za www.minetrack.co.za

Slurry valve specialists

VALVES

Established in 2006, Fluid Power Valve Technologies (Pty) Ltd manufactures the Waferand-Flanged Model Clarkson-type Knife Gate Valves, in sizes: 50mm – 700mm. All sleeves and parts are interchangeable. Our valves are locally produced and manufactured in Gauteng, South Africa. Excellence and innovation built into every design!

304/316/2205. Removable sleeves on either side of the blade provides a bi-directional, bubble-tight seal with no metal parts in contact with the slurry.

They conform to the minimum threshold for Local Content & Production of 70%.

Available in mounting to table D – ANSI and BS standards.

The Mining Charter 3 stipulates Preferential Procurement via these locally produced and manufactured valves. Flanged-and-Wafer Series Knife Gate Valves (FGV & WGV): Our Slurry Flanged-and-Wafer Style Knife Gate Valves are equivalent/interchangeable with the KGA-FGV and KGDWGV series of the Clarkson-type Knife Gate Valves. All spares are interchangeable. Sizes range from: 50mm700mm. Built with a cast SG Iron GR. 42/WCB or fabricated body and features a heavy-duty stainless-steel blade; Options:

The types of actuation that are available: Hand Wheel – Gearbox – Pneumatic – Hydraulic – Electric. Applications: • Mining & Mineral Processing. • Chemical & Soda Ash. • Power Generation. • Pulp & Paper. • Sand & Gravel. • Environmental & Effluent. Valve Body: • Lubrication ports on both sides of the valve body.

Slurry Wafer-series Knife Gate Valves (WGV): Sizes range from 50-700mm.

22

Pipes, Pumps and Valves Africa - Mar/Apr 2021

VALVES

Slurry Flanged-series Knife Gate Valves (FGV): Sizes range from 50-700mm.

• Flushing port at the bottom. • Open/Closed lockout brackets standard, ready for optional factory-supplied lockout pins. • Adaptable frame (yoke) design can be field modified to take Air Cylinder/Hydraulic Cylinder/Handwheel/Gearbox or Electrical Actuator. With a collective 197 years of experience in the valve industry, we offer 24/7 breakdown advice and technical support. We are committed to excellence; quality manufacturing of

high-performance products is our aim.

The brand “Clarkson”, is used for reference purposes only and does not imply that any part is the product of this manufacturer. Fluid Power Valve Technologies, +27 (0) 11 452 5668, valvesales@fluidpower.co.za, www.fluidpower.co.za

FLUID POWER GROUP OF COMPANIES

Valve Technologies

Pipes, Pumps and Valves Africa - Mar/Apr 2021

23

Drop tight for decades – delivering quality valves for Africa

VALVES

Over the past four decades valve manufacturer Stelkon has built a reputation of delivering products suited to Africa’s unique conditions. The company recently changed hands and newly established Stelkon North is motivated to carry the baton going forward. In Africa the only industrial certainty is often uncertainty. It is an environment that requires equipment to be engineered to operate under extremely harsh operating conditions that can deal with the unexpected, while doing the expected.

to expand our footprint into Africa. We have also wanted to expand technologically and this is the ideal platform for our business as a whole.”

Rienzi Duvenage, the developer and original owner of Stelkon’s diaphragm non-return valve patents and four generations of patent improvements, knows this only too well. “Africa is a robust environment that requires solutions that are efficient, dependable and reliable,” he tells Pipes, Pumps and Valves.

“We have started production even though we are still constructing and the first orders out of the newly built facility were delivered in March and April this year.”

Next to him is Basie Heckroodt, the Managing Director of the newly established company, Stelkon North that is situated in Modder River near Kimberley and that bought the manufacturing and commercial rights for the diaphragm non-return valves from Stelkon last year. “The decision to purchase these rights was easy. We found a product that we thought not possible,” he says. “It also allows us the ability to diversify our current operations and

According to Heckroodt, a new factory has been established in Modder River and is partly completed.

Fit-for-purpose Non-return valves, also sometimes referred to as check valves are intended to close when a pump stops and to prevent any fluid flowing back. These one-way valves have one major requirement – no leakage. Duvenage made it his life’s work to deliver just that. “For non-return valves water tightness is the single most important element. This is a fourth-generation valve which has been developed and improved over the years. Hydrodynamics has resulted in a valve that is not only

Basie Heckroodt, the Managing Director of the newly established company, Stelkon North and Rienzi Duvenage, the developer and original owner of Stelkon’s diaphragm non-return valve patents. 24

Pipes, Pumps and Valves Africa - Mar/Apr 2021

VALVES

more efficient and better, but also weighs less,” he says. “Once installed it is drop-tight for decades. It does not leak.” The operating core of the valve consists of a centre plate and a rubber diaphragm. This rubber, originating from Malaysia, is super soft and can stretch 830%. It is also super resistant against abrasion and tearing. Duvenage says these natural rubber diaphragms are highly favoured by water utilities in Africa. “We have taken the time to develop and deliver a highly efficient product with zero maintenance requirements. As far as we know this is the only valve with only one moving and wearing part that has an exceptionally long operational life,” he says. Considering that maintenance of non-return valves and foot valves remains one of the biggest challenges in Africa, Duvenage says this is not the case with the Stelkon valve, as it does not need to be serviced for decades. Furthermore, should the one moving part ever require replacement, it is simple enough that the user can do so themselves - on site - with minimum production downtime. “These valves were designed and developed for African countries, where the maintenance culture and infrastructures are not well developed yet. Ultimately, especially for foot valves there is no priming time loss and it comes with major operating costs saved,” he explains. “Furthermore, it removes pressure spikes, reduces water hammer, operates completely silently, and of course, stays drop-tight, even after wear.”

bespoke and made to the customer’s requirement and need.” Taking it forward According to Heckroodt, a new policy has been adopted for the marketing of the diaphragm non-return valves. “Since the marketing focus of the principal over the last decade, was mainly on exports to African countries South of the Equator, approximately 90% of production was exported. The quest of Stelkon North is to achieve intensive distribution of the valves in all geographic areas of South Africa and the rest of Africa.” He has also retained Duvenage’s experience as he has been contracted to provide technical and marketing support for the manufacture, sale and distribution of the Stelkon diaphragm non-return valves. “Intensive distribution is going to be achieved by extending the existing network of locally situated sales representatives to commercially serve the industry in Africa.” At present, companies and financially independent individuals with a successful track record of valve sales are being sought to join the network for supplying this range of exceptional non-return valves and foot valves which provide decades of drop tight operational life to first maintenance. Both Heckroodt and Duvenage are excited about the developments of recent months.

Whilst the product does not necessarily have the lowest price tag it does have one of the lowest life cycle costs.

“The product is also manufactured wholly in the Northern Cape boding well for technology development in the province and provides much-needed economic stimulus.”

The target market, says Duvenage, are users who want to make a once in a lifetime purchase with no periodic functional checks or maintenance costs. “Our valves are

Stelkon, +27 (0) 84 606 0425, stelkon@heckroodt.co.za, Pipes, Pumps and Valves Africa - Mar/Apr 2021

25

10 Hydraulics tips you need to know

BEARINGS

Seals, gaskets and o-rings are all key components to the success of hydraulic applications. Without these components, high pressure systems would be impossible. Selecting the right material, durometer and temperature and a complete understanding of a hydraulic system allow engineers to ensure quality performance in every fluid power application. Outside factors are a vital component of hydraulic systems. Demands placed on hydraulic systems constantly change as automotive, aerospace and oil and gas industries require greater efficiencies. Just as selecting the best hydraulic fluid requires a basic understanding of fluid characteristics, choosing the best sealing material requires an in-depth understanding of factors that may influence performance. Temperature Range: All possible environments must be taken into consideration before selecting a material. Where will the application be used, and what types of climate will the application be exposed to? Will Ozone be a factor? FKM compounds, for example, may only function to -25°C – not necessarily suitable for all possible temperature requirements. Applications that may be exposed to extreme environments require full communication between customers and manufacturers. Fluid Compatibility: Depending on the chemistry of the given oil and temperature, the amount of swell can vary. Today, elastomers exist that swell very little when exposed to water or oil. Too much swell can cause deterioration, cracking or even premature failure – which is why it is critical to keep this in mind. Choose the right polymer to ensure full and proper

26

Pipes, Pumps and Valves Africa - Mar/Apr 2021

function. Fluids and seals should be checked to make sure they are compatible, and will not interfere with proper operation. Even new fluid additives can attack rubber seals. New amine preservatives in hydraulic oils can attack standard FKM seals, causing premature failure. The amine additives attack the backbone of the polymer, resulting in embrittlement of the rubber. O-Ring friction is more common than you think. The need to reduce o-ring friction and wear is a major factor in product design for hydraulic valves and cylinders, pneumatic tools and plumbing devices. There are two ways to help reduce o-ring friction. Evaluate the o-ring and gland conditions. Many times, a gland width may not be large enough to allow space to accommodate the o-ring volume. This is a crucial factor in proper o-ring function. Reducing seal squeeze will decrease the overall seal friction. Just be sure these adjustments do not compromise the performance of the o-ring. A gland calculator can also be a useful tool in giving accurate guidelines for application values like compression, stretch and volume fill. Introduce lubricity to the seal material. Lubricants that are compatible with system components are extremely helpful in reducing friction. They are great for dynamic applications where the rubber seal is moving during use.Internally lubricated compounds have proven especially effective in applications requiring low friction performance without the reduction of squeeze. PTFE powder can be milled into commonly used rubber compounds to reduce friction and improve abrasion resistance. Erucamide and Oleamide can be added to

BEARINGS

rubber to bloom to the surface after molding to reduce initial stiction in dry applications.

account responsible compression set values for the various seal materials.

A standard o-ring can in fact be used for non-circular grooves. An o-ring provides a simple and economical solution for an axial face seal gasket. For non-circular grooves, circular o-rings can be formed to fit. In order to use a standard circular o-ring, the inside corner radius of the groove should not be less than three times the o-ring crosssection diameter. Just be sure to use the recommended gland design for static axial seals.

Hydraulic applications may require frequent design improvements (and that’s OK). Let’s say, for example, an o-ring part needs to pass a port in a piston application. This may cause damage to the seal, but several improvements can be made to alter the design:

The length of the o-ring centerline should be equal to the length of the groove centerline. Below is an equation to assist in determining the o-ring inside diameter: O-Ring Inside Diameter = (Groove CL length / 3.14) – O-Ring CS If a standard circular o-ring cannot be applied to your face seal application, contact appropriate professionals for assistance with designing a custom-molded gasket solution. O-Ring cross sections may not always be circular. When initially removed from the hardware, the o-ring may be oval-shaped. It is the deformation of the o-ring that provides a seal. When squeezed, the cross-section of the o-ring resists with a normal force – this force creates the initial barrier for sealing. As the o-ring continues to function in the hydraulic application (and experiences thermal cycles, exposures to chemicals and pressure cycles) the stress in the rubber material will begin to relax. This relaxation or permanent deformation is compression set. Compression set should be expected with most applications and seal materials. In the case of excessive compression set, the seal has lost its resilience – the normal force required for maintaining a sealing barrier. Application failure will usually be detected at low pressures. The seal and gland design standards take into

• Reduce the inside diameter of the o-ring, so the nominal stretch is in the 10 percent range. This will help keep the o-ring tight against the piston or spool component. • Break the edges of the port where it meets the bore. This is difficult on small-bore components, so a trick might help: Drop a piece of piano wire into the port and spin – the edges at the bore surface will break. • Design the o-ring cross-section to be as large as possible. Design the port diameter to be as small as the application will allow. Multiple small ports may provide the necessary flow. • Increase the full bore diameter at the location of the port. This will relieve squeeze on the perimeter of the o-ring. Just be sure that there is a gradual transition between the bore diameters so the seal can be loaded again gently. Chamfering is key in hydraulic and pneumatic applications. If the part lacks a quality lead-in chamfer, a portion of the seal may be pinched on the outer diameter for a piston (or inner diameter for a rod-type application). The ideal leadin chamfer is 15° to 20°. For a piston configuration, the major bore diameter should be near the assembled outer diameter of the seal, and a rod configuration should have the minor chamfer diameter near the assembled inner diameter of the seal. Piston seals are always constructed with an interference fit. In order to avoid damage during part installation, lead-in chamfers and rounded edges must be made on the cylinder Pipes, Pumps and Valves Africa - Mar/Apr 2021

27

BEARINGS

barrel. This process of chamfering allows for minimal damage and easy function in hydraulic applications. When sealing end caps, radial seals are superior to axial seals. Many designers want to incorporate an axial face seal between the cylinder and cap component. However, the performance of the face seal is highly dependent on the clamp force of fasteners or threads in the cap itself. There is little room for hard stops to control squeeze on the gasket, which means the cap is tightened to a “feel.” A radial o-ring seal configuration is better suited for cap and plug applications. Whether a male or female gland, the hardware dimensions control the amount of squeeze on the seal – not the torque of the fastening mechanism. As long as the seal assembly is engaged over the cylinder outer diameter, the performance of the o-ring seal is not dependent on the fastener or thread torque. This type of configuration will provide quality seal performance over wide pressure ranges and conditions. It’s normal for rubber to initially stick to an application. Some units that have been idle for extended periods of time are difficult to cycle initially. The rubber material may adhere to the mating hardware surface, creating a high breakaway force. It is important to recognize that rubber acts like a highly viscous fluid. Over time, the seal material will tend to flow into the micro-features of the hardware surface finish. This process will resemble mechanical adhesion. A highly polished hardware surface will also create a type of suction between the two mating surfaces. In all dynamic sealing applications, the addition of a lubricant will greatly reduce friction and extend the seal life. The recommended hardware surface finish for dynamic seal applications is a maximum of 16 Ra, with the ideal being between 8-12 Ra (micro-inches). Applying a matte finish to the o-ring has helped in light duty applications. The right hydraulic seals begin with the proper material. O-Rings are affordable, simply produced and have versatile applications in automobiles, engines, medical uses and aerospace. They function well under diverse environments due to the diverse scope of material used in fabrication. Understanding the range of materials available – and

their tendencies – will help in determining which is most appropriate for an application. Nitrile (Buna-N): Widely used offering excellent resistance to oils, hydraulic fluids and fuels. Ideal for applications in hydraulic and pneumatic systems. Temperature Range: -40°C to +135°C. HNBR is in the same family as NBR but offers better ozone, higher temperature and weather resistance Ethylene Propylene: Has gained wide seal industry acceptance for its excellent ozone and chemical resistant characteristics. It is ideal for outdoor weather-resistant uses. Works well with water, steam, brake fluids and alcohols. Fluorocarbon (Viton™): Offers excellent resistance to petroleum products, solvents, broad range of chemicals and high temperatures. Excellent for a variety of applications, both static and dynamic, such as seals for automotive, chemical processing and aircraft fuel systems, vacuum service and other high temp uses. Neoprene: Functions well in refrigeration units of air conditioning systems. Neoprene compounds offer resistance to wide range of Freon as well as giving some resistance to the oils used from lubricating these systems. Polyurethane: Offers outstanding abrasion resistance and tensile strength. Ideal for seals used under hydraulic pressure and applications where highly stressed parts are subject to wear. Polyurethane is often used in hydraulic cylinders and valves, pneumatic tools and firearms. Urethanes do have a limited temperature range and are more susceptible to compression set at higher temperature. The majority of hydraulic system failures are a result of contamination. High dirt environments require extra consideration when it comes to contamination control. This could lead to internal leakage, lowering the efficiency of hydraulic pumps, motors and cylinders. Valves could lose the ability to control flow and pressure within the system. Without minimizing contamination, the following malfunctions may occur: • Degradation (changes over time in pump flow rates, valve leakage and wear of cylinder barrels causing speed decline) • Transient or intermittent failures • Catastrophic – complete failure of a system Contamination in hydraulic systems can be broken down into three different categories – gaseous, liquid and solid. Air can lead to a reduction in lubricating properties, liquid can cause rust and solid particles can cause significant surface degradation. However, there are a number of ISO standards for measuring and reporting the levels of contamination in fluids. Making sure you have new oil filtration systems in place, and management to monitor contamination, will help in keeping systems clean. Remember to do the following: • Proper fluid selection for a system – know your environment • Proper fluid handling, including storage • Regular system maintenance https://www.applerubber.com/fluid/ HydraulicsWhitepaper.pdf

28

Pipes, Pumps and Valves Africa - Mar/Apr 2021

We offer valves for precision processes - and demandingapplications Our valves fulfill the highest of standards and are designed for many years of safe and reliable operation. Our service specialists regularly check, monitor and maintain all relevant system components - depending on what has been agreed. Our modular framework agreements offer you individual service and spare parts concepts. And we even go one step further. We additionally check systems for efficiency in order to reduce operating costs and increase productivity. For example, with the SES System Efficiency Service.

ZTS GATE VALVE

GATE VALVE AKG-A/AKGS-A

STAALWEDGE GATE VALVE AKDS/AKD

NORI 500

Contact our dedicated Valves Sales Engineers for all your Valve requirements Tel: 011-876-5600 • Email: info-za@ksb.com KSB Pumps and Valves (Pty) Ltd www.ksb.com/ksb-za Your B-BBEE Partner

BOA - H

“What water means to us” – Xylem’s shared mission to solve water

WATER

On World Water Day 2021, Xylem celebrates the value of water and the amazing water operators and other users of water whom we partner with every day to protect and optimize this precious resource for communities around the world. Xylem is marking this day through a series of activities, including the announcement of Water Heroes Academy, a new initiative between Xylem and City Football Group’s global foundation program, Cityzens Giving, to empower Young Leaders to deliver innovative projects that leverage football to provide vital water education in five cities around the world. Additionally, we are launching Xylem Watermark’s 5th Annual company-wide Make Your Mark 30-Day Challenge, a month-long initiative for employee and stakeholder volunteers to come together to participate safely in community events, virtually and through fundraisers, to raise awareness about water-related issues. We are also taking time to honour this year’s theme of Valuing Water: What does water mean to you? Below are reflections from Xylem colleagues on this all-important question – and on our shared purpose and passion to solve water and help create a more sustainable world. On behalf of Xylem Making Waves, we wish you a happy World Water Day! Anna Hildell, Managing Editor, Xylem Making Waves

30

Pipes, Pumps and Valves Africa - Mar/Apr 2021

What does water mean to you? Patrick Decker, President and CEO, Xylem: “I grew up in Newburgh, Indiana, during the time when the Cuyahoga River in Ohio, the next state over, became so damaged from industrial pollution that it caught on fire. It became front page news and was a major factor in starting the environmental movement in the U.S. In Indiana, I witnessed the same terrible impact of pollution on the Ohio River and my hometown, located right on its bank. I still carry those images in my mind. Seven years ago this month, I joined Xylem as CEO, and it’s my great honor to lead a company of 16,000 colleagues around the globe dedicated to working with our customers to solve water for their communities. To me, water is about looking beyond challenges and seeing extraordinary possibilities. We all need this precious resource to survive. Water is also a catalyst for economic and social progress, and the key to a healthier, safer and more sustainable and equitable world. For those of us who have the privilege to work in water, it’s also a calling. To all the heroic water operators around the world protecting and serving their communities, and

WATER

all others in the water sector innovating and making a difference, I give my heartfelt thanks on this World Water Day. Let’s solve water.” Shobha Nair, Director, International Sales, Xylem India: “Water for me is life. It’s the natural resource that is essential for sustainable living on earth. I am conscious of the value of water every day. Here many women start their day by storing water for drinking, cooking and other household activities, as water supply for many is only available for a few hours per day. Many women in rural India also walk miles to fetch potable water for their family. My journey in Xylem started 10 years ago and during these years I have had the opportunity of working with a wide customer base who have different water-related challenges, which our technologies have helped to solve. Being a past Xylem Watermark Ambassador, I have had an opportunity to connect with people living at the base of the pyramid, facing the most extreme water and economic challenges, and I am so glad that Xylem has developed technology to help them. I feel proud of working in an area where I am able to contribute my talents to solve water challenges. Looking at the intensifying water issues across the globe, I believe it is vital to adopt best engineering practices like drip irrigation, water recycling and reuse techniques, among others, and behavioral practices like changing water use habits to save every drop of water, our own natural resource.” Mudasser Iqbal, Director, Xylem Digital Solutions: “I experienced water scarcity first-hand as I grew up during late 80’s in Jeddah, Saudi Arabia. Waiting for water tankers to deliver water every few days, cherishing every drop of water we used as we did not know when the tankers would be able to come around next, and having to purchase drinking water at three times the price of gas to run the car has taught me important lessons about the value of water, that I strive to pass on to my kids. Though by chance I have ended up making some contribution to the world’s water

problems through technology, I feel blessed and eternally thankful to being part of the water journey and commit to striving for the day when no child has to wait for days to access clean drinking water." Flora Klise, Xylem Intern and MIT BS Mechanical Engineering 2021: "I grew up in Mystic, CT – just blocks from both Long Island Sound and the Mystic River. I am now finishing up my undergraduate years at MIT where my coursework centered on policy, sustainability and engineering has intersected on the subject of water. The collaborative culture and hands-on curriculum at MIT allowed me to test a novel desalination technology for agriculture, build an autonomous aquaculture robot, apply water diplomacy frameworks to modern conflicts, and design a humanitarian family water filter. My internship with Xylem Ignite, a global initiative working to educate, engage, and inspire youth about water, has broadened my perspective of the water industry and strengthened my passion for water. Inspired by engineers, innovators, and changemakers, I am empowered and proud to be part of the future of water." Christopher Palassis, Director of Sensor Development, Advanced Technology & Innovation: “I have always loved visits to the ocean. There is something magical about that boundary between land and water, as well as water’s transformative power. It wasn’t until I began working in water 13 years ago at Xylem’s YSI business that I really began to appreciate the fragility of this precious resource by gaining an understanding of the delicate balance water lives in and the impacts our practices can have on its quality. But, it wasn’t until I was able to take a step back and view complete watersheds via satellite did the connectedness of water really come into view – each drop, forever on this planet, in different forms, performing the vital task of sustaining life. To me, water is life and must be passionately protected. I’m so proud to be able Pipes, Pumps and Valves Africa - Mar/Apr 2021

31

WATER

to work on Xylem’s Advanced Technology and Innovation team where I have the opportunity to collaborate with our customers and partners to discover and develop the next generation of water technologies to solve water. It’s an extraordinary privilege.” Anna Hildell, Managing Editor, Making Waves: “Growing up in Sweden in the 1970’s, I was surrounded by water from an early age. Not only the cold and grey brackish waters of the Baltic Sea that surrounded the island my family lived on, I also spent a lot of time in and on the lake close to our house. In the winters I spent hours and hours skiing and skating across the lake, and during summer days my friends and I swam, dived and played in the water. For the first years of my life my family didn’t have access to hot water in the house we lived in. In the summer, our shower was a water hose behind the old house we lived in, heated by the sun. During cold winters I remember washing up in a big bucket on the kitchen floor with water that my mother had heated on the stove. Growing up like this, it made me really appreciate the value of water and what a difference access to, in my case, hot water means. I try to educate my children to appreciate and not take clean water for granted and to live sustainably. Today, I still live on the same island, with the Baltic Sea right outside the windows of my family’s home. To me, water is everything, and I am so proud to be at Xylem in my role – helping tell the story of water.” Alexis de Kerchove, Director of Marketing and Business Development, Water Infrastructure and Europe Commercial Team: “Marine Biologist was my dream job as a child, and I was always fascinated by water. The strength of this element and the beauty of its nature were just so intriguing. When I had the opportunity to participate in a three-week

32

Pipes, Pumps and Valves Africa - Mar/Apr 2021

deep sea research project on the RSS Discovery, I found conviction in my passion. When land is far away behind and cannot been seen anymore, and a storm sweeps the ship deck with waves of the size of a house, I realized that this element, which I only knew until then as a free beverage or a place to swim in warm days, was actually in control of my fate on earth. Several years later, a tsunami took thousands of human lives away in the Pacific Ocean, and by chance spared the one of a dear friend working as a WASH volunteer in an NGO in Sri Lanka. Only following such an event can one understand the need to learn more about water, how to preserve it, and how to control it in order to nurture, protect and preserve life on this planet. Today’s changing environment brings new challenges to the coming generations. Climate change leads to more frequent extreme weather events and seasonally makes water scarce even where it was assumed abundant. New pathogens and human-made contaminants are making water a potential direct threat to human health and ecosystems, while it is so often taken for granted as clean and safe. As a father of four kids, the challenges become personal, and the dream that I had as a kid turns into a mission to build a more resilient world where access to safe water supply and sanitation is secured for all. Today, as part of my work at Xylem, I aim at partnering with water users, managers, engineers and policymakers to discuss the challenges, navigate through the latest innovations and technologies, and find together the solutions that truly will address their need and solve their greatest water issues.” Xylem Africa, +27 (0) 11 966 9311, Chetan.mistry@Xyleminc.com, www.xylem.com

Connecting Global Competence

Sub Saharan Africa's leading trade fair for water, sewage, refuse and recycling November 4, 2021 July 13 - 15,2 -2021

Gallagher Convention Centre, Johannesburg, South Africa

Showcase your solutions to over 8000 industry players & decision makers! IFAT Africa has established itself as Africa’s leading trade fair for water, sewage, refuse and recycling. The trade fair provides a broad overview of the environmental technologies available in sub-Sahara Africa, with a full and comprehensive range of product categories. The show is the gateway for international companies to the African market and for African enterprises to the global market, connecting with national and international industry partners.

NEW FEATURE: Renewable Energy Zone - Powered by IFAT Co-located trade fairs

SECURE YOUR SPACE TODAY: Tel: +27 11 476 809 • Email: ifat@mm-sa.com www.ifat-africa.co.za | ifat@mm-sa.com

@IFATAfrica

@IFATAfrica

@IFATAfrica

Skills, collaboration needed to overcome growing water challenges

WATER

Capacity development and closer collaboration between public and private sector stakeholders will be necessary if South Africa is to halt its declining water security challenge. This is according to industry experts and advisors to the IFAT Africa trade show and forum, who was speaking to mark South Africa's National Water Week 2021, from 15 to 22 March. Benoît Le Roy, Environmental, Technology & Project Alchemist, Founding Member of the South African Water Chamber NPC and Advisory Board Member of IFAT Africa, says South Africa’s water security has been declining year on year. Recent moves by community groups to legally challenge local water authorities and take the management of water and wastewater into their own hands are indicative of the levels of frustration emerging, he says. “Unfortunately, some of the recent successes by community groups will offer only temporary relief,” he says. The challenges are complex and multidimensional. We have a Master Plan to attempt to address them, but no progress has been made in implementing it. Water supply and management problems are a symptom of ineffective municipalities, and there are now around 110 of those currently being reported, compared with 60 a year ago.” Le Roy says urgent moves need to be made to decentralise water infrastructure management; upskill and capacitate local government to be able to implement water security

34

Pipes, Pumps and Valves Africa - Mar/Apr 2021