ENDORSED BY SAPMA, SAPSDA, SAVAMA AND VAMCOSA

Eight tips to boost pump piping efficiency

JAN/FEB 2023

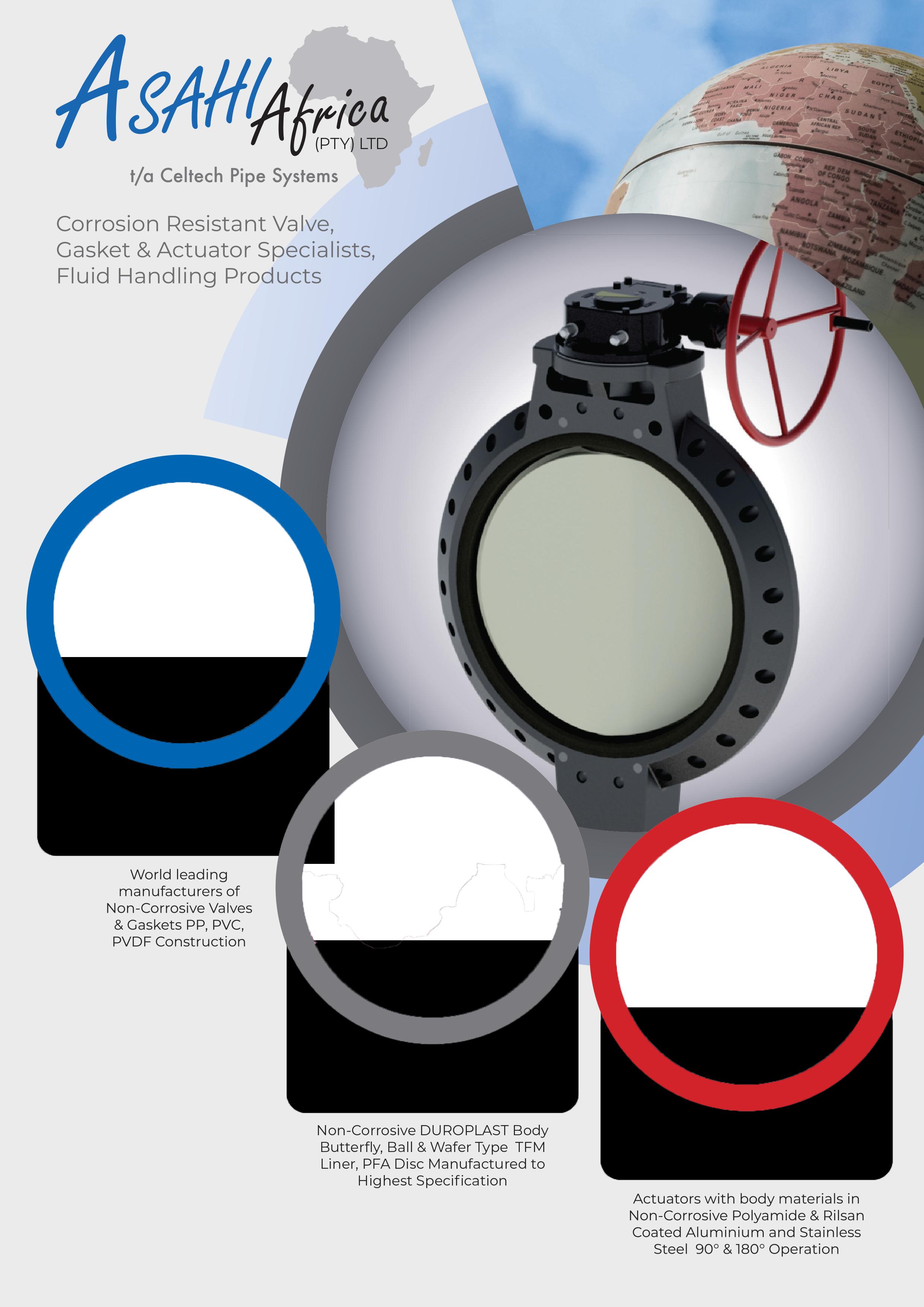

Our valves fulfill the highest of standards and are designed for many years of safe and reliable operation. Our service specialists regularly check, monitor and maintain all relevant system components - depending on what has been agreed. Our modular framework agreements offer you individual service and spare parts concepts. And we even go one step further. We additionally check systems for efficiency in order to reduce operating costs and increase productivity. For example, with the SES System Efficiency Service.

ZTS GATE VALVE GATE VALVE AKG - A/AKGS - A NORI 500 BOA - H Contact our dedicated Valves Sales Engineers for all your Valve requirements Tel: 011 - 876 - 5600 • E mai l: info - za@ksb.com KSB Pumps and Valves (Pty) Ltd www.ksb.com/en-za Your Level 1 B-BBEE Partner

We offer valves for precision processes - and demanding applications.

STAALWEDGE GATE VALVE AKDS/AKD

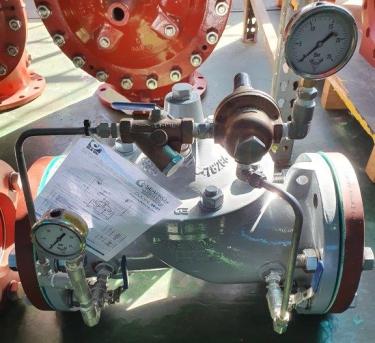

On the cover

Invincible Valves, +27 (0) 11 822 1777, enquiries@invalve.co.za, www.invalve.co.za

Pipes, Pumps & Valves Africa

Managing Editor: Surita Marx

Tel: +27 (0) 87 700 9834

Cell: +27 (0) 83 281 5761

Email: info@pumpsandvalves.co.za

Web: www.pumpsandvalves.co.za

Sales: Peter Rametsi

Email: sales@pumpsandvalves.co.za

Production Manager: Xane Roestroff

CONTENT Pipes, Pumps and Valves Africa - Jan/Feb 2023 3 Disclaimer: Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers SAPMA or VAMCOSA The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication. Advertisers Asahi Africa 29 Bezares 17, 37 Bilfinger 27 Bray 35 Conexpo IBC Cornerstone 13 Integrated Pump Technology 41 Invincible valves OFC, OBC IPR 15 KSB Valves IFC Lifting & Pumps Golf Day 31 Lifting Placements 21 Pleix-Quip Africa 39 Seapro SA 32 Stewarts & Lloyds 19 Vesconite Bearings 45 Wilden Pumps CS Xylem 23 COVER STORY Delivering value to customers the Invincible way 4 PIPES Eight tips to boost pump piping efficiency 6 PUMPS Never lose alignment again 10 Vesconite labyrinth seal improves desalination pump performance 12 SCADA systems are essential for a smart and sustainable water sector 14 The purchase price of a pump is becoming less and less important 15 The consequences of fitting that surprisingly expensive low priced peristaltic hose 18 How to control and limit contamination in a hydraulic system 20 Pump and valve innovator finds a test rig technology that talks the torque 22 Pump Rental offers benefits that are hard to beat 26 Reach new heights with Atlas Copco’s PAC H pumps 28 Reducing energy consumption in fluid power systems 30 More scope for Grindex pumps as African market grows 31 VALVES Ratio reducing valves in the water industry 34 WATER Does South Africa have a water crisis or simply a water problem? 36 Utility reduces aeration energy use by 32% with liquid diffuser cleaning 38 ADVERTORIAL 20 years of moving forward with PVC pipe technology 8 Bezares at Conexpo 2023 16 How AODD Pumps Can Satisfy All Demands In Mining Operations CS INDUSTRY NEWS Overview of the 2023 budget speech 13 Assessing industrial hydraulic system efficiency 40 BUYERS GUIDE 43

COVER STORY

Delivering value to customers the Invincible way

High-quality valve products and ancillary equipment supplier Invincible Valves prides itself on service excellence and flexibility, always striving to enhance every customer’s bottom line. Pipes, Pumps and Valves Africa sat down with Managing Director Pam du Plessis to find out more about the latest developments in the company.

There is no denying the past few years have been difficult. Notwithstanding the ongoing impact of the global Covid pandemic, economic conditions have remained challenging for manufacturers across the board. Surging commodity prices, geopolitical conflicts, supply chain disruption, high inflation and interest rates have impacted production lines requiring resilience from companies both large and small as many fight for survival.

Fearless and always up for a challenge Du Plessis and her team have not withered under the pressure, but rather taken the challenges thrown their way turning them into an opportunity to grow the business.

“The company had been experiencing unprecedented growth for several years prior to the pandemic leading to the decision to expand our operations. We had simply outgrown our facility. Just before Covid, we purchased a building close to our existing facility in Knights, Germiston,” she says. “Of course, the pandemic was unprecedented and unplanned putting a slight dent in our plans which saw us place the project on hold.”

Many a leader would have opted to can the entire thing, but not Du Plessis. As the world returned to slightly more normal circumstances she decided to go ahead with the expansion and in April this year, Invincible Valves will open its brand-new factory that is currently undergoing extensive revamping and upgrading.

The more than 2000 square meter under-roof facility heralds a new era for the valve manufacturer. Set to streamline its operations, it will introduce even more efficiency allowing the company to improve on its already brilliant track record.

According to Du Plessis, the expansion allows the company to transform its current factory into a warehouse housing its large quantity of stock while the new facility will be the manufacturing hub.

“Our current factory operates over two levels which make for a lot of back-and-forth movement in the production process. We have designed the new facility to allow for a sleek operation that is bespoke to our needs.”

Standing the test of time

According to Du Plessis, Invincible Valves’ success can be contributed to its solid foundation.

“We have a very clear strategy and operating model,” she explains.

Such as their decision to hold vast amounts of stock. Unlike many other manufacturers who have opted to reduce inventory levels amidst tough economic times, Du Plessis has opted to increase her stock levels.

“It is quite simple really,” she says frankly. “If I don’t have the stock, I can’t sell it. At the same time, however, due to our high level of stock availability, we are able to keep our clients' downtimes to a bare minimum and are able to offer a vast range of products within short periods of time.”

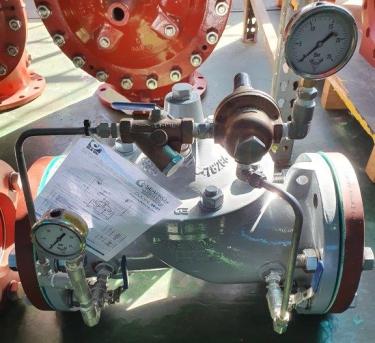

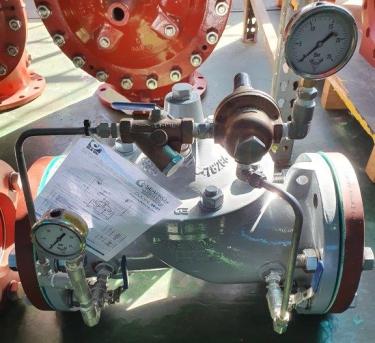

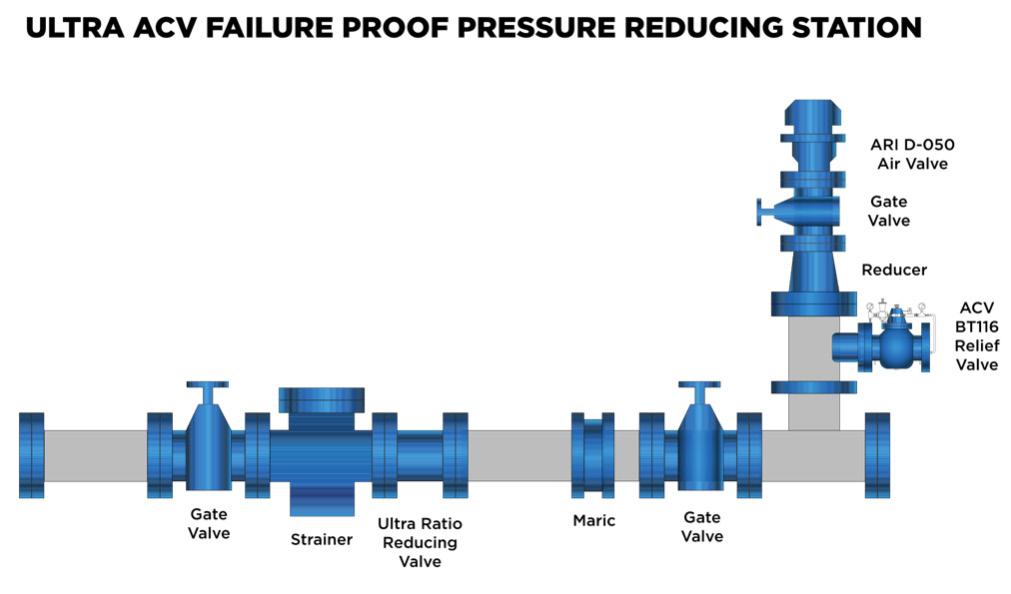

This operating model was the saving grace of the company during Covid. “We were identified as an essential service and even though we had to operate with far fewer staff to meet isolation guidelines, we had the stock available and could continue as normal for the most part.”

Du Plessis is not one that shies away from a challenge. “Times are tough but it is about riding the wave and remaining agile and flexible, meeting the needs of one’s customers. For us at Invincible, customer-centricity is everything. We are committed to finding solutions that meet each and every customer’s specific needs. We don’t follow a one-size fits all approach and we make sure we are able to service all of our customers to the same high standard.”

She attributes the company’s success to its ability to evolve and build on previous successes. “Our business model is one that allows us to deliver faster lead times. The decision to reinvest our money into stock is one that works for us and has allowed us to grow our footprint not only locally but also across the continent.”

Moving further afield

The growing role of exports is an exciting development for Invincible Valves. “We are seeing increased interest from around Africa and are involved in several projects on the continent.”

Whilst projects locally have still been slow to pick up after the pandemic this has not been the case across the rest of Africa, especially in the mining sector which is seeing high levels of interest. “There is a definite increase in demand for quality products on the continent,” says Du Plessis. “While we are competing with cheaper products that are flooding the market, the need for robust, quality products in Africa is high,” she says. “In some parts of the market, there is a trend to buy based solely on price but it is not something that we will ever offer at Invincible. We will never trade quality for the price as we don’t see it as being cost-efficient in the long run.”

She said with the valve market growing in Africa she was optimistic for the future. “We already have an established footprint and we are determined to grow this even more. Our new factory will add value to the service that we offer and improve our ability to deliver quality valves to the market quickly. Our goal always has and will be to be the preferred provider for valves and ancillary equipment on the continent.”

Invincible Valves, +27 (0) 11 822 1777, enquiries@invalve.co.za, www.invalve.co.za

Pumps and Valves Africa - Jan/Feb 2023 5

Pipes,

Eight tips to boost pump piping efficiency

When it comes to optimizing pumping systems, the piping and additional end-use equipment are just as important as the pump itself. Here are eight ways you can assess your piping system’s configuration to minimize life-cycle costs.

Select the proper pipe diameter

Cost plays a big role when specifying piping. While smaller diameter pipes cost less, the higher friction and overall head loss generated through the increased velocity is significantly greater. As a result, systems with smaller pipes may require more power or even a larger pump, and those energy costs will accrue over the lifetime of the system. Larger diameter pipes, on the other hand, have higher material and installation costs, but generally lower friction losses. To optimize a piping system, make sure to consider both initial costs and the extra energy required to use smaller diameters. There are several software packages that can help you calculate the life-cycle costs associated with the variety of pipe sizes required for complexed systems. The Hydraulic Institute offers a Pump System Optimization and Assessment course that covers the tools and software to support these calculations as part of pump system optimization.

Minimize pressure drops

Poor flow profiles will promote uneven flow and increase energy costs within a pumping system. Unfortunately, space constraints often preclude ideal piping system layouts. In this case, look for ways to smooth out sharp bends and expansion and contraction transitions. Also, keep your pipes as straight as possible. When designing new systems, install valves and system components so they are in line with the pipe run.

Choose low-loss components

Service requirements, such as maximum working pressure, open and close cycles, hand wheel torque, and stem leakage, often drive valve selection. Often, for applications in which overall service requirements are modest, designers typically trade efficiency for upfront cost. Take globe valves, for example.

Engineers like them because they are simple and inexpensive, but the flow path through the valve has a relatively high coefficient of friction. Switching to a different type of valve may decrease those losses and the overall life-cycle cost of the pumping system. For designers and assessment professionals who want to dive deeper, the Hydraulic Institute offers a free web-based Engineering Data Library (edl.pumps.org) that provides the resources to determine the typical resistant coefficients for valves and other fittings.

Size valves properly

System designers often add safety margins and oversize pumps to incorporate safety margins to account for such unknowns as actual pump performance, pipeline fouling and scaling, and future system demands. This safety margin often leads to engineers to specify a larger pressure drop across the valve than necessary.

The result is an undersized valve that has a high energy or friction loss. The same is true when specifying valves to

6 Pipes, Pumps and Valves Africa - Jan/Feb 2023 PIPESPIPES

handle maximum system flow. Designing for much greater than normal flow creates excessive pressure drops across the valve under typical operating conditions.

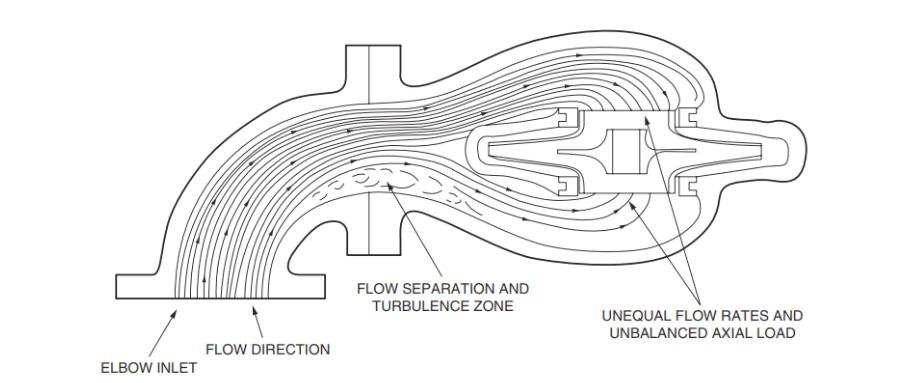

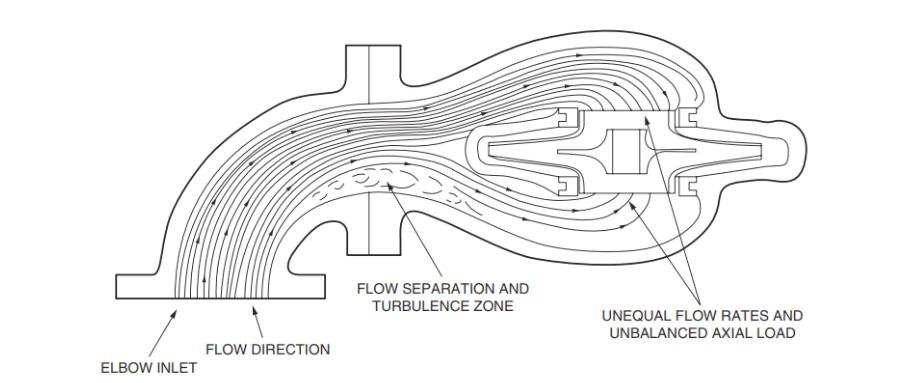

Provide uniform flow into the pump

Rotodynamic pumps operate most efficiently with a uniform inlet flow profile. This smooths the fluid’s transition from the suction nozzle to the impeller eye, which then imparts energy to the fluid by accelerating it along the vane to its tip. If the flow is no uniform, it will prevent the smooth transfer of energy. Non-uniform flow may also cause excessive vibration, which can shorten pump life, and weaken pipe welds, mechanical joints, and supports. When designing new pumping systems, provide as much straight pipe as possible upstream of pump suction nozzles. For existing systems, the closer short-radius elbows and valves are to the suction nozzle, the more likely they will create a highly turbulent flow that diminishes pump performance. This is particularly important when the suction pressure into the pump is low and the velocity is high. Figure 2 shows the flow separation and turbulence zone of a short-radius elbow mounted directly to the suction nozzle of a double suction pump. If an elbow is required just upstream of the suction nozzle, consider switching it to a long-radius elbow or install flow straighteners, such as baffle plates or turning vanes in the elbow to smooth the transition into the pump. This works well as long as the pressure drop across the straightener does not infringe on the necessary NPSH margin.

Limit air and vapour entrapment

Air or vapour entrapment is the result of a poor system layout or fitting selection. The collection of air or vapour occurs when the pumping system does not have a constant rising slope or it lacks air release valves at high points. When this occurs downstream of the pump, the air or vapour pockets reduce the effective liquid flow area within the pipe creating a throttling effect similar to a partially closed valve. For piping upstream of the pump, the pockets may cause pressure pulsations that degrade the performance of the pump. If space permits, use eccentric reducers and sufficient straight pipe leading up to the pump suction nozzle.

Suppress vortex formation

Free surface vortices occur in both tanks and wet wells when the fluid level drops too close to the suction inlet of a pump or submerged suction piping. When free surface vortices appear (see figure 3), air will enter the pump. This could trigger a loss of suction head and degrade performance. In severe cases, the pump could lose its prime. Since most centrifugal pumps are not self-priming or submersible, service personnel would have to fill, restart, and vent the pumps manually. Also, too much air could damage mechanical seals, packing, and impeller wear rings. Monitoring water levels with simple sensors or using an automated water level system will ensure the pump or suction piping has adequate submergence. For degraded pump performance, or mechanical issues dealing with submerged vortices, please reference ANSI/HI 9.8 Rotodynamic Pumps for Pump Intake Design.

Support your piping

A pump and its connected piping rarely align perfectly during installation. To accommodate this, installers or service personnel turn to manual mechanical corrections. If they are significant, this mechanical pipe strain force will pull the pump out of alignment, reduce the service life, and, in severe cases, cause catastrophic failure. To prevent this from happening, piping around the pump should be properly supported and restrained using pipe anchors and hangers. This also reduces vibration and extends pump service life.

To learn more about this topic, visit (pumps.org/standards) and reference the Hydraulic Institute Standards ANSI/HI 9.6.6-2022 Rotodynamic Pumps for Pump Piping, ANSI/ HI 9.8-2018 Rotodynamic Pumps for Pump Intake Design, ANSI/HI 14.3-2019 Rotodynamic Pumps for Design and Application, and ANSI/HI 9.6.2-2021 Rotodynamic Pumps for Assessment of Applied Nozzle Loads.

Hydraulic Institute, training@pumps.org, www.pumps.org

Pipes, Pumps and Valves Africa - Jan/Feb 2023 7 PIPES PIPES

20 years of moving forward with PVC pipe technology

Proudly celebrated its 20th Birthday in 2022, Sizabantu Piping Systems has grown from a trading company to one providing the marketing and sales function for a major South African thermoplastic pipe manufacturer - Molecor.

Sizabantu is a Southern African agent for a world leader (Molecor) in thermoplastic (PVC-O) pipe technology and is a joint venture partner in a production facility with Molecor in Richards Bay Industrial Development Zone.

Significantly, all the Sizabantu management throughout Southern Africa are qualified and highly experienced people who have been in the thermoplastic piping system industry for many years. They know quality products, customer service, product availability and commercial competitiveness are paramount in this highly competitive market.

They currently supply high quality, locally manufactured, thermoplastic piping system products into the Southern African market. The maximum diameter and pressure rating of the PVC-O pipes available is substantially greater than previously available and has enabled Sizabantu to compete in markets that were hitherto beyond the scope of previously available thermoplastic piping systems.

MPa to 36 MPa – a incredible 260% increase.

In the 1970s. the PVC industry entered the mining services market following a successful project, led by Dr Ken Hart. A high-impact pipe PVC-HI (SANS 1283) was developed that satisfied the mining industry requirements and enabled PVC pipes to be used for underground services. Following on from this work, another development project, led by Mike Osry, developed PVC-M (SANS 966-2) in the mid-1990s by adding impact modifiers, commonly CPE (Chlorinated Polyethylene), or Rubber Toughened Acrylics, or a combination thereof, to the PVC material to increase its impact strength. This enabled the material to exhibit “tough” characteristics that facilitated the reduction of the Design Coefficient (C) from 2 to 1.4 thereby increasing the Allowable Design Stress (σ) from 12.5 to 18 MPa.

About forty years ago PVC-O (Oriented Unplasticised Poly Vinyl Chloride – SANS 16422) was developed. The molecular orientation process results in the improvement of physical and mechanical properties of the material. In the intervening forty years, there have been improvements in PVC-O material from Classification 315 material initially to Classification 500 material currently – the nomenclature is ten time the MRS (Minimum Required Strength) of the material.

The latest PVC-O material, Classification 500, must have an MRS of not less than 50 MPa at 50 years, that with a Design Coefficient (C) of 1.4 gives a σ-value of 36 MPa –where σ = MRS/C. This is a substantial improvement, that is twice the Allowable Design Stress (σ) of PVC-M, made possible by improved in-line production technology which, Sizabantu Piping Systems’ Spanish technology partners Molecor excel at, and their TOM® 500 PVC-O pipes are produced locally in Richards Bay.

PVC pressure pipes

PVC pressure pipes were first used in Germany about eighty-five years ago. About sixty years ago PVC pipes were introduced into South Africa but were not enthusiastically received. Today, for example, more than ninety-five percent of domestic sewerage reticulation pipes are PVC –things have changed.

Scientists, polymer technologists and processing engineers have enabled the Allowable Design Stress (σ) for HDPE to be increased from 5 MPa to 8 MPa – a substantial 60% increase. However, the increase in PVC’s strength, enabled by improved technology, is even more substantial, increasing from 10

Innovation - TOM® 500 PVC-O

Innovation is one of Molecor’s core values. With TOM® 500 PVC-O branded pipes, they have increased the range of PVC-O pipes from the previous limit of 315 mm diameter PN16 (PN is the working pressure in bar) to 630 PN25, with the M-OR-P3136 system in 2010. Then in 2013 to 800 PN20, with the M-OR-P3180 system. Then

ADVERTORIAL

to 1000 PN16 in 2020 and to 1200 PN16 with the M-OR-P5012 system in 2021. Currently, the complete range of pipe diameters is available up to PN25 bar working pressure. These are exciting developments for the thermoplastic pipe industry, that has enabled it to compete in the large diameter high pressure pipe market, that was previously beyond its capability.

pipelines, a market that steel and ductile iron has dominated historically. PVC-O pipes are lightweight, have negligible friction increase over time, do not corrode, do not require expensive cathodic protection, give labour intensive emerging contractors equal opportunity to compete, have extremely high impact strength, low creep, low celerity and extremely low embedded energy – maybe it is the material to help save the Earth?

As government, metros, municipalities and local authorities strive to provide services to more people, with an everincreasing demand, and limited funding the advantages of using TOM® 500 PVC-O thermoplastic pipes and fittings becomes self-evident.

These innovations and the latest high technology polymers have enabled the service life of TOM® 500 PVC-O thermoplastic pipes to be greater than 100 years – that is now the duration demanded by owners and consultants. This is more than twice the ISO (International Standards Organisation) protocol requirement that thermoplastic pipes’ design service life shall not be less than 50 years, which is 438000 hours on the polymer’s Creep Rupture Regression Curve shown in Graph1. This property of TOM® 500 PVC-O thermoplastic pipes is one of the cornerstones of Sizabantu’s success, together with its industry expertise, customer service culture and local manufacturing facility. These attributes have also enabled Sizabantu to grow their export business into Africa with one of its largest irrigation schemes, in Angola, an example of the success in this market. They illustrate that despite the competitive nature of the market, they are succeeding and prove an axiom of today’s world – if you are standing still, you are probably going backwards.

PVC pipe technology has improved substantially, and is continuing to improve, thereby giving the pipeline industry proven materials to use for large diameter, high pressure, bulk supply

The future prospects appear to be promising for the product. More than 4 km of 1000 mm OD PN16 pipe have already been supplied and installed in Europe in 2021 and the first 1000 m OD pipes are expected to be supplied in South Africa in 2022. This will be another significant milestone for the South African thermoplastic pipe industry.

Sizabantu, proudly@sizabantu.com, exports@sizabantu.com, www.sizabantu.com

PIPING SYSTEMS

ADVERTORIAL

South Africa

Never lose alignment again

How you can save time & money by using electric packages with a modular design. Pump packages that are used for dewatering and bypass purposes often take a beating – from operation on a job site to getting transported to a job site in the first place.

With labour costs rising and raw material availability pushing suppliers, reliable acquisition, operational durability and low maintenance remain critically important. These factors have raised concerns over pump vibration on electric-driven packages and the resulting problems it can cause, namely the loss of pump and motor alignment.

This article takes a closer look at solutions to this problem and how electric packages with a modular design can overcome many of the challenges associated with alignment.

What causes vibration?

Vibration occurs when a pump and electric motor assembly are not professionally aligned, and many times this process can be overlooked or not performed since it is labourintensive, tedious and requires an experienced service professional. This process must also be repeated any time the pump is moved to a new location or shows signs of vibration.

When it’s not done properly, it can lead to long-term vibration-related maintenance issues, including seal failures, unexpected power losses and – in worst case scenario situations – a broken shaft. These issues can also cause pump users to completely rule out using an electricdriven pump, since they assume the cost and efficiency savings won’t offset any alignment issues.

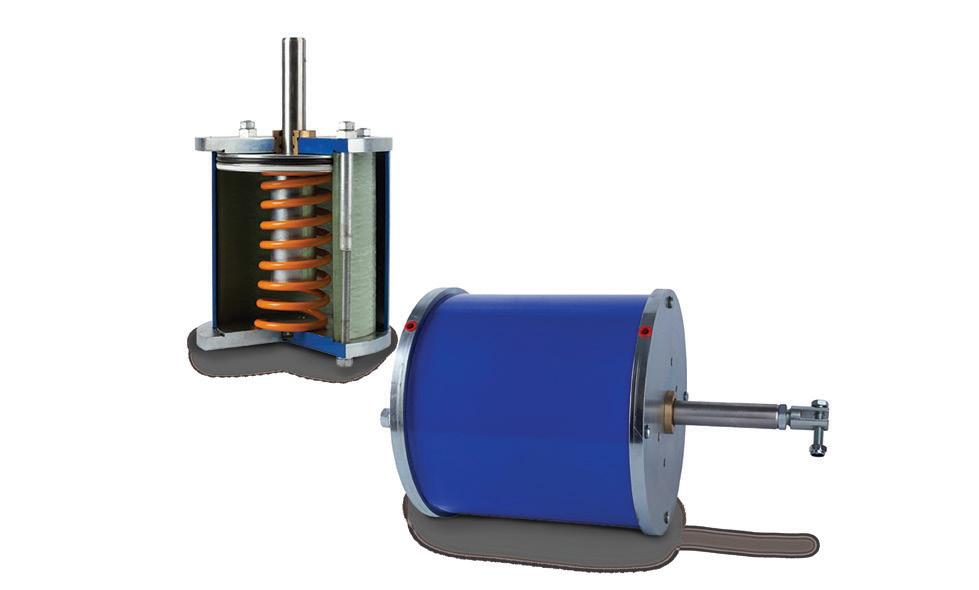

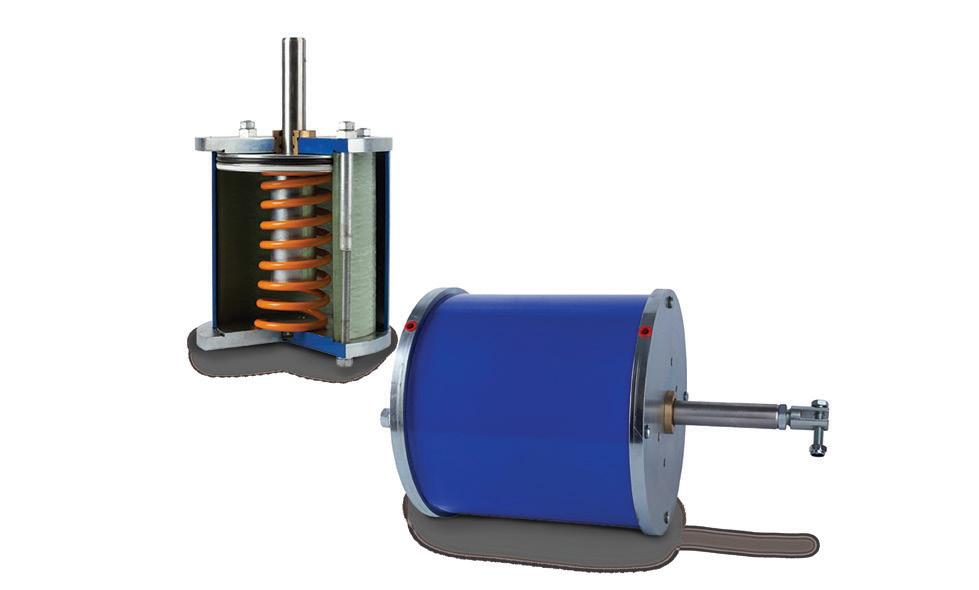

The solution to vibration: motor stool design

The solution to the vibration challenge is permanent alignment, achieved using a bracket that rigidly connects the pump and motor together. This bracket, also known as a motor stool, is engineered to precise tolerances to ensure that the coupling remains permanently aligned and protected. It eliminates any concerns with shifting during transport or operation, saving countless hours of service time. If this method of assembly sounds familiar, it’s because it takes its inspiration from a typical diesel

coupling with a bell housing that’s bolted to an engine. However, in the case of an electric pump package, users benefit from the energy efficiency that electric motors offer without sacrificing performance, power or alignment. How does permanent

operators?

alignment benefit owners and

In addition to the cost savings from the overall efficient operation that comes with an electric motor, owners benefit in several other ways, including time savings related to setup, maintenance and pump life:

Pumps can be fully operational in hours, Not days, after transport.

A pump and motor system is typically large, heavy and bulky, weighing in at several tons. For their initial placement, they may be shipped hundreds of miles, encountering bumps, stops and turns along the way. Once they arrive, they are unloaded by a forklift, jostled around and set on site. From there, they might be moved as mobile dewatering needs change within an area. If the unit is used as a rental asset, it will be sent back to a storage facility only to be transported again to its next job.

One example of this is a temporary municipal application, like a sewer bypass. In addition to the initial transport to the site, additional issues may occur: the ground may not be level, a suction pipe may not be fully supported, and the pumps frequently cavitate.

In dewatering and bypass applications such as this, time is always valuable. Municipal installations in most cases have urgent pumping needs, and there is typically no time to spare to perform onsite alignment once the unit arrives – and alignment takes time. It requires exacting laser measurements that are not only time-consuming but also expensive. With a rigid motor stool design, the need for alignment or realignment is eliminated. A robust, modular design with a motor stool setup focused on portable rugged use is perfect for customers who need strong equipment operating quickly.

In fixed installations, the system designer may determine that grouting is not required due to the rigid alignment, opting instead to just secure the package to a rigid slab with anchors. This also saves ample time during the installation process.

Operational durability & low maintenance.

When an alignment isn’t performed or is done too quickly, the misalignment will lead to vibration issues. In time, this vibration can result in seal failures, oil leaks, shortened bearing life and more. In extreme situations, this vibration can cause the coupling to fail and the shaft to break. Consistent vibration also leads to pumps that need to be rebuilt. Again, with a rigid motor stool design, vibration

10 Pipes, Pumps and Valves Africa - Jan/Feb 2023 PUMPS

isn’t a concern because misalignments will never be an issue.

Even permanently installed pump and motor packages that never move can suffer from misalignment over time. Despite their bulk, electric pump packages can be very sensitive to movement. Non-zero nozzle loads are unavoidable, and misalignment and the resulting vibration concerns can occur due to nozzle loads. Misalignment can also happen when regular maintenance is performed on a pump or motor. A motor stool protects against misalignment that may occur during the life of a pump.

Mining applications provide good examples of these vibration and maintenance concerns in action. Mines are often hazardous environments, and pump packages are usually at risk of being hit by trucks and other pieces of equipment. A rigid motor stool eliminates alignment concerns that result from everyday use of the unit itself or the environment it’s operating in.

Pump packages used in mines are also frequently moved around the job site and have pipe and hose exerting loads on the pump and base. This makes a strong pump/ motor connection even more important since the resulting vibration can cause misalignment otherwise. These pump packages also offer streamlined maintenance since the modular design can be disassembled quickly, helping to reduce operating costs over the life of the system.

Reliable acquisition: modular designs are

Easy to quote & can have faster lead times

Systems that feature a rigid bracket assembly are designed to be modular, which can help users get an electric pump package onsite for operation more quickly and efficiently than custom-built units. The modular design is built using interchangeable parts, delivering upfront time savings for the system designer as well. Custom-built units take longer to engineer and often require specialized parts. A modular design makes the sizing and quoting process faster and the use of standard parts drives down lead time.

How does quoting work?

Franklin Electric streamlines the ordering process with FE Select, a 24/7 online and mobile-friendly tool that instantly helps formalize deliverables with printable and downloadable quotes: no waiting for a callback.

Users input parameters and the tool does the rest: fully specifying what products are recommended, including

the necessary components, a list price quote for the system, and links to related product documentation and performance curves.

FE Select walks through the process from start to finish. Users can do either a basic search that requires only primary application data, such as flow and total dynamic head demands; or a more advanced selection that considers some additional performance requirements.

The user’s application inputs generate several results, sorted by hydraulic efficiency. The list can easily be narrowed down based on the parameters that are most important to the user: suction/discharge size, power requirements, NPSH and other relevant factors.

For electric pump packages, FE Select offers a configurator tool that provides users with clear visibility of product selection, price breakdown, available options and overall product performance on the performance curve.

Once a user finds the ideal pump and impeller size that fits their performance needs, they can easily continue from the pump curve page into the configurator tool. Here they can customize an electric pump package to meet their application requirements. This gives users the ability to build out their unique package quote with live line-item pricing updates; there is no need to wait on quote requests and responses to sales inquiries. After selecting and pricing an electric package, users can save their quote to either view later, or move their selection into the ordering process.

When thinking about these benefits, it’s important to remember that often facilities and users may operate more than one pumping system. Worrying about alignment for a single unit is a big enough concern; consider those alignment needs across three, six or more units, and the benefits of permanent alignment multiply.

Whether for mine dewatering, municipal bypass, industrial processing or another application entirely, alignment matters. Electric-driven pump packages that feature a rigid motor stool design reduce time-consuming alignment work, saving owners and operators on initial setup costs as well as maintenance costs down the road.

Franklin Electric South Africa, +27 (0) 11 723 6500, info@franklin-electric.co.za, franklin-electric.co.za

Pipes, Pumps and Valves Africa - Jan/Feb 2023 11

PUMPS

Vesconite labyrinth seal improves desalination pump performance

A desalination plant in the Middle East commissioned a 6 MW pump with a Vesconite labyrinth seal in 2022. This is according to the product manager at a large Austrian technology company tasked with designing the pump.

His company advertises that “thanks to today’s state-ofthe-art technologies, potable water and desalination plants are able to achieve levels of safety and efficiency that were previously unimaginable”, and these are some of the considerations that he uses when he develops products for this industry.

It was initially for efficiency reasons that the pump OEM engaged with Vesconite.

Wear rings and seals, such as those produced by Vesconite Bearings, exhibit 5% efficiency gains, the product manager says.

With high power intensities, the savings from these gains become increasingly important and have resulted in the whole world striving for more efficiency in the technologies that they employ, he notes.

Interestingly, the technology company believes that Vesconite Bearings’ main differentiating factors are its service and its flexibility.

The product manager informs that a competitor had in one case quoted a seven-to-12 week delivery time from the placement of an order, as compared to a week’s dispatch time for Vesconite.

“Sometimes a lengthy delivery time is not acceptable for us,” he says.

Vesconite’s service and support was also a distinguishing factor in choosing labyrinth seals made from Vesconite selflubricating no-swell bearing materials.

The product manager explains that Vesconite Bearings was willing to discuss the technology company’s design requirements and did not simply dismiss them as impossible to achieve.

As a result, the labyrinth seal was produced applying the close clearances that the client desired.

“We were able to search for solutions together,” describes the product manager.

The technology company has been using Vesconite parts for five years and estimates that between 40 and 60 pumps globally have between 80 and 100 Vesconite parts installed on them.

These are used in a variety of industries, including desalination, which is becoming an important way to secure drinking water for urban needs.

Vesconite Bearings, +27 (0) 11 616 1111, vesconite@vesconite.com, www.vesconite.com

12 Pipes, Pumps and Valves Africa - Jan/Feb 2023 PUMPS

Overview of the 2023 budget speech

The minister of finance, Enoch Godongwana, presented his budget speech before parliament. Cornerstone would like to provide you with a summary of the main points without getting bogged down in the political jargon.

improve their systems and increase their revenue-raising capabilities. As a result, we expect SARS will not become any easier to deal with going forward, as they are under ever more pressure to collect more taxes and reduce unnecessary refunds.

Cornerstone has listened attentively to the Minister of Finance’s budget speech for the upcoming 2023–2024 tax year. We believe there are a few key takeaways that all businesses and individuals should keep in mind during the coming year.

Renewable Energy Incentive

The highlight of the speech was the announcement that there would be a tax incentive for renewable energy spending to ease the stress on households and businesses caused by load shedding. The most significant incentive is for businesses, which can deduct 125% of all renewable energy investments for two years beginning March 2023. This means that if your business spends, SARS will allow your business to reduce the income it gets taxed on by R125 for every R100 that was actually spent. This incentive is interesting because there is neither a minimum nor a maximum. This incentive is interesting because there is neither a minimum nor a maximum. In essence, if your company (not an SBC) pays R1 million to install solar power, you would save R337,500 in corporate income tax. This expansion in Section 12B is exciting as it allows companies to install renewable energy without being impacted by load shedding. The more modest incentive for

individuals only applies to rooftop solar panels and is valid for one year beginning March 2023, with a rebate of 25% of the cost of the panels, up to a maximum of R15,000. While this sounds disappointing, it is not quite as bad as it might first appear.

The Minister specifically called this a “rebate,” and rebates reduce the amount of tax you need to pay, not the amount of income SARS taxes you on. In other words, the incentive applies after your income is multiplied by your tax bracket percentage. For example, if you are in the 36% tax bracket, an R15,000 rebate would cover R41,667 worth of your income, thus putting more money back into your pocket and making solar power more accessible.

SARS

It was said that SARS did better than expected and brought in R93,7 billion more in taxes than planned over the past year. In practice, we have seen the effect of this as SARS is becoming more stringent and heavy-handed with audits, rejecting disputes, and demanding payments. We have also seen a rise in the number of taxpayers who are caught avoiding or not paying taxes. There is also a proposal to increase SARS funding, specifically to

Tax rates

The only other notable news from the budget speech that should be relevant to almost everyone is that there are no changes to the business income tax or VAT rates. Also, individuals tax brackets, tax rebates, and medical aid credits will only go up by the amount of inflation.

There are a few interesting points that are worth mentioning

• Government is considering revisions to the ‘two-pot’ retirement system to be effective 1 March 2024

• The sugar tax will remain unchanged for two years going forward

• Alcohol and tobacco tax will increase by 4.9% from 1 March

• Public sector wages will increase depending on the ongoing negotiations with unions

In the end, the budget speech was much shorter than expected, and a lot of attention was paid to SARS’s ability to collect taxes in order to pay for government projects and rising debt costs.

Cornerstone Financial Services Group, marketing@cornerstonefsg. co.za, www.cornerstonefsg.co.za

INDUSTRY NEWS

Pipes, Pumps and Valves Africa - Jan/Feb 2023 13

SCADA systems are essential for a smart and sustainable water sector

The current water crisis confronting South Africa is due to the sector still largely being burdened by ageing infrastructure, water quality issues and pipe bursts resulting in 41% of leakages attributable as non-revenue water. “There is room for improvement, but only if the sector can adopt and embrace change,” argues Joyce

Power and Water Local Division Sales Manager at ABB.

Cutting-edge solutions can be deployed to ensure sustainable management of the complete water lifecycle. This would mitigate the impact of natural disasters such as drought and floods. Such solutions are centred on supervisory control and data acquisition (SCADA) systems.

SCADA is the most widely used automation system for water applications globally. In a world where every drop of water counts, water and wastewater plants play a critical role in bridging the gap between the growing demand for and scarcity of this precious resource. Automation and control technologies are at the core of the challenge.

For example, ABB Ability™ Symphony® Plus SCADA can easily be adapted or engineered for a broad spectrum of applications in the water and wastewater industry, including water distribution networks, water pumps, water transmission pipes, drinking water, water mains, pumping stations and wastewater treatment.

“The flexibility and scalability of SCADA makes it ideal for the entire spectrum of clean power and water installations, be they locally or remotely operated plants, fleets or networks,” notes Moganedi. It allows for specific plant processes to be monitored, controlled and managed.

Moganedi,

This ranges from visual oversight of operations to access to real-time information to monitor plant performance and flag any issues that are cause for concern. It also makes remote operations possible to boost efficiency and productivity. “Most importantly, the ability to predict any failures and deploy mitigating measures timeously allows us to manage our water infrastructure assets smartly,” argues Moganedi. However, the uptake of SCADA systems in the water sector is hampered by a lack of project funding and slow implementation.

“Responsible and efficient water usage can only be achieved by the automation, electrification and digitalisation of South Africa’s water plants to ensure safe, smart and sustainable management of the water cycle,” highlights Moganedi. Only when plants are automated can responsible water use be effectively implemented.

ABB, +27 (0) 10 202 6995, contact.center@za.abb.com, www.global.abb

14 Pipes, Pumps and Valves Africa - Jan/Feb 2023 PUMPS

The purchase price of a pump is becoming less and less important

Due to the worldwide price increase of raw materials, pumps have become more expensive in the past 2 years. However, energy prices in Europe have risen much faster. We have calculated different situations and each time the share of the initial purchase price in the Total Cost of Ownership has dropped spectacularly over the past 2 years.

We calculated with the purchase price of the pump from 2 years ago and with an energy price of € 0.2 / kWh how long it took for the pump to consume its own value in energy. For pumps that run 40 hours a week, this was between 2 to 2.5 years for smaller pumps and up to less than 1 year for large pumps.

With today's prices and an energy cost of € 0.4 / kWh (which is still conservatively calculated), a pump often consumes its own cost price of energy within 6 months.

Energetic efficiency becomes more important

Hence our statement that the purchase price of a pump becomes less important, but its energetic efficiency all the more so. A pump that is 10% cheaper to purchase, but consumes 5% more electricity, costs as much after a year as the more expensive pump. For all subsequent years, you pay the difference in purchase price to your energy supplier every year. And don't forget that a pump with an efficiency of 60% consumes on average 5% more energy than another with an efficiency of 63%!

At Packo we have done a lot of research over the past 15 years to increase the energy efficiency of our pumps and it has been one of the most important points of attention for all newly developed pumps ever since. Today we can say that we have a range of hygienic centrifugal pumps with one of the highest, if not the highest, energy efficiency on the European market.

An optimal selection guarantees a lower energy bill

In addition to a solid hydraulic design of the pump, an optimal selection also determines the amount of the energy bill during the life of the pump. Packo developed an advanced pump selection package that gives you an overview of the initial investment and energy consumption at a glance depending on operating point, viscosity, number of operating hours per week, etc. and this with both an IE3 and IE4 motor.

Packo Inox Ltd, pumps@packo.com, www.packopumps.com

Pipes, Pumps and Valves Africa - Jan/Feb 2023 15 PUMPS

Round-The-Clock Dewatering 24/7 365 C M Y CM MY CY CMY K IPR-PVA-180x65.pdf 1 2022/09/01 15:42

Bezares at Conexpo 2023

Bezares will participate in the CONEXPO-CON/AGG 2023, where it will showcase its latest innovations in the industry.

NEWimproved

Solenoid-based ELECTRIC ACTUATORS

PTOs VALVES

Bezares is a leading global manufacturer of power take-o s and hydraulic systems, and it is our pleasure to showcase our products and services at the Conexpo fair in the USA.

At Bezares, we are committed to delivering high-quality and reliable products to our customers. Our state-of-the-art manufacturing facilities and expert engineers ensure that every product we produce is of the highest quality, built to last and operate e ciently.

Our extensive range of products includes power take-o s, hydraulic pumps, valves, and accessories for all types of vehicles and machinery. We o er a wide variety of PTOs that are compatible with all types of transmissions, including manual, automatic, and automated systems. In addition, we provide customized solutions for speci c applications, ensuring that our customers have access to the best products to meet their speci c needs.

At Bezares, we are dedicated to providing our customers with exceptional customer service. We o er technical support, training, and after-sales service to ensure that our products are performing at their best. Our team of experienced professionals is always available to answer any questions or concerns our customers may have.

We take pride in our commitment to sustainability, and we constantly strive to improve our processes and minimize our impact on the environment. We implement green initiatives in all aspects of our operations, from our manufacturing facilities to our product design and packaging.

At Bezares, we value our partnerships with our customers, suppliers, and employees, and we are committed to building long-lasting relationships that bene t everyone involved. Our participation at the Conexpo fair is an opportunity to strengthen our connections with our customers and introduce our brand to new potential partners.

We invite all attendees to visit us at the Conexpo booth #S82301 and learn more about our products and services. We look forward to showcasing our latest innovations and discussing how we can help meet the needs of the construction and heavy equipment industries. Thank you for considering Bezares as your partner in power take-o s and hydraulic systems.

Bezares

bezares@bezares.com bezares.com

16 Pipes, Pumps and Valves Africa - Jan/Feb 2023 6 Pipes, Pumps and Valves Africa - Jan/Feb 2023

A D VER T ORIAL

Pipes, Pumps and Valves Africa - Jan/Feb 2023 17 Pipes, Pumps and Valves Africa - Jan/Feb 2023 7 SEE YOU @ BOOTH #S82301 A D VER T ORIAL PUMPS AND MOTORS BENT-AXIS PISTON VANE GEAR 20 450 BAR (Max) 30 450 BAR (Max) 40 450 BAR (Max) 50 450 BAR (Max) 60 450 BAR (Max) 80 450 BAR (Max) 110 450 BAR (Max) FR He a v y Duty M e d i u m ytuD Tw i n Flo FR2 45 300 BAR (Max) 80 300 BAR (Max) 125 300 BAR (Max) MR

The consequences of fitting that surprisingly expensive low priced peristaltic hose

In any industrial setting, the balancing act between cost savings and profitability is a careful one. The mining industry for instance - and driven by a need for profitability, efficiency and yield maximisation - is one of the toughest industrialised working environments in which to achieve this balance.

Too often in such a competitive arena, companies are driven to keep purchase costs as low as possible and resort to fitting non-OEM aftermarket spare parts into sophisticated pieces of equipment. The approach undermines the company’s ability to keep up with tight production schedules and ensure minimal downtime, as the non-OEM aftermarket parts seldom stand up to the rigorous duty that the OEM part was designed for and, ultimately, ends up impacting on uptime, resulting in production losses. In the recent case study at one of the largest copper producers in SADC, the discovery of the hidden costs of buying a “surprisingly expensive low-priced” peristaltic hose was realised. For commercial reasons the mining company chose to fit a non-OEM hose in a Verder peristaltic pump. Production bore the brunt of this commercial decision, as the “surprisingly expensive low-priced” hose failure rate was an average of three failures per week resulting in production stoppages, and increased maintenance and manpower requirements. Due to the production stoppages Verder was asked to investigate the reason for the failures and present a solution, the remedy was simple - fit an OEM hose.

The exercise of buying and fitting “a surprisingly expensive low-priced hose” in an attempt to reduce inventory costs and minimise expenditure proved to be an expensive choice. While non-OEM aftermarket hoses may cost less on initial purchase, using hoses with incorrect dimensions and hoses of inferior construction leads to frequent hose failures, which in turn leads to the unplanned stoppages, production losses and unavoidable maintenance costs.

These direct unavoidable costs will be the replacement of lubricant and premature gearbox failure due to the ingress of the pumped media into the gearbox caused by the burst hose, and the cost of another replacement hose. The OEM hose was fitted to the DURA Pump and run under the same operating conditions. Records have been kept over this time - to measure the conditions and timing until a potential failure of the Verder OEM hose – yet the results have been astonishing. The non-OEM hose had failed and been replaced on average three times a week. In comparison the Verder OEM hose (installed on 1 December 2021) is still in operation on the date of writing this article, without failure or loss of production throughput. The cost saving has far outweighed the cost saving of the surprisingly expensive low-priced hose.

Every Verderflex hose is manufactured to tight specifications for consistent wall thickness, to ensure that the fibre reinforcing is embedded centrally when the hose is constructed. With the precision manufacturing process, the need to carry out machining of the hose outside diameter is eliminated. The Verder hose has a signature textured finish, and this finish enhances lubricant adhesion to the hose, thereby reducing surface friction between hose and shoe. Lower surface friction leads to lower temperatures, but that’s a technical conversation for another time. The importance of correct pulsation dampeners and other technicalities that affect hose life cannot be understated - just dimensional differences will have an influence on hose life which leads to costs associated with unplanned stoppages. The construction of the OEM hose plays an integral part in the life span of the hose. One must consider that the OEM is here for the long haul and that their hoses have undergone extensive testing in their own equipment.

To be sure that you are fitting an OEM hose you will notice that all Verderflex hoses have a clear colour coded identification stripe and Verder branding along the length of the hose, indicating the material of construction. If the hose that you are fitting in your Verder peristaltic pump does not have these markings, you can be sure that while you may be saving upfront costs by buying cheap, you will most certainly be buying at least twice.

Verder Pumps, +27 (0) 11 704 7500, info@verder.co.za, www.verderliquids.com/za

18 Pipes, Pumps and Valves Africa - Jan/Feb 2023 PUMPS

Stewarts & Lloyds support several industries across the spectrum including but not limited to Agricultural, Building, Construction, Engineering, Fire Protection, HVAC, Mining and Plumbing.

Stewarts & Lloyds supply value-added steel pipe systems for the conveyance of petrochemicals, liquids and gases in the petrochemical, mining and potable water industries. Stewarts & Lloyds fabricates various pipe systems, piping spools and related fittings to customer requirements:

Threaded and Coupled System

Shoulder Pipe System

Grooved Pipe System

Flanged Pipe System

Stub and Flanged HPDE Systems

Stewarts & Lloyds offer coatings and linings including, galvanizing, painting, rubber lining, cement mortar lining, denso wrapping, etc to meet your project requirements. Stewarts & Lloyds stock various specifications of pipe with associated fittings, flanges and valves:

Seamless pipe to ASTM/ASME A106/SA106

Welded pipe to SANS 62, SANS 1182 and SANS 719

LDPE, HDPE, PVC

Stewarts & Lloyds is a proud distributor of Kent Water Meters, Plasson Compression and Electro

STEEL & TUBE | PIPES & FITTINGS | VALVES | PUMPS | IRRIGATION | FENCING | ROOFING | HARDWARE Alrode South • Bloemfontein • Booysens • Boksburg • Brits • Durban • Exports Fluid Control Epping • Exports Steel & Tube • George • Irrigation • Pumps • Port Elizabeth • Kimberley Klerksdorp • Mahikeng • Nelspruit • Polokwane • Pretoria • Pipes, Fittings & Valves • Rustenburg Robertville • Springs • Steel & Tube • Vereeniging • Vaal • Wetton • Witbank • Windhoek • Wynberg THE ADVANTAGE OF A NATIONWIDE BRANCH NETWORK! Head Office (Bedfordview) 011 553 8500 Pipe & Fittings Focus Branch: Cnr Dan Jacobs St & Vereeniging Rd, Alrode, Gauteng, RSA Phone: 011 917 0778 / 0000 Email: pipesandfittings@sltrading.co.za

How to control and limit contamination in a hydraulic system

You hear a lot in the hydraulic field how a majority of hydraulic system failures can be attributed to some kind of contamination. In the beginning of my career, I spent a lot of time repairing hydraulic pumps and motors.

From a repair point of view, close to 100 percent of all the failures looked at that were attributed to some kind of contamination. So, it’s really important that we find a way to limit all types of contamination in our hydraulic system. An excellent first step for achieving contamination control is to come up with a contamination control or fluid contamination test plan. This plan should ensure cleanliness (which improves reliability and efficiency in a hydraulic system), the use of proper filtration and regular monitoring or testing of the fluid, to determine if the plan has been successful.

Contamination types and sources

Solid particulate contamination is generally measured in microns, which is a millionth of a meter — these are extremely small particles. When considering contaminants in a hydraulic system, we have to think about a more than just solid particulate, like dirt or wear metals. Contaminants can also be fluids or gases. But how to they get into the system? One way that contaminants get into a hydraulic system is what is referred to as inbuilt. Those are the contaminants that are left over in the system from the actions of building the hydraulic system. You can have weld slag from welding on tanks or welding on pipes. You can have grind dust that’s left in a reservoir that hasn’t properly been cleaned out. You can even have things that were left in a reservoir, like sandwich bags! These are

generally larger contaminants and are quite easy to filter or to get out of the system. The next type is ingressed contaminants. These are the contaminants that comes into a hydraulic system during the action of a hydraulic system. Most systems have breathers. Contaminants can be pulled into the reservoir along with the air. Those are ingressed contaminants. Many machines have cylinders. When a cylinder extends, dirt or debris gets on the cylinder shaft, and when the shaft is retracted, contaminants can get by the scraper and enter the system. These are also considered ingressed contaminants. Again, those are relatively large and thereby somewhat easy to filter out of a system.

Finally, we have generated contaminants. These are the wear products of the movement of different surfaces against each other in a hydraulic system such as in a pump, motor, or valves. These contaminants can be smaller than three microns and can be created under extreme pressure and high temperatures, which makes them very hard. These are the contaminants that cause other contaminants or accelerate the wear process in a system. Beyond these solid contaminants, liquid and air can negatively affect a system. The number one liquid that damages a hydraulic system is water. Water from condensation or humid air gets into a reservoir through a breather during the day when the machine is running. At night, when it is shut down, it condenses water vapor, and the droplets get into the hydraulic system. Over time, that can build up.

Liquids contamination can also be other hydraulic fluids. Do you have a process within your plant so that the proper fluids are going into the proper reservoirs? If you have a hydraulic reservoir and you put lubrication fluid in it, then it is going to affect the hydraulic fluid. The pumps aren't going to like it. The cylinders aren't going to like it. In some industries like steel mills, they use water glycol, a waterbased fluid. If you dump a petroleum-based hydraulic fluid into water glycol, you get a Jello-like substance that clogs all the filters and can really damage pumps.

Air can also be a contaminant, or at least something that damages the components in a hydraulic system. Air molecules and water molecules do not have the same load bearing characteristics that hydraulic fluids and lubrication fluids do. Under extreme pressure, those molecules implode and cause high temperatures, a process called cavitation. These mini implosions can damage hydraulic fluid as well as components.

Hydraulic fluid and wear

In training classes, I often ask the students: what is the

PUMPS 20 Pipes,

and Valves Africa - Jan/Feb 2023

Pumps

most important component in a hydraulic system? Many people say it is the pump, motor or servo valves. I always make a case that the most important component is the hydraulic fluid. After all, the hydraulic fluid is the only thing that touches everything else in the system.

Hydraulic fluid is something that people put in and simply expect it to work. We have to be careful of chemical compound formation or acid buildup in fluids, which deplete the additives, and reduce the life of the hydraulic fluid. Many hydraulic components have very small orifices that are essential to their operation. These small orifices can be blocked by small particles in the 1 to 5 µm range. This blockage will cause the hydraulic components to fail and the system to lose its ability to function. Wear in the system is also critical. There are different kinds of wear in a hydraulic component, including: abrasive wear, erosive wear, adhesive wear, and fatigue.

Abrasive wear is where you have two moving surfaces riding on a lubrication film and particles can get into that clearance. They act like a cutting tool and chip away and scratch things. A bearing might have a clearance of 1 to 3 microns; it’s not the larger 25-micron particles that cause a problem in here, because they can’t get in that clearance. They bounce off and get flushed away. It’s the extremely small particles that can really do damage where the small clearances are. Erosive wear is caused by particles that “attack” the surface or “edge” of a component and remove material from that surface due to momentum effects. Servo and proportional valves are particularly sensitive to this form of component wear.

Adhesive wear is caused when the lubrication layer between two moving surfaces breaks down; this can allow the two surfaces to come together under extreme loads and friction. The two surfaces are then “cold welded” together. When the two surfaces are forced apart, particles from both surfaces are released. These particles can be very damaging to the systems as they are small and are can be much harder than the surfaces that created them. Lastly, fatigue wear happens over time, because of loads and pressures. Here, you begin to get fissions or little ripples in surfaces. Over time, you will get cracks. Contaminants get forced down into those cracks and act as wedges that chip away at the surface to make it rough — and pull away particles and send them downstream. Why is wear so important? It is important because it causes

dimensional changes or clearance changes within the components, which increases the leakage and lowers the efficiency of the system. Even worse, the small particles that are generated accelerate the wear process. It’s like a snowball at the top of the hill. It starts small and as it rolls down, it gets bigger and bigger and bigger.

Why filter?

The objective of the filtration process is to reduce the level of contaminants present in a hydraulic system, and to maintain an acceptable level of cleanliness — no matter what contaminants are being generated and ingressed into the system. By maintaining this balance, the following benefits are achieved:

• Extended component life

• Enhanced system reliability

• Reduced downtime and servicing costs

• Safety of operation

• Extended fluid life

The filter performance is essential to reducing contaminants in the systems. There are standardized tests that give us common ground when comparing different filter options. Filter performance can be measured by efficiency (beta ration), dirt holding capacity (DHC), and pressure drop (delta P). The performance criteria as well as fluid and temperature compatibility should be considered when choosing a filter. The location of the filter will ultimately depend upon the reason for fitting it. If it is for direct component protection, then the filter must be installed immediately upstream of the component concerned. If it is fitted to control potential sources of dirt, then it must be installed downstream of that source. If it is for general control, then it can be positioned in any of the flow lines which see the majority of the flow.

There are many locations for fitting filters in hydraulic systems. The potential positions are can be in the pressure line, the return line, or offline. Wherever the filter is located, it is essential that it is easily seen, so the blockage indicator can be observed, and it is easily accessible, so that the element can be readily changed.

Stauff Corp, sales@stauff.com, www.stauff.com

PUMPS

Africa - Jan/Feb 2023 21

Pipes, Pumps and Valves

Pump and valve innovator finds a test rig technology that talks the torque

To analyse the long term performance and reliability of hard working valves and pumps, serial innovators Manchester-based Bifold Group has adopted digital torque transducers from Sensor Technology Ltd for two of its specialist test rigs.

An inter-generational commitment to advancing science and engineering has seen Bifold transform from a 19th century mining lamp maker into a leading manufacturer of instrument valves and accessories, piping valves and pumps for the oil, gas and wider industrial markets.

It has particular expertise in subsea and wellhead control systems and has also developed market leading technology in areas such as solenoid valves with ultra-low power requirements.

Its corporate development is just as impressive as its technical advancements. Over the last 10-15 years it has consistently grown profits by 50% a year, and is on course to clear £33m this year.

During this period it has moved into bespoke premises, created about 250 high value jobs, developed new products and technologies and entered high tech markets around the world. Today 95% of its output is exported.

By using the power of computer aided design many of Bifold’s products are built to custom designs, yet they are produced to very short lead times thanks to the efficiency of internet communications.

To maintain this standard, sample products and components are comprehensively tested so that their reliability and capabilities are never in doubt.

Bifold is as innovative in developing its test regimes as it is in advancing its product technologies and business systems. So when it wanted to assess the effects of wear on its long-life valves it set about designing a special test rig.

Engineer Andrew Laverick recalls: “We wanted to measure the power required to operate the valve to see how it changed over time and with long term use.”

“It was clear that the best way to do this was to measure the torque input over an extended period.”

“We were open to any design concept for the test rig, but soon found ourselves gravitating towards a TorqSense solution because the Sensor Technology engineers were so helpful and really knowledgeable about test rigs.”

Sensor Technology’s Mark Ingham explains: “TorqSense has been used on many test rigs over the years and I was delighted to hear the Bifold engineers say how easy it is to use and how robust the software is.”

Laverick again: “As a test engineer you are almost resigned to long set up procedures and software that falls over at the drop of a hat. But Sensor Technology has designed these problems out of their TorqSense equipment, with the result that we were able to complete our long term test procedures with the minimum amount of fuss and heartache and well within the allotted time schedule.”

In fact Bifold has since bought a second TorqSense which is being fitted to a new test rig used to assess the performance of mission critical chemical injection pumps, as used at oil and gas wellheads and on process pipelines.

“This project is proceeding well,” says Laverick, “and is allowing us to further develop our abilities to quickly provide bespoke equipment for ultra demanding applications, safe in the knowledge that it will perform faultlessly over a long working life.”

22 Pipes, Pumps and Valves Africa - Jan/Feb 2023 PUMPS

Sensor Technology Ltd, info@sensors.co.uk, www.sensors.co.uk

CONDITION MONITORING

AND OPTIMISATION

CONDITION MONITORING TO OPTIMIZE YOUR BOTTOM LINE

The optimyze™ modular condition monitoring solution provides health guidance and predictive maintenance advice for rotating and fixed assets such as pumps, motors, heat exchangers and steam traps. It periodically monitors system vibration and temperature and allows everyday users to access simple-to-use monitoring tools from iOS or Android mobile devices.

Using predictive analysis, optimyze identifies potential problems with your equipment before they occur, to help you manage system reliability and maintenance. Information is monitored, collected, stored and analyzed in the optimyze sensor. This allows you to understand the current health and historical trends of your assets, create maintenance reminders and generate detailed reports. As a result, you can perform preventative maintenance before issues become critical to uptime.

Benefits:

• Predictive maintenance to monitor the health of mechanical and electrical assets

• Asset management including asset location, size and manufacturing date

• System transparency to optimize reliability

• Optimized reporting that helps to simplify documentation, manage system maintenance and inform purchasing

• The ability to automatically share data with multiple local users

• Conveniently monitor system conditions on our simple-to-use mobile application

Industries:

• Commercial Building Services

• Manufacturing

• Agriculture

• Water Utilities

Applications:

• Monitoring the vibration of pumps and motors

• Monitoring the temperature of pump bearings

• Monitoring the temperature of motors to prevent overheating and winding damage

• Monitoring the performance of heat exchangers

• And more

xylem.com

optimyze™

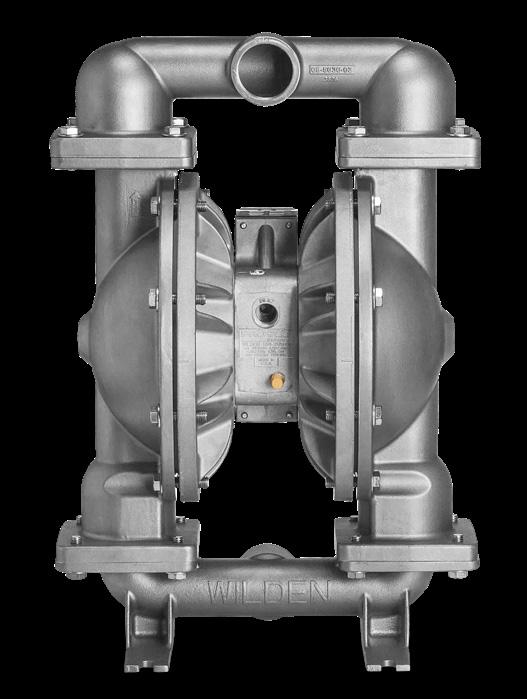

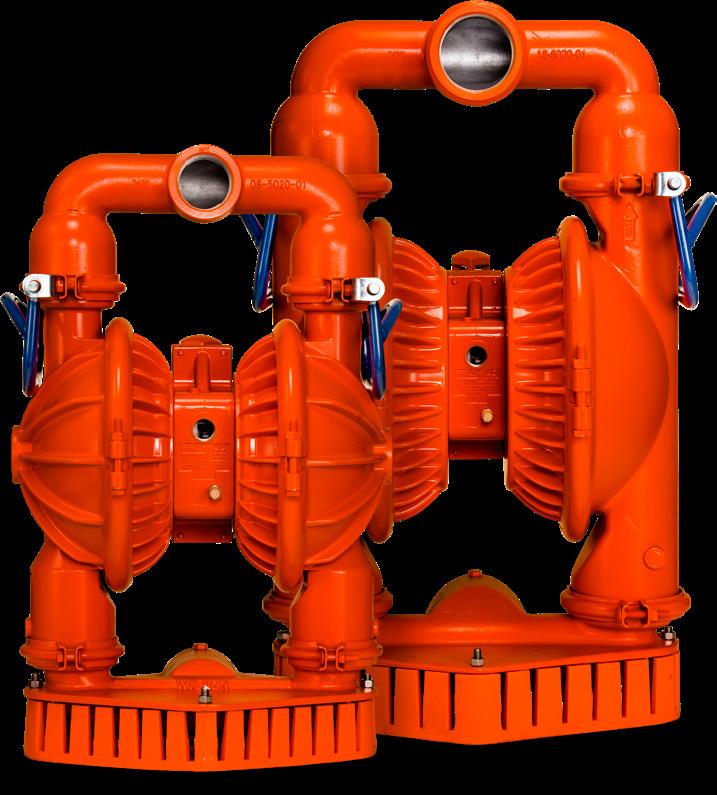

How AODD Pumps Can Satisfy All Demands In Mining Operations

In an industry that features a number of harsh, but oftentimes delicate, liquid-handling challenges, Wilden ® Air-Operated Double-Diaphragm (AODD) Pumps have consistently risen to the occasion

By Fernando Meneses

In an industry that features a number of harsh, but oftentimes delicate, liquid-handling challenges, Wilden ® Air-Operated Double-Diaphragm (AODD) Pumps have consistently risen to the occasion

Mining is one of the world’s most important commercial enterprises, with operations spread across the globe that are gathering an almost inexhaustible list of valuable commodities. According to the World Mining Congress’s World Mining Data 2020 report, 17.7 billion metric tons of mined products were recovered in 2018, up from 11.3 billion metric tons in 2000 and nearly double 1985’s 9.6 billion metric tons. Individually, China (23%), the United States (12.1%), Russia (9.2%) and Australia (7.2%) were the most prolific producers, with their total 51.1% of production more than the rest of the world combined. This growth is expected to continue, meaning that mining operations will need to rely on pumping technologies that offer robust, reliable and safe service in a number of critical liquid-handling applications. In many instances, positive displacement air-operated double-diaphragm (AODD) pumps can be the best choice for many of those applications.

The Challenge

While mining might appear to be a rough-and-tumble operation, there are many complex and delicate operations that must be performed properly. This requires pumping technology that can operate reliably in harsh and remote locations, even when submerged, or when tasked with handling particulate-laden liquids or toxic/corrosive products, and also one that is able to be maintained and repaired simply so downtime is lessened. The pumps must also be light enough to be manually moved from location to location within the mine itself.

Here are some of mining’s liquid-transfer operations and the ways that centrifugal and progressive cavity pump technologies can fall short in satisfying them:

• Mine Dewatering: Removing excess water from the mine is a 24/7/365 operation and the water that is recovered can be full of particulates as large as 3-4 mm (0.12-0.16”) in size. Centrifugal pumps require special materials of construction to protect against impeller wear caused by the abrasive particles and are also not dry-run capable.

• General Service: Here, you need an easy-to-operate pump that can reliably run dry, strip lines, operate at low speeds, produce high flow rates, and be easy to maintain and repair. Centrifugal pumps simply do not possess these capabilities.

• Corrosive Liquids: Corrosives will damage the wetted parts of centrifugal and progressive cavity pumps. This requires the use of special mechanical seals that can result in high maintenance, repair and replacement costs.

• Press Filter: Press filters clean the liquids that are produced in the mines and the solid-laden liquids can damage centrifugal pumps’ internals unless expensive materials of construction or linings are used. Also, press filters create strong discharge-pressure variations that can force the centrifugal pump to operate away from its Best Efficiency Point (BEP). Variable frequency drives (VFDs) and controllers can be used, but they are expensive.

• Product Transfer: In every product-transfer instance, the pump may be asked to run dry, while discharge-pressure variation can also generate strong vibrations and high radial loads. Since centrifugal pumps cannot run dry, they need protection from this condition or the addition of special seals. However, all of these upgrades still cannot totally protect against a catastrophic failure.

How AODD Pumps Can Satisfy All Demands In Mining Operations

The Solution

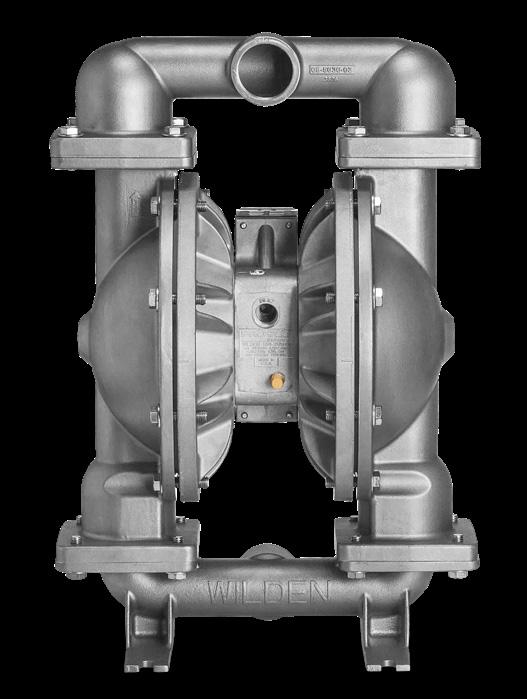

AODD pumps are able to perform effectively in mining applications because their method of operation allows them to handle variable flow rates and pressures, while being dry-run and line-strip capable, and nimble enough to transfer liquids that are shear-sensitive or high-viscosity, as well as slurries laden with rocks, pebbles and other particulates.

The simple design of the AODD pump features few moving parts and comparably lower speeds, which improves reliability and simplifies maintenance, while the pump’s seal-less construction results in fewer leaks. AODD pumps are available in both metal (most commonly aluminum, ductile iron and cast iron) and plastic (polypropylene and PVDF) housing constructions, while a wide array of elastomers can be used in the diaphragms, which eliminates many chemical-compatibility concerns.

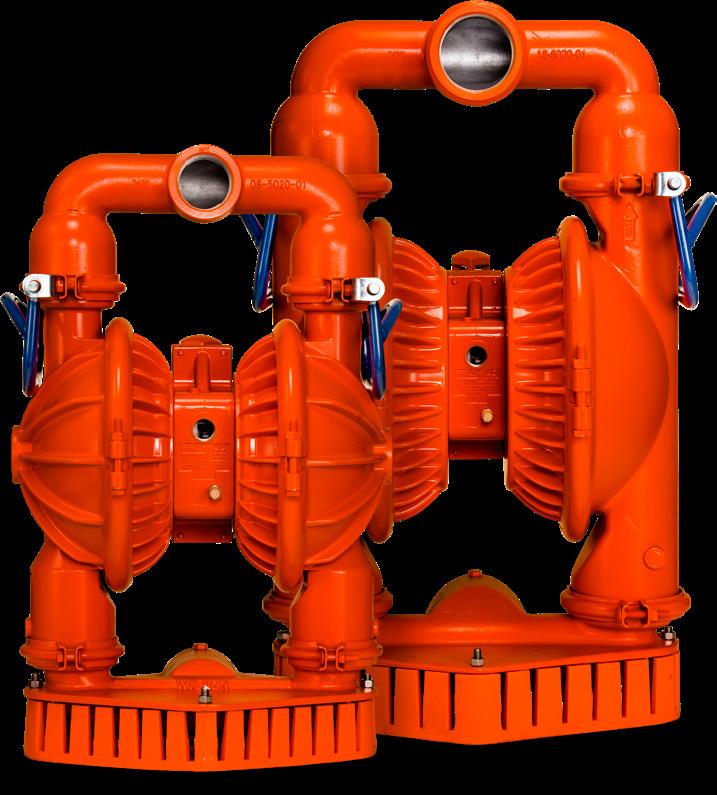

Wilden®, whose founder, Jim Wilden, created the AODD pumping principle in 1955, has been dedicated to developing technologies that meet the needs of mining operations. Wilden offers three AODD pump models that excel in mining applications:

• Brahma ® Series AODD Pumps: The Brahma pumps, which feature a bolted configuration, are ideal for applications that require the handling of liquids featuring large solids. They have a unique top-inlet/bottom-discharge flow orientation and flap valves that allow the passage of large solids with no risk of damage as a result of product entrapment or the settling of solids within the pump’s internal flow paths.

• Stallion ® Series AODD Pumps: The Stallion pumps feature a clamped design with carrying handles for portability. They have large internal clearances and flow-through paths for easy passage of large solids with no chance of clogging. An altered ball/seat check-valve assembly enables solids passage, while a polyurethane screen base increases pump durability.

• Pro-Flo ® SHIFT Series: Pro-Flo SHIFT pumps feature clamped or bolted configuration. Their design offers the choice of different chamber materials, including metal and plastics, even Kynar, which is capable of handling high levels of abrasive materials. The Pro-Flo SHIFT also has the most efficient Air Distribution Systems (ADS) on the market, capable of reducing air consumption by up to 60%.

All of the Brahma, Stallion and Pro-Flo SHIFT pumps are able to be outfitted with a variety of diaphragm styles – including the newer Chem-Fuse, EZ-Install and Reduced-Stroke models – in a varying array of materials, such as Wil-Flex™ (Santoprene®), Geolast®, Polyurethane, Buna-N®, EPDM, Neoprene, FKM and PTFE.

Conclusion

Wilden AODD Pumps are the best option for mining applications because they offer considerable operational advantages. These include comparably low-speed operation with high flow rates, dry-run, line-stripping, self-priming and deadhead capability, along with increased operational safety and a reduction in maintenance/repair costs that can be incurred by pump technologies that are not designed to handle the abrasive/corrosive or solid-laden liquids that are common in mining operations.

Wilden® Brahma® Series AODD Pumps have a unique top-inlet/bottom-outlet bolted design that allows them to effectively handle the passage of large solids with no risk of damage caused by product entrapment or the compromising of flow paths.

The large internal flow paths of Wilden® Stallion® Series AODD Pumps help ensure that there will be no clogging during the transfer of solids-laden liquids, while their convenient carrying handles give them lightweight portability for use in a number of critical mining applications.

How AODD Pumps Can Satisfy All Demands In Mining Operations

Wilden® AODD Pumps excel in the many diverse liquid-handling applications found in mining operations because they are able to offer a wide range of options to the user, from bolted/clamped design, metal/plastic materials of construction, and a complete roster of diaphragm styles and materials.

Pump Rental offers benefits that are hard to beat

While there is sometimes a case for buying dewatering pumps and associated equipment outright, renting offers so many advantages that it should always be given close consideration. This is the view of Lee Vine, managing director of dewatering and dredge pump rental specialist IPR.

He says that IPR is seeing a strong shift towards the rental model. “We started up just seven years ago and, since then, we’ve had to continuously add pumps to our fleet to meet ever growing demand from a range of industries, most especially mining and construction,” he states.

“We now have more than 200 pumps in our rental fleet, able to handle almost any pumping task. Our line-up includes submersible drainage and dewatering pumps, slurry and sludge pumps and diesel-driven pumps. We also offer dredging systems and hydro mining solutions.”

Vine believes that one of the prime advantages of renting is that it eliminates the need for upfront capital expenditure, which – depending on the type of equipment that is required – can be considerable. “Many companies –particularly if they are start-ups or are experiencing tough trading conditions – simply cannot afford to make this type of financial commitment,” he says. “If this is the case, rental is the ideal solution.”

He points out that purchasing does not make business sense if the equipment required is only used on an intermittent basis. “If you’re going to buy pumps, for

example, then you need to get the maximum utilisation out of them. If you only have an occasional need for pumping, then I would strongly recommend renting. It is madness to buy expensive equipment and then leave it standing for long periods.”

Ownership also brings with it the problems of maintenance. “Pumps need to be maintained and this normally means that people with the required competence need to be permanently employed to undertake this task,” he says. “When you rent from IPR, we provide this service. Our skilled and experienced technicians undertake all servicing and maintenance on site on a 24/7 basis. We also, of course, ensure that machines are in tip-top condition before being sent out to customers.”