LOUIS MARTLEW

DESIGN FOR INDUSTRY

PORTFOLIO

About me

I am a 4th year Design for Industry student looking for a Junior Designer role. I have completed two industry placements during my time at University and I am now available for full time work come.

Having grown up in the Lake District my work is orientated around the protection of the environment and user. I hope to showcase this in my work.

Louis Martlew Industrial Designer

Skills:

Sketching.

Model making.

Sewing.

Pattern Creating.

Machine Knowledge. CAD.

Rendering.

Creative Thinking.

Photography

Experience:

Restrap.

6 month placement.

March 2023 - September 2023

David Irwin Design Studio. 4 month placement.

March 2022 - June 2022

1

Photoshop Illustrator In Design Premiere Pro Experience Design Solid Works Fusion 360 Rhino Vectorworks Keyshot

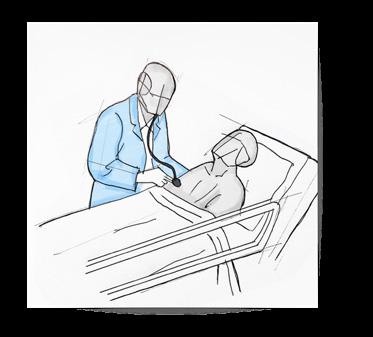

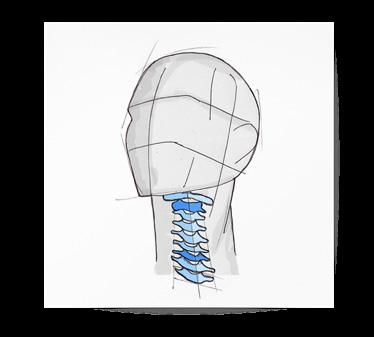

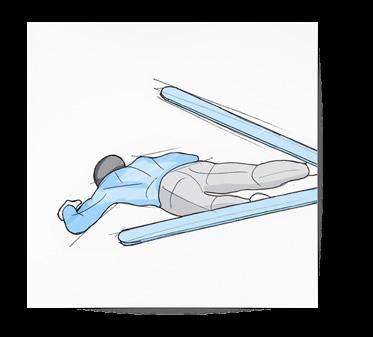

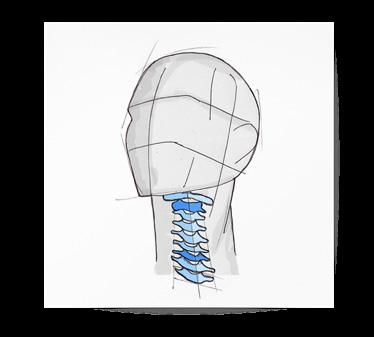

A flexible neck protector to prevent cervical spine injury through hyperextension.

This project was run by company RDD+.

3rd Year, 4 Week

2

3RD YEAR, 4 WEEK

RDD

The Problem

Accident Injury Movement Rescue Spine

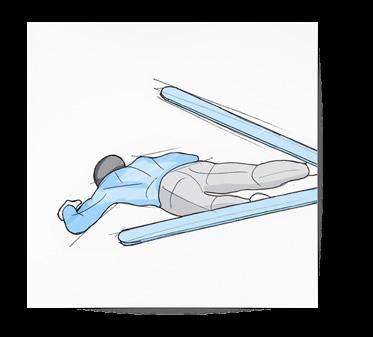

Wearing a helmet changes the head and neck biomechanics, increasing the risk of spinal injury.

Skiers are prone to fall forwards. This leads to cervical spine hyperextension.

Spinal injuries make up 42% of severe injuries. With the cervical spine being the most common.

C2 (30%) and C7 (20%) are the most commonly fractured vertebrae.

On average it cost £835 to be rescued from the piste due to injury at Tignes ski resort, France.

https://sjtrem.biomedcentral.com/ https://www.tignes.net/ https://academic.oup.com/ https://teachmesurgery.com/ https://sjtrem.biomedcentral.com/

3

PROBLEM

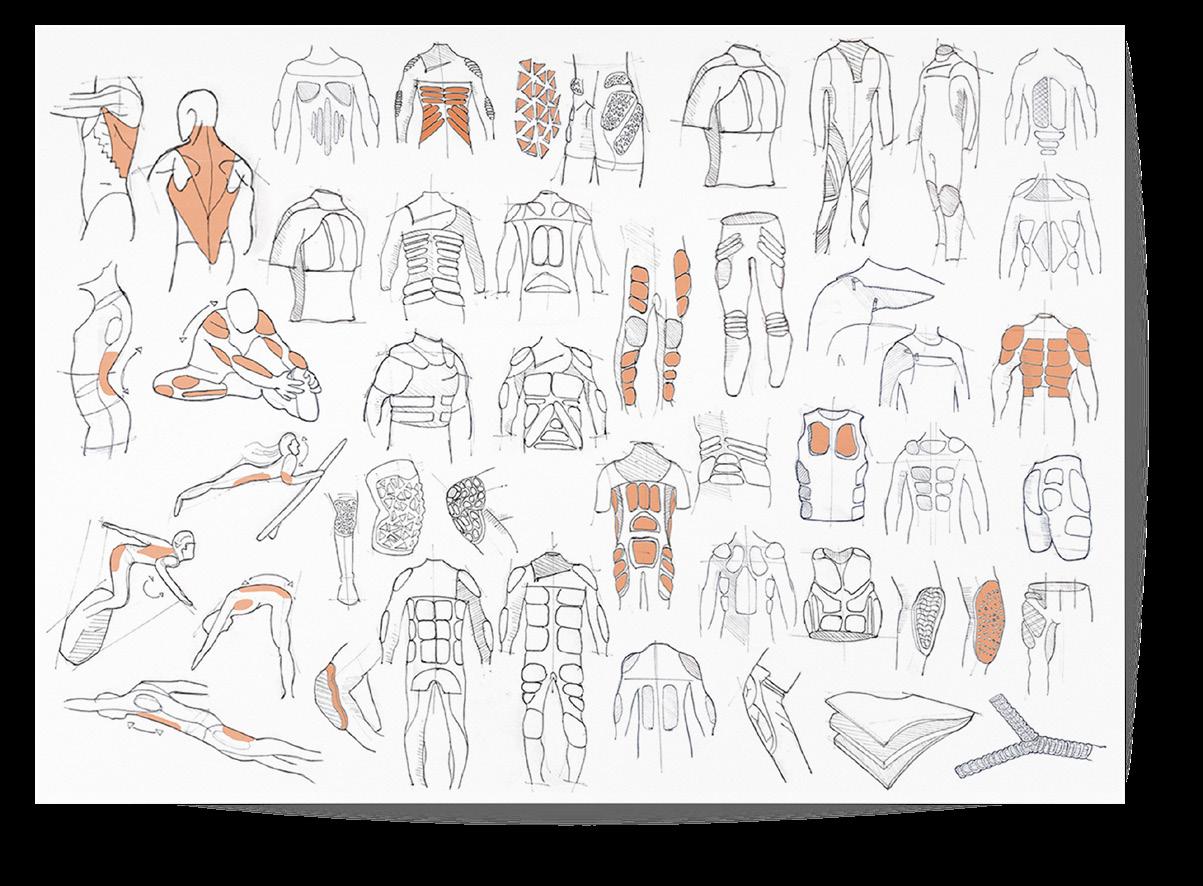

Ideation

Analysing the movement of the neck and fitting of ski helmets

I created initial ideas exploring fastenings, shape and function. Through quick prototypes.

The result is a highly functional, very simplistic product that utilises industry standard manufacturing techniques using very little materials and external components.

4

IDEATION

MERINO WOOL

5

WOVEN NYLON ELASTIC POM CORD STOPPER

SHOCK ABSORBENT MEMORY FOAM COOL GEL

FINAL PRODUCT

NYLON 66 RIPSTOP OUTER LAYER

2nd Year, 6 Week

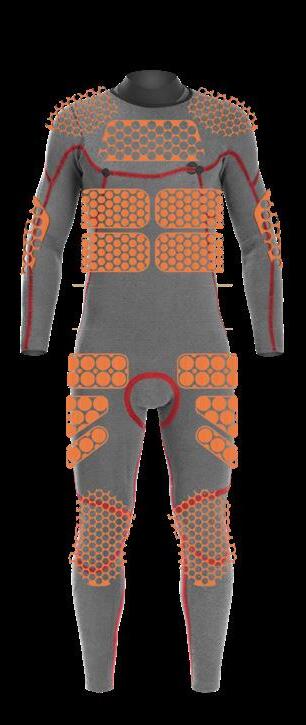

Design a product that adopts biomimicry to protect us in the areas we are active.

This project was run by company HEXR.

6

2ND YEAR, 6 WEEK

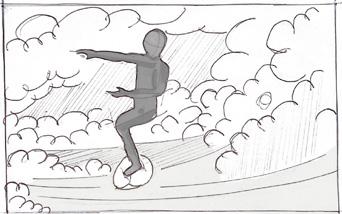

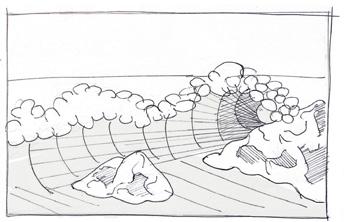

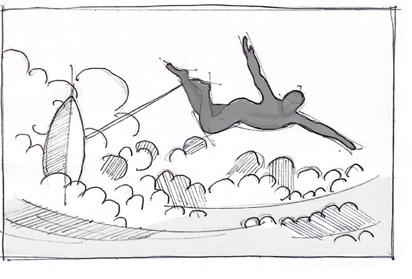

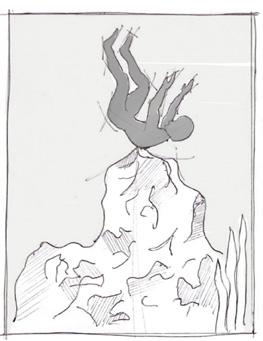

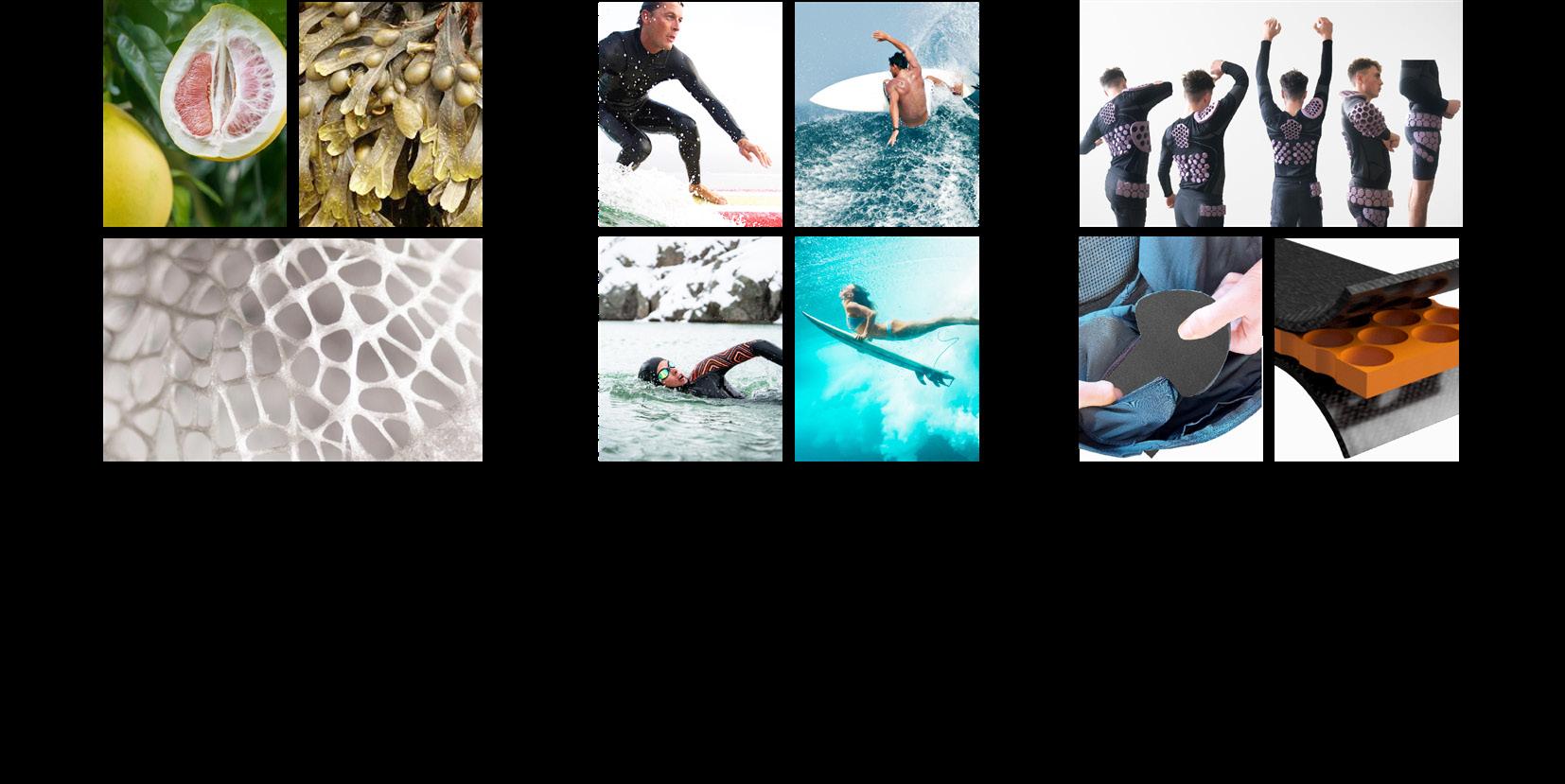

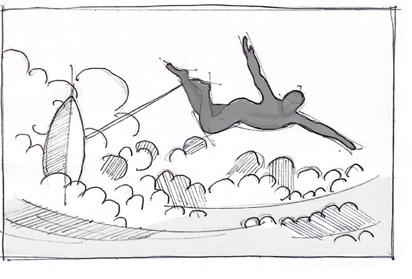

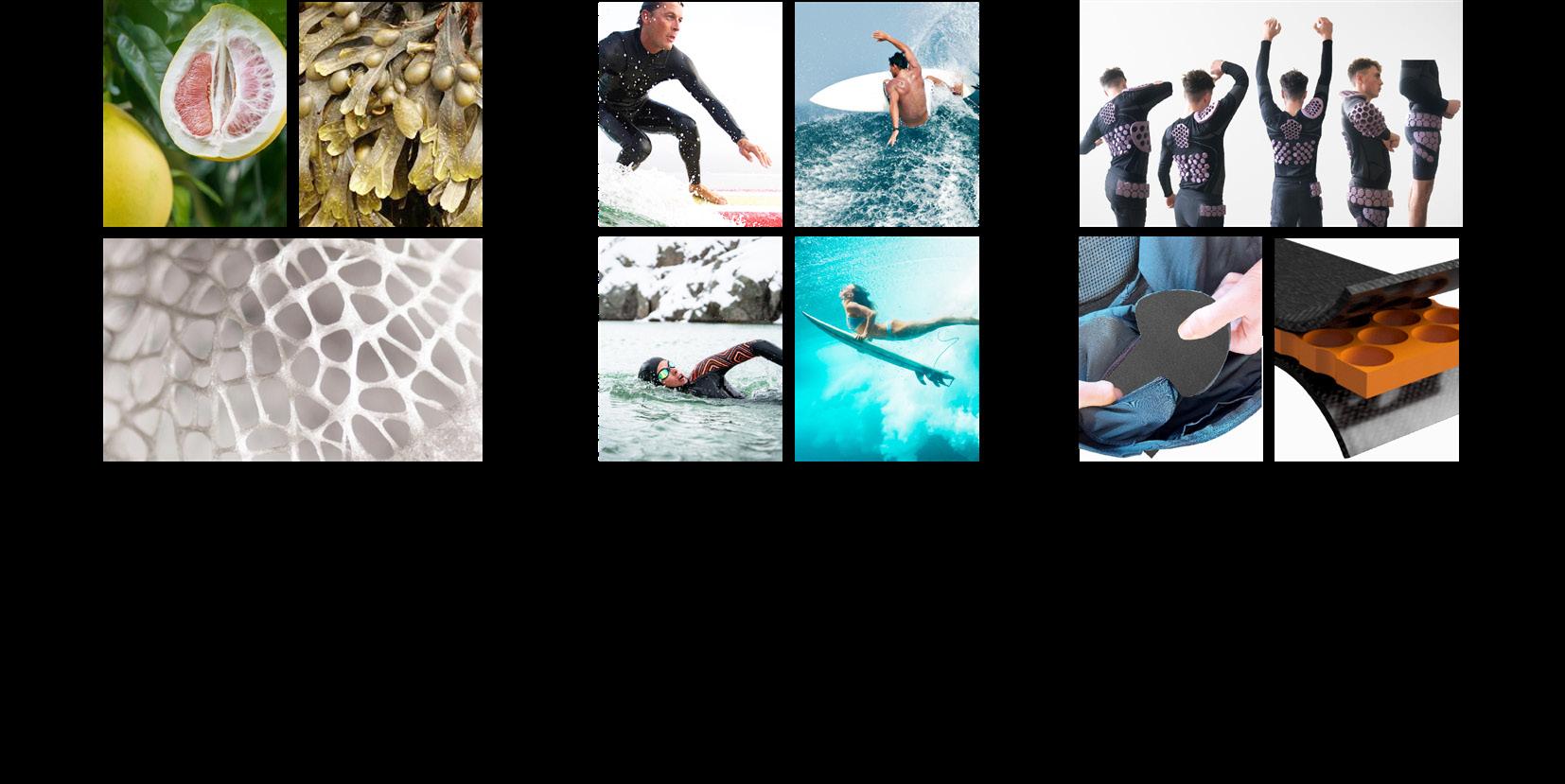

Big waves are one of the most common hazards in surfing, and it is easy to figure out why. A big wave carries tons of energy and when it breaks, a huge wave can break bones, keep someone underwater for a long time, and even slam a surfer against the ocean floor.

https://www.surfertoday.com/

7

PROBLEM

Layers for absorbency

strength, Lattice structure

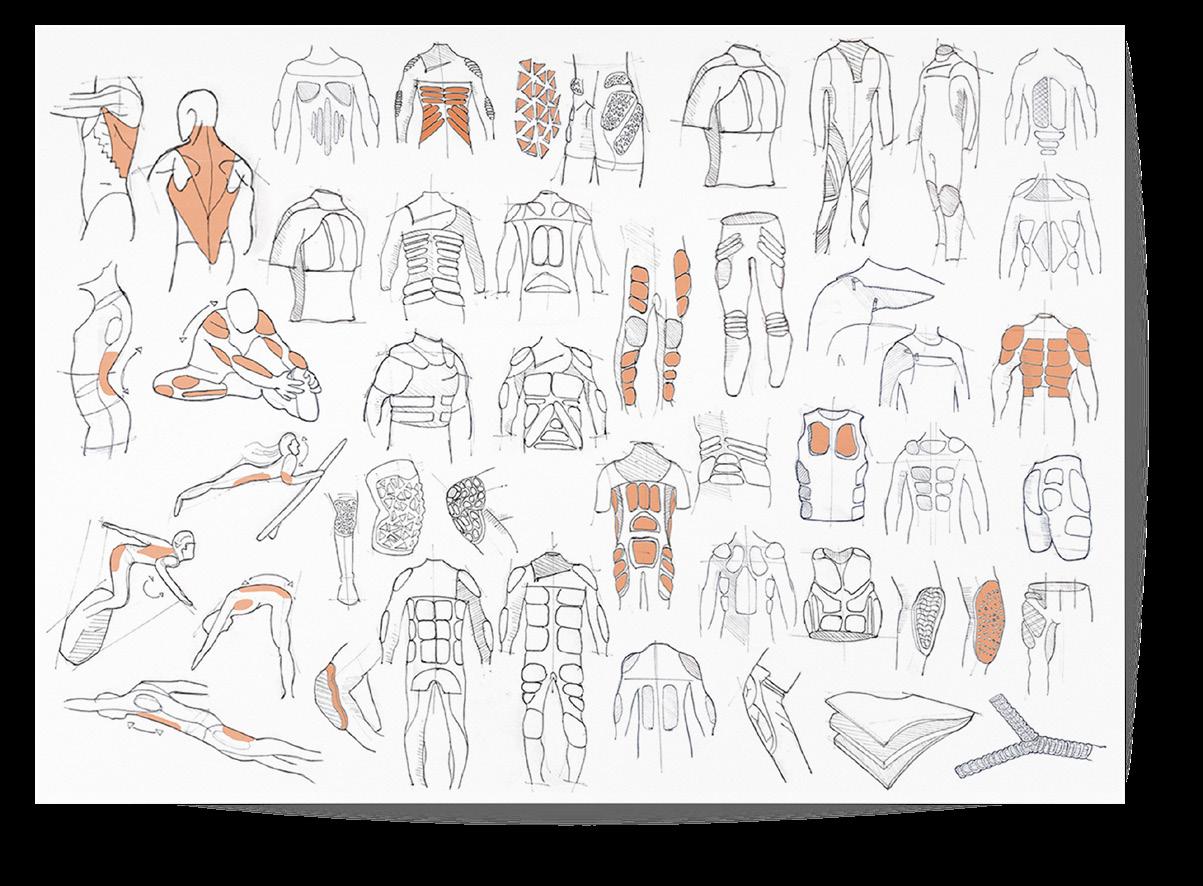

Biomimicry Movement Concepts

Pomelos have a compressible skin that consists many interconnected air cells. Kelp contains gas-filled floats. This enables buoyancy.

Wetsuits are commonly made from neoprene due to its insulating properties. A wetsuit must ensure warmth, agility and buoyancy.

Using foam I tested different structures targeting organs and muscle groups that are used and damaged in big wave surfing.

8

Air Sacks Targeting muscle groups

Agility

Buoyancy

Circumduction of arm Removable

Warmth

Maintain flexibility

D30

foam layered

RESEARCH

Exploration

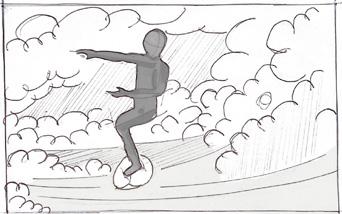

A focus on the use of D30 foam due to its impact absorbency and malleable proprieties. Utilising the lattice structure to create air pockets to maximise buoyancy.

9

IDEATION

foam.

Inner neoprene layer.

Final Product

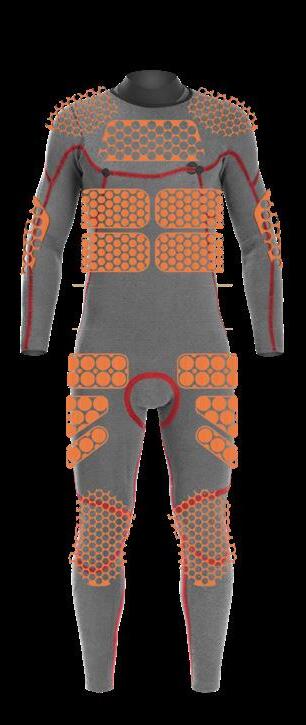

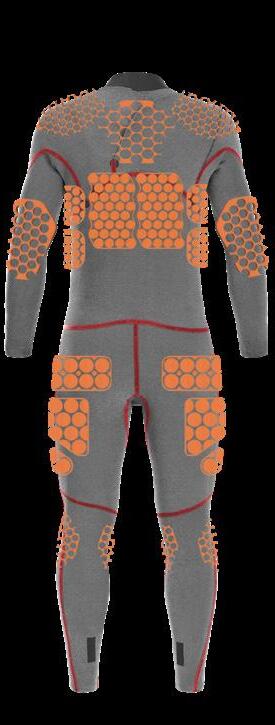

The final solution maximises buoyancy and protection. Using D30 non-newtonian foam welded onto neoprene using an ultrasonic weld to create air pockets.

Lattice structure for flexibility.

Dense sections to create less buoyancy. Recycled holes from other sections.

10

FINAL PRODUCT

D3O

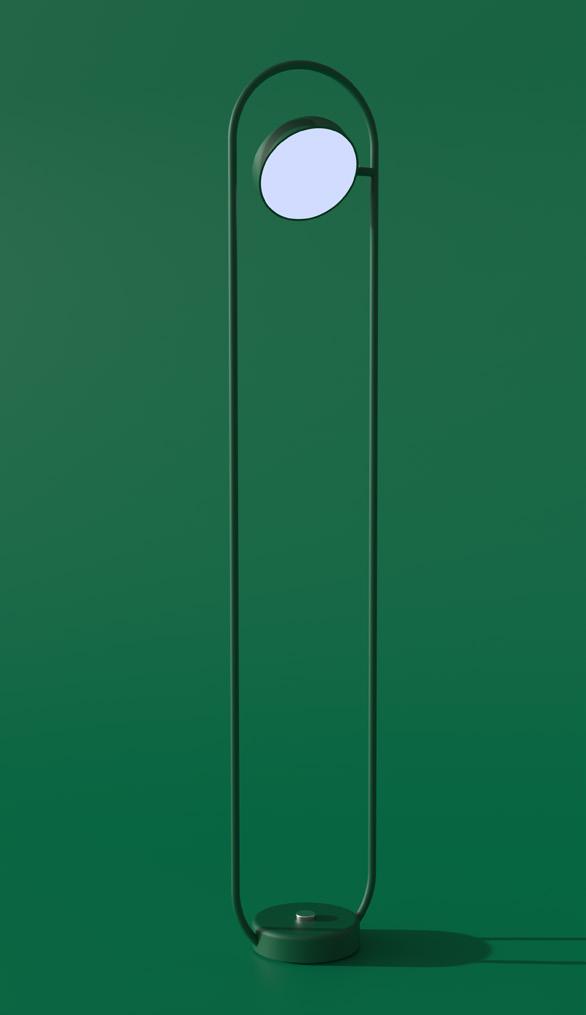

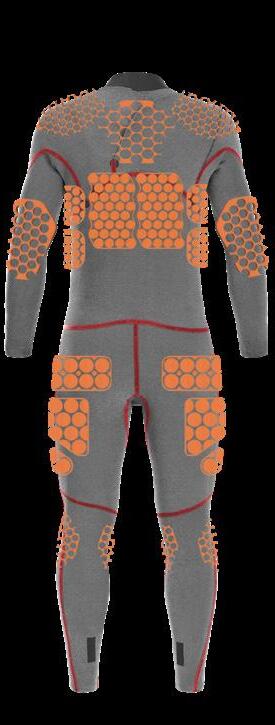

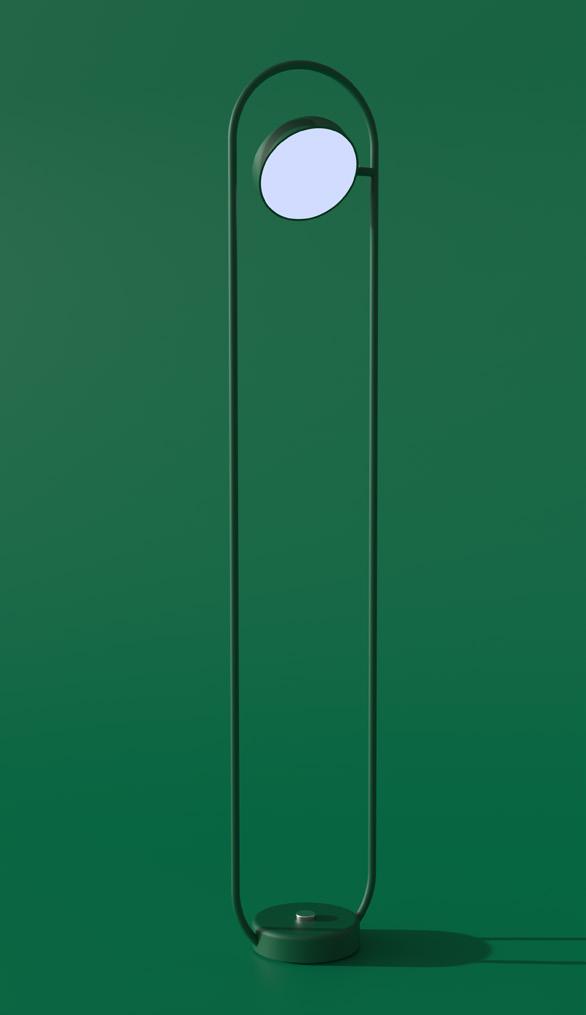

Pēs Lamp.

3rd Year, 8 Week

A portable mid high reading light. Creating a peaceful setting and the sense of warmth.

11

3RD YEAR, 8 WEEK

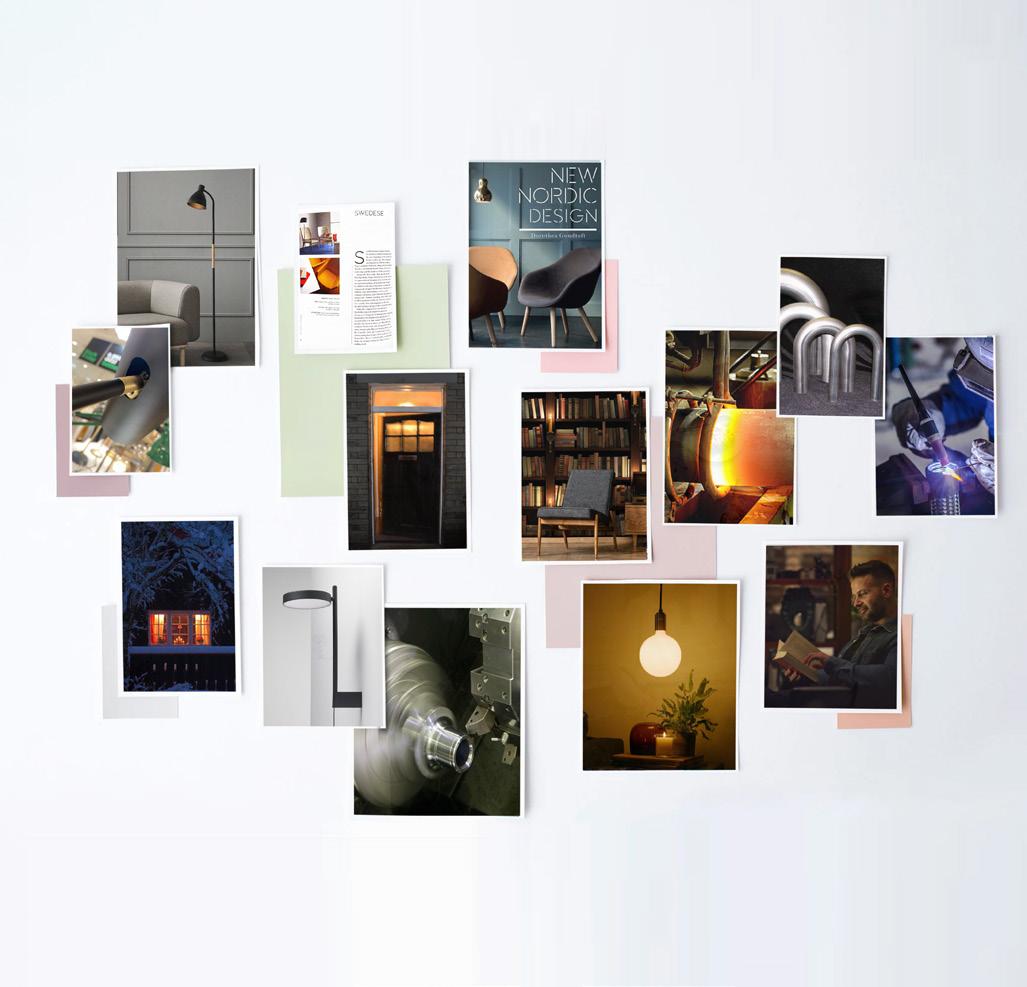

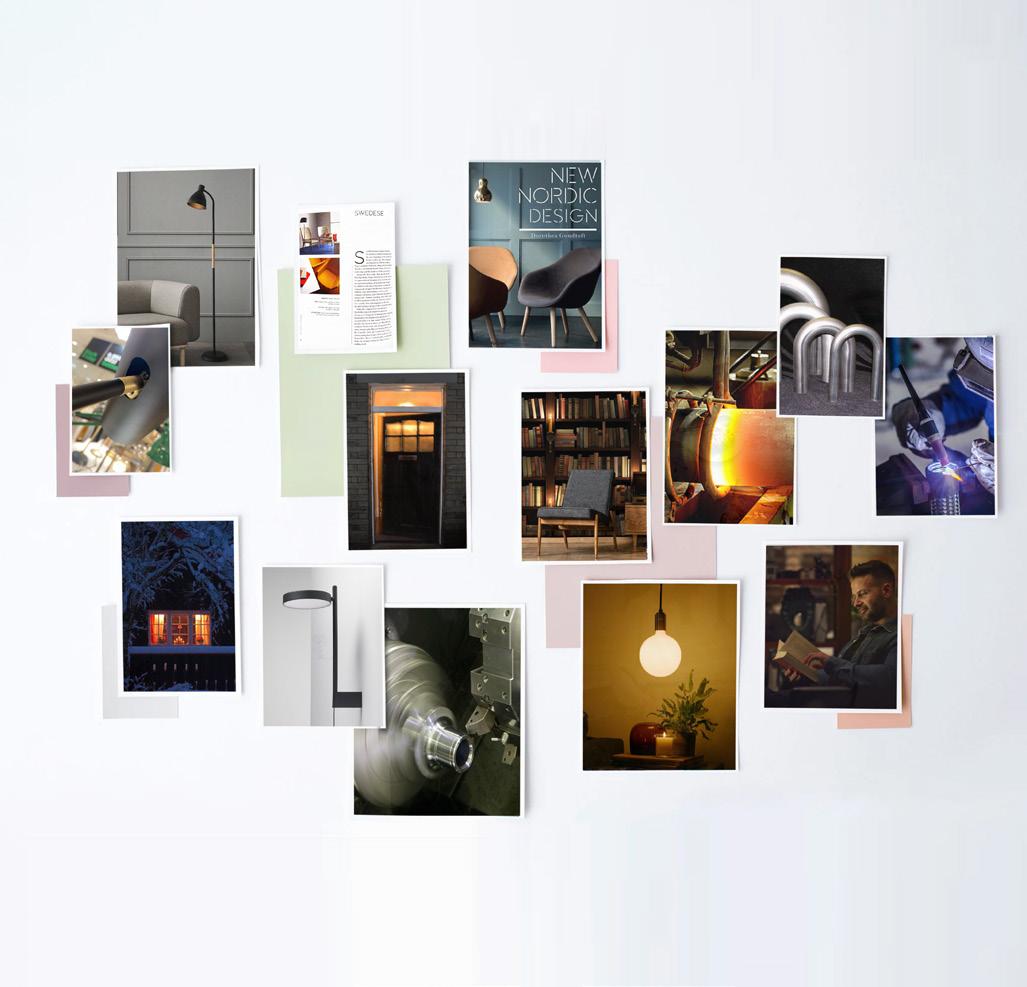

Mood Board

When I walk through the streets of Newcastle, my eyes are drawn to the lit up windows. The contrast in light from dark to bright and the association of warmth. I researched into the use of steel and was inspired by the book, “New Nordic Design”.

12

RESEARCH

Change to angle

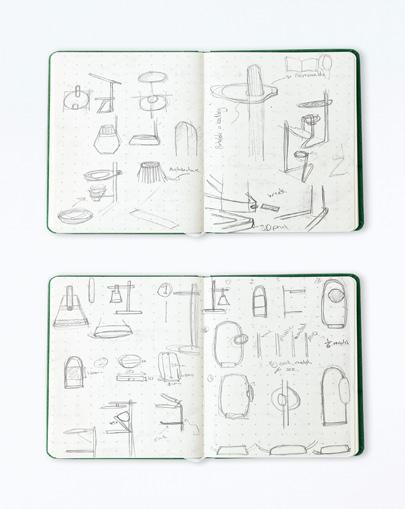

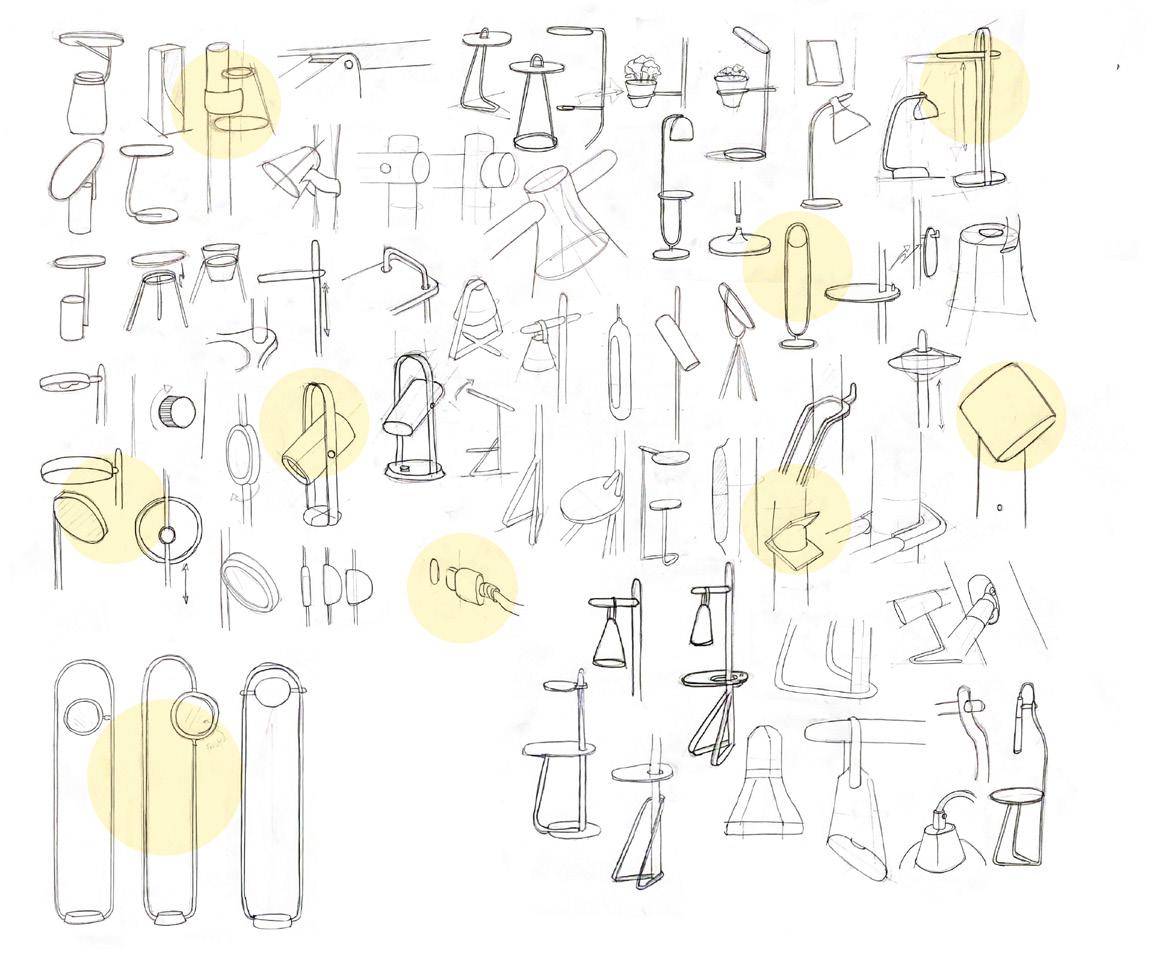

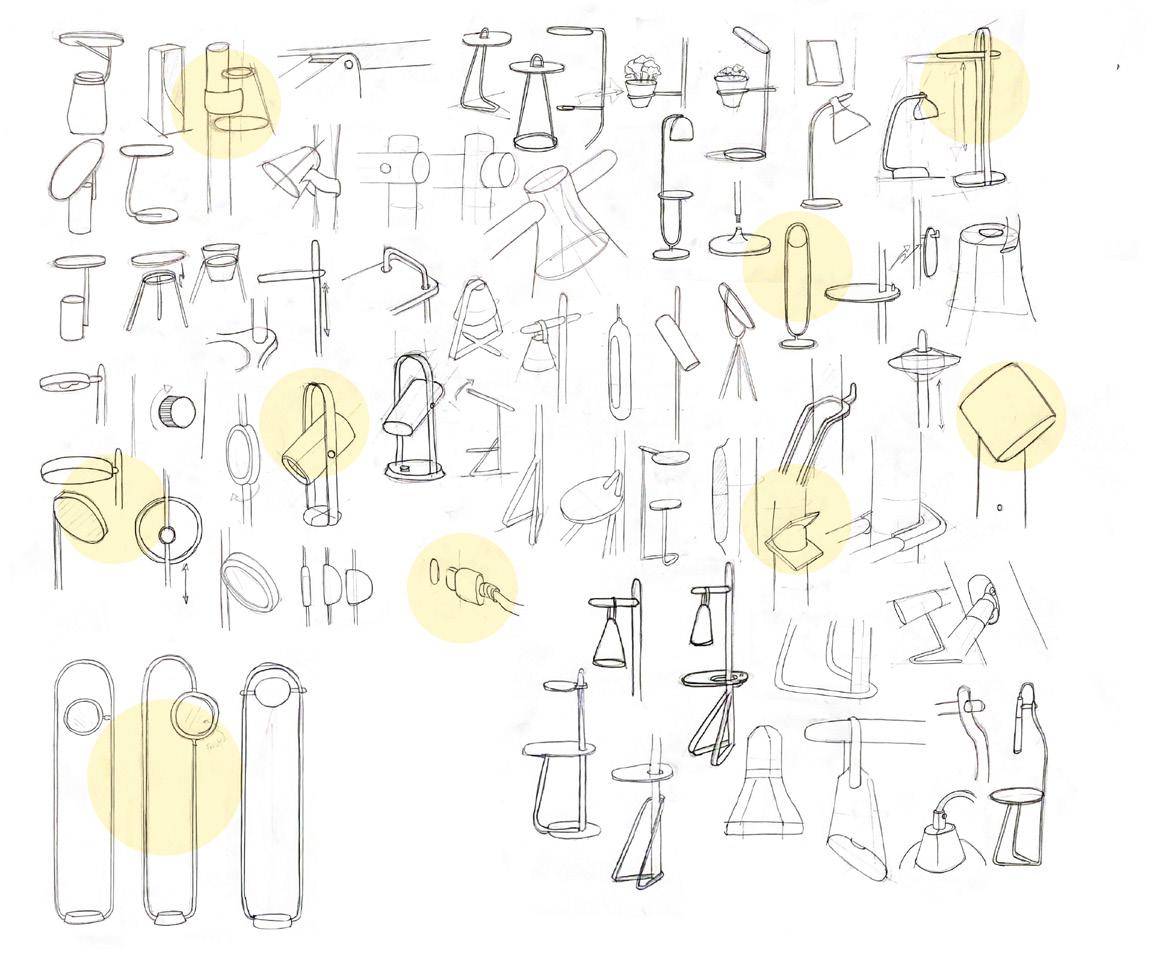

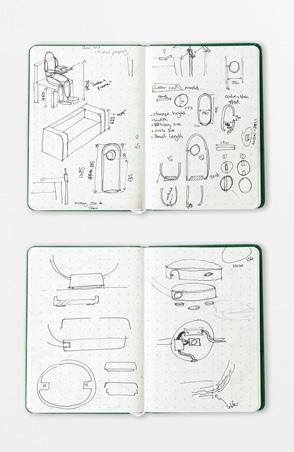

Ideation

Initial sketches. Experimenting with form, shape and function. Steering towards a standing light and how it could be used.

Warm

Adjustable

Steel

Exploring multi functions Shape to soften light

13

-

-

-

-

wireless - Ambient

Frosted glass

IDEATION

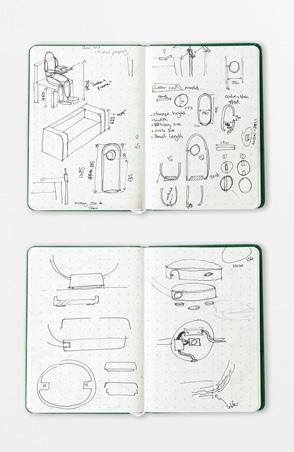

Sketch Models

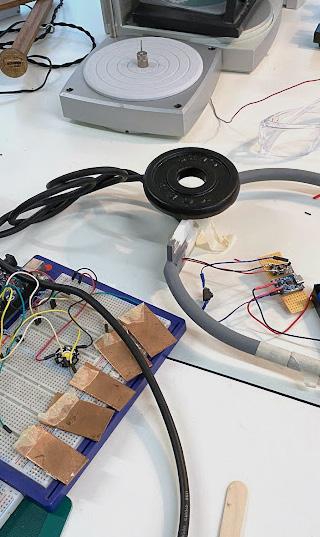

Development through sketch modelling. Quick 1:1 prototyping of the lamp changing the width, height, lamp head and base.

Sketching the internal system of the base and modelling changes to height and form.

14 SKETCH MODELS

Development

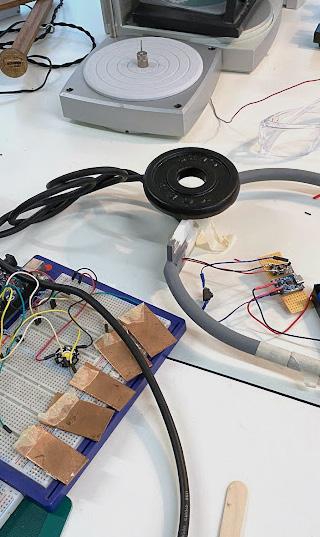

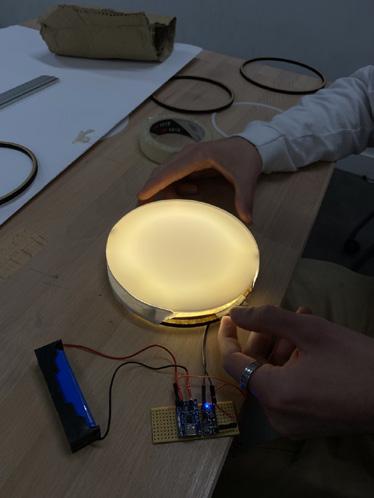

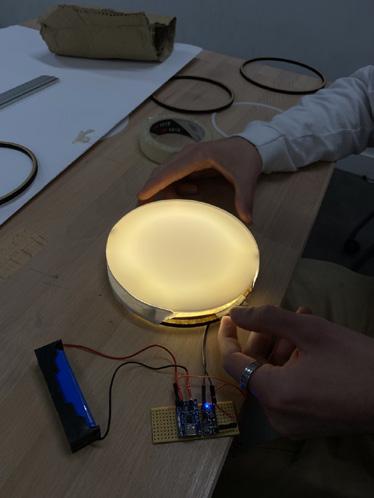

Testing different lights and fittings to prevent spotlight on the opal acrylic cover. Aiming to create a constant glow.

I used a chargeable battery and threaded the wiring through the frame. I focused on CMF during the manufacturing process of this prototype.

15 DEVELOPMENT

Light Cover

Aluminium

Spun

Front of Light

Low-Density

Polyethylene

Injection Moulded

Turning Mechanism

Stainless Steel

Die Cast

Allen Head Screws

Stainless Steel

4mm x 6mm

Tubing

Stainless Steel 1/2 Inch

Machine Bent, Brazed Joint

Button

Aluminium

Spun

Base

Stainless Steel

Die Cast

Battery, circuit, removable steel

base to fix poles and replace parts.

16

TECHNICAL

Final Model

Powder coat: Matt Black, Medium intensity.

Prototype manufactured using steel, foam, 3D printed internal parts, opal acrylic and matt black acrylic.

17

4th Year, 6 Week

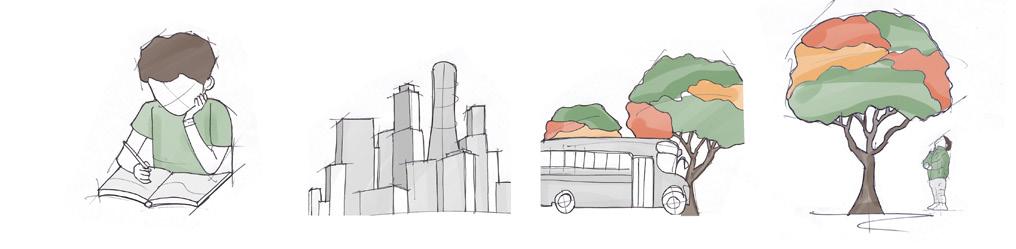

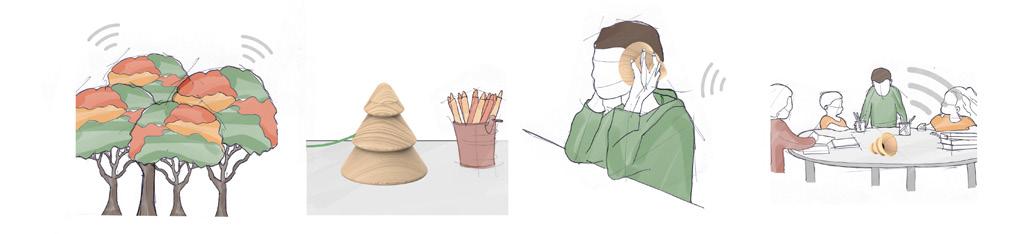

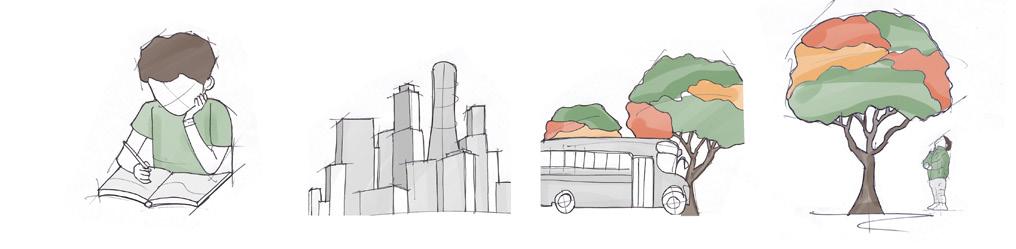

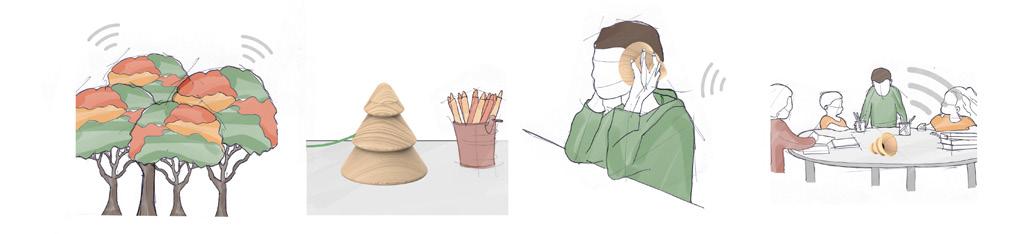

Inner Woods is an affordable service that provides the opportunity for children in urban areas to access the benefits of forest school from within their classroom.

18

4TH YEAR, 6 WEEK

Insights

According to recent research, people in northern cities have access to fewer parks than their southern counterparts.

https://www.rethinkingpoverty.org.uk/

Listening to woodland sounds for just one minute resulted in people feeling 30% more relaxed.

www.mentalhealth.org.uk

Dr

Dr

Mark Wetherell,

Professor of Psychology.

Several studies have found that exposure to nature can reduce symptoms of ADHD and anxiety.

Anon., 15/05/2020. Benefits of Nature for Kids. Bright Horizons.

85% of children agreed that being in nature made them very happy.

Two-thirds of school respondents said they don’t practice Forest School.

https://www.gov.uk/ [Accessed 20 10 2023].

DOI:10.13140/RG.2.2.21521.38248

“Greater access to green space reduces stress hormones. However, people lack the opportunity In the North East”

“People need educating on the benefits of green space in order to connect and solve the intention behaviour gap.”

19

RESEARCH

Proposal.

In collaboration with Stomping Ground forestry school I aim to provide the opportunity for primary schools in urban areas access the benefits of nature.

There are 90 primary schools in Newcastle that are within a distance of 14 miles to Stomping

There are over 10,000 forest schools operating in the UK.

“When we teach art we put on soothing music to keeps the noise level to a minimum. It is used as a behaviour management strategy.”

Stomping Ground is an organisation that runs forest school in Newcastle Upon Tyne for neurodiverse children.

Miss Katie Dand, Primary school, Senior TA, Year 4.

“We aim to create long-term connections by bringing people together. Provide long term growth for the forest and schools.”

Miss Helen Haran, Commercial Manager, Stomping Ground.

20

FURTHER RESEARCH

Development

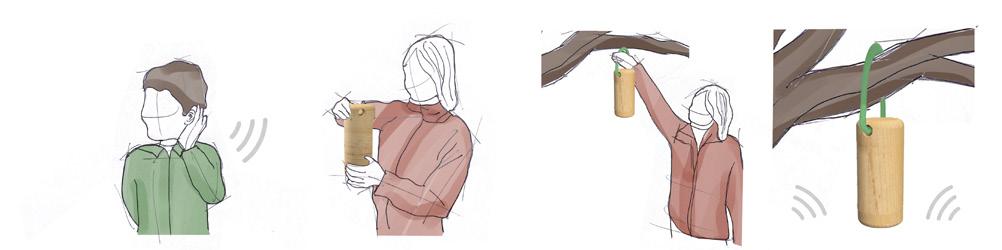

Taking inspiration from trees at Stomping Ground’s site I explored different forms. I then conducted product testing, capturing the process in a video to demonstrate its functionality.

21

Youtube Video

Testing

DEVELOPMENT

Children find it hard to concentrate and relax. They lack access to the benefits of nature.

Transport to Stomping ground site. Education in the health and wellbeing of the forest.

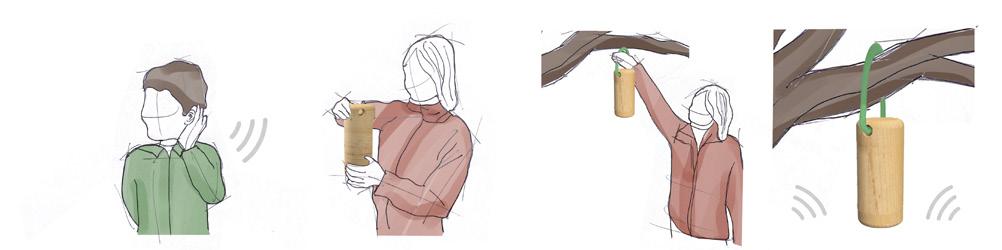

Using product to listen to their surroundings. Helen puts together the device. The device is hung on the chosen spot. The device is powering on.

Live broadcasting is now ready. Flipped over product produces no sound.

Twist the body to reduce noise and cup to ear.

“Fantastic. It allows children to carry on their learning in the classroom and create ownership of the space. Especially those schools that don’t have the funding to make repeat visits.”

Or place on the table for all to hear.

“You have created a commercial package that will help people understand the existing benefits of Stomping ground. This will help us to expand to more schools.”

22

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

USER JOURNAL

“I like the way it feels in my hand. It is easy to hold up to my ear. It makes me feel relaxed.”

“I am listening to where I made my den, It reminds me of how fun it was in the woods.”

Testing

Focusing on circular system thinking I created the two products using felled wood from Stomping Ground. I gave the product to Ava and Romi, two six year old girls to receive their feedback.

23

TESTING

Six Month Placement

“Louis has an outstanding work ethic and willingness to learn. Open to new ideas and constructive criticism, he has taken on board the concept of rapid prototyping and confidently backs up his workings. Louis truly became a member of the team and surpassed all expectations with his time here at Restrap.”

Danny

Lane Product Design, Manager.

NDA-Confidential

24

SIX MONTH PLACEMENT

Soft Goods

During my time at Restrap, I underwent a two-week training program covering the operation of various machines, with a focus on the sewing and cutting departments. I designed and developed products, ranging from initial prototypes to refined end-products.

25 SOFT GOODS

Packaging

Alongside soft goods I designed and tested packaging. My goal was to make simplistic yet efficient designs that are user friendly and easy to assemble/disassemble when modelled on the shop floor.

26 PACKAGING

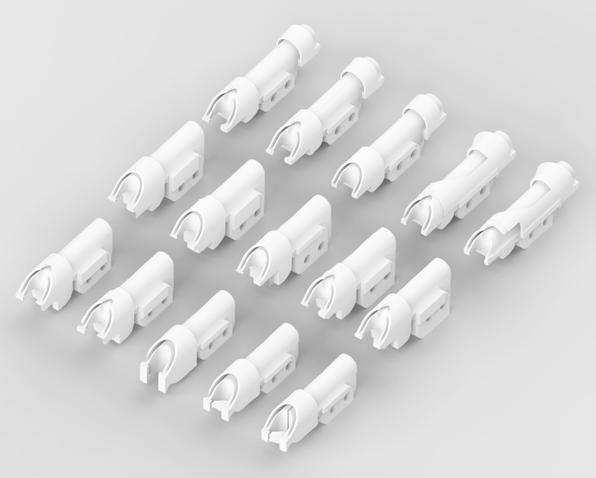

Manufacturing

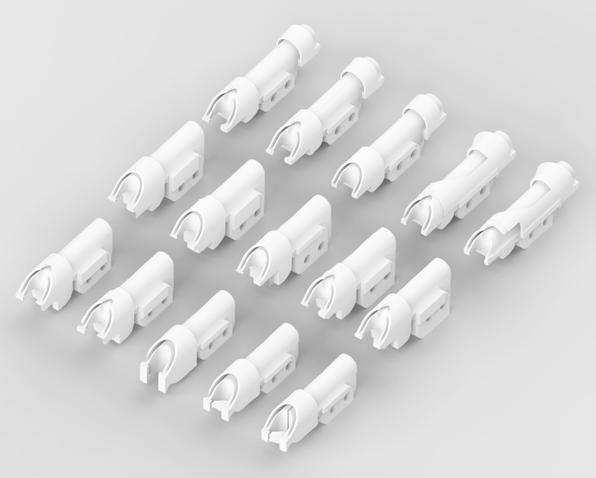

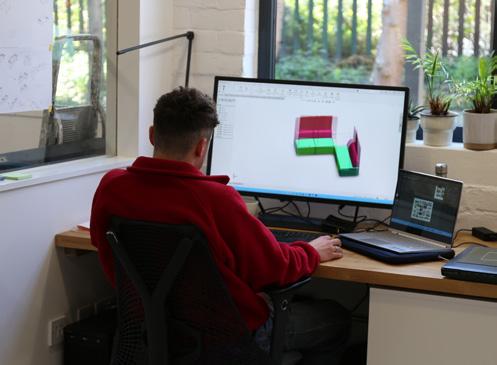

One day a week I focused on manufacturing design. I tessellated files for CNC cutting and created machine components in order to increase efficiency in the manufacturing process. One component I worked on was a 3D printed cover stitch binder.

27 MANUFACTURE

Four Month Placement

David established his Design Studio in 2011 working with leading manufacturers and design led companies such as Luum, Habitat, Deadgood and Juniper, operating specifically within the spectrum of contemporary furniture, product and lighting.

28

FOUR MONTH PLACEMENT

29 CONFIGURATIONS

ReWork

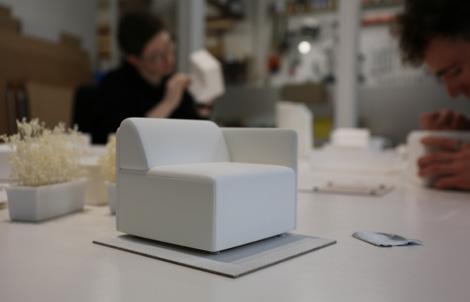

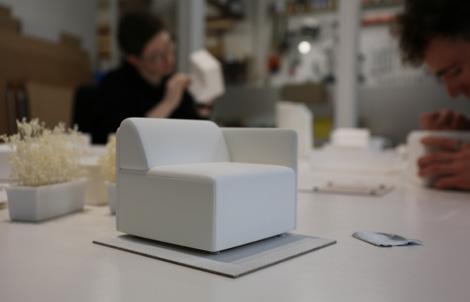

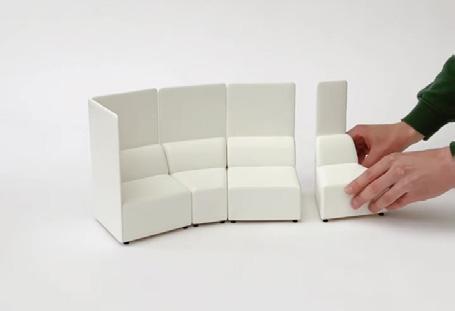

Working with Deadgood: I created both models and collaborative/formal configurations of the modular system

ReWork. Focusing on the modern workplace and how this can be used to help sell the product. Using 3D printing I created 1:6 scale models. These were presented at the showroom to clients.

30

MODELS

Hobbies

Having grown up with outdoor enthusiasts for parents, I find myself following in their footsteps. I document the sports I love on a mix of 35mm film and digital photography.

31

HOBBY

Personal Email: louismartlew@gmail.com

University Email: louis.martlew@northumbria.ac.uk

Mobile: +44 7717946404

Linkedin: www.linkedin.com/in/louis-martlew Instagram

blog: louismartlew_design

Thank you.

Dr

Dr