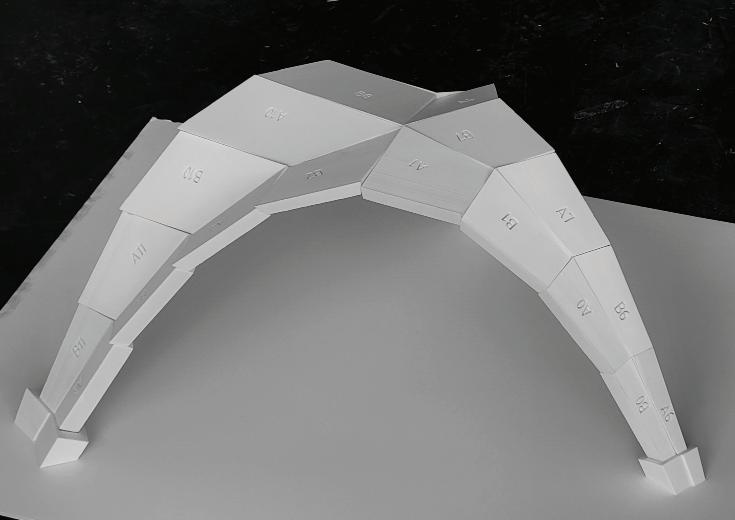

HEMPLIME + FREE-FORM HYBRIDS

Sustainable Design Through Material and Computational Innovation

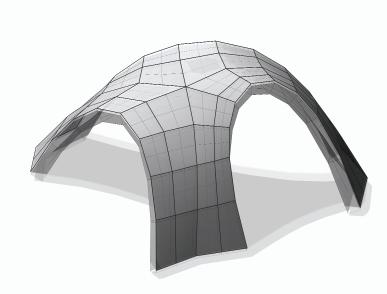

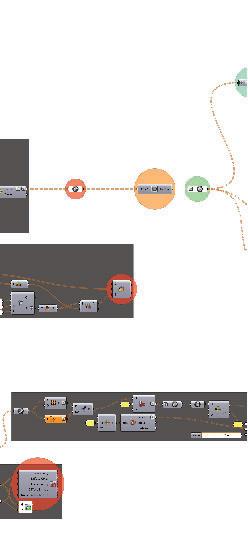

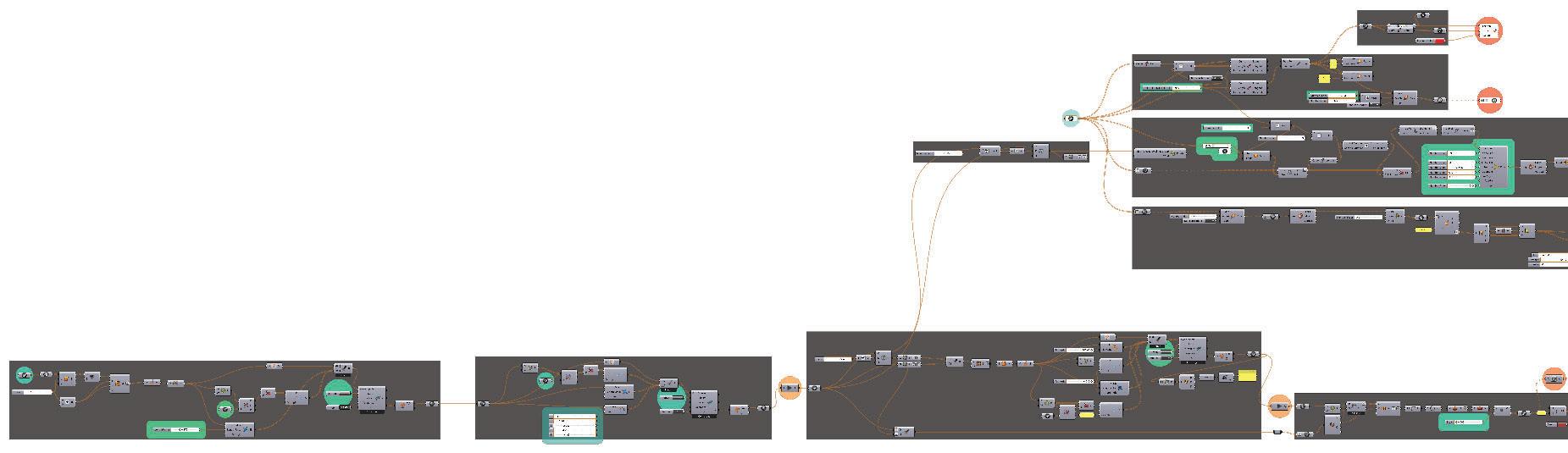

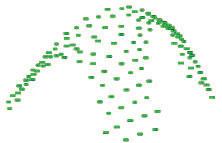

Ethan WahlAs architects become more environmentally conscious, they are exploring alternative eco-friendly materials. This thesis integrates hemplime, a sustainable and carbon-negative material, with progressive computational design and fabrication techniques to create a research pavilion that showcases its potential capabilities. This research expands the knowledge on sustainable and carbonnegative materials by emphasizing hemplime’s benefits and promoting its adoption in future projects. Ultimately, this thesis aims to inspire architects to prioritize sustainability and consider innovative design strategies that utilize eco-friendly materials and structural efficiency, paving the way for a more sustainable and carbon-negative future in architecture.

SEEDS & FLOWERS

Animal Feed

Food Oils

Cosmetic oils

Healthcare Oils

Food

Pharmaceuticals

HURD/SHIV & BAST FIBER

Clothing

Paper

Pulp

Bio-composites

Insulation

Textiles

Animal Bedding

Cultivation

Mulch

Construction

LEAVES

Tea

Pharmaceuticals

Animal Feed

ROOTS

Soil Nutrients Revitalization

Soil Aeration

Medicine

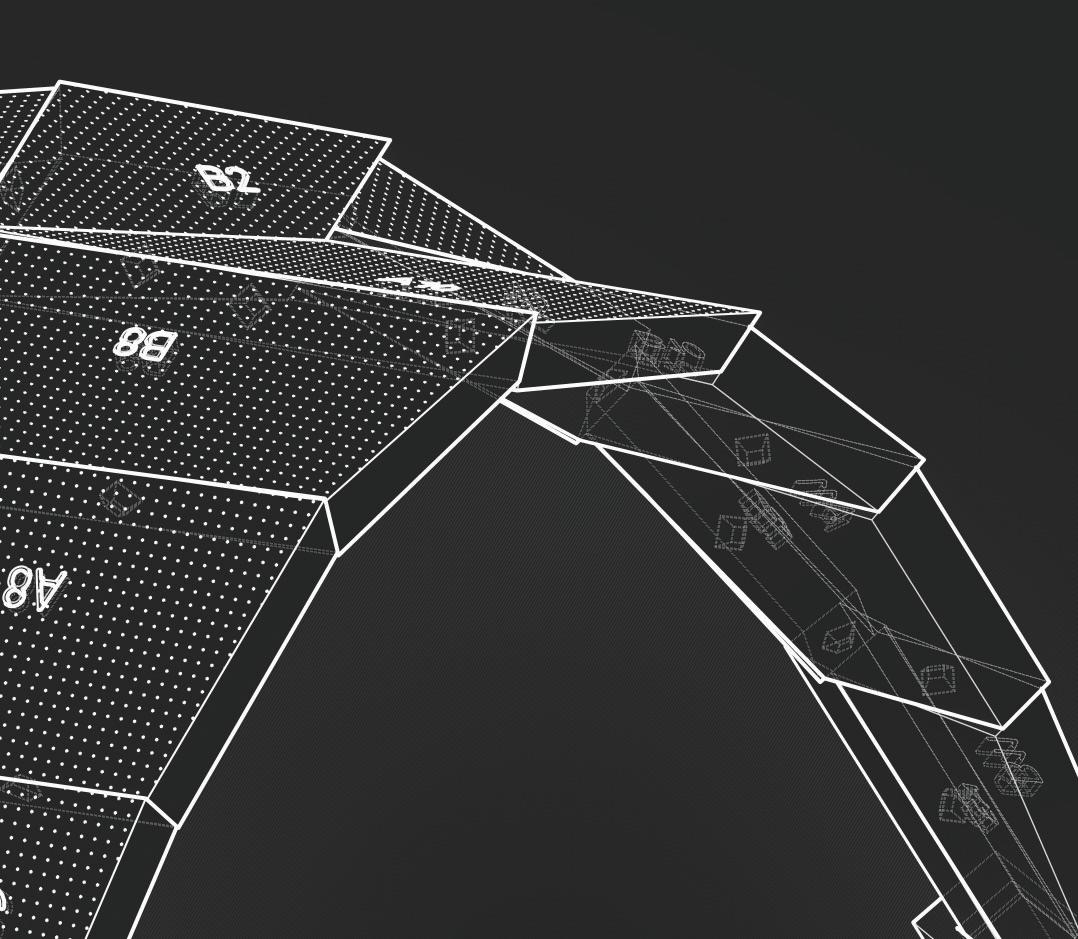

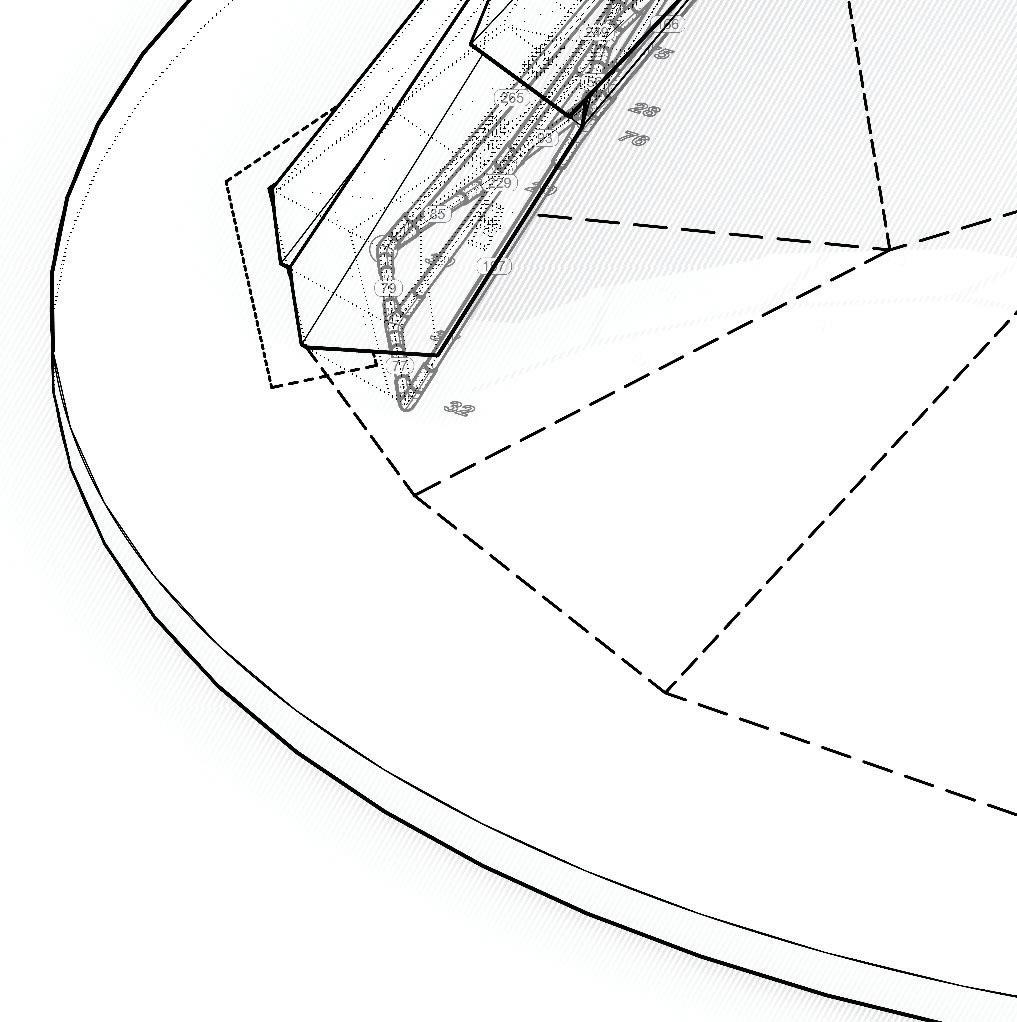

Hempcrete Roof Insulation

Hempcrete Flooring Insulation

Hempcrete Interior Wall Ins

Hempcrete Fire Resistance

Hempcrete Roof Insulation

Hempcrete Flooring Insulation

Hempcrete Interior Wall Ins

Hempcrete Fire Resistance

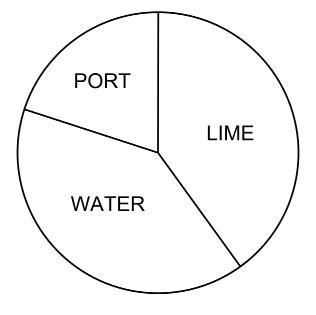

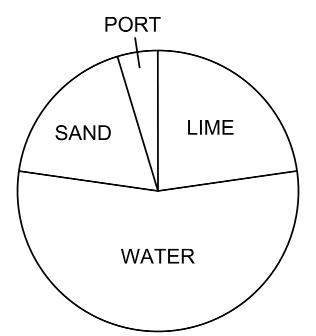

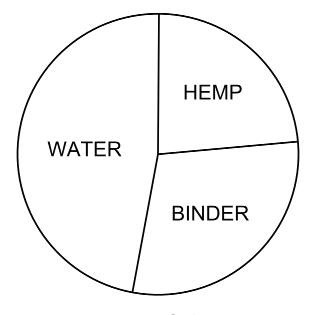

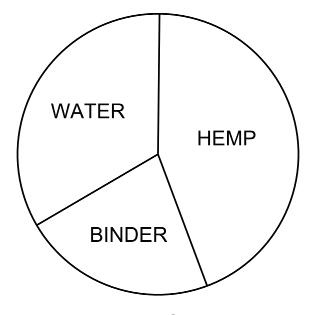

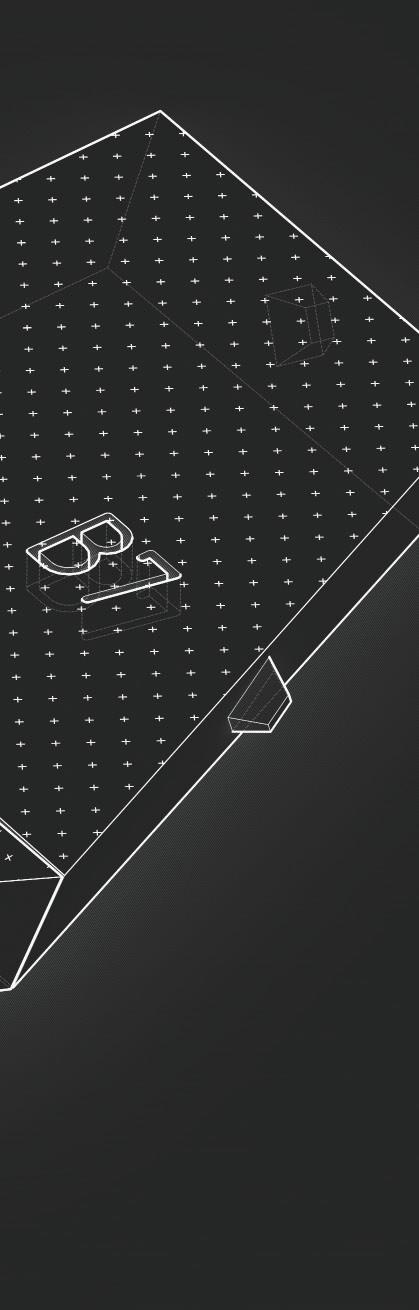

Test

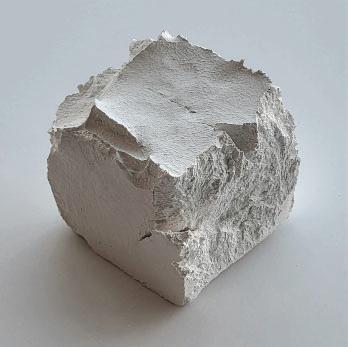

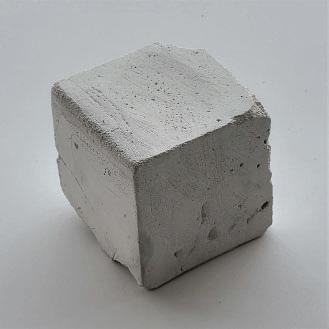

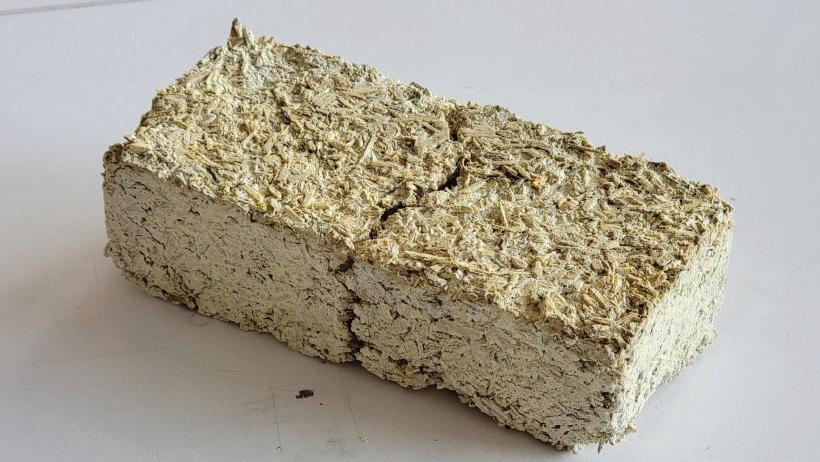

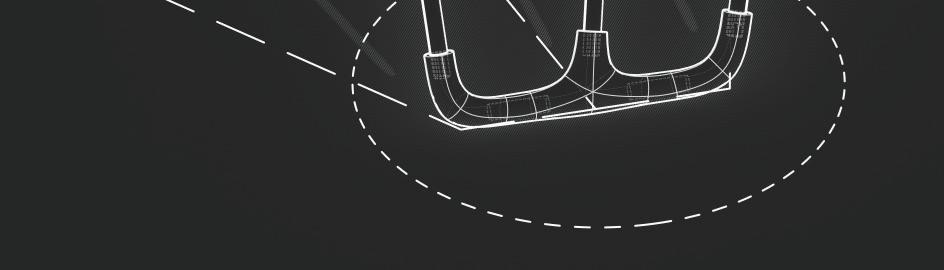

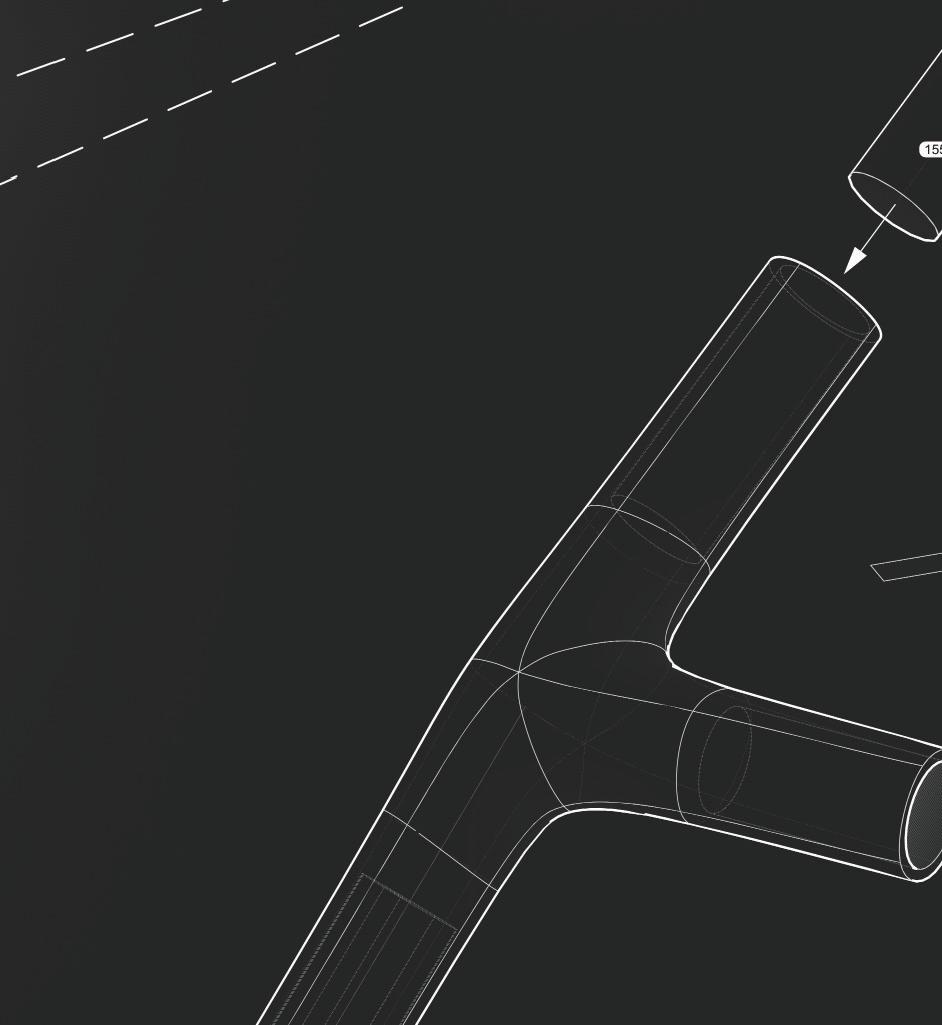

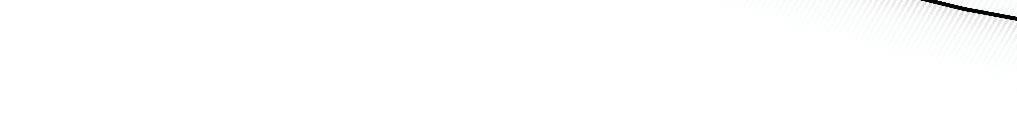

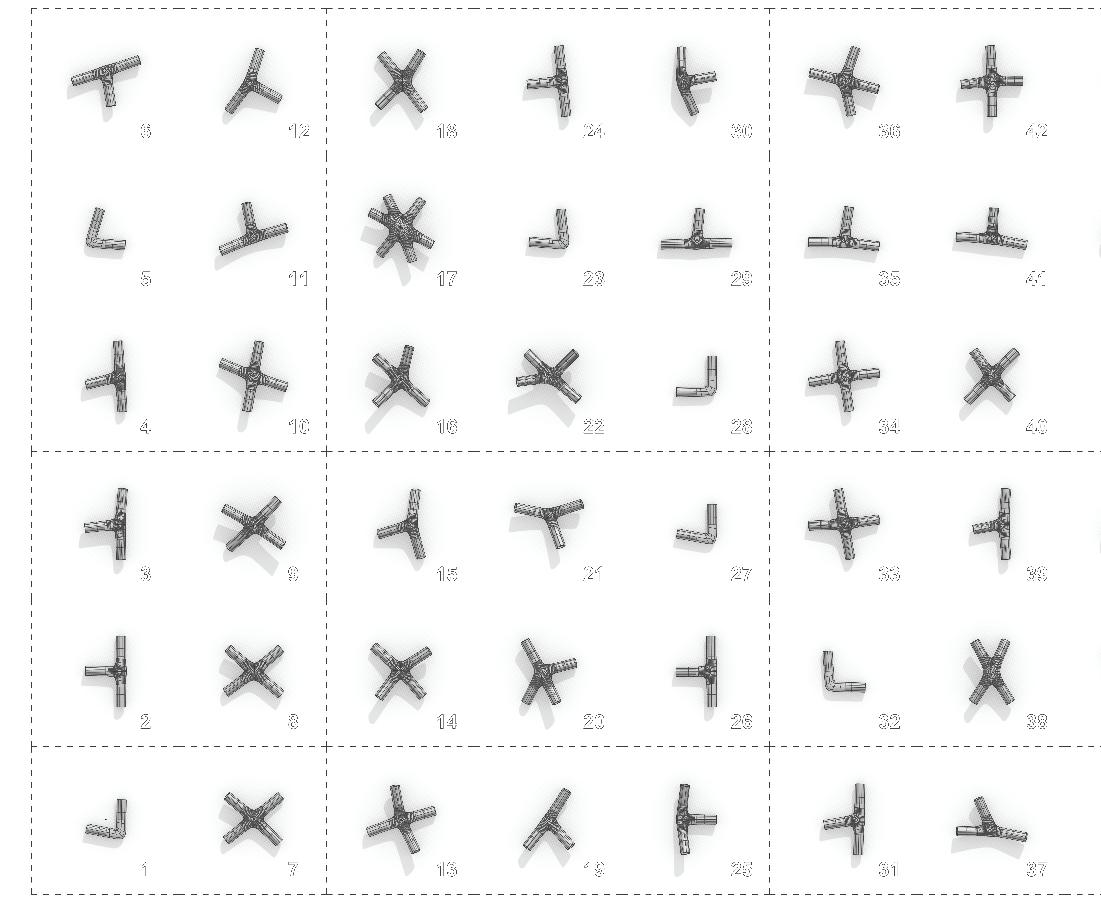

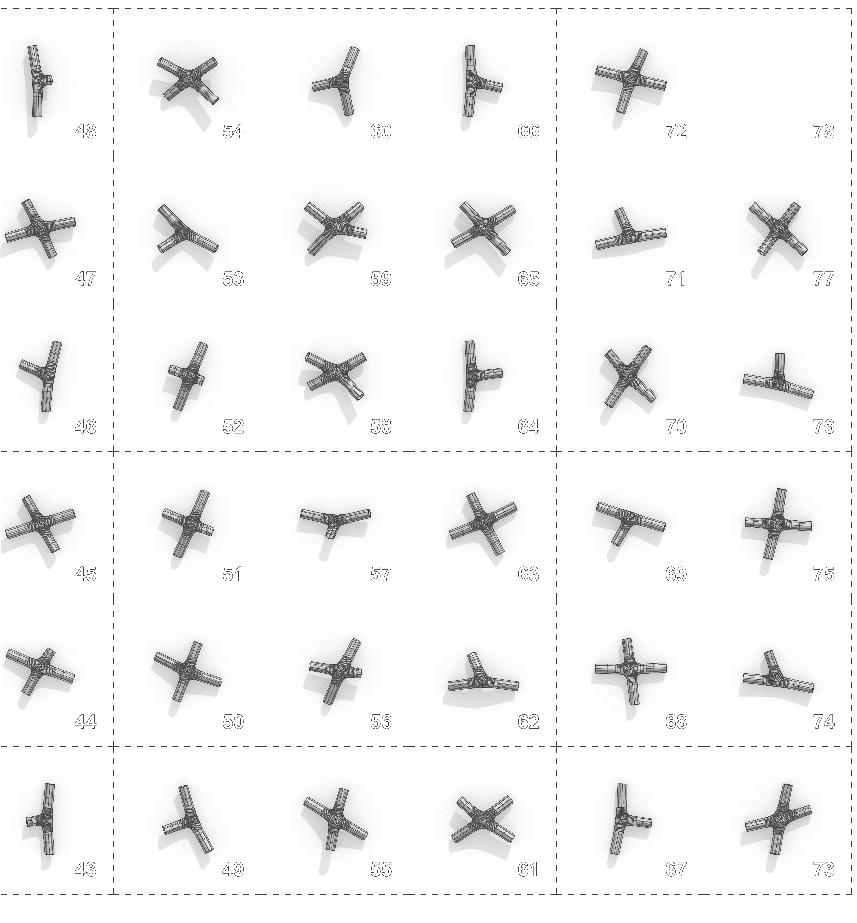

Prefabricated Hemplime load-bearing blocks

sulation

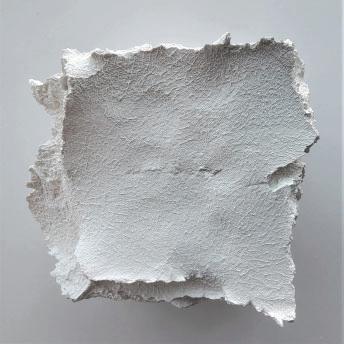

Hempcrete Exterior Wall Finish

sulation

Hempcrete Exterior Wall Finish