RDF Processing Plant Solutions | Sustainable Waste-to-Energy

by Maan Enviro Technologies

At Maan Enviro Technologies, we are proud to offer innovative RDF (Refuse Derived Fuel) processing plant solutions that empower businesses to manage their waste more effectively while generating sustainable energy. Our state-of-the-art plants convert non-recyclable waste into high-quality fuel, providing an eco-friendly solution that helps industries reduce landfill dependency and contribute to renewable energy production.

What is RDF Processing?

RDF processing involves transforming waste, particularly non-recyclable materials such as plastics, paper, and other mixed waste, into a valuable source of energy. This process not only prevents waste from accumulating in landfills but also serves as an alternative fuel for energy generation.

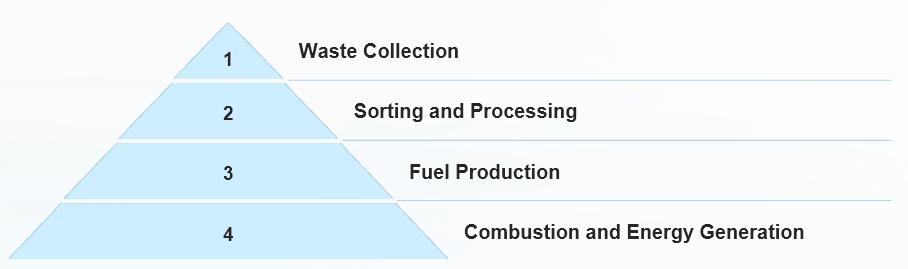

How Does an RDF Processing Plant Work?

Waste Collection and Sorting: Waste is first collected and sorted to remove any recyclables and noncombustible materials.

Shredding: The remaining waste is shredded into smaller pieces to enhance the fuel quality and ease of combustion.

Densification: The shredded waste is then compressed and densified into uniform fuel that can be used in power plants or industrial furnaces.

Energy Generation: The processed RDF is used to generate electricity and heat, which can be harnessed for industrial or municipal use.

Advanced RDF Technologies

Advanced RDF (Refuse Derived Fuel) technologies represent the latest innovations in the treatment and conversion of waste into energy. These technologies aim to increase the efficiency and sustainability of RDF production while improving the environmental impact of waste management processes. Key advancements in RDF technology include better integration with Waste-to-Energy (WtE) solutions, automated segregation using trommel screens, and innovative drying and shredding techniques.

▪ Integration with Modern Waste-to-Energy Solutions

Advanced RDF technologies are integrated into Waste-to-Energy (WtE) plants, turning waste into useful energy like electricity and heat. This process helps reduce landfill waste while providing a sustainable energy source.

▪ Automated Segregation Using Trommel Screens

Trommel screens are large rotating drums used to automatically sort waste. They separate recyclable materials from non-recyclable ones and can be used to make RDF. This automation makes waste sorting faster and more accurate, improving RDF quality.

▪ Innovation in Drying and Shredding Techniques

Advanced drying and shredding methods help prepare waste for RDF production. Modern drying techniques remove moisture efficiently, while shredders break down materials into smaller pieces for better burning in energy plants. This increases RDF’s energy output and reliability.

Benefits of RDF Processing Plants

1. Reduction in Landfill Use: RDF processing plants divert significant amounts of waste from landfills, preserving space and mitigating environmental hazards like groundwater contamination and methane emissions.

2. Energy Recovery: By converting waste into fuel, RDF plants recover energy from materials that would otherwise go to waste, supporting a circular economy where resources are reused.

3. Lower Carbon Emissions: RDF reduces dependence on fossil fuels, contributing to lower greenhouse gas emissions and aligning with global sustainability goals.

4. Cost-Effective Waste Management: RDF provides a practical solution for managing large waste volumes. The energy generated can offset operational costs, making it a financially viable option.

5. Supporting Sustainability: By transforming waste into energy, RDF processing plants promote sustainable waste management and resource efficiency.

Importance of Sustainable Waste Management

Environmental Impact Resource Conservation Public Health

Landfills release methane, a harmful greenhouse gas. Managing waste sustainably helps fight climate change and safeguard ecosystems.

Recycling and waste-to-energy solutions save resources and lower the need for new materials, supporting both the economy and the environment.

Poor waste disposal can harm health. Sustainable methods keep communities safe and the environment healthy.

Challenges in RDF Processing

While RDF (Refuse Derived Fuel) offers numerous benefits in energy generation, its processing comes with challenges that need to be addressed to improve efficiency and environmental performance. Key challenges include:

▪ Addressing Moisture and Impurities in Waste

One of the main challenges in RDF processing is the high moisture content in waste materials. Excess moisture can reduce the energy content of RDF and complicate its handling. In addition, waste often contains impurities such as metals and chemicals, which must be removed during the processing stage to ensure the quality of the fuel. Managing these issues requires effective drying and sorting techniques to create high-quality RDF.

▪ Compliance with Environmental Regulations

RDF processing must meet strict environmental regulations. These laws focus on reducing emissions and ensuring that the waste-to-energy process does not harm the environment. Compliance requires advanced technologies to manage air quality, handle waste responsibly, and monitor pollution levels, making regulatory adherence a key part of RDF production.

• Transportation and Storage of RDF Fuel

Transporting and storing RDF can be challenging due to its bulk, moisture content, and sometimes inconsistent quality. Proper storage solutions are needed to prevent degradation, and transportation systems must be efficient to ensure RDF reaches energy plants without delays. This requires careful planning and investment in logistics to maintain the fuel's effectiveness.

Overview of RDF (Refuse-Derived Fuel)

Scope of RDF in Energy Generation

Refuse Derived Fuel (RDF) is emerging as a significant component in the field of energy generation, providing a sustainable solution to both waste disposal and energy needs. RDF is produced by processing non-recyclable waste materials, such as plastics, paper, and textiles, into a fuel that can be used in energy plants. As traditional fossil fuels become increasingly unsustainable, RDF offers a cleaner, renewable alternative. Here's an overview of its role and growing importance in energy production.

Future of RDF Processing

The future of RDF (Refuse Derived Fuel) processing holds great promise as new technologies and trends continue to shape the industry. Here’s a look at the key factors influencing its future:

Upcoming Technologies and Trends

Innovative technologies are constantly evolving to improve RDF processing. Advances in sorting and recycling technologies, such as better automation and AI, are expected to make waste segregation more efficient and reduce contamination. Additionally, improvements in drying and shredding techniques will enhance the energy content of RDF, making it a more reliable fuel source. These trends point to a future where RDF is processed with higher efficiency, better quality control, and minimal waste.

Potential for Scaling Waste-to-Energy Solutions Globally

As countries around the world seek cleaner energy solutions and better waste management, the potential for scaling waste-to-energy solutions, particularly through RDF, is significant. Many regions with limited waste disposal options or high reliance on fossil fuels could benefit from expanding RDF-based energy production.

Role of RDF in Achieving Sustainability Goals

RDF is key to achieving sustainability goals by offering a dual benefit: managing waste and providing renewable energy. By reducing reliance on landfills, lowering greenhouse gas emissions, and generating clean energy, RDF plays an important role in transitioning to more sustainable energy systems.

In the future, RDF processing will continue to evolve with better technologies, increased adoption worldwide, and a crucial role in helping achieve a greener, more sustainable world.

Why Choose Maan Enviro Technologies?

• Proven expertise in developing advanced RDF processing systems.

• Commitment to delivering sustainable waste-to-energy solutions.

• Use of advanced technologies, including Trommel Screens and MRF systems.

• Comprehensive support, from system installation to maintenance.

• Integration of legacy waste management and MRF systems for maximum efficiency.

Learn more about how Maan Enviro Technologies can transform your waste management systems with cuttingedge RDF processing solutions. Visit us at https://maanenviro.com/rdf-processing-plant or contact us directly for tailored solutions.

For more information about Maan Enviro Technologies and rdf processing plant:

Official Website: https://maanenviro.com/, GMB: https://maps.app.goo.gl/d5aKXNzX2ALBTr3L8

Contact Number: 9584979888

Official Mail ID: info@maanenviro.com