17 minute read

Building diversity in NZ’s steel industry

In an industry first, Steel Construction NZ (SCNZ) has demonstrated its commitment to diversity and inclusion by publishing its Building Diversity in the Steel Industry article in English and te reo Māori.

SCNZ is the voice for New Zealand’s structural steel industry. It works to promote the benefits of steel solutions in construction, the value the industry contributes to local communities and the high-value career opportunities that it offers. The industry organisation’s bilingual publication tells the story of D&H Steel Construction’s apprenticeship programme, which embraces diversity and equal opportunity. “D&H Steel has long prided itself on its commitment to family, equal opportunity and diversity,” D&H Steel Construction managing director, Wayne Carson says. “We have a strong track record of supporting young people from diverse backgrounds to grow, develop and achieve their goals through hard work and focus.” Partnerships with organisations like Māori and Pasifika Trades Training, Unitec and Gateway offer a good fit with the Auckland-based structural steel contractor. D&H Steel benefits from a structured approach to bringing new blood into the business while also enabling it to help futureproof the industry and make a difference in the community. “While we are proud to bring this story to life in both of New Zealand's official languages, English and te reo Māori, the real story is about our industry’s commitment to encouraging diversity and equality in the structural steel workplace,” SCNZ general manager, Darren O’Riley says. “D&H Steel is one of many businesses in our industry exemplifying this ethos.” SCNZ has recently developed a Sustainability Policy, which includes a pledge to implement the Aotearoa Steel Industry Transformation Agenda. It identifies best-practice requirements to guide the industry towards future success, and highlights what an effective transformation should look like.

Apprentice Angela Adams.

Apprentice Jarrod Tahi

Read more about SCNZ diversity and sustainability focuses:

1. The bilingual Building Diversity in the Steel Industry article (Te Whakatipu Kanorau I Te Ahumahi Mait) can be downloaded from the SCNZ website: www.scnz.org/case-study-10-dhsteel-nga-umanga-mahi-i-te-maitaicareers-in-steel. 2. SCNZ’s Sustainability Policy can be viewed on its website: www.scnz.org/sustainability-policy.

Fast facts about the steel industry

• 127 structural steel fabrication companies nationwide • Current annual capacity estimated at 120,000 tonnes; approximately 100,000 tonnes was produced in the past 12 months • Today, structural steel’s market share is more than 50 percent nationwide • In Christchurch, due to the material’s proven seismic performance, steel has grown its share of the multi-level construction market to almost 80 percent, up from virtually nil prior to the Canterbury earthquakes • 69 percent of structural steel contractors employ an average of four apprentices.

Get on board, navigate the future with FICEP!

VALIANT

Automatic CNC drilling and band sawing line for profiles

Accurate - advanced pincher clamping system and new hold down system with two independent cylinders

Productive - enhanced auxiliary axis (with 300 mm stroke) on each independent drilling spindle/head

Capable - the underside scribing device, also with sub-axis positioning permits up to fourside simultaneous scribing operations

Efficient - automatic tool changer holding up to 14 positions per head – significant increase of tools availability

FICEP has many installations in New Zealand to showcase every steel fabrication need.

www.ficepgroup.com

Area Sales Manager Mr. Francis Lee Mobile: +64 (0) 21 448 568 E-mail: francis.lee@ficep.it

No composite steel flooring job is too Big

Or too small.

About Steel Construction New Zealand

SCNZ aims to advance the interests of New Zealand’s diverse steel construction industry by promoting the benefits of steel solutions in building and infrastructure projects. Members include manufacturers of structural steel and steel products, distributors, fabricators, designers, detailers, galvanisers, and paint and building supply companies. SCNZ provides its members with technical advice on the latest in steel design trends and standards, networking opportunities and a representative voice with key industry and government decision-makers.

For more information, please visit: www.scnz.org.

Apprentice Junior Faamausili

The Agenda aligns with BRANZ’s Industry Transformation Agenda, the Construction Sector Accord and is based on the NZ Treasury’s Living Standards Framework. “We have pledged to contribute meaningfully to the Living Standards Framework and to the Construction Sector Accord, creating shared value for our members, our people and our communities,” Darren says. “One of the pillars of the agenda relates to human capital and a commitment to promote diversity within the industry, which this bilingual publication is in support of.” Qualified and skilled tradespeople are in short supply in New Zealand but there is an increasing number of trades jobs, particularly in light of COVID-19 when it is no longer possible to access the skills offshore. At the same time, Māori and Pasifika, and women, are underrepresented in skilled trades positions. What’s more, Kiwis have typically been steered towards a university education ahead of the trades, and the impact on the structural steel industry has been significant. “Our industry’s focus on building a more diverse workforce will help to ensure the long-term sustainability of the structural steel sector,” Darren says.

14 Manchester Place, Te Rapa, Hamilton 3241 Ph: 07 850 0120 Fx: 07 850 0129 Email: pmp@perry.co.nz SCNZ

PO Box 76403 Manukau Auckland 09 263 5635 info@scnz.org www.scnz.org

14 Manchester Place, Te Rapa, Hamilton 3241 Ph: 07 850 0120 Fx: 07 850 0129 We’ve got you covered Email: pmp@perry.co.nzYour Complete service provider for all of your Grating and Hot Dip Galvanising requirements The reassurance of protection both inside and out Perry Metal Protection has been strengthening steel through Hot Dip Galvanizing (HDG) in New Zealand since the early 1970’s. With Operations in Auckland, Hamilton, Tauranga, Wellington, and Christchurch Perry Metal Protection offers the most comprehensive galvanizing service in New Zealand

for a quote today!

Tray-dec

New Zealand Ltd

09 820 9133

info@traydec.nz www.traydec.nz

NELSON STUD WELDING

09 820 9133

sales@nelsonstud.co.nz www.nelsonstud.co.nz

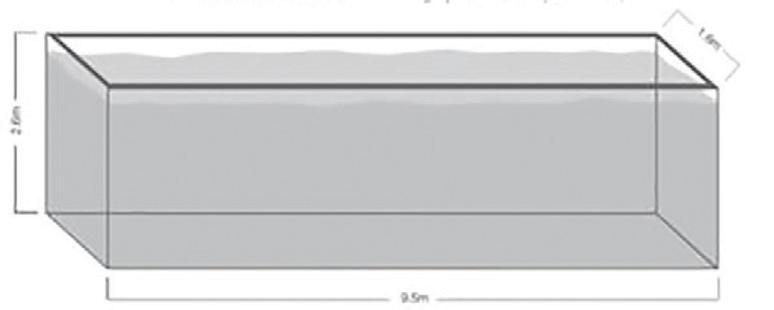

Hamilton Galvanizing Facility

The zinc bath dimensions are 9.5m long by 1.6m wide by 2.5m deep

ACRS set to raise the new sustainable steel

The scheme enables consumers, industry and government to confidently source high quality constructional steels produced under high standards of environmental, social and ethical management and will help combat ESG confusion through the steel supply chain.

Australasian Certification Authority for Reinforcing and Structural Steels (“ACRS”), the leading independent steel certification authority for Australia and New Zealand, recently announced the Australasian launch of a certification scheme that will dramatically improve buyers’ ability to source high quality, ethically and sustainably produced steel for construction across Australasia. The Scheme will ensure that the public knows that steel installed in their homes, high rise commercial and residential buildings and across Australasian infrastructure meets the highest global standards. ACRS has partnered with the leading international construction steel certification authority, CARES, to introduce its market leading Sustainable Constructional Steels Certification Scheme into the Australasian markets – to be known as the SCS Scheme (‘SCS’ or the ‘SCS Scheme’). The Scheme ensures that construction steel entering Australia and New Zealand from anywhere in the world meets the highest global environmental, social and ethical standards, using independent certification of ESG criteria and performance indicators. Despite Australia and New Zealand importing significant volumes of steel to meet expanding building and infrastructure needs, many existing sustainability schemes fail to provide adequate, independent verification of the supplier's claims regarding the sustainability of the materials supplied to consumers. There is rapidly increasing demand for a premium, independent verification scheme in the area of steel sustainability, that provides surety there is no producer bias, misrepresentation or dilution of the expected certification process. Australians and New Zealanders will now be able to determine with confidence the sustainability performance of the steel procured. Australian and international steel producers are working hard to reduce their emissions – around 7% of global CO2 emissions are generated by the industry. The SCS Scheme will help steel producers and processors measure, monitor and improve the sustainability performance of their products and will strengthen industry efforts already underway to combat greenhouse gas emissions. As construction will play a major role in postpandemic economic recovery across Australia and New Zealand, this Scheme will help building designers, specifiers and customers make informed decisions about the materials they are buying. Commenting on the Australasian launch of the SCS Scheme, Philip Sanders, CEO of ACRS, said “This is an important development not just for the Australasian steel industry but for the general public. “We all look at vehicle emissions and ethically produced clothing but how about the steel that holds up our infrastructure and buildings? “This internationally recognised, bestin-class sustainability scheme will help leading producers better demonstrate the sustainability of their product and it will give the general public confidence that our cities are being built with environmentally and ethically sourced steel. “Global demand for sustainable steel is growing in line with increasing public and government demand. Many Australian and New Zealand government projects are demanding it.” Commenting on the partnership with ACRS, Lee Brankley, CEO of CARES said the launch of CARES’ SCS scheme into the Australasian markets represented a “real turning point” for the industry. “Recent events have confirmed, more than ever, how important it is to build confidence in the provenance of safety critical products, like steel, entering the construction supply chain. “CARES is proud of its long track record in operating an SCS scheme which has gained global recognition and the partnership launched today with ACRS is a real turning point for the sector in Australia and New Zealand.”

bar with certification scheme

Lee said CARES, based out of the UK, has grown its reach globally as more manufacturers and clients have sought to lock in the confidence that comes from verified, independent, third-party scrutiny: “Whether it is constructors, their consultants or consumers, all our stakeholders are entitled to know the full story behind the products they are choosing to rely on for a secure, sustainable future.”

Scheme provides a clear public benefit

The Scheme’s supplier mapping evaluation and management systems requirements provide insights into labour conditions and human rights risks in sourcing and production. The Scheme aligns to the UN convened Sustainable Development Goals - ‘The Global Goals’ - and measures and monitors a comprehensive range of criteria through the global supply chain, including ethical business practices; modern slavery, human rights and labour conditions; environmental impacts (including circular economy and climate change); fair supplier treatment and the socioeconomic impacts of the steel value chain. Raw material and transport data combined with independently verified production and life cycle emissions data supports the development of the products carbon footprint and Environmental Product Declarations – prerequisites of the scheme. This enables accurate data, for example the Global Warming Potential, per tonne of product, to be easily accessed by designers and specifiers. On product bar marking and digital product labelling allow 100 percent traceability on all verified products from manufacture to site.

Supporting international trade and commerce

The Scheme already certifies over 40 producers and suppliers in 13 countries. Products certified under the Scheme are approved inputs for a range of international building and infrastructure rating systems. It is currently seeking recognition from the Green Building Council of Australia and is compatible with the recently released Responsible Steel Standard. The UK’s Building Research Establishment Environmental Assessment Method (BREEAM) recognises the Scheme as a ‘responsible sourcing certification scheme’; with the US LEED building rating system and the Hong Kong CIC scheme also recognising its Environmental Product Declarations (EPD).

Helping to accelerate the ongoing transition to an environmentally friendly construction industry

The Scheme assesses producers annually against benchmark sustainability performance, assisting the better performing producers independently verify environmental and social performance of their product and its production processes. Utilising a Rosette Rating System, credits are awarded to recognise and incentivise levels of performance exceeding mandatory levels, enabling organisations to better understand and plan a ‘transition pathway’ from current performance levels to an aspirational ‘sustainable’ steel production represented by a ‘4 Rosette Rating’. This rating requires zero emission steel production, responsible sourcing, good safety record, sustainably produced and processed constructional steel, with a digital record. For steel specifiers and procurement teams, the Scheme’s easy to access producer performance data and information allows them to more easily and accurately assess and demonstrate the expected certification requirements of the leading construction firms and government. Ryan Alexiou, a regional environmental manager at Multiplex, said “Governments, clients and the community expect the construction industry to operate and build in an ethical and sustainable way. “The SCS Scheme will help suppliers not only demonstrate high quality products, but also best practice standards for environment, safety and trade through their supply chains.”

Benefits for firms seeking SCS certification

With the introduction of SCS certification, product conformity, traceability, and sustainability certification will all now be available through ACRS. Firms seeking both independent premium product and sustainability certification can now do so through one certification body. The independence and rigour that ACRS is renowned for in Australia and New Zealand will help achieve the desired quality, environmental and socially responsible outcomes across the construction industry.

Additional points on the SCS certification scheme

The Scheme covers steelmaking (billets, blooms), production of intermediate materials (e.g. wire rod, slabs) and finished materials (e.g. steel bar/coil and structural steels), and fabricated materials (mesh, processed bar and welded fabrication). The Scheme is compatible with ACRS’ traceability provisions in ACRS “Stage 1” (Manufactured Product) and “Stage 2” (Fabricated Product) certification plus the Traceability scheme for traders and distributors. ACRS is the sole certification body in Australasia for delivery of CARES’ SCS, the internationally recognised scheme that is compatible with ACRS’ existing certification schemes and meets local market needs.

About ACRS

Founded in 2001, the Australasian Certification Authority for Reinforcing Steels (ACRS) is Australasia’s leading, not-for-profit, independent steel certification authority. ACRS provides the most technicallyrigorous, internationally-aligned, independent steel certification scheme to Australian and New Zealand Standards. It has audited and certified over 100 suppliers from more than 24 countries to Australian and New Zealand Standards.

Structural Steel Compliance – Doing it Right?

All products and processes utilized in the manufacture and erection of a steel structure need to have some degree of quality control, quality assurance and compliance certification.

The Building Act is the governing legislation, and Standards, Specifications, and Codes of Practice usually define a mechanism for complying with the Act. It is well recognized and understood that the raw steel materials must be accompanied by material certificates, and AS/NZS materials can only be certified if the certificates are ILAC MRA endorsed by an accredited organization. What does this mean? Accreditation is “the independent evaluation of conformity assessment bodies against recognised standards to carry out specific activities to ensure their impartiality and competence”. ILAC stands for “International Laboratory Accreditation Co-operation”. New Zealand’s Signatory to ILAC is IANZ (International Accreditation New Zealand) while in Australia it is NATA, CNAS in China etc. Other aspects of safety and building legislation require accreditation for compliance testing; for example plant that falls under the PECPR (Pressure equipment, cranes and passenger ropeways) regulations. There are many aspects of steel structure fabrication and erection that can benefit from engagement of an accredited organisation to perform inspections.

Risks inherent in this approach are:

• Overseas sourced products may be certified by inspection staff who lack independence and/or competence (In accredited organisations this has been independently verified) • In-house inspection records may be produced without appropriate procedures to ensure impartiality • Test method(s) may be inappropriate (Accredited organisations must have procedures to prevent use of incorrect methods) • The extent of testing may be inadequate (Accredited organisations must have policies to correctly apply standards and specifications) • BCAs or Construction Reviewers may reject the inspection reports at a later stage In the steel fabrication arena we frequently come across certificates and test reports from non-accredited individuals or organisations which show the testing deficiencies.

We have seen: • Unqualified personnel operating outside their proven skill set • Uncalibrated and unsuitable equipment • Misleading or incoherent test results • Serious departures from Standard or

Specification requirements. These problems exist in weld procedure and welder qualification tests, NDT and welding inspection during fabrication, and especially with the requirements for staged inspections during protective coating application. In summary all compliance inspection of welding, bolting and coating should be carried out by qualified or certified personnel working within an accredited company; and with compliance work performed by such an accredited inspection company then Clients, BCAs and Designers can have confidence in the inspection reports or certificates provided.

The benefits of using accredited suppliers:

Independent verification of: • Competence and certification of personnel, including eyesight • Quality systems to ISO 9001 and ISO 17020/17025 • Equipment suitability & calibration • Documented procedures • Reporting which meets the requirements of the standard • Impartiality and confidentiality

The risks of not using accredited inspection companies:

Current standards and specifications impose requirements on personnel competency, but often do not address the other vital quality aspects necessary for the delivery of valid compliance documents. We have seen unqualified personnel operating outside their proven skill set, uncalibrated and unsuitable equipment, misleading or incoherent test results and serious departures from Standard or Specification requirements.

www.sqa.co.nz | e. admin@sqa.co.nz | p. 03 381 1670

Consultancy Services

• Material Conformance Verification • Fabricator Third Party Audits • Coatings Compliance • Welding Compliance • NDT Level III Services

Inspection Services

• Structural Steel Inspection • Protective Coatings Inspection • Bolt Tension Testing • Rope Access Inspection • Remote Visual Inspection • Hull Thickness Surveys

NDT Services

• Radiography • Ultrasonic Testing • Magnetic Particle inspection • Liquid Penetrant Inspection • Eddy Current Testing

form of advertising you can measure, then increase or decrease, so you can manage your workflow accordingly!

You’ve probably heard people talk about digital marketing, Google AdWords, online traffic, SEO and social media. Then on top of all that, you need to have a lead generating web presence with good traffic etc.

This can sound complicated – but it doesn’t have to if you talk to the right people.

Let’s start with the basics

Right now there are people looking for a business just like yours. However, if you don’t have AdWords, there’s a very good chance they’ve just clicked one of your competitors’ websites.

Most businesses would benefit from Google AdWords. It’s simple to set up, it’s fast, you set the monthly budget, and you can see the results immediately.

Included is a complimentary call tracking service to measure daily results, plus you get a monthly report that’s explained in as much detail as you like.

We have many success stories where people have thought marketing is a waste of money, but have finally found something that gives them a transparent Return on Investment.

If you would like to be our next success story, please call or email: enquiries@fatweb.co.nz

We have offices throughout New Zealand and can discuss your needs over the phone or by Skype. Don’t let another year go by without truly discovering what digital marketing can do for your business.

With years’ of experience and having delivered outstanding results, we have some of the best digital experts in the business.

We are so confident, that if you aren’t 100% happy after the first month, you won’t pay a cent for the management fee. And if you mention this ad, set-up is free – a service other companies charge up to $3,000 for.

FREE call tracking, which means you can actually hear recordings of the phone calls coming into your business to see if your staff are doing things correctly or if they need more training. This tool can make a massive difference to the FAT on your bottom line.

Available to the first 25 people who book a consultation.

With over 15 years’ experience - we know what we’re doing.

- 38 Lowe St, Addington, Christchurch 8011, New Zealand - Level 6, 3-13 Shortland Street, Auckland CBD, Auckland 1010

Call 0800 FATWEB, or email enquiries@fatweb.co.nz to book a FREE consultation.