4 minute read

How to handle your beef cattle: Part 6

from ProAgri BNZ 07

by ProAgri

Loading ramps and dipping How to handle your beef cattle: Part 6

Advertisement

Loading platforms

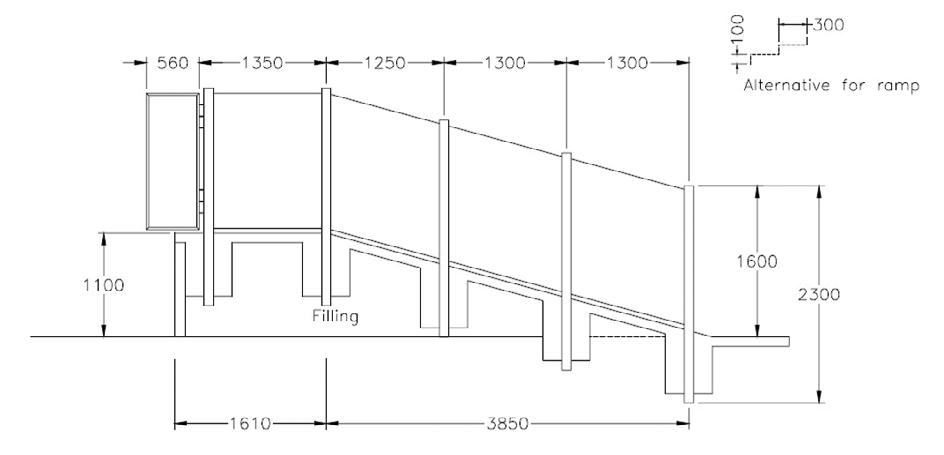

A loading platform must be designed in such a way that the cattle can be loaded fast enough so that the first animal does not get a chance to walk back. The height of the loading platform is determined by the height of the back of the truck or transportation vehicle. As general directive, a height of 1,1 m to 1,2 m for trucks will suffice.

A loading platform which is built at a steep angle causes injuries, therefore, the gradient must not exceed 16°. This is equal to a one meter increase over 3,5 m horizontal distance or 1,1 m increase over 3,85 m.

Loading platform floors can become very slippery and must therefore be made very coarse. A diamond pattern is recommended. The width of the loading platform is the same as that of a crush, which is approximately 750 mm. For the collection of cattle, a wider loading platform can be used. Figure 1 shows the construction of a loading platform. Figure 2 shows the offloading platform.

Cattle are normally afraid of heights and a loading platform with a solid floor and solid sides gives the best results. Loading platforms must however be provided with swing gates which can swing open into the truck. This will prevent cattle from jumping off between the truck and the loading platform. Telescopic sides which can be extracted into the truck are also suitable, but if they are bent by the cattle, they can impair the operation.

It is preferable that the top of the loading platform should be horizontal for approximately 1,5 m. A curved loading platform with an inner radius of 4,5 m gives better flow results than a straight loading platform. The loading platform must also have a catwalk on the sides on which the handlers can move to help with the loading process.

Additional equipment Tilting table

This apparatus basically consists of three parts, namely the neck clamp, tilting crate and tilting mechanism. The neck clamp opens the entire width of the crate and has a head piece on which the animal’s head rests after it has been tilted. The tilting crate has two straps that pull the animal tight and gates that swing open. The floor plate also swings open to make the animal more accessible. The tilting mechanism consists of the differential of a motorcar, fitted with pulleys and a crank handle. One person can therefore tilt the animal. The only disadvantage of tilting an animal is that as soon as the animal has regained its balance, it starts panicking. Gestating cows can injure themselves and even abort.

Benefits of the hoof lifting crate:

• The animal remains standing up- right. This means that gestating cows can be handled safely. • The apparatus is adaptable. • The apparatus can be easily moved and transported.

Figure 1: Loading platform

three parts, namely a neck clamp, crate and hoof lifting mechanism. The neck clamp is designed in such a way that it can open the entire width of the crate from the bottom to the top. The crate consists of a framework of steel pipes and angle iron with a broad band made of hessian sacking that supports the animal while being handled. The hoof lifting mechanism lifts the animal’s hoof to the back so that the hoof may be clipped. Uses of the hoof lifter are as follows: • Castration of calves • Dehorning and dosing • Branding or freeze branding

Next month we shall look at dipping facilities. Published with acknowledgement to the ARC Agricultural Engineering for the use of their Beef Cattle Handling Manual. Visit www.arc.agric.za for more information.

Figure 2: Offloading platform

NoseRing® Wean with ease | No stress | Next to the mother

NoseRing • Wean with ease • No stress • Next to the mother ®

Whole Concepts cc

PO Box 1806, Vryburg,8600, South Africa Tel: +27 (0)53 927 4999 Cell: +27 (0)82 459 9451 E-mail: judy@nosering.co.za www.nosering.co.za Tel: +27 (0)53 927 4999 Cell: +27 (0)82 459 9451 judy@nosering.co.za

www.nosering.co.za

PO Box 1806, Vryburg, 8600, South Africa

Every drop is precious

KSB has been providing pumps and valves for more than 60 years to the farming community and other industries in South Africa and Sub-Saharan Africa.

Our pumps and valves help farmers to get the water where it is needed. Whatever the agricultural application, KSB - the right partner for you

Your B·BBEE Level 1 Partner