DESIGN FOR MANUFACTURING & ASSEMBLY MMA-ARCHITECTS.COM MASSA MANUFACTURING & ASSEMBLY

02 -MASSA MANUFACTURING & ASSEMBLY-

Table of Content

03MMA-ARCHITECTS.COM -

CHALLENGES PROCESS HVAC SYSTEM

VACUUM

1 2 3 4 5 6 7 | | | | | | |

INTRODUCTION APPROACH

SANITARY WASTE SYSTEM

SYSTEM

“

E veryone is familiar with the Traditional Design-Bid-Build approach and the associated pitfalls. Everyone is also familiar with the Design-Build approach as well. Although an improvement of the latter, but still pitfalls.

Massa Manufacturing & Assembly has re-imagined the construction site. MMA has designed and implemented a system of factory fabricated components that assembles in less time, with less mess, and less disruption.”

04 -MASSA MANUFACTURING & ASSEMBLY-

05MMA-ARCHITECTS.COM -

06 -MASSA MANUFACTURING & ASSEMBLY-

O ur approach focuses primarily on design, innovation, prototyping, manufacturing, & assembling.

Utilizing the manufacturing and assembly system, we have constructed multiple health clinics (between 2200 sq ft to 7000 sq ft), with minimal disruption to retail sales or adjacent spaces.

07MMA-ARCHITECTS.COM -

08 -MASSA MANUFACTURING & ASSEMBLY-

Speed to Market

O n average, all aspects of the project, from permitting, to assembly, to inspections, occur on an accelerated schedule, as most components are engineered and constructed in a controlled factory setting, and assembled at the site.

Permit approval time is significantly reduced, as the major components of the construction are considered furniture and not subject to standard review. Onsite construction time is reduced, as MMA has engineered and developed pre-fabricated systems for every major construction

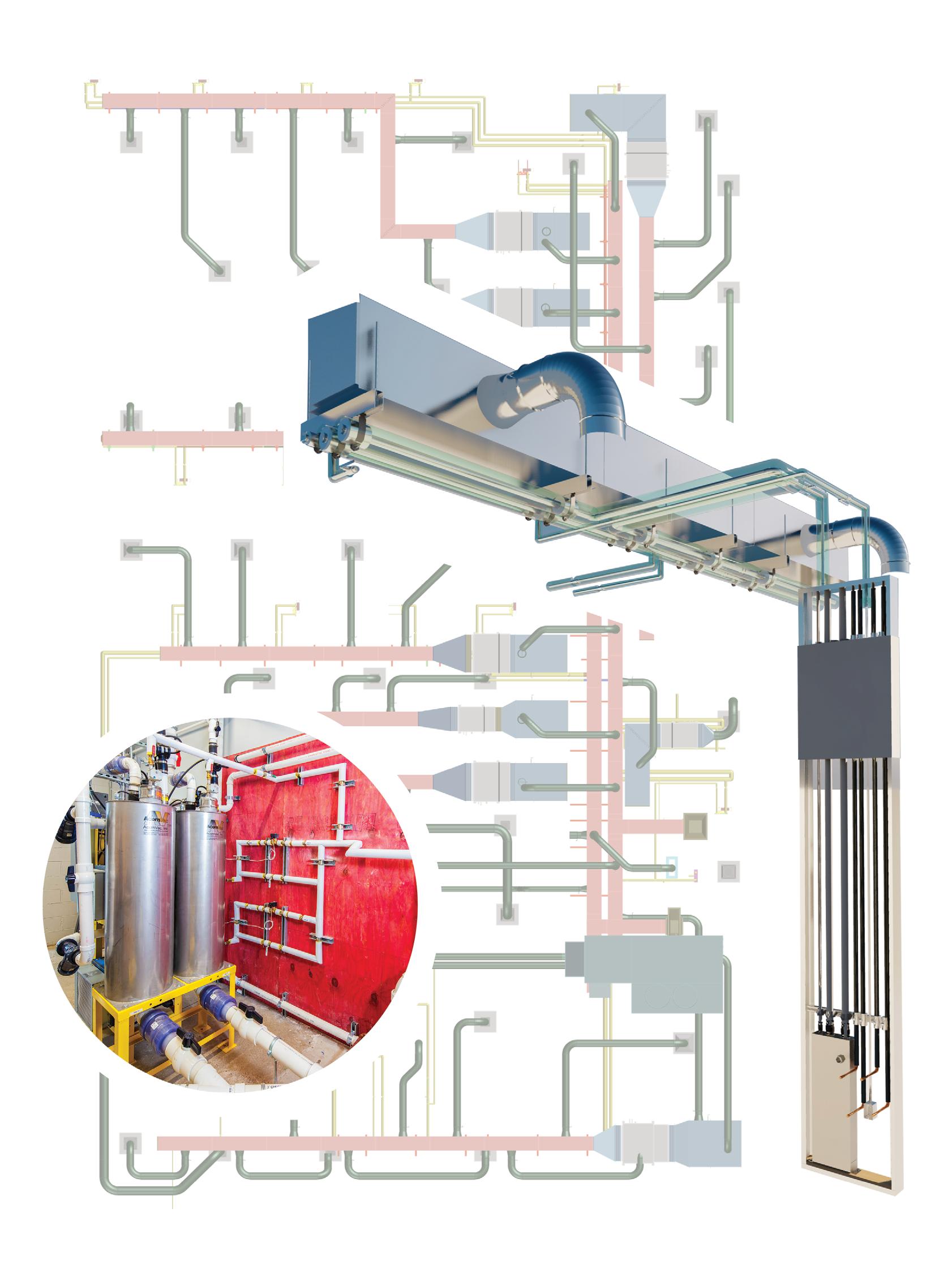

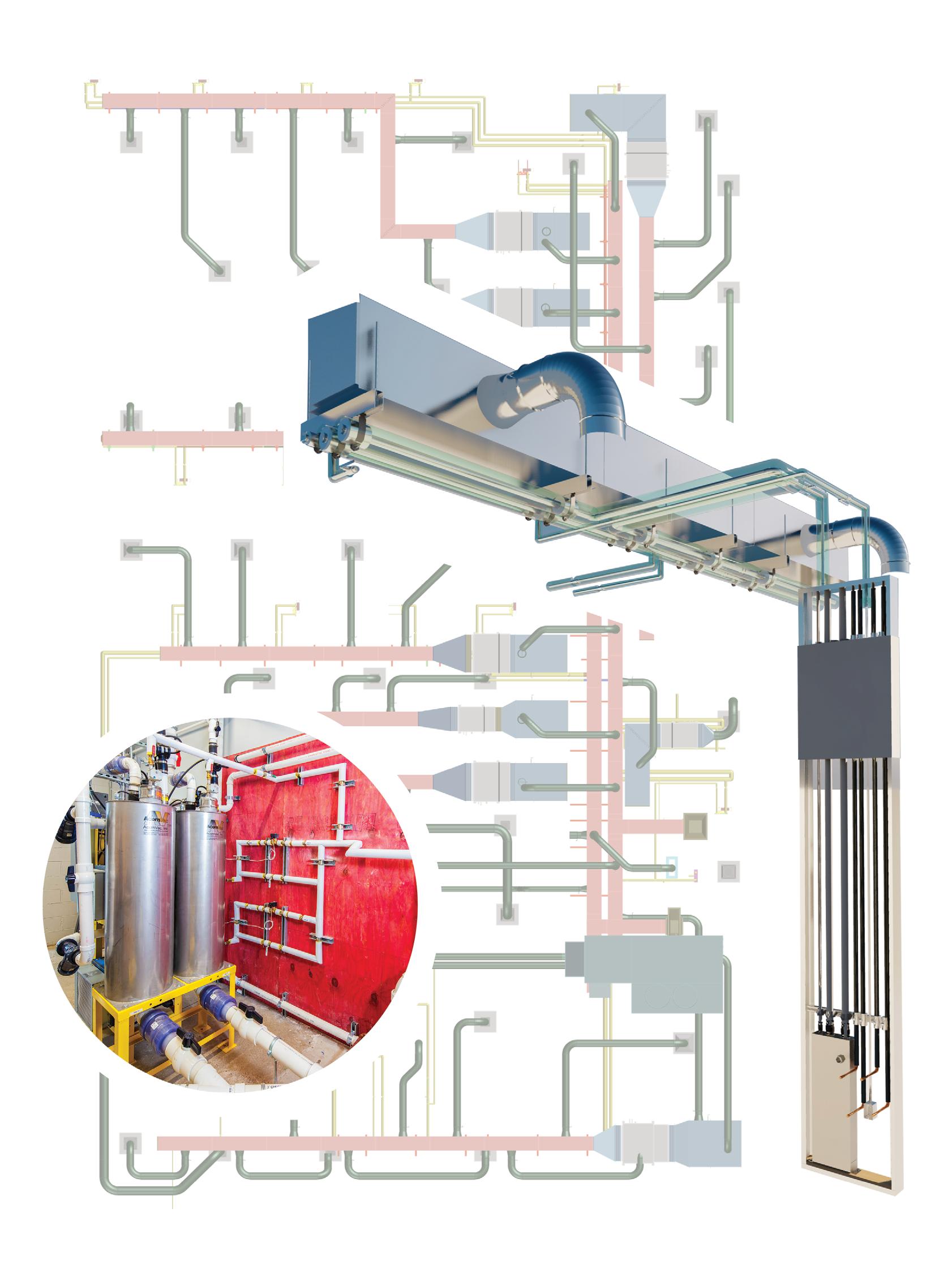

Above ceiling, the mechanical ductwork is designed and fabricated on racks that also integrate the plumbing and cable management.

These racks are up to 20 feet in length and are hoisted into place upon arrival. The plumbing system is a vacuum system, so no trenching is required (except for the single sanitary connection to the main) and all sanitary occurs above the ceiling.

As the wall system is modular and does not penetrate the ceiling, the ceiling grid is able to be installed continuously, cutting down on install time and materials. The same goes for the flooring, in that it is run continuously and the walls are placed upon the flooring. Again, this cuts down on the time of the install and limits the waste of materials due to cuts. There are much lesser trades involved resulting into reduced coordination time and better efficiency.

12 -MASSA MANUFACTURING & ASSEMBLY-

Reduced permit approval time as major components are considered furniture and not subject to standard review

13MMA-ARCHITECTS.COM -

The automobile industry has been light years ahead of the construction industry right from their onset.

14 -MASSA MANUFACTURING & ASSEMBLY-

Low Impact Quality Control

The integrated system that MMA has designed, engineered and manufactured allows for a construction build that is of higher quality, consistent between locations, and more durable, all while producing less waste.

Some of our primary focuses were on controlling quality and repetitive installation techniques by controlling means and methods. Controlling means and methods, means you are manufacturing and no longer allowing sub-contractors to interpret what they need to build.

Allowing subcontractors to control means and methods results in different project outcomes and that does not benefit the owner, especially when you are scaling. This becomes even more evident where you cannot find good labor consistently.

DfMA is the vehicle to drive the majority of the work off the physical sites and into controlled manufacturing environments and significantly reduce the labor force needed to complete the project in

The Cold shell provided to us becomes our assembly space. Our initial due dilligence with scheduling and manufacturing allows us the flexibility to operate within the grey box without impacting any adjacent spaces. Everything on the site is packaged, shipped and utilized to reduce waste helping keep the site clean and dust free something you would only experience at an assembly line. in a facility of 7500 sq.ft, only two dumpsters of waste are created when compared to dozens with the traditional age old method thereby reducing waste and helping the environment.

15MMA-ARCHITECTS.COM -

“If you have to reinvent the wheel every time you get in the car, then your journey is limited by the time it takes you to repeat the same process you did last time just to get moving. Why not use the wheel already created & spend your time enjoying the ride.”

- Unknown

16 -MASSA MANUFACTURING & ASSEMBLY-

Uniformity

H istory has proven repeatedly that for large-scale production, pre-manufacturing outweighs the advantages of stick building.

Cleanliness

I n the process MMA follows, everything is basically pre-manufactured in a plant and assembled on site.

Modularity provides limitless features, and since the modular components are produced in a controlled environment, the quality of workmanship and finish is uncompromising. This provides much needed uniformity for scalibility and reconfiguring spaces. If one can achieve the sweet spot of a component scale that can be applied across many project types, then one can improve the scalibility of that component, and also improve it’s cost effective nature. General manufacturing principles dictate that the more units of the same type you can sell, the lower the cost you can sell them to a point.

All the premanufactured assemblies are extremely light and only require lifting into place and hung with scissor lifts and screw guns, eliminating any use of heavy equipment on the floor.

As we utilize our patented vacuum system throughout the facility there is basically no trenching required other then a solitary connection. The plug and play nature of Our modular walls do not require any patching or speckling allowing the site to remain spotless throughout the course of

Our standardizied HVAC rack systems, vacuum systems, and demountable walls allows us to be modular and reconfigurable. The ease of wall mounting equipment and fixtures with magnets on the

17MMA-ARCHITECTS.COM -

“Less dust and debris equals less cleaning and floor repair which in turn saves on cost.”

18 -MASSA MANUFACTURING & ASSEMBLY-

Modular Rack

21MMA-ARCHITECTS.COM -

27MMA-ARCHITECTS.COM -

28 -MASSA MANUFACTURING & ASSEMBLY-

29MMA-ARCHITECTS.COM -

30 -MASSA MANUFACTURING & ASSEMBLY-

31MMA-ARCHITECTS.COM -

32 -MASSA MANUFACTURING & ASSEMBLY-

35MMA-ARCHITECTS.COM -

36 -MASSA MANUFACTURING & ASSEMBLY-

38 -MASSA MANUFACTURING & ASSEMBLY-

39MMA-ARCHITECTS.COM -

40 -MASSA MANUFACTURING & ASSEMBLY-

41MMA-ARCHITECTS.COM -

42 -MASSA MANUFACTURING & ASSEMBLY-

44 -MASSA MANUFACTURING & ASSEMBLY-

45MMA-ARCHITECTS.COM -

46 -MASSA MANUFACTURING & ASSEMBLY-

48 -MASSA MANUFACTURING & ASSEMBLY-

49MMA-ARCHITECTS.COM -

50 -MASSA MANUFACTURING & ASSEMBLY-

52 -MASSA MANUFACTURING & ASSEMBLY-

53MMA-ARCHITECTS.COM -

54 -MASSA MANUFACTURING & ASSEMBLY-

57MMA-ARCHITECTS.COM -

60 -MASSA MANUFACTURING & ASSEMBLY-

61MMA-ARCHITECTS.COM -

62 -MASSA MANUFACTURING & ASSEMBLY-

63MMA-ARCHITECTS.COM -

64 -MASSA MANUFACTURING & ASSEMBLYSTUDIO B, 3297 ROUTE 66 NEPTUNE, NJ 07753 DIRECTOR OF BUSINESS DEVELOPMENT 732.898.7878 MMA-ARCHITECTS.COM INFO@MMA-ARCHITECTS. THANK YOU