OPERATION MANUAL

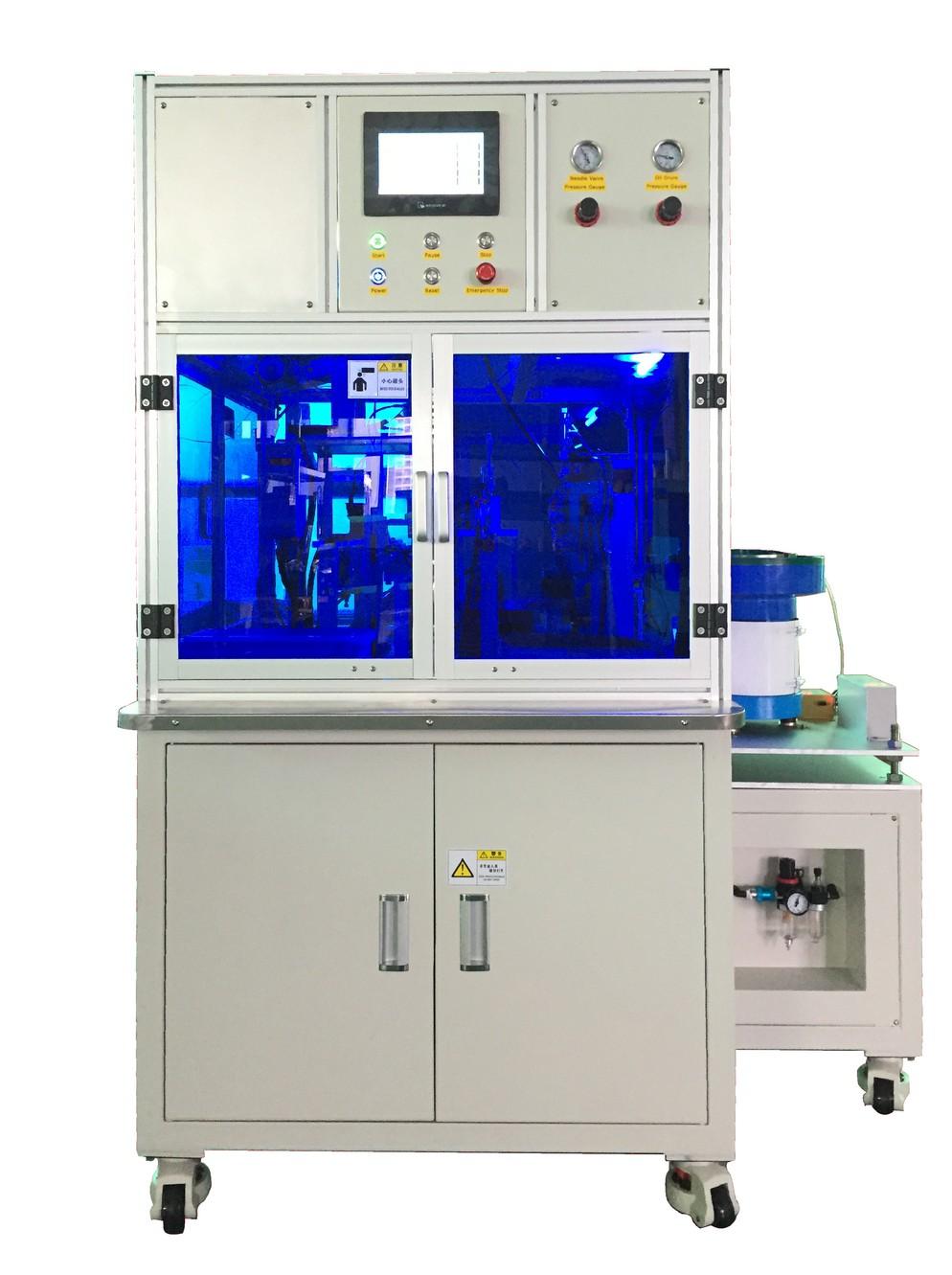

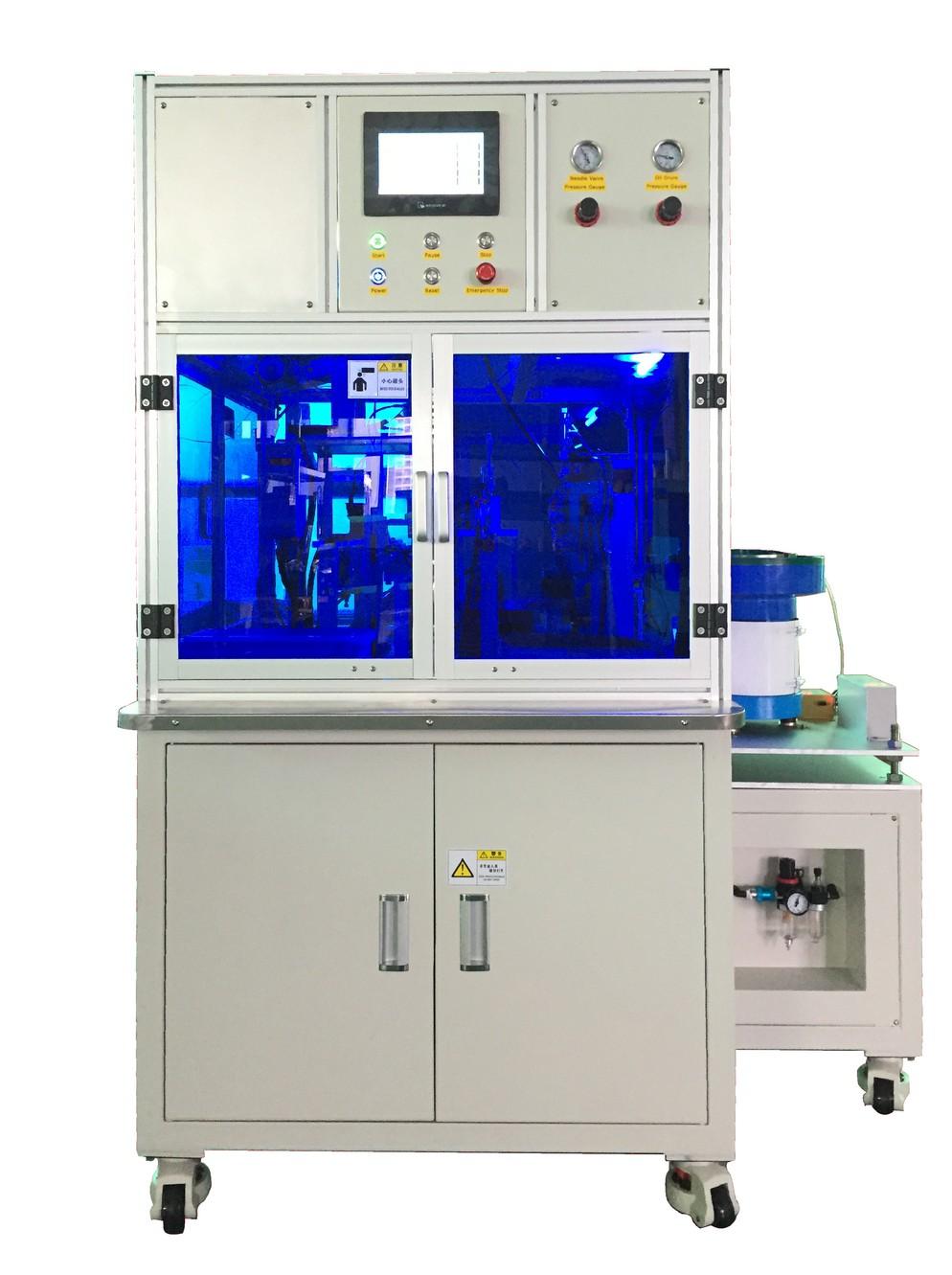

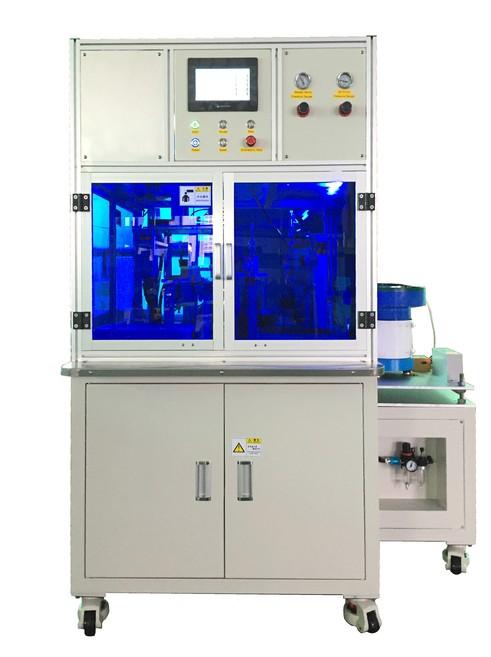

Fully-auto Oil Injection Machine

CBD & THC

Main Technical Specification :

• Quality

• Precision

• Customization

• High Yield/output, Auto Capping

• User Friendly

• Affordable

• Easy Maintenance

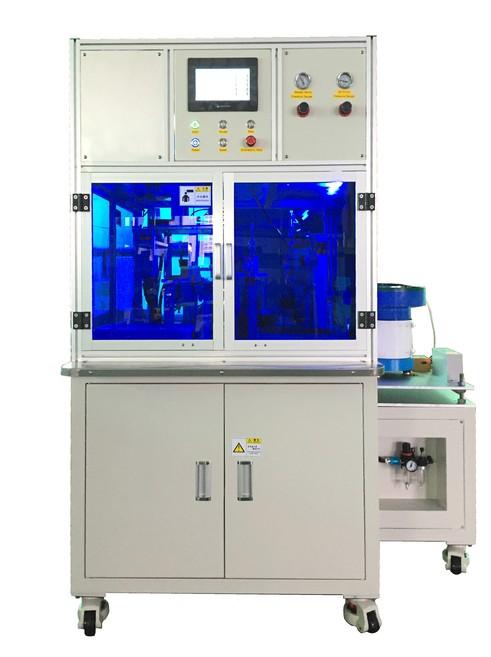

1. Size : L1050mm X W880mm X H1600mm

2. Output: 800-1000PCS/HR ( Depending on capacity of cartridge and oil )

3. Voltage: 3-phase 208V

4. Air Pressure:0.5~0.8Mpa

5. Weight : Around 350KG

Thank you for purchasing Buddy oil filling machine.

*Read this manual thoroughly in order to properly use this machine. Be sure to read “For Your Safety” before you use the machine. It will p rotect you from possible dangers during operation.

*After having read this manual, keep it in a handy place so that you or the operator can refer to it whenever necessary.

1

FOR YOUR SAFETY

Safety Precautions

The precautions stated in this manual are provided for the customer to make the best use of this prod uct safely, and to provide preventive measures against injury to the customer or damage to property.

Be sure to follow the instructions

Various symbols are used in this manual. Please read the following explanations to understand what each symbol stands for.

Symbols indicating the Degree of Damage or Danger

The following symbols indicate the degree of damage or danger which may be incurred if you neglect the safety notes.

Warnings

Cautions

These “Warnings” indicate the possibility of death or serious injury.

These “Cautions” indicate the possibility of accidental injury or dam age to property.

Symbols indicating the type of Danger and Preventive Measures

The following symbols indicate the type of safety measure that should be tak en.

Indicates the type of safety measure that should be taken.

Take care. (General caution)

Indicates prohibition.

Never do this. (general prohibition)

Do not disassemble, modify or repair.

Do not touch. (contact prohibition)

Indicates necessity

Be sure to follow instructions.

Be sure to unplug power supply from wall outlet.

Be sure to check grounding.

2

FOR YOUR SAFETY

Warnings

Be sure to check grounding.

Improper grounding can cause electric shock or fire.

Be sure to use within the voltage range indicated on the unit. Failure to do so may cause electric shock or fire.

Plug the power cord into the wall outlet firmly. Failure to do so can cause the input to heat up and may result in fire. Make sure that the power plug is clean.

Be sure to unplug the power cord from the wall outlet when you e xamine or grease the machine.

Failure to do so may cause electric shock or fire.

Stop operation and unplug immediately whenever you sense any abnormalities, such as a pungent odor. Immediately contact the d ealer from which you purchased the product.

Continued operation may result in electric shock, fire or malfunction.

Install the product in a place which can endure it’s weight and co nditions while running.

Be sure to leave a space greater than 30cm between the back of the equipment and the wall. Installation in an insufficient or unstable place can cause the equipment to fall, overturn, breakdown, or overheat.

Do not attempt to disassemble or modify the core components of the equipment.

Disassembly or modification may cause electric shocks, fire or malfunc tion, no after-sales service will be provided either.

3

FOR YOUR SAFETY

Warnings

Use the machine indoors where no flammable or corrosive gas is p resent.

Emission and accumulation of such gasses could lead to fire.

Don’t touch the oil barrel when the equipment is heating.

Failure to do so may result in thermal burns.

Be sure to unplug the power cord from the wall outlet if the equipment will remain unused for long periods of time. Gathered dust could lead to fire.

Be sure to use power in the proper voltage range. Failure to do so may result in fire or malfunction.

Keep the equipment and the power cables away from water and oil. Failure to do so may result in electric shock or fire.

Turn off the equipment before inserting and removing cables. Failure to do so may result in electric shock, fire, or malfunction of the equipment.

Keep the scram (emergency stop )switch within reach of an operat or while running the equipment.

Failure to do so may lead to danger since the equipment cannot be stop ped immediately and safely.

Regularly check that the scram (emergency stop) switch works pro perly.

Failure to do so may lead to danger since the equipment cannot be stop ped immediately and safely.

4

FOR YOUR SAFETY

Cautions

Be sure to check grounding.

Improper grounding may cause malfunction or defect.

Use the Desktop Machine in an environment between 0 to 40 degre es centigrade with a humidity of 20 to 95 percent without condens ation.

Failure to do so may result in malfunction.

Use the machine in an environment where no electric noise is pres ent.

Failure to do so may result in malfunction or defect.

Use the machine in an environment where it is not exposed to dire ct sunlight.

Failure to do so may result in malfunction or defect.

Be sure to confirm that tools such as the electric screwdriver unit, etc. are properly connected.

Failure to do so may result in injury or defect.

Check the mounting screws regularly so that they are always firml y tightened.

Loose screws may cause injury or defect.

Be sure to check the wiring to the main unit. Improper wiring may cause malfunction or defect.

Be sure to secure the movable parts of the equipment before trans portation.

Failure to do so may result in defect or injury.

Do not bump or jar the machine while it is being transported or ins talled.

This can cause defects.

5

CONTENTS 1. Operation Guideline and Preparations 1.1 Work Flow-----------------------------------------------------8 1.2 Machine Placement-------------------------------------------8 1.3 Power and Air Supply-----------------------------------------8 1.4 Manual Switch/ Digital Controller/Fiber Amplifier -----------9-11 1.5 Installing and Testing-----------------------------------------12-15 2. Operation Instruction 2.1 Reset-----------------------------------------------------------16 2.2 Auto Run------------------------------------------------------16 2.3 Start Oiling----------------------------------------------------16 2.4 Cleaning Material ---------------------------------------------17 2.5 Cleaning System-----------------------------------------------17 2.6 Adjustment location for funnel conveyer----------------------18 3. Operation Interface 3.1 Startup picture-------------------------------------------------19 3.2 ①Manual Interface--------------------------------------------20 3.3 ②Manual Interface--------------------------------------------21 3.4 ③Manual Interface--------------------------------------------22 3.5 Oiling Interface------------------------------------------------23 3.6 Temperature Interface-----------------------------------------24 3.7 ④Manual Interface--------------------------------------------25 3.8 ⑤Manual Interface--------------------------------------------26 3.9 ⑥Manual Interface--------------------------------------------27 3.10 Automatic Control--------------------------------------------28 3.11 Parameter Setting-------------------------------------------- -29 3.12 Alarm Screen--------------------------------------------------30 4. Troubleshooting------------------------------------------------31-32 5. Accessories and Spare Parts-----------------------------------33 6. Care and Maintenance-----------------------------------------34 6

1. Operation Guideline and Preparations

1.1 Work Flow

Unpack and Inspection

Machine Working Zone

Power and Air Supply

Installing and Testing

Auto Run and Start Oiling

System Cleaning

7

1.3.2 Power 3-phase 208V

Air Regulator

1.3 Power and Air Supply

1.3.1 Connect Power cord and Air Pipe

1.3 Power and Air Supply

1.3.1 Connect Power cord and Air Pipe

,

Air

Pressure 0.5-0.8Mpa. Air Valve(blue parts), to the left is to Close, to the right is to Open.

Power Air Intake

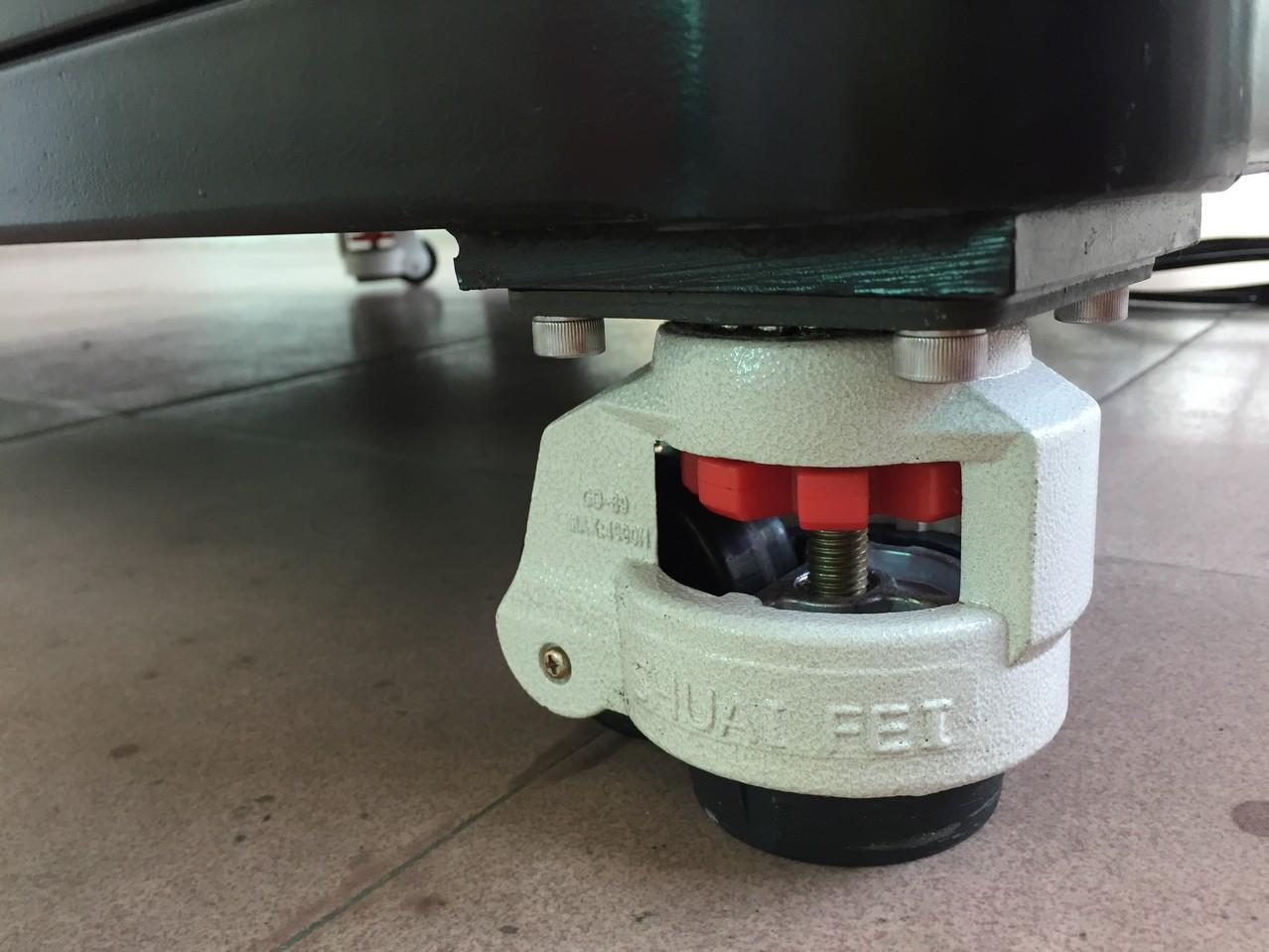

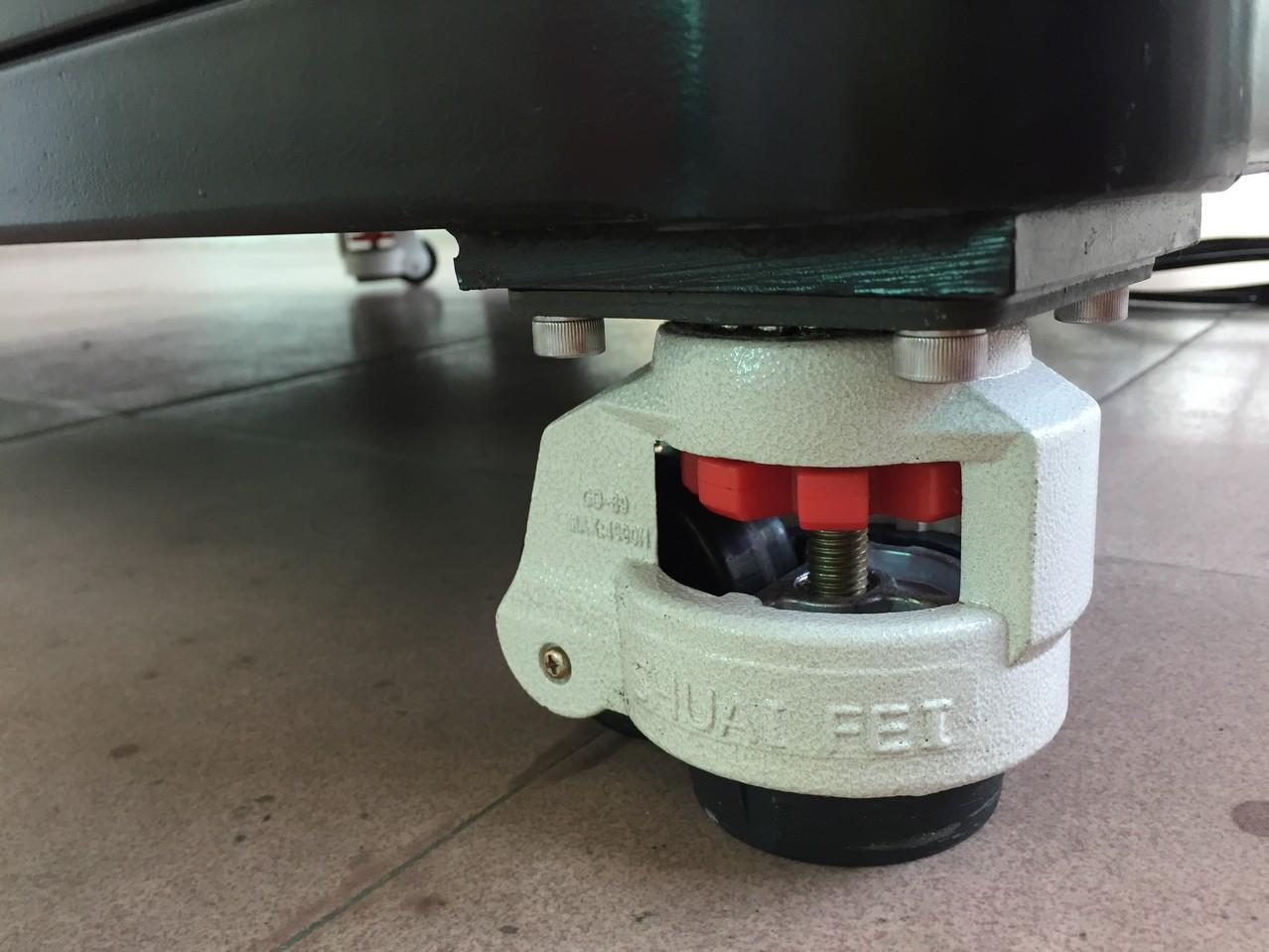

1.2 Machine Placement

Turning red nob upwards to lock machine from movement, Turning downwards to unlock machine for relocation.

Air Valve

8

Pressure Gauge

Adjusting Valve.

Suggested Air Pressure:

Needle Valve: 0.4MPa, Oil Drum: 0.3MPa.

1.4 Manual Switch

1.4.2 Needle Valve Pressure Gauge, Oil Drum Pressure Gauge, independent

1.4 Manual Switch

1.4.2 Needle Valve Pressure Gauge, Oil Drum Pressure Gauge, independent

9

Adjusting Valve Adjusting Valve

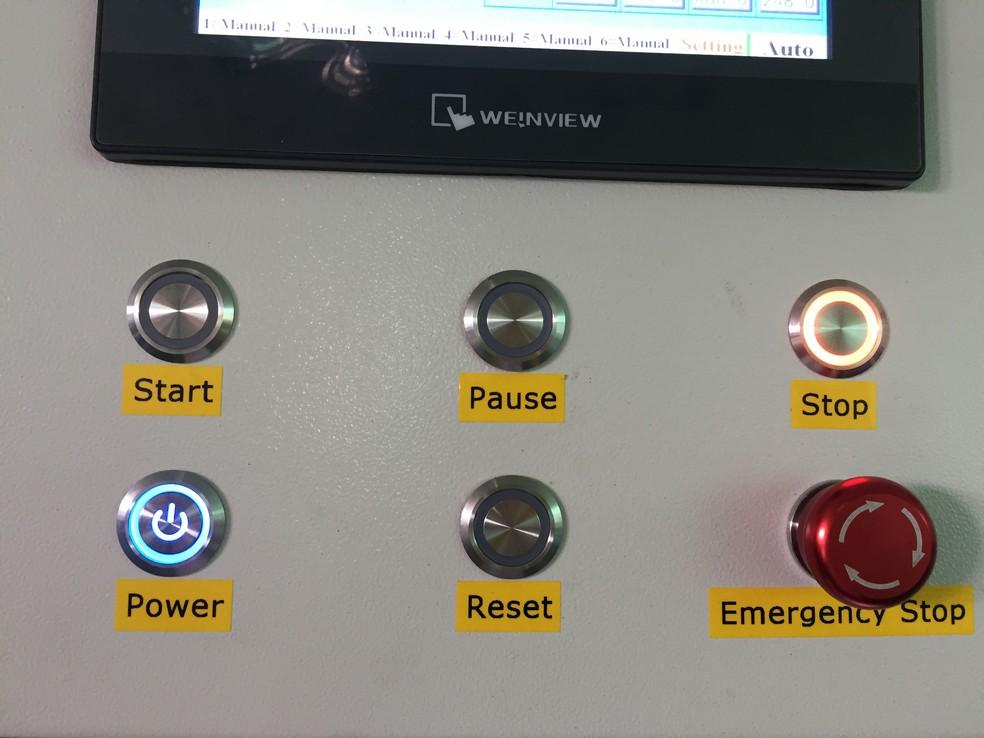

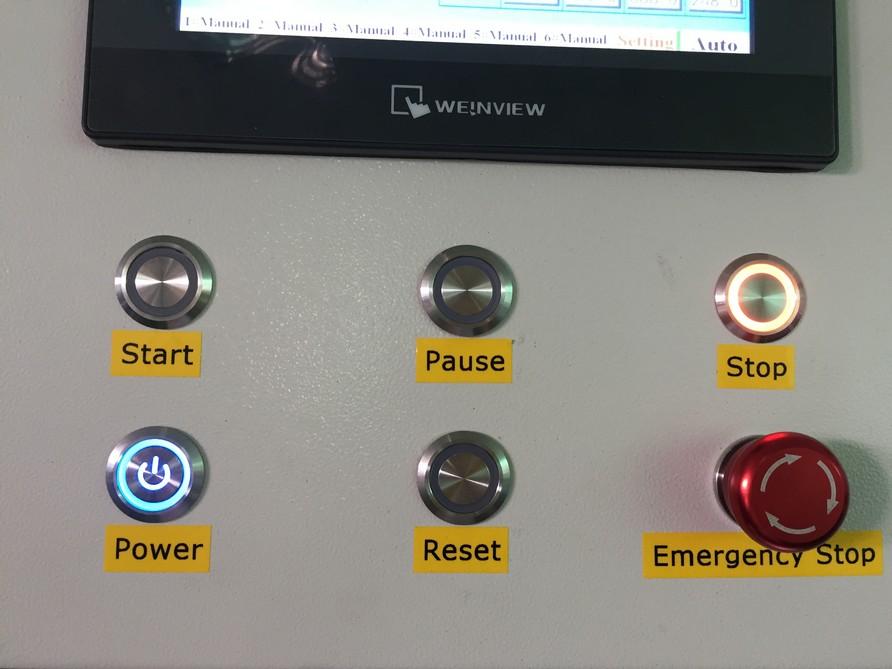

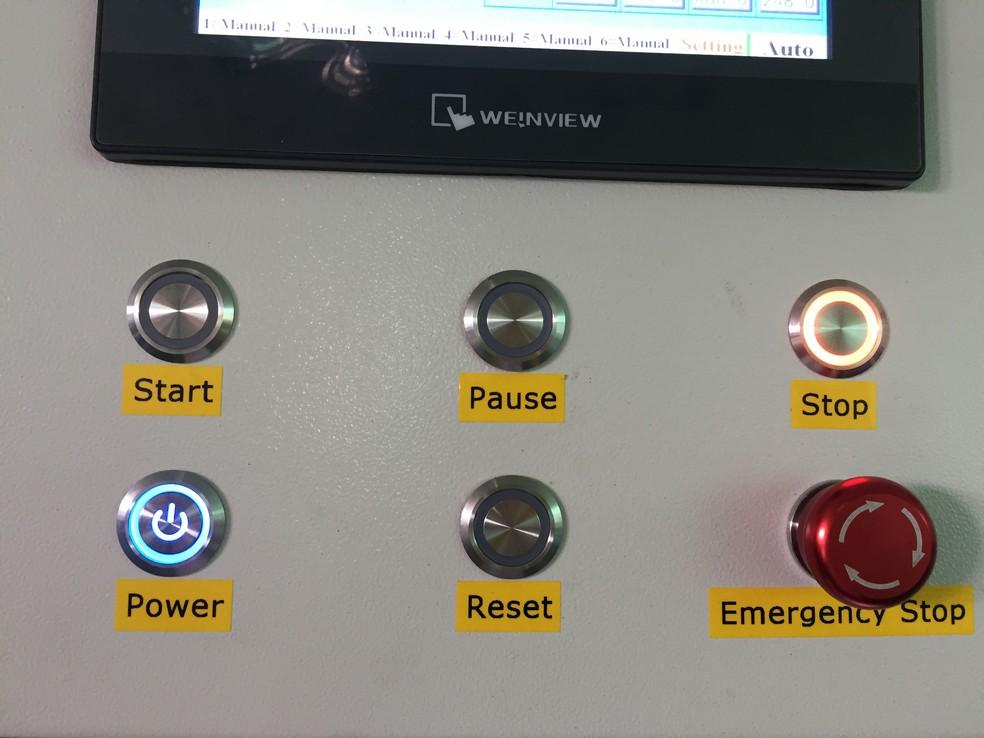

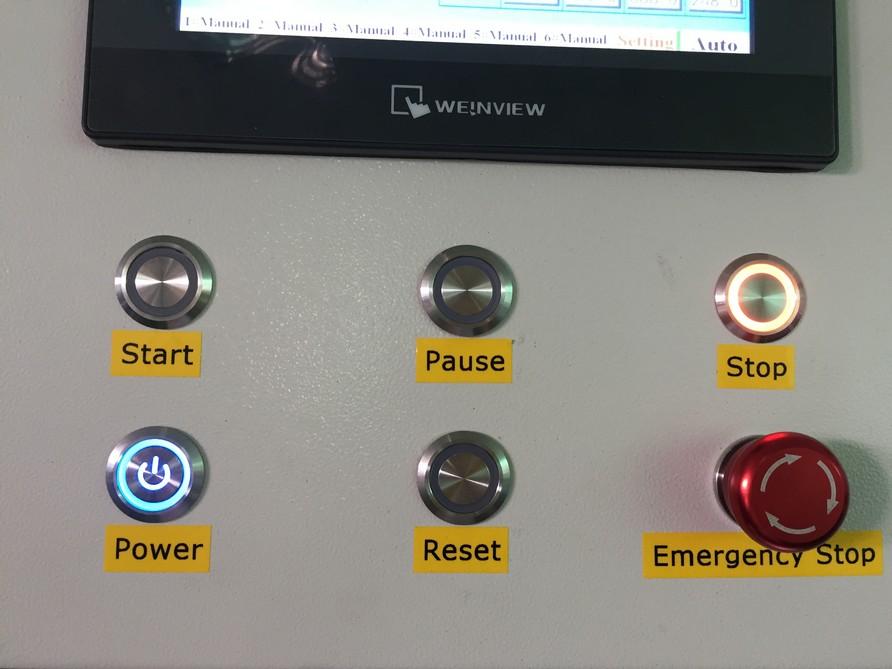

1.4.1 Start, Pause, Stop, Power, Reset, Emergency Stop.

1.4.4 Digital Controller for Vibratory Feeder, to adjust feeding speed by changing Voltage and Frequency, it will be turned on automatically when machine is in running mode. It has been pre-set by factory, normally no need further adjustment.

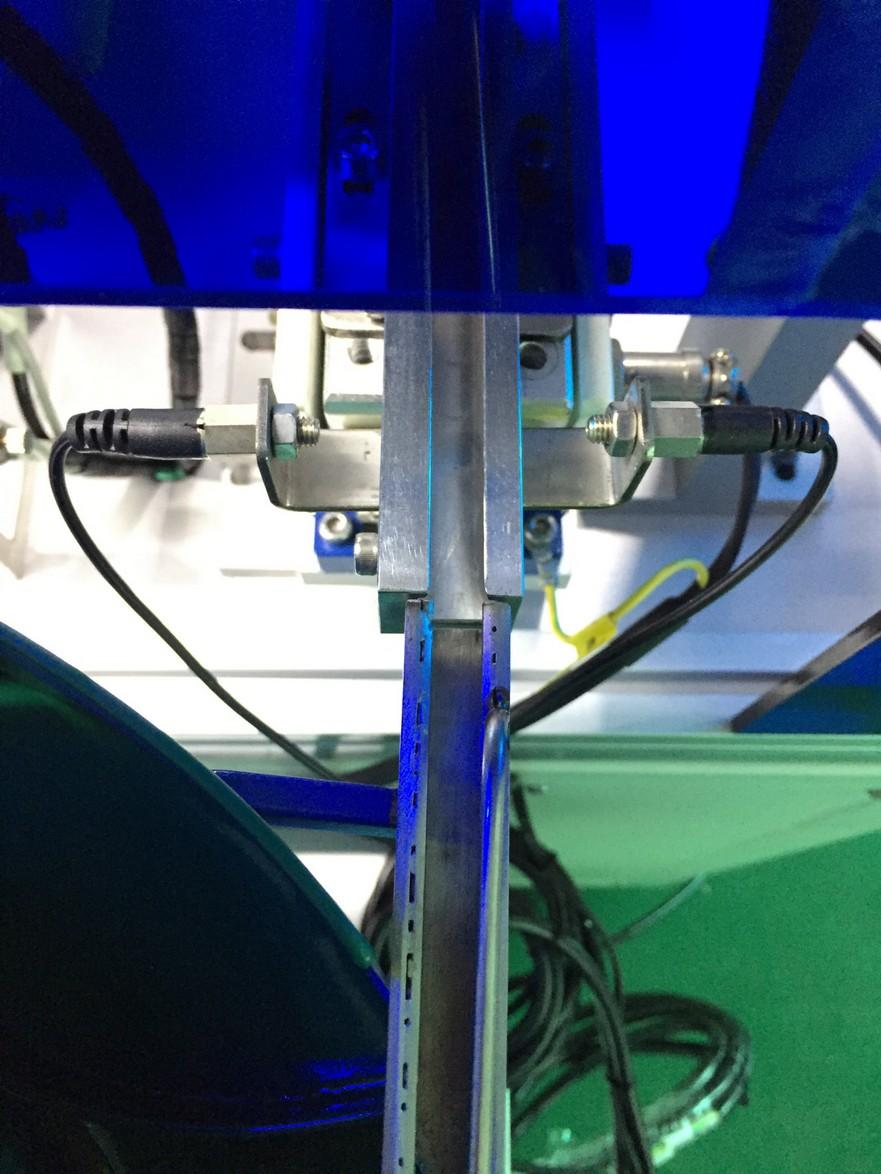

1.4.5 Fiber Amplifier

Variable Frequency Digital Controller

For Vibratory Feeder

Saturated Accelerate Remote Stop Lock Vol+ Vol-

Frequency ▲

On Delay FUNC

Off Delay ▼

Soft Start

ON/OFF

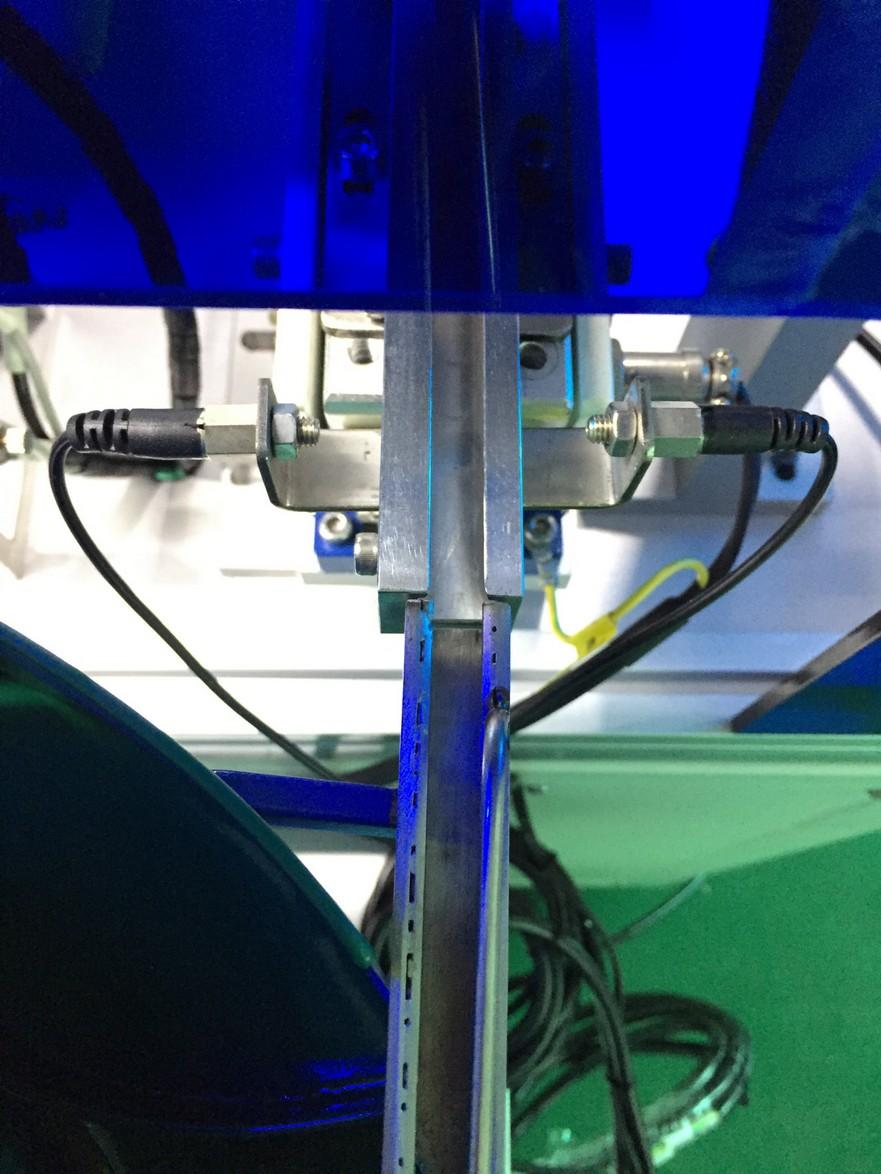

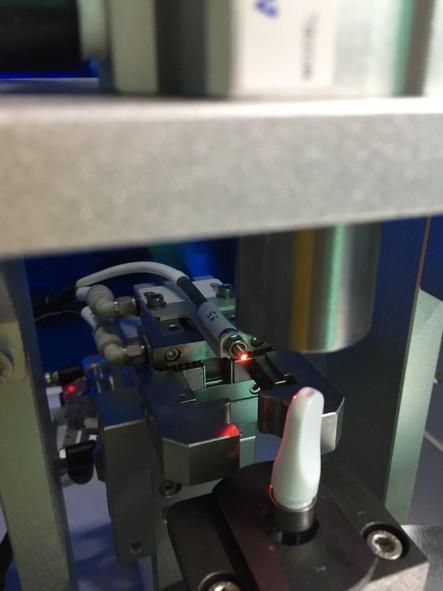

Fiber Amplifier is to detect and sensor whether material is in position. B is preset from factory, C is current, when Current is bigger than pre-set, D indicates red , material in right location ; No indication, material not in place.

● ● ● ● ●

A B C D 10

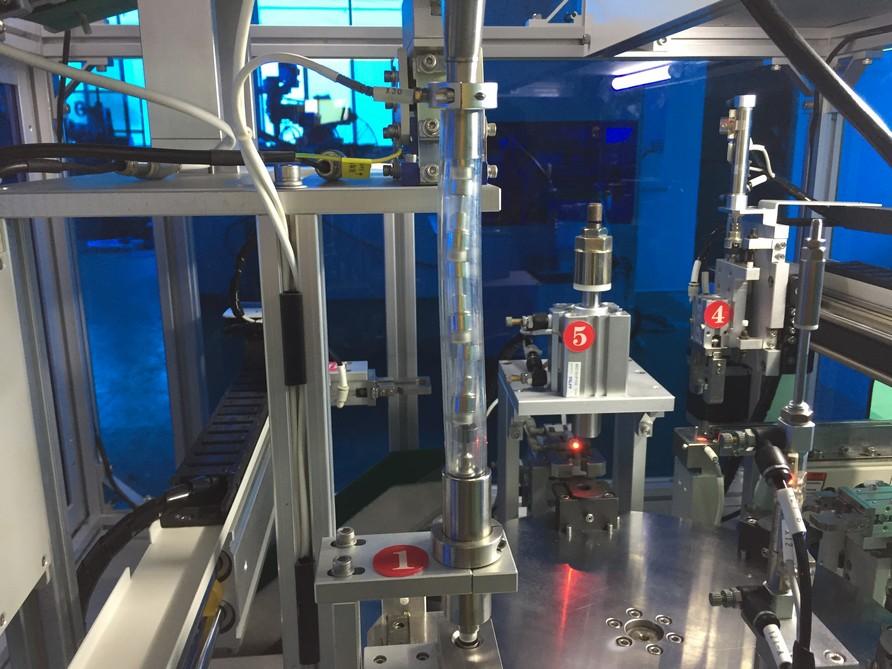

For the detailed location and function of sensors see as below.

A-X32 to detect workstation① feeding fixture material.

A-X5 to detect workstation⑤mouth piece material.

A-X7 to detect workstation④mouth piece material.

A-X34 to detect workstation① Vibration material.

⑥ material.

11

A-X33 to detect workstation①pushing material.

A-X30 to detect workstation① feeding material.

A-31 to detect workstation

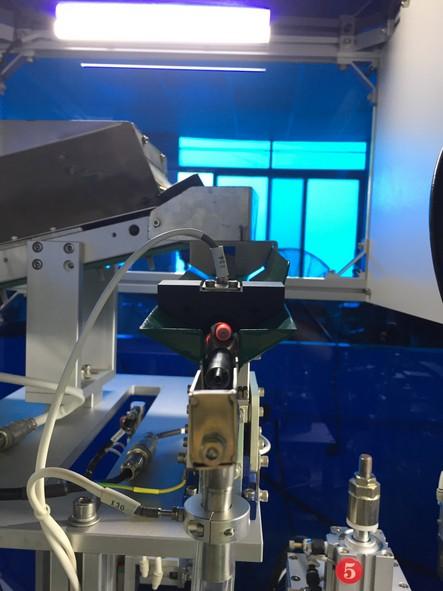

1.5 Installation and Testing

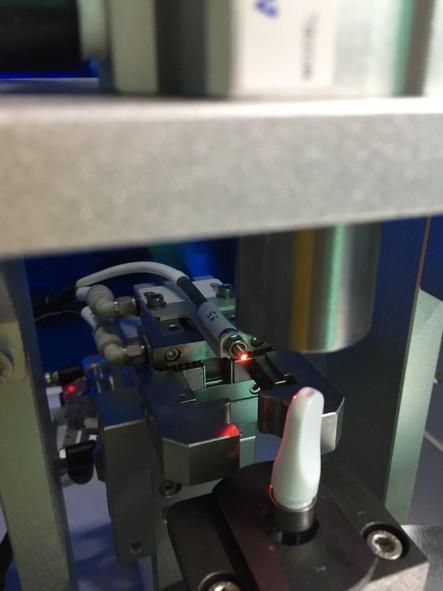

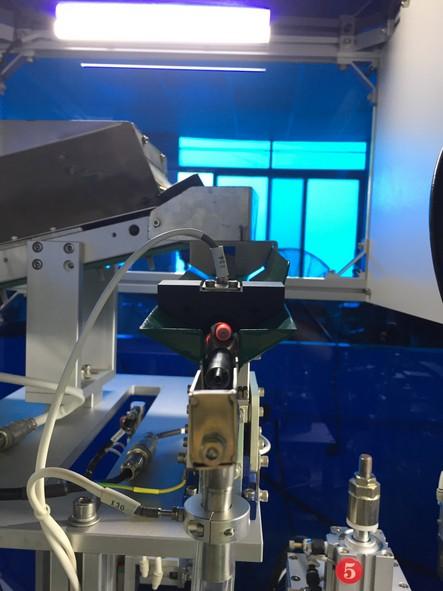

1.5.1 Install Injector

Place injector into holder, tighten screw, must be aligned with bottom location fixture.

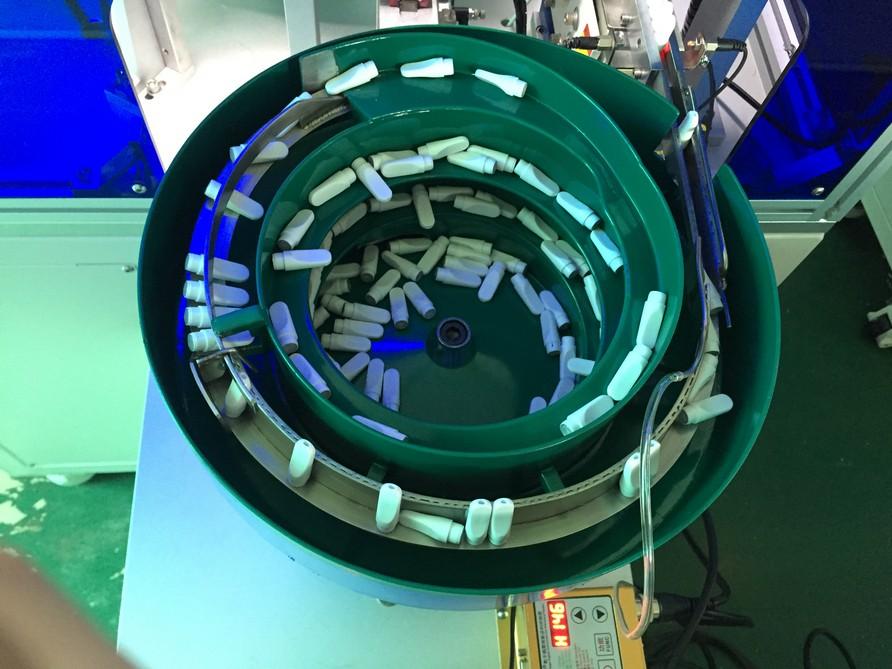

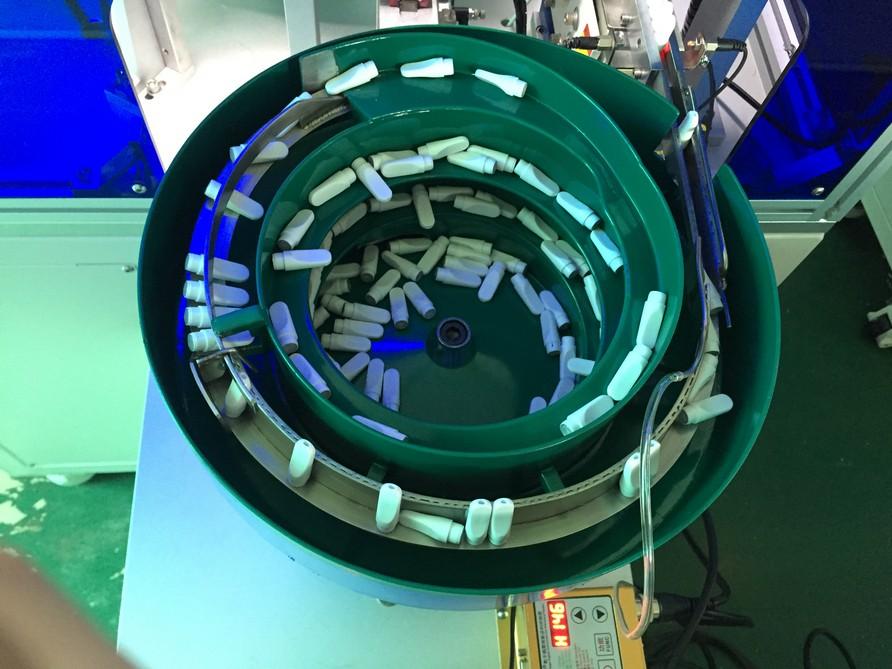

1.5.2 Install vibration

Load mouth piece into the middle of vibration plate. When install vibration plate, please align at joi nt to make sure the mouth piece can go smoothly from vibration plate to workstation.

Keep clean of vibration plate: Wipe dust and other stains on the surface of vibration plate by alcohol and cloth, at regular intervals .

1.5.3 Cartridges Oil container

Load Containers into feeding funnel gently!

plate and load mouth piece

plate and load mouth piece

12

1.5.4 Filling Oil Drum :

Open Drum container , unscrew ① to take Oil drum out for filling. Shut off Air Valve② ,no air should be in at this point, open Pressure Relief Valve④ , pour Oil in at certain amount, capacity 0.3~0.9L , no more than 0.9L !!! Then shut off Pressure Relief Valve④ , turn on Air Valve ② 。 Make sure to follow the above sequence of operation!

Air Valve ② downwards is to open, allow air flow, maintain air pressure in Oil drum. During Oil filling, no air pressure in drum, close Air Valve and open Relief Valve. Note: Fill pre-heated oil to drum if the oil is too thick.

Don’t touch Oil Drum during heating.

1.5.5 Power and Air Supply On.

System will alert for low Oil level, then follow above procedure to fill oil drum.

1.5.6 Check Emergency Stop switch on ( Clockwise )

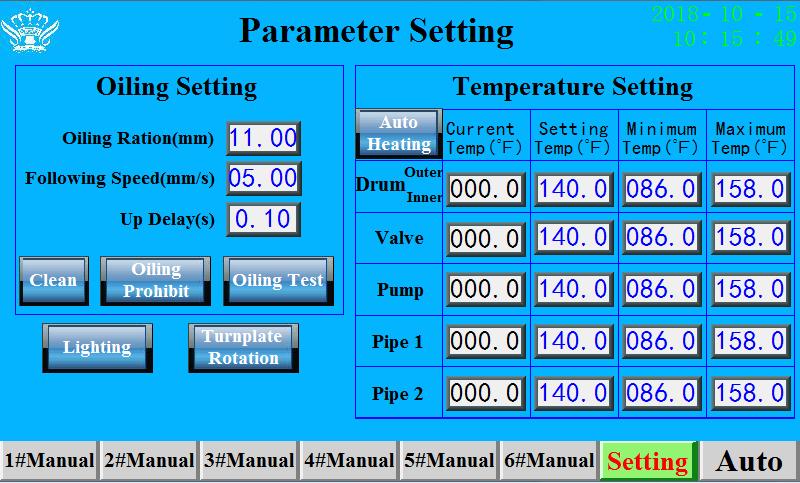

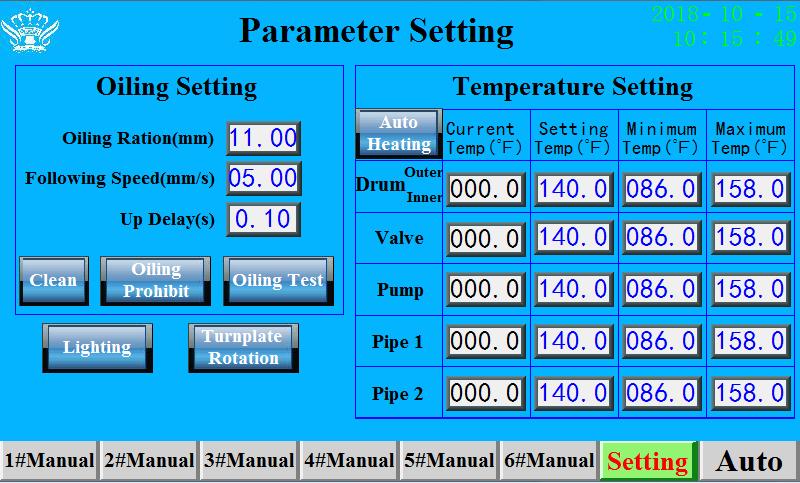

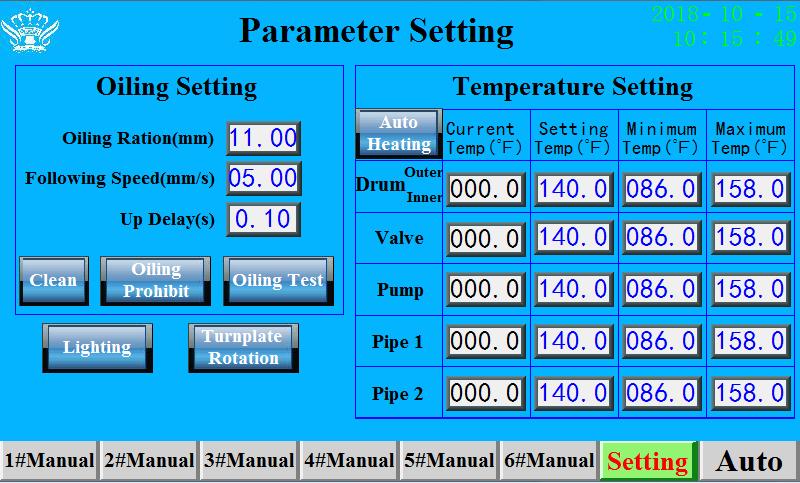

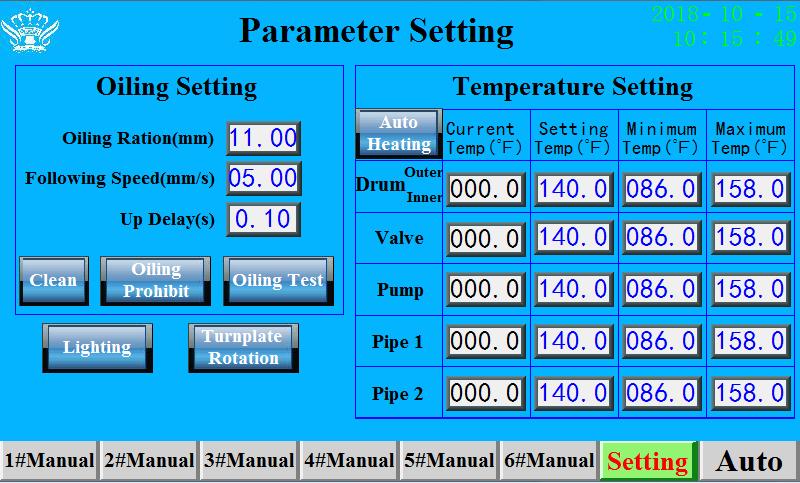

1.5.7 Click “Setting“enter into ”Parameter Setting“, Click “Auto Heating”. Oil pipe, Oil Pump ,Oil valve and Oil Drum will be heated automatically. Thicker the Oil, Higher the temperature. It may vary depending on the viscosity of oil. After heating for a while, check current temp for Oil pipe, Oil Pump ,Oil valve and Oil Drum, machine could reset and start working only when these temp. achieve Minimum Temp. (How to enter to Setting Interface please refer to Chapter 3.)

1.5.8 Reset

Before resetting the machine, make sure no cartridges in any workstations, and all the temp. achieve Minimum Temp. Press the Reset button for 3 seconds and release, the indicator light flickers, once the indicator light stay in yellow light means reset completed.

③ ①

②

13

④

1.5.9 Purge excess air from tubes before fill Run. Very Important: After reset the machine for the first time, don’t start oiling before eliminate air trip through Oiling system.(Place a small cup or plastic bag under the oil injector to collect the oil)

1.5.9.1 Close Air Valve, open Air relief Valve in the oil drum.

1.5.9.2 Select “Parameter Setting“, click ”Clean“.

1.5.9.3 Press and Hold “Clean“ for 3 seconds , check Injector for air trap until consistent oil flow, press Clean again to stop.

“Clean“ Button also used for System Cleaning Workflow

14

Power On Setting Parameter Setting 1.Empty Oil Drum 2.Parameter Setting 3.Replace Injector with silicon pipe 4.Temperature setup OK Clean

1.5.10 Setting Oil Ration and Oiling Test

After purging air, Reset the machine again. Press “Setting”, enter “Parameter Setting” .

1.5.10.1 Oiling Ration

“Oiling Ration” , to adjust oil volume per each injection, the greater number is, the more oil volume. Max.14mm!!! 1mm=0.08ml Oil, it may vary based on oil viscosity. Once Oiling Ration set, place a cartridge into fixture of workstation② , press Turnplate Rotation, the fixture will rotate to workstation③, press “Oiling Test” , Injection starts at workstation③ , press Turnplate Rotation again, take the cartridge out from workstation④ , please verify Oil Volume until getting the required volume.

1.5.10.2 Oiling Speed (How to enter into Oiling interface, Details to refer chapter 3) In Oiling Interface, both Oiling Ration ① and filling speed can be adjusted.”Guide Motor“Auto Speed②and “Oiling Motor”Auto Speed③, higher the number, faster the filling. Don’t suggest to change factory setting unless it is necessary.

15 ① ② ③

2. Operation Instruction

2.1 Reset the machine ( Note : No materials should be in any one of 6 stations before Reset, all temperature must achieve to Minimum value) light on top of machine stays on yellow after resetting.

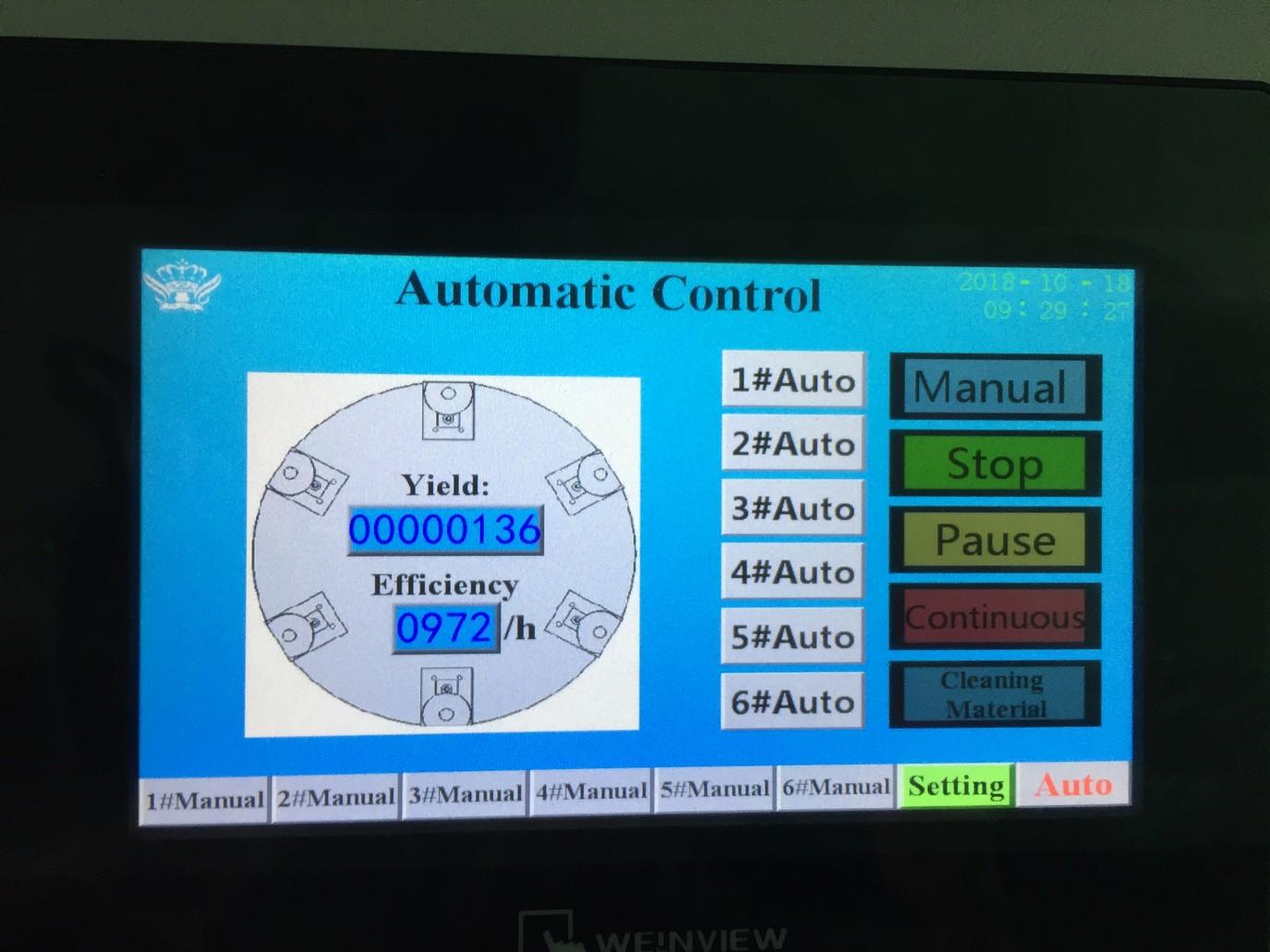

2.2 Click Auto, click Manual then indicates Auto, the machine will run in Auto Mode. The atomizers will go down from the hopper to the delivery pipe, until the feed delivery pipe in workstation① is full of atomizers, you can run filling oil.

2.3 Press Start button, machine runs oiling. The completed filled cartridges will come out from the following outlet. Please use a soft container to place these filled cartridges, in case scratched or bruised . And take out the filled cartridges every once in a while. After production, turn the Power off

16

2.4 Cleaning Material

Once working cycle completed, select Automatic Control Mode, click Cleaning Material, 6 workstations are being emptied, in order to Reset machine for next cycle.

2.5 Cleaning Oil Pipe and Oil Drum

Replace injector with silicon pipe, other end connects to disposable tank, fill oil drum with warm water at 140~158℉, close air relief valve, open sliding valve for cleaning cycle. When cleaning completed, no more flowing water from silicon pipe, close sliding valve, open air relief valve, fill with water continue cleaning until cleaned, put back injector for next operation.

17

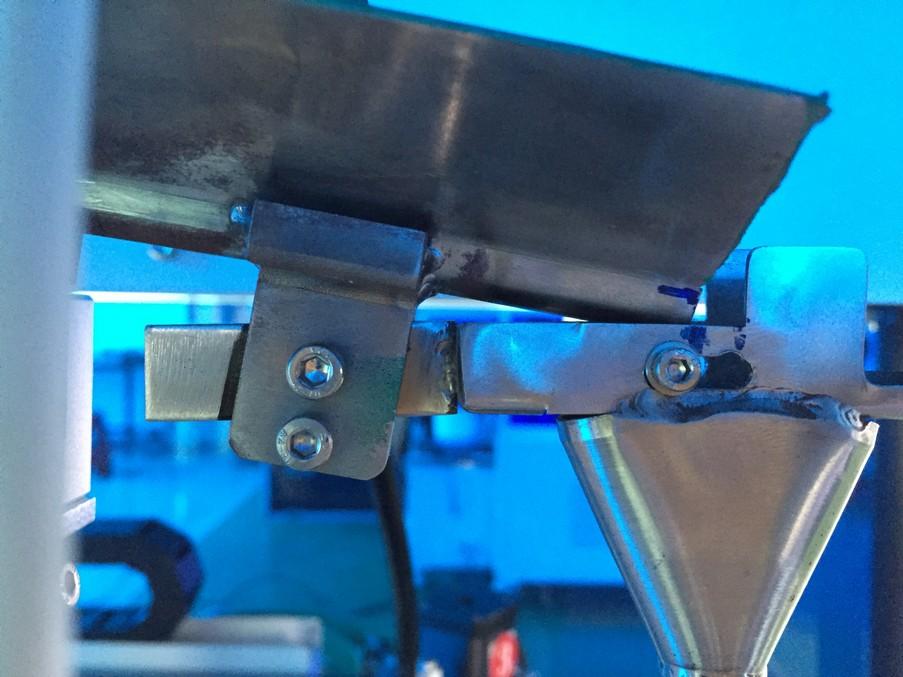

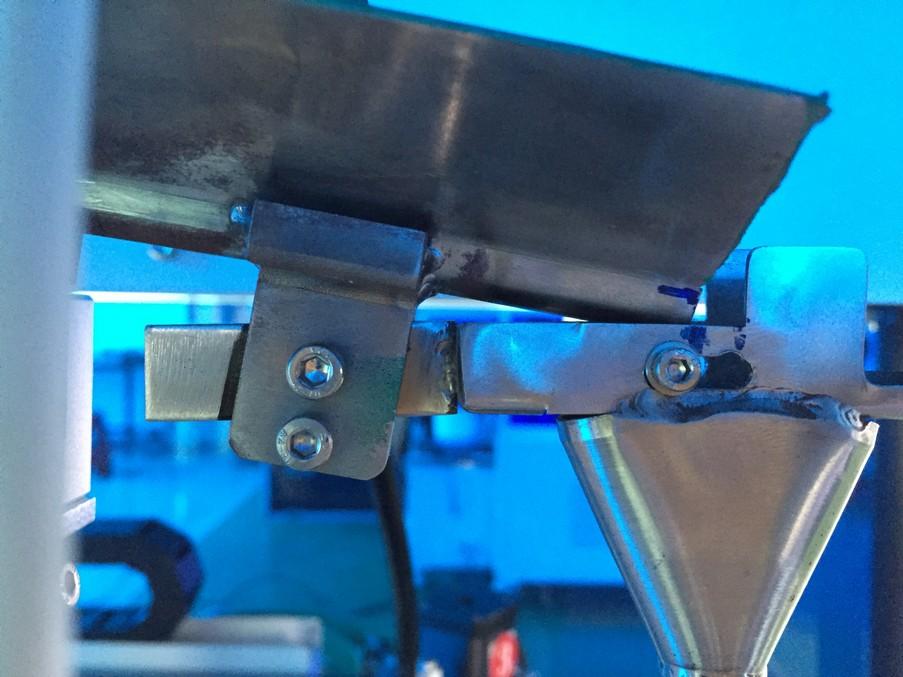

2.6 Adjustment location for funnel conveyer

For 1.0ml and 0.5ml cartridges, location for funnel conveyer is a little different. A operation video will be provided to show how to install.

18

For 0.5ml cartridges

For 1.0ml cartridges

3.Operation Interface

3.1 Startup picture

Turn on the power switch to display startup picture.

Click screen anywhere to enter Automatic Control interface .

Click into 1#,2#,3#,4#,5#,6#Manual interface, system requires Password, factory default PW is 111111, then Enter.

Indicator light on the top

Green: normal operations

Red : abnormal conditio n

Yellow : after reset condition

19

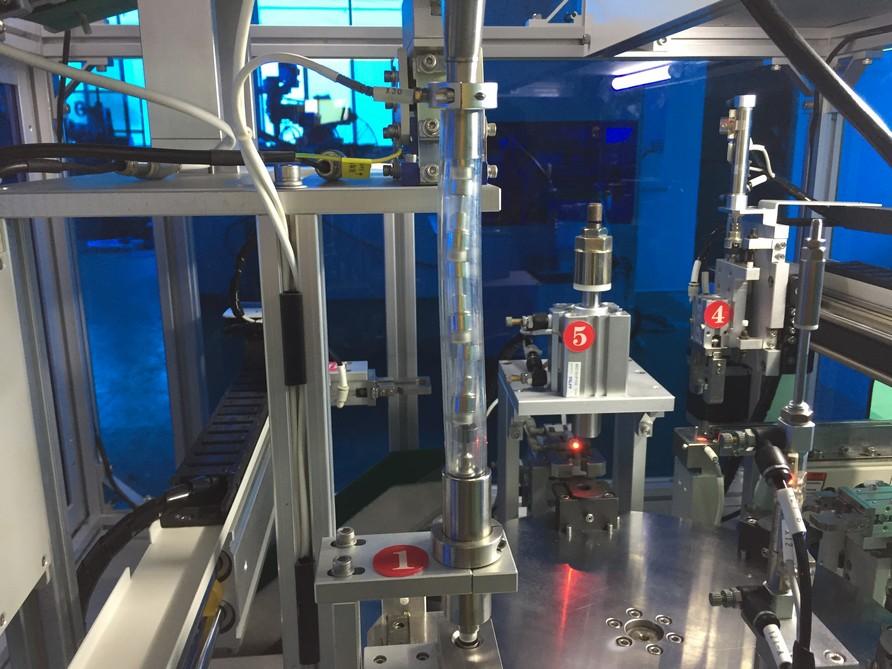

3.2 ① Manual Interface

Motor Speed

Turn

Funnel Auto

Pushing

Vibration Switch

Feeder Motor speed

Feeder Motor Rotation

Sensor automatic control for feeder motor and vibration

Pushing Cylinder Forward and backward

Vibration Switch

20

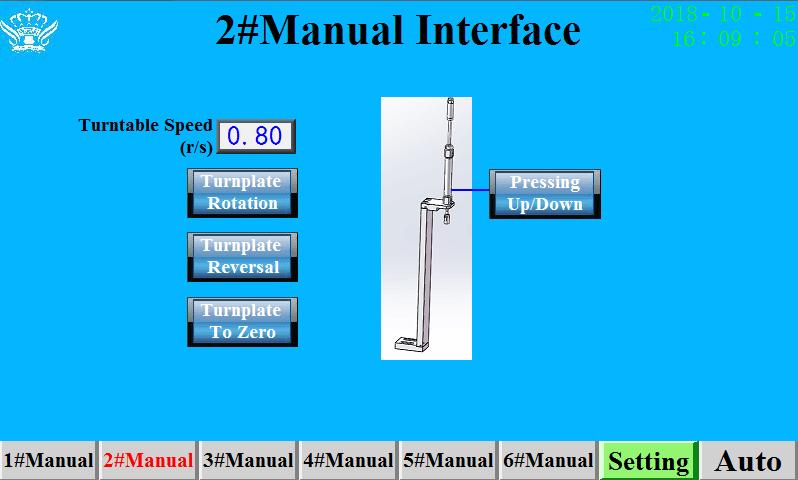

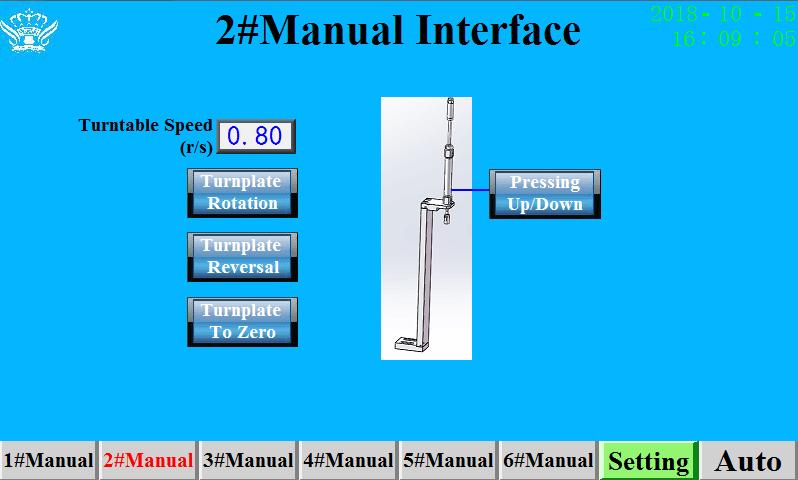

3.3 ② Manual Interface

Turntable Speed

Turnplate Rotation

Turnplate Reversal

Turnplate To Zero

Pressing Up/Down

Turntable Speed

Turn plate, counter clockwise one step

Turn plate, clockwise one step

Turn plate back to Origin

Pressing cylinder up/down

21

3.4 ③ Manual Interface

UP/Down

To Zero

Current Position

To Oiling Position

To Safe Position

Following

Oiling Valve Up/Down

Back to Origin

Current Position

Oiling Position

Injector move to the safe position waiting for next oiling

Injector move with the oil level

22

Corotation

Reversal

To Zero (Guide Motor)

To Oiling Position

To Suction Position

Forward

Backward

To Zero ( Oiling Motor )

Forward Ration

Oiling Valve

Clean

Oiling Prohibit

Guide Motor Manual speed, clockwise

Guide Motor Manual speed, counter clockwise

Guide Motor back to Origin

Guide Motor auto speed to injection position

Guide Motor auto speed to inhalation Position

Oiling Motor manual speed forward

Oiling Motor manual speed backward

Oiling Motor back to Origin

Oiling motor movement to control amount of Oil , Max.14mm

Open to inject, Close to Stop

System Cleaning or eliminate air

No injection, machine adjustment only

3.5 Oiling Interface

23

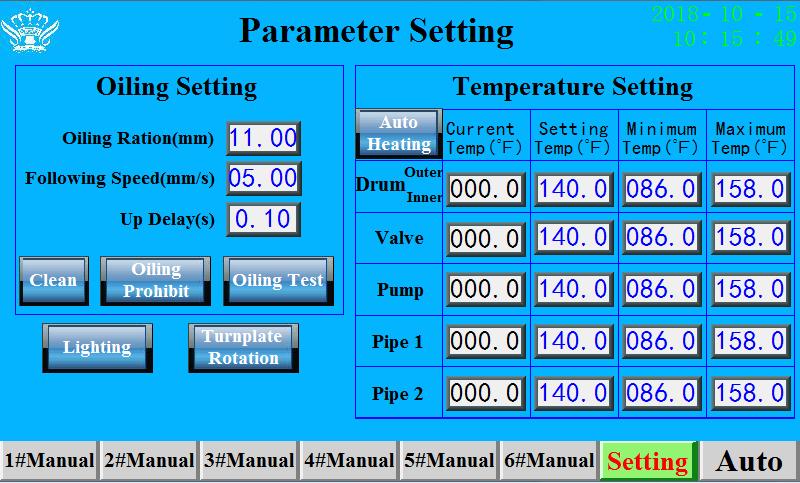

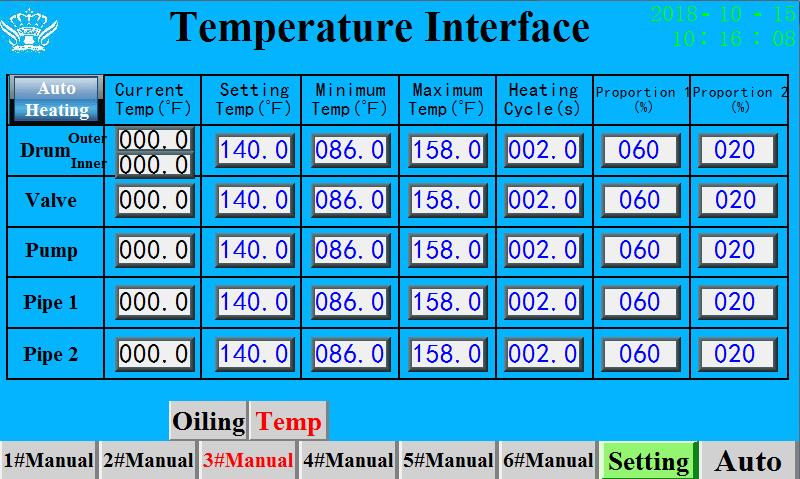

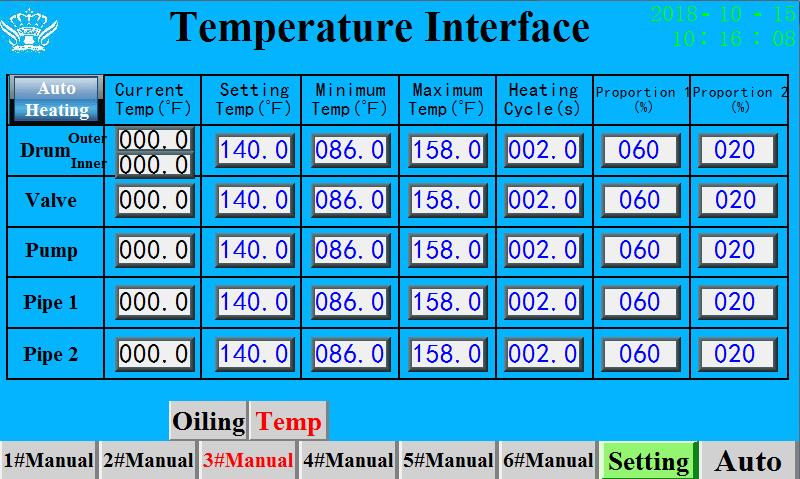

Current Temp (℉)

Setting Temp (℉)

Minimum Temp (℉)

Maximum Temp (℉)

Auto Heating

Current temp of outer drum, inner drum, oil valve, oil pump, oil pipe 1 and oil pipe 2

Setting temp of outer drum, inner drum, oil valve, oil pump, oil pipe 1 and oil pipe 2

Minimum temp of outer drum, inner drum, oil valve, oil pump, oil pipe 1 and oil pipe 2

Maximum temp of outer drum, inner drum, oil valve, oil pump, oil pipe 1 and oil pipe 2

Oil drum, oil valve, oil pump and oil pipe all heat at the same time.

3.6 Temperature Interface

24

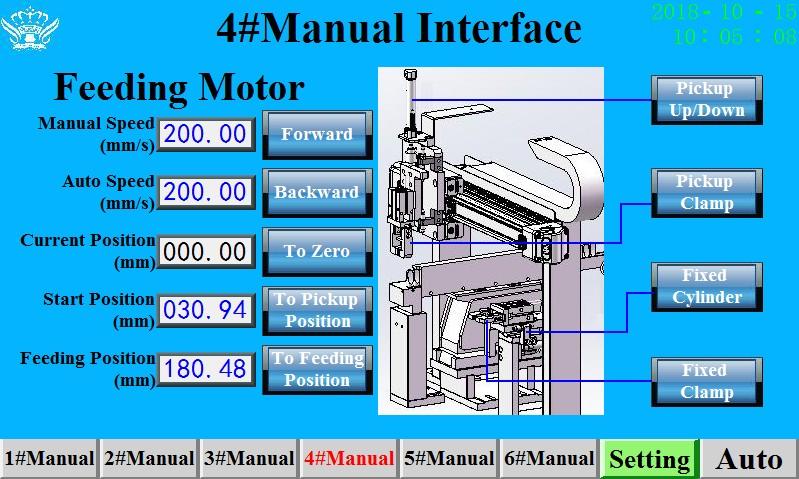

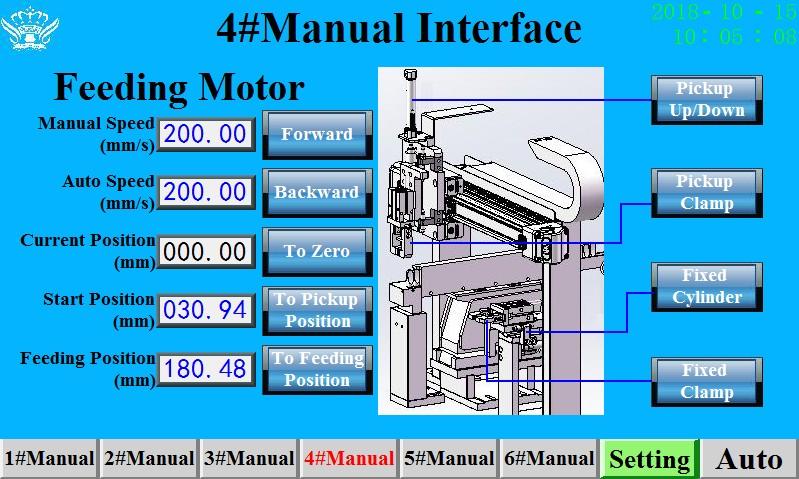

Manual Speed

Auto Speed

Current Position

Start Position

Feeding Position

Forward

Backward

To Zero

To Pickup Position

To Feeding Position

Pickup Up/Down

Pickup Clamp

Fixed Cylinder

Fixed Clamp

Feeding Motor Manual Speed

Feeding Motor Auto Speed

Feeding Motor Current Position

Feeding Motor Start Position

Feeding Motor Feeding Position

Feeding motor manual speed to “ +” direction

Feeding motor manual speed to “ -” direction

Feeding Motor back to Origin

Feeding Motor to pickup position

Feeding Motor to install position

Feeding cylinder up/down

Feeding clamp open/close

Fixed Cylinder

Fixed Clamp

3.7

Interface

④ Manual

25

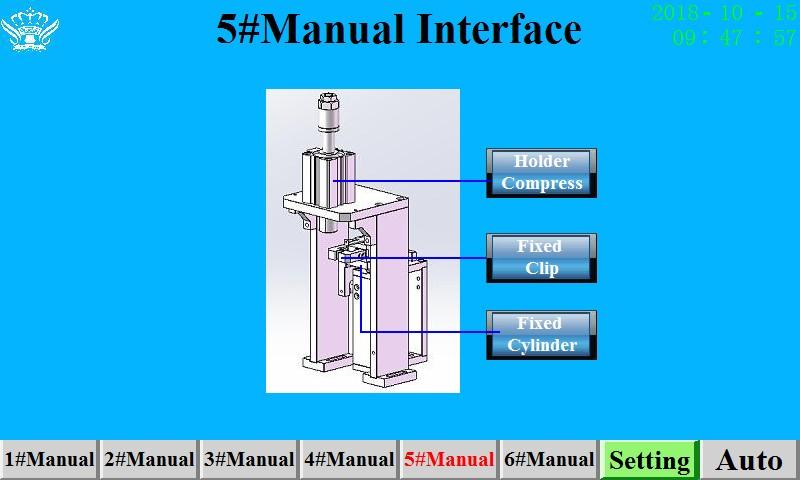

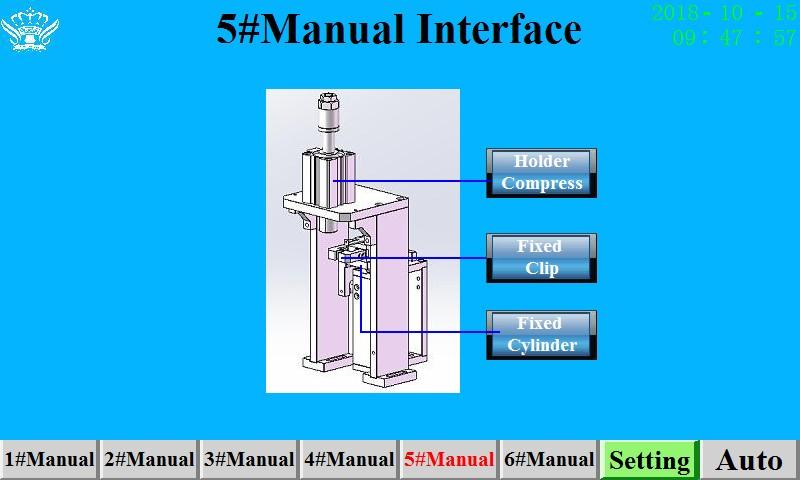

3.8 ⑤ Manual Interface

Holder Compress

Fixed Clip

Fixed Cylinder

Holder Compress Cylinder

Fixed Clip

Fixed cylinder forward/backward

26

3.9 ⑥ Manual Interface

Unloading Up/Down

Unloading Clamp

Unloading Translational

Unloading Up/Down Cylinder

Unloading Clamp

Unloading Cylinder move left/right

27

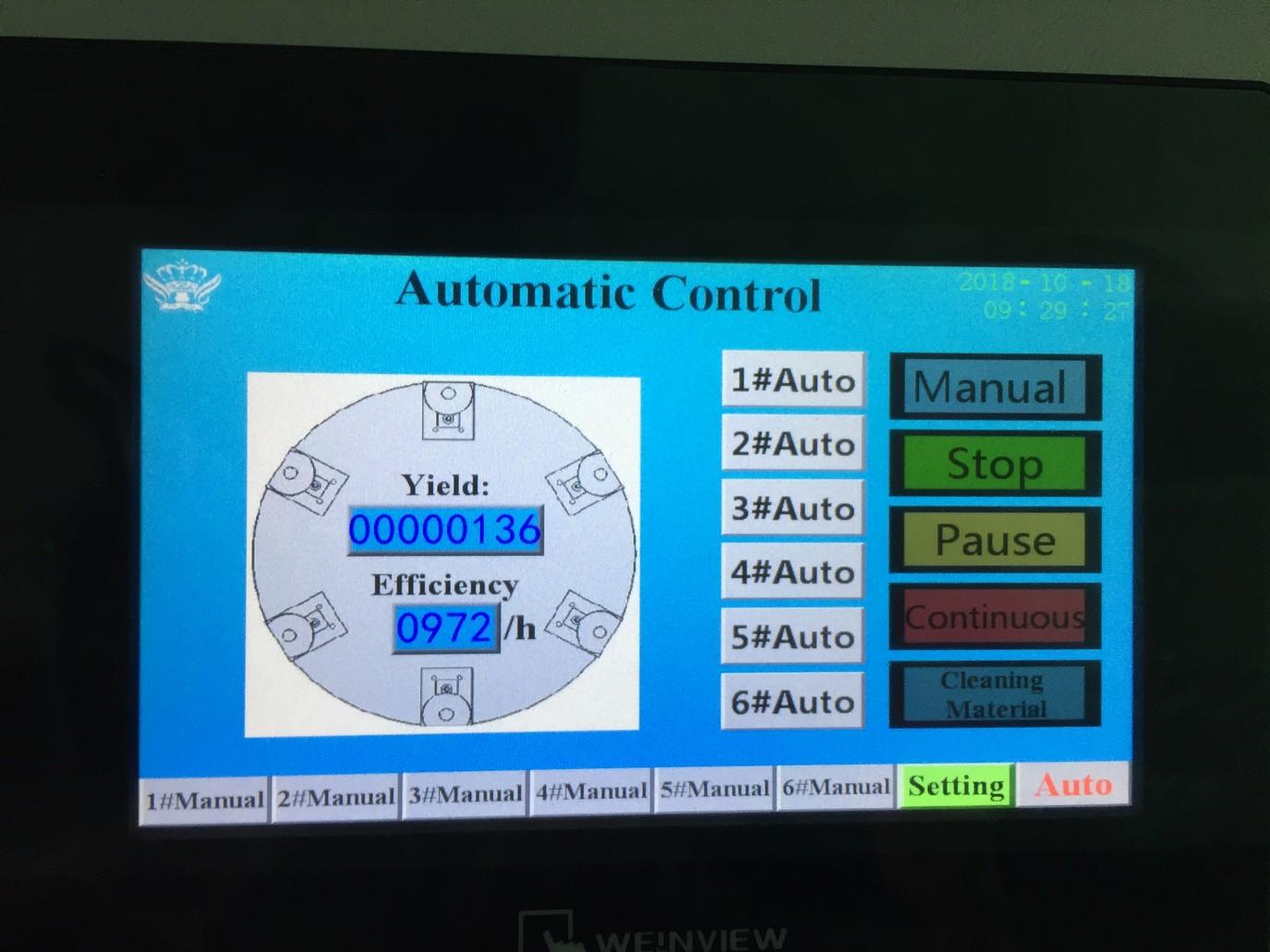

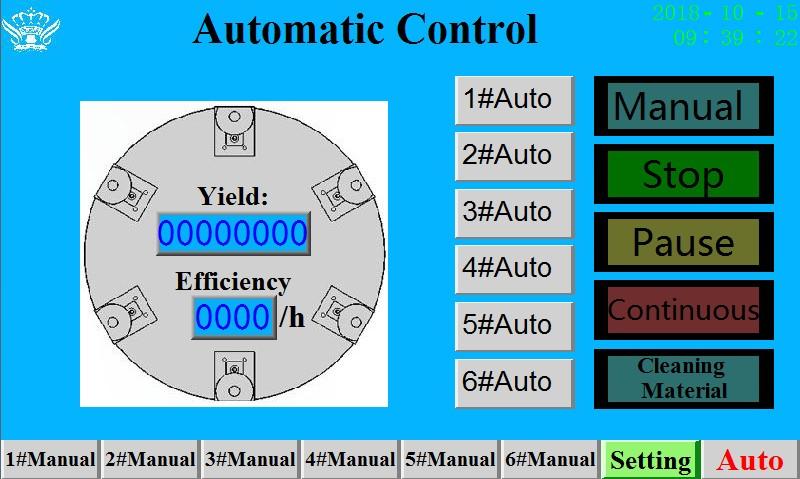

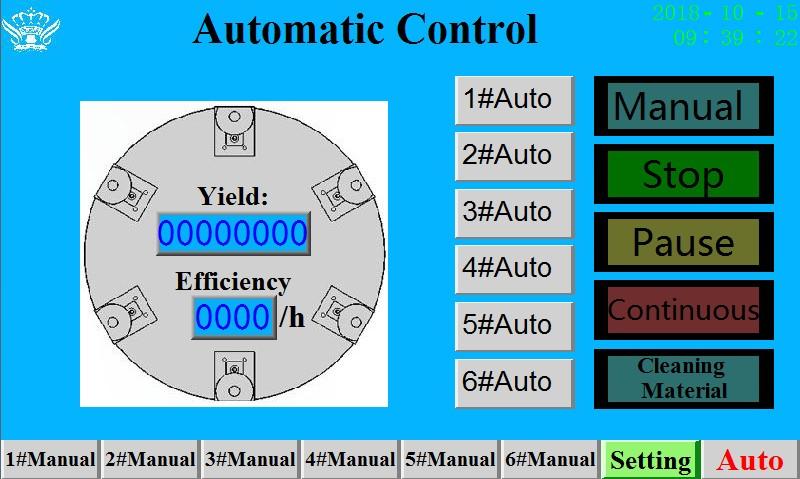

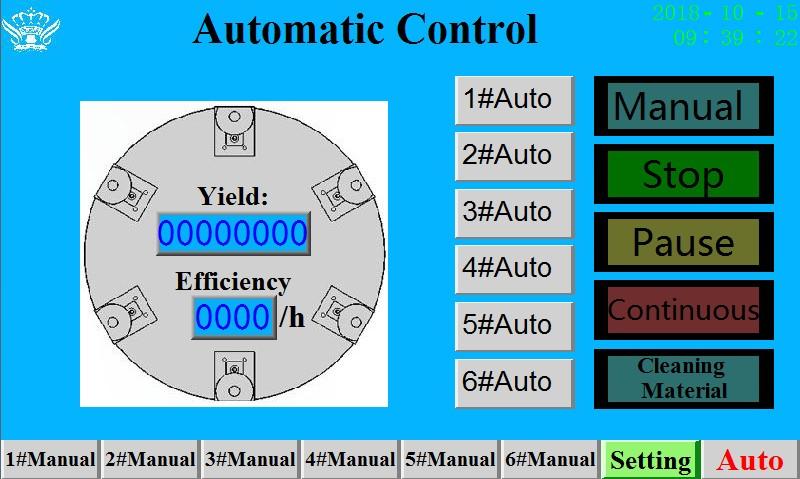

Manual/Auto Manual and Auto Mode Switching

Stop/Running Stop and Running Mode Switching

Pause

Continuous/Single Step

6 indicator

Pause for temporary stop

Machine test in Continuous mode to complete whole cycle; Machine test in Single step for each station.

6 indicator for material readiness of each station

1-6#Auto Red means normal, Black means stop or complete

Cleaning Material

Page 17

3.10 Automatic Control Yield Output QTY

Efficiency Hourly Output

28

Clean Page 14

Oiling Prohibit No Oiling, machine test only

Oiling Test Test the oiling amount of Oil

Auto Heating Oil Drum, oil valve, oil pump and oil pipe Auto Heating at the same time

3.11 Parameter Setting

29

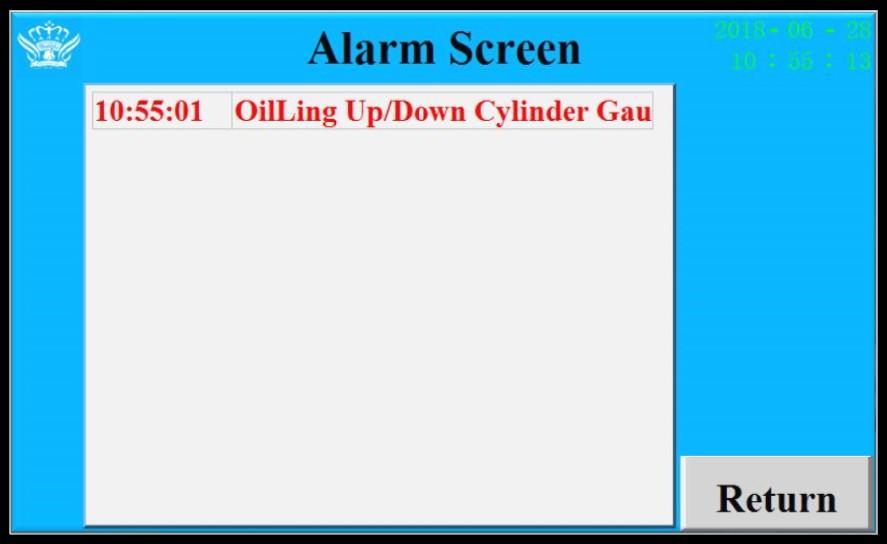

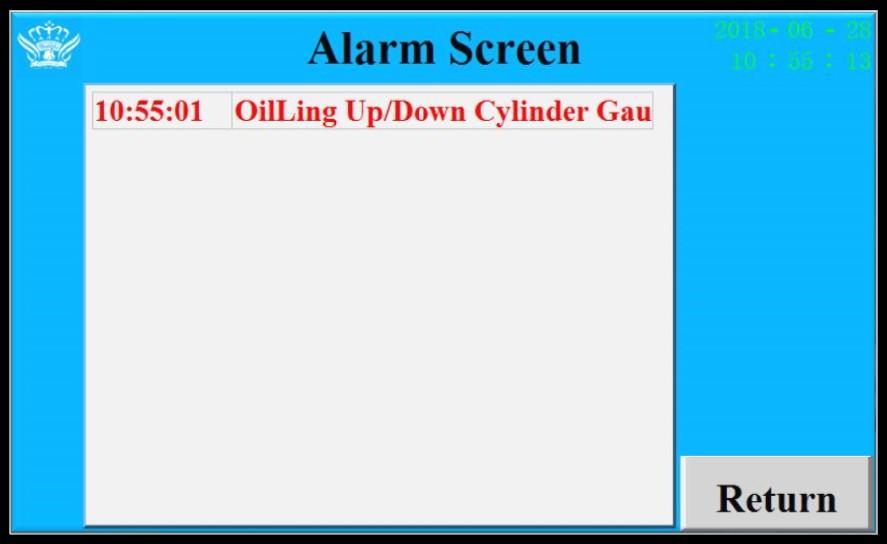

3.12 Alarm Screen

Show fault and timing occurred.

30

4. Troubleshooting

Failures Solution

Stopping Overtime

Cleaning Subject Overtime

Resetting Overtime

1#Overtime

2#Overtime

3#Overtime

4#Overtime

5#Overtime

6#Overtime

Check whether the cylinder is abnormal, the sensor is normal, workstation complete working.

Check whether the cylinder is abnormal, the sensor is normal, workstation complete working.

Check whether the cylinder is abnormal, X31,X32

Check #1 Cylinder, X32,X33,X30,X34 sensor

Check #2 Cylinder

Check #3 oiling up/down motor, oiling pump and Temp.

Check #4 Cylinder, X7 sensor, feeding motor

Check #5 Cylinder, X5 sensor

Check #6 Cylinder, X31 sensor

X33 Gauging Abnormal(1#Station) Check #1 Cylinder, X33 sensor

Pushing Cylinder Gauging Abnormal(1#Station)

Press Cylinder Gauging Abnormal(2#Station)

Holder Pickup Up/Down Cylinder Gauging Abnormal(4#Station)

Press Holder Cylinder Gauging Abnormal(5#Station)

Holder Fixed Cylinder Gauging Abnormal(#5Station)

Unloading Up/Down Cylinder Gauging Abnormal(6#Station)

Holder Fixed Cylinder Gauging Abnormal(4#Station)

Oil Drum Low Level Alarm(Oiling Station)

1.Check Cylinder

2.Check Sensor

3.Check I/O

4. Check Solenoid Valve

Not enough Oil, fill oil into the barrel.

31

4. Troubleshooting

Failures Solution

Holder Lose(6#Station) Take out the cartridge

X7Gauging Abnormal(4#Station) Check mouth piece material is in position

X30 Gauging Abnormal(1#Station) Check #1 , no material

X31 Gauging Abnormal(6#Station) Check #6, X31 sensor, material still in fixture and in position

Oiling UP/DOWN Motor Alarm(3#Station)

Turn plate Overtime

Holder Feeding Motor Overtime(4#Station)

Oiling UP/DOWN Motor Overtime(3#Station)

Guide Motor Overtime(Oiling Station)

Oiling Motor Overtime(Oiling Station)

Subject Motor Overtime(1#Station)

Check Speed Setup

X32 Gauging Abnormal(1#Station) Check X32 sensor, material still in fixture and in position

Running With Null

No material/ Testing

Oil Drum Temperature Alarm(Oiling Station) Oil Drum Temp. abnormal

32

5. Accessories and Spare Parts

Injector (20g)

Phillips Screw Driver

Screw Driver

Allan Wrench 1set

Fixed Wrench 2pcs

Silicone Cleaning Pipe 1pc

6. Care and Maintenance

6.1 Keep unit clean after each production.

6.2 Check the rails regularly for lubricant.

6.3 When unit is not in use, clean all pipes, and turn off power supply and air source.

Spare Part QTY

5pcs

1pc

1pc

33

1.3 Power and Air Supply

1.3.1 Connect Power cord and Air Pipe

1.3 Power and Air Supply

1.3.1 Connect Power cord and Air Pipe

1.4 Manual Switch

1.4.2 Needle Valve Pressure Gauge, Oil Drum Pressure Gauge, independent

1.4 Manual Switch

1.4.2 Needle Valve Pressure Gauge, Oil Drum Pressure Gauge, independent

plate and load mouth piece

plate and load mouth piece