2 minute read

Rat’s Nest

from SoaringNZ Issue 48

by mccawmedia

Bob Lock, Maintenance engineer Gliding Hutt Valley sends us this cautionary tale.

Diaphragm panel damage

Advertisement

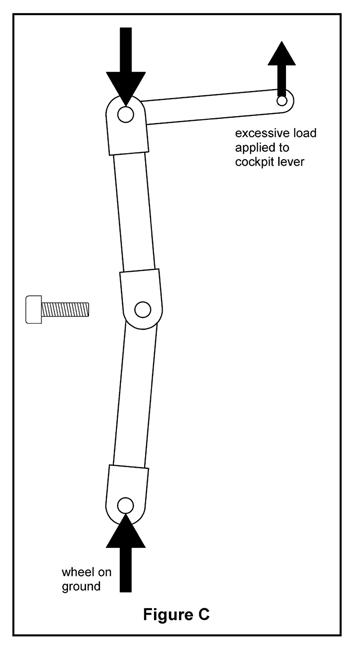

At the beginning of November I commenced an annual inspection on our ASK 13 trainer. Whilst operating the control column to produce aileron deflection, a scraping / squeaking noise was evident in the starboard wing. Closer inspection revealed serious rat damage to the root rib diaphragm panels and the rib structure at the aileron/brake rod aperture, plus a substantial hole gnawed through the brake box slot rear panel, around the

internal view of the brake box panel

inner brake pivot locking stirrup with one of the two stirrup bolts rendered less effective.

More serious investigation was carried out with the use of a CCTV camera on an extending boom, courtesy of our chief tow pilot Tom Clarke, which allowed visual inspection to the outer end of the brake box. The remaining areas were viewed with an endoscope through piercings in the fabric. The results were disturbing.

A rat’s nest was found at the outer end of the brake box containing large amounts of foreign material, including safety notice labels robbed from the cockpit! The fabric at the nest site was severely contaminated and impregnated with urine to the point that the fabric strength had been reduced to almost zero.

To add insult to injury, the vermin had destroyed two of the three aileron felt guide bearings and support structure.

Part of the heavy staining on the fabric

extent of the repair required to the root end double diaphragm No 1 rib structure

Also, several diaphragm panels through which the aileron and brake operating rods pass were severely chewed. The aileron rod drooping and rubbing on the remaining bearing support structure was responsible for the scraping noise.

Gaining access and carrying out the necessary repairs entailed extensive surgery and two months of every available moment of spare time.

Recommendation to operators and maintenance personnel.

Do not ignore strange/unusual noises in operating systems without thorough investigation. Check any staining that appears and any change of ‘feel’ in control operation no matter how small. They may be the tip of the iceberg.

Shows upper surface access holes, there was also a similar sized hole required in the lower surface below the one in the foreground.

Exclusive Agents Australia & New Zealand