69 minute read

2 CROWS BREWING FLYING HIGH IN NOVA SCOTIA

2 CROWS BREWING CO

FLYING HIGH

A BREWERY THAT TURNED FIVE YEARS YOUNG AT THE START OF 2022, HALIFAX-BASED 2 CROWS BREWING CO REMAINS A BRAND FOCUSED ON QUALITY, EDUCATION, AND TRANSPARENCY. THEY ARE ALSO EVOLVING, INNOVATING AND EXCELLING ALONG THE WAY. HEAD BREWER JEREMY TAYLOR TALKS US THROUGH HIS OWN JOURNEY IN BEER AND WHERE THE NOVA SCOTIA BREWERY GOES NEXT.

“One of the things I love most about this business is that we’re a brewer-driven brewery. Yes that means the margins might not be as good as they can be and yes, Mark swears at me sometimes but if that means I get to make the beers and he has to sell them then that’s ok!” laughs Jeremy Taylor.

Taylor is the head brewer and co-founder at Halifax-based 2 Crows Brewing Co. Along with husband and wife duo Mark and Kelly Huizink, the trio have created a business that has become one of Canada’s most regarded outfits.

Located on Brunswick Street in Downtown Halifax, the brewery is on the doorstep of the Halifax Citadel National Historic Site, home to a fortress that, thanks to its role back in the 18th century, is to thank for Halifax existing as a city today.

And while much has, unsurprisingly, changed throughout Halifax in that time, the Citadel’s brewery neighbour has been on a journey of its own since starting out back in early 2017.

Before he got into beer, Jeremy Taylor was working at the BC Centre for Excellence in HIV/AIDS, a mere 5,500km west in Vancouver.

“I conducted genetic sequencing of the HIV virus,” he says. “I would check out the predominant strain of HIV in somebody’s system and then based on that, recommend a cocktail of drugs to beat up that strain. I really enjoyed it, as it was really important work. But I didn’t really want to be a lab rat for the rest of my life.”

Being able to brew more lagers is super exciting because they are beers I really enjoy making and really enjoy drinking,” Jeremy Taylor, 2 Crows Brewing Co

It would just so happen then that a gift from his wife Elaine Moody (then partner) from Dan’s Homebrewing, would put Taylor on the path to a different profession.

“It was a really, really simple homebrew kit from Dan’s Homebrewing in Vancouver. It was basically a bucket with a false bottom that you would wrap in a blanket to keep warm. It really lit a spark in me,” he recalls. “I’ve always enjoyed baking, cooking and working with flavours, so getting that kit and being able to play with yeast a little bit was really enjoyable. Being able to tinker a little while geeking out on the science aspect was something I was passionate about.”

While Taylor didn’t class himself as anything resembling a “beer fanatic”, he approached the field with the drive and desire to create. However, he was enamoured by beers such as Fat Tug, the Northwest-style India Pale Ale from BC’s Driftwood Brewery and a move to Edinburgh, Scotland would broaden his horizons further.

“I found myself aged 27/28 having worked in lab jobs that paid a decent wage alongside good hours. While brewing appealed, I didn’t want to go in mopping floors. If I wanted to get where I wanted to be, I knew I’d need to study first,” he remembers. And by 2013, that meant undertaking an MSc Brewing and Distilling in Edinburgh at the venerable Heriot-Watt University. “My mum is from there while my dad is from London originally, so I spent a decent amount of time in the UK when growing up. At that point, Canadian brewing programmes were in their infancy, and I had no connection to the courses in the US or Germany so Edinburgh was the perfect fit.”

He adds: “I also appreciated that Heriot-Watt offered an MSc and considering my laboratory work was tied to academia, it gave me an option to pursue that element of brewing in the future.”

Taylor enjoyed his time in the “fantastic” city of Edinburgh. With some memorable drinking experiences and some….harder to remember. “Being surrounded by people so passionate in both brewing and distilling was inspiring,” he recalls. “I built lifelong friendships from that programme, which I really value. It was a great time.”

Upon completing his studies, Taylor was offered the chance to return home with a role at Bridge Brewing Co in North Vancouver.

“They hired me straightaway, which was pretty foolish of them!” he smiles. “I learned a lot at Heriot-Watt but you have your head in the books a lot of the time. Joining Bridge allowed me to express myself more on the production side, which was a great experience.”

Working at Bridge for nearly three years not only involved Taylor overseeing a site move that increased capacity ten-fold, it also enabled him to flex his creative muscles with recipe formulation. Beers that would go on to win awards along the way, too. “To get that experience in production along with the confidence of winning awards was a special feeling. It made be realise I could do this,” he says.

But following that valuable, rewarding time with Bridge, it was time for something new. While Taylor’s family reside on Vancouver’s North Shore, his wife Elaine hails from Dartmouth in Nova Scotia and the plan was always to move there. “Vancouver is home and it’s a cool place to hang out, but it’s very big, busy and expensive. Knowing that I’d be on a brewer salary, it’s not somewhere I would see myself able to have a family and settle down,” he says. “So moving to Halifax was part of the long term plan.

“At Heriot Watt, I developed a business plan for a Halifax-based brewery. But being a brewer, I completely neglected the financials and instead focused on market research, what kit I’d need and things like that!”

Enter Mark and Kelly Huizink. Half Belgian/ Half Dutch, Mark found himself in Halifax some 20 years ago for University. It’s here he’d meet Kelly, who was born and raised in the city and someone that was enthused with the idea of opening a local business.

“Mark is an accountant but he decided he didn’t want to be sitting in an office staring at the computer, so they were actually simultaneously developing a business plan for Halifax-based brewery,” says Taylor.

“But being an accountant, he was only focusing on the financials and completely neglected the brewing aspect. So he got to the point where it was all coming together, and he was needing a brewer to be part of that.”

He would reach out to a family friend Ali Hosein, who went to school with Taylor. While Hosein is from the area, he was working and living elsewhere, with no immediate plans to return to Nova Scotia.

“Thankfully though he knew that I had plans to make that move, he put us in touch and I flew out to meet Mark and Kelly so we could discuss our plans and put them together,” he explains. “We realised that we were definitely aligned in terms of the type of beers we wanted to be making and what our what our priorities are were.”

Taylor adds: “It’s a great partnership because I’m allowed to focus on the beer and I leave them to focus on the numbers!”

It was the Christmas of 2015 when the team would visit some potential premises. While a site opposite the current location at 1932 Brunswick St was initially eyed, they were then shown what would become the now home of 2 Crows.

“At first we felt it just looked like the bottom floor of a condo building, which didn’t really excite us. But once inside, we saw the potential it had. From the flooring that we could easily specify to withstand the tanks, to the 23 foot-high ceilings, it offered a lot,” says Taylor. “So I suppose we just stumbled across the place, and we’re grateful.”

He adds: “So come May 2016 my wife Elaine and I packed our car and drove out here, with construction starting the next month.”

And while there were hopes to open the doors at the end of that year, 2 Crows would eventually open to the world in January 2017. Brewing at 2 Crows takes a 24hl (20bbl) DME brewhouse, brewing into 48hl (40bbl) unitanks. The brewhouse is a 2 vessel system featuring a combined mash/lauter tun and a combined kettle/whirlpool.

It’s a great partnership because I’m allowed to focus on the beer and I leave them to focus on the numbers!,” Jeremy Taylor, 2 Crows Brewing Co

Beers at 2 Crows are markedly diverse in style. Recent anniversary releases include a Barrel-aged Berliner with Concord grapes, a Lagered Wild Ale w. Oranges and Kekfrankos Grapes, a Baltic Porter w. Marquette Pomace and Cocoa Nibs and a Saison/Lager Hybrid w L’Acadie Pomace.

These complement Belgian Table Beers, Pale Ales and the incredibly-popular AC Light Lager.

“AC Light Lager takes the idea of local beer to a new level by utilizing barley grown on PEI and malted by Shoreline Malting Co., whole-leaf hops grown by Lakeview Hops in New Brunswick, and beautifully soft Halifax water,” says Taylor. “It has become more important than ever to support local partners of the craft brewing industry. By sourcing local ingredients we are celebrating the rich culture and history of Maritime growers while simultaneously reducing its supply chain, costs and the carbon footprint of the beer it produces.”

Taylor is conscious of the ever-changing demands from the consumer and aware that a brewery such as 2 Crows needs to adapt to these dynamics, too.

“We’ve always tried be fairly forward-thinking and to keep our fingers on the pulse of what’s going on in the world,” he says. “I think people appreciate that. But it’s all about balance, too.

“There’s still a major part of the consumer base that are more ‘traditional’ in their tastes, which means much of what we do is lost on them, and that’s fine. It’s up to us to do what’s best for us. That means being excited about the beer but producing beer that will hopefully sell some decent volume, too.”

And the recent AC Light Lager, which sees demand outgripping supply, is one such example.

“My beer preferences have evolved, just as everybody’s preferences have changed, so we have shifted production somewhat on what people want,” he says. “Being able to brew more lagers is super exciting because they are beers I really enjoy making and really enjoy drinking. And it seems that others do as well!”

In the five years since starting out, 2 Crows Brewing Co has made an indelible mark on the Canadian brewing landscape. It’s making fantastic beers, served on-site from one of Halifax’s best beer spots. But for the team, the business also needs to mean more than the liquid itself.

“Since day one we’ve been focused on being good community members,” he says. “But in recent years, events in and outside of beer made us realise it’s no good quietly thinking this way. We need to act on it.”

This has involved partnering with Change Is Brewing, a local BIPOC collective that aims to give underrepresented people in the food and drink sector a voice. They have also raised funds for and worked with organizations such as the Africville Heritage Museum, Mi’kmaw Native Friendship Centre, Laing House, Make a Wish and ALS Society of Nova Scotia.

Taylor goes on: “We want to make this place as welcoming as possible. We want to be diverse and we want to be open. We have an Equity Diversity statement posted here at the brewery and online, too. This means working with everyone and making beer for everyone.

“We want 2 Crows to be a place that’s representative of the whole community and that is safe for the whole community.”

STABILITY

FOAM STABILITY FOR CRAFT BREWERS

THE STABILITY OF BEER SCIENCEFOAM IS A CRITICAL CHARACTERISTIC THAT REFLECTS BEER QUALITY AND IS ONE OF THE FEW CONSUMER PERCEPTIBLE METRICS FOR BEER, AND AS SUCH IS A VERY IMPORTANT CHARACTERISTIC TO MEASURE AND MAINTAIN FOR CRAFT BREWERS. HERE ROB MCCAIG, A SENIOR ADVISOR, TECHNICAL SERVICES AT FIRST KEY CONSULTING, TAKES A CLOSER LOOK AT POTENTIAL ISSUES AND VARIOUS SOLUTIONS WHEN IT COMES TO FOAM. Many things can affect foam stability, from raw materials to the brewing process and the packaging process. Use of adjuncts as well as hops, and the act of dry hopping can affect foam stability. Mash regime, boil control, clarification (filtration and centrifugation) all exhibit effects on beer foam. In packaging, CO2 control can affect foam stability as well. This paper will discuss those important aspects 36 | SPRING 2022 of foam stability that can be controlled by the craft brewer. It will also describe simpler methods useful to the craft brewer for monitoring foam stability.

The importance of beer foam to the consumer cannot be overstated. It is one of the few beer analytics that is immediately noticed by the consumer. A good foam head is looked at favourably by the consumer, enhancing their beer-drinking experience and can cause a consumer to overlook some minor deficiencies in the beer.

There is a direct correlation in the consumers mind to better quality. Beer foam is protective, preventing the direct contact of oxygen with the liquid beer, thereby slowing down oxidation. Beer foam, by its’ nature enhances the beer flavour, as the aroma carried in the beer foam can define the beer. Beer foam also helps to reduce beer bitterness by trapping some of the bitter compounds, removing them from the beer liquid.

Of course, too much foam on a beer can be negative in most cases, although Pilsner Urquell in Czech Republic has created three different pours with ever increasing foam, such that one pour is 100% wet thick creamy foam (called Mliko). The varying amounts of foam create different characters in the beer that make each type of pour a different flavour.

Phil Leinhart, Senior Advisor, Technical Services at First Key Consulting says: “Along with the obvious senses of smell and taste, beer drinkers also use sight for the enjoyment of beer. One of the most enticing visual aspects of a well poured beer is a creamy, stable head”

Beer foam is essentially all about surface tension. A nucleation site is required to create the CO2 bubble, but the beer must have carbonation and contain components that are foam positive, such as proteins from the malt and iso-alpha acids from the hops. The bubbles created want to destabilize and burst owing to the incredible amount of surface tension in the round shape, but the foam active compounds help to stabilize and maintain the bubbles.

Foams with smaller bubble size are more stable, which is exhibited when nitrogen is used. Nitrogen is more stable in beer and as such created smaller, tighter more stable bubbles that are longer lasting as foam. The foam has a collectively huge surface area, such that a pint of beer foam can have the equivalent surface area of a normal sized room. Finally a nucleation site is required in the vessel or the container beer is contained in to create the bubbles which eventually become the foam head.

In measuring beer foam, the consumer generally looks at amount of foam, the creaminess of the foam, the collapse rate (or foam stability) and the cling or the foam that remains on the side of the glass. Most of the methods for measuring foam only look at foam stability, i.e. how long lasting is the foam. The standard method in use is the Nibem foam tester. A sample package of beer is cooled to a standard temperature and dispensed in a measuring device creating an excess of foam over the device. The Nibem unit has a probe that measures the time required to reduce the foam 30 mm.

In order to standardize, the Nibem is maintained in a room with a constant temperature and pressure. Other devices such as the Steinfurth foam analyzer and the LG-automatic foam tester will also measure the foam stability albeit in different manners, but still generating the foam stability in time (usually seconds). This equipment is expensive and can be beyond the budget of a craft brewery. Other methods exist that can be accomplished without expensive specialized equipment.

The Constant method is one that can be used for minimal cost. In this method a well rinsed 1 litre beaker is used. Beer is

pre-equilibrated to 4oC, and the package is placed in a clamp in a stand, 4 cm above the beaker. The clamp is inverted, pouring the beer rapidly into the beaker in up to 5 seconds. The package is allowed to drain for an additional 15-20 seconds.

The beaker is covered with a glass petri dish and the beer liquid height, and the total height (beer liquid plus foam) is measured at intervals of 1.5, 2, 3, 4 and 5 minutes after covering. The foam height is calculated as the difference between the total height and the beer liquid height. If done under standard conditions this test can be used to compare production to determine if foam is remaining stable, increasing or decreasing.

One simple elegant method from the “Pope of Foam”, Charlie Bamforth involves adding 5 mL of degassed beer to a screw-top tube (15 cm length by 1.5 cm internal diameter). The tube is shaken in a 40 cm arc 10 times in 3 seconds. The foam height and liquid heights are measured from the tube bottom 30 minutes after shaking. The larger the foam, the more stable the foam is. This can be standardized to measure production as per the Constant method.

To truly measure foam from a customer perspective a beer is poured into a standard beer clean glass generating 1-2 inches of foam. Examine the foam under good illumination looking at foam colour (dull or white), texture (smooth even foam or are there rough patches) and are the bubbles small or large and even? Using a stopwatch allow the head to collapse and mark the time required for the beer liquid to show through. As in the previous two methods, this can be used under standard conditions to assess the production consistency.

If a brewer is having issues with foam, what can affect foam? Raw materials and brewing and packaging processes can all influence final beer foam. In terms of raw materials overmodified malt reduces foam owing to the reduction of the larger protein molecules that are foam positive. As more modification takes place, these proteins are broken down and are no longer foam positive. Conversely, if the malt is under modified, more of the foam active proteins are still whole and therefore increases foam.

Higher friability and lower total soluble nitrogen will also reduce foam as in both cases lower protein is available. The use of most adjuncts decreases foam in that it will result in less malt therefore less protein. The use of wheat and barley as adjunct though will be foam positive and result in better foam quality. Hops play a role in promoting better quality foam. Isomerized extracts are better than pellets which are better than whole hops for foam, so the more processed the hop the better for foam.

Iso-alpha acids in foam promote better foam cling while the use of hop oils and dry hopping in the process will result in poorer quality foam. The use of dried yeast will adversely affect foam quality. If re-using yeast, increased generation numbers will result in poorer foam quality, a good target is no more than 10 generations.

However, when propagating new yeast, the first generation usually has poorer foam. Any parameters that adversely affect yeast growth such as higher temperatures and higher wort dissolved oxygen will result in poorer foam quality. Anything adversely affecting yeast health results in poorer foam.

In the brewhouse, wet milling is better than dry milling for foam. A protein rest or extended protein rest is foam negative as this results in the breakdown of the foam positive proteins more. Higher mash in temperatures, lower mash pH and reducing mash oxygen pickup is better for foam quality. Extended mashes are poor for foam as are the use of kettle finings. By reducing the residency time in the whirlpool and reducing wort cooling time, foam quality is improved. Of course, higher gravity brewing with adjuncts where the malt is reduced will result in poorer foam quality.

In fermentation, gentler yeast handling is foam positive, storing yeast with minimal mixing and at temperatures near, but not below 0oC. Pitching with lower viability yeast reduces foam. Daily removal of spent yeast in the fermenter and yeast removal improves foam quality by eliminating the leakage of exogenous proteinases from the yeast that reduce foam positive proteins.

Lower temperatures during fermentation is better for foam, aiding in improved yeast health and the reduction of exogenous proteinases. Over foaming of fermenters in fermentation is foam negative as some of the needed proteins are left clinging to the sidewall of the fermenter. Stirred fermentations and rapid cooling after fermentation both results in poorer quality foam because of the pressure they put on yeast health.

In ageing, a shorter cooling/filtration or centrifugation run improves foam quality as does reduced handling or transfers (ie unitank process is better than using separate fermenter and ageing tank). Colder run temperatures and the use of nitrogen on tank transfer can both improve foam quality. In filtration, membrane filtration is more foam positive than diatomaceous earth filtration.

The use of tannic acid for physical stabilization (i.e. haze) is foam negative but the addition of a small amount of zinc (0-2 ppm) is better for foam. Natural carbonation (krausening) is better than the use of a mechanical carbonator, and the use of a ribbon carbonator is more foam positive that a pinpoint carbonator.

The use of a nitrogen/CO2 mix in packaging will improve foam. Aseptic packaging (no pasteurization) will result in poorer foam quality because of the non-destruction of proteases. Over gassing on fillers will reduce foam as will the use of wetting agents or defoamers in bottle rinsers. In final package the use of widgets and in dispense, the use of sparklers can increase foam quality.

If there are issues with foam, the brewer can look closely at his raw materials, the type and amount used as well as process in resolving foam issues. It must be noted though, that the brewer should employ a systematic scientific process in changing raw materials and process in order to determine the exact source of the foam issues.

MASCOT BREWERY

WE MUST AFFECT A CHANGE

MASCOT BREWERY’S AARON PROTHRO WANTS TO SEE MORE MORE ACCEPTANCE, MORE ACCESSIBILITY, AND MORE INCLUSIVITY IN CRAFT BEER. AND HE BELIEVES TO AFFECT A REAL CHANGE, IT MUST START AT THE TOP.

“I always admired craft beer’s ability to build communities. I just never felt that I belonged to any of them.”

It’s April, spring has sprung and that means the Toronto Blue Jays have returned to their home at the Rogers Centre for the first games of the latest campaign in the AL East.

It also means that things have got busy, really busy for Aaron Prothro and his team at Mascot Brewery. The brewery’s King Street West location, which opened its doors back in 2019, is only a 10 minute walk from the 53,000 capacity stadium.

turned en-masse, Prothro is musing about the other such group.

“When we opened up at our original spot back in 2015 I was excited about the location, excited about the project and excited about beer. But I knew I also probably had a different perspective on things than many of my peers,” he recalls. “I was an outsider, you know?”

Son to an African-American father and a Caucasian mother, Prothro says someone of his background “wasn’t represented” in the world of beer.

He explains: “When it comes to beer, there are barriers put up. There are many positives but there is also a lot of pretension and elitism. “That contradicts my values as a human but also in how I want to operate a business. I feel the main purpose of craft is bigger than the liquid. It’s about bringing people together over beer. When you’re constantly focusing solely on the product itself, you run the risk of falling into an echo chamber.

“You should aim to create a sophisticated, unique, delicious product but also desire to provide a space that is both inclusive and welcoming. We need to do more to ensure craft beer is accessible for all.”

And one key way Prothro strives to do just that is Mascot Brewery’s popular King Street West location and later this year, its Etobicoke brewery and taproom, too. “The taproom was integral is creating exposure for Mascot and helping it evolve into what it is today,” he says. “This journey has been one of exploration. I don’t think our vision has ever changed, our purpose has never changed. We are hopefully just becoming better articulating things.”

Downtown is know as Mascot King, a destination for all things craft. Located at 220 King St. West it’s Mascot’s brew bar, beer garden and bottle shop. It’s designed to be a fun and inviting space where beer fans can enjoy a wide variety of freshly brewed beers on tap. It also boasts a beautiful backyard beer garden where patrons can enjoy a pint under the sun. The bottle shop features all the Mascot favourites for consumers to bring home and enjoy.

Elsewhere, Mascot’s production facility in Etobicoke is a premises that also has an event space, taproom and bottleshop. While the patio opened last summer, Prothro expects taproom to be fully-operational this year.

“Hospitality is all about servicing people,” he says. “There are many extremely passionate people in the world of beer, I’m one of them. But I think when it comes to the bigger picture, it has to be about more than that. It can’t just be about the liquid or the beer itself.”

Being accessible is of huge importance to Prothro, just as being an inclusive business is, also. And that means starting right at the top.

“It starts from what your vision is, and what your purpose as a brand is, and how you infuse that purpose into your operation?” he asks. “So when it comes to onboarding, you need to be asking relevant questions.”

Prothro explains: “We have a culture questionnaire for onboarding and we’re very focused on making sure that our values at Mascot are infused into our hiring practices. You can’t have a team that doesn’t share those values.” Another area Prothro has an unequivocal passion and drive is through industry collaboration. And Mascot has recently engaged in a black-owned brewery collaboration initiative.

“I don’t feel that people, especially people of colour or anybody that’s different, should be asking for a seat at the table for acceptance,” he says.

“Acceptance should be the standard and I think through black ownership is really how we affect change. As an owner, you are able to curate your own space that represents what your values are. And I think that’s how you really affect change in this space is more diverse ownership in the craft beer space.”

Prothro adds: “So the black-owned brewery collaboration initiative is really about putting an exclamation mark on that point.

“We talk about having a seat at the table but for me it’s about building the table. And I think that for Mascot, as a higher purpose, it’s about changing the perspective on what craft actually is. And

“With the lack of diversity inclusivity in the space, I think that exists because there’s no leadership in ownership. These collaborations are our Batman signal, it’s our way to saying ‘guys, you know we’re here and we want you to work here’.” “We deal with a very exploratory consumer. They want to try different things. Whether that’s a lager, DDH IPA, pineapple, ginger and cucumber sour or a chocolate and coffee stout,” he argues. But this lager focus doesn’t mean the brewery will slow down its innovation in other spaces, either.

These values and that ethos are front and centre of everything Mascot does. Just like its commitment to making great, high-quality beers, regardless of style. And many of these are imbibed first hand at its ever-popular Mascot King location. While Prothro has a passion for all of these types of beers, his burning desire is to ensure Mascot’s name is synonymous with great lager. “We want to redefine what a new age lager is,” he says.

“We started with lager and we want to play in that space a lot more. So that means different yeasts, different processes, different flavours and different experiences. We want lager to be our niche and we’re excited by it.

“Our objective over the next year is to redefine what a new-age lager is for us. And using lager as a Trojan horse, so to speak, to create interesting flavour profiles, that people will hopefully be more open to He explains: “I think we make change through accessibility. I think we make change through targeting people who have been disenfranchised in the craft beer space. So that’s through making a Filipino beer, through making a Punjabi beer, a West-Indian beer.

“It means going to those communities and trying to collaborate with leaders in those communities to make these beers, because craft beer doesn’t really talk to those people.”

And with Prothro at the helm, there’s no risk of the conversation dying down anytime soon.

“It’s all about thinking differently, about getting new perspectives,” he says. “If you only talk to the same people about the same things then you’ll all think and do the same. I don’t want that, I want to be challenged on how I think and what I do. And I believe craft beer could all do with a little bit more of that.”

BOTANY

THE BOTANY OF BEER: ANATOMY OF A BOOK

GIUSEPPE CARUSO TEACHES FOREST BOTANY AT THE MEDITERRANEAN UNIVERSITY IN REGGIO CALABRIA AND BIOLOGY AND AGRICULTURAL FOCUSBIOTECHNOLOGY AT THE ISTITUTO TECNICO AGRARIO “V. EMANUELE II” IN CATANZARO, ITALY. HE HOLDS A DOCTORATE IN ENVIRONMENTAL AND APPLIED BOTANY AND RESEARCHES THE FLORA AND VEGETATION OF SOUTHERN ITALY, AS WELL AS HABITAT RECOVERY AND RESTORATION PROCESSES. HE IS ALSO A BEER EXPERT AND TASTER. 46 | SPRING 2022

When a few years ago I was asked, as a botanist, to lecture for a homebrewing course, I had been fatally forced to think about the variety of roles played by plants in the brewing process. It was immediately clear I would need to overcome my pubbased-knowledge of the beer universe, as well as to get full understanding of the most important processes involved in beer brewing.

On the other hand, while I was taking my first steps into the huge world of the relationship between plants and beer, it was impossible to imagine how far this research could go. If from the beginning it had been clear I had to write five hundreds botanical files and to draw as many botanical iconographies, I would probably have given up. Instead, the project has grown slowly and gradually, although several times, a relatively close end has suddenly disappeared because of the additional brewing plants species found, in the meantime, inside some dusty book or obscure website from the other side of the world.

While my understanding of the brewing process was maturing, I started thinking ofbrewers as chefs. Both jobs rely on skill, based on tradition and scientific knowledge, to put together different ingredients, using appropriate tools and activating specific processes, in order to get a final product, be it a dish or a beer. Above all, a deep knowledge on ingredients is fundamental for every chef, as well as for every brewer. Unfortunately, despite every effort, it was impossible to find a book not focused on

And even those books on ingredients, were mainly focused on barley, hops, water, yeast. It’s just the long term consequence of the culture of Reinheitsgebot, The Purity Law imposed by William IV of Bavaria, back in 1516, stated that beer could be made just with barley malt, hops, water – and later – yeast, as the only permitted ingredients. This liberticide law, openly against gruit philosophy – that of ales made with a wide range of different herbs, often direct expression of a territory’s native flora – was seemingly responsible for the extinction of many endemic ale styles across continental Europe, and later, British Islands.

Main beer ingredients today are exactly those imposed by purity law. So, water, barley (malted or not), hops and yeasts. The rest, maybe only with the exception of other grains such as wheat, durum wheat, corn, rice, rye, oat, etc. is usually considered as “other ingredients”, a generic definition including hundreds and hundreds of different plants.

The first task, along the long way of writing The Botany of Beer/An Illustrated Guide to More Than 500 Plants Used in Brewing, was the ex-novo creation of a detailed list of plants worldwide used in brewing. Digging into the brewing literature was immediately clear that each single book on beer included a limited number of plant species, and just one of them treat more than two hundred species.

Numbers apart, many criticalities emerged from the analysis of existing literature. The first issue jumping at the eyes of the botanist was the frequent use of common plant names, instead of the scientific ones. Common names are often ambiguous, suggesting sometimes the same name different plants or, on the contrary, the same name identifying different species.

The scientific name is usually univocal and unambiguous, and that’s why professional botanists prefer to use Latin binomial. Other ordinarily missed information regarding brewing plants are the morphological description of the plant, its biogeographical origin, ecology, cultivation area. No book seems to consider the species similar to known brewing plants (e.g. other species belonging to the same genus), as well as the taxa of subspecific rank (different subspecies or varieties could provide different characteristic to beer).

And, maybe more important, totally absent are crucial information on features which contribute to shape those of beer (e.g. biochemical composition of brewing plant) or styles (in which beer styles a brewing plant is used) or examples (commercial beers brewed with a specific plant). Finally, the source of the information on the brewing use of each specific plant is systematically unavailable, such as a detailed scientific picture of the plant (which simplify the identification of that species).

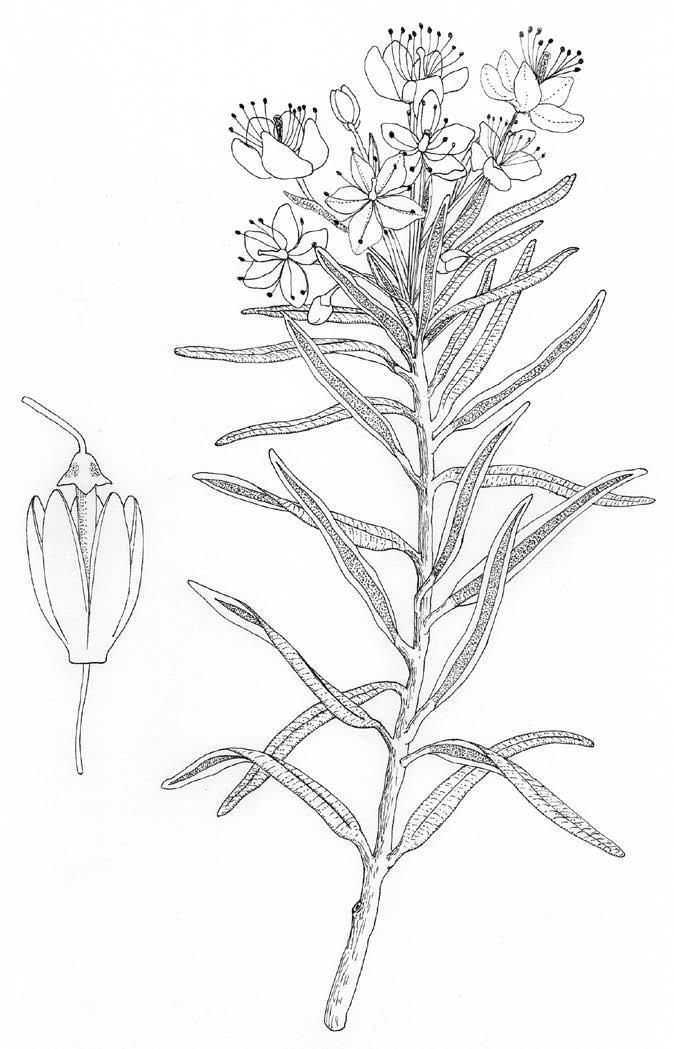

The foreword, written by Marika Josephson (co-owner and brewster at Scratch Brewing Company in Ava, Illinois) foregoes other introductive contributes occurring in the initial part of the book. The rest is made, as suggested by the book subtitle, by more than 500 botanical beer-making profiles, each containing those information lacking in other books.

So, in addition to the correct scientific name (including genus, species and author who first described the species), the plant file contains the name of the botanical family to which that species belongs, an ink iconography, a detailed morphological description (following the consolidated scheme: root, stem, leaf, flower, fruit, seed), a short list of the closely related species; then, information on the geographic distribution and the ecology of that species, and even where it is cultivated.

Aside from botanical features, brewing information include: plant organs used in beer-making, possible toxicity, chemical composition, beer styles in which that plant is used. For those plants providing wood that somehow comes into contact with the beer during the brewing process (e.g. seasoning, smoking, etc.), also the characteristics of that specific wood are described. The file ends with recording the sources of brewing application of the studied plant. This, repeated 502 times, covers most of the 600 pages of the book, that ends with a glossary intended for non-botanical readers, an extensive bibliography, and an index of common names.

Putting all known beer plant ingredients – accompanied by significant botanical, biogeographical, ecological and agronomic information – together with the best available brewing knowledge in a single volume, is not only an unprecedented editorial project, but constitutes a deeper and more original cultural challenge, which aspires to broaden the horizons of the world of beer. If aim of the book was to offer an encyclopaedic knowledge on plant brewing ingredients to beer industry – first of all brewers – on the other hand the tools of botany are addressed to a wider awareness, to support sustainability (if wanted), and to promote a more authentic enhancement of the territories.

The brewer who wants to strongly identify his beer with a specific territory, for marketing or ethical reasons, now has the basic phytogeographic information to support correct choices. He can buy raw materials from local organic farmers, or maybe even from foragers, as well as other products useful in the taproom promoting a neighbourhood economy with a reduced environmental impact.

An approach like this puts de facto the brewery at the center of a virtuose locally sustainable supply network. That’s exactly what Scratch, or better – Marika Josephson and Aaron Kleidon – are actually doing in Southern Illinois. On the other side, those brewers with an international mood, can more consciously buy exotic raw materials at the opposite side of the globe. But again, they can do it now with a renewed awareness.

While Craft Revolution seems wearily switching from IPA to IPA, dosing hops with increasingly unlikely names, there are hundreds of other intriguing brewing ingredients that promise to open an exciting New Frontier. It would certainly be a pity if the brewing world would linger for a too long on the reassuring positions gained, when there is a whole world out there waiting to be put back into play.

Too many plants widely used in the past in the brewery, are today absolutely neglected as beer ingredients. Other plants have sadly been forgotten in the folds of history. Some plants lend themselves to reviving extinct beer styles, while others certainly could help characterize new styles invented by the brewers creativity. Botany, after all, did its part of the job.

The fig (Ficus carica) is commonly used in the brewing industry in many Mediterranean countries Such suggestions, as well as other inevitable considerations, have certainly contributed to persuading Jennifer Crewe, head of Columbia University Press, to invest will and energy in this ambitious project. The Botany of Beer seems to have really everything needed to inspire important change in the beer industry. But projects like The Botany of Beer, which promise to contribute to change, need visionaries. The Author and publisher have shown the direction. Now, it’s up to the brewers.

Inula magnifica, a species endemic of eastern Caucasus, whose root is used in brewing

Illustration of Ledum palustre subsp. palustre, a species widely used in the preparation of gruit in northern Europe a few centuries ago. His northern American relative, Ledum palustre subsp. groenlandicum, is used today by some brave brewers in Canada

IN TRIBUTEJOHN PICARD A BREWERY FROM THE GROUND UP. LITERALLY JOHN PICARD, THE FOUNDER OF RAMBLIN’ ROAD BREWERY FARM, RECENTLY PASSED AWAY. HE WAS JUST 60 YEARS OF AGE.WHEN JOHN FIRST EXPLORED THE IDEA OF CREATING A PREMIUM CRAFT BREWERY IN HIS HOMETOWN OF LA SALETTE (NORFOLK COUNTY), WAYNE S. ROBERTS HAD THE PRIVILEGE OF HELPING BRING HIS BRAND TO LIFE. HIS WAS A STORY OF OVERCOMING INNUMERABLE OBSTACLES TO ACHIEVE A TRIUMPHANT LAUNCH AND CONSISTENT GROWTH AS THE LOCAL BREWERY EVERYBODY LOVED TO VISIT.

For over two years, John and I had been staying in touch. He was planning on launching his craft brewery. I had craft beer experience with the Upper Canada, Steam Whistle and Creemore Springs brands. “Let’s meet for a tour,” John suggested. “Absolutely,” I agreed. “See you there.” Arriving in Waterford, I naturally presumed the brewery would be located there. But it’s actually where John did the manufacturing for his spiffy, Picard-brand chain of tasty treat and snack stores. “Uh, where’s the brewery, John?” I asked. “Well, it’s a little out of the way so, follow me to get there. Look for the Canadian flag. We’re on Swimming Pool Road, south of La T here is a special kind of soil in Norfolk County, Ontario called Fox Coarse. That was among the very first things John Picard wanted me to now about his sion was to make delicious, farm fresh beers that featured the flavour and character of locally grown hops. The soil would pave the road to success. Salette. And drive fast, right?” he said. Right. John’s idea of driving fast, on rainsoaked country roads, was akin to fleeing armed gunmen as you hurtled along behind nascent craft brewery. RACING ON THE ROAD TO RAMBLIN’ ROAD his pick-up truck version of a hover craft. If his tires ever touched the road, it was by Most people don’t know about Fox Coarse, or that Norfolk is Ontario’s Garden. It’s generally more famous for its tobacco legacy, and the revelry and raunch in Port Dover every Friday the 13th. My first road trip to Norfolk County in the Spring of 2012 saw me arrive on a cold, dreary day in the pumpkin festival town of Waterford. That’s where John suggested we meet. It had been mistake. He flew. And when he said, “look for the Canadian flag,” he was referring to a giant mural painted on the entire north wall of his brewery, measuring 120’ feet long by 30’ high. It did not flap in the wind. But when you discover, as I did from John Picard, that Norfolk is one of the most raining heavily for a few days and the roads were... challenging. After an extensive tour and impassioned briefing by John, who talked prolific and essential growing regions in Canada, you appreciate the soil’s importance. Because all that growing happens in fertile Fox Coarse. It was on and in that exact soil that John Picard grew his Ramblin’ Road Brewery Farm. As a farmer himself, born and raised in Norfolk, John knew the potential of the soil. So, before he put a shovel in the ground to create his brew house, he planted hops right on his John Picard and Wayne S. Roberts at the property. For John, his pas- Ramblin’ Road’s hop garden in full bloom Brewery Farm, November 2019 50 | SPRING 2022 BREWERS JOURNAL CANADA

about as fast as he drove, we parted company with a commitment to regroup in a few weeks.

Driving back to Toronto, I was impressed, inspired. John had a compelling vision, and he knew why and how his beers would be special. He had big ideas about a destination location. I instinctively knew he could accomplish it all. My head was filled with ideas from the start.

QUICK! LET’S LAUNCH A NEW BREWERY!

What followed in the ensuing weeks and months was a whirlwind collaboration to develop all the necessities for a successful launch. The most important of which was the beer itself. John invited my opinion on his recipes as they were fermenting. They tasted great right out of the tanks!

I spent many summer days that year touring the county and hanging with John to get a feel for the community. Even attended a pre-opening dinner event at the annual Norfolk County Fair in October. John offered a sneak peek there of his (as yet) unbranded beer for an intensely curious crowd. They loved it.

Shortly after that dinner, on a brilliant, sunlit Saturday morning in December 2012, the parking lot at John Picard’s all new Ramblin Road Brewery Farm was packed by nine o’clock for the Grand Opening at ten.

Later that afternoon, every bottle of beer John and his team had packaged was sold. The following weekend, same deal. Ramblin’ Road was a hit, and still is to this day, becoming an established destination location for the Norfolk and surrounding community. And it further cemented John’s country road cred as one of the county’s most favoured sons. Success followed success with award winning brews, the addition of the most addictive kettle chips you’ve ever tasted, and later, a restaurant upstairs serving up fresh, local beef burgers and authentic chipper fries you can’t resist.

The Brewery Farm became a gathering place for festivals, car shows, club meetings, weddings ... you name it, it happened at Ramblin’ Road. For John, it was a playground where he could create unique beers; a pulpit to debate and kid around with his neighbours and naysayers; and a joy to watch it catch on so well with people who gravitated to it every day of the week.

This year, nearly a decade on, Ramblin’ Road was sailing along, and the future held much promise for bountiful growth.

THE ROAD AHEAD CHANGES

Ramblin’ Road main entrance Later, in a private grave side ceremony, they laid him down in the good earth of Norfolk County. In the same Fox Coarse soil he grew up on, and on which he’d built a distinctive craft brewery that has grown to become a beloved fixture in Ontario’s Garden.

John’s journey along the Ramblin’ Road ended abruptly and all too soon earlier this year.

A robust and active man, he fell ill in late 2021 and, despite valiant efforts throughout the first weeks of 2022 to arrest the progress of his illness, John suffered a fatal setback and passed away on March 14th. He was only 60.

The impact in Norfolk was sudden and overwhelming. At his visitation, hundreds lined up, just like they did for that boffo Grand Opening in 2012. At his funeral service, on a glistening, bright morning in late March, in his hometown of Waterford, his family and friends paid tribute to his life, his legacy and his love of community. It was standing room only. All who spoke in the chapel that day shared the same narrative. He was a local hero and a legendary personality, and now he was gone.

And while John’s travels are over, his family is adapting, the brewery staff and community are rallying, and the journey along the Ramblin’ Road continues.

Wayne S. Roberts was John’s friend and co-conspirator. As president and creative director of Toronto’s Blade Creative Branding, he created a complete branding program for John’s brewery, including the name, brand narrative, packaging, cinematic video, and a host of other tactics that launched and helped grow John’s iconic brewery on Swimming Pool Role in La Salette. Drop in some time. Look for the Canadian flag.

Video link: The Road to Ramblin Road https://www.facebook.com/watch/?v=1350244581700870

HOMEBREWING

The sector, reimagined

CONTENTS

SPRING 2022

We are thrilled to introduce you all to Mark Hubbard, a decorated award-winning homebrewer who hails from Toronto, Ontario. He shows us why having hobbies like homebrewing can be a great creative outlet that allows us to expand our knowledge while expanding our circle of friends! He is a prominent member of Canada’s largest homebrew club and is excited to share with us his passion for learning all things homebrewing, love for those funky beers (and bottling), along with ways to incorporate brewing into the philanthropic side of your life.

Brew Sheets

Mark has generously provided us with his secret recipe for “Cream Abdul-Jabbar” - a brew that earned him multiple awards at the nation-wide Brew Slam competition! Mark also noted that Brown Ales are missing out on the attention they deserve and provided us with his “Hogtown Brown ‘’ that is sure to re-acquaint us with this lovely beer style.

Gadget Corner

We’re going in a new, exciting direction in this journal issue. Join Sheena Strauss as she takes us on an uncharted journey! As homebrewers are adding more tech & tools we start to see some exploring the lab side of brewing and Sheena will show you how you can take your gear and build upon it to become something of a ‘mad-scientist’ in your homebrew lair. This will be a multi-part series that everyone can find something to enjoy so strap in!

Brew Day Tips - Spent Gains…Three Ways!

For this brew day tip, we are thrilled to showcase a special guest contributor, Ainslie Forbes, from the Food Ferments department at Escarpment Labs. Ainslie was kind enough to take us through multiple methods of how you can take your brew day spent grains- and prepare them so that you can explore many recipe options while minimizing brew day waste.

From Janes and Joes to all-out Pros

Hailing from Beamsville Ontario (close to Niagara Falls), we have Brewmaster and Director of Operations Sarah Casorso from Bench Brewing Company. Sarah’s start into the commercial side of brewing was born of ambition, drive, and making connections.

62

64

67

70

Brewing Up Something New

The long awaited Spring is finally here. For many Canadians, it is a time to get out and hike, garden, and enjoy a beer on the patio. For us homebrewers, it can also mean there is an extra spring in our step as we get excited for the outdoor brew days in the warming sunshine, planting hop rhizomes, teaching buddies how to brew, building something new for the brewery, finding new and creative ways to utilize brew day wates, and participating in Canadian Homebrew Day on Saturday June 4th, 2022.

In true blooming fashion, for Spring 2022, we have assembled a great cast! From a funky homebrewer that is passionate about growing with community, a pro brewer that grew a career from the ground up, a homebrewer hatching the beginnings of a homebrew lab, and a food ferments specialist who takes a scientific approach to drying spent grains that encourages brining the circular economy to our brew days. We hope you enjoy and find inspiration for growth and new beginnings within your journey!

We want to hear from you!

Fellow homebrewers (all brewing types welcome), we are inviting you to reach out to us by emailing Sheena at knwl.on.tap@ gmail.com to play an active role in shaping our homebrew community.

We want to provide opportunities for the community to help continue to build something great together.

We have also created a Survey for you to give us feedback on the Homebrew Journal and what you would like to see from us this year. Use the QR code below to access the survey.

Thank you all for reading, contributing, and the kind words you share. Your support helps the Canadian homebrew community grow and we wish you all a brewtastic Spring!

Happy Brewing Everyone! :D

Cheers!

BEAUTY

HOMEBREWER FOCUS local breweries. My homebrewing experience began 5 years ago, brewing my first batch (an APA) in the spring of 2017. I brewed roughly every two weeks for the first few years and I’ve now got over roughly 130 batches under my belt… though I’ve slowed down quite a bit over the last year. Over time, as friends began enjoying my beers, that helped to motivate me too. Today, it’s the never-ending challenge of brewing the best beer possible and the benefit of always having whatever styles I feel like in the fridge that still excites me about brewing. Before I started homebrewing, a friend and I went to a U-brew/ferment-on-premise place to “brew” a batch of beer. We just dumped bagged wort into a bucket and added some yeast, and came back to bottle it two weeks later. I felt like surely there IN SIMPLICITY IN THIS EDITION WE’RE PROUD TO PRESENT MARK HUBBARD. A DECORATED COMPETITION BREWER FROM TORONTO WITH A BREWING PHILOSOPHY OF “KEEP THINGS SIMPLE AND ALWAYS BE LEARNING!” Mark is a fellow homebrewer that I happened to come across on IG one day. We have a lot of similarities, with our brew system, working in pharma, and having a nostalgic attachment to an iconic Toronto-based homebrew supply shop - Toronto Brewing! This is a place where I used to make day trips to the big city and shop for five recipes at a time! (This was before shops opened up closer to home.) Mark also makes awesome labels for his bottles and his mixed-fermentation brews are a thing to behold! This is one brewer that you will want to follow on the socials as he takes you on his homebrew journey.

SERVING BEER I BREWED WITH MY FRIEND CHRIS AT PEOPLE’S PINT!

Mark Hubbard

o o o o o Instagram: @fullcircleales Toronto, ON Clubs: GTA Brews Homebrewing for 5 years Brews: Beer

Humble Beginnings

I started drinking craft beer several years ago when I discovered that there were so many different, flavourful styles out there and not just crushable lagers. This inspired me to try to brew my own, to learn more about the different flavours and how they’re made, and to see if I could make beer at home that’s as good as what I got from 58 | SPRING 2022 BREWERS JOURNAL CANADA

HOMEBREW BUDDIES

BREWING AT PEOPLE’S PINT

was more to brewing than that, so I looked up homebrewing afterwards to see what the process was like and it sounded right up my alley, so I bought John Palmer’s “How to Brew”, visited the local homebrew shop - Toronto Brewing - and the rest was history! I also work in the biopharma industry so some of the equipment/process similarities and a hyper-hygienic mindset helped me to learn quickly!

A Fast Learner With a Competitive Spirit

Soon after brewing my journey began I became a member of GTA Brews, Canada’s largest homebrew club. I have been a member since 2017. Being part of a club has made a huge difference in my homebrewing journey. Talking to a mix of new and veteran brewers over the years has been so valuable and I’ve learned a lot from each, and made some great friends. Our club, as well as many others, also run some fun events like in-person meetings, advent calendars, ingredient bulk buys, and more, so I highly recommend trying to join one for anyone new to brewing.

Competitions have also been a big part of my brewing journey. I began entering some comps on the national circuit in 2018 and won a few medals which was quite exciting in only my 2nd year of brewing. I’m quite a competitive person so I decided to give competitions my all in 2019 and set were brewed with malt extract in a 5 gallon aluminum pot but, like many new homebrewers, the switch to all grain came quickly. I bought a better kettle, a mash tun, and a few gadgets like a refractometer, pH meter, and so on. I’ve been brewing with the same equipment for years now.

a goal of finishing top 20 in the Brewer of the Year circuit. I planned my batches carefully around comp dates, and ended up taking home 25 medals across 10 national comps and 2 local comps. I ended up 5th in the BOTY standings! I was super-proud of beating my goal as well as for helping GTA Brews win Club of the Year! I’ve only entered one competition since the pandemic started, and likely won’t give the BOTY circuit my all again as that was a lot of work and planning, but I will always look forward to Brew Slam each year.

Keep It Simple, and Focus On the Fundamentals

In terms of brewing my beer, it seems like everyone has an electric all-in-one system nowadays, so I guess I’m kind of old school in this respect. I have an 8 gallon kettle that doubles as my HLT, and a 5 gallon Igloo cooler with a false bottom that I use as my mash tun. I heat my strike water in my kettle then mash in, and then add sparge water to the kettle and heat it. I run the first runnings off into a bucket, add my sparge water to the mash tun, and then add the first runnings and sparge runoff into the kettle and begin the boil. I don’t even own a wort chiller, and just make an ice bath in my kitchen sink that I plunge my kettle into.

Other than slowly adding more fermenters for sour beer, my equipment really hasn’t changed that much. My first five batches Needless to say, there really isn’t anything special about my equipment that makes a big difference in my beer. (If it works, why change it?) I’m definitely not a gear head as I believe having a solid process and understanding all the fundamentals of brewing makes way more of a difference in the quality of my beer than owning the newest, shiniest equipment. My advice to new brewers: Don’t worry about spending hundreds of dollars on fancy, brand-name equipment - get your process down pat first!

I buy nearly all of my equipment and ingredients from Toronto Brewing. They have everything a homebrewer would need as well as some super-helpful and friendly employees, and I always love stopping in. They also ship nation-wide!

Nothing Beats a Good Bottle of Funk!

I absolutely love mixed-fermentation beers, so my fermentation equipment is split between clean and funky beers. I’ve got one temperature-controlled fermenter for clean

beers (as more than one clean batch at a time would be way too much beer for me!) It’s an SS Brew Bucket with a Fermentation Temperature Stabilization system (FTSs) running into a mini fridge for temperature control. For the longer term mixed-culture beers, I’ve got three stainless and two plastic fermenters… none of which are temperature-controlled. In terms of packaging I’m among the maybe 1% of homebrewers who, after many years, still bottle condition all of their beer! I’ve never minded bottling and since all my funky/sour beers would get bottled anyway, I just didn’t see the point in investing in or figuring out the whole kegging and keezer process. I like taking bottles out with me and gifting them to friends too, so I’ve never really considered changing up my packaging technique… despite many others trying to convince me!

Brewing Is My Rewarding Creative Outlet

My favorite aspect of homebrewing is just having something in my life that challenges me and takes some thought and work, with a tasty outcome at the end. I think having hobbies is important for adults, and homebrewing has provided me with a creative outlet, goals and continued learning, and helped me meet many great people. I’d recommend it for anyone who enjoys beer and has the time to dive into a new hobby and give it their all. It’s very rewarding once you get all set up and know what you’re doing.

And I’ve certainly had some memorable homebrew experiences. Taking the cake, would have to be the few times where I’ve been able to serve my beer to the public at a local brewery called People’s Pint Brewing Company; a brewery which has homebrewing roots and are really great supporters of our club and the hobby in general! The first time was as part of a club event for Toronto Beer Week where a bunch of GTA homebrewers brewed beers to serve there to show the public that good beer can be brewed at home. The other time was for a charity comedy event, and two of my closest homebrew friends and I each brewed a beer for it and served them during the comedy show. I’m proud to say that the event raised over $2,700 for the Alzheimer Society of Ontario!

Parting Advice For New Brewers

Finally, if I had to give some advice to new homebrewers, part of it would be everything you would normally hear frequently from other experienced brewers: control your fermentation temperature, clean and sanitize very diligently, minimize oxygen exposure, and learn how to treat your water. But honestly, what I think improves homebrew quality the most is just becoming immersed in the hobby. Go to club meetings, read books, listen to podcasts, ask lots of questions, brew frequently, enter competitions, talk to others about your recipes, and so on. If you have the time to go all in with this awesome hobby, you’ll see your beer improve by leaps and bounds very quickly. There is no substitute for solid fundamentals and Mark shows us all we can be great brewers with any equipment and that expanding your knowledge base, being active in your local homebrew scene, setting goals - and of course brewing a boatload of beer! - is going to up your game while making some amazing friends along the way!

I hope this shows that we are our own brewers with our own journeys and stories to share and I love to see brewers of Mark’s caliber being so passionate and involved in the community, helping to make each and every one of us great!

VORLAUFING, THE OLD FASHIONED WAY

THE WALL OF FAME

A SOUR BEER OF MINE WITH RASPBERRIES

BOTTLING A SOUR BEER WITH CHERRIES

BREWING A 1 BBL BATCH AT A LOCAL BREWERY IN NEW BRUNSWICK, WHERE I’M FROM

MY TYPICAL BREWDAY SETUP

SPARGE RUNOFF

Cream Abdul-Jabbar

RECIPE INFORMATION BATCH SIZE: 5 GALLONS OG: 1.047 SG FG: 1.007 SG IBU: 10 TRY THEM YOURSELF... SRM: 3.1 ABV: 5.3 GRAIN BILL: O 4 LBS 2 ROW O 2 LBS 6 ROW O 1.5 LBS FLAKED CORN O 0.25 LBS CARAFOAM

MASH SCHEDULE: Mash for 60 minutes at 150OF BOIL SCHEDULE: O 60 MIN: 0.5 OZ LIBERTY O 10 MIN: 0.5 OZ LIBERTY O 10 MIN: 1 WHIRLFLOC TABLET AND 1/2 TSP YEAST NUTRIENT FERMENTATION: Escarpment Cali Ale or other clean, attenuative ale yeast 1 vial of ClarityFerm at yeast pitch Ferment at 65OF for two weeks NOTES A great easy-drinking summer beer, especially if you’re unable to brew lagers. This is my winningest beer in competitions, winning Gold at the last two Brew Slams! I target a water profile of 60 ppm Ca, 60 ppm SO4 and 40 ppm Cl, and a mash pH of 5.25. Carbonate to 2.8 vol. CREAM ABDUL-JABBAR CREAM ABDUL-JABBAR 62 | SPRING 2022 BREWERS JOURNAL CANADA

RECIPE INFORMATION BATCH SIZE: 5 GALLON OG: 1.057 SG FG: 1.010 SG IBU: 23 SRM: 22 ABV: 6.2% Hogtown Brown

GRAIN BILL:

O 6.25 LBS 2 ROW O 1.25 LB MUNICH I O O O O O 0.75 LBS BROWN MALT 0.5 LBS CRYSTAL 60 0.5 LBS PALE CHOCOLATE MALT 0.5 LBS FLAKED BARLEY 0.25 LBS GOLDEN NAKED OATS

MASH SCHEDULE: Mash for 60 minutes at 154oF

BOIL SCHEDULE: O 60 MIN: 0.5 OZ NEWPORT OR OTHER CLEAN BITTERING HOP O 10 MIN: 1 WHIRLFLOC TABLET AND 1/2 TSP YEAST NUTRIENT O 5 MIN: 1 OZ CASCADE FERMENTATION: Escarpment Cali Ale (or an English/Irish ale yeast if you’d prefer a bit less attenuation) Ferment at 68oF for two weeks NOTES:

Brown ales don’t get much love anymore but I adore this beer. Super malty and flavourful with a nice smooth body. I target a water profile of 60 ppm Ca, 40 ppm SO4 and 60 ppm Cl, and a mash pH of 5.35. Carbonate to 2.3 vol.

HOGTOWN BROWN

BREWING UP A HOMEBREW LAB

FOR THIS GADGET CORNER, WE ARE GOING TO BRING YOU

GADGET CORNERSOMETHING THAT HAS YET TO BE DONE. FOR THE NEXT FEW ISSUES WE WILL BE TAKING YOU ON THE JOURNEY OF A HOMEBREW LABORATORY BUILD THAT WILL BRING TOGETHER SOME OF THE GADGETS WE HAVE HIGHLIGHTED ALONG THE WAY WITH SOME NEW ONES THAT WILL ALL COME TOGETHER IN THE SERIES “BREWING UP A HOMEBREW LAB”. by Sheena Strauss @knowledge.on.tap 64 | SPRING 2022

As you take a look around online and in your homebrew club, you may start to see there is more interest in learning about the quality and yeast-wrangling side of brewing. Looking to preserve and repitch your favourite go-to strains? How about obtaining yeast from that special bottle-conditioned brew? What about having fun while exploring a whole new world of brewing by obtaining more data to really finetune your recipe creations. Are you ready to take that step? Perhaps you are even closer than you thought as you have been collecting gadgets and metric gathering instruments throughout your homebrewing journey.

I am excited to take you on this journey with me as this is something I have been wanting to do for many years. To complement the Homebrew Journal, I will be making a series of YouTube videos (for the first time ever) to capture this journey with you all and provide a more personal touch. I’ve been laying low for a bit on IG to help prep for this along with some other surprises and looking forward to seeing you all online again on @knowledge.on.tap.

Let us all learn, create, and share together! :D

And who knows, maybe with your own homebrew lab you can have a competitive advantage at landing a job in a commercial brewery?

Let’s get it started!

First Thing’s First - Perfection is the Enemy of Good!

This is something I always tell myself because setting the goal of perfection is a sisyphean task, very often smacking up against the wall of diminishing returns. Failures breathe life into our knowledge base and make our foundations stronger. It also helps us to be more empathetic, gain insights that can be used elsewhere, give us the confidence to face more issues that come our way and share our experiences with others. Bottom line: we will mess up AND we will learn from it and be brewtastic because of it!

Second - Save Up $$

We all know that brewing can be an expensive hobby depending on how you choose to move throughout your journey. Depending on where your interests are, the challenges you choose to accept, the time and space you have, and financial resources available to save, it will naturally mould and shape the outlook of the lab. That said, ‘Rome wasn’t built in a day’ right? Rolling it out in phases will help a lot for the wallet and make it way more manageable and enjoyable. You want time to play with your new toys too, right?

Taking time with a phased rollout may help financially as you may get lucky and be able to find some used equipment online, from a local university or business, in auctions, etc. And you may also be able to wait for a good deal if items go on sale. Let people know in your networks what you are looking for and see if anyone can help seek out some deals or share a connection they have.

For example, I used to work in the quality lab in pharma, and every time there was glassware that wasn’t up to the ‘audit-readiness’ standards they would throw them out. I asked if they were going to donate to a highschool lab and they weren’t at the time so I “offered” to help reduce the waste a little by taking it off their hands. The glassware is good pharma laboratory grade borosilicate from VWR. There was even an awesome sales rep I was talking to about my homebrew lab and they had a pipette to donate to the cause!

Third - Inventory Audit & Purchase Lists

Before getting carried away with that dream bubble (it is fun though, right?!). Let’s take a moment and take inventory of what we currently have for the lab and list out our basic lab needs and wants to plan and save up for. Listing these out can prevent purchasing items you already have, remind you of what you may need to purchase, and help guide your phased journey.

For myself it looks like this:

Try not to be intimidated by the list above and the names used for items may not all sound very familiar right now - like with anything new or relearning something that was taught in school you are not expected to remember or know this. The goal is to give an example of my current approach and as I’ve been brewing for some time, and have worked in a quality lab,

I have a few things collected.I will guide you through my journey and, soon enough, you too will become more familiar with the terms and equipment, how you can use a kitchen appliance as a home sterilizer (looking forward to testing this out), why a microscope can be useful, and so much more.

Now on to Phase I: Source and Purchase a Lab Bench

I was going back and forth on whether I wanted to build a table and make an epoxy resin top with a cool bottle cap design that also showcased other items that inspired me throughout my journey. The time and learning process alone was a bit of a non-starter for me at the time, so that was out.

Then I moved on to looking online and at auction sites to see if I could get a traditional lab bench from what you may have seen in highschool or a really awesome Laminar flow fume hood - how cool would that be, right? I haven’t seen anything that would fit my budget so now I am set on the tried and true, easier to clean and sanitize (e.g. with 70% isopropyl alcohol) stainless steel table. Keep in mind the surface material must be chemical and flame resistant, and cleanability will be factors necessary to consider when taking into account the ability to create a clean aseptic environment for dealing with microorganisms.

As you can see from the photo, I do not have that piece yet. (in progress)

Once the table is in place we get everything set up and ready, I will take you through what the next Phases will be.

SPENT GRAINS… THREE WAYS!

I ABSOLUTELY HAVE TO INTRODUCE YOU TO A FRIEND AND FELLOW CO-WORKER FROM

ESCARPMENT LABS’ FOOD

FERMENTS DEPARTMENT, AINSLIE FORBES. HER CREATIVE, PASSIONATE SPIRIT RESONATES WHEREVER SHE IS AND YOU CAN USUALLY FIND HER

RESEARCHING FOR THE NEXT PROJECT/TOOLS

TO RESOURCE OR BUILD. AND IN THE NEW FLEX

LAB SHE CAN BE FOUND

CREATING RECIPES AND EXPERIMENTING WITH ALL SORTS OF FOOD FERMENT PROJECTS

LIKE KOMBUCHA SCOBYS, SOURDOUGH, KOJI, HOT SAUCE, AND MORE. AINSLIE ALSO WORKS

TIRELESSLY TO CREATE, PLAN, AND EXECUTE DELICIOUS MONTHLY FOOD FERMENTS LUNCHES AND SENSORY PANELS FOR ALL TO ENJOY!

by Ainslie Forbes

Introduction by Sheena Strauss

We have shown you recipes to use your brew in and even what you can do with wet spent grain, now what about how to make and use dry spent grain?

For this issue of the Homebrew Journal, Ainslie will be experimenting to come up with the best way to keep your spent grains for post-brew day recipes.

Take it away Ainslie!

Brewing can be very wasteful with all the water and grain used. An awesome way to cut down on the waste of your brewing process is to reuse your spent grains. It may seem overwhelming dealing with a bunch of wet grain, but it can be very quick and an awesome way to add unique flavour to your cooking. I am gonna go over a few ways to process your grain efficiently and safely using what you already have in your kitchen.

The most important thing is to process your grains right away. If you let your grains sit for too long the moisture in them can cause mold growth or other pathogens. If you’re not ready to deal with your spent grains right away you can always freeze them on a sheet pan and thaw them when you are ready.

There are three main methods which I’ll go over. Freeze drying is arguably the easiest out of the three, followed by dehydrating, and oven drying.

BREWDAY TIPSMethods Freeze Drying Is by far the most foolproof. Unfortunately, it is the most out of reach for people because of the equipment needed. Most people don’t have a freeze dryer. What I love about this method though is that you can spread all of the spent grains on the trays and turn on the machine and it will be ready in the next 2 days. No need to babysit. SPRING 2022 | 67

Is another great option if you have access to one. There are also some affordable dehydrators available online or at a variety of department stores. Most dehydrators have holes big enough for the spent grain to slip through though so to help mitigate this use parchment paper cut to size and place spent grains on top. In the specific dehydrator I used, it had a hole in the middle of the tray, so I made sure to cut a hole in the parchment in the same space to allow air flow. I then set the temperature to 105℉ (40°C) and left it on for a weekend.

Oven Drying

Is by far the most tedious method, but is the most attainable without buying another machine. For best results, turn your oven onto the lowest setting possible, ours was around 160°F (70°C). Spread spent grains on a baking tray that is lined with parchment paper and put them in the oven. This method will take anywhere from 8 to 12 hours (or more!) Make sure to stir every so often, I suggest every 30 minutes in order to prevent burning and or cooking. If your oven holds moisture, make sure to pay extra attention to stir often to let the steam out. If, like me, you aren’t able to finish dehydrating the spent grain in one day you can always freeze the tray as is and start again when you have time.

1. Freeze Dried: Has a softer mouth feeling, Tastes the most like the original grain. Optimal to still add a nutty flavour but remain as a neutral. 2. Dehydrated: Has a more rough texture and tastes a little bland. Definitely, my least favourite of the three. 3. Oven Dried: Has the roughest texture and tastes almost caramelized. A very pleasant taste for a recipe that needs a deeper flavour.

Next Steps

Although you can use the spent grains whole after dehydrating, I like turning them into spent grain flour. Using a blender, I will add the dehydrated grains and blend them into a fine powder. It can then sit in your pantry for months until you want to use them.

What to Make

You can make a ton of recipes with spent grains. My favourite way to find new recipes is to modify an existing recipe. First I’ll find a recipe that I think will benefit from the nutty flavour that spent grain brings. Then I’ll check the ingredients; if the recipe has one AP flour, whole wheat flour, orwhite flour, I suggest replacing around 5-15% of it with spent grain flour. If your recipe

1.

2. 3.

has a mix around 66-75% white flour or 25-34% whole wheat flour I suggest replacing all of the brown flour. You can also replace ingredients like oats with the whole spent grains. Overall, I suggest starting with a smaller replacement and gradually increase until you achieve your desired flavour without compromising the integrity. And don’t forget that you will need to increase the amount of sweetener in the recipe because the sugar that was in the grain will now be in your beer! ATTN: Make sure to write the grain profile on the container of spent grain so you can know all of the allergens.

Ainslie’s Favourites:

o Spent grain pancakes: Using the “Joy of o Cooking” cookbook. Dog treats: Make sure there are no rice o hulls or hops! Fancy Crackers: Again, make sure grains have no rice hulls!

FROM JANES AND JOES TO ALL-OUT PROS

RUBBING HOPS FROM OUR HOPS FIELD PRE-HARVEST. THIS PARTICULAR DAY, I WAS SELECTING BINES TO DO IN OUR FIRST ESTATE WET HOP BEER

Name: Sarah Casorso Location: Niagara Falls, Ontario Brewery: Bench Brewing Company Time in Professional Brewing: 5.5 years Job Title: Director of Operations and Brewmaster Time as a Homebrewer: 5+ years Daily duties: I more or less touch all facets of the manufacturing department! This includes process and recipe development, innovation, production planning and scheduling, facilities maintenance, hiring, people management and, of course, I pop in to do a brew here and there!

How did you transition from homebrewer to where you are now?

I actually got my start brewing on an 8HL brewhouse! However, I have helped out friends homebrew here and there in between production brewing.

I am where I am now partly because of ambition and partly due to being at the right place at the right time! I skipped the school part and got my start on the job, there was a lot of self-learning.

THIS WAS RIGHT WHEN WE FIRST STARTED BREWING OUR FIRST BATCHES OF BEER AT BENCH. MARC AND I WERE BREWING AND LEARNING THE SYSTEM TOGETHER

What inspired you to pursue this as a career?

The creative aspect is most appealing to me! It’s so satisfying getting to taste that final product you designed.

WE WERE STILL UNDER CONSTRUCTION AND SO WE HAD TO WEAR HARD HATS!

Fun homebrew story?

I would recommend not having rambunctious dogs around when you’re trying to finesse a good sparge and lauter over to the kettle…no tails caught fire but some small vessels were tipped. :D

Advice for homebrewers?

Patience! Like anything, practice makes perfect. Don’t get discouraged if a batch doesn’t work out, there are many variables that can make homebrewing a good beer quite challenging.

What exciting things are you currently working on?

We have an awesome little 4HL pilot system here at Bench that has been our backbone for innovation for the last couple years. Currently, we’ve been trying out some new post-fermentation adjuncts that have turned out really well, including an

Oak pilsner and an Earl Grey Blonde Ale with local honey! We’re also always trialling new fun

IPA’s and fruity funk beers!BREWING ON OUR 4HL PILOT SYSTEM

STEPPING UP THE MASH AND PITCHING YEAST AT THE END OF BREW