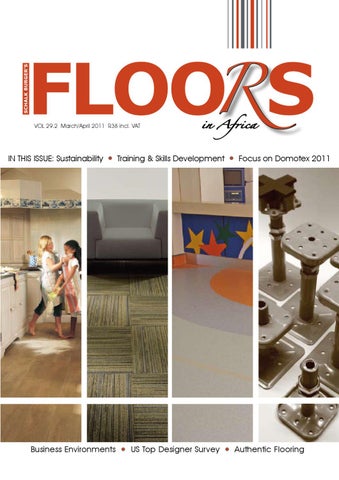

VOL 29.2 March/April 2011 R38 incl. VAT

IN THIS ISSUE: Sustainability • Training & Skills Development • Focus on Domotex 2011

Business Environments • US Top Designer Survey • Authentic Flooring

REFERENCE Guide

COVER STORY Almost 40 years of outstanding customer service Formed almost four decades ago, Peter Bates Flooring has been providing a superb service to customers with the installation of a wide range of quality floorcoverings. A pioneer in the realm of access flooring, Peter Bates Flooring is recognised as being a leader in this genre of the floorcovering industry, and has also gained an outstanding reputation for quality installation and customer service with a sales programme that also includes carpets and carpet tiles, wood and laminate floorcoverings, and vinyl sheeting and tiles. A recent revamp of the company branding has taken place….see the full Peter Bates profile on pages 32-35 of this issue.

51

73

85

93

Access Flooring Bates Access Flooring Peter Bates Flooring

p97 FRONT COVER, p32 - 33

Adhesives / Coatings a.b.e. Construction Chemicals Chryso SA FloorworX Smoothedge Tile & Floor Care Zimbo’s Trading

p47 p47 p55 p49 p92 p5

Carpets Belgotex Floorcoverings H&M Flooring Nexus (Belgotex Floorcoverings) Peter Bates Flooring Selborne Carpet Wholesalers Van Dyck Carpets

p2 p43 p2, p58 - 59 FRONT COVER, p32 - 33 p48 p6, p12 - 13

Ceramic, Porcelain and Stone Falcon Tiling Products H&M Flooring Tile Africa Tiletoria

V OLUME 2 9.2 • MAR CH/APRIL

•

2011

p41 p43 p31 Inside Back Cover

To page 5

F LO O R S M a rc h A p r i l 2 0 1 1

3

COMING UP! RESIDENTIAL MARKET:

COMMERCIAL MARKET:

Three hot topics in the next issue that will make it hard to put down! Don’t miss this one!

Carpets

DISTRIBUTION:

135 000 COPIES What does partnering with the GREAT FLOORING GUIDE give you? A B C D E F

Aproximately 1 million actively buying consumersB Spend less, reach more Largest décor print order in S.A Multi-platform exposure: print, online & exhibitions Experienced expertise ALL OF THE ABOVE

This is our annual review of the carpet sector and, as the main feature, it covers inspiring carpet ideas, materials, and design applications to broaden the specifiers’ professional creativity. This article will feature new products as well as tried-and-tested carpeting for decoratively finished interiors, and we will look at the latest trends that are happening both locally and overseas.

Final Floor Solutions

Some systems and treatments are essential, others merely cosmetic, but architects, designers, contractors and developers need to know what is available in the wonderful world of floor finishes. Trims, joints, coatings, sealants, screeds, mats and rugs, skirtings, application techniques, aftercare, anti-slip treatments, polishes, antistain treatments – the list is endless, but this issue will aim to bring all these solutions to the fore to enable people to get the very best out of their floors, in terms of both aesthetics and functionality.

Residential Specification Choices

DEADLINE: 31 MAY 2011 DISTRIBUTION SCHEDULE AUGUST 2011 • DECOREX JOHANNESBURG 4 000 copies SEPTEMBER 2011 • Tuis 60 000 copies • Home 36 000 copies • ELLE DÉCORATION 31 000 copies

OCTOBER 2011 • FLOORS in Africa 4 000 copies ONGOING • Online publishing (supported by on-line advertising andpress releases)

Tel 012 347 7530 Fax 012 347 7523 E-mail joanna@mediainafrica.co.za Website www.mediainafrica.co.za

This feature is dedicated to the flooring product options for security complexes, townhouses and upmarket residences. We will be speaking to real estate managers, design professionals and developers to find out what specification options are available.

Roxanne Mancini: roxanne@mediainafrica.co.za Joanna Papastamopoulos: joanna@mediainafrica.co.za Tel: +27 12 347 7530 www.mediainafrica.co.za

REFERENCE Guide Cleaning & Maintenance FloorworX Matco Marketing MilliCare

p38 p71 p7

Exterior Flooring & Paving Belgotex Floorcoverings H&M Flooring

p2 p43

Industrial, Resin & Concrete Flooring a.b.e. Construction Chemicals Cemcrete Chryso SA Flowcrete SA Lafarge SA Sika SA StonCor Africa Resilient Flooring Belgotex Floorcoverings FloorworX H&M Flooring Peter Bates Flooring Polyflor SA Tuff Floors

continued from page 3

p47 p84 p47 p61 p78 - 79 p37 p40

p2 Inside front cover p43 FRONT COVER, p32 - 33 p50 p64

Underfloor Heating Speedheat

p65

Seamless Flooring H&M Flooring Quartz Carpet StonCor Africa

p43 p3, p9 p40

Training & Skills Development Belgotex Floorcoverings Academy Cemcrete FloorworX Lafarge SA

p80 - 81 p84 p82 - 83 p78 - 79

Wood, Laminates & Bamboo Barrow Flooring H&M Flooring Peter Bates Flooring Rhoms Timberworld Suntups Solid Wooden Flooring Teragren Tiletoria

Back Cover p43 FRONT COVER, p32 - 33 p98 - 99 p39 p69 Inside Back Cover

Accessories and other Falcon Tiling Products Genesis Kirk Marketing Pretoria Institute for Architecture The Office Plant Transiton Transport (Transportation)

p41 p8 p29 p101 p105 p102 - 103

Note: Editorials excluded, listed in alphabetical order

Wood specifying

at its best! MEMBER

“TM”

S.A. WOOD & LAMINATE FLOORING ASSOCIATION

Cape Town +27 21 511-4693 | Johannesburg +27 11 794-1012 info@zimbostrading.co.za | www.zimbostrading.co.za

F LO O R S M a rc h A p r i l 2 0 1 1

5

leaders in the flooring sector.

FLOORS is about ceramics, carpets, vinyls, wood, laminates, marble, granite, cement, stone ... any floor you can think of. It is also about accessories like rugs, adhesives and tools. Readers are welcome to contact us for any information. FLOORS is published six weekly by Media in Africa (Pty) Ltd. The views expressed by contributors are not necessarily those of the editor or publisher. We accept no responsibility for information published. PUBLISHER: Media in Africa (Pty) Ltd. Contact information: Tel (012) 347 7530 Fax (012) 347 7523 International: +27 e-mail: floors@mediainafrica.co.za PO Box 25260, Monument Park, 0105; Republic of South Africa Unit G, First Floor, Castle Walk Corporate Park, Cnr Nossob & Swakop Streets, Erasmuskloof Ext. 3, Pretoria, RSA

Unique Authentic Flooring: Original floor type applications

Founder:

EDITORIAL Comment Liezel van der Merwe

Roxanne Mancini

Second quarter here we come! Floors in Africa is excited about what the industry will reveal this year, and with positive feedback from the industry we look forward to a wonderful year for everyone in this very niche sector of the built environment. In this issue we focus on many important topics, namely Sustainability (pg 51 ), Training & Skills Development (pg 73), Authentic Flooring (pg 85), and Business Environments (pg 93): In the search for Sustainability: Sustainability isn’t just about using a product with a green label for your flooring application. Floors in Africa takes an in-depth look at lifecycle costs, innovative green technologies and flooring products that have a minimal impact on the environment. Needed Training & Skills Development: The success of a company can be attributed to skills development of stakeholders and information sharing within the industry. This issue takes a look at what training initiatives and skills development are being undertaken by industry

offer an unmatched aesthetic appeal. This feature will

Schalk Burger

ensure that specifiers, designers and developers have all

Editor:

the solutions and product information they need for these

Liezel van der Merwe Cell 082 7700 799

real traditional and sought-after flooring installations. Demanding Business Environments: Office parks and commercial enterprises have a different set of requirements and range of flooring product solutions. This issue will focus on the trends and techniques for flooring in business environments. We also as always offer you views and news from around the world with our much-anticipated Domotex Review (pages 16-27). If you couldn’t attend, don’t worry – in the pages that follow we will direct you to the most important feedback from this gigantic international showcase!

Financial Director: Fanie Venter

News Editor: Dave Soons Tel 012 807 7012

Business Unit Manager: Roxanne Mancini Cell 082 779 5751

Business Unit Co-ordinator:

FLOORS In Africa also brags its latest appointment –

Madelein Smith

Joanna Papastamopoulos (yes, Greek!) She will assist

Client Support:

from a client excellence point of view.

Joanna Papastamopoulos Cell 072 300 0867

Floors Sincerely,

Design and Layout: Jakolien Strydom

Financial Manager: Gerda Bezuidenhout

Proofreader: Liezel van der Merwe

Roxanne Mancini

Signa Evans

EDITOR

BUSINESS UNIT MANAGER

REPRO & PRINTING: Business Print Centre

8 173

FI nena ot uv raet i Foonc & u sD: eAsui tghne n t i c F l o o r i n g

With the world’s largest range of high quality

For your copy of

finishing profiles for floors and walls always

the new Genesis

delivery anywhere in South Africa.

0800 00 6173,

in stock, choosing Genesis ensures on-time Ask for our full colour 108 page catalogue

and discover what makes Genesis the market leader for quality, choice and service in the flooring profile market.

catalogue, call

email genesis@tfc.co.za or visit the genesis website:

www.tfc.co.za

www.tfc.co.za Toll Free 0800 00 6173

www.tfc.co.za Toll Free 0800 00 6173 www.tfc.co.za Fwww.tfc.co.za LO O R S M a rc h A p r i l 2 0 1 1

Innovation & Design

Do it right first time, every time! “Our architect recommended using Quartz Carpet. We wanted the job done properly the first time – with professionals and guarantees. We were thrilled when we discovered flooring that could be used inside our bathroom, as well as outside around the pool.” Kathy Gibb (owner)

T

he architect, Michael Borgstrom from Archilab, needed to open the apartment up as much as pos-

sible, working with minimal materials, and he said, “We like to use Quartz Carpet around the pools and in showers and bathrooms because of its non-slip properties and its continuous effect.” “There are other players in the so-called seamless market, but they do not offer the same product, so Quartz Carpet is pretty much in a category of its own,” he said. Kathy the homeowner continues that she is absolutely thrilled with the finish, “It is neat, it looks and feels great and it wears very well. We have had tenants in that apartment, so it was important that the fittings and finishes handle well,” she said. Jeremy Stewart from Quartz Carpet was not surprised by their comments and adds that the architect has done a great job with the apartment and says that such is their faith in the product that Quartz Carpet offers a 5-year warranty, which extends to the non-yellowing of the floor, once it is exposed to South Africa’s harsh UV conditions. Tel: 086 1782 789 Website: www.quartzcarpet.co.za

F LO O R S M a rc h A p r i l 2 0 1 1

9

Innovation & Design

Héctor

Unlimited Space

Ruiz-Velázquez’s

When asked to transform the attic space of an early 20th Century building in Madrid into a selfcontained, modern living space, architect Héctor

I

nstead of taking the existing rooms as a starting point, Ruiz-Velázquez

placed a large three-dimensional object in the space, creating a play of heights and a second level. The mezzanine-like structure not only provides a separate sleeping area and extra storage, but also screens off a kitchen area and bathroom. Entitled Unlimited Space this has been built out of ‘a total freedom of layers’. As if the design would be a three-dimensional object, every one of the rooms or points of the home can be located by specifying the axis of coordinates. The result is the power to move around in a few square metres at different heights, going up and

Ruiz-Velázquez had to think outside the box, and

down, offering a new experience of

created multiple level living in a single storey

to explore the space. The transition

space for the Ceramic House project.

roominess in the context of a home, between the rooms is continuous and lets the movement flow freely across the numerous levels.

10

F LO O R S M a rc h A p r i l 2 0 1 1

Innovation & Design

Floors in Africa contacted Héctor Ruiz-Velázquez for his comment, and he said, “This is a dry system installation that can be totally reused if someone has to move from the house to another one. Because of the way is built it is totally sustainable (dry system doesn’t have a heavy construction), and it minimises the environmental impact because of not having waste on site,” he says. “It is also without noise in the installation, which is good for the environment.” The spatial flexibility that transforms this home is an innovative housing concept which adapts itself to the actual necessities and to the new usages, where roominess, brightness and time flow in a multifunctional space without corners or precedence. It is also about expanding the parameters of interior design as well as the conventional trends of arrangement. This project was in response to an assignment by ASCER (Asociación Española de Fabricantes de Azulejos y Pavimentos Cerámicos – the Spanish Association of Tile and Ceramic Flooring Manufacturers) for the creation of a new living concept, where the ceramic tile receives special treatment that turns it into the indisputable protagonist of the space. Ceramic tile is a material which, due to its versatility of application, offers multiple possibilities in its planimetry. According to the architect’s objective, the ceramic tile thus transforms itself into an excellent dynamic entity able to offer the luxury of working in three dimensions. “Change and continuation” and “tradition and innovation” simply unfold with a new angle on the use of ceramic material. “The conquest of the square metre has become one of the major concerns of our times. The unaffordable prices and the shortage of living areas in the city have called for a redefinition of the spaces we live in,” says Ruiz-Velázquez. “In this attic design of only 50m² in the centre of Madrid, we tried to use every centimeter of available space, combining efficiency, spirit and sensibility by means of aesthetics

Héctor Ruiz-Velázquez’s

and function.” Héctor Ruiz-Velázquez has a degree in architecture from the University of Virginia, USA, and founded his own architectural office in 1992 as a culmination of an extensive professional practice that includes large-scale architectural projects to corporate image concepts. A characteristic of his studio is its diversity not only in its cultural aspects but also regarding the professional disciplines. The studio covers projects from urbanism to graphic design, industrial and interior design, photography, as well as integral corporate images. Projects by Héctor Ruiz-Velázquez have been featured in numerous international and global publications and he has been invited to lecture at niversities and public and private institutions in different parts of the world.

F LO O R S M a rc h A p r i l 2 0 1 1

11

Innovation & Design

12

F LO O R S M a rc h A p r i l 2 0 1 1

Innovation & Design

F LO O R S M a rc h A p r i l 2 0 1 1

13

Innovation & Design

US Top Designer Survey 2010 Floor Focus, the well-respected magazine for the

but corporate work is nearly back to 2008 levels. Here are the top

US flooring industry, runs an annual survey of the

over the previous year.

four; all the others recorded 5% or less with little if any variation

250 top designers to find out their views, trends

2010

2009

1. Healthcare

32%

33%

results for 2010 are very interesting.

2. Education

20%

23%

A

3. Government

25%

19%

4. Corporate

10%

4%

and preferences for flooring materials, and the

fter 2009, which had been described as the toughest year in recent memory for the US design community – with the

recession and the credit crisis the main causes – there was some recovery during 2010, including the corporate sector which had been one of the hardest hit the year before. Vinyl flooring also set the pace during 2010.

Designers’ priorities With quality the top priority for the first time since 2007, and style selection dropping to second place, ‘confidence in company’ is even

In another sign of how tough things are, the survey shows signs

more important this year, and price takes a definite back number.

of a faltering commitment to sustainability by the architectural and design community, although it still continues to play a central role

2010

in the greening of the built environment.

2009

1. Quality

25%

19%

turer’s commitment to sustainability as the most important factor in

2. Style selection

24%

25%

deciding who to do business with. Only 61% consider the green

3. Confidence in company

27%

11%

elements of a floorcovering as important when specifying prod-

4. Service

13%

16%

However, not a single designer in the survey names a manufac-

ucts, compared to 73% two years ago.

Top Projects Designers reported on their top three projects of 2010 and the results show a continued growth in government jobs as well as small office work, which is largely tenant improvement. Healthcare

5. Appearance retention/performance

9%

13%

6. Personal relationships

5%

3%

7. Salespeople

4%

5%

8. Price

3%

6%

9. Commitment to green

0%

2%

was down 4% and hospitality was also down, as were large and

What influences product choice?

medium corporate jobs – down for the third year.

This item is where the US market differs from the South African the 2010

2009

most, because ‘Mill reps’ at 43% has doubled over the past five years

Healthcare

26%

30%

as the biggest influence on product choice, and ‘Contract dealers’ is

Total Corporate

24%

22%

Large & Medium (non-Fortune 500)

(12%)

(15%)

Fortune 500

(5%)

(5%)

Small office

(7%)

(2%)

Total Education

22%

20%

Technical advice

University

(16%)

(16%)

There is a swing away from designers turning to each other for

Other

(6%)

(4%)

advice as the Internet takes over for the first time.

Government

10%

7%

to have the same influence locally. ‘Architect folders’ has remained steady at 30% (down 7%, at second), but all the other choices come in at less than 10%.

Institutional/Public space

7%

8%

2010

2009

Hospitality

5%

8%

1. Internet

26%

25%

Retail

3%

3%

2. Other designers

21%

25%

2%

3. Mill reps

19%

14%

Residential

2%

4. Contract dealers

14%

13%

5. Magazines

13%

14%

Healthcare topped this list for the third year in a row, and education

6. Mill literature

4%

5%

once again claimed the second spot; government work weakened,

7. Fibre producers

3%

3%

What new markets are you going for?

14

third with 7% (up from 2% the previous year), but these don’t seem

F LO O R S M a rc h A p r i l 2 0 1 1

Innovation & Design

Technical details

Looks – the modern, contemporary, cutting-edge looks are

Stain resistance always seems to be cited as the most important technical detail, and even more so this year. Wear layers shows the biggest gain.

today’s ‘in’ trend although there is still a leaning towards the sophisticated and the classic looks. Wood visuals are out.

Hot products 2010

2009

2008

Carpet tile is still leading the pack by a wide margin, linoleum has held

1. Stain resistance

97%

92%

77%

the second spot for three years, and luxury vinyl is climbing the list.

2. Backing

66%

76%

55%

3. Wear layers

62%

55%

47%

4. Environment

61%

66%

73%

1. Carpet tile

73%

77%

4%

5. Safety

56%

57%

51%

2. Linoleum

46%

41%

23%

6. Antimicrobials

53%

51%

39%

3. Luxury vinyl tile

44%

36%

16%

40%

35%

46%

35%

41%

9%

2010

7. Lifecycle costs

51%

51%

48%

4. Bamboo

8. Fibre brand

43%

53%

38%

5. Rubber

2009

Don’t use

Key manufacturer features

6. Ceramic/porcelain

31%

31%

0%

7. Cork

29%

35%

50%

Warranties and Turnaround time tend to be the most important

8. Sheet vinyl

29%

27%

16%

9. Hardwood

27%

18%

28%

10. Area Rugs

25%

25%

49%

11. Stone

25%

20%

17%

12. Laminate

19%

16%

34%

13. VCT

14%

17%

10%

14. 6ft. rolls

13%

13%

42%

15. Broadloom

7%

5%

7%

manufacturer features and this year they tied, with half the designers saying these will make or break a purchase. Once again Custom Work lost ground. Make or

Added

No impor-

break a

benefit

tance

purchase Warranties

49%

49%

2%

Fibres

Turnaround time

49%

46%

5%

1. Nylon

25%

15%

14%

Sustainability

30%

62%

8%

2. Wool

15%

20%

59%

Custom Work

8%

59%

33%

Specification Process Wish List

Top Problems Improper installation remains the top problem, but it must be seen as an improvement at 30%, considering it was at 50% five years ago.

(not ranked)

The main designer gripes were focused on pricing issues, and lack of consistency in the provision of information; in these cases they were looking for standards. Sampling also comes under scrutiny regarding waste and sustainability.

2010

2009

1. Improper installation

30%

30%

2. Poor maintenance

20%

29%

3. Product quality problems

16%

10%

structure is ridiculous and that even with quoted material costs and

4. Slow delivery

8%

6%

an estimated installation cost, there is still no accurate way to predict

5. Moisture

8%

6%

price. Lower price is a perennial wish.

6. Inconsistent pricing

7%

7%

7. Bad product advice

4%

7%

8. Poor project management

3%

2%

Comment was also made on inaccurate samples and low-VOC adhesives not performing.

What’s in now? Colours – Neutrals top the colour trends with designers, reflect-

Open, realistic pricing of designs, with ‘everyone being on the same page’, and a better understanding of costs to help with selection on a budget are the main concerns. Most designers say that the pricing

Better information and universal terminology on products to be able to make better comparisons. More testing information required. Better sampling. Here the accent is on the environmental issue of carpet books being a waste – particularly with the advent of the Internet, although the websites must deliver quickly, including pictures, and with better online depictions of images, and more installations shown. Improved green: the main points are calling for a standard format

ing flooring’s support role in interior design, but this year they are

for green qualities; making recycling mandatory; more consistency

particularly trendy and more nuanced than ever, particularly with

and less cost in take-back programmes; improvement on quality and

a wide range of greys. Green is also strong; purples and red hit the

price points of green products.

bottom of the list. Patterns – Organic patterns continue to lead the trend, along

Other wishes on the list include faster lead times, better communication (more knowledgeable staff ), improved installation; the stopping

with contemporary, clean looks. Linear patterns are still favourites,

of contractors from changing specifications, and the elimination of

but natural look-alikes and circles seem to be out of favour.

false claims about no-wax floors.

F LO O R S M a rc h A p r i l 2 0 1 1

15

Focus on Domotex 2011

Hot new product trends

at Domotex 2011

Every year Domotex provides a wonderful showcase for innovations and new products, and 2011 was certainly no exception. Here is a selection of some of the ideas and trends which demonstrate the fact that the floorcovering industry is a mine of ingenuity, creativity and imaginative ideas.

1 Claimed to be the world’s first industrially manufactured hardwood

face design software, that offers a new ecological approach to the floor-

flooring with naturally curved lengths that follow a tree’s natural

ing industry. The timber usage efficiency is significantly higher than

growth, which means that no two floors are alike.

straight-board solid floors, resulting in more floors per harvested wood.

This truly innovative technology combines a scanning system for the

www.bolefloor.com

boards, custom-made algorithms which optimise the cut, and floor sur-

2

Introducing the next generation of resilient elastic flooring, this patented interlocking system is laid quickly, cleanly, and simplywithout the use of adhesives. This new collection includes 12 attractive wooden designs, each

For the first time, this company is launching composite parquet floors that are finished with high quality oil, to meet the demand for a 100% authentic look and feel. The oiled parquet floors are ready for immediate use and do not require any waxing or sanding. In addition to the enhanced natural and matt effect, this oil makes the floor more resistant to stains and scratches than other oils. These oiled floors are also very easy to maintain. A stain can easily be wiped away or cleaned with the maintenance kit. Combined with a regular clean using its proprietary oil care, the parquet floor is kept fresh and healthy. After a local or total treatment, light scratches disappear. www.quick-step.com

4

equipped with a 0,5mm wear layer and additional PU coating. www.windmoellerflooring.de A product innovation that brings together the natural beauty and strength of wood with the convenience and durability of vinyl tiles. It is a luxury tile solution uniquely constructed with a wood veneer layer and reinforced with a thick protective vinyl wear layer to ensure a long-

Wool is an eco-friendly product

lasting, extremely resistant and easy to maintain surface.

that provides comfort, durabil-

With a non-repeating natural wood design, it offers an elegant and

ity and easy care properties. It

highly practical solution for the high traffic needs of the retail and hos-

also has the ability to insulate

pitality sectors with simple and quick installation.

the room, reduce noise pollution

www.tarkett.com

and balance the humidity within

3

a location, plus it is non-slip, anti-static and flameproof: a very modern fibre. Flatwoven carpets are one of the trendiest products currently available, using combinations of natural wool, flax and jute. Also available in rugs. www.creatuft.be

16

F LO O R S M a rc h A p r i l 2 0 1 1

5

Focus on Domotex 2011

These innovations in the realm of laminate flooring and adhesive-free One of the latest state of the art solu-

laying systems are regarded as having been developed as the new

tions is the introduction of a new

premium brand for the trade. Unusual laminate flooring collections will

locking system for cork floors, which

be created with the new brand, each of which will stand out for their

is a single action installation system

special characteristics.

with angling on the long side and a

The PoS presentations will be of correspondingly high quality. In

flexible tongue to fold the short side,

the company’s own shops or areas with special brand equipment, this

making it faster and easier than con-

product will be presented to customers in a noticeably premium look.

ventional locking systems.

The trend studies of the company show that customers are either

This is one of the most advanced

increasingly looking for good value offers, or something exclusive. The

locking systems on the market. The

new premium brand meets the customer demand for exclusivity.

flexible tongue inserted in the floor-

7

www.extravagant.classen.de

board makes it possible to install the cork flooring with a single action, and it is anticipated that this type of installation will gradually replace the conventional angling/snap and angling/angling systems. www.wicanders.com

6 10

The success of its collection with 24 water-resistant floors incorporating the Hydro Plus technology without bevels, has convinced this company to make this range available on bevelled products, with an elegant

10Less noise…more style with acoustically absorbent flooring that delivers excellent sound isolation. It muffles 20dB of sound in

micro-bevel on the four sides of the plank.

comparison with the average 4dB

This ensures there is no risk of seeping or deformation, so those floors are extremely suitable for high moisture rooms like the bathroom,

reduction offered by other types

laundry and kitchen but can also be used in the rest of the house. Dirty

of hard floor. That’s five times

shoes, kids trying to do the dishes, leaking washing machines.... no

less noise and five times more

problem at all !

comfort.

www.berryfloor.com

8

www.ivcgroup.com A wide range of tufted artificial grass that can hardly be distinguished from real grass; produced with high quality yarns, they are very durable and require very little maintenance. Ideal for gardens, public green areas, playgrounds and much more, artificial grass has become a real option in public spaces. www.orotex.com

11

Using the latest technology this company displayed its new Saxony collection that is distinctive because of its broad, colourful stripes combined with matching solid colours and trendy silk-look products Contract and domestic carpet made from polyamide presents an innovative product portfolio with the option to add any individual design. This new segment combines its strengths with innovation. The newcomers in the standard range incorporate the trendy silk-look aspect for a splendid presentation as shiny floorcoverings made from 100% Imprel polyamide and designed for heavy wear areas. www.baltagroup.com

9

Described as being a new dimension of floors, Italian design and creativity make this a unique and exciting floor with finishes in wood, stone, metal and natural materials combined with the resistance of vinyl floorings. Designed for areas with medium and heavy traf-

12

fic such as shops, showrooms, cafes, restaurants, airports and stores, this range reveals a world of emotions, styles and moods, guaranteeing very high performance and durability; it is also a floor that is easy to maintain and fast to lay, supported by all the certification required by current legislation. www.virag.com

F LO O R S M a rc h A p r i l 2 0 1 1

17

Focus on Domotex 2011

Still hand in hand with the latest trends, this new laminate collection achieves simplicity and balance. This is reflected by the ongoing success of white floors for interiors, which has a feeling of satisfaction and creates trust, bringing calmness and hope in times of stress. With white ranges already on the market, 2011 sees a shift being made to a warmer shade of white, moving away from the cool effect. Within this context the importance of feelings and intuition is also growing and has led to emotional design, which means that sensual materials and structure that you can feel are becoming more important. This has been translated into a new range of planks in a unique size. www.quick-step.com

13

Water and laminate is not an issue anymore with the invention of the first 100% water resistant laminate floor. Because of its unique qualities, this product can be used for extensive residential and commercial applications where traditional laminate flooring cannot. There is a complete range of warm and cosy wood designs

14

with different finishings and matching skirtings, together with a collection of stone designs with the same look and feel as the wood designs. www.aquastep.be Here a new colour concept for its injection-moulded products is launched by this company with the creation of five new colour

With this new, eco-sustainable protection system this company provides a complete range of var-

15

ranges. In addition, a further function scale has been created for the company’s line of functional floors for sports and marine applications. Over 30 colours are available with each range being associated

nishes, oils, grouts and accessories

with an emotion and featuring colours that are harmoniously coor-

for parquet which combine perfect-

dinated.

ly with their innovative adhesives

www.bergoflooring.com

for laying wood. This provides easy

16

application and maintenance, and long-lasting protection, even for highly stressed parquet. There are six products in the system: a solvent-free water-based grout with a low VOC emission level for joints in wood floors treated with a water-based varnish; twocomponent water-based primers; and a choice of varnishes providing a high resistance to wear and abrasion, particularly those with intense pedestrian traffic.

wood looks. One range has nine popular wood finishes, and the other provides planks with nine rustic finishes to meet any commercial or home requirement. Quiet, hardwearing and easy to keep clean, these ranges are hypoallergenic; have an anti-scuff urethane finish; are suitable for underfloor

www.mapei.com

17

The introduction of two new ‘long plank’ laminates with truly natural

heating up to 30ºC; very low VOC’s; and are provided with a microIn producing rectangular carpet tiles the company states that the

bevel edge for ease of cleaning. www.mflor.eu

buildings blocks of design are no longer ‘one-size-fits-all’. This col-

18

lection enables designers to ‘think beyond the box’ and the pattern and texture allows for thoughtful new proportions, enabling a wide variety of patterns such as weave, stagger, herringbone, brick, boxed in, half basket and basket weave. This means the tiles can be laid in more ways than ever, and whether you go vertical, diagonal, straight across, or develop your own design, the instructions are simple. www.shawcontractgroup.com

18

F LO O R S M a rc h A p r i l 2 0 1 1

A 2011 collection featuring fascinating surfaces and unusual structures for these upmarket carpets and rugs, including a range that features a wide variety of material compositions, with the blend of various materials in shimmering deep pile, soft acrylic and colourful felt inlays creating exciting patchwork patterns with graphic decorative elements. www.arteespiona.com

19

Focus on Domotex 2011

This flooring manufacturer brought its exciting new ‘active wall’ mod-

Described as taking new direc-

ule system to Domotex. This attractive addition to the accessories

tions in floor design and com-

range comes with added value for the trade. With this original, stable

pletely rediscovering the world of

profile system, flooring can now be installed as decorative elements

flooring, this company has devel-

on vertical surfaces such as wall panels, enabling floors and walls to

oped new freely-scaled carpet

be matched.

tiles – textile flooring with a spe-

‘active wall’ consists of top quality aluminium profiles into which all

21

cial new underlay that ensures

this company’s flooring - even of different element thicknesses – can be

that the tiles can be safely laid on

inserted. What is ingenious about the system is that its components such

slippery surfaces – an innovation

as coat hooks, hat hooks, shelving brackets and TV mounts can be used

so unique that it warranted its

to design not only smart wall panels but also functional shelving, coat

own patent.

racks and TV walls. ‘active-wall’ can be used anywhere in the home, and

The tiles can be positioned

creative ideas can be implemented fast in commercial areas, shops and

quickly, simply and flexibly to

exhibitions.

add lifestyle impulses to living spaces time and again. This new

www.witex.com

range is started with three qualities in a total of 16 colour varia-

20

tions. www.vorwerk-carpets.com Producing an elegant and durable ceramic-like surface, this new and innovative hard flooring has all the resistance and durability of stone and ceramics but is much faster and easier to prepare and install. With a three layer construction, it offers a tough ceramic-like surface laminat-

Intelligence and sustainability are focal points at this company, with innovative concepts, con-

ed to dense fibreboard (breakthrough technology) for ultimate stability.

23

This product is light to transport and its click system makes easy work of laying or replacing, so there is minimal business disruption for com-

stant technological advances and

mercial areas. It brings a wide range of traditional stone, wood and

long-range vision, both economi-

eye-catching contemporary designs to this new, strong and sustainable

cally and ecologically, being the

flooring, making it ideally suitable for shops and stores, hospitality and

elementary principles.

housing.

This approach certainly

www.tarkett.com

matched the big focus on sustainability noticed throughout

22

the Domotex exhibition this year. www.vorwek-teppich.com

24

Here is an easy-fix system for indoor floors or exterior wood decking that makes installation child’s play! High-quality rubber spacers ensure perfect installation and excellent ventilation of the planks, thanks to the innovative assembly system. This system required no wood padding, which also makes it perfect for restoring old decks and terraces; just lay it down and it’s completed!

Launched at Domotex last year, this product has undergone a slight name change for the brand with the addition of a new colour concept. These colours were previously available in board material, by which the furniture, walls and other interior components could be matched with the colour of the flooring. These 6 contemporary colours were launched in a long and wide board. (1800 x 160 mm) with an integrated underlayer in cork which provides a ‘solid’ sound while walking on the floor; the feeling and sound are comparable with a classical, fully glued down wooden floor. Moreover, this collection is also FSC certified and there is no formaldehyde added in the production process. This colour approach means that the name has changed with the

www.tilo.com

addition of Deluxe, as the availability of these colours is not exclusive for the original collection any more. The ‘Deluxe’ name refers to the fact

25

that this flooring is the masterpiece of the company’s collections and also 100% ecological. In other words you get a piece of nature in your home, without damaging nature. www.par-ky.com

F LO O R S M a rc h A p r i l 2 0 1 1

19

Focus on Domotex 2011

Domotex highlights flooring trends for 2011/2012 According to Domotex, the 2011/2012 season

This design trend reflects the undiminished interest in a natural

will be dominated by four key trends that can be

flooring, for example, may feature irregular, uneven surfaces. Wood

look that appears authentic and hand-crafted. Parquet and wood

described as follows: the rustic vintage style; the

will have an authentic natural look and thus may be treated with

modern, romantic Scandinavian style; the new

– or even processed to create patchwork effects.

industrial minimalism; and the Global Spirit.

Rustic Vintage Style

natural oils, burnished, distressed or treated to appear roughly sawn In Hannover this year it was possible to experience vintage charm and authenticity, not just visually but in a tangible, haptic way. Instead of disguising the natural structure and graininess of wood, this style draws attention to its natural attributes. The rustic, authentic look of wood – for example, oak and old wooden floorboards – is integral to this unpretentious natural style. The same distressed, antique look can also be seen in laminate and resilient floorcoverings to recreate this style. The distressed, worn look, furthermore, extends to carpets and rugs, which may have faded or over-dyed colours, or appear to have been coarsely hand-woven – a look that is either authentic or achieved through realistic photographic printing.

The modern, romantic Scandinavian look

QUICK-STEP

20

F LO O R S M a rc h A p r i l 2 0 1 1

STEPENI

Focus on Domotex 2011

Light-coloured woods – chalked, bleached, white and grey-toned

istic reproductions of honeycomb structures, crystals, computer cir-

– are intrinsic to the contemporary style of Scandinavian home

cuits and motherboards, as well as other geometric shapes, tend to

interiors. Colours such as warm skin and brown tones harmonise

be positioned to form random and irregular patterns, but this style

with shades of grey-pink and violet.

may also feature batik designs and washed fabric effects.

Carpets are chunky-woven yet soft, while other floorcoverings such as laminate, resilient and textile floorcoverings tend to be

Global Spirit

striped – sometimes the stripes are subtle and irregular. The sensitive interplay of colours and variations in the thickness of carpet pile, as well as patterns using colours of similar subdued tones, is characteristic of this style.

The new industrial minimalism

ARTE ESPINA

TARKETT

By contrast, industrial minimalism is more about a utilitarian perfectionism that is underlined by shiny polished surfaces or extremely matt surfaces to create new random and interesting visual effects. The flooring designs for this modern style are inspired by such images as raw steel, metal fencing and grids, concrete and industrial materials, and hi-tech motifs. Cool blues, as well as black, white and grey tones dominate. Stark stripes, geometric designs, computer graphics and photo-real-

The fusion of ethnic styles with Western industrial minimalism makes a new and interesting statement in which the vibrant colours of exotic lands contrast with the understated mono-colours of the Bauhaus style – brilliantly colourful but not garish. The richness and diversity of the patterns are fundamental to this style. For example, traditional Oriental carpets may be dyed, the motifs digitalised or combined with new geometric shapes or patchworkstyle patterns. Dark tropical woods are favoured or indigenous woods treated to imitate tropical hardwoods or bamboo. Cross-grained woods are put together in patchwork designs.

F LO O R S M a rc h A p r i l 2 0 1 1

21

FloorForum is a huge success Focus on Domotex 2011

Once again, the FloorForum 2011 event, presented in conjunction with the recent Domotex exhibition, was a great success in showcasing high-quality, ultra-modern carpets for the 2011/2012 season.

A

rranged in the display categories Nature, Classic, Tecno and Opulence, FloorForum was styled by the internationally

acclaimed designer Ulf Moritz and staged by 25 exhibitors, whose presentations offered visitors fascinating insights into trend-setting colours materials and patterns. For buyers from high-end home furnishing and furniture stores, retailers of floorcoverings, creative interior decorators, interior designers and architects, this ‘trend-show’ is always a source of inspiration for modern interiors and exciting design.

Nature (I go back to nature)

He feels that items in this category are always up to date, providing technical solutions with functional practice, dynamic coolness, a hi-tech look and new designs of high performance.

Sustainability and naturalness were the core values of this display

Classic (My home is my castle)

category; the designs are ecologically friendly but also address very

This category depicted sophisticated quality carpets that bring

human needs such as comfort, security and the sense of belonging.

immaculate style and a touch of class to the home. The superior

Idyllic harmony, cocooning and longing for intimate space are

materials – plus exclusive design and superb crafting – demonstrate

natural needs, and these were combined in this category with eco-

originality and consistent quality. These ‘comfortable’ materials encom-

logical sensibility, care for natural resources, sustainability, and the

passed exclusive originals that are statements of classic values.

authenticity and durability of modern floorcovering products.

Tecno (Look, I’m cool)

The luxury products here were characterised by their exclusive style,

Vitality, energy, and enthusiasm for urban environments gener-

idiomatic design and clean, modern look, but a hint of extravagance

ate unique and modern creations and epitomise the cosmopolitan

and unashamed opulence also added a feeling of frivolity and joy.

lifestyle of the exhibits in this category, which presented modern

22

Opulence (All I need is luxury)

Here were shown exciting, passionate and fantastic styles with an

patterns, vibrant colours, and hi-tech aesthetics that Moritz best

exclusive and playful flair, described as brilliant, luxurious, extrava-

describes as being beautiful, functional, funky and cool.

gant, dominant creations inspired by fashion.

F LO O R S M a rc h A p r i l 2 0 1 1

Focus on Domotex 2011

Winners of firstever AWareness

1st

AW, a European manufacturer of broadloom carpet, announced the winner of its firstever AWareness Award at Domotex 2011. The AWareness Award is intended to be an annual award that aims to promote new design talent and raise awareness for the concept of ‘upcycling’: the idea that value can be generated from old and used carpet by turning it into innovative, beautiful new products.

A

s part of its commitment to sustainability, AW is helping to reduce the amount of carpet that is returned to landfills

every year but also making the industrial process more sustainable, and has decreased its waste by 22% since 2006 and its energy consumption by 15% since 2002. This year’s competition, in which 80 young designers from some of Belgium’s leading art and design establishments took part, attracted

2nd

a very high standard of entries, all of which were applauded by the chairman of the judging panel, Belgian-based international designer Stefan Schöning, for their creativity and, at times, ingenuity. The winner of the competition was the piece ‘Plof’, submitted jointly by Vincent Welleman, Yves Verhaegen, Pim Van Eijk and Oskar Vermeylen. Schöning said, “The piece is about ‘what you see is what you get’. It is a cool seat with endless possibilities in terms of colour, shape and usage.” The runner-up was another joint entry by four students, namely Nienke Ijpelaar, Mieke Keukelier, Stien Lambrechts and Elien Sockeel, and was given the name ‘Tapis Assis’. This was a versatile piece of fur-

we received for

niture made from the underside of a carpet treated with water-

this year’s award,

based resin compound.

it’s clear that the

Third place was awarded to Maghalie Dooms for her creation ‘The

design community

carpet disappears through movement’, a stunning fashion concept

holds these values

which tells the poetic story of carpet being used as clothing before

dear also. I look

slowly falling apart and disappearing through movement.

forward to a long and

“Each entry was assessed in terms of its originality, functionality,

3rd

fruitful relationship with

durability and feasibility as well as the actual proportion of carpet

Europe’s young designers,

used in the final product,” said Schöning. “What especially impressed

and to continuing working with

me, however, was the level of innovation in all the entries. The issue

them to help make our industry more

of waste is an important one for the carpet industry and I person-

sustainable, and more creative, than ever.”

ally take great satisfaction that so many talented young designers

AW’s commitment to sustainability and innovation can also be

have come together to present new ideas that not only address this,

seen in its product range, which now includes carpets made from

but do so in a fun and thought-provoking way.”

new sustainable raw materials such as bamboo and flax yarn and

Erik Deporte, AW’s managing director, commented, “At AW, we take the issues of environmental sustainability and creativity very seriously

combinations of these yarns with wool. The company has also recently launched a new ‘à la carte’

and the AWareness Award is just one example of how we put this

bespoke carpet service, further expanding the range of choices

commitment into practice. Judging by the quality of the submissions

available to the design-conscious consumer.

F LO O R S M a rc h A p r i l 2 0 1 1

23

Focus on Domotex 2011

Another great performance by Domotex

Domotex 2011 was bigger, better, and more trendy than ever before – and FLOORS in Africa was there

access to an extensive overview of the world market for carpets and

in the presence of editor Liezel van der Merwe.

floorcoverings, where they can directly compare providers and conditions while conducting concrete sales talks and discovering the latest

T

trends and developments at a single, concentrated venue.

so many South African visitors this year – more than I have ever seen in

layers, interior furnishers and painters, and this year more than 180

the past – and too many to be able to speak to them all, particularly as

exhibitors were showcasing products and innovations geared directly

I was concentrating on meeting various international companies and

to the floor laying trades, concentrated in the exhibition sector of floor

seeking the latest trends in all types of floorcoverings, which in itself is

laying, cleaning and application technologies.

otally impressed with the sheer size and enormous activity that this leading exhibition always commands, Liezel says, “There were

a daunting task given the enormity of the event.” The importance of this exhibition was reiterated by Stephan Ph.

This exhibition is always a firm date in the calendar of the skilled trades. Some 20% of all visitors are active as parquet recliners and floor

Domotex is much more than just a trends and information barometer: above all, it represents the global business platform for the interna-

Kühne, a member of the Messe Managing Board with responsibility for

tional floorcovering industry. 82% of exhibitors and 56% of visitors

Domotex who said, “A total of 1 350 exhibitors from 70 countries came

come from outside Germany.

to Hanover to display a raft of impressive interior decorating trends, featuring new materials, colours and patterns.” “Domotex 2011 was a complete success in terms of being a

The strong business focus in Hanover is underscored by the high percentage of decision-makers among visitors. Some 71% of all visitors come from top management echelons and 89% are involved in pur-

trends barometer and business springboard for the interna-

chasing decisions at their companies, so the organisers are proud to say

tional floorcoverings industry,” he said, “and business is back up

that only at this four-day show can exhibitors present their products to

again, thanks largely to the momentum generated by new trends

such a highly international audience, and locate the right partners to

and innovations.”

help them tap new markets and maintain existing contacts while laying

“The high level of interest demonstrated by our visitors and the readiness to invest among the wholesale/retail sector as well as amongst

24

Domotex boasted a plethora of innovations and highlights from the residential and commercial property sector. Here visitors had

the groundwork for global business relations. Anyone that is sorry they missed this spectacular event should

interior decorators, designers and architects has resulted in a highly

diarise the next one, which will take place in Hanover from 14 to 17

successful four days,” he added.

January 2012.

F LO O R S M a rc h A p r i l 2 0 1 1

Focus on Domotex 2011

Road to Domotex

The competition organised by Van Dyck Carpets to give recognition to members of the Top Carpets Group for sales growth on Van Dyck products during 2010 was a great success.

“The winning team”

to Domotex On the train

rs’ with the ‘Vrystate rican flag flying Af h ut So e th g Keepin

P

rizewinners were presented with a great opportunity to visit Domotex, the world’s biggest floorcovering expo, and reflect-

ed the enthusiasm with which the competition was received. Prizes were awarded to the Best Performer that showed the best growth 2009-2010 (Per region); and the Best Performer Countrywide (Total sales). The Regional winners were:

Italian cuisine at its best

Johannesburg – Shaun d’Hotman, Top Carpets Alberton Top Carpets Kroonstad – Sarie Kotze Top Carpets East London – Ray Burbidge Top Carpets Tygerberg – Ryno Douma The Best Branch Award went to Top Carpets Athlone – Shafeeq Omar

o got Guess wh st girl the prettie

Manie Kriel of Top Carpets Vereeniging also went to Domotex as a winner from the Top Carpets Group. The Van Dyck hosts for this competition were Bernd de Smedt and Eric Ward, and Barry Hatch and Brian Hoyle from Top Carpets’ head office also attended. Bernd de Smedt says that this was a highly successful promotion, and Van Dyck Carpets will be running the Road to Domotex Competition 2011 with enthusiasm again this year. Van Dyck Carpets Tel: 031 913 3800 Toll free: 0800carpet (0800227738)

We left the g ood looking guys out of th is one

Website: www.vandyckcarpets.com

F LO O R S M a rc h A p r i l 2 0 1 1

25

Focus on Domotex 2011

contractworld.award 2011 The winners of the contractworld.award 2011 competition came from Australia, the Netherlands, Austria and the Czech Republic this year, each receiving this prestigious international architectural prize in Hannover, Germany, on 15 January 2011, in conjunction with Domotex, the world’s biggest

The first prize in this category went to Wiel Arets Architects from the Netherlands for their V-Tower project, which is part of the Eindhoven industrial park. The slimline, 13-storey building is admired for its dramatic geometric lines. The visual impact of the interior is enhanced by outstanding views looking out from all sides. According to the judges, “the interior of the office building has a pleasing and positive effect which complements the attractive impact of the building on its urban setting”.

trade fair for floorcoverings (contractworld takes place every year as part of Domotex Hannover).

T

he chairman of the panel of experts judging the competition, Kim Herforth Nielsen, who presented the awards, said, “I found

it really exciting being on the panel for this contractworld.award. I was profoundly impressed by the number of entries and the high quality of the projects.” A total of 525 offices from the field of architecture and interior design from across the world took part in Europe’s most highly respected and valuable architectural prize (worth 60 000 euros). The award for innovative interior design concepts is presented to outstanding and trendsetting interior concepts in several categories: office environments; creative hotel interiors; innovative shops; and conversion projects. The main criteria considered by the judges were the quality, functionality and aesthetic value of the projects, as well as innovative

Category: Hotels/Spas/Catering facilities

solutions with respect to the treatment of space, materials, colour and

This category includes hotels, guesthouses, spas and wellness suites,

surface or texture.

restaurants, cafes, bistros, bars, lounges, clubs, casinos and canteens.

Category: Offices/Administration buildings This category covers projects including banks, insurance companies, government departments and local authorities, conference and congress centres, studios, workplaces (large and small).

26

F LO O R S M a rc h A p r i l 2 0 1 1

First place in this category went to the architects’ office of Oskar Leo Kaufmann from Austria for their Alpine hotel, Ammerwald, which is located 1 100 metres above the bottom of a narrow valley in the

Focus on Domotex 2011

Category: Conversion Covering the conversions of buildings originally constructed for religious, cultural or public use, such as churches, monasteries/convents and railways stations, plus derelict industrial buildings which have been redesigned and structurally altered to serve a new purpose. Austrian Tirol. Whereas the façade is made of resilient materials suited

First prize in the Conversion category was awarded to the Vyšehrad

to the climate and the location, only warm, natural materials are used

Atelier practice located in the Czech Republic for its project Atrium D.

for the interior.

The inner courtyard of Prague’s Technical University remained unused

The judges’ assessment: “This project makes an outstanding

for many years before the architects transformed the 18x24 metre

overall impression: the simplicity of the materials, the outstand-

space, covering it with a roof to create a multifunctional, two-storey

ing realisation and attention to detail all contribute to the strik-

hall with an industrial character – a factory for producing ideas.

ing appeal of the building.”

The jury said: “What was once a redundant space is now an area

Category: Shops/Showrooms/Exhibition stands This is a category dealing with shop concepts, stores, showrooms and sales floors, exhibition stands, shopping centres and malls. The Aesop Stores project by the March Studio in Australia won first prize in this category. Aesop is a skincare company based in Melbourne, for whom the architects designed three quite original stores, each ideally suited to its regional context but equally appropriate for a company currently enjoying worldwide growth. Thus, the architects opted for locally sourced building materials, favouring recyclable materials at all times. The most eye-catching feature of the Adelaide store is a ceiling made from 7 500 ambercoloured bottles. The judges commented: “The Aesop stores are exemplary for the way in which they embody and convey the corporate identity of the company.”

of central importance to the university – it stimulates interaction between the students and is a crucible for creative ideas.” Finally, four special awards for avant-garde projects went exclusively to ‘New Generation’ architects and interior designers (up to the age of forty). A short list of new generation representatives from each of the main categories was drawn up. The winners were selected on the basis of live presentations which finalists hold in front of the panel during contractworld. Further information on the work of the ‘live jury’ and contractworld can be found online at www.contractworld.com.

F LO O R S M a rc h A p r i l 2 0 1 1

27

Getting further into green! Projects

Having recently changed their house colours to

green in order to present a distinctive new image to the market, it is perhaps fitting that Peter Bates Flooring was the selected flooring contractor for the new Nedbank Corporate Head Office Phase II in Sandton, which was the first building to be GBCSA Green Star Certified in South Africa.

B

y anybody’s standards this was a huge project with over 32 000m² of floor area – all based upon the Freestanding Type

DYEMENSION DYNAMIX

1 steel access floor system marketed and installed by Peter Bates, which is ideal for general office environments where the finished floor height varies from 100mm to 850mm. The all-steel Type 1 Freestanding System exhibits superior load performance and optimum strength, with the panel positively locating onto a aluminium head supported by a conductive gasket to provide a solid, quiet, and easily accessible solution. This system has no screws, making it ideal for easy access to the plenum, which for this project was 350mm deep to accommodate the required services.

DYEMENSION DYNAMIX

Peter Bates won the carpeting contract after a strict and competitive tender process, which included the provision and installation of the custom-made Nedbank Sandune carpet tiles manufactured by Dyemension Dynamics Corporate Carpet Tiles (Pty) Ltd using the Antron lumina yarn system. These 500mm x 500mm structured, textured loop-pile Dynabac loose-lay carpet tiles were developed and manufactured specifically for Nedbank in conjunction with their design team, resulting in a carpet tile which, in addition to being certified suitable for heavy-

SOLIDfEEL

contract installations and Greenstar – IEQ13 compliant, the tiles are manufactured in South Africa resulting in relatively short lead times required when re-ordering additional or attic stock. As a dedicated carpet tile manufacturer Dyemension Dynamix is totally committed to the attainment of world-class standards in

like VOCs in the required products, which meant that materials were send to international testing labs for certification,” he says.

the procurement of local content, manufacture and conversion of

However, good product selection, planning and strict controls

carpet tiles to suit the client’s specific requirements, from graphic

both on and off site ensured that the building achieved a 4-Star

tufting to printed graphics.

Design rating from GBCSA in October 2009, and a 4-Star As-Built rat-

The Dynabac backing system, used in the manufacture of the Nedbank Sandune carpet tiles, installed on this project comprises a

ing in September last year. With Clint Hastings managing the access flooring installations to

Greenstar compliant composite compound developed specifically

the East block, and Pierre Urtel being the carpeting project man-

for the flooring industry as a dimensionally stable, fully flexible car-

ager for this prestigious installation, Peter Bates Flooring scored yet

pet tile backing system.

another success in the corporate market, with the whole project

Marco Zornitta of Nedbank said the company set out to claim this

completed within the overall contract period of twelve months.

accolade right from the conceptual stage, but it was not without

Peter Bates Flooring

its challenges to ensure that it was the first four-star rated

Tel: 011 830 2350

building in the country.

Fax: 086 528 7502

“Most of the contractors, manufacturers and suppliers had little experience of what was required with regards to green star require-

28

ments – even to the point that there was no local testing for things

F LO O R S M a rc h A p r i l 2 0 1 1

E-mail: marketing@peterbates.co.za Website: www.peterbates.co.za

Projects

Structural Movement Joint M.Trim has a range of locally manufactured and pricesensitive structural movement joint covers for floors and walls that may experience large movements.

FLOOR AND WALL FINAL SOLUTIONS

available through Kirk Marketing

Aluminium structural wall corner joint cover

T

Aluminium structural floor joint cover

he aluminium covers are anodised matt silver as a stan-

Aluminium structural floor joint cover

Aluminium structural floor joint cover

Aluminium structural wall joint cover

PVC structural movement joint cover

dard, but they can also be provided in any matching colour

on the powdercoat paint charts or anodised to another eight different colours as per the M.Trim anodised range. The PVC structural movement joint cover for vinyl flooring that is used for 2-3mm vinyl flooring allows for movement of ±5mm and is PVC-welded to the vinyl sheeting. Available in black and dark grey. The wall joint covers are in aluminium and are held in place with spring steel clips. There are two joint covers available – on a straight wall and on a wall corner. The wall joint can be 15-35mm in width. The sightline of these joints is 48mm for the straight wall and 40mm for the wall corner joint. The aluminium structural floor joint cover is available with or without clips in widths of 76mm and 106mm. Butyl tape is used with the joint cover without clips and is often recommended for those with clips, as it takes up the unevenness of the floor and prevents the possible hollow sound of the covers.

M Trim is a brand of PVC, brass, aluminium, stainless steel and anodised profiles used for tiles, carpets, vinyl and laminate floors.

Kirk also has a range of structural movement joints that will take horizontal movement of ±5mm and that have a 38mm sightline, for tile joints with depths of 13mm, 17mm and 39mm. A retrofit structural joint with a sightline of 120mm and

Quality Profiles for wood and laminate floors.

Quality Tile Cleaners,Strippers and Sealants.

a depth of 15mm is also available. The flexible PVC inserts used in the structural joints are available in black and dark grey and are either smooth (hospital insert) or ridged (standard insert). For more complicated loading and differential movement, Kirk recommends the Vexcolt range of movement joints. Whatever your structural movement requirements Kirk should have a solution; contact your closest Kirk branch, and they will be glad to help you. Kirk Marketing Head office 011 444 1441

Cape Town 021 949 2226

KwaZulu-Natal 031 564 1175

Port Elizabeth 0860 KIRKPE

Structural movement and expansion joints for floors, walls, columns, ceilings, roofs, car garages, bridges. Fire Barriers also available.

GAUTENG Tel: +27 11 444 1441 Fax: +27 11 444 1165 CAPE TOWN Tel: +27 21 949 2226 Fax: +27 21 949 4531

PVC curvable profiles for multishaped flooring. Commercial and domestic applications.

KWAZULU NATAL Tel: +27 31 564 1175 Fax: +27 31 564 1143 PORT ELIZABETH Tel: 0860 547573 Fax: 086 688 4980

E-mail: sales@kirk.co.za Website: www.kirk.co.za F LO O R S M a rc h A p r i l 2 0 1 1

29

Projects

Tile Africa Contracts supplied tiles and bathroom ware for the extension to the Birchwood Hotel and OR Tambo Conference Centre in Boksburg, Gauteng.

Tile and bathroom ware for Birchwood Hotel

Umbria ceramic non-slip tiles

“W

e are proud to be associated with this development and to have supplied tiles for the interior and exterior as well as accessories for the

bathrooms,” says Craig Irvine, national manager for Tile Africa Contracts. The project entailed the expansion of the hotel by 215 rooms. Tile Africa Contracts supplied approximately 2500 sheets of rustic porcelain mosaics, Manchester baths, Sydney wall-hung and Gallery toilets, as well as Demola bathroom accessories including three-litre stainless steel dustbins for the bathrooms. “The mosaics are installed from floor to ceiling in the centre of the walls as a 300mm backdrop for the shower rose and mixer, in a contrasting colour to the tiling to create an interesting focal point and accent for the bathrooms,” says Diana Ford, owner of Delineo Projects, specialists in interior design and project management, and the interior designers for the extensions to the Birchwood Hotel. From the Delineo team, Allison O’Keeffe was full-time project manager on the project, assisted by Michelle Hobson as designer, and together they were responsible for specifying the finishes to the extensions. In addition to the mosaic tiles, Tile Africa Contracts supplied 4500m² of 330x330mm Umbria ceramic non-slip tiles in Burnt Sienna for the outside walkways. “On the walkways we used the Umbria tile which complements the wall colours chosen for the building and its neutral colour allows it to blend into the

Rustic porcelain mosaics for Birchwood Hotel.

beautiful gardens. The non-slip capabilities of the tile comply with the client’s requirements for a safe environment for the guests,” says Ford. With a national network of representation through the 37 Tile Africa retail branches, and the backing of sister companies Johnson Tiles and TAL Adhesives, Tile Africa Contracts supplies tiles, bathroom ware and specialist products for commercial and industrial applications on a national scale. “We offer an invaluable service to architects, contractors and specifiers, and the materials we supply are in line with local and international standards,” says Irvine. For more information on Tile Africa Contracts call 011 979 0327 or visit the website: www.tileafrica.co.za.

30

F LO O R S M a rc h A p r i l 2 0 1 1

Sizzling specifications for fire station

Projects

The floor and wall surfaces of the Umhlanga Fire Station in Umhlanga Ridge, Durban, called for 2 000m² of very specific tiles that were successfully specified and supplied by Tile Africa Contracts for the interior and exterior of the building.

T

he fire station protects some of the region’s most valuable properties and high-rise infrastructure, including the Gateway shopping centre.

Durability and low maintenance were required of the floor and wall coverings, and the tiles supplied by Tile Africa Contracts met these specifications. Kerastar Themis, a full-body porcelain tile was specified for the interior floor. The tile comes with a 50-year guarantee from the manufacturer, Johnson Tiles in Greece, and boasts exceptional surface hardness, wear characteristics and chemical resistance. “The Kerastar tile was ideal as the floor tiles have to withstand the scuffing of boots and rubber-soled shoes,” says Craig Irvine, national manager for Tile Africa Contracts. Other tiles supplied include Desert Sand 300 x 300mm porcelain tiles and Silver Blue 300 x 300mm slate tiles that were applied to the exterior façade. The tiles contribute to the green building practices of the building as they reduce the maintenance and upkeep required. It was crucial that the tiles required no additional treatment or sealants once installed. The exterior and interior tiles had to be natural, durable and non-slip. According to the architects, eThekwini City Architects, the challenge was that they were looking for a maintenance-free product. “The purpose of using tiles was to avoid having the walls treated in future, as part of a new greening concept,” says Bruce Clark, of Bruce Clark Associate Architects, working as a consultant to the eThekwini City Municipality. The exterior blends in with the neutral textures of the buildings surrounding the fire station, but was not painted as this would require ongoing maintenance. The interior walls were painted to allow for upkeep as firemen return from call-outs with dirty clothing. “We have set a new precedent for the specification of tiles for fire stations in KwaZulu-Natal,” says Yvonne Dalton, architectural consultant for Tile Africa. Further information on Tile Africa Contracts can be obtained by phoning 011 979 0327 or visiting the website www.tileafrica.co.za.

F LO O R S M a rc h A p r i l 2 0 1 1

31

Insight

Access flooring The Peter Bates Group was instrumental in introducing access flooring to the South African market after the company was founded in 1973. We have since established ourselves as market leaders and trend setters within the African market. Our cumulative installation experience, project management expertise, infrastructure with sufficient resources, and 24 hour backup service has insured that new and existing customers continually turn to us for installations of any size and complexity.

Vinyl “Resilient flooring refers to flooring materials which have a relatively firm surface, yet characteristically have “give” and “bounce back” to their original surface profile from the weight of objects that compress its surface. Resilient flooring materials are made in various shapes and sizes including both tile and roll form and because of its durability, comfort under foot, aesthetic appeal, long lasting beauty and cost effectiveness is used in a wide range of commercial and residential applications.

32

F LO O R S M a rc h A p r i l 2 0 1 1

Carpeting Locally produced soft flooring has developed tremendously over the years and the standard of quality, craftsmanship and flexibility from a design and fibre technology point of view has allowed locally produced soft flooring in either carpet tile or broadloom to become world class standard. With sustainability on everyone’s mind locally produced soft flooring products do stand up to the challenge that have been set by international standards from a sustainability point of view.

Wood laminate Laminated flooring consists of interlocking planks that is placed on top of concrete slabs, plywood, vinyl flooring and any floor finish that is hard and consistently flat. It is not fixed to any subfloor and for that reason relatively easy to install and cost effective. There are many different types of laminated floors with varying levels of quality. Hence it is very important that you purchase your flooring product from an appointed dealer with membership to the South African Laminated Flooring.

“Flooring at its best!” Since 1973 0861 PETER(73837) www.peterbates.co.za

Insight

Renewed enthusiasm and

P

style for future growth

eter Bates, who founded the company in 1973, was one of the first pioneers to recognise the need for development of computer access flooring,

and set about advocating its use to everyone that would benefit from such a facility – in all sectors of the market. Access flooring was slow to become accepted in the marketplace, but the

Peter Bates Flooring (formerly known as the Peter

construction and IT industries have come to realise the value of provid-

Bates Group) has been servicing the Southern

ing an engineered solution to efficient office and computer management

African flooring market with great success for over

ever-increasing demand.

40 years, and has become a market leader not only in soft flooring but access flooring as well.

and operation, and Peter Bates Flooring is in the forefront of meeting this It is interesting to note that the first big installation (37 000m²) completed by Peter Bates in 1981 was for Standard Bank, which is still retained as a valued client by the company. (See the inset with this article that indicates some of the larger projects that have been undertaken by the company.) On the 1st of May 2004, the group changed hands and Peter Bates Flooring is now 66,6% black-owned, having achieved a BEE rating of a Level 4 Contributor. In addition, the company has excellent relationships with all the local manufacturers. Let’s take a look at the people that steer the ship:

Kevin Kwan, Managing Director Previously from an auditing background, where in he completed his B.Compt (Hons), Kevin joined Peter Bates in 1992 and quickly learnt the ropes of running a business which, he says, was very different from the auditing environment – not a From left to Right: Priyan Papia (Financial Manager), Michelle Barnard (Receptionist), Sheneen Adams (Accounts), Aletta Madau (Canteen), Jessica De Jeso (Creditors Manager), Stephanie Kok (Debtors Manager)

simple case of debits and credits! Kevin was appointed as an alternate director in 1996, financial director in 2000, and into his current position as managing director in 2004. “2004 was a watershed year in that we took over the company. Looking back it was a mountain to climb but, equipped with raw enthusiasm and a desire to succeed, we attacked the task at hand,” he says. “Now, six and a half years later, we can say we have pulled it off, but this is all due to the people that work for us.” Asked for an overview of the company’s performance, Kevin says, “Going forward we need to build on the qualities, integrity and service that have got us this far; we are never too old to learn but will never stop trying to be one of the leaders in our field as a specialist flooring company that provides the highest level of service to all market sectors through appropriate and well-organised resources.”

Contracts Managers from Left to right are as follows: Enoch Mbaso, Mark Lowery, Pierre Urtel, Amos Lushaba (back), Levias Mathonsi (front), Lance Ngobeni, Thabo Nyakale, Stephen van Tonder, Leon Botha, Blair Newman (back), Leon Ho, Gary Gutteridge