VOL 29.5 July/August 2011 R38 incl. VAT

Wood, laminates & bamboo • Sticky side of flooring • Concrete floor design Value for money options • SA students’ best in the world • Insight into wine cellars

REFERENCE Guide

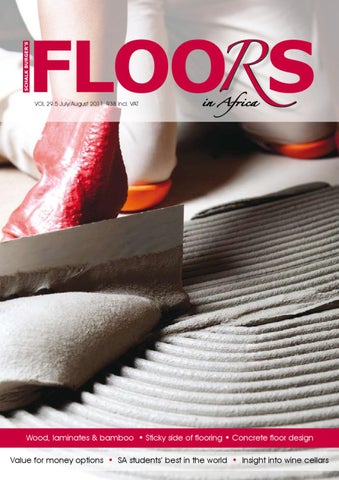

COVER STORY Professional choice TAL is the professional choice when it comes to tiling. It is a leading supplier of tile adhesives, primers, additives, grouts, screeds, waterproofing, floor repair compounds and tiling tools and therefore a one-stop-shop for tiling solutions. TAL is changing its product packaging to simplify the selection process for the end-user and tiling contractor. Its packaging may be changing, but customers can still expect the same reliable, top quality products that they’ve come to trust from TAL. See pages 54-57 in this issue.

29

49

63

81

Access Flooring Peter Bates Flooring

p15, p79, p92

Adhesives / Coatings FloorworX

p61

TAL

Front Cover, p54-55

Zimbo’s Trading

p5

Carpets Belgotex Floorcoverings

p2, 84-85

Nouwens Carpets

Inside Front Cover

Peter Bates Flooring

p15, p79, p92

Van Dyck

p6, p20-21

Ceramic, Porcelain and Stone Falcon Tiling Products Tiltoria

p45 Inside Back Cover

Cleaning & Maintenance

V OLUME 29.5

•

JULY/AUGUST

•

2011

FloorworX

p95

Matco Marketing

p23

Safic

p28

Sebo

p23

To page 5

F LO O R S J u l y Au g 2 0 1 1

3

Don’t miss the next issue of FLOORS in Africa! It has some rather special features that cover a wide range of floorcovering interest. Take a look below to see what you can expect:

Industrial flooring

This issue is dedicated to the hi-tech flooring solutions for the industrial sector. We will be taking a look at the latest projects and the unique range of products that have been customised for industrial flooring.

Cleaning & Maintenance & Repairs

Maintaining, cleaning and repairing floors are specialised services and once the product of choice has been issued and installed there are many after-installation facets to consider. How will the floor be maintained? What cleaning programmes should be adopted and what happens should repairs be needed? All these aspects affect the lifespan of the floor and should not be ignored. What does the industry have to offer? We will report back in this feature.

High-traffic areas

High-traffic areas demand floors that can handle high impact from the high flow of feet. If an application needs to handle 1000 footfalls per square metre per minute, what kind of floor will be considered? Airports, hotels, shopping centres, entertainment centres, theatres and restaurants need a specific set of technologies and products. We speak to some of the leaders in high-traffic flooring installations to find out what architects and designers need to know about these applications.

Roxanne Mancini: roxanne@mediainafrica.co.za

Tel: +27 12 347 7530

Joanna Papastamopoulos: joanna@mediainafrica.co.za

www.mediainafrica.co.za

Fax: +27 12 347 7523

REFERENCE Guide

Training & Skills Development Belgotex Floorcoverings Academy

continued from page 3

p90-91

Wood, Laminates & Bamboo

Industrial, Resin & Concrete Flooring abe Construction Chemicals

p78

Barrow Flooring

Cemcrete

p73

Bedson Flooring & Decor

Cement & Concrete Institute

p70

Ecostrong

Back Cover p35, p88-89 p41

p7

Floorquip

p11

Lafarge SA

p75

Floorworx

p38-39

Mapei

p62

Peter Bates Flooring

p15, p79, p92

Pharaoh Cement

p80

Rhoms Timberworld

p42-43

Flowcrete SA

Suntups Solid Wooden Flooring

p37

Sika

p67

Teragren

p47

Verni

p77

Traviata

p25

PMSA

p66, p68, p69, p71

Zimbo’s Trading

p5

Resilient Flooring Belgotex Floorcoverings Peter Bates Flooring Polyflor SA

p2 p15, p79, p92 p26

Seamless Flooring Quartz Carpet

p3

Sports & Exterior Flooring Belgotex Floorcoverings Van Dyck

Accessories and other Cersaie

p44

Decorex

p76

Falcon Tiling Products

p45

Genesis

p59

Kirk Marketing

p27

Pretoria Institute for Architecture

P97

SA Decor & Design p2 p6, p20-21

p98

Transiton Transport (Transportation)

p86-87

Note: Editorials excluded, listed in alphabetical order

Wood specifying

at its best! MEMBER

“TM”

S.A. WOOD & LAMINATE FLOORING ASSOCIATION

Cape Town +27 21 511-4693 | Johannesburg +27 11 794-1012 info@zimbostrading.co.za | www.zimbostrading.co.za

F LO O R S J u l y Au g 2 0 1 1

5

EDITORIAL Comment

Liezel van der Merwe

Roxanne Mancini

2011 officially sees itself entering into the second half of the year! For some it’s been a half year of new ways of thinking and doing business and for others it’s been just plain tough this year. Good news is that what you think and how you perceive things literally creates your reality. Choose a great outlook and your customers will react! Everybody likes to do business with happy, positive people – and, rest assured, there is business out there and people are spending money. The question you need to ask yourself is, ‘What can I change so that they will do business with me?’! In the next few pages you will find fresh new ideas, wellresearched articles and an insightful review on new products, trends, projects and much more information to benefit from. The old adage “knowledge is power” remains in today’s ever-changing markets. In this issue we focus on the following feature highlights not only to make note of but to inspire you into great ways of thinking about flooring: Wood, Laminates & Bamboo: Every year, this feature generates a lot of interest and feedback from industry and readers. We will be taking a look at new bamboo products, the latest developments in wood as well as the variety of laminates available in the flooring market. See more on page 29. Adhesives & Installation: It is essential for the flooring experts to keep up with pre-floor requirements as well as the installation methods in order to ensure that the floorcovering delivers on expectations. Adhesives used and installation methods carry a heavy weight when considering what floor to install. We look at the latest developments and techniques to keep them up to date. See more on page 49. Cement & Concrete: This smooth, liquid stone continues to provide durable and attractive floors. We will be looking for some of the most innovative cement and concrete technologies as well as the best and most recent projects. See more on page 63. Cost Effective Flooring: Developers and specifiers often have to stick to strict budgets, which isn’t always an easy task. We will be looking at economic alternatives and affordable solutions that give you the durability, look and quality application you need. See page 81. With the new Consumer Protection Act hot on everyone’s agenda I encourage you, if you haven’t already, to get to know how this act will affect the daily operation of your company as well as the exciting marketing messages you embark on. We are here to assist you with any queries. The next time we chat spring will be upon us presenting itself with a brand-new season of joy! Happy reading!

FLOORS is about ceramics, carpets, vinyls, wood, laminates, marble, granite, cement, stone ... any floor you can think of. It is also about accessories like rugs, adhesives and tools. Readers are welcome to contact us for any information. FLOORS is published six weekly by Media in Africa (Pty) Ltd. The views expressed by contributors are not necessarily those of the editor or publisher. We accept no responsibility for information published. PUBLISHER: Media in Africa (Pty) Ltd. Contact information: Tel (012) 347 7530 Fax (012) 347 7523 International: +27 e-mail: floors@mediainafrica.co.za PO Box 25260, Monument Park, 0105; Republic of South Africa Unit G, First Floor, Castle Walk Corporate Park, Cnr Nossob & Swakop Streets, Erasmuskloof Ext. 3, Pretoria, RSA

Founder: Schalk Burger

Editor: Liezel van der Merwe Cell 082 7700 799

Financial Director: Fanie Venter

Features & News Editor: Dave Soons Tel 012 807 7012

Business Unit Manager: Roxanne Mancini Cell 082 779 5751

Business Unit Co-ordinator: Madelein Smith

Client Support: Joanna Papastamopoulos Cell 072 300 0867

Design and Layout: Jakolien Strydom

Financial Manager: Gerda Bezuidenhout Liezel van der Merwe

Roxanne Mancini

EDITOR

BUSINESS UNIT MANAGER

Proofreader: Signa Evans

REPRO & PRINTING: Business Print Centre

OOP

Innovation & Design

UP STUDENTS A University of Pretoria (UP)

and nominated 24 projects for an award.

alumnus last week reaffirmed that graduates from

Ho Chang, announced the winners of the

winners. The chairman of the jury, Yung

the University’s Department of

Award at a ceremony with more than 450

Architecture are ranked amongst

Centre on 9 June 2011.

R

guests held in New York’s Guggenheim According to the jury: “The winning projects are related to the DNA of recognisable

uann van der Westhuizen, a

architects or architectural styles, but they

MArch(Prof ) graduate of UP’s 2009

are another evolutionary step beyond that

architecture studio, was announced as one of eight winners of the prestigious Hunter Douglas Award at Archiprix International 2011 that rewards the work of the world’s best graduates in architecture, urban design and landscape architecture. Archiprix International is an international network for young, talented architects throughout the world and biennially it invites 1 400 universities worldwide to select and submit their best graduation projects. For the 2011 edition held in the United States of America Archiprix International received over 300 projects from 70 countries, a new record number.

8

The jury reviewed all submitted projects

Out of these nominees they selected 8

the best in the world.

F LO O R S J u l y Au g 2 0 1 1

Best in the world!

Ruan van der Westhuizen

Innovation & Design

DNA, and stand out because of the authen-

Architecture graduates amongst the best in

tic voice of the individual designers and

the world. He added that the achievement

the clear positions they take. They are all

represented the collective dedication of the

very powerful projects and go beyond style.

staff and student body to excellence in the

What they have in common is poetics.”

built environment.

Van der Westhuizen’s dissertation,

This is the fourth major accolade award-

completed under study leader Jacques

ed to students of UP’s Department of

Laubscher and mentor Marianne de Klerk,

Architecture in the last 12 months. A year

achieved top honours in the Department

ago Jacques Orton’s electronic disserta-

in 2009.

tion received an international award from

It proposes a public bathhouse in the

the Networked Digital Library of Theses

Marabastad precinct in Tshwane and inves-

and Dissertations; in September 2010

tigates the ritual of cleansing in an urban

Carla Taljaard, Stephen Steyn and Warwick

environment, thereby celebrating a funda-

Manley won the national Murray & Roberts

mental human act. Informed by the context

Des Baker competition; and in February

and the potential of social integration, the

Jankel Nieuwoudt won the DesignHub

built form is layered to provide graded

Respond-Renew-Revitalise Competition

levels of privacy. The full document of his

sponsored by Saint Gobain, in which the

study is available at http://upetd.up.ac.za/

Department was also named best university

thesis/available/etd-1.

participant.

Laubscher, who also coordinated the

For further information: Ruann van der

2009 final-year studio, said that he believes

Westhuizen 082 825 9407 / e-mail:

this award once again positions UP’s

ruannvdw@gmail.com / nico.botes@up.ac.za

F LO O R S J u l y Au g 2 0 1 1

9

Innovation & Design

AWARDS

Nemeth & the Loeries

With the entries now closed for the 2011 Loerie Awards, FLOORS in Africa takes a look at the two top awards from the 2010 event – com-

Silver Loerie 2010: Circa on Jellicoe Art Gallery by studioMAS architecture & urban design.

mented on by eminent trend forecaster David Nemeth. The 2010

The Circa Gallery Extension is located in

Loeries attracted almost 3000 entries in all categories.

video installations and sculptures of large

Rosebank, Johannesburg, designed to display scale, and equipped to host art auctions. It consists of a flexible gallery space, business space, offices, storage, and a roof terrace, and was completed in November 2009. The façade of the building comprises anodised aluminium fins that combine with a green woven material. Natural light enters into the internal spaces while allowing views in and out of the gallery, which has a 85m² lounge opening onto a 20m² facing deck which provides views of Johannesburg on the third floor of this gallery. Dave Nemeth says: The oval shape of the Circa building with the shuttering-style cladding creates an immediate statement of being a modern design without replicating the kind of design we tend to see abroad. The shuttering has an African feel to it and the overall colouring blends in with the environment, yet still creating a major focal point. I particularly enjoyed the clever integration of nature into the architecture with the vertical gardens. The lighting of the building was also cleverly thought through, ensuring its creative visibility at night.

Grand Prix Loerie 2010: British Airways Slow Lounge by Tonic Design & Grid Worldwide Branding With the concept and design provided by Grid Worldwide Branding in collaboration with Tonic Design, this unique idea scooped the pool at the Loeries last year, as one of the four Grand Prix winners. Heidi Brauer, Comair’s Executive Manager for Group Marketing, said, “We are delighted with these awards that recognise the hard work and innovative thinking of our design teams.” “In an ever-accelerating world, the SLOW Lounge concept was inspired by the growing international trend towards appreciating life’s journey as much as achieving the end goal. The lounges are created from

Circa on Jellicoe Art Gallery

10

F LO O R S J u l y Au g 2 0 1 1

the customer’s point of view to ensure an

Innovation & Design

British Airways Slow Lounge exceptional experience before one even

Apple iMacs, a Nintendo games room, pri-

The overall feel of the interior has an

departs on one’s journey. In fact we had an

vate meeting spaces and business facilities.

immediate calming effect based on the

e-mail from a customer who said the only

In addition, each SLOW Lounge also con-

careful selection of materials and simple

problem with SLOW was that his flight left

tains an on-site spa offering massages and

clean lines, and the interior is rounded off

on time!� said Brauer.

wellness treatments.

by a very thoughtful and carefully planned

The SLOW airport lounges, situated in the Johannesburg, Durban and Cape Town domestic terminals, provide a perfect

Dave Nemeth says:

use of lighting, further enhancing the

The Slow Lounge by Grid Worldwide

relaxed mood.

Branding and Tonic Design shows an

Overall these projects show a carefully

sanctuary from the fast pace of travel and

extremely successful collaboration between

planned thought process, although very

modern life.

two disciplines, namely graphics and inte-

different in approach and statement. We

rior design. I believe the future of design, as

see strong future trend elements coming

with many other disciplines, will be based

through in each project which allow these

on collaborative work.

to stand apart from current design ideals.

Features include a chef, a coffee barista, wine tasting from a monthly selection of

Importing

the finest South African wines, a library,

Create an impression

direct from Germany

Part of the Aluvert Group

Contact Lesinda on 011 624 2584 or Adele Grobler on 083 653 5301/ orders@floorquip.co.za F LO O R S J u l y Au g 2 0 1 1

11

Insight: Wine Cellars

WINE CELLARS

Going the wine route!

On a recent sales visit to Cape Town, Joanna Papastamopoulos of

Jacob van Renen, son of Sebastiaan Valentijn van Renen (Snr). Sebastiaan Valentijn van Renen originally masterminded the wine-farming venture on High Constantia. Convinced

FLOORS in Africa took the opportunity to have a quick look at four of the

that the soil would be of the same excep-

most reputable wine estates in the area and, more specifically, what they

that the climate of the hills would give

tional quality as Groot Constantia’s and the wine its particular flavours, they

prefer for their floors.

planted 110 000 stocks of the Muscadel grape on the hillside. Shortly before Sebastiaan Valentijn van Renen died in May 1821, Jacob transferred the farm to his younger brother, Sebastiaan Valentijn Jnr who named the property ‘Sebastiaan’s High Constantia’. He soon established the reputation of his farm, and by 1827 its wine was commanding the same prices in England as wines from the already renowned Groot Constantia and De Hoop op Constantia. By 1841 Groot Constantia and High Constantia were the sole competitors in the area, Cloete relying on antiquity and tradition, Van Renen on his competitive prices. High Constantia, in its heyday, comprised three main buildings set amidst gardens, lawns and trees. Notable was a great oak near the cellar. In its branches was constructed a platform where family and friends took their ease.

. . . mystic interrelationship between earth and climate in the Constantia Valley.

On a small corner of the original land, David van Niekerk is restoring ‘High Constantia’ to its former winemaking glory. They are planting stocks and producing from their cellar (a structure that is reminiscent of High Constantia’s

Uitsig Constantia Winery clay brick tile entrance

S

they echo the gracious past of the forouth African winemaking has a history

Pontac, red and white Muscadel and a little

mer estate, give new life to the subtle

dating back to 1659 when it was instigat-

Chenin Blanc.

flavours born of the mystic interrelation-

ed by Jan van Riebeeck, the founder of Cape

Joanna’s ‘mini-survey’ started at High

Town, and at one time Constantia was consid-

Constantia in Cape Town, which is being

ered one of the greatest wines in the world.

restored to its former winemaking glory

On 2 February 1659 Jan van Riebeeck produced the first wine recorded in South Africa. In 1685, the Constantia estate was established

ship between earth and climate in the Constantia Valley. Joanna says, “My visit here was very

under David van Niekerk and wines are

short and there was no one available

once again issuing from its cellar.

to show me around, but the flooring

Established in 1693, High Constantia

throughout was squared clay tiles which

in a valley facing False Bay by the Governor

Winery began its historic journey as part

are reputed to help with cleaning the

of the Cape, Simon van der Stel. His Vin de

of the Dutch East India Company outpost,

floor as clay does not absorb the water.”

Constance soon acquired a good reputation,

originally called Wittebomen because of the

but it was Hendrik Cloete, who bought the

abundance of silverleaf trees.

homestead in 1778, who really made the

In 1806 a section of this land bordering on

The Groot Constantia Estate, founded in 1685, contains the finest surviving example of Cape Dutch architecture and

Groot Constantia to the north was granted

one of South Africa’s foremost historical

fied wine made from a blend of mostly Muscat

to William Duckett – the British Agricultural

monuments and tourist attractions.

de Frontignan (Muscat Blanc à Petits Grains),

adviser. In 1813 this land was bought by

name of Constantia famous, with an unforti-

12

original home for wine) wines that, while

F LO O R S J u l y Au g 2 0 1 1

Commander Simon van der Stel of the

Insight: Wine Cellars

Dutch East India Company arrived at the Cape supply station in 1679. Estranged from his wife he arrived in the company of his children and sister-in-law, Cornelia Six. Back in the Netherlands van der Stel had gained a solid background in viticulture at his vineyards in Muiderberg. There he learnt the art of wine and brandy making which he was soon to implement in the Cape. Van der Stel received title to 891 morgen (about 763 hectares) on 13th July 1685. The land stretched southwards to the neighbouring free burgher farms of Steenberg and Zwaanswyk and to the north it reached as far as the wooded area named The Hell. Van der Stel named his farm Constantia. It is thought that he named it after Van Goens’ daughter in recognition of his help and support in obtaining the farmland. Another theory is that the farm was named after the ship Constantia which, with the Alphen, was anchored in Table Bay. The original manor house appears to have been designed in a late Dutch Renaissance style. The traveller Francois Valentijn (16661727) described it as a double-storey dwelling with two or three steps leading to a front room or voorhuis, the floor of which was paved with white marble and red stone. There was a big pentagon in the shape of the Castle of Good Hope tiled into the centre of the floor. On both sides of the voorhuis were grand rooms, also with white marble floors. Agricultural activities on Constantia

Steenberg Vineyards polished concrete entrance

“Their wine tasting facility is very big and floored with the original clay bricks all round – for the same reason that clay does not absorb water. The whole winery has a very rustic look!” Groot Constantia Winery wine tasting area, using clay brick tiles F LO O R S J u l y Au g 2 0 1 1

13

Insight: Wine Cellars

included viticulture, and Constantia wine

admirals, captains and other dignitaries cov-

became renowned in Europe. In 1709 there

eted the Constantia label and treated their

operational farm and one of South Africa’s

were 70 000 vines on the farm and Van der

special guests to it.

most visited tourist attractions, where a wide

Joanna says: “Groot Constantia is a fully

The heritage of Groot Constantia would be

range of quality estate wines are created and

name Constantia is irrevocably linked to the

incomplete without regarding its setting. As

sold seven days a week. Various other attrac-

most famous wines made in South Africa.

important as the product of the vine is, so

tions, including restaurants and museums,

the beauty and significance of the priceless

make a visit an unforgettable experience.

Stel produced 5 630 litres of wine. Thus, the

Constantia wine was coveted across the globe. Limited volumes were made and it was

Manor House and the buildings grouped

so expensive that it was exclusively bought

around it are unequalled examples of Cape

scenery is spectacular, the winery kept spot-

and consumed by the aristocracy of the

Dutch architecture both in majesty and sim-

less and the staff well dressed and very

world. Members of the British Royal House,

plicity. The collection of artefacts, including

friendly. My experience here was extremely

Napoleon Bonaparte, Louis Philippe of France,

furniture and art, reflects the rich cultural tra-

harmonious. The view was filled with beauti-

Frederick II (The Great) of Prussia, governors,

dition of the Cape.

ful shrub bushes of grapes – acres long. The

“I was taken on a tour whilst visiting. The

sun was setting as I left and this provided the most magnificent and picturesque panorama overlooking the vineyards. “Their wine tasting facility is very big and floored with the original clay bricks all round – for the same reason that clay does not absorb water. The whole winery has a very rustic look!” Constantia Uitsig, known until 1940 as Constantia View, was the home of the Lategan family for five generations, which had ancestors who arrived in this country in 1735. Constantia Uitsig had been a portion of Simon van der Stel’s original grant of Groot Constantia. In 1894 Willem Lategan married Antoinette Bredell of Schoemanshoek, and with her inheritance he built the present homestead of Constantia Uitsig. In 1988 the farm was purchased by David and Marlene McCay. Together they have

High Constantia Winery Fermentation room, using clay brick tiles

restored the farm to its former glory, and Constantia Uitsig now boasts award-winning wines, three world-renowned restaurants, a private cricket oval, a spa and a 16-room luxury hotel. In 2006 fifty percent of the wine estate was bought by a consortium. Just 20 minutes from the heart of the city, Constantia Uitsig is truly Cape Town’s own Vineyard. The breathtaking rural beauty of a valley, where vineyard rows stretch up the mountainside, is unique in today’s overcrowded world. Joanna says, “This beautiful winery has three award-winning restaurants on the estate. They are La Colombe, Constantia Uitsig and River Café. Here I also got to

. . . wonderful wine tasting room with original wooden flooring planks . . . Uitsig Constantia original solid wood planks

14

F LO O R S J u l y Au g 2 0 1 1

taste the best dry red wine ever (Constantia Uitsig 2003). “They have a wonderful wine tasting room with original wooden flooring planks where you can enjoy the fruitful tastes of all their produced wine. Here the entrance is floored with concrete tiles.”

Insight: Wine Cellars

Steenberg Vineyards holds the distinction of being the oldest farm in the picturesque Constantia Valley, which is generally considered to be South Africa’s premier winegrowing region. With its cool, sea-facing slopes and majestic granite ridges, this vineyard has developed a worldwide reputation for producing excellent Cape wines. The land was originally granted to a widow, Catharina Ras, in 1682 and wines were first produced on the farm in 1695. The farm was first known as Swaaneweide – the feeding place of swans; it was only later renamed Steenberg, in honour of the imposing mountain which towers over it. Steenberg is the southernmost wine farm in the Constantia Valley, where it benefits greatly from the cooling influence of nearby False Bay. Since 1990 there is 60ha under vine, of which 48ha has grown to bear fruit. Steenberg boasts a state-of-the-art modern winery.

“. . . original clay bricks were laid for their (lesser) water absorption characteristics.”

The cultivars on the farm at the moment are: Cabernet Sauvignon; Pinot Noir; Nebbiolo;

Groot Constantia Winery Fermentation towers using clay brick tiles

Merlot; Shiraz; Sauvignon Blanc; Semillon. Their most renowned wines, Sauvignon Blanc Reserve and Catharina’s – a red Bordeaux blend named after the founder of Steenberg – have won many awards under the expertise of winemaker John Loubser, and the cellar has the capacity to produce around 70 000 cases. A major feature of the cellar is the vinotheque, where bottled wines are kept under ideal conditions until ready to be enjoyed. The luxurious Steenberg Hotel is situated on the farm, with restaurants, spas and a golf course. Joanna says, “This is another most beautiful vineyard. They also have a top-class restaurant called Bistro sixteen82 (named after the year they were established) and they have placed a polished concrete floor throughout the Bistro as well as the wine tasting area. “Catharina’s Restaurant which overlooks the great views of False Bay also plays a big role in the Steenberg winery as many locals and foreign visitors dine in this 90-seater restaurant. Once again, in the winery itself the original clay bricks were laid for their (lesser) water absorption characteristics.”

Steenberg Vineyards wine holding with clay brick tiles

Professional

0861 PETER(73837) www.peterbates.co.za

F LO O R S J u l y Au g 2 0 1 1

15

Insight

INVESTMENT

Carpets of distinction

A carpet is an accessory for a home or business, and is generally considered a rare purchase. Following the acquisition of a new car or property, buying a carpet can be one of the most expensive purchases a home or business owner will make and, although flooring options on the market are numerous and span broad price brackets, it is crucial that consumers consider their purchase as an investment, chosen for practicality, style and value reasons.

Nouwens Carpets is known for its premium quality and style offerings to suit the needs of both domestic and commercial environments . . . Nouwens Contracta Spec

16

F LO O R S J u l y Au g 2 0 1 1

Insight

will last for years. Whatever space is being carpeted, the best advice that Nouwens can give is that consumers should spend as much as they can afford, because the value of investing in a quality carpet is that it will last a lifetime.

Moving forward From time to time, established brands need to re-look themselves and test their modernity and relevance to current consumers. Nouwens Carpets found itself at a point in its lifecycle where it needed to do just that, and received valuable feedback both from the trade and long-term customers alike. The focus was to revitalise – not re-invent – the brand, and also maintain what had made it appealing in the past, while adapting to changes in society and the competitive landscape. Working with brand agency GRID, Nouwens strategically formulated where it wanted to be and what it wants to represent as it moves into its 50th anniversary year and beyond. The Nouwens Carpets brand is renowned for its craftsmanship, quality and heritage – valuable brand attributes that it didn’t want to lose when revisiting its corporate identity. Likewise, its reputation for delivering a premium product needed to remain intact, with the significance of wool playing a pivotal role in perceptions both currently and moving forward.

Nouwens Madison Square

A

In order to be truly effective, Nouwens

s an industry that is continually on

wearing, spill-blocking and odour-elimina-

the move due to changing trends,

ting, and retains its good looks and perfor-

the carpet market is one that is unlikely to

mance characteristics for longer.

disappoint – given that the consumers’ pur-

On the professional front, the Nouwens

chase will add style and modernity to their

Contracta Spec is a perfect option for deco-

interior space.

rators or designers. The secret of its success

It is therefore important for consumers to

lies in the original wrap-spun and nylon

understand the advantages of making an

base, which makes the carpet both afforda-

informed decision when purchasing a carpet.

ble and unbelievably hardwearing – which

And who better to provide guidance than

means the Contracta is long-lasting, even

one of the specialist players in the industry –

under high traffic. This, together with its

Nouwens Carpets.

stylish plush appearance, has made it an all-

Nouwens understands the dilemmas involved when choosing a carpet so, before

round favourite. For domestic and premium commercial

making a rushed decision based only on

areas, Madison Square is an excellent choice

price, the advantages of investing in a car-

due to its value and style. In its current

pet must be considered. Nouwens Carpets

‘multi-roll’ mode, Nouwens has tailored

is known for its premium quality and style

Madison Square with pure new wool to

offerings to suit the needs of both domestic

meet the aesthetic needs of our times and

and commercial environments, because a

demonstrate a return to nature. The greatest

Nouwens carpet is comparatively harder-

pleasure, however, is that the carpet’s look

recognised that the entire brand-building exercise had to be a fully integrated one, and include a refreshing and modernising of Nouwens Carpets’ overall corporate identity, a reinforcement of the brand tag-line, and a fresh marketing thrust to act as a launch pad to take the ‘new look’ Nouwens to market. As a result, the company has developed a stylish, personalised luxury brand architecture that it is now proud to introduce. While this is a first sample, Nouwens looks forward to unveiling ever more of itself, building on its strong brand heritage as it moves through the rest of 2011 and into 2012. Nouwens Platinum Partners & Nouwens Appointed Dealers: A complete and updated list of Nouwens Platinum Partners and Nouwens Appointed Dealers appears by region at www.nouwens.co.za. For more information: 011 796 5180 / 031 502 5730 / 021 447 2856 / 058 622 1101 / enquiries@nouwens.co.za

F LO O R S J u l y Au g 2 0 1 1

17

Products & Ser vices

CHANGE

Into the future

Van Dyck Carpets is South Africa’s longest established carpet brand,

T

hrough continual product innovation, new product launches, recolouring

of popular existing ranges and the signing of partnerships with international and local flooring partners, Van Dyck

established in 1948, and the company and its products are associated

will remain at the forefront of flooring

with and renowned for superior style, quality and performance.

in relation to the recent announcements

technology in South Africa – particularly made by the company. “It’s time for a change at Van Dyck Carpets and we have embarked on a new branding strategy, which incorporates a fresh look to our logo and corporate vision that encompasses the fast-changing pace of our external environment,” says Dr Mehran Zarrebini, CEO of Van Dyck.

The Brand “The aspiration and reach of this branding strategy is necessarily broad, as it touches on a wide range of activities that occurs within our organisation. You will notice that ‘carpets’ has been dropped from the branding of the company due to the diversified nature of products that we now manufacture at Van Dyck,” he says. “We are no longer simply a carpet manufacturer. We are an organisation that manufactures a wide variety of products that serves various market segments both nationally and internationally in the textile flooring industry. We are an organisation of international reach.”

New logo “Our new logo represents a new strategic direction for Van Dyck. The new logo colour depicts our responsibility towards the environment. It is our goal to ensure that environmental concerns shape every aspect of our strategy and action,” Zarrebini continues. “We should not be satisfied with waiting for regulatory mandates to take effect. It is our intention to be at the forefront of environmental responsibility and ensure that we leave a legacy of a clean and sustainable environment to our future generations.” “Moreover, we have refreshed the font type, removed the diamond and the new logo will become a prominent feature of our branding. The whole look and feel of the logo gives a younger and more modern impression that reflects the energetic yet experienced attitude towards our

Vertigo

18

F LO O R S J u l y Au g 2 0 1 1

customers.”

Products & Ser vices

TigerTurf versatility

Corporate Vision “Our corporate vision encompasses a compelling story about the future, which all of us should enthusiastically embrace. There are two very distinct and important parts to our new vision. Firstly, it includes an emphasis on ethics. As an ethical business, we must act as responsible citizens of the communities in which we operate. Secondly, we stand behind the weight of our new corporate logo that, as a growing organisation, we must not ignore the need for a sustainable society and minimise our impact on the environment,” he says. “It is our aim to be a world-class manufacturer of soft floorcoverings as defined by the customers we serve – an organisation that has in its DNA honesty, integrity and hard work, and is committed to enhancing society’s ability to build a sustainable future through environmental and socially responsible practises.” “In summary, the key to our success is dependent on the energy, goodwill and outward-looking attitude of all of our employees. With this in mind, Van Dyck is positioned to deliver its aspiration of being the first choice for soft flooring in South Africa and beyond,” he concludes. For more information: 031 913 3800 /

Fibre extrusion & this is part of the R80 Mio capital expenditure programme.

0800227738 or www.vandyckcarpets.com.

F LO O R S J u l y Au g 2 0 1 1

19

Products & Ser vices

ADHESIVES

Getting sticky

With more than 50 years’ experience in the local and international flooring industry, Denver Coleman, Chairman of Polyflor SA, answers questions posed by installers, architects and readers on their flooring challenges.* The question in this issue deals with adhesive applications.

“W

hat are the most common mistakes made during adhesive applications?” Godfrey Nkosi, Pietermaritzburg

There are some basic rules to follow for

Before applying any adhesive always

the successful application of adhesives:

adhere to the following guidelines:

A pressure-sensitive adhesive,

1. Always follow the instructions of the

Test the subfloor for moisture, as

approved by the flooring manufactur-

specific manufacturer of both the

too high a moisture content will

er and recommended by the adhesive

flooring and the adhesive you are

result in a poor bond of the sheet

company, can be used.

using – don’t assume that they will

flooring/tiles to the screed (typi-

The adhesive manufacturer will rec-

remain the same for all products you

cally this should be less than 75%

ommend the correct fine notch trowel

use regularly, as there are constant

RH or less than 3,5% moisture

to ensure the correct amount of adhe-

changes and improvements being

content).

sive is applied to the floor screed.

made by manufacturers.

Ensure that the screed surface has

After that, a short hair or mohair paint

been well swept, or preferably

roller ‘wetted’ in the adhesive and

vacuumed, to remove all dust as

rolled out can be used to effectively

Control floorcoverings and for earth-

this will result in a poor bond.

flatten the trowel marks and allow the

ing strips. If alternative adhesives are

Ensure that the screed surface is

adhesive to rid itself of all moisture

used, they must be recommended

sufficiently smooth, as any imper-

before applying the floor material.

by the adhesive manufacturer as fit

fections will mirror through the

If this is not correctly done, moisture

for purpose and approved by the

floor sheet especially when the

will be trapped beneath the flooring

flooring supplier.

floor is cleaned/sealed/buffed – at

material, causing bubbles.

which time it will be too late to

This method is a successful way of

rectify.

eliminating trowel ridges that show

mended trowel blades with the spec-

Adhesives should not be used if

through the floor.

ified notches as this will firstly apply

the ambient or screed tempera-

In certain situations a light coat of

the correct amount of adhesive and

ture is below 8-10ºC (or otherwise

adhesive applied to the underneath of

secondly limit the profiling through

as per manufacturer’s instruc-

the floor sheeting and allowed to dry

of trowel marks.

tions), and adhesive should not be

thoroughly (using pressure-sensitive

stored at such low temperatures,

adhesive only) will act as a contact

2. Use conductive adhesive for all Static

3. Always use the correct and recom-

4. Do not use re-notched trowel blades,

otherwise under any of these con-

system and create a more secure

unless they have been professionally

ditions they will perform poorly.

bond. Do not try this with a standard

re-notched by the manufacturer, and

Adhesives should generally be

wet-set acrylic!!

very definitely do not use any trowel

just touch-dry when applying the

Always read and follow all manufactur-

blades that have been notched with a

flooring material – if too dry the

ers’ instructions!!

hacksaw or anything similar.

bond will be poor or, if flooring is

If you have any flooring questions relating to design, installation, problems or commentary you wish to share with Denver, please e-mail him at info@polyflor.co.za with ASK DENVER in the subject line or phone Blythe at Polyflor on 011 609 3500. *The views expressed in this article are not necessarily the views or opinions of FLOORS in Africa and may not be applicable to all resilient floorcoverings. This article has not been solicited or sponsored by FLOORS in Africa.

applied too soon, either water or

5. Make sure that after applying the

22

To avoid trowel marks:

solvent will be trapped below the

floor sheeting the floor is rolled

flooring. Either will cause bubbles

with a 68 kg roller as soon as pos-

later on (depending on the type of

sible to effect transfer of adhesive to

adhesive used) which are difficult

the floor sheeting which will give a

to fix.

strong bond, and also eliminate the

The 68 kg roller should be clean

trowel marks showing through the

and smooth to prevent scuff/dam-

sheeting.

age to the flooring product.

F LO O R S J u l y Au g 2 0 1 1

Products & Ser vices

SEBO HARD FLOOR MAINTENANCE

Reliability as standard Built by professionals for professionals Proffessional results , effortlessly It has never been easier to make hard floors shine Perfect choice to maintain hard floors Easy to maintain Super gloss finish Longer Lasting Ideal for : Medical practices , hotels , shops etc. Easy , effective , efficient Hygienic Prolong life of floor

F L O O R S J u l y A u g 2 0 1 1 23

Products & Ser vices

FLOOR COLOUR

Choose wisely Quartz Carpet has increased its colour range to 40 standard colours, but excitingly, the stone can now also be tinted to any Pantone colour with recent developments in the company’s makeover.

W

hen choosing room colours it is advis-

able to start on the floor and work your way up. The floor area comprises a sixth of the total space in a room, just like your ceiling. This amount of space is bound to have a large impression on the overall room colour scheme. Whenever specifiers think of colours for their projects they often think of the walls or the main furniture pieces and accessories. However, the flooring in a room is one of the single biggest elements of a project’s interior décor, playing a pivotal role in setting the mood and ambience of a room. A bit of effort spent on flooring colour can pay huge dividends in the overall success of an interior decorating scheme for your project. A neutral colour scheme can have advantages, making it easier for you to redecorate or change the look of your

. . . flooring in a room is one of the single biggest elements of a project’s interior décor . . . 24

F LO O R S J u l y Au g 2 0 1 1

space, simply by highlighting different furnishings and accessories. A neutral background of white, beige or cream can easily look very different if

Products & Ser vices

accented with different colours and textures such as warm berry tones in velvet versus black and grey shades in cool linen; or earthy browns versus formal elegance in dark shades. The functional aspect should always be the first consideration and this can in fact help to narrow your choices. For example, flooring for an area of high traffic may not benefit from being too pale in colour, as this would show up stains and dirt easily. Similarly, dark shades tend to make small rooms smaller so this needs to be accented in too. Fortunately, Quartz Carpet has created colours throughout the entire colour spectrum from neutral whites to blacks incorporating the greens, blues, reds, greys and earthy browns. If you don’t find a colour here, just choose any Pantone colour or Plascon, Marmoran and Dulux colour and it will be made up. Finally, consider the entire project when choosing flooring colours in different spaces and remember that a good dÊcor flows seamlessly from room to room or from office to office. For more information: 086 178 2789 / www.quartzcarpet.co.za

F L O O R S J u l y A u g 2 0 1 1 25

Products & Ser vices

FINAL SOLUTIONS Stainless Steel Profiles Stainless steel is a very hardy and versatile material and its anti-corrosive properties make it a very popular material to specify amongst the professionals. Bespoke items in stainless steel are often sent to the Kirk team with our only limitation being a maximum length of 4m and a maximum

FLOOR AND WALL FINAL SOLUTIONS

available through Kirk Marketing

thickness of 3mm.

“The Matrix” Architects entrance stairs in PE.

P

Stainless steel tile-in skirting

Stainless steel tile listello

Stainless steel tile-in corner protector

rofiles can be made in all available grades of stainless steel and Kirk can help in the selection of the correct grade of stain-

less steel, if all the relevant information is supplied. In special cases Kirk can produce samples for approval before commencing. Lead times apply to these products and the cost of the profile can vary – depending on the amount ordered per profile. The price can be prohibitive if small quantities of specialised items are manufactured, however this can be discussed at the design phase.

KIRK

Brass movement joint

Stainless Steel movement joint

The beauty of working with stainless steel is that it is possible to achieve a variety of profile shapes such as top hats, angles, U-channels, lip channels, architraves and bespoke items – all to the architect or designer’s specifications, with each profile having its unique dimensions. Off-the-shelf items such as different height straight edges, square edges, round edges, corner protectors, listellos, internal skirtings,

M Trim is a brand of PVC, brass, aluminium, stainless steel and anodised profiles used for tiles, carpets, vinyl and laminate floors.

formable straight edges, and more, are readily available as stock items from the Kirk warehouses. The different finishes of stainless steel include polished, brushed

Quality Profiles for wood and laminate floors.

Quality Tile Cleaners,Strippers and Sealants.

and satin, giving the specifier more opportunities to meet the aesthetics required. Stainless steel profiles are often used on tiled floors and walls, with columns, stair edges, dividers, listellos, tile edges, and in public bathrooms, shopping centres, airports and other high-wear areas. They can also be used internally and externally, but it is best to get advice from your Kirk salesperson so that the correct grade is selected. Please contact your nearest Kirk branch for advice and help in your design of any stainless steel profiles you might require. For further information: 011 444 1441 / sales@kirk.co.za / www.kirk.co.za.

Structural movement and expansion joints for floors, walls, columns, ceilings, roofs, car garages, bridges. Fire Barriers also available.

GAUTENG Tel: +27 11 444 1441 Fax: +27 11 444 1165 CAPE TOWN Tel: +27 21 949 2226 Fax: +27 21 949 4531

PVC curvable profiles for multishaped flooring. Commercial and domestic applications.

KWAZULU NATAL Tel: +27 31 564 1175 Fax: +27 31 564 1143 PORT ELIZABETH Tel: 0860 547573 Fax: 086 688 4980

E-mail: sales@kirk.co.za Website: www.kirk.co.za F LO O R S J u l y Au g 2 0 1 1

27

Products & Ser vices

MILESTONE

Turning thirty!

On the 1 October 2011, Safic (Pty) Ltd, a sister st

NEW

Upright vacuum cleaners

Sebo, a German company with a 25-year history

company of FloorworX turns 30. This marks an

in manufacturing high-quality vacuum clean-

important milestone in the history of this company.

ers, claims to be the global leader in commercial

T

he total solution package offered by Safic includes both chemicals and equipment, and caters for most key market segments, includ-

upright vacuum cleaners having sold over three million since its inception.

ing food and beverage; industrial and commercial; healthcare as well as specialised industries such as aviation and heavy moving vehicles. As a listed company, and given Safic’s impressive track record on triple bottom line principles, their business approach is driven by key fundamentals, such as their ISO systems, as well as their responsible care commitments. Safic was the first ever chemical company in South Africa to be awarded all three ISO certifications namely ISO 9000, 14000 and OHSAS 18001. The company has recently launched its 100ml sachet range. This maintenance range is set to serve facility management, retail and healthcare sectors. This flexible product offering ensures clients exceptional product quality while at the same time addressing many of their key buying concerns – ease of use; application, as well as triple bottom line principles including health, safety and environmental responsibility. For further information: 0860 4 72342 or sales@safic.co.za or www.safic.co.za.

A

Features of the Dart 1 & 2 – for the technically minded SEBO DART 1 - 31cm cleaning head - ‘Flex-neck’ - 1300W Suction motor - 175W Brush motor - Hospital-grade filtration - On-board hose - Crevice nozzle and clamp - 4-level height adjustment SEBO DART 2 - 37cm cleaning head - 200W Brush motor - Other features as per DART 1

imed at providing a user-friendly operation, the advanced design of Sebo vacuum cleaners ensures quality construction,

superb cleaning performance, easy maintenance and high filtration as standard. The new Dart range of vacuum cleaners has been developed to provide even better performance, and with a powerful suction and brush action they can lift carpet pile and remove deeply embedded dirt and grit. The Dart 1 and Dart 2 models in this range offer professional per-

formance in a lightweight, versatile and easy-to-manoeuvre machine, designed to be agile, user-friendly and to achieve superb cleaning results quickly, easily and economically. With two brush widths (Dart 1 = 31cm; Dart 2 = 37cm) these models are ideal for small and medium-sized areas, and their ‘flat out’ performance means that they have the ability to reach and clean under furniture and right up to skirting boards with their low-profile ‘L’-shaped cleaning heads. The ‘Flex-neck’ of the Dart gives 90º vertical and 180º horizontal movement, providing superb manoeuvrability for fast cleaning around obstacles. Also, when detached from the power head, the Dart is transformed into a lightweight, powerful suction machine which can be carried around with its comfortable carrying handle. All fitted with a 9,5m cable which allows an extensive cleaning range, these models have an easy and hygienic bag change operation. The bag drops easily into position and is firmly fixed in place when the cover is closed. The sealing cap ensures that all dirt and dust is safely secured when handling the bag. A wide range of optional accessories is available from Sebo, and for the technically minded the technical details of these two models appear in the box given with this article. For further information: 086 111 4250 / sebo@internext.co.za / www.sebo.co.za

28

F LO O R S J u l y Au g 2 0 1 1

Wood, Laminates & Bamboo There is an old business maxim that says the only

wood – long the favourite of the affluent, upmar-

thing constant is change, and this could not be

ket home or prestigious building – found itself

more applicable to wood, laminates and bamboo

under pressure from the environmentalists looking

floors than today. They look alike, they feel the

to preserve the rain forests, and from the advent of

same, they have many similar attributes, and they

laminate flooring which offered a faux wood floor

are all under pressure in different ways, often rely-

at considerably less expense.

ing on innovative technology, to save the day. Solid

F LO O R S J u l y Au g 2 0 1 1

29

Feature Focus: Wood, Laminates & Bamboo

SHUTTERSTOCK

WOOD, LAMINATES & They might BAMBOO seem similar, but…

30

F LO O R S J u l y Au g 2 0 1 1

Feature Focus: Wood, Laminates & Bamboo

There is an old business maxim that says the only thing constant is change, and this could not be more applicable to wood, laminates and bamboo floors than today.

T

– keeping the floor in a pristine and perfectly hygienic condition. Laminates are also stainand fade-resistant. Most brands use a click fixing system which makes installation – together with any

hey look alike, they feel the same, they

ings a run for their money.

replacement requirement at a later stage –

Because laminate surface finishes replicate

easy. With the quality surfaces and textures

are all under pressure in different ways,

the look of all the popular hardwoods with a

of laminate floors these days they are often

often relying on innovative technology, to

high degree of proficiency, it was the natural

mistaken for wood, even by experts.

save the day.

wood sector that bore the brunt of the initial

have many similar attributes, and they

Solid wood – long the favourite of the affluent, upmarket home or prestigious build-

campaigns. Realising that one of the main selling points

Most laminate floors sold in this country are imported from reputable manufacturers in Europe where there are stringent technical

ing – found itself under pressure from the

for laminates was that the consumer could

requirements imposed by the EPLF (European

environmentalists looking to preserve the

get a floor that could look like any wood in

Producers of Laminate Floorcoverings) to

rain forests, and from the advent of laminate

a whole range of different exotic hardwoods

ensure that the consumer or specifier can rely

flooring which offered a faux wood floor at

at a much lower cost than the real thing, and

on the quality.

considerably less expense.

with no need for waxing, sanding, oiling or

In the same vein, SAWLFA (The Southern

any other treatments in order to keep it clean

African Wood & Laminate Flooring

development of engineered wood flooring,

and looking good, laminates began to take

Association) has been established locally and

which fits neatly between the two extremes.

considerable market share in these areas.

training instigated to ensure their members

The answer has been provided by the

Laminates, strongly marketed as wooden

Capitalising on their success, the laminate

provide the very highest standards of work-

flooring – which it is not – gained market

manufacturers soon developed other inno-

manship.

share with its ease of installation, unim-

vations with a wide variety of natural stone

Bamboo is great

peachable surface finishes, low maintenance

lookalikes and even, tiles that replicated

Bamboo is potentially a superbly green floor-

and equally low cost, but is finding increas-

ceramic tiles – but this latter development

ing material. How the bamboo is managed,

ing competition from alternative floorcover-

does not seem to have met with much suc-

harvested, and ultimately made into flooring

ing materials such as vinyl which now com-

cess locally.

can impact its greenness to a degree.

pete on aesthetic appeal in replicating the look of a solid wood floor. And then – to compete with them all – along comes bamboo, a grass that provides a wood-look floor, a long service life, and its credentials held high in the esteem of the environmentalists. But is bamboo as green as

However, the nett result was that, although

. . . laminate surface finishes replicate the look of all the popular hardwoods with a high degree of proficiency.

Widely regarded as one of the planet’s fastest growing plants – some species can grow up to a metre in a day – a bamboo plant reaches full maturity within five years as opposed to 40-50 years for many species of hardwood trees. If harvested correctly so that a viable portion of the stalk and roots remains, the bam-

we think it is? there was no general agreement or collusion

boo needn’t be replanted; it can simply regen-

options, beginning with laminates which

between the various companies, most other

erate, and an acre of bamboo can provide far

started all the rumpus in this sector before

flooring manufacturers seemed to decide to

more flooring than an acre of trees.

the green lobby got going.

‘fight laminates with fire’, which has led to the

Why laminates?

development of engineered wood flooring,

carbon sequestration, since fast-growing trees

The introduction of laminate floorcoverings

large-format ceramic and porcelain tiles in

absorb carbon quicker than others such as

to South Africa just a few years ago – backed

wood and stone looks, and luxury vinyl tiles

oak or pine trees. Although it’s technically a

by considerable promotional campaigns

in similar patterning – all aimed at obtain-

grass, bamboo is classified as a timber within

– caused quite a stir in the local market,

ing or regaining a share of the market from

the construction industry for its characteristics

particularly as it was readily accepted by the

laminates, and all laying claim to be doing

and appearance.

residential sector and was seen to be mak-

just that!

Let’s take a serious look at the three ‘wood’

ing inroads into areas traditionally served by

So, it could be said that the boot is now on

This rapid cycle translates into increased

The World Wildlife Fund estimates that an acre of bamboo can store 6,88 metric tonnes

the other foot but, in general, laminates are

of carbon per year, about 70% more than an

still a less expensive, easier to install answer

acre of hardwoods. Once bamboo is turned

fly-by-night products and operators, plus the

for those that want the appearance of wood

into flooring or furniture that won’t rot due to

ensuing shoddy workmanship by the ‘bakkie

within a lower budget.

the treatments applied, then that carbon can

other flooring materials. Once laminates had got over the problem of

remain fixed for decades.

brigade’ and companies that disappeared

These hardwearing floorcoverings are

(with their guarantees!) once they found

very easy to keep clean. Dirt and dust can

The endangered panda does not feed on

floors failing, they set about the task of taking

be quickly and completely removed from

Pyllostachus Pubescens commonly known

market share and it wasn’t long before they

the smooth surface of laminate flooring by

as Mao or Moso bamboo – the only bamboo

were giving almost all the other floorcover-

brushing, vacuum cleaning or damp cleaning

suitable for flooring or furniture boards – and

F LO O R S J u l y Au g 2 0 1 1

31

Feature Focus: Wood, Laminates & Bamboo

highest grade of glues, as specified by reputable local importers, and thereby achieve the lowest class emission ratings. But, like any industry (just as with laminates and engineered flooring manufacturers), there are factories that manufacture bamboo flooring as cheaply as possible using the cheap alternatives to expensive glues that emit higher levels of formaldehyde, which can have serious health consequences for consumers. The answer is to insist on verification – by an authoritative and independent source – of the growing, harvesting and manufacturing methods used of any bamboo flooring, preferably by asking for the FSC certification, in the same way that the sustainability of regulated hardwood operations is verified by the Forest Stewardship Council. Nevertheless, bamboo makes a superb floorcovering both in looks and functionality, providing a stunning appearance for any room that will match any décor or furnishings. Apart from the natural colours that bamboo provides, the planks can be obtained with stained or dyed surfaces in a myriad of colour choices and finishes. Solid bamboo floors can be refinished at least 5 times (without worrying about the thickness of the “wear layer” as with engi-

SHUTTERSTOCK

neered flooring) if ever needed, so in pracThe flooring planks are factory finished, so sanding and sealing is not required, and they can be installed over almost any type of subfloor, using either a traditional tongue-

is thereby unaffected by this industry. The

policies, largely putting paid to many of the

and-groove connection or the popular click

last point in bamboo’s favour is its robust-

bad practices. In fact, the opposite is true –

system, in the same way as engineered wood

ness.

China’s National Forest Restoration Program

– glued down, nailed or installed as a float-

has a planned afforestation of 4 million

ing floor.

The plant will grow in a variety of climates

Bamboo floors also exhibit extraordinary

and soils and can flourish unaided by chemi-

hectares annually. In 2007 the forest area in

cal fertilisers, pesticides or traditional farm-

China grew by 5,196 million hectares. During

strength, and the strand-woven varieties are

ing equipment. Bamboo producers also

2008 they planted more than 2,5 billion trees

claimed to be harder than oak, maple and

claim that the plants’ extensive root systems

covering 5,29 million hectares. In 2009 this

many of the exotic Brazilian hardwoods.

prevent soil erosion.

program has seen an additional 2,6 billion

Easy to keep clean in the same way as

There is an argument that many Asian

trees planted, covering about 5,412 million

laminate flooring, bamboo is ideal for com-

producers have been aggressive with their

hectares. As you can see they are exceeding

mercial or residential applications where

planting, often at the expense of old wood-

their target every year.

it can meet all the technical and aesthetic

lands and their attendant ecosystems. This argument is unsubstantiated for two reasons: Due to prolific growth of the extensive natural Mao bamboo forests, there has been no incentive for planting at the expense of the other timbers. In the late 1990’s (29th April 1998) the Chinese government reformed their forestry

32

tice, they can truly last lifetimes.

F LO O R S J u l y Au g 2 0 1 1

There are bamboo factories that use the

. . . bamboo is ideal for commercial or residential applications where it can meet all the technical and aesthetic requirements,

requirements, enhance any décor, and last a lifetime.

Wood? Yes, but solid or engineered? The most diehard hardwood flooring specialist will admit that, even leaving aside the environmental issues, the modern engineered wood flooring has the edge, although solid wood flooring is still available

Feature Focus: Wood, Laminates & Bamboo

the core and is available in almost any hardwood species. Thus, this product has the natural characteristics of the selected wood species but it has been designed to provide greater stability, particularly where moisture or heat pose problems for solid hardwood floors. Engineered floors can be provided as tongue-and-groove board, although they are also available using the unique ‘click’ system made popular by laminate floors. Another main attribute is that although the consumer gets a floor with a natural hardwood surface, this design uses considerably less of the natural material to achieve the same effect and performance. The lifespan of engineered wood floors is what you would expect from a wood floor. Some brands of engineered flooring have a thin wear layer that can only be re-coated

. . .this design uses considerably less of the natural material to achieve the same effect and performance.

TERAGREN

and cannot be sanded and refinished as new

and in regular demand. So, let’s look briefly at solid wood, and first discuss the old argument of whether factory

oped with space-age technology, and need no waxing. Prior to the development of engineered

again once they get worn (in the same way that solid wood flooring can be renewed), but they can still provide an average lifespan of between 30-40 years depending on traffic. Other brands or styles can have a thicker 2-4mm thick wear layer that can be completely sanded and refinished 2-5 times

finishing or custom sanding and finishing on

hardwood flooring, hardwood products

if ever needed. These thicker wear layer

site is best.

could not be installed on-slab or in a base-

engineered floors can last from 40-100 years

ment without a special subfloor system.

before having to be replaced – which adds

In truth, you should feel comfortable with either choice if you are using a professional

Now it is possible to enjoy real hardwood

installer, but modern factory finishing offers

flooring in those areas, without all that fuss

many advantages, including being inspected

and expense, with the advent of engineered

than traditional solid wood flooring, but less

for defects at the mill so you receive first-

hardwood flooring – a special cross-ply

so than bamboo flooring, and purchasing

choice product every time, whereas on-site

construction that eliminates the problem of

this flooring helps to reduce exploitation of

finishing depends on the quality of the work-

expansion and contraction usually associ-

the exotic woods. For every square metre of

manship that day.

ated with solid hardwood.

16mm (3/4 inch) thick solid wood flooring

Factory-finished flooring usually installs

Engineered hardwood flooring

greatly to their appeal. So, engineered wood flooring is Green

approximately four times that area can be

quicker and without the dust and odours

The term, engineered hardwood flooring is

manufactured into engineered wood floor-

involved with on-site finishing. However,

somewhat misleading. This type of flooring is

ing, making this the best flooring (barring

even though factory-finished flooring comes

100% real wood – “engineered” only refers to

bamboo) to conserve exotic forests.

in a variety of colours, on-site finishing

the manufacturing process.

allows for closer colour matching with exist-

Engineered hardwood flooring is a multi-

Wood, laminates or bamboo? The choice is yours and, in an honest attempt to ‘draw the

layer product comprising a core of plywood

battle lines’, we hope this has relieved the

or HDF, or a less vulnerable wood to hard-

reader of some doubts or misconceptions,

are available in either high-gloss or matte.

wood, and has a top layer of hardwood

and assisted in the decision-making for your

Both types have exciting new finishes devel-

veneer that is affixed to the top surface of

next wooden floor.

ing woodwork or cabinets. Both factory finishes and on-site finishes

F LO O R S J u l y Au g 2 0 1 1

33

Feature Focus: Wood, Laminates & Bamboo

SOLID WOOD

Totally natural product

Despite the fact that so many different types of floorcovering have

and harvesting of timber from the forests is

entered the market in recent years that try to copy the aesthetic

Bedson’s company-owned forests in Uruguay

appeal, texture and performance of solid wood, no other type of flooring offers the warmth, beauty, and value, of this totally natural product.

strictly controlled to ensure sustainability. form part of a 300-year sustainable project. The planting was done in accordance with The Forest Stewardship Council’s (FSC) strict principles and guidelines to preserve the bio-diversity and ensure sustainability, and in effect this ensures that the planting and growth of the trees far exceeds the amount of harvesting each year. This sustainable forest management makes it possible to harvest wood without any serious impact on the environment, because trees are a renewable resource that can be replaced time and time again. Also, wood is a carbon-neutral product that produces oxygen during its growth cycle and stores carbon during its service life. The maintenance of today’s solid wood floors is easy! The new technology in stains and finishes calls for regular cleaning that takes little more than sweeping and/or vacuuming, with occasional use of a professional wood floor cleaning product. Although it may be many years before

. . . solid wood flooring is the only option available that is completely sustainable, being both renewable and recyclable.

W

necessary through excessive wear, solid wood products, on average, have a thick ‘sandable surface’ (the wood that is above the tongue-and-groove level of the installed floor), and can be installed using nails. Lastly, solid wood tends to be less expensive than engineered wood, but this, as

ood flooring enhances the décor

environment. However, there is a popular

with the thickness of the sandable surface,

of any room, and provides timeless

misconception that solid wood flooring is

depends on the quality of the engineered

not eco-friendly.

wood (most inexpensive engineered wood

beauty that will increase in value throughout the years – in fact, it is regularly stated by

This is totally untrue and, fortunately, the

products are ‘veneer’ wood floors, and not ‘engineered’).

estate agents that houses with wood floor-

facts are clear: solid wood flooring is the only

ing sell faster and for higher prices than

option available that is completely sustain-

houses without.

able, being both renewable and recyclable.

of 200 000 m² including 40 exotic and

Also, because wood does not collect dust

hardwood species. With its headquarters in

affordable, because when other flooring

and other allergens, many leading health

Pretoria, the company has regional offices

options are looking tired and worn out,

associations agree that wood floors are the

and warehousing in Cape Town and Durban,

solid wood floors will still look beautiful

perfect choice for a healthy home.

and recently opened an exquisite new show-

This also makes today’s wood floors

without any loss of performance. Some

In addition, solid wood flooring has the

Bedson Timbers holds a stock in excess

room in Silverton, Pretoria. But Bedson’s mar-

solid wood floors have been known to last

smallest impact on our environment. It is

keting is not restricted to this country as it

for hundreds of years.

carbon-neutral, uses fewer fossil fuels and

provides a considerable service throughout

less water consumption in its production,

Africa and the Indian Ocean islands.

Public awareness about environmental issues is at an all-time high and, increasingly,

and has one of the longest service lives of all

consumers are doing their part by choosing

flooring options.

products that have a minimal impact on the

34

sanding of the solid wood floor becomes

F LO O R S J u l y Au g 2 0 1 1

However, it is essential that the management

For more information: Head Office, 012 803 4376 / KZN 031 736 1022 / www.bedsonflooring.co.za

www.bedsonflooring.co.za great flooring guide|2011 0861 BEDSON

COMMERCIAL SPECIFYING

The only South African manufacturer of solid hardwood flooring and decking. A seamless transition between indoor and outdoor living.

Head Office: Pretoria, Gauteng c/o Axle & Battery St, Willows Business Park, Silverton Ext. 52 T 012 803 4376 E sales@bedson.co.za Branch: Hammarsdale, Kwa Zulu Natal Unit 2 - Complex 4, 121 Main g r e Rd, a t fHammarsdale looring guide|2011 T 031 736 1022 E david.gearing@bedson.co.za

Feature Focus: Wood, Laminates & Bamboo

LAMINATES

Why indeed!

Since laminates were introduced to South Africa , they have made considerable impact on the hardwood markets, but have also made inroads into other sectors that were traditionally the domain of vinyl, ceramics, and others.

T

PRODUCT FOCUS Exciting new ranges Traviata Flooring Systems, established distributors of laminate flooring, has recently partnered with two global manufacturers to bring exciting new ranges to South Africa.

he advent of engineered wood is claiming back some of the mar-

ket share lost by hardwood – and vinyl, ceramic, and other materi-

als have started jumping on the bandwagon by developing wood and stone look-alikes to compete with laminates. To get an authoritative view on the current state of the market from a laminate viewpoint, FLOORS in Africa posed five pertinent questions to the Southern African Wood & Laminate Flooring Association (SAWLFA), and the response is shown here. What is the effect on laminates with ‘new’ materials entering the market? Laminate as a floorcovering has nowhere near reached its full potential and the use of laminate will continue to increase in the long term. New products such as floating vinyl flooring will become more popular but will still only take a small part of the total laminate, wood and engineered wood flooring market. Where it is felt that laminates do a better job, and why? As long as the correct laminate is used in an installation it can be the first-choice product for almost every application; laminate is easier to repair than a ceramic tile, looks more natural than carpet, and is a healthy choice for people with allergies. The quality of the installation and the underlay also determines how well a laminate will last. What are the latest developments in laminate flooring? Laminate has come a long way since the first product was introduced to South Africa. The latest developments include better locking systems which are easier to install and speed up the application process. The décors on laminate are improving all the time, and with the introduction of realistic surfaces that are hard to tell from real wood, laminate is set to become the leader in flooring solutions for the DIY person looking to complete a weekend project. How do you see the future for laminates, both technically and from a sales/market share viewpoint? The future for laminate flooring in South Africa is looking good, and with the introduction of better quality laminate and the improved

raviloc, a luxury vinyl wood-plank, is the cutting edge of solid vinyl technology. Using a patented click-all-round system it

forms a truly floating resilient floor that has great aesthetics, is very hygienic and easy to clean and maintain. These attributes together with its Ceramic Bead wear layer have

seen Traviloc find easy acceptance in the hospitality and leisure markets. Ideal for hotels, restaurants, spas and other commercial applications, Traviloc has to date been so successful that new patterns and finishes are already being planned for mid-year. Also in the Traviata sales programme is a range of genuine wood

click-and-lock joint systems, laminate flooring is easy to install and will

veneer flooring under the brand name of Par-Ky, which gives the

change the look of a room in a matter of hours. Installing ceramic tiles

look and feel of real wood without the price or cost to nature of

or fitting carpet is difficult and thus not an option unless you have the

solid wood.

correct tools and experience.

Ideal for upmarket applications such as hotel bedrooms, lounge

Laminate flooring is the obvious answer for the DIY market; with lim-

areas and superior residences, the Dia-Pro finish means you never

ited skill and a few tools normally found in most homes even the most

have to re-sand or refinish Par-Ky. New veneer processing technol-

inexperienced DIY-er can achieve a good-looking floor.

ogy and the use of a high-density fibre (HDF) core makes exotic spe-

Any general observations? Ensure you buy your laminate from a reputable company and do not

cies achievable, affordable and hardwearing. To support these new products, Traviata has recently formed a

try to save money by using inferior products, installers or underlay –

commercial division which will focus on specified commercial proj-

and always use felt pads on the bottom of furniture.

ects and carries the technical backing as well as the commitment to