18 minute read

SMART MANUFACTURING

ADVISORS

Mike Shatford

Advertisement

is an expert in the field of technology development and commercialisation. His company Design Energy Limited has completed over 100 significant projects in this vein by consulting for and partnering with some of New Zealand’s leading producers. Among Mike and his team’s strengths are industrial robotics and automated production where the company puts much of its focus.

Matt Minio

Managing Director, Objective3D Matt has extensive hands on experience as a user and supplier of 3D Printing technology. He comes from a mechanical design and engineering background with 25 years’ experience in multiple high end 3D cad applications across a range of industries, including aerospace and automotive. He has been heavily involved in the 3D printing evolution - from initial early prototyping to todays advanced 3d printing technologies producing production parts straight off the printer. As Managing Director of Objective 3D, he provides Stratasys, Desktop Metal and Concept Laser 3D printing solutions to a host of industries across Australia and New Zealand.

Sandra Lukey

Sandra Lukey is the founder of Shine Group, a consultancy that helps science and technology companies accelerate growth. She is a keen observer of the tech sector and how new developments create opportunity for future business. She has over 20 years’ experience working with companies to boost profile and build influential connections.

Greg Morehouse

Greg founded Motovated Design & Analysis in 1999 with a vision to “cost effectively engineer our client’s vision”; through the use of advanced techniques, superior tools, and boundless enthusiasm. Working for VW & Audi as a mechanic, and then with Boeing & Hercules Aerospace as an Engineering Analyst, provided Greg with 40+ years of real world design and analysis experience. Greg is a world-class analyst and provides training and advanced technical support to manufacturers and some of the FEA resellers throughout New Zealand.

Schneider introduces Easy UPS 3L 500 and 600 kVA

Schneider Electric has introduced Easy UPS 3L, the newest part of the Easy UPS 3-phase Uninterruptible Power Supply (UPS) range, extending the medium range to 500 and 600 kVA

(400V) for external batteries. The Easy UPS 3L simplifies and streamlines configuration and service, delivering high availability and predictability to medium and large commercial buildings, data centres, and light industrial UPS applications. With its compact footprint, highly available parallel and redundant design, and robust electrical specifications, Easy UPS 3L protects critical equipment in a wide range of environments from damage due to power outages, surges, and spikes. It is up to 96% efficient to bring predictability to utility costs. Easy UPS 3L includes a wide battery voltage window and accommodates a variety of battery configurations including battery banks. It comes with a full range of options and accessories making it easy to integrate into different environments.

“Thanks to an exceptional combination of competitive specifications; robust, flexible, and fault-tolerant design that enhances availability; and an optimised footprint that saves valuable real estate, the Easy UPS 3L is the ideal choice for easy business continuity and optimised investment, whether it’s on your shop floor or in your electrical room,” said Mustafa Demirkol, Global VP, 3-Phase UPS Offer Management & Marketing, Schneider Electric.

“It is easy to configure, easy to use, and easy to service. By further extending the Easy UPS 3-phase range, Schneider Electric continues to fill a market need by offering easy, robust, and competitive solutions that prioritise safety, efficiency, and availability for today’s connected businesses.”

Customers benefit from Schneider’s global service setup with strong local networks of service specialists that provide customers with a complete range of services throughout the entire Easy UPS 3L lifecycle. The startup Having the highest payload rating in the compact class, SESTO Magnus is designed to automate material handling processes in manufacturing, commercial and healthcare industries. Specially built for tight navigation in space-scarce facilities, SESTO Magnus is able to autonomously travel through spaces as narrow as 0.9 metres wide while avoiding obstacles in its path. Its bi-directional same-speed capability means the autonomous mobile robot can reverse out of dead ends without doing a spot turn. With the world easing into the Covid-19 new normal, there is an accelerated urgency for manufacturers and non-manufacturing industries to quickly automate their processes while ensuring safe management measures such as staggered workforce or spilt team arrangements. SESTO Magnus’ small and low profile is designed with manufacturing, healthcare and commercial facilities in mind. Its intelligent software controls enable it to operate safely in narrow passageways and amongst people. Using a single mobile platform, SESTO Magnus is highly versatile and can be configured with limitless applications of autonomous material transportation. service is included to ensure the Easy UPS 3L is properly and safely configured for best performance, reliability, safety, and peace of mind. It offers resiliency against harsh environments with conformal coated printed circuit boards, replaceable dust filter, operating temperature of up to 40°C, and strong overload protection, all of which make Easy UPS 3L a reliable solution for business continuity. And provides less system complexity and saves on CapEx investment, making it ideal for medium and large commercial buildings and light industrial

SESTO Magnus autonomous mobile robot for materials handling

SESTO Robotics has launched SESTO Magnus - a bi-directional, compact autonomous mobile robot able to carry loads up to 300kg.

applications. From components and parts in manufacturing, to laundry and meal services in hospitality and care facilities, to central sterile services and dispensaries in hospitals, the autonomous mobile robot can be fitted with various top module configurations, customisable to requirements. Current manual handling and transportation processes are often time-consuming and error-prone. In addition, repeated manual handling of heavy loads may lead to labour injuries and accidents. With SESTO Magnus, it reduces the dependency on manual labour which has become a priority for many companies in recent months, as COVID-19 caused major disruptions to the availability of on-premise employees. Powered by SESTO’s proprietary user-friendly interface, operators can easily deploy the robot for material transportation using a tablet or laptop. The robot provides high uptime of up to ten hours on a single charge and fast battery charging in three hours.

Equipped with low range 270⁰ 2D Lidars on the front and rear, SESTO Magnus ensures safety with its improved navigation and obstacle detection capabilities.

Using AI to predict new materials with desired properties

An artificial intelligence approach extracts how an aluminium alloy’s contents and manufacturing process are related to specific mechanical properties.

Scientists in Japan have developed a machine learning approach that can predict the elements and manufacturing processes needed to obtain an aluminium alloy with specific, desired mechanical properties. The approach, published in the journal Science and Technology of Advanced Materials, could facilitate the discovery of new materials. Aluminium alloys are lightweight, energy-saving materials made predominantly from aluminium, but also contain other elements, such as magnesium, manganese, silicon, zinc and copper. The combination of elements and manufacturing process determines how resilient the alloys are to various stresses. For example, 5000 series aluminium alloys contain magnesium and several other elements and are used as a welding material in buildings, cars, and pressurized vessels. 7000 series aluminium alloys contain zinc, and usually magnesium and copper, and are most commonly used in bicycle frames. Picking up goods from a box, helping to take samples and dispensing cans from a machine – all done by robots! Whether articulated arm robots, delta robots or linear robots: Treotham has all three kinematics as Low Cost Automation solutions available. To enable users to try out in advance which robot is best suited for their application, Treotham now offers igus robot control, a software for the simulation and programming of all igus robots. “As a mechanical engineering company, we are very familiar with the different kinematics, so the next logical step for us was to develop a correspondingly simple and intuitive robot control system”, says Alexander Mühlens, Head of automation technology Experimenting with various combinations of elements and manufacturing processes to fabricate aluminium alloys is time-consuming and expensive. To overcome this, Ryo Tamura and colleagues at Japan’s National Institute for Materials Science and Toyota Motor Corporation developed a materials informatics technique that feeds known data from aluminium alloy databases into a machine learning model. This trains the model to understand relationships between alloys’ mechanical properties and the different elements they are made of, as well as the type of heat treatment applied during manufacturing. Once the model is provided enough data, it can then predict what is required to manufacture a new alloy with specific mechanical properties. All this without the need for input or supervision from a human. The model found, for example, 5000 series aluminium alloys that are highly resistant to stress

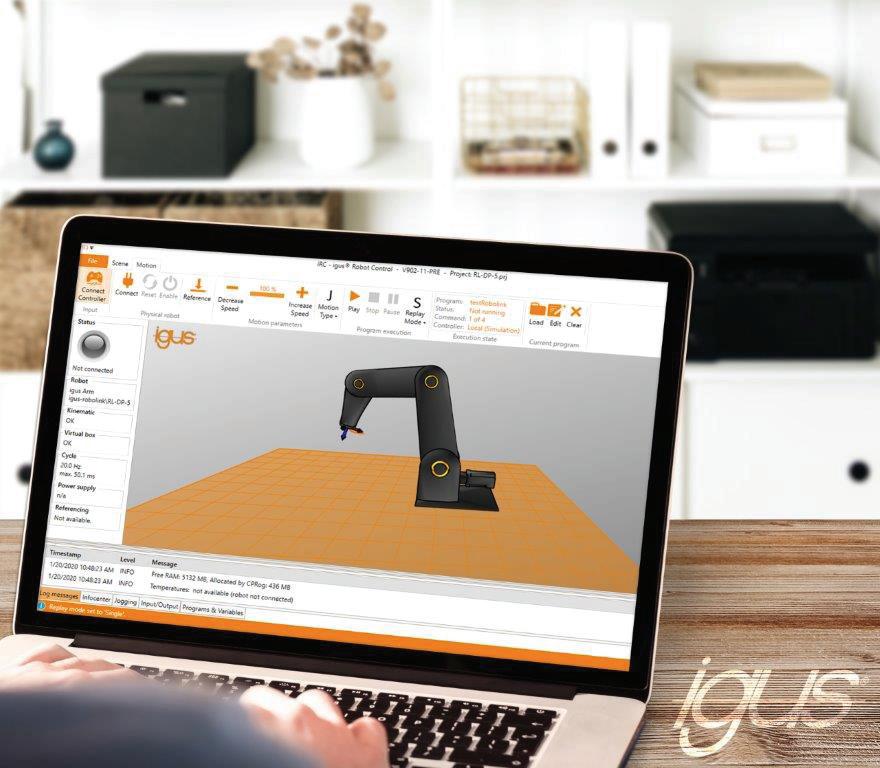

igus robot control: free simulation and cost-effective

To programme robots with ease, igus has now developed control software for its low-cost automation solutions. igus robot control is available online free of charge and offers the user an easy introduction to automation. Different robot kinematics can be programmed and controlled. A digital twin simulates the movements. In this way, the user can programme a suitable solution before purchase. The cost-effective igus robot hardware, for example, a linear robot with switch cabinet, is supplied by Treotham.

and deformation can be made by increasing the at igus GmbH. The special feature: the software is available online free of charge and license-free. In the software there is a digital twin for all igus robots, which can be simulated and taught like the real robot. The robot control system is also used later to programme the robot intuitively. Every programming can be applied to the real robot afterwards.

Easy programming of robots

With igus robot control, the user can freely move all axes of the digital twin via a 3D interface. By means of a teach-in function the robot can be programmed very easily, even without a robot connection.

manganese and magnesium content and reducing the aluminium content. “This sort of information could be useful for developing new materials, including alloys, that meet the needs of industry,” says Tamura. The model employs a statistical method, called Markov chain Monte Carlo, which uses algorithms to obtain information and then represent the results in graphs that facilitate the visualisation of how the different variables relate. The machine learning approach can be made more reliable by inputting a larger dataset during the training process.

To do this, the user must manually move the robot to the desired position and define how it is to be moved. The process is repeated until the desired motion profile is created. Matching end effectors, such as grippers, are easy to add and the tool centre point adjusts automatically. Virtual boxes can also be installed, for example, to prevent the robot from colliding with a machine. The igus robot control can also be connected to a higher-level control system, either via interface communication with Digital IO or via Ethernet communication using IP address.

Seequent keeps world at work on major projects

High-growth geoscience software company Seequent is accelerating the development of its cloud-based solution Seequent Central, enabling organisations to continue work on critical, large-scale, earth, environment and renewable energy projects in the COVID-19 impacted environment. Central works alongside Seequent’s other geoscience analysis, modelling and collaborative technologies, to contribute understanding to subsurface geoscience and engineering design solutions. The cloud-based solution allows people in any location to visualise, track and manage geological models created for infrastructure and critical services projects, in a centralised, auditable environment. A wide range of stakeholders can readily access highly visual up-to-date information to manage risk and make better environmental and investment decisions, to progress projects. Seequent CEO, Shaun Maloney, says: “We’re working alongside customers to do everything we can to make it possible to meet the demands and operational challenges they may be facing in the current environment. Seequent’s software is being used on hundreds of diverse projects across the globe, ranging from infrastructure projects including large-scale rail, road and tunnel projects across North America, Europe, and Asia-Pacific; renewable energy projects in the US, Finland, Iceland, Indonesia, Philippines and New Zealand; mining and exploration projects in North and South America, Africa and Australia; and environmental projects such as groundwater management in North America, Europe, Africa and Asia-Pacific. Projects include:

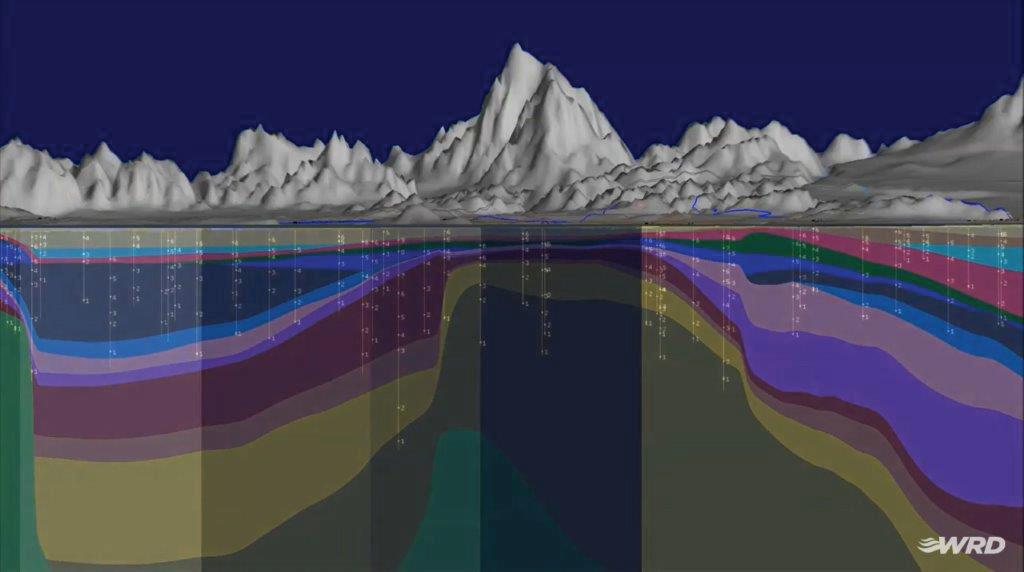

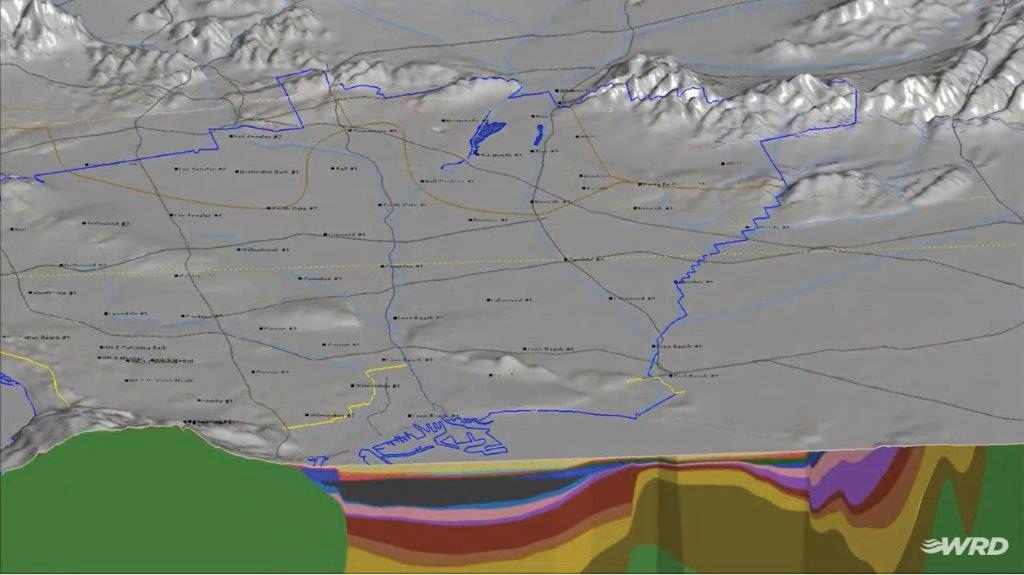

The Water Replenishment District - Groundwater management in Los Angeles

The Water Replenishment District (WRD), the largest groundwater agency in the State of California, has the important job of managing and protecting local groundwater resources for over four million residents. WRD’s service area covers a 420 square mile region of southern Los Angeles County, the most populated county in the United States. The 43 cities in the service area, including a portion of the City of Los Angeles, use about 250,000 acre feet (82 billion gallons) of groundwater annually which accounts for approximately half of the region’s water supply. Through WRD’s Water Independence Now Program, the district has become completely sustainable using local resources including advanced treated recycled water to replenish groundwater supplies. To enhance management of these valuable water resources, the District has created a full 3D high resolution digital geologic and groundwater model of the Central and West Coast Basins (Basins). The model significantly advances their understanding of the groundwater flow systems and helps identify contaminated sites in both Basins. The District created a range of visually descriptive models in Seequent’s Leapfrog Works using extensive and diverse data sets that are regularly updated including - geologic, hydrogeologic, geophysical, groundwater contamination, well inventory (from 350 groundwater monitoring wells), seawater intrusion, and other types of data. The District’s team works together remotely on the same data in real-time with Seequent Central.

Uncovering Mineral Assets in Mexico

Canadian mining company First Majestic, focussed on silver production in Mexico, currently owns and operates the San Dimas Silver/Gold Mine, the Santa Elena Silver/Gold Mine and the La Encantada Silver Mine. The company is pursuing the development of its existing mineral property assets with industry practice modelling using Seequent’s solutions. First Majestic use Seequent’s Leapfrog Geo to develop a realistic presentation of the geology at each site (complex silver deposits with multiple veins), and Leapfrog Edge to aid resource estimation – and when geologic models are changed resource estimates also change dynamically. Seequent Central allows the company to publish models and resource estimates – so they are immediately available to everyone from the mine geologists to management in real time.

Utah FORGE geothermal energy project, USA

Seequent is half way through a five-year partnership with the Utah FORGE (Frontier Observatory for Research in Geothermal Energy) project at the University of Utah. The project is sponsored by the U.S. Department of Energy (DOE), with the aim to provide research on enhanced geothermal systems (EGS). The Utah FORGE project team is using Seequent’s solutions to visualise the subsurface at the FORGE site near the town of Milford. The site has been researched since the 1960s, with many wells drilled in the vicinity providing a lot of data in different

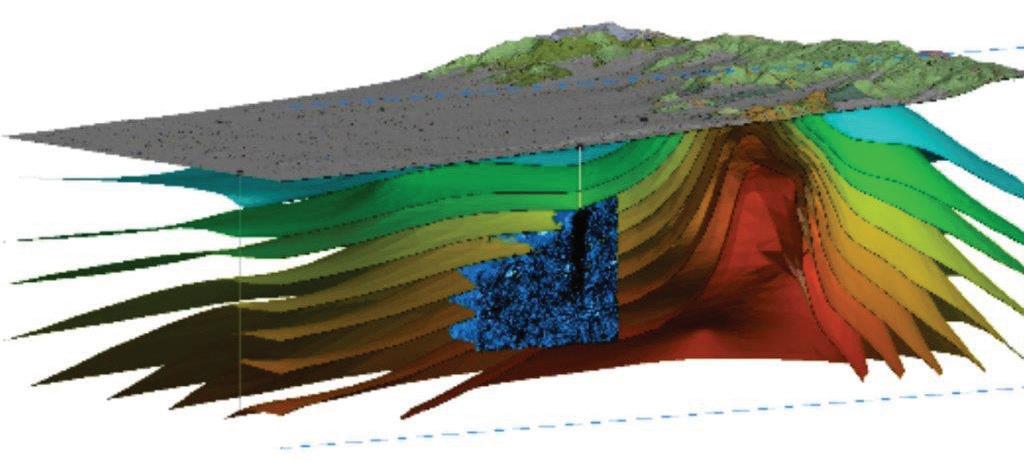

WRD created a geologic and groundwater model of California’s Central and West Coast Basins in Seequent’s Leapfrog Works

datasets. This data is reconciled in Leapfrog Geothermal, Seequent’s 3D modelling solution for the geothermal industry, and Seequent Central is used to manage and visualise the team’s geological data and models centrally.

Temperature distribution at the FORGE site visualised in Leapfrog Geothermal

Only 14% of all our engineers are women. We want to change that.

Join us and scores of other Kiwi organisations that have galvanised around one common goal: 20% more women engineers by 2021.

Life-Changing medical device with Stratasys additive manufacturing

Bluefrog Design, originally named 3CD, was founded in 1990 by Chris Samwell. With 30 years of combined experience as industrial design consultants, the small but expert team at Bluefrog is nothing if not versatile. Bluefrog serves a wide range of industries including consumer goods, packaging, transportation and medical. Although their clients’ specialities are very diverse, they all look to Bluefrog for innovation. Bluefrog needed the freedom to escape traditional design constraints at every stage of product development. One that could produce fully functional, advanced prototypes with industry-rec ognized, engineering-grade materials. In a quest to find a solution, the team turned to additive manufacturing.

Overcoming complexities

Bluefrog’s versatility is best exemplified by their ability to find solutions to seemingly insurmountable challenges. The team was recently approached by a young man suffering from paraesthesia, a condition that causes inexplicable burning, tingling or prickling sensation across the skin. For this patient, the only way to ease his pain was to ensure that his clothes touched his skin as little as possible. Despite interventions from doctors, no solution had been found. But it was clear to Samwell the patient could benefit Traditional single-purpose industrial robots are losing ground to affordable, easy to use robots and peripherals that can be flexibly redeployed for a wide range of applications. This empowers manufacturers to gain even greater productivity increases from their automation investments. OnRobot is extending its commitment to ongoing customer empowerment with the launch of a software update for its popular, 2.5D camera-based Eyes vision system. The new features, which enable Eyes to be deployed in quality inspection applications and on mobile setups, include one-shot detection for multiple objects, colour and blob detection and automatic landmark calibration tools designed to speed cycle time for mobile robot setups.

New visual inspection features for reduced cycle time and fast ROI

Eyes’ new inspection features enable the system to easily sort, inspect, or pick and place unstructured objects using colour and contour detection – a capability that is beyond most competing vision systems. This detection method requires no workpiece teaching and finds items based on colour and size information input by the operator. Eyes’ inspection features can be used to inspect parts removed from CNC machines, for example, or to check greatly from a custom device he could wear with minimal skin contact that would also minimize his skin contact with his clothing. The device had to be customized to his body, resting only on the areas that were not affected by his condition. Bluefrog Design’s team knew this complex case required a realistic prototype and final product in as little time as possible. They began by creating a complex 3D scan of the patient’s body, which was converted into a 3D printed prototype on their FDM 3D printer. Once tested and modified, the final version was produced in the tough, medical-grade ABSPlus material, chosen thanks to its advanced material stability over time. Notably, due to the round-the-clock capability of the Fortus 3D printer, this process took just three days, a dramatic turnaround for a patient who had been suffering for years.

Lightweight, innovative breakthroughs

Thanks to the complex 3D scan of the patient’s body, the team was able to isolate the areas of the patient’s chest that were not affected by paraesthesia, in order to determine where on the body the device could be hung. Given that the device would need to be worn every

OnRobot expands product capabilities

day, they also needed to consider its exact weight IMM parts for excessive or inadequate material after part has been moulded. The tools also support manual inspections: operators can set up a camera and inspection program, manually place a workpiece in view and execute inspection. No robot required. The update also provides users with one-shot detection for multiple objects, allowing the system to pick all workpieces with only one picture. This reduces complexity for users and improves cycle times. The update includes tools that allow users to request specific workpiece types and specify gripper clearance parameters.

Adding Eyes to mobile robots

A new landmark feature has been added to Eyes’ powerful toolkit, enabling easy deployment of

and shape. It needed to be organic, easy-to-wear and completely personalized. Stratasys additive manufacturing offered the ability to create a lattice-based design with minimal fuss. They were able to reduce the weight of the device even further and save up to 60% of the material that traditional production methods would consume. From testing through to the final part, Stratasys additive manufacturing enabled control to optimise the design. They would not have been able to create such a high-performing, unique solution without it. www.objective3d.com.au

Eyes on mobile robots and setups with carts, trays, and pallets. The Landmark feature makes it simple to program mobile robots to move from station to station using end user-defined Landmarks as their guide. Landmarks can also be used to initiate specific robot operations: for example, when Eyes detects the arrival of a mobile cart in its workspace loaded with parts for picking, it can easily switch to pick & place routines.

Covid-19 accelerates robotics in Southeast Asia

The coronavirus pandemic has accelerated robotics and automation adoption globally, including in Southeast Asia. Companies are reassessing their production processes to meet growing demand while simultaneously dealing with a shortage of workers and social distancing restrictions. Automation is crucial, especially for SMEs who are more vulnerable to disruptions, due to smaller cash reserves and a more limited customer base. SMEs account for between 89 and 99 percent of enterprises in the region. Companies now have an ideal solution as collaborative applications offer a fast, easy and affordable alternative to bulky traditional industrial robots.