3 minute read

Checklist for worksite safety – basic repeats

april - may 2021 Repetition key to remembering important safety points

There are a frightening number of easily preventable manufacturing workplace hazards with the potential to cause incidents or injuries

Advertisement

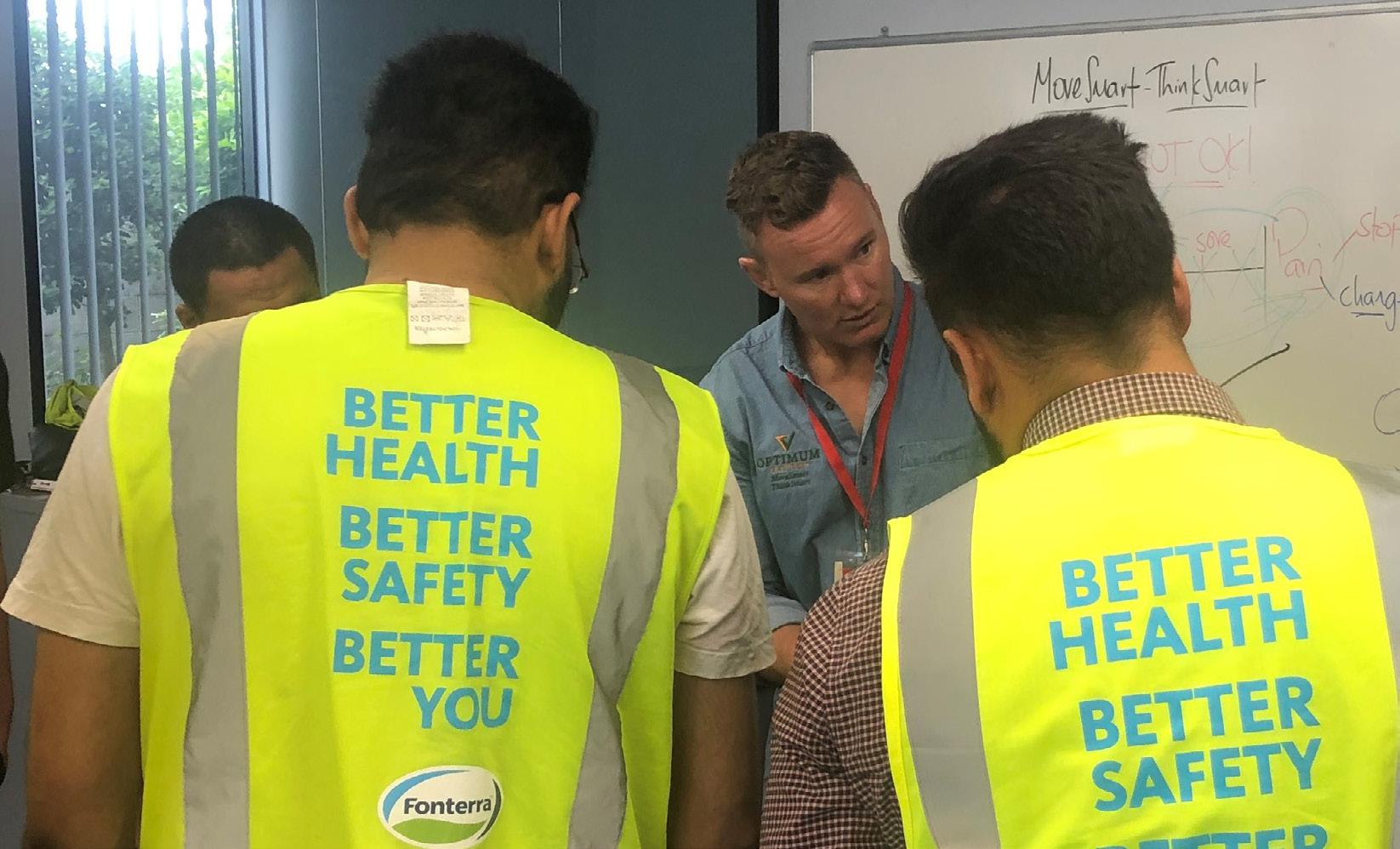

Going over important workplace safety topics will really help to reinforce the message. It is a key reason for companies to host regular safety meetings to discuss manufacturing safety topics and tips.

When you are working with a tool day in and day out or doing the same repetitive task over and over again, it’s easy to get complacent and forget about basic manufacturing safety tips.

Workers need to be reminded of the most common-sense safety and awareness issues—like depending on the industry and the type of hazards your workers are likely to face.

What should safety managers cover in terms of workplace safety tips and topics? What points can you talk to employees about, often over again and again, that will drive home important health and safety topics for work, yet keep employees engaged and informed?

keeping hands away from sharp edges.

Because these topics can often be boring or dry, it’s easy to lose employees’ interest—which means your important message is less likely to be received.

To keep workers engaged, try incorporating videos, playing a game, breaking into teams for a project or experiment, and encouraging group discussions.

There is no shortage of topics available for you to cover, but not all of these subjects will apply for every type of manufacturing. Customise your list of manufacturing safety topics

Equipment use, safety, and maintenance

• How and why to keep machine guards in place • Machine operation and safety • Equipment training and certification • Inspections and routine maintenance • The importance of safe and efficient workspaces

Personal protective equipment (PPE)

• Different types, purposes, and applications of PPE • How to wear and use PPE properly • Maintaining PPE, and when to repair or replace • Safe disposal of PPE

Hazard communication • The dangers of chemical leaks or exposure • Proper labelling procedures • What to do in the event of a hazardous materials incident • Maintaining a library of material safety data sheets (MSDS)

Fall protection

• How to prevent one of the most common workplace injuries • Falls can happen from heights or ground level • Identifying potential fall risks and risk factors • Integrating fall protection

Fire prevention and preparedness

• Identifying potential fire hazards • Reducing fire risk • Fire extinguisher training • Escape routes, plans,

and responsibilities • Reporting violations and hazards

Hazardous waste management

• Current hazardous waste regulations, and updates • Disposal protocol for hazardous waste • Best practices for handling hazardous waste • Storage, labelling and inspection

Hand safety

Cuts and lacerations are among the most common, as well as one of the most readily preventable types of workplace injury, and hands are a worker’s number one tool, so hand safety tips definitely deserve their own section.

If you’re planning a hand safety toolbox talk, you can promote and encourage hand safety by discussing these hand safety tips in the workplace: • Choosing the right tool for the job

• Hand safety awareness activities • Checking equipment before starting a job • Proper storage of sharp tools and objects • Safe use of tools or equipment with moving parts • Hand attire—when it’s best to remove jewellery or wear gloves • Staying alert and focused at work • Keep workspaces tidy and organized