Woodruff Buzz

Achieving a Culture of Inclusive Excellence 2022-23 ANNUAL MAGAZINE

GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING GEORGIA INSTITUTE OF TECHNOLOGY

Woodruff Buzz is published annually for the students, faculty, staff, alumni, and friends of the George W. Woodruff

School of Mechanical Engineering at the Georgia Institute of Technology.

SCHOOL CHAIR

Devesh Ranjan

EDITOR

Ashley Ritchie

WRITERS

Chloe Arrington

Catherine Barzler

Christa M. Ernst

Steven Gagliano

Jason Maderer

Tess Malone

Steven Norris

Georgia Parmelee

Péralte C. Paul

Ashley Ritchie

Melinda Rose

Emma Ryan

Ian Sargent

Joshua Stewart

DESIGNER

Ashley Ritchie

PHOTOGRAPHERS

Mayar Allam

Chloe Arrington

Ahmet Coskun

Rob Felt

Candler Hobbs

Gary Meek

Ashley Ritchie

Ian Sargent

Ankur Singh

Steve J Swieter

Adam Thompson

Thomas Voisin

Ben Wright

Zoo Atlanta

George W. Woodruff

of Mechanical

© 2023

STUDENT SUCCESS 06 Student Notes 07 Helen Grenga Outstanding Woman Engineer Award 08 Woodruff Strong 10 Engineering A New Way to Feed Gorillas 12 Student Innovation Competition RESEARCH PREEMINENCE 18 Faculty Notes 20 The McDowell Lab 22 Groundbreaking Lymphoma Tumor Model Paves Way for New Therapies 24 Building Georgia with AI and Manufacturing 34 A New Framework for Measuring Stability During Walking COMMUNITY AND CULTURE 42 Alumni Notes 43 40 Under 40 44 CoE Alumni Awards 46 Women of Woodruff TABLE OF CONTENTS 08

School

Engineering Georgia

Technology 801

Atlanta,

404.894.3200 me.gatech.edu nremp.gatech.edu Social:

Copyright

Georgia Institute of Technology 20 44 24

Institute of

Ferst Drive

Georgia 30332

/megeorgiatech

MESSAGE FROM THE CHAIR

On behalf of everyone at the George W. Woodruff School of Mechanical Engineering, I am proud to present our new magazine, Woodruff Buzz, produced annually for our students, faculty, staff, alumni, and friends.

The first edition of our magazine is filled with buzzworthy stories related to student success, research preeminence, and community and culture — the three key focus areas of our strategic plan. The plan, released earlier this year, includes a new mission statement, aspiring vision, and actionable goals and objectives, and will guide our initiatives through 2030.

As many of you know, the Woodruff School is an inclusive, innovative, and thriving educational and research environment committed to fostering the next generation of intellectually curious and globally engaged leaders who are empowered to create solutions to society’s most challenging problems and dedicated to improving the human condition. The depth and breadth of our mechanical engineering and nuclear and radiological engineering programs have led to national rankings that place us in elite company. Our mechanical engineering undergraduate program is second according to U.S. News & World Report, while we rank fifth in our graduate mechanical engineering program and eighth in nuclear engineering.

Last fiscal year was full of remarkable achievements. We secured $67.8 million in new sponsored research awards, the highest in Woodruff School history. As you flip through these pages, you’ll see the funding is giving our faculty a rich set of research opportunities, such as the chance to transform the Advanced Manufacturing Pilot Facility (AMPF) into the Artificial Intelligence Manufacturing Pilot Facility (AI-MPF), the chance to develop new technologies and programs to close the nitrogen loop and revolutionize agriculture, and the chance to engineer bioinspired materials needed to realize the Navy’s advanced capabilities in deep sea environments. Our faculty have also made innovative contributions in other fields. Associate Professor Matthew McDowell researched new materials for the next generation of high-capacity batteries; Professor Ankur Singh led a team of researchers in the development

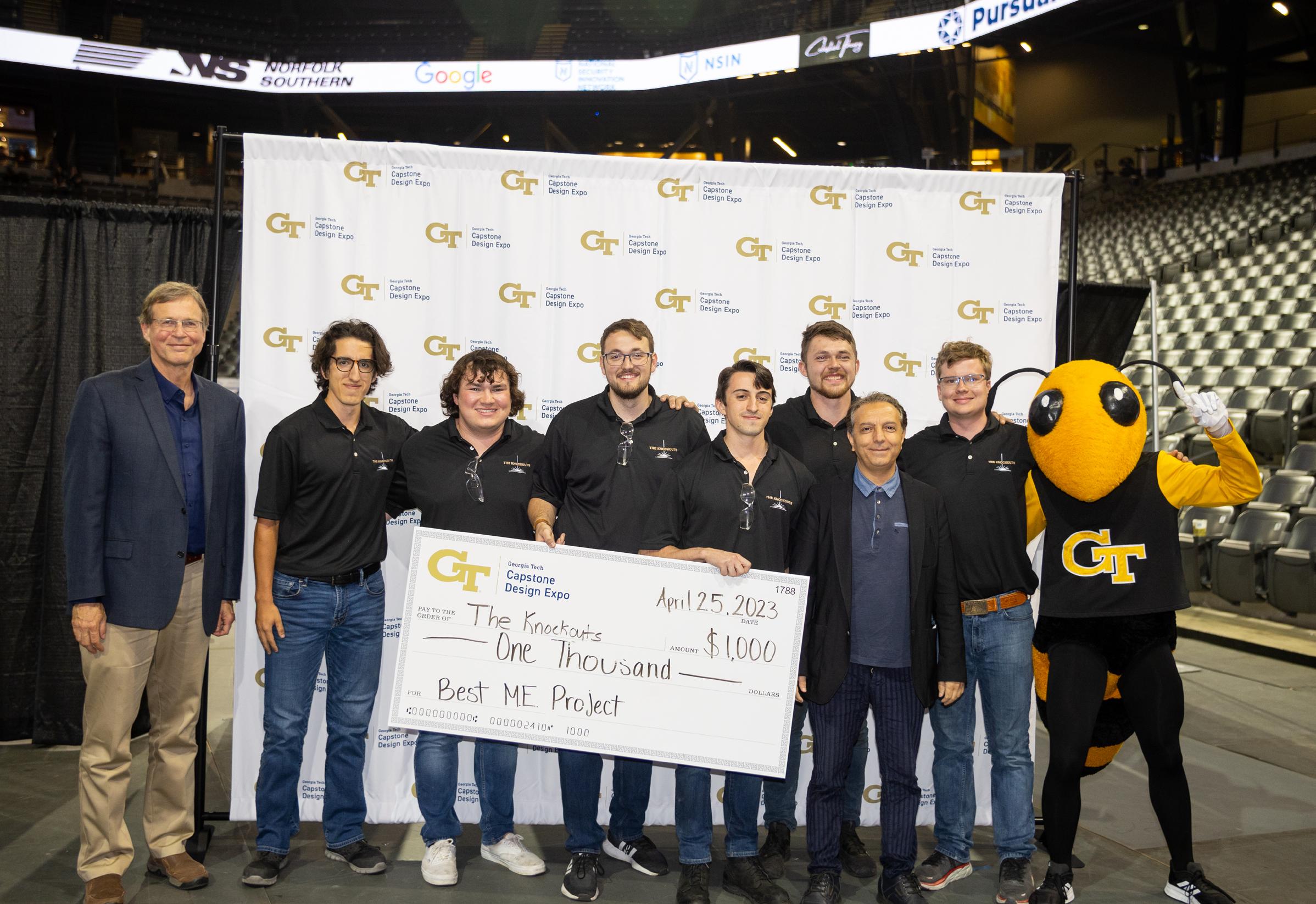

of a promising breakthrough for targeted cancer therapies; and Associate Professor and Woodruff Faculty Fellow W. Hong Yeo developed a wireless monitoring patch system to detect sleep apnea at home, to name a few. Members of the Woodruff School community won many notable awards during the 2022-23 academic year. Associate Professor Aaron Young won the NIH Director’s New Innovator Award; Assistant Professors Akanksha Menon and Ye Zhao were awarded NSF CAREER Awards; G.P “Bud” Peterson received the 2022 Max Jakob Memorial Award; and Marta Hatzell received the Institute’s Outstanding Achievement in Early Career Research Award. Our students also continued to shine. Mechanical engineering students took home first, second, and third place in the College of Engineering’s (CoE) annual Student Innovation Competition – Promoting Equity and Access, which asks students to propose a creative solution to a problem affecting marginalized populations on campus; and students Carolina Colón, Lina Daza Llanos, Elyssa Ferguson, Alison Jenkins, Maria Sattar, and Jordyn Schroeder were awarded the inaugural Women of Woodruff (WoW) fellowships. WoW, a newly launched initiative spearheaded by members of the Woodruff School Advisory Board, aims to provide resources and programming that will allow Georgia Tech to attract, support, and retain women students and faculty in mechanical engineering. Our staff members were also recognized for their hard work and dedication. Cary Ogletree earned a Leadership in Action Award from the Institute; Michelle Graham received the CoE Soaring Jacket Award; and the S.H.O.E Cabinet, consisting of Lula Baker, Melody Foster, and Ann Lamb, won the CoE Staff Innovation and Process Improvement Award and the Institute’s Cultivating WellBeing Award for creating an inclusive environment in the Woodruff School where staff members feel valued and are enabled to reach their potential. Finally, three of our alumni were named to the Class of 2022 40 Under 40 and four alumni were recognized with CoE Alumni Awards, including G.B. Espy and Deborah Kilpatrick who were inducted into the Engineering Alumni Hall of Fame.

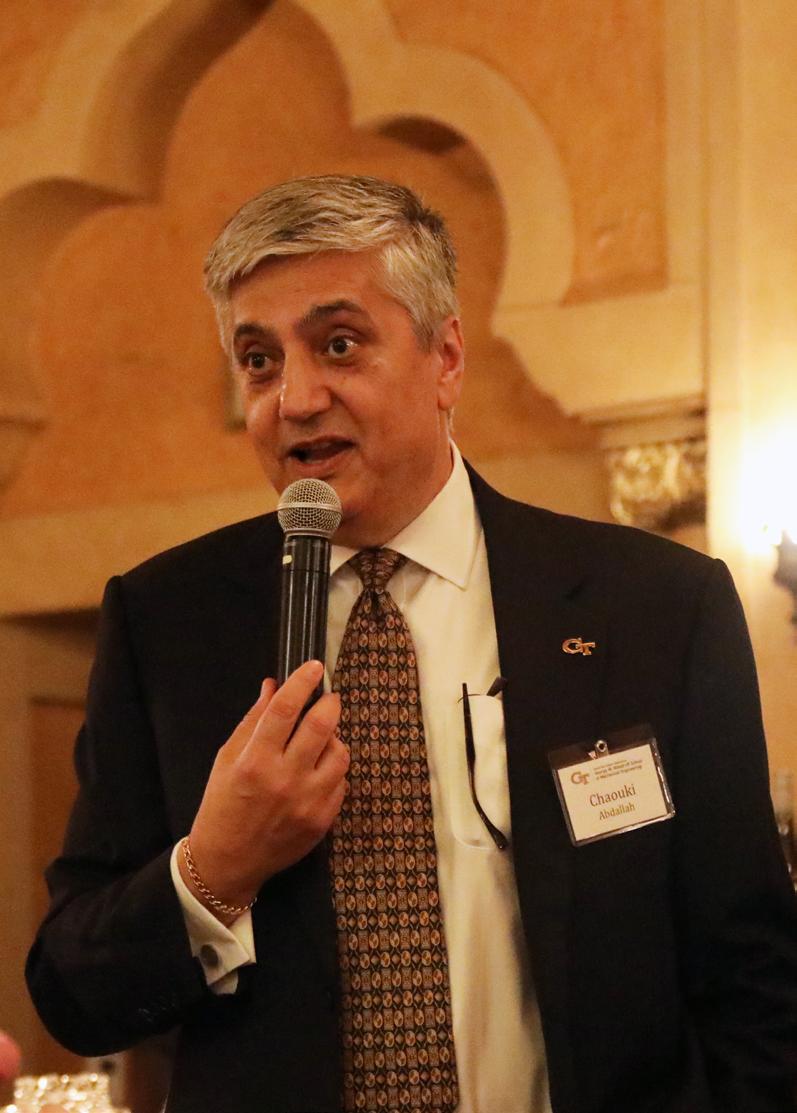

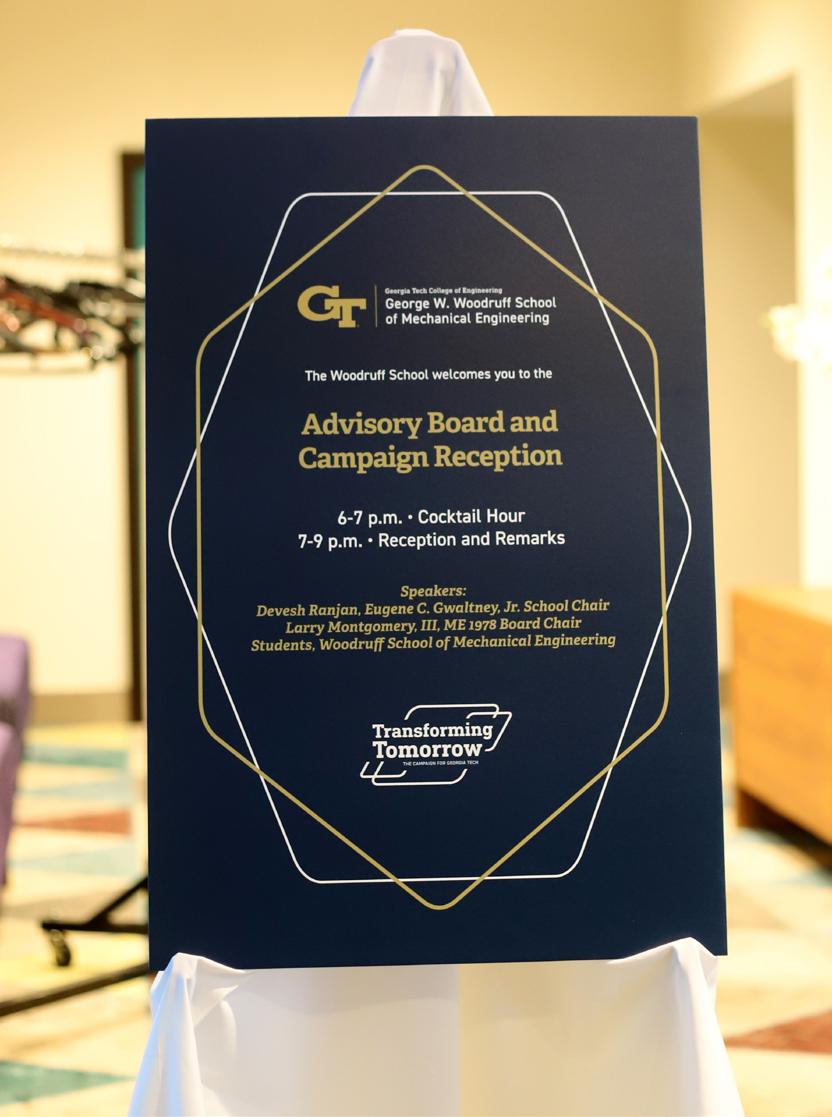

The Woodruff School also celebrated major milestones and new initiatives during the last academic year. We hosted an event at the Fox Theatre to celebrate the 60th anniversary of the Nuclear and Radiological Engineering program and hosted an Advisory Board and Campaign Reception that shined a light on our community of engineers who are transforming tomorrow through their leadership, volunteerism, and philanthropic support. We also launched a new program, Woodruff Strong, that is one of the School’s top priorities during the comprehensive campaign, Transforming Tomorrow: The Campaign for Georgia Tech. Through Woodruff Strong, we seek to raise $30 million for scholarships and fellowships, academic support services, and health and wellness resources.

To conclude, all of our success wouldn’t be possible without outstanding members of the Woodruff School community. I am immensely proud and grateful for your ongoing contributions and commitment. Over the next year and beyond, I look forward to our continued collaboration and I am confident that, together, we can strengthen our impact locally, nationally, and globally as we continue to achieve a culture of Inclusive Excellence.

Best Regards, Devesh Ranjan

Eugene C. Gwaltney, Jr. School Chair and Professor

3 2022-23 ANNUAL MAGAZINE

ABOUT THE WOODRUFF SCHOOL

MISSION

The George W. Woodruff School of Mechanical Engineering is an inclusive, innovative, and thriving educational and research environment committed to fostering the next generation of intellectually curious and globally engaged leaders who are empowered to create solutions to society’s most challenging problems and dedicated to improving the human condition.

TOP RANKED PROGRAMS

No. 2

Mechanical Engineering Undergraduate Program

(U.S. News & World Report, 2024)

No. 5

Mechanical Engineering Graduate Program

(U.S. News & World Report, 2023-24)

No. 8

Nuclear Engineering Graduate Program

(U.S. News & World Report, 2023-24)

VISION

The Woodruff School will be a student-centered, research-focused, and service-oriented community recognized for its outstanding education, the development of leaders, and the creation of innovative technological solutions that improve society and the human condition. We will embrace the diversity of our collaborative community, the foundational principles of engineering and science, and ethical behavior as we achieve a culture of inclusive excellence.

4 GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

DEGREES AWARDED, 2022-23

451 269 B.S. Degrees

Degrees

68

DEGREES

The Woodruff School offers:

2 B.S. Degrees

7 M.S. Degrees

6 Ph.D. Degrees

CUTTING-EDGE RESEARCH

Acoustics and Dynamics; AI, Informatics for ME (AI2ME); Automation, Robotics and Control; Bioengineering; ComputerAided Engineering and Design; Fluid Mechanics; Heat Transfer, Combustion, and Energy Systems; Manufacturing; Mechanics of Materials; Medical Physics; Micro & Nano Engineering; Nuclear and Radiological Engineering; Tribology

FACULTY AND STAFF

95 Tenure-Track Faculty

81 Staff

17 Research Faculty

15 Non-Tenure Track Faculty

ENGINEERING SCHOLARS

1819 Undergraduate Students Fall 2022

$67.8M

946 Graduate Students Fall 2022

Total Expenditures

Other $332,474 FY23 Total Expenditures ($101,819,591) Sponsored Research $60,213,256 GT Foundation $7,152,074 State $34,121,787 5 2022-23 ANNUAL MAGAZINE

FY23 New Sponsored Research

FY23

Awards FINANCES $101.8M

M.S.

Ph.D. Degrees

Sherry Adadi was selected for the International Atomic Energy Agency Marie Sklodowska-Curie Fellowship Programme for 2023.

Amro Alshareef received an NSF Graduate Research Fellowship.

Bettina Arkhurst was named a 2022-2023 Novelis Scholar.

Max Asselmeier received an NSF Graduate Research Fellowship.

Eyas Ayesh received the 2022 Millennium Fellowship.

Matthew Barry was awarded the Sandia National Laboratories’ President Harry S. Truman Postdoctoral Fellowship in National Security Science and Engineering.

Alexander Chipps received an NSF Graduate Research Fellowship.

Jonathon Faulkner was awarded a threeyear DOE graduate fellowship through the Office of Nuclear Energy’s University Nuclear Leadership Program.

Student Notes

Elyssa Ferguson was awarded a RBI Graduate Research Fellowship.

Carlos Fernandez was selected to join the second class of Brook Byers Institute for Sustainable Systems (BBISS) Graduate Fellows.

Nina Sara Fraticelli-Guzmán was named the student winner of the 2022 Diversity Champion Award at the 14th Annual Georgia Tech Diversity Symposium.

Madeline Garell received the Sigma Xi Best M.S. Thesis Award.

Rodrigo Gonzalez received the Sigma Xi Best Ph.D. Thesis Award.

Yutong Guo was awarded the 2022 Andrew J. Lockhart Postdoctoral Fellowship.

Daniel Johnson was named a 2022-2023 Novelis Scholar.

Kathryn Kelly was named a 2023 Goizueta Foundation Fellow.

Velin Kojouharov received the 2022 Millennium Fellowship.

Matthew Krecicki was awarded a first place prize in the Innovations in Nuclear Technology R&D Awards sponsored by the DOE, Office of Nuclear Fuel and Supply Chain.

Patience Lamb was selected for the International Atomic Energy Agency Marie Sklodowska-Curie Fellowship Programme for 2023.

Abir Muhuri received an NSF Graduate Research Fellowship.

Bailey Painter was awarded a three-year DOE graduate fellowship through the Office of Nuclear Energy’s University Nuclear Leadership Program.

Walter Parker was named a 2022-2023 Novelis Scholar.

Lauren Paulson received the Brooke Owens Fellowship.

Alexandra (Lexie) Schueller was named a 2022-2023 Novelis Scholar.

Nathan Zavanelli was named an ARCS Scholar and recipient of the Imlay Foundation Global Impact Award.

M.S. Student Attends Science Outside the Lab Workshop

Caroline Greiner, an M.S. student in the George W. Woodruff School of Mechanical Engineering, recently attended the six-day Science Outside the Lab workshop in Washington D.C.

The event is sponsored by the Nanotechnology Collaborative Infrastructure and invites a select cohort of graduate students to meet and interact with policymakers, regulators, journalists, and others who work at the crucial intersection of science and government.

Greiner, a Charlotte native, saw firsthand the input science has in advising a large bureaucracy and in turn, how various agencies provide the framework for regulating and promoting scientific

innovation.

“I wanted to attend the Science Outside the Lab workshop to learn about opportunities in science policy for people with technical STEM backgrounds,” Greiner said. “I learned so much about how science policy is spread across different levels and branches of government and how STEM students can contribute to and find a career in science policy.”

During her time in D.C. Greiner met scientists working in various roles of state and federal government. This included visits to the Environmental Protection Agency (EPA), the National Science Foundation (NSF), and the U.S. Senate.

“The highlight was attending a meeting

at the Organization of American States (OAS) on the National Mall and learning about science diplomacy,” Greiner said. “I thought the only way scientists could be involved in the government was to work as a scientist or engineer at a national lab or for the National Institutes of Health, but that is not the

6 STUDENT SUCCESS

GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

Lillian Tso Wins 2023 Helen Grenga Outstanding Woman Engineer Award

Lillian Tso, an undergraduate student in the George W. Woodruff School of Mechanical Engineering, has been awarded the 2023 Helen Grenga Outstanding Woman Engineer Award. Named after the first full-tenured female engineering professor at Georgia Tech, this award recognizes the outstanding achievements of a female engineer each year.

Tso, who will graduate in December, says she is incredibly honored to receive the award and expressed her gratitude to those within the Woodruff School. “I am so thankful for all the support I have received from the mechanical engineering department: my professors, classmates, advisors, and mentors,” Tso said upon learning of her win.

“I want to thank my mom for all her support as well,” she added. Tso’s mother, also an engineer, was one of two females to graduate in her class. “She has always given me someone to look up to.”

With a personal philosophy to “say yes” to opportunities that come her way and to always be on the lookout for new experiences, Tso has had a rich and eventful time as an undergraduate including interning at NASA, blogging for Georgia Tech-Europe, and bikepacking across Newfoundland, Canada through Outdoor Recreation at Georgia Tech (ORGT).

“I can think of no one more deserving of this award,” said Associate Chair for Undergraduate Studies and Professor Brandon Dixon. “Lillian’s intelligence, personal demeanor, and contagious enthusiasm for the opportunities available to students within the Woodruff School and Georgia Tech are such a visible example that our students are our greater asset.”

Tso has also been actively involved with the Flowers Invention Studio, recently serving as President of the largest student-run makerspace in the nation. According to Dixon, it was her leadership that ensured the community and culture that many worked so hard to build not only survived through the height of the pandemic but thrived.

With the goal to inspire other students and to give back to the Georgia Tech community, Tso has taken on mentorship and volunteer roles whenever possible.

“I have focused on giving back and mentoring younger mechanical engineers to give them the same opportunities which I received,” she said. “I believe it is so important to help the next generation of engineers move up to the next rung of the ladder!”

In addition, Tso joined the Society of Women Engineers (SWE) soon after enrolling at Tech and credits this as an integral part of her college experience.

“The women in SWE have been my inspiration, my support system, and my friends for the past four years, and I would not have been able to accomplish much without them,” she said.

One ‘SWEetie’ in particular, who Tso considers a close mentor, is Katie Bishop, EE 2023. Bishop has helped guide Tso through her minor in aerospace and encouraged her to apply to the Brooke Owens Fellowship in 2022, which she won.

After graduating later this year, Tso plans to pursue a master’s degree in mechanical engineering, continuing her journey at Georgia Tech.

New Program — Woodruff Strong — to Strengthen Student Support

There are many barriers to student success in higher education. They range from unmet financial need to inadequate student support to academic-related stress and more. The George W. Woodruff School of Mechanical Engineering and Devesh Ranjan, Eugene C. Gwaltney, Jr. School Chair and professor, are determined to remove these obstacles through a new program that focuses on student well-being and building a stronger community within the School.

Woodruff Strong will serve as one of the School’s top priorities during the comprehensive campaign, Transforming Tomorrow: The Campaign for Georgia Tech.

Over the next five years, the program seeks to raise $30 million for scholarships and fellowships, academic support services, and health and wellness resources.

Since becoming Chair, Ranjan has been focused on meeting the needs of Woodruff School students. His goal is to ensure mechanical engineering and nuclear and radiological engineering students have access to a remarkable education as well as opportunities and resources outside of the classroom that will prepare them for their future careers and help them succeed.

“By partnering with alumni, parents, friends, corporations, and

foundations, we can transform students’ lives and in turn, empower them to create a better future for our community — locally, nationally, and globally,” said Ranjan.

Woodruff Strong will strengthen the School’s commitment to supporting students across three key areas:

Access: The School will expand access to one of the top mechanical engineering and nuclear and radiological engineering programs in the nation by increasing the number of need-based and merit-based scholarships and fellowships awarded annually, in particular for firstgeneration, underrepresented minority, and women students.

Success: The School will enhance student success by increasing academic support services, developing cohort, alumni, and corporate mentorship programs, and hosting career and culture-building activities.

Academic Well-Being: The School will improve academic wellbeing by increasing health and wellness resources, in partnership with the vice president for Student Engagement and Well-being, such as 24/7 online counseling services, hosting mental health awareness events, and offering mindfulness programming.

“With such a large undergraduate and graduate student population

8 STUDENT SUCCESS GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

– larger than most colleges of engineering – a focus on these important needs of Woodruff School students is timely,” said Professor Emeritus Raymond P. Vito.

Vito, who is also passionate about helping Georgia Tech students succeed, was one of the founders of the Georgia Tech InVenture Prize and has been pivotal in the creation, development, evolution, and delivery of the CREATE-X program.

“Through Woodruff Strong, we will not only help our students be successful at Georgia Tech but also in their careers,” he added.

Philanthropy and the Power to Transform

Woodruff Strong builds on the School’s existing initiatives to support students.

Mechanical engineering graduate student Jairo Y. Maldonado-Contreras is a member of the first class of students to receive the Woodruff School First Generation Fellowship. The fellowship, made possible through a partnership with Shell, awards $2,500 to first-generation graduate students who demonstrate excellence in academics, factoring in research and external recognition.

“As a recipient of the Woodruff School First Generation Fellowship, I feel empowered to achieve my goals while embracing my status as a first-generation student,” said Maldonado-Contreras.

Maldonado-Contreras is a member of the Exoskeleton and Prosthetic Intelligent Controls (EPIC) Lab, led by Associate

Professor Aaron Young. His research focuses on developing intention recognition algorithms that allow lower-limb robotic prostheses to execute the intended movements of users across a variety of environments – ramps, stairs, and level ground. After completing graduate school, he plans to become a professor.

Another group that supports students is the Mechanical Engineering Grad Student Mental Health Committee. It was initially formed as an ad hoc committee during the 2019 fall semester as a way to improve the culture around mental health among graduate students. In three years, the group has worked to implement initiatives, improve policies, and initiate dialogue to ensure Woodruff School students can succeed without compromising their mental health and well-being.

Studies have shown that poor mental health is linked to poor academic performance – resulting in low test scores, poor attendance, and a greater chance of withdrawing from college.

“Creating an inclusive academic environment requires providing for the needs of those who are most vulnerable in our community. Some students may not be in a vulnerable place today, but that does not mean they won’t face a circumstance in which they become vulnerable in the future,” said Bettina Arkhurst, a member of the Mechanical Engineering Grad Student Mental Health Committee. “Support would let students know that even if things in life go wrong, the Woodruff School won’t let them slip through the cracks – they are seen,

Ways to Support Students in the Woodruff School

Undergraduate Limited-Income Scholarship, $100,000: With 2,477 first-generation college students currently enrolled at Tech, the timing to continue to develop customized programming and resources that will better serve firstgeneration students’ needs is ever-present. An endowed scholarship will empower underrepresented students to break barriers and become a helluva engineer.

Graduate Fellowships, $150,000: The graduate student body exceeds 1,000 students, however, a mere fraction, less than 5%, benefit from a fellowship. It is essential that we prioritize investments in our graduate program to recruit and retain top engineering talent.

Renovation of the Instruction Labs, $200,000+: Located on the second floor of MRDC, the instructional labs serve as a learning and immersive experience for over 20 classes and more than 1,000 students annually. The labs need to be updated to better serve the needs of a top engineering program. An investment in the instruction labs will include naming opportunities.

cared for, and can access help, financial and otherwise when they need it most.”

As an example of potential support, Arkhurst points to funding that would facilitate systemic support for students who may be facing toxic work environments, a mental health crisis, or other difficult life events, including the loss of a loved one or having to support a family member in need.

“Supporting students in this way would be a game-changer,” she said.

Off to a Strong Start

Woodruff Strong’s fundraising initiative is already off to a strong start. Since the beginning of the 2022-23 academic year, the Woodruff School has been rolling out pieces of the program with great momentum.

In August, the School announced Women of Woodruff (WoW), an organization made up of College of Engineering alumnae and friends who are committed to ensuring women mechanical engineering and nuclear and radiological engineering students and faculty have the tools they need to thrive.

In addition, Gurudev Sri Sri Ravi Shankar, a globally revered humanitarian leader, visited Georgia Tech to engage in a conversation about managing stress and developing mental resilience. More than 500 students, faculty, and staff attended the event, “#TechMeditates – a Dialogue on Mental Wellness with Gurudev Sri Sri Ravi Shankar,” hosted by SKY at Georgia Tech.

9 2022-23 ANNUAL MAGAZINE

Did you know you can make a gift of any amount directed to support your area of interest in the Woodruff School? Reach out to our development office to learn more. Jaimie Hayes Senior Director of Development giving@me.gatech.edu 404-385-8345 Eden Kahssai Associate Director of Development giving@me.gatech.edu 404-894-7413

Engineering A New Way to Feed Gorillas

A team of Georgia Tech researchers has built an automatic feeding machine for gorillas at Zoo Atlanta that allows the primates to more naturally forage for food. Their ForageFeeder replaces the zoo’s previous feeding protocols, which had staff deliver food to the habitat at set times and locations.

With the new machine, feeding times can be set for different intervals every day. This encourages the gorillas’ natural feeding behavior, giving them additional random foraging opportunities throughout the day.

“Feeding behavior in wild primates is an important part of their daily lives. Gorillas typically eat and continuously move during daylight hours,” said Josh Meyerchick, senior keeper of primates at Zoo Atlanta and one of the paper’s co-authors. “We needed an additional tool to help increase their natural feeding behavior, which can provide a source of development and more natural social interactions than human-based feeding.”

The ForageFeeder was built by two Georgia Tech students — an engineer and a computer scientist — in collaboration with zoo staff. The undergraduates constructed it with affordability in mind: The $400 machine is open source and easy to manufacture and modify, which allows zoos around the nation to replicate the device.

The invention and a how-to-build-it guide is published in the journal HardwareX.

A New Idea Without a Good Solution

Andrew Schulz was a familiar face at Zoo Atlanta before earning his Georgia Tech mechanical engineering Ph.D. in 2022. He would sit with the elephants most days, studying how the animals stretch their trunks and use them to inhale food and liquids.

In January 2020, Meyerchick made the short walk from the gorilla habitat to see Schulz.

“They wanted me to look at a new project that wasn’t working correctly,” remembered Schulz, now a researcher at Germany’s Max Planck Institute for Intelligent Systems. “They had built their own automatic feeder for the gorillas using a deer feeder powered by a motorbike battery. A good idea, but it wasn’t ideal.”

Deer eat smaller food than gorillas, who typically consume turnips, sweet potatoes, carrots, and other items. When the deer feeder couldn’t handle the chunky shapes, the zoo asked Schulz for help.

He took the idea back to campus and brainstormed with his

10 STUDENT SUCCESS GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

Vertically Integrated Project (VIP) team of fellow mechanical engineering students. The VIP program, which includes more than 1,500 students every semester, allows students and faculty advisors to partner on long-term projects that bridge the gap between research labs and classroom curricula.

The team tinkered with concepts but then had to pause because of the pandemic. By the summer of 2021, everyone on the team had graduated, so Schulz turned to Maggie Zhang and Nima Jadali. The duo would make the project a reality.

Experience Beyond the Classroom

For the next year, Zhang and Jadali went back and forth with the zoo, testing various methods and parts.

Zhang, the engineer, kept the deer feeder bucket, added some acrylic materials, and printed the remaining parts with 3D and laser printers on campus. It was a trying process.

“I thought I had the skills to pull it off as a third-year student. But then everything kept breaking,” said Zhang, who graduated in May from the George W. Woodruff School of Mechanical Engineering. “I had already taken ME 2110, which taught me how to implement designs. Struggling on a project outside the classroom gave me new insight into engineering: when you fail, you have to find a passion to fix it that extends beyond getting a bad grade.”

Jadali, the computer scientist, built the

electronics, software, and a remote trigger to activate the feeder. He purposely used simple circuits, batteries, and wires to make the machine easy to replicate.

“This project was deceptively difficult,” said Jadali, who also graduated in May. “Often times with my research, I’m the only person who sees and tests much of the code I write. Then it goes into a blackhole after the project ends. This was different; it had to work long after I created it. That’s something I’ve never faced in a research setting.”

Fall Feedings

The ForageFeeder has been in place at the zoo intermittently since August. At first, the gorillas didn’t know what to make of it. During the first feeding, the primates ran away and looked confused when the food suddenly sprayed around their habitat.

Now it’s a regular, but random, part of the day. The primates don’t know when it will activate or what kinds of foods it may deliver.

The feeder is suspended in a tree about 15 feet off the ground. When it’s time to eat, food falls out of the bucket into a tray, where a rotor spreads the treats in a circular pattern, much like a fertilizer dispenser. The food can be distributed as far as 30 feet from the feeder.

“This is a great example of how technology can positively influence animal welfare. Zoo Atlanta is a local, nonprofit institution, and it was great to see Georgia Tech students learning by doing. Technology has been improving human lives for years, and now it’s

the gorillas’ turn,” said David Hu, professor in the Woodruff School and faculty advisor of the project.

The device hasn’t been up long enough for researchers to deeply dive into behavioral data and determine how much the gorillas are moving, nor how much more of the habitat they’re exploring.

“But I’m confident we’re going to see statistical data that confirms what we’re already seeing: more foraging behavior,” Meyerchick said.

If they like what they see in the data, the gorilla care team plans to add as many as three more feeders to the current habitat, which houses nine gorillas.

As the team continues to explore modifications to make the process and equipment more durable, other Zoo Atlanta keepers have asked Zhang if a modified version could be used in habitats for other animals. Since installing the gorilla feeder, she and her Capstone Design Expo team created a device to feed the Zoo’s treedwelling Angolan colobus monkeys.

“Engineers must always respect the projects we work on, even if they’re for animals,” Zhang said. “I find the zoo projects very interesting because your intended audience can’t provide any feedback. If the device stops working, the animal doesn’t tell you. If they rip it apart, you can’t tell them to stop. It’s good to anticipate the problems of a design and figure out its solutions before it’s sent into the real world.”

11 2022-23 ANNUAL MAGAZINE

“I find the zoo projects very interesting because your intended audience can’t provide any feedback. It’s good to anticipate the problems of a design and figure out its solutions before it’s sent into the real world.”

—Maggie Zhang

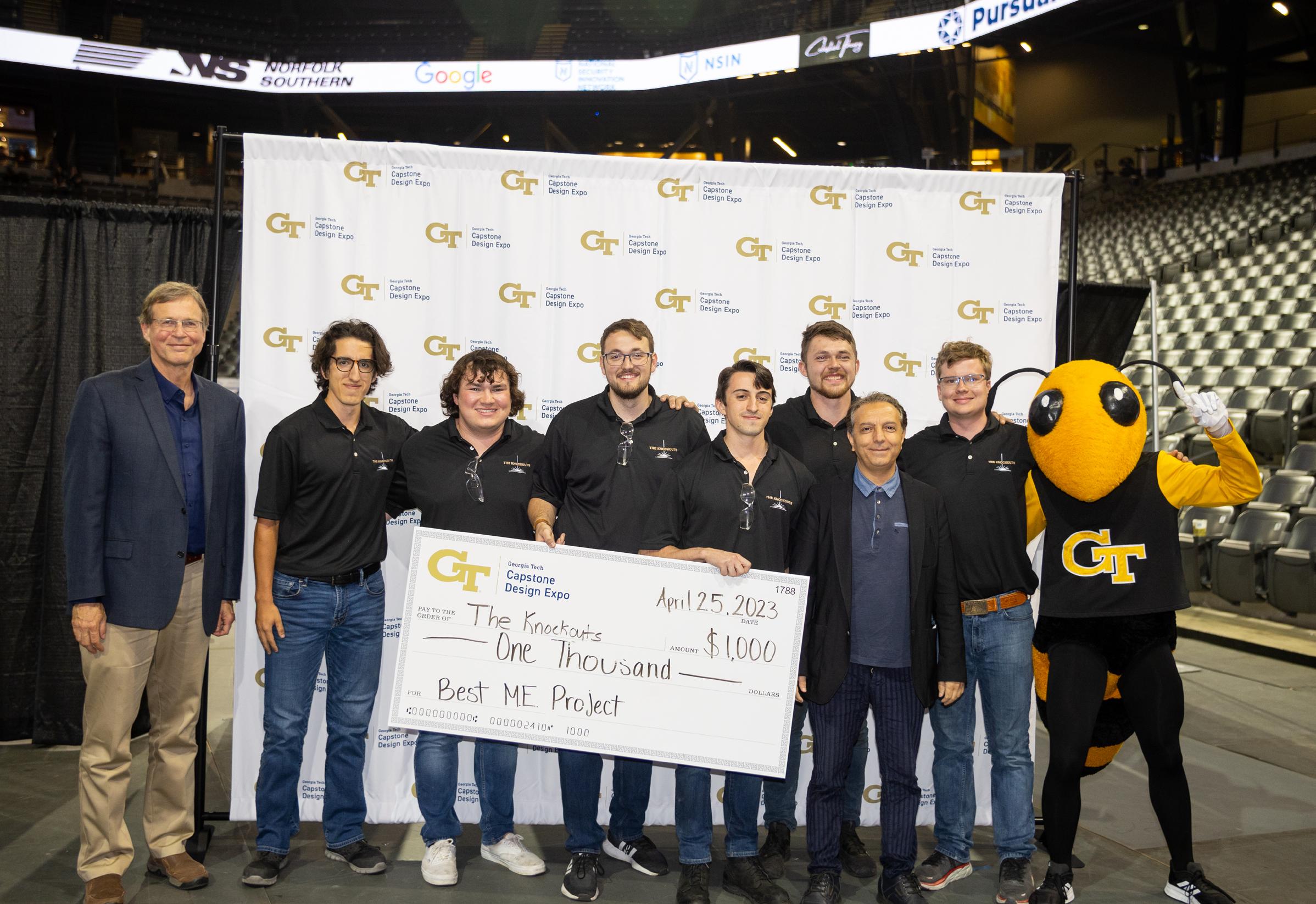

Virtual Reality Learning Tools Win Top Prize in Student Innovation Competition

When Siva Appana, Ian Kwuan, and Jathin Gadiparthi set out to make learning more accessible and interactive, the solution – virtual reality (VR) visualizations – felt initially elusive. The lightbulb moment for the three mechanical engineering students came on one of their late-night brainstorming sessions.

“As a visual learner, I convert any ideas into mental images, which aid significantly in my understanding,” Appana said. “Once I realized that I unconsciously do this, I realized that 3D animated visuals will help students better understand concepts.”

The team’s idea won the first-place prize in the College of Engineering’s annual Student Innovation Competition – Promoting Equity and Access (SICPEA), which asks students to propose a creative solution to a problem affecting marginalized populations on campus. Other teams won second and

third place with projects that seek to improve students’ access to groceries and keep underrepresented minorities from abandoning engineering careers.

The competition is designed to build awareness around issues of equity and access among engineering students while improving the College community. The competition is coordinated by the College’s Diversity, Equity, and Inclusion (DEI) Council, and the top three teams win cash prizes.

“SICPEA remains an important spoke in our network of student innovation competitions because it brings students together to think about how we as a community can put into action Georgia Tech’s values of diversity, access, and well-being,” said Mark Losego, a member of the College’s DEI council who helps coordinate the competition and an associate professor in the School of Materials Science and Engineering.

12 STUDENT SUCCESS GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

“Food insecurity is a huge issue on college campuses and correlates with lower GPA, attendance, and completion rates.

When students are focused on how to afford their next meal, they are not able to put their full effort into academics.”

—Devasena Sitaram

Dean Raheem Beyah discussed the winning idea from the 2023 Student Innovation Competition - Promoting Equity and Access over lunch with GT VizTools team members (clockwise) Siva Appana, Ian Kwuan, and Jathin Gadiparthi.

Anastasia Schauer and August Kohls — now siblings-in-law — had long wanted to write a paper together about engineering education, and the College’s innovation competition gave them the opportunity.

First Place: GT VizTools

“A picture is worth a thousand words,” Appana said. “Our proposal for GT VizTools expands visualization beyond whiteboards or textbooks to implement animations and interactivity, using libraries developed for VR headsets.”

The team proposed an open-source library of digital course content that could be accessed via VR headsets, which would be available for checkout at the Georgia Tech Library. Easy access to improved visualizations of course content could aid understanding and offer creative ways to prepare for exams, the team suggested.

“Especially in engineering and the sciences, visualization is important for helping students to comprehend and internalize topics they are learning in their classes,” Kwuan said. “We aimed to create an innovation that would add a layer of interactivity and realism to representations of many course topics.”

Gadiparthi said that interactivity would have helped him in classes like linear algebra, where 3D visualizations can represent concepts better than 2D.

“This is the tool that I wish I had,” he said. “By being a part of this project, I like to think I would be helping people in situations similar to mine.”

Appana, Kwuan, and Gadiparthi won $3,000 for the GT VizTools proposal and lunch with engineering Dean Raheem Beyah. Moving forward, the team hopes to begin prototyping course content and then starting a student organization focused on bringing GT VizTools to life.

“Planning out GT VizTools with my two friends has been a very positive group project experience,” Kwuan said. “What we have done so far in this competition certainly feels rewarding; we’ve had some fun moments working late through the night together on this, and I hope to continue with them on this innovation in the long run.”

Second Place: GroceryJackets

Devasena Sitaram, Grace Marek, Nicole Sen, Priyali Bandla, and Shreya Terala focused on improving access to grocery stores, an issue they said heavily impacts low-income students and those with dietary restrictions. By making it easier for students to get to the store and then to prepare affordable meals, the team hopes to improve educational equity.

“Food insecurity is a huge issue on college campuses and correlates with lower GPA, attendance, and completion rates,” said Sitaram, a third-year mechanical engineering student. “When students are focused on how to afford their next meal, they are not able to put their full effort into academics.”

Team members surveyed students about food access and costs. Many of their respondents didn’t have access to a car and nearly half cited cost as an obstacle to getting groceries. They also looked at U.S. Department of Agriculture data, which classifies the campus neighborhood as a food desert since there’s only one grocery store within a mile. To improve access, the team proposed a rideshare app that would connect students with cars to those without to offer rides to nearby grocery stores.

“It was so amazing to see issues that my friends and I struggled with — exasperation at the lack of access to fresh nutritious foods that were affordable and impact our experience at Tech — inspire a potentially actionable solution,” said Bandla, a third-year industrial engineering student.

Third Place: The Inclusive Interdisciplinary Innovators

Anastasia Schauer worked with Carnegie Mellon student August Kohls to dig into data about why underrepresented minorities (URMs) leave engineering fields to present ideas for retaining them.

The two Ph.D. students noted that the National Society of Black Engineers has reported seven in 10 Black engineering students leave the field before finishing their degrees compared to 50% for all races. Meanwhile, underrepresented groups also change fields after graduation, according to data from the National Center for Education Statistics. The center reported that Black, Hispanic, and Native American students account for 21% of science and engineering bachelor’s degree recipients yet just 11% of the workforce.

Through a survey of former engineers at various stages of their careers, Schauer and Kohls found that the key to increasing retention might be incorporating interdisciplinary studies into engineering, in the classroom and beyond. The team proposed several different means of doing this, including interdisciplinary internship and research opportunities, interdisciplinary projects starting in students’ first year, bachelor’s and master’s programs across fields, and more guest lecturers from other disciplines in engineering classrooms.

Schauer, a mechanical engineering Ph.D. student, said they’re just getting started with their work and will share their findings more broadly this summer.

“I’m excited that our work was accepted to be presented at a conference,” she said. “We’ll be sharing it at the American Society of Engineering Education conference at the end of June.”

13 2022-23 ANNUAL MAGAZINE

Mechanical Engineering Student Bikes Across America

Baltimore-to-San Francisco ride raises money for teen cancer patients

There’s no denying that college can be a challenge — a test of what you have learned, your time management skills, and your fortitude. But second-year Georgia Tech mechanical engineering student Mjay Choi was still feeling like he wanted to see how far he could push himself.

What could be the ultimate test? What about biking across the United States?

“Always challenge yourself,” Choi said. “That is the only way to make yourself stronger.”

He found an opportunity to raise money and awareness for young adult cancer patients with the nonprofit Ulman Foundation. Choi jumped at the opportunity to support the cause, having lost both his grandparents to different forms of the disease.

But Choi was not a competitive cyclist. Other than leisurely rides with his family, he’d never attempted anything like a 4,000-mile bike trek. The team at Ulman provided him with some guidelines to prepare, and he started training at the Campus Recreation Center with more frequent cardio. As he finished his first year at Tech, Choi was preparing to pedal from Baltimore, Maryland, all the way to San Francisco, California. Choi and a team of other cyclists averaged 80 miles of biking every day. He and his fellow riders often relied on the kindness of strangers to make the journey.

“In some locations, we had meals and places to stay planned ahead,” Choi explained. Sometimes, the team would camp under the stars. But in other places, community members would find out about the fundraising effort and would offer to make a hot meal or provide lodging for the cyclists.

Choi said some of the first days of the 70-day ride were most difficult. For a rider with little experience, the mountains of West Virginia and southern Pennsylvania in the early June heat were daunting.

“Eventually, my body started getting used to the rides every day,” he said.

The team of 30 cyclists Choi rode with started riding extra miles so they could collect pictures with state signs as trophies of their triumph.

“We’d get so excited to make it to another new location,” said Choi. Eleven states and seven national parks in total. “The best experience of my life so far,” he said.

As for favorite locations, Choi says the vistas of the American West helped not only make the ride easier but reshaped his view of the United States.

“Yosemite National Park was amazing,” said Choi. “Cycling through different elevations and enjoying scenery was a once-in-a-lifetime opportunity.”

Although his goal was to raise money for cancer patients, he also learned a lot of life lessons.

“Live in the moment; it’s now or never,” said Choi.

Choi says he’d challenge himself all over again if he had the chance. His advice: “Ask yourself, ‘Will I regret my decision in five years?’ If you think the answer is yes, then make a different decision.”

14 STUDENT SUCCESS GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

Jesse Bruner and Carolina Colón, graduate students in the George W. Woodruff School of Mechanical Engineering, recently received the Woodruff School First Generation Fellowship. Sponsored by 3M and Shell, the fellowship provides $2,500 in funding to first-generation graduate students who demonstrate excellence in academics and research.

Jesse Bruner is a first-year Ph.D. student studying nuclear engineering. Originally from Orlando, Florida, Bruner spent two years working in the Washington state area, including a stint with the Pacific Northwest National Laboratory.

“It’s nice to receive the fellowship,” Bruner said. “I was moving from across the country, which was costly, and not having to pay anything out of pocket for the first semester was really helpful and allowed me get started here at Georgia Tech with smooth transition.”

With one semester completed, Bruner says he enjoys the quality of his classes and connections he has been able to make with peers and faculty in the Nuclear & Radiological Engineering and Medical Physics program.

“I have already learned so much just being here,” said Bruner. “The program provides lots of opportunities for me to travel to conferences, to apply for other sources of

Students

Receive Woodruff School First Generation Fellowships

funding, and meet people at other labs; it’ s been a lot of good things.”

Recently Bruner attended a conference at the Oak Ridge National Laboratory in Tennessee. He is also involved in a current project at Lawrence Livermore National Laboratory in California, where he’s studying pulse shape discrimination for antineutrino detectors.

Bruner, who is also a bassoonist with the Georgia Tech Symphonic Band, has found interests in diagnostic imaging, radiation therapy and nuclear propulsion. After graduation Bruner hopes to continue working in a national lab.

Carolina Colón is a first-year bioengineering Ph.D. student. Originally from Quebradillas in northwest Puerto Rico, Colón says monetary awards like the Woodruff School First Generation Fellowship mean she, for the first time, can focus on her studies and research without the need for a fulltime job.

“If I did not work 50-something hours, I would not have been able to attend school at all,” Colón said. “So even $500 or $1,000 can be the difference between being able to go to school versus having to delay by another semester.”

For Colón, the fellowship is not just an appreciation of her personal academic achievements, but of a significant

acknowledgment of the diverse challenges first-generation students face in higher education settings.

“It’s kind of like a ‘we hear you; we see you’ kind of thing,” Colón said.

Colón’s academic focus blends her aeronautical engineering background with CAR-T cell therapies. Her long-term goal is to develop methods for implementing cell therapies on a large scale, and eventually creating the means to make the technology available to astronauts on hazardous longduration missions.

“It has a lot of potential to be a one size fits all therapy,” Colón said. “Right now, these therapies cost close to half a million dollars, making treatments inaccessible to most of the population, so one of the few ways you can bring the price down is by scaling their manufacturing.”

Doing so first requires extensive research into T-cell biology and resiliency, which Colón is hoping to incorporate into her dissertation.

The Woodruff School First Generation Fellowship was established by Shell in 2020 and is part of a continued effort by the Woodruff School to provide a broad range of funding opportunities for current students.

15 2022-23 ANNUAL MAGAZINE

HyTech Racing Celebrates Success at Formula SAE Electric Competition

HyTech Racing, Georgia Tech’s student-led electric racing team, placed tenth overall at the 2023 Formula SAE Electric hosted at Michigan International Speedway. The competition challenges student teams from around the world to design, build, and present the bestperforming electric formula race car. Along with their impressive placing, the team broke two standing records at the event, lateral and longitudinal acceleration, claiming the title of fastest vehicle to have competed in this competition.

The electric vehicle competition was introduced by SAE in 2013 and this year over 60 teams participated. Each year, teams use vehicles powered only by electrical motors and compete in two different types of events, static and dynamic. In the static events, teams participate in real-world scenario challenges such as explaining and justifying their vehicle costs and defending their designs to EV industry leaders. After passing all static events, team vehicles compete in the dynamic portion. Cars compete for the fastest time on straight-line acceleration, skid pad, autocross (single lap), and endurance lap (22 lap) events.

Hytech Racing’s overall top ten placing was due to their impressive and consistent results in the individual events. The team finished first in the acceleration and skidpad tests, second in the autocross event, and fifth in design.

“While results are great, our culture encourages the team to fall in love with the process,” said Hytech Racing President and mechanical engineering student Akshat Jain. “Our mission of building the next generation of engineers through the pursuit of vehicle performance encouraged members to give their absolute best effort.”

All members actively participate in all parts of the vehicle construction, including experimental circuitry, material characterization, and computational fluid dynamics. According to the team, building such a car like this requires a tremendous amount of innovation.

“Last year, our chief engineer mentioned the transition to all-wheel drive and compared it to being a quantum leap for the performance of our vehicle. While our car was at peak performance in 11 months, it required significant changes to our design, some of which included a planetary gearbox for the hub motors and a redesigned suspension. The simulation-backed design decisions were promising, however, there was a lot of doubt about the team’s ability to execute such drastic changes in a single season and every day was filled with a stream of never-ending problems,” said Jain.

For this year’s build, on top of challenging and complex engineering problems, the team also dealt with external factors such as supply chain issues. In the end, the results of the competition were a reflection of the dedication of the team, and several members also received internship offers as a result of their work.

There is no time to waste though, according to Jain the team is already looking forward to next year’s competition. “The real magic takes place in the preparation for the event that begins when the competition ends,” he said.

16 STUDENT SUCCESS GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

Back to Back Drone Racing Titles Further RotorJackets Goal of Expansion

April was a month of national championships at Georgia Tech as Buzz was crowned the nation’s best mascot, and the RotorJackets took home their second straight Collegiate Drone Racing championship.

Tech’s team, comprised of four racers, narrowly emerged from the field of 15 schools and 52 individual pilots to take home the title following two days of competition at the Fayette Fliers Field in Tyrone, Georgia. While scores from the qualifying round and the previous races in the knockout round are compiled into a sum, it was RotorJackets’ vice president Tanner Beard who put his team in the lead in the final race of the competition. Beard also finished in second place in the individual competition, but it’s the team’s accomplishment that he’s proudest of.

Beard and outgoing team president Luke Lawver started flying first-person view (FPV) drones together in 2018 before officially founding RotorJackets in the fall of 2020. As Beard, a mechanical engineering student, and Lawver, an aerospace graduate student, get set to leave Tech, the pair couldn’t have imagined the success the group has achieved in a short time.

“I’m just very proud of how far it’s come. We started out practicing on fields with PVC pipes, and our gates and materials were falling apart. We didn’t really have anything, but we were able to build everything up, and we’ve practiced every single weekend for events like this,” Beard said.

The team learned the layout of the championship track just two weeks before the event, but practicing from first light to sundown was nothing new for the RotorJackets. The hard work and preparation continued up until the last

Georgia Tech Motorsports Celebrates Top 10 Finish

minute as the team was forced to replace a drone the night before the competition. But the two senior members of the team were impressed by first-year computer engineering student Ian Boraks – the incoming president – and Dylan Wyckoff, in his first-ever drone race. Wyckoff is a third-year computer science major and will take over as the club’s treasurer.

Both relished the opportunity to fly alongside their experienced teammates and are now focused on continuing their legacy in pursuit of a three-peat.

Other than winning titles, the club also wants to expand the drone-flying community on campus. When the fall semester begins, monthly events will be held on Tech Green, where all students can learn how to fly. No experience is necessary, and all equipment will be provided. Not all club members are racers, and the benefits of learning the skill go well beyond the group.

“The cool thing about FPV as a hobby is that, especially as an engineering major or someone in any STEM field, it teaches you a ton of practical skills that are incredibly useful in your dayto-day job,” Lawver said. “We build all of our drones basically from scratch, so you can learn about electrical hardware design, mechanical hardware design, and software engineering and dive into whatever areas you want. Or, you can just treat it as a black box, and you’ll have fun with it.”

Using the skills they’ve acquired, the RotorJackets have expanded their footprint at Tech, using drones to enhance coverage of events like the iconic Mini-500 as well the Pi Mile, and they’ve assisted Athletics in creating digital content.

Georgia Tech Motorsports (GTMS), one of the oldest competition teams operating at Georgia Tech, placed in the overall top 10 at the 2023 Formula SAE Michigan held at Michigan International Speedway. GTMS placed seventh overall in the competition, breaking into the top 10 for the first time since 2008 and achieving their highest placing since 2004.

GTMS is made up of 75 students from different majors across the Institute, with most students hailing from the George W. Woodruff School of Mechanical Engineering.

The Formula SAE competition challenges teams of university undergraduate and graduate students to conceive, design, fabricate, develop, and compete with formula racing-style vehicles. Teams compete under the hypothetical scenario they are working for an engineering firm that is designing, fabricating, testing, and demonstrating a prototype vehicle.

Teams are required to participate in a series of events, both on and off track, and have the chance to demonstrate their creativity and engineering skills against groups from other universities around the world.

GTMS team lead Eli Kuperman broke down the team’s success, highlighting the impressive improvement from last year’s 23rd overall placement.

“While we only finished top 10 in one event, it’s important to note our consistency in finishing well in every event pushed us into the overall top 10 results,” stated Kuperman. “Our sights are set high for next year.”

GTMS scored consistently well in all aspects of the event where their model vehicle was tested in areas including endurance, acceleration, design, cost, and sales presentation.

“We could not have done this without the support of the Institute, the Woodruff School, and our gracious sponsors,” said Kuperman. “Every student on GTMS owes their experience to the support of the aforementioned parties, so from the bottom of our hearts, thank you.”

17 2022-23 ANNUAL MAGAZINE

Antonia Antoniou was promoted to professor.

Marian Axente joined as adjunct assistant professor.

Costas D. Arvanitis was promoted to associate professor and named Woodruff Faculty Fellow. He received the Woodruff School Mentor of the Year Award. He received a $3 million, five-year R01 grant from the National Cancer Institute to apply thermal targeting by Magnetic Resonance guided Focused Ultrasound to increase anti-HER2 CAR T cell delivery and potentiate therapy against breast cancer brain metastasis.

Nazanin Bassiri-Gharb joined the NSF as program director in its Division of Materials Research within the Directorate for the Mathematical and Physical Sciences.

Nico F. Declercq was promoted to professor.

Shaheen Dewji was selected to join the ICRP Task Group.

Brandon Dixon was named Associate Chair for Undergraduate Studies.

Anna Erickson was promoted to professor. She received the Arthur Holly Compton Award in Education and the National Landis Young Member Engineering Award. She was named an ELATES Fellow.

Alper Erturk was named Ring Family Chair. He received the Woodruff School Culture Champion Award (Faculty).

Andrei G. Fedorov was named Regents’ Entrepreneur.

Andrés J. García received the Founders Award from the Society for Biomaterials. He co-founded a company called iTolerance that is developing immunomodulatory biomaterial technology, bringing it further into clinical trials, commercializing it, and ultimately making it available to patients.

Srinivas Garimella received the Sigma Xi Sustained Research Award. He was also named an ASHRAE Fellow.

Faculty Notes

Samuel Graham was named an AAAS Fellow.

Peter Griffiths joined as academic professional.

Marta Hatzell received the Institute’s Outstanding Achievement in Early Career Research Award.

Yuhang Hu received the SES Young Investigator Medal for 2023 and the Eshelby Mechanics Award for Young Faculty. She was named Woodruff Faculty Fellow.

Amit S. Jariwala received the CoE Outstanding Teacher Award (MidcareerSenior), the Woodruff School Mentor of the Year Award, and the Georgia Tech Student Government Association Advisor of the Year Award (for Invention Studio). He was awarded the Georgia Tech Hesburgh Award Teaching Fellowship in Fall 2022 and the Woodruff Academic Leadership Fellowship in 2023.

Yogendra Joshi joined DARPA as a program manager in the Microsystems Technology Office.

Surya Kalidindi was reappointed Regents’ Professor.

YongTae Kim was named Woodruff Faculty Fellow.

Dan Kotlyar was awarded a grant from Idaho National Laboratory to collaborate on implementing a computational transient system capability via INL’s MOOSE framework to analyze components of an NTP system including the reactor core during startups and shutdowns.

Shreyas Kousik joined as assistant professor.

Thomas Kurfess was elected President of ASME. He was appointed to the Department of Energy National Nuclear Security Administration Advisory Committee for Nuclear Security and appointed to the Department of the Navy Science and Technology Board.

Michael J. Leamy was appointed Interim Director of Graduate Student Services.

Seung Woo Lee was named Woodruff Faculty Fellow. He received the award for Sigma Xi Best Faculty Paper.

Timothy C. Lieuwen was named Interim Chair of the Daniel Guggenheim School of Aerospace Engineering.

Peter Loutzenhiser was named an ASME Fellow and Woodruff Faculty Fellow.

David L. McDowell received the ICF Paul C. Paris Gold Medal and the ASME Worcester Reed Warner Medal for 2023.

Matthew McDowell won an ECS Battery Division Early Career Award.

Shreyes N. Melkote received the 2023 SME Gold Medal.

Akanksha Menon was recognized as a DARPA Riser. She was also selected as a Class of 1969 Teaching Fellow by the Center for Teaching and Learning (CTL) at Georgia Tech.

Roxanne Moore received the CoE Outstanding Faculty Achievement in Research Award (Research Faculty).

G.P. “Bud” Peterson received the 2022 Max Jakob Memorial Award.

Raghuram V. Pucha was named the 2023 Zeigler Outstanding Educator.

Jerry Qi was named SES J.R. Rice Medalist. Devesh Ranjan was chosen as a Fellow for the Academy for Innovative Higher Education Leadership program.

Gregory Sawicki received the 2023 ASB Founders’ Award.

Ankur Singh, in collaboration with Emory, received a $2.76 million, five-year R01 grant from the National Cancer Institute to study the interactions between patientlevel factors, tumor genetics, and the tumor microenvironment as features that contribute to racial disparities in diagnosis, survival, and treatment.

18 RESEARCH PREEMINENCE GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

Suresh K. Sitaraman received the Richard Chu Award and the Best Associate Editor award from the IEEE Transactions on Components, Packaging, and Manufacturing Technology.

Vanessa Smet was selected as a Class of 1969 Teaching Fellow by the CTL at Georgia Tech.

Aaron Stebner received the Woodruff School Research Award.

Susan Napier Thomas was inducted into the 2023 Class of the AIMBE College of Fellows. She also received the Biomaterials Award for Young Investigator for 2022.

Mike Tinskey received a Ford Research Award to study ways to reduce severity of automotive collisions using both data analytics and energy absorbing devices.

Shannon Yee was named Woodruff Faculty Fellow.

W. Hong Yeo was awarded an IEN-EX Seed Grant. In collaboration with Emory, he received a $2.46 million grant to develop intelligent tools for assessing heat exposure effects.

Aaron Young received the NIH Director’s New Innovator Award. He was promoted to associate professor and named Woodruff Faculty Fellow.

Fan Zhang was named a CoE Cybersecurity Fellow.

Ye Zhao received an ONR YIP Award and the Woodruff School Research Award.

Ting Zhu received the 2023 ASME Centennial Mid-Career Award, the CoE Outstanding Faculty Achievement in Research Award (Midcareer), and the Woodruff School Research Award.

FACULTY SPOTLIGHT: Assistant Professor Shreyas Kousik

Get to know one of the Woodruff School's newest faculty members

What brought you back to Georgia Tech?

As I worked through grad school, academia seemed a better fit for me than industry. When it came time to apply for faculty jobs, I was so excited to see that the Woodruff School had a job posting specifically looking for roboticists – coming back here was my top choice. I already knew how it felt to be an ME undergrad here, so I was excited to connect with the students. On top of that, Georgia Tech has an incredible robotics program that is growing quickly, so I was thrilled to add to the cutting-edge research at a place that was already home.

Why did you choose a career in academia?

After working in a wide variety of internships, I realized that I was more pulled towards the fundamental math of why robots work than creating products or services. Of course, it’s possible to do a lot of R&D work in industry (for which getting a Ph.D. is a prerequisite). But for me, doing research while also teaching students feels much more fun than working at a company. Besides research and teaching, I’m passionate about improving diversity, equity, and inclusion in engineering. I think academia gives me the biggest lever to make an impact.

What classes will you teach?

First and foremost, ME 3017 System Dynamics. I took this class with Professor Ye-Hwa Chen in 2013, and it made me fall in love with system modeling and control. That one class is honestly why I still work in the field today. In the longer term, I hope to teach optimal control and a robot safety special topics class.

What is the focus of your research?

I work on robot safety. If we really want to put robots everywhere, working near and around people, I believe we must be able to justify exactly why and how they are safe. Often, we can write down safety in a somewhat straightforward way on the whiteboard, but it quickly becomes challenging to transfer that definition onto real robot hardware. So, I’m really interested in developing theories paired with numerical representations that let us make strong statements about real-world safety.

What is the biggest challenge of being a new professor on campus?

It is challenging to know what to prioritize. As a Ph.D. student or postdoc, you can do teaching, research, and service at the same time, but there’s usually an advisor as a fallback point of contact and support. As a new professor, you immediately have a million tiny problems to solve, but you’re also the fallback point. However, the mechanical engineering faculty and staff are doing a great job of setting me up with mentors and addressing my millions of questions.

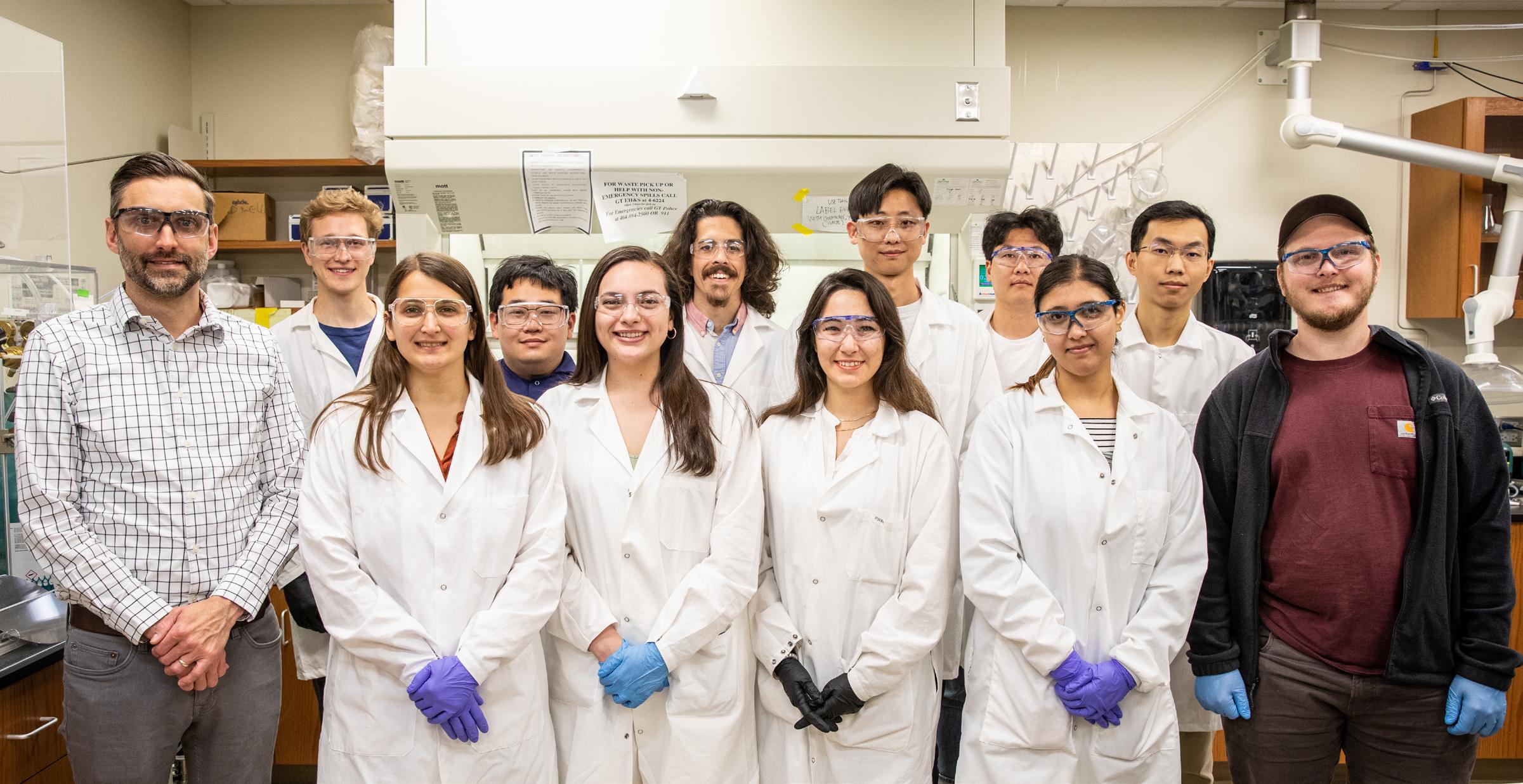

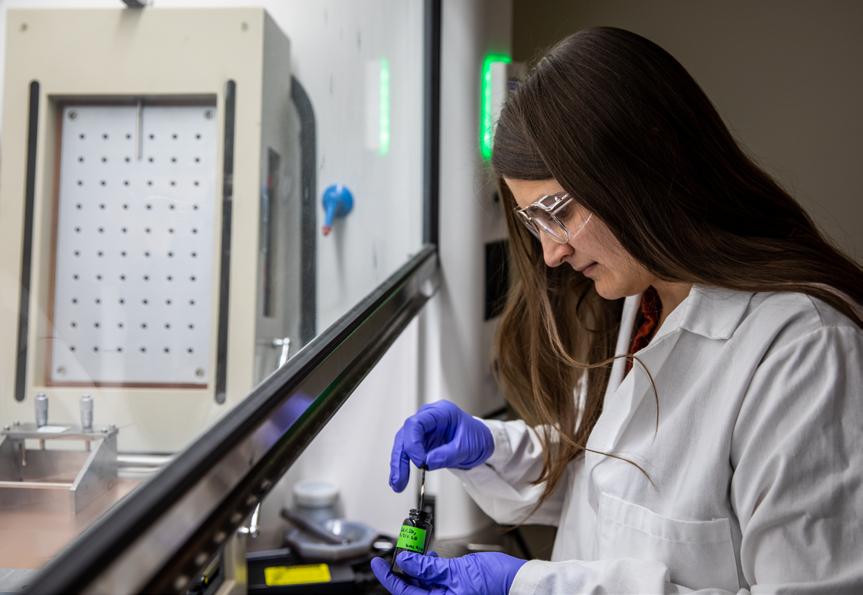

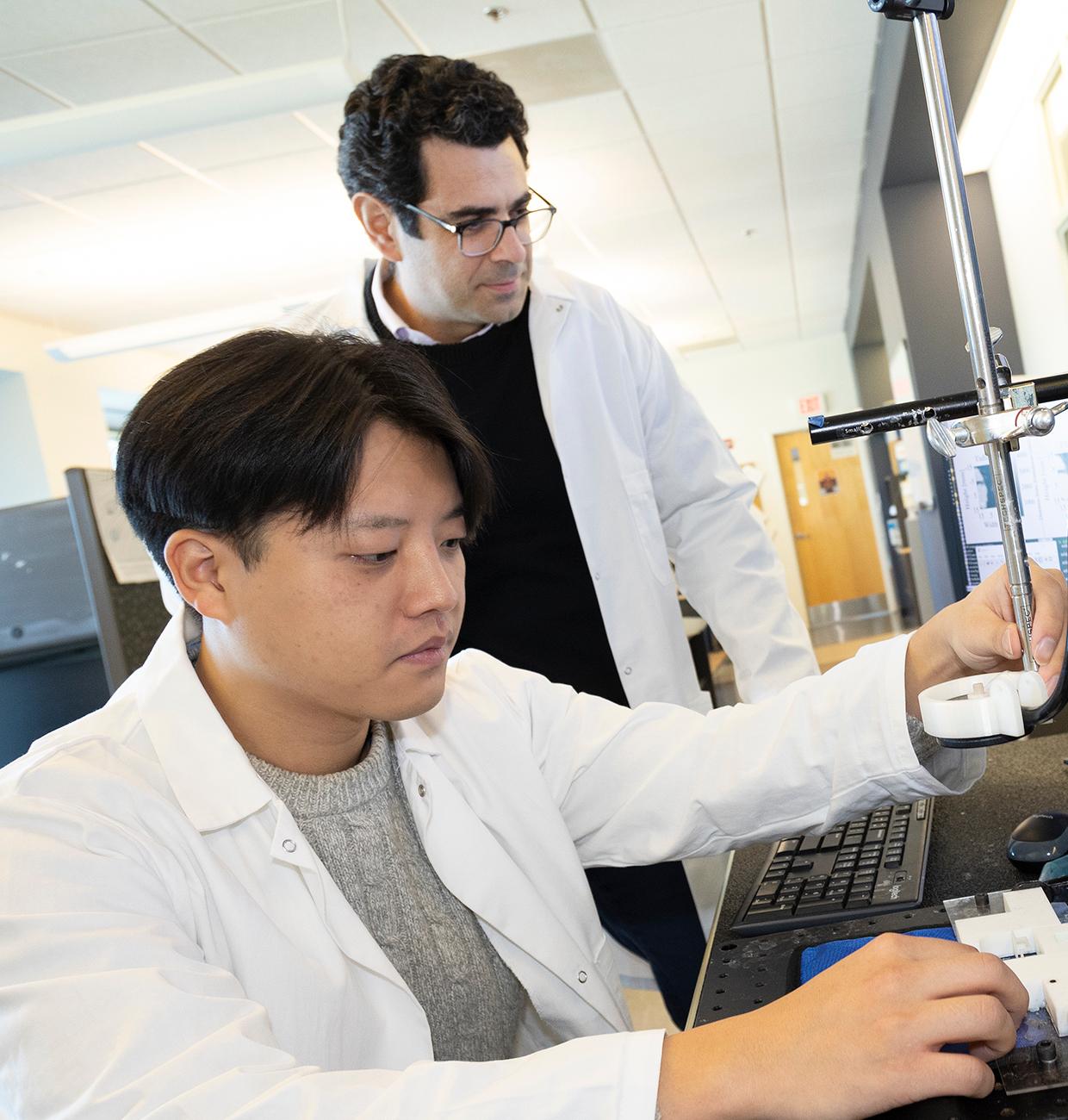

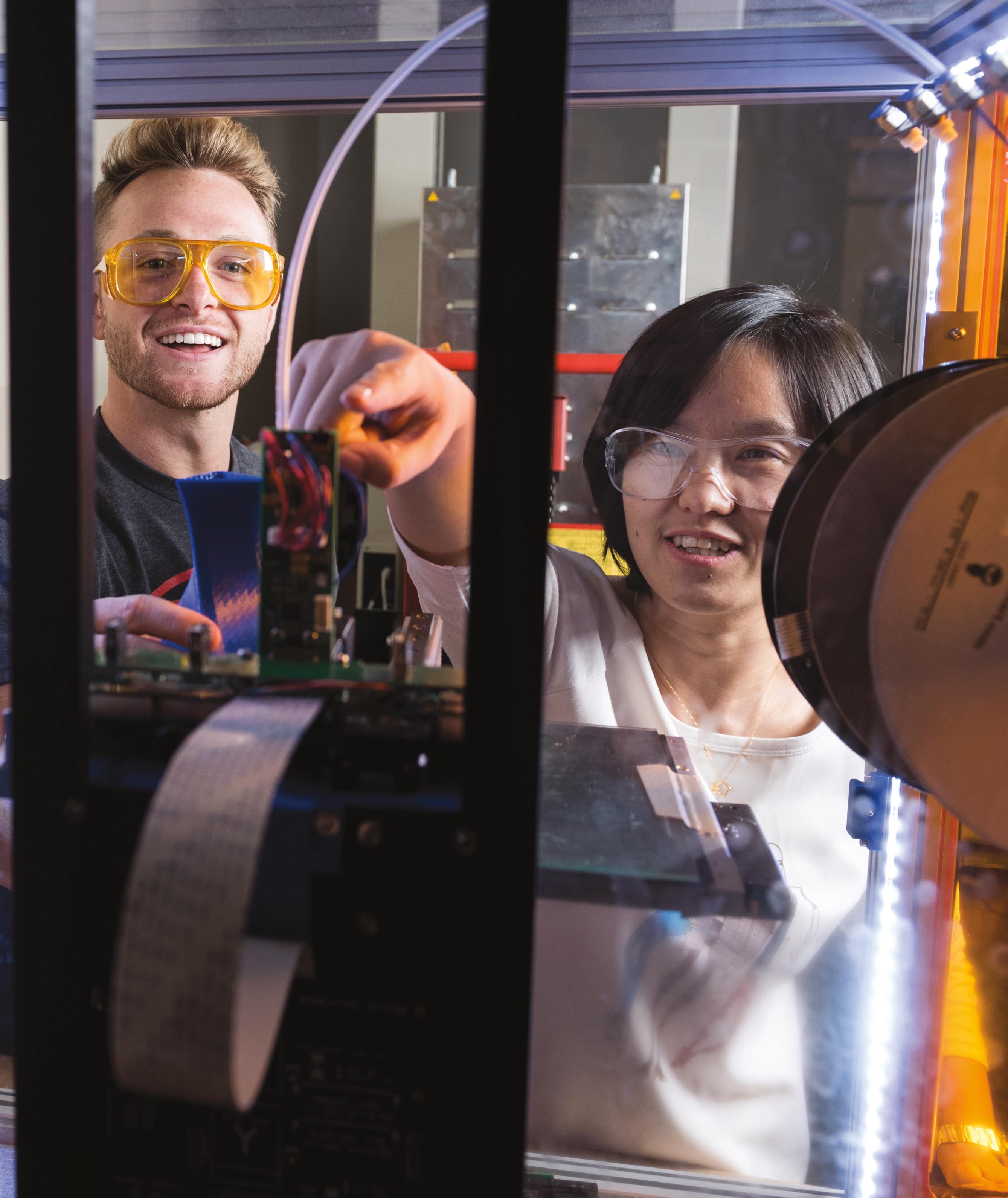

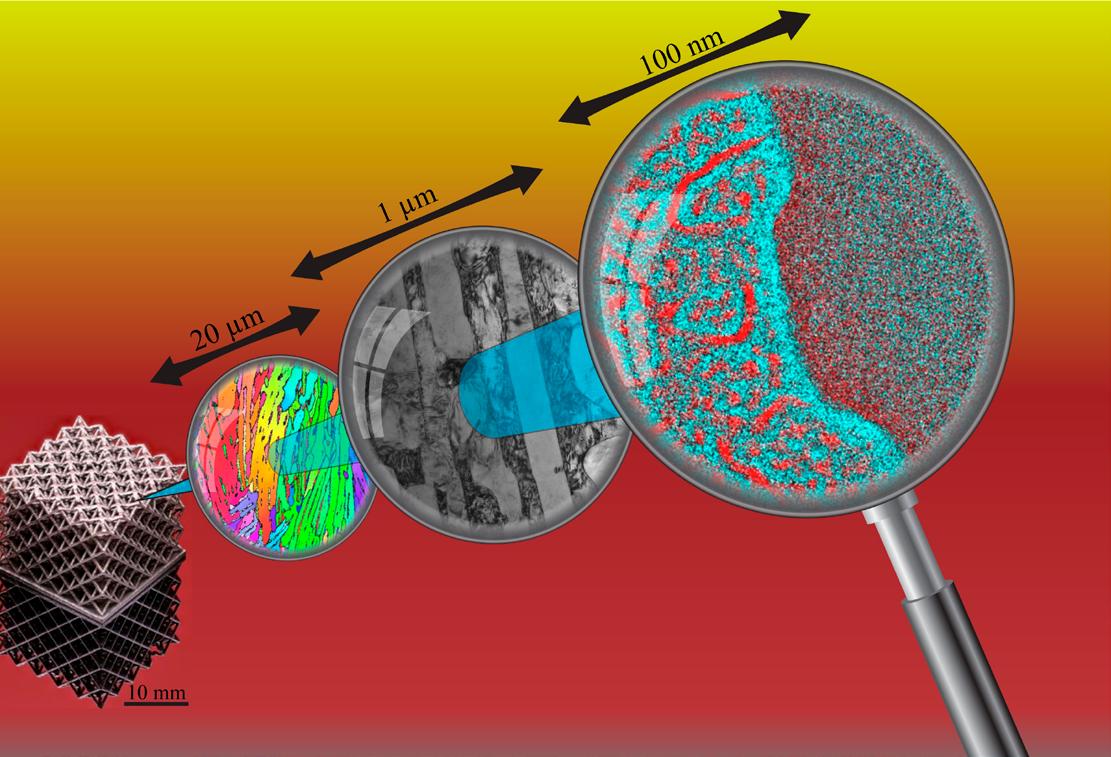

The McDowell Lab at Georgia Tech is Shaping the Future of Battery Technology

Batteries. They come in numerous shapes, sizes, and lettered designations; they power everything from telecoms satellites to children’s toys; your TV remote goes through them too quickly and a dead one in your car will have you asking strangers for help.

Like so many items of convenience we only register the impact batteries have on our dayto-day life when they begin to falter. On most occasions these failures are at worst a nuisance, but as the number of hybrid and fully electric vehicles on the market grows, and as more economies aggressively pursue alternative fuel sources, the reliability and longevity of batteries will play a dominant role in how we create, store, and use energy.

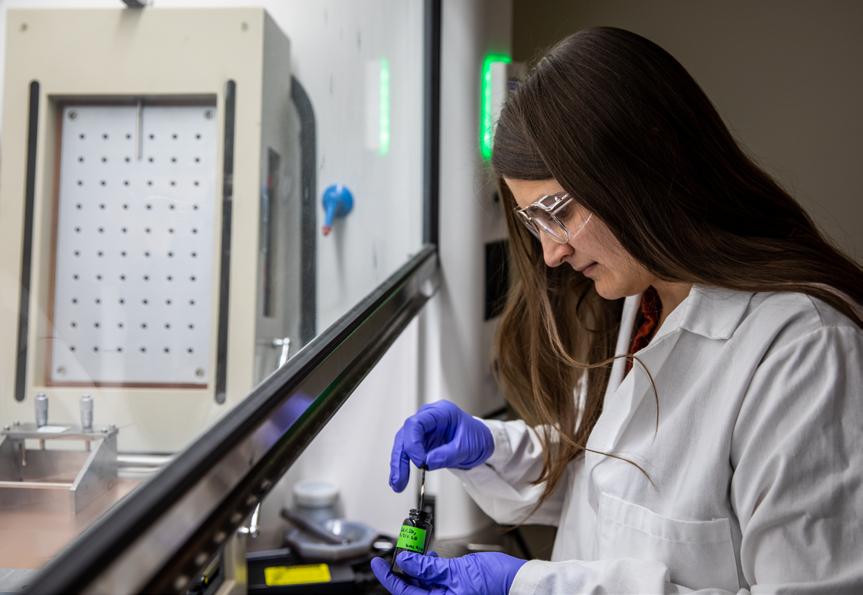

Researching new materials for the next generation of high-capacity batteries is

Matthew McDowell, associate professor in the George W. Woodruff School of Mechanical Engineering and director of the McDowell Lab. By understanding how these different materials react to numerous charging cycles, his team hopes to help lead the charge toward longer-lasting batteries.

An Atlanta native, McDowell first took a serious interest in batteries as a graduate student at Stanford University.

“I figured that batteries would be a very important technology to enable widespread clean energy use and vehicle electrification,” McDowell says.

The complex materials used in batteries were another reason McDowell shifted his academic focus. Batteries have been constructed using a

range of elements and minerals, from copper, zinc, lead, and even sulfuric acid. Nickel and lithium are two elements currently in use in lithium-ion batteries. Because of their high energy densities, lithium-ion batteries make up the bulk of batteries in consumer electronics, including those used in electric vehicles.

Still, researchers like McDowell and his team are looking for ways to improve energy density and long-term durability while reducing charging times, which remain obstacles in the electric vehicle market.

“Lithium-ion batteries are great,” McDowell says. “However, for cars that drive further on a charge, and for next-gen applications such as hybrid-electric aircraft, we need batteries that can store more energy. My group is working

20 RESEARCH PREEMINENCE GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

on new materials for batteries that can store more energy while being able to charge and discharge over many cycles.”

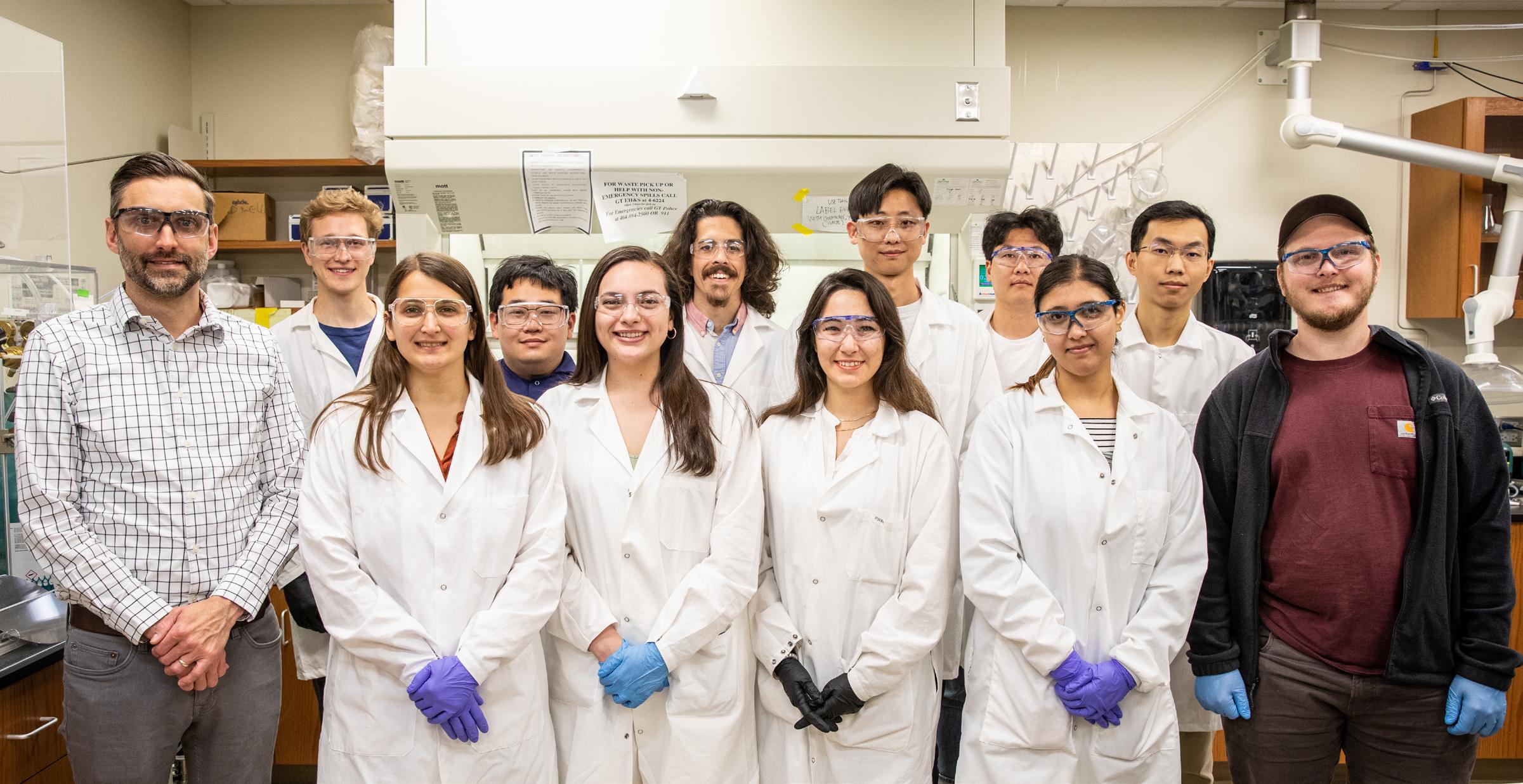

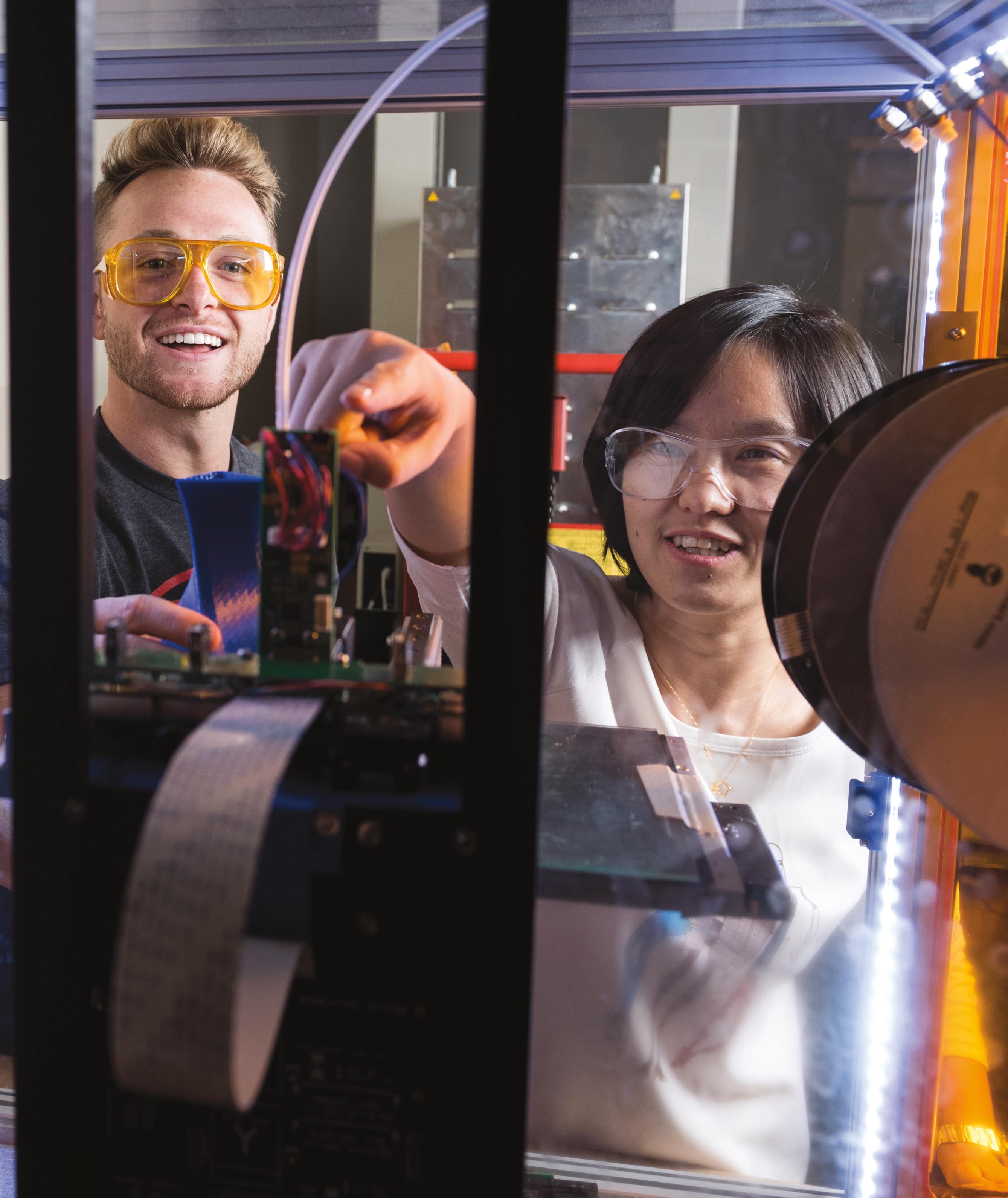

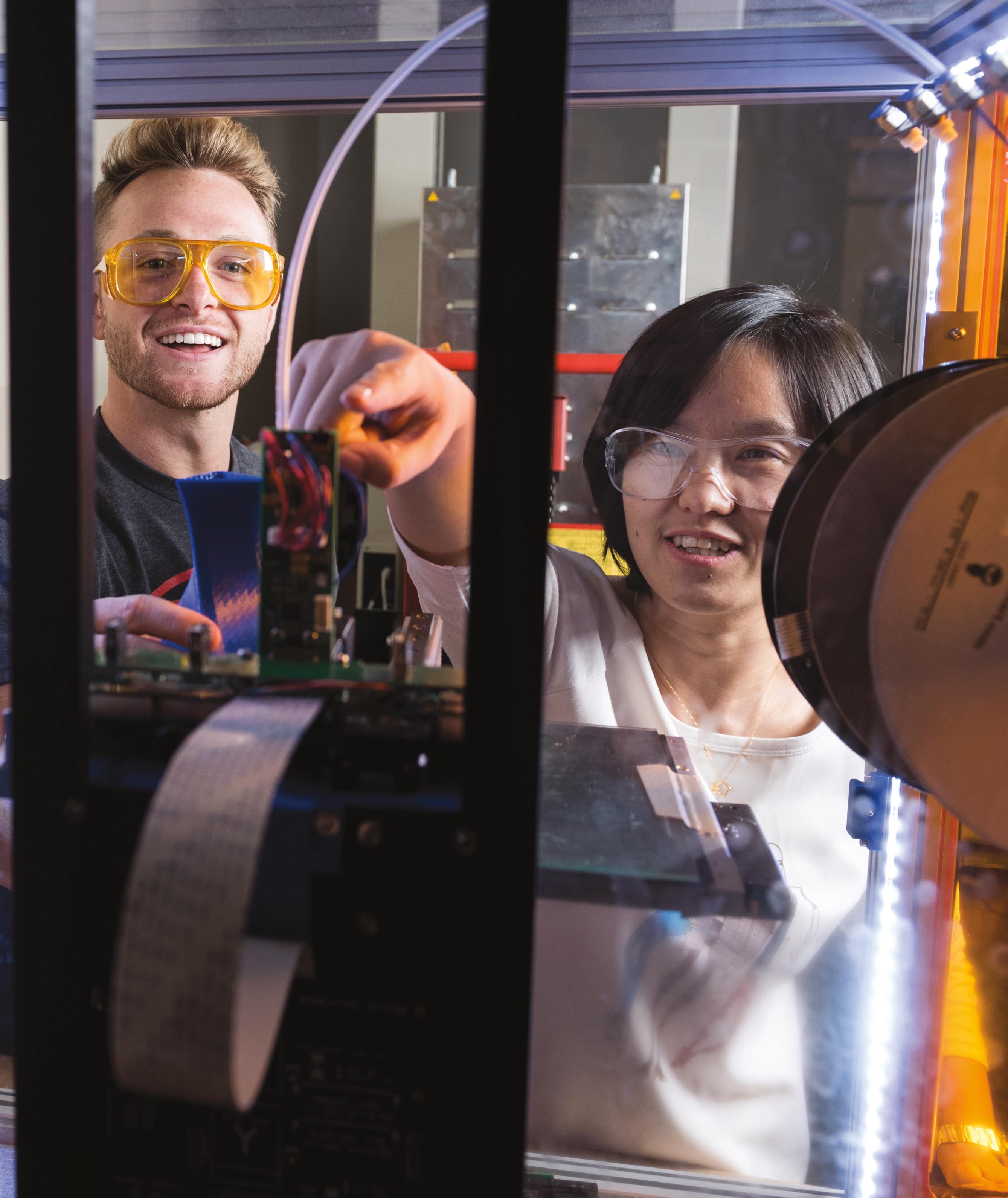

The group hard at work in the McDowell Lab consists of an affable team of 19 graduate students and post-doctorates.

Talia Thomas, a mechanical engineering Ph.D. student from Fort Meade, Maryland, joined the McDowell Lab in 2022 and has enjoyed the chance to fuse green chemistry and sustainable practices into battery science. She praised the positive lab culture and mentorship she’s received from colleagues and peers.

“[Professor McDowell], the postdocs and fellow grad students are always excited to share their knowledge and help me grow as a scientist and researcher,” Thomas says. “I feel empowered and supported to do cool science that benefits humanity.”

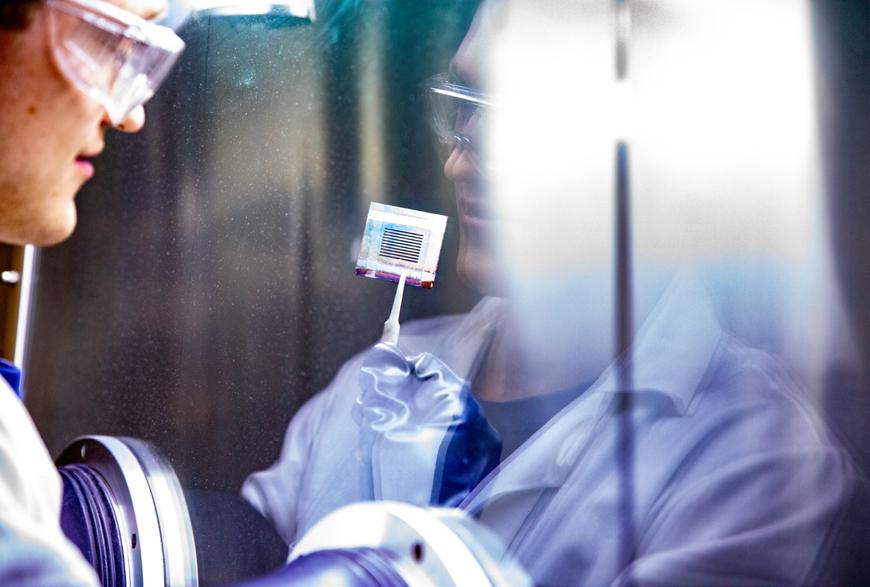

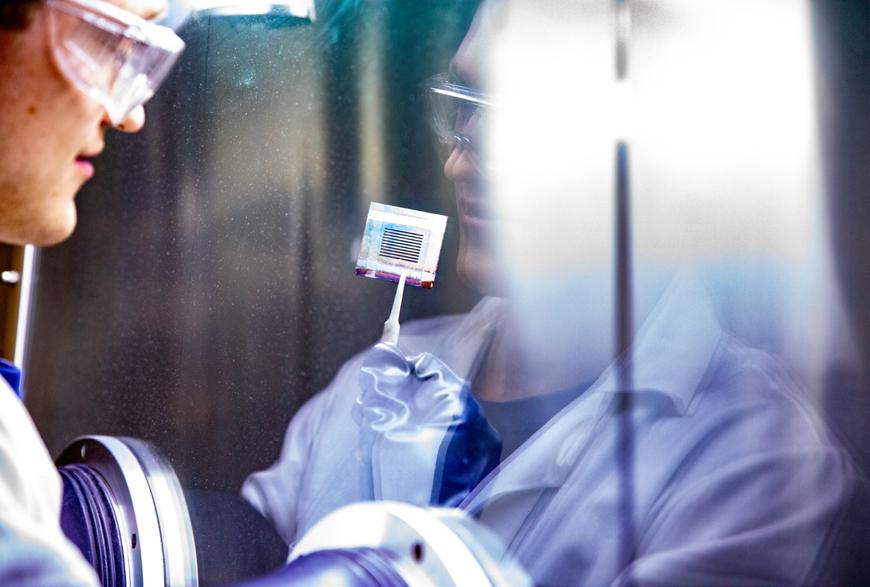

The lab has made recent progress studying solid-state battery technologies, which have even more energy density than lithium-ion batteries. Packed with a highly conductive non-volatile medium, solid-state batteries are seen as a safer and more powerful energy storage alternative.

“We have recently discovered the mechanisms that limit the performance of high energy electrode materials in solid-state batteries,” McDowell says. “We have also developed new electrode materials which can charge and discharge very fast – in other words, you wouldn’t have to wait long at a charging station to recharge your car.”

The research into solid-state batteries has helped Lars Nelson, a Ph.D. student in the McDowell Lab studying materials science and engineering. The Charleston, South Carolina

native has been with the lab for two years and describes the work as “impactful” and of personal importance.

“Being in the lab has given me several awesome opportunities to lead and conduct research at multiple national lab facilities,” Nelson says. “That has resulted in some exciting data that will shape my Ph.D. going forward.”

Nelson plans on returning to the national lab setting to continue solid-state battery material research after completing his Ph.D. He’s also highly appreciative of the time and help he’s received in the lab, and says he’s become a much stronger researcher because of it.

A May report by the World Meteorological Organization indicated a 66% chance that global temperatures would increase beyond

the 1.5 degrees Celsius limit set by the 195 national signatories of The Paris Agreement. As natural and manmade events drive climate imbalance, the potential impact of the research done by McDowell and his lab isn’t lost on anyone working there, including McDowell.

“I see batteries as a key part of enabling a clean energy future,” McDowell says. “Renewable energy, like solar and wind electricity, cannot be produced all the time, and cheap and efficient batteries are needed that can store renewable energy when it is produced so it can be used later. In addition, batteries enable the electrification of vehicles to avoid fossil fuel emissions. The next few years will see advances in batteries for all these applications, and I am particularly excited about new chemistries that are enabled by using solid-state battery technologies.”

21 2022-23 ANNUAL MAGAZINE

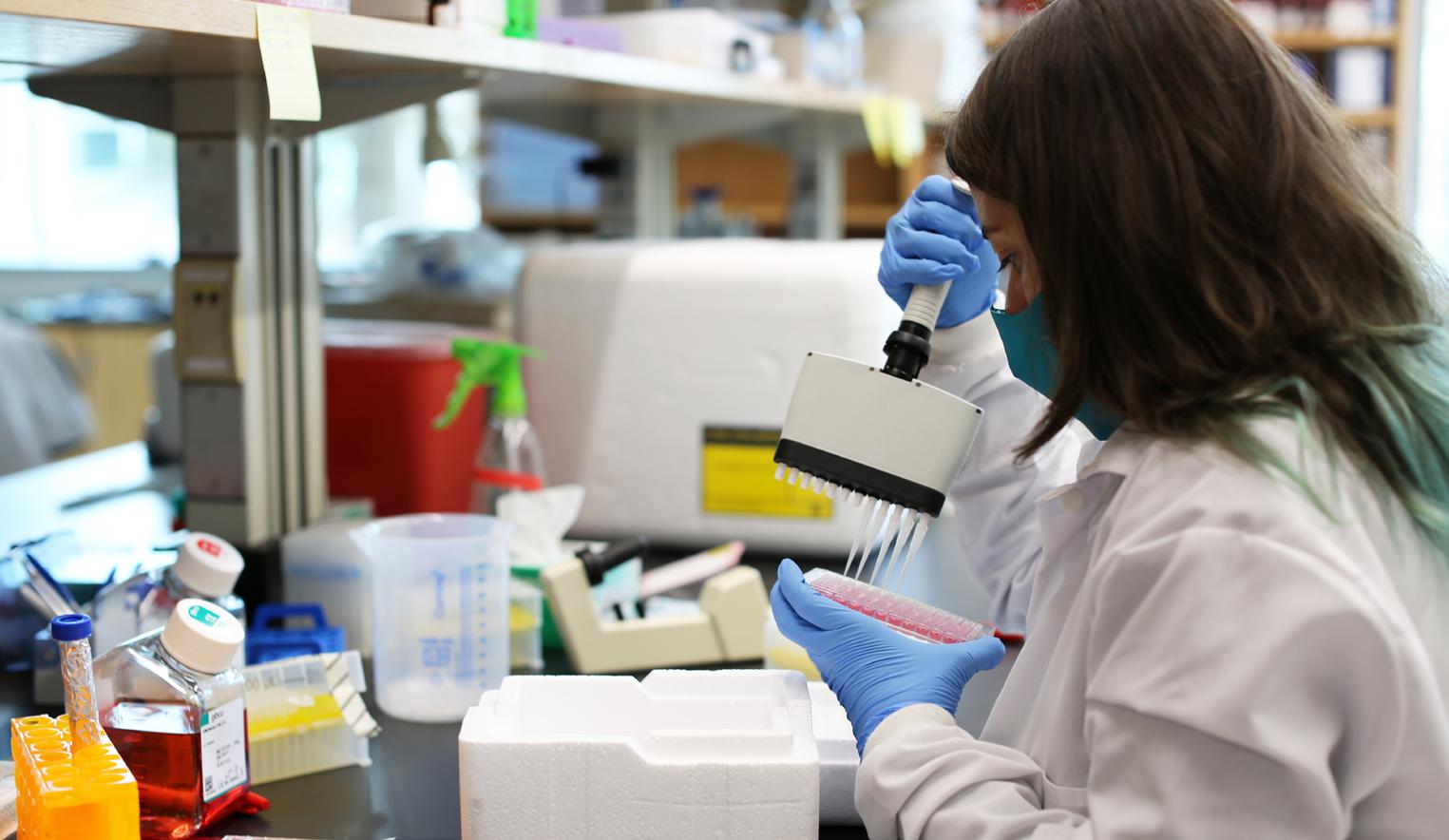

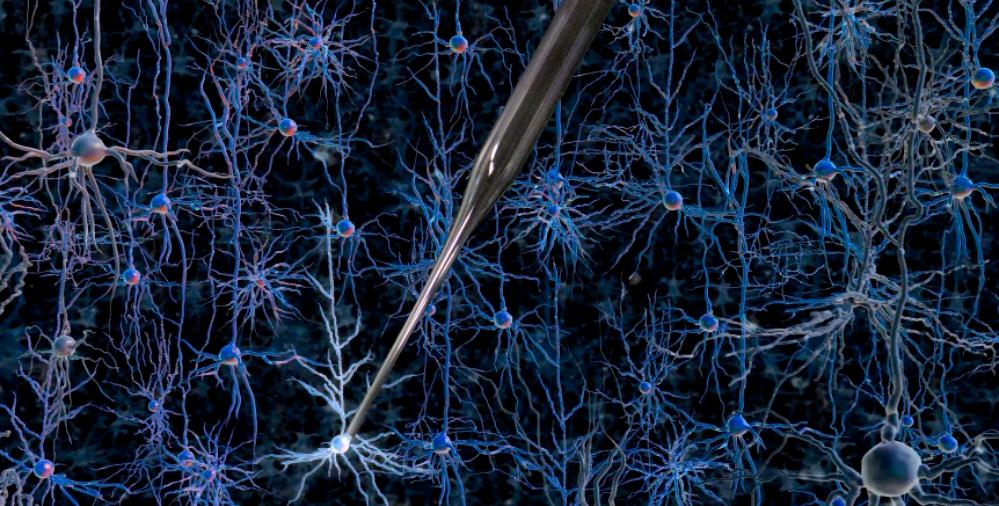

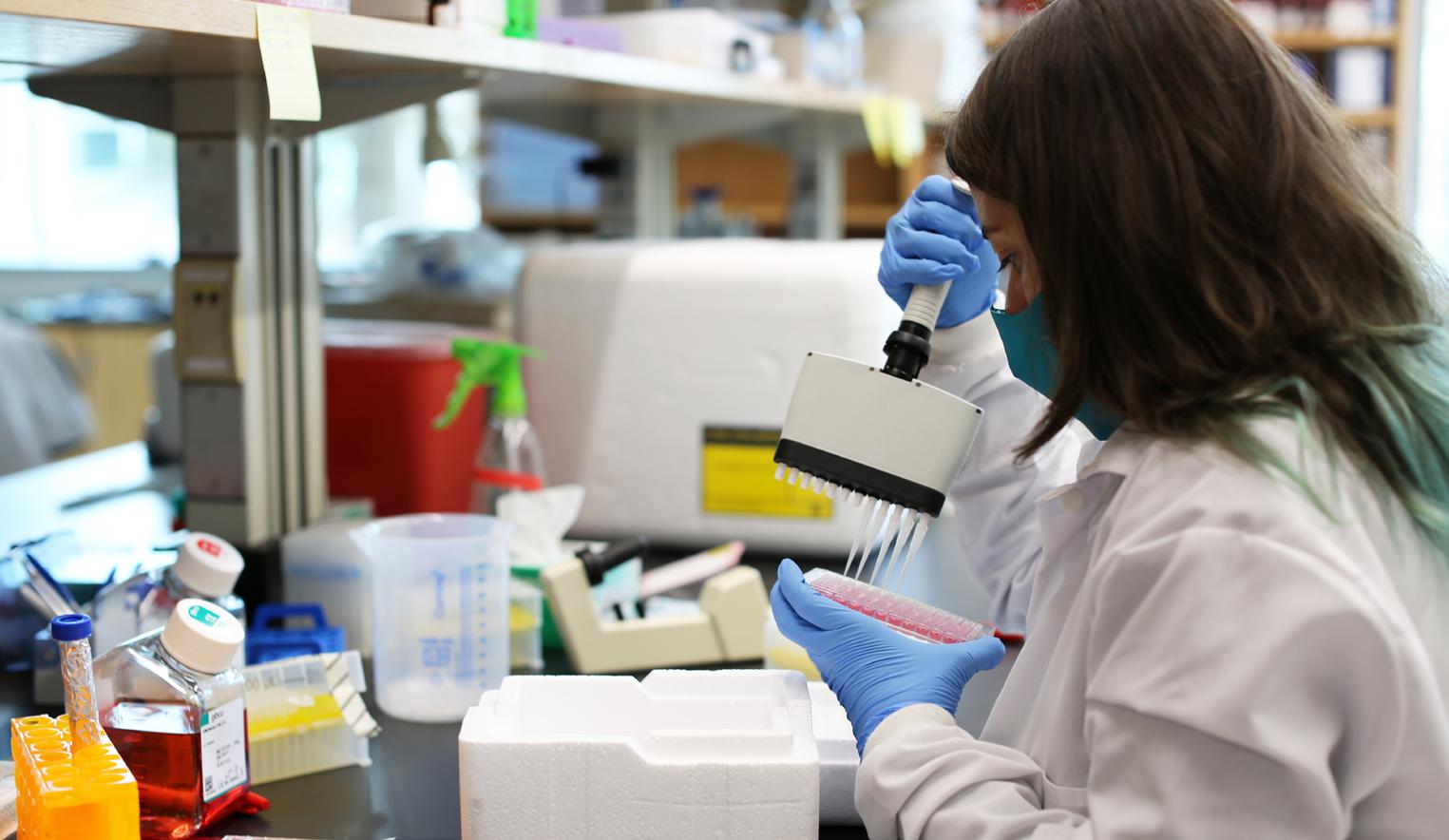

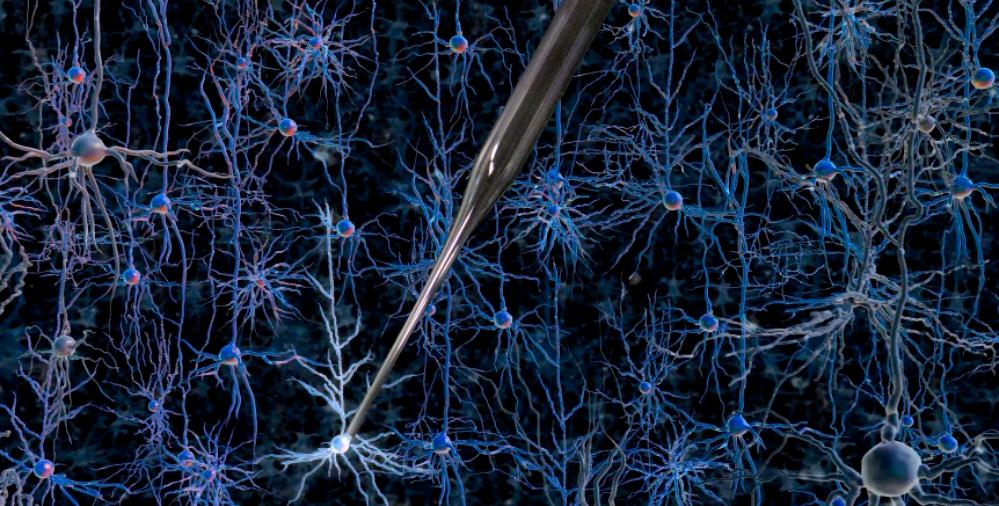

Groundbreaking Lymphoma Tumor Model Paves Way for New Therapies

In recent years, innovative cancer drugs that target specific molecular drivers of the disease have been embraced as the treatment of choice for many types of cancer. But despite significant advances, there is still a lack of understanding about how the complex interactions between a tumor and its surrounding environment in the body affect cancer progression. This problem has become a well-known roadblock in making novel treatments effective for more people.

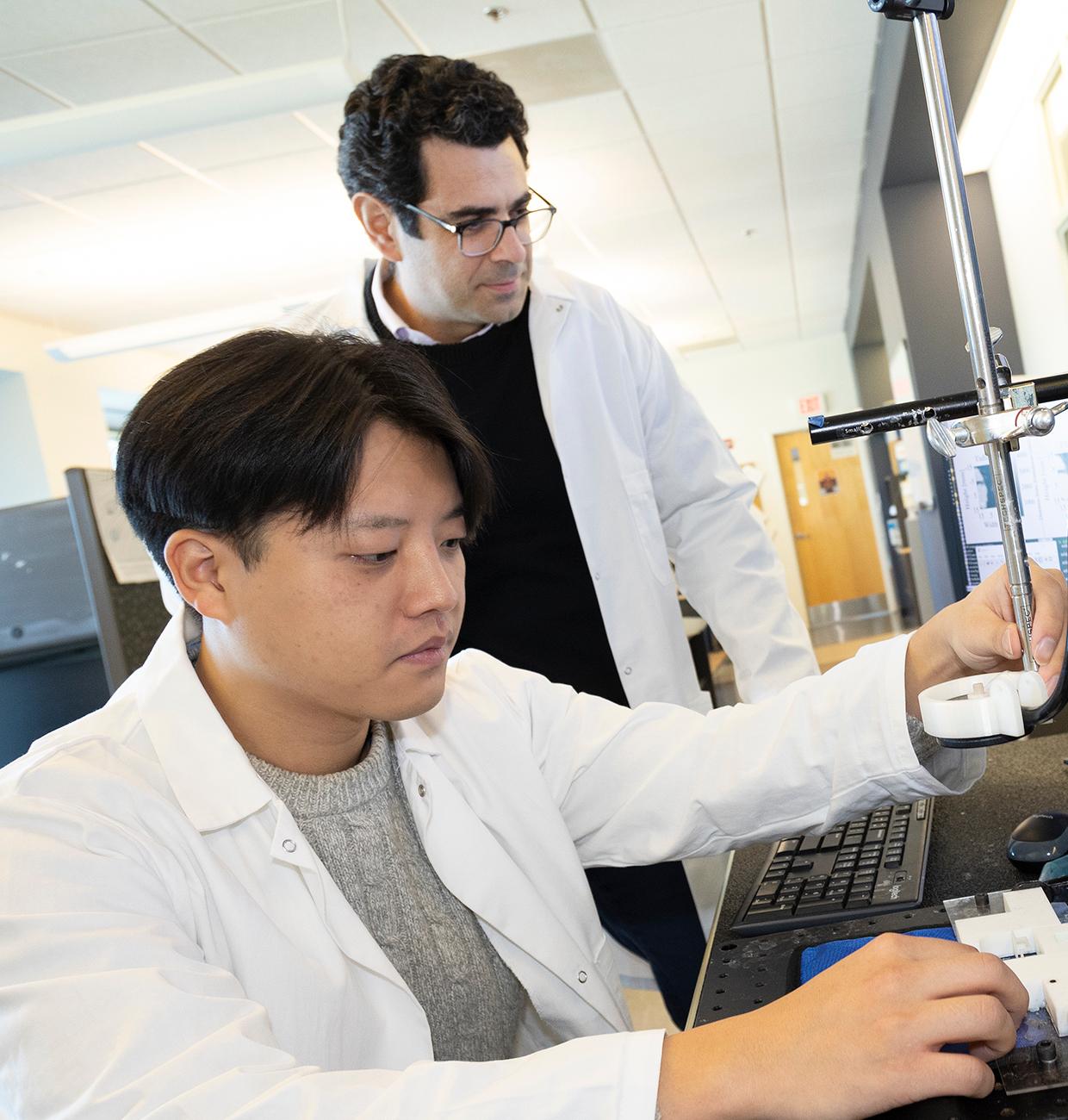

Ankur Singh, professor in the George W. Woodruff School of Mechanical Engineering and the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory University, led an international team of researchers in the development of a promising breakthrough for targeted cancer therapies.

The team bioengineered a synthetic tumor model to understand and then demonstrate how the tumor microenvironment impacts the effectiveness of targeted therapies for a specific type of lymphoma called Activated B Cell-like Diffuse Large B cell lymphoma (ABCDLBCL). Their synthetic tumor model could change the game for designing and testing personalized cancer therapies. The research

paper, which features an interdisciplinary team from institutions across the U.S. and around the world, was published in the journal Nature Materials.

A Cutting-Edge Tumor Model

Recent treatments for ABC-DLBCL that target specific molecular signals of the disease are in clinical trials. But, while the treatments have shown to be effective in lab testing (in vitro environments) and in mice (in vivo), they have proven less effective in humans, with over 60% of patients not responding.

“We wanted to understand how specific changes that happen in the microenvironment empower the lymphoma tumors to not respond to these drugs when administered in patients,” Singh said. “The ultimate goal is to build a patient-derived tissue model that represents the tumor and can be grown outside of the body, in order to truly understand the factors and conditions that control tumor behavior.”

22 GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING

To accurately test new therapies, a model tumor microenvironment should closely mimic the nuanced interactions that happen in a live tumor. But to understand those conditions, which can vary wildly from case to case, the researchers needed real patient data.

The researchers examined more than 1,100 ABC-DLBCL lymphoma patient samples to understand the molecular profiles of their tumors. For each sample, they used RNA sequencing and imaging to identify the composition, stiffness, and mechanical properties of the tumor tissue, along with other factors that play a role in how tumors grow and respond to treatment.

Combining what they learned from the patient data, the researchers designed a synthetic hydrogel-based model of the lymphoma tumor microenvironment. They bioengineered the model to have the specific qualities and characteristics seen in the microenvironments of the samples. Specifically, by modifying the hydrogel with cell-binding adhesive peptides and presenting immunological signals, they were able to recreate the intricate biological, chemical, and physical characteristics that are present in a live tumor microenvironment, including protein signals, tumor stiffness, and more. The customizable hydrogel proved to be supportive of tumor samples obtained from patients, a phenomenon that has not been previously demonstrated for lymphomas.

Combining Therapeutics

The team illustrated the viability of their model by testing how the tumors responded to a new type of inhibitor drug known as mucosaassociated lymphoid tissue lymphoma translocation protein 1 (MALT1 inhibitors) currently in human trials.

The researchers observed that, when being treated by MALT1, several tumor microenvironment factors related to the tumor cells — including T cell signal CD40 Ligand, collagen-like extracellular matrix, and the level of tissue stiffness — all empowered the tumor, helping the cancer cells resist responding to the new inhibitors even at high doses.

The researchers then sought a way to overcome the dampened tumor response by combining therapeutics that simultaneously suppress multiple aberrant oncogenic pathways in the same tumor cell. They found that when they used MALT1 and another inhibitor to target multiple pathways at the same time, they were able to promote more tumor death in the cells.

One of the major challenges is that tumors can engage multiple pathways in the cells to keep fueling the survival of tumor cells. However, the combination treatment was so powerful that, even in the presence of tumor microenvironment factors that supported tumor survival, they could still be overcome by the combination of therapies.

To validate the results from synthetic tissues developed in lab, the researchers then implanted actual patient tumors in an immunocompromised mouse model to determine how the patient tumors responded to the new therapies.

“We live in a world where we can claim a lot based on in vitro treatments, but the obvious question is always what happens in vivo,” Singh said. “What’s amazing is that we predicted this exact result in our synthetic model.”

Moving Forward

The researchers’ work clarifies the complex relationship between malignant ABC-DLBCL tumors and their dynamic surrounding environment, while highlighting the crucial importance of considering the tumor microenvironment when creating treatments that combine therapeutics.

The team’s work will help clinicians prioritize clinical trials of certain therapies and enable scientists to create more rational therapy combinations that could improve patient response rates to treatment. This is especially relevant for the potential of personalized treatment for lymphoma, as two individuals with the same cancer may benefit from different combinations and dosages of therapeutics.

A large portion of the patient samples used in creating the tumor models were provided by Emory through a collaboration with oncologist Jean Koff, one of the authors of the study.

“From a clinician’s standpoint, this work is very exciting because it exemplifies how findings from large genomic datasets may be translated into development of therapeutic strategies in lymphoma,” Koff said. “Singh’s cutting-edge organoid technology allows us to explore how patient-specific changes in the tumor microenvironment impact response to therapeutic agents, thus helping to deliver on the promise of precision medicine.”

The project further initiated a new partnership between teams at Georgia Tech and Emory and strengthened existing collaborations with Cornell Medicine. The teams will continue to work together to investigate molecular pathways that may be targeted to improve treatment outcomes for lymphoma patients.

The research comes at an important time in the field of drug testing. The FDA has begun to encourage alternatives to animal testing for pharmaceuticals. Singh’s powerful synthetic model that faithfully mimics real tumor environments is likely to be an example for other cancer researchers to follow for in vitro drug testing.

The research was funded by the National Institutes of Health, the National Cancer Institute, and the Wellcome Leap HOPE program.

23 2022-23 ANNUAL MAGAZINE

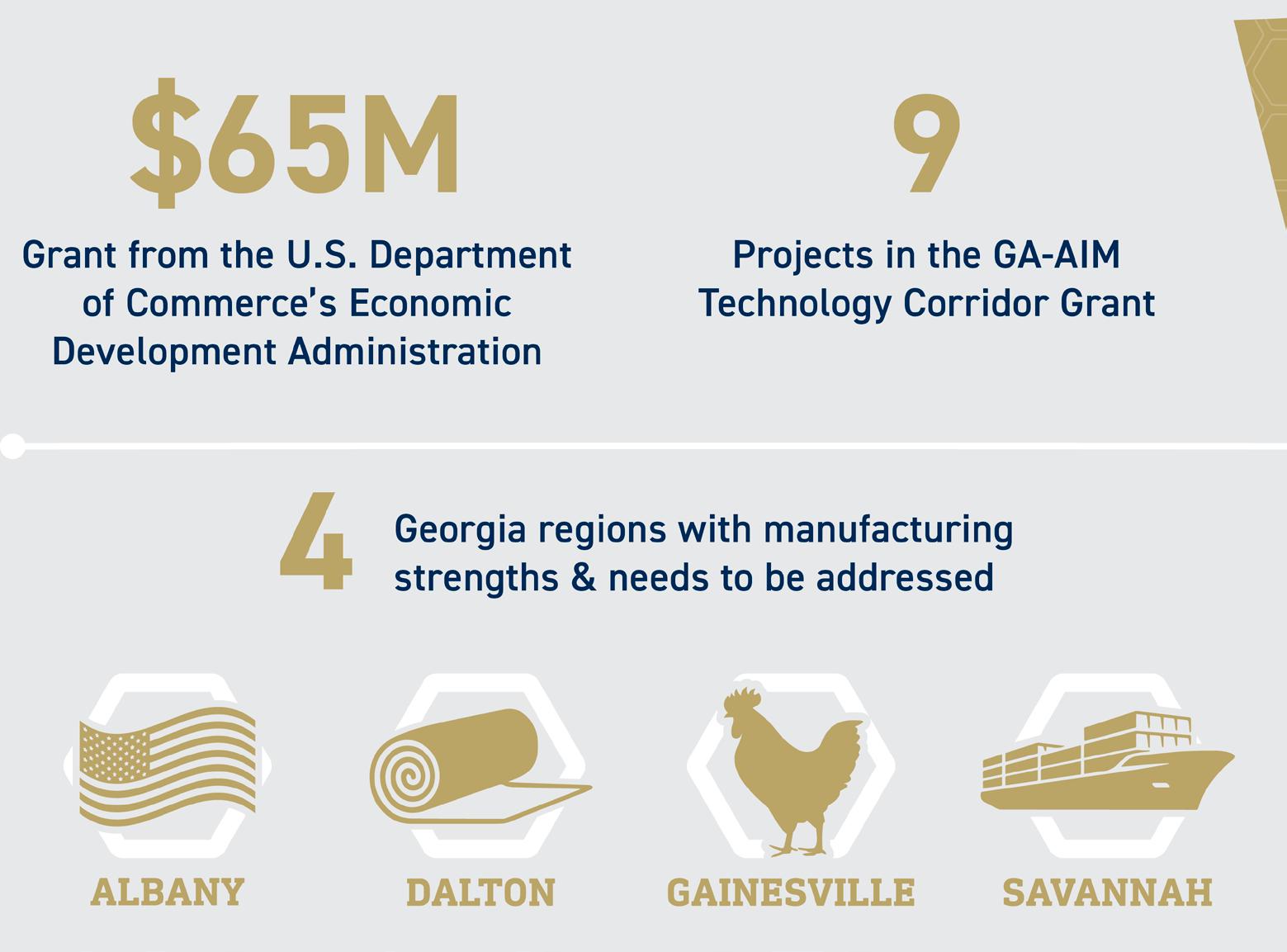

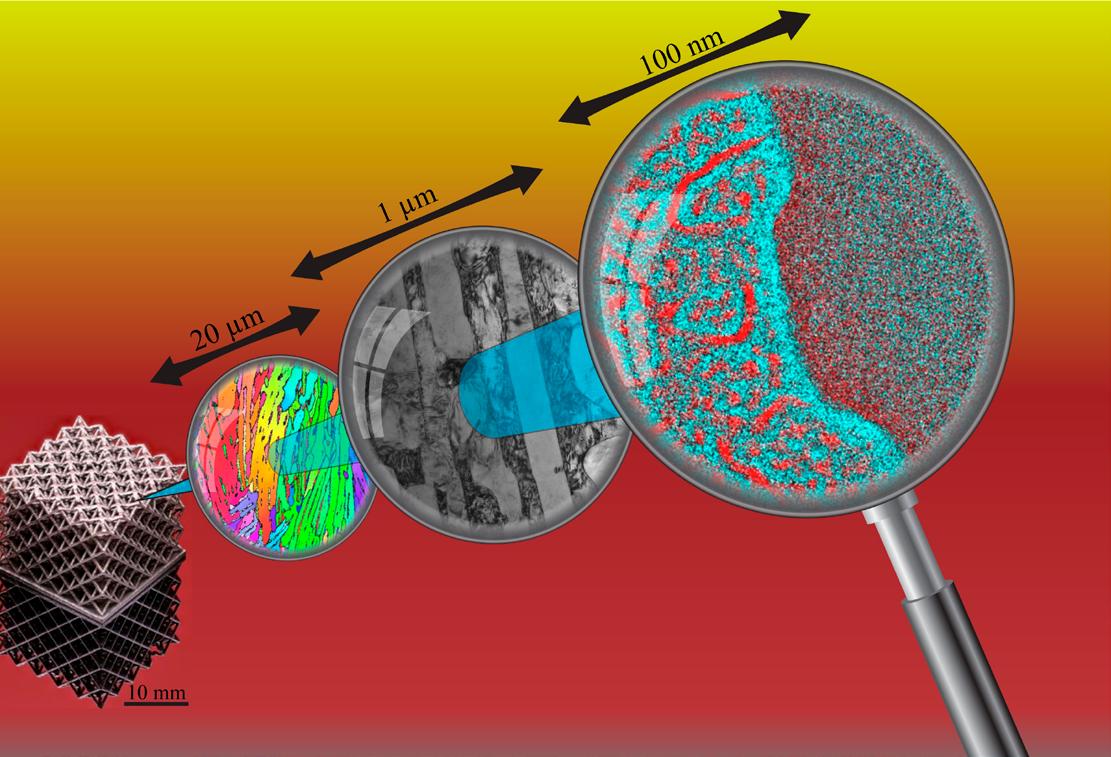

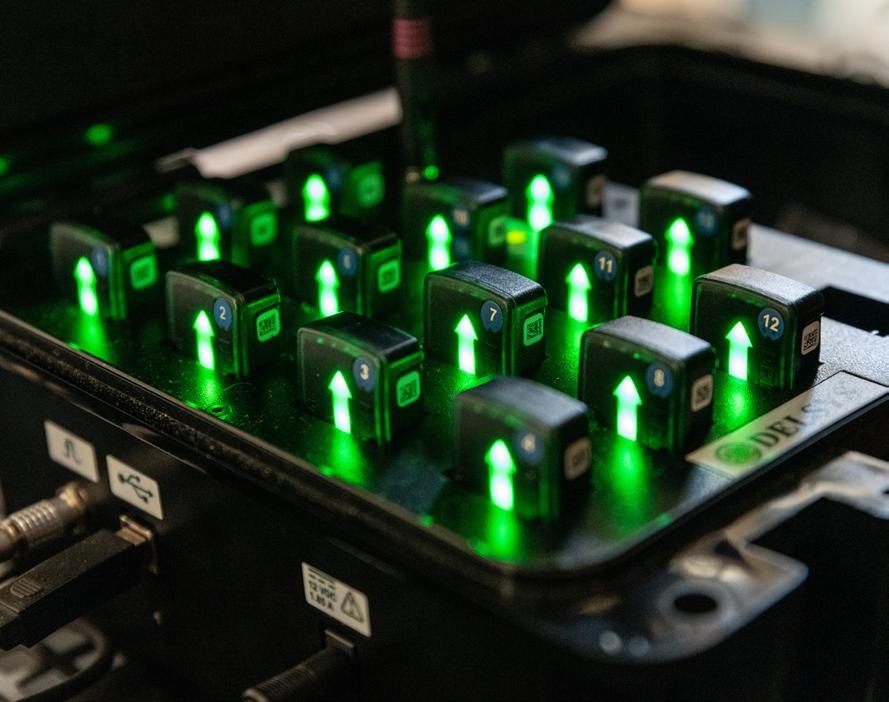

Building Georgia with AI and Manufacturing

Aaron Stebner outlined an aggressive plan for artificial intelligence and manufacturing when he applied for a faculty position in 2019. In his cover letter, he promised “to establish the Georgia Institute of Technology as a world leader in additive manufacturing of solid materials (ceramics & metals) R&D, especially in the fusion of data sciences and AI to create new, world-leading technologies.”

Stebner thought it would take 10-15 years of incremental steps and funding to achieve the goal. He was wrong.

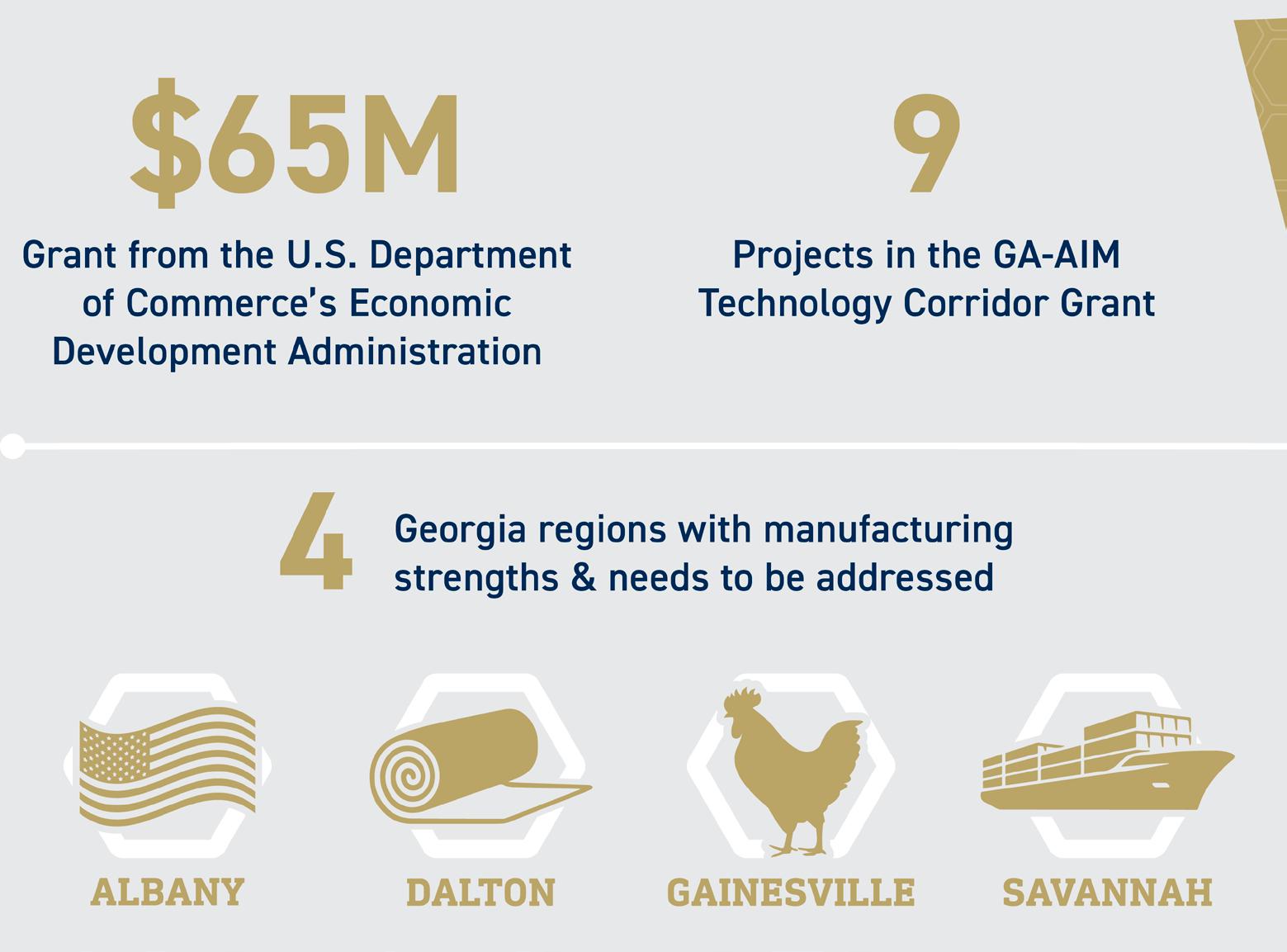

Thanks to a new $65 million grant from the U.S. Department of Commerce’s Economic Development Administration, announced by President Joe Biden, Stebner’s plan will begin to become a reality — and include the entire state of Georgia and all of its manufacturing sectors from agriculture to airplanes — two years after arriving on campus.

The largest of the nine projects within the larger Georgia AI Manufacturing (GA-AIM) technology corridor grant will allow Stebner and Georgia Tech to transform the Advanced Manufacturing Pilot Facility (AMPF) into the Artificial Intelligence Manufacturing Pilot Facility (AI-MPF). The 24,000 square-foot facility on 14th Street will more than double in size after Georgia Tech and statewide GAAIM partners were selected as one of 21 Phase II awardees in the $1 billion Build Back Better Regional Challenge (BBB) competition, part of the Investing in America’s Communities initiative under the American Rescue Plan Act of 2021.

The AMPF is a flagship component of the Georgia Tech Manufacturing Institute (GTMI). The facility is a testbed where basic research results are scaled up and translated into implementable technologies, coupled with education and workforce training. The

fields include additive/hybrid manufacturing, composites, digital manufacturing/Industry 4.0, and industrial robotics.