Mento Hoses and Couplings Catalogue 9. Quick Couplings 9. 5. EDITION Snap Tite H Series 9-1 9-2 Snap Tite 61 - Parker 6600 Series ISO A 9-3 Snap-Tite 72 - Parker 60 Series ISO B 9-4 Snap Tite 78 - Parker 6100 Series 9-5 Snap Tite 75 Series 9-6 Snap Tite 71 Series 9-7 Tema T Series 9-8 Tema HP 1500 Series 9-9 Faster VVS Series 9-10 Parker 3000 Series 9-11 BOP QR 74 Series 9-12 Rectus 23 Series 9-13 Rectus 96 Series Breathing Air 9-14 Rectus 27 Series Safety Cam-Lock 9-15 Cam-Lock type King Crimp 9-17 Claw Couplings 9-18 Air Receiver Manifold Assembly 9-19 Laux Model C 9-20 Nor Couplings 9-21 TW Couplings Storz Couplings Boss Couplings 9-22

Quick Couplings

H, IH & PH Series -- Couplings for Hydraulic, Pneumatic and General Purpose Use

Featuring...Snap-tite quality with built in reliability and flow characteristics over the competition.

H Series

Couplings for Hydraulic, Pneumatic and General Purpose Use

H, IH & PH Series -- Couplings for Hydraulic, Pneumatic and General Purpose Use Advantages of H Series

Advantages of H Series

Sizes — 1/8” – 4”

Advantages of H Series

Sizes — 1/8” – 4”

— 1/8” – 4”

Metals — H Series Quick Disconnect Couplings are available in four metals – steel, brass, aluminum and 316 stainless steel. A variety of protective finishes are available. Please consult factory.

Metals — H Series Quick Disconnect Couplings are available in four metals – steel, brass, aluminum and 316 stainless steel. A variety of protective finishes are available. Please consult factory.

— H Series Quick Disconnect Couplings are available in four metals – steel, brass, aluminum and 316 stainless steel. A variety of protective finishes are available. Please consult factory.

Seal Versatility — Wide choice of standard and special seal materials enable the H, IH & PH series to handle a great variety of fluids.

Seal Versatility — Wide choice of standard and special seal materials enable the H, IH & PH series to handle a great variety of fluids.

Sleeve Lock — Sleeve lock option aids in preventing accidental disconnection of the coupling. To disconnect, align the pin in the body with the slot in the sleeve and retract sleeve.

Sleeve Lock — Sleeve lock option aids in preventing accidental disconnection of the coupling. To disconnect, align the pin in the body with the slot in the sleeve and retract sleeve.

(Valve & Valve) Quick Disconnect

(Valve & Valve) Quick Disconnect

— Wide choice of standard and special seal materials enable the H, IH & PH series to handle a great variety of fluids. SNAP

Low Pressure Drop — The two-piece body construction permits larger flow passages than the designated size of the coupling, permitting greater flow while maintaining low pressure drop and provides end fitting versatility.

Low Pressure Drop — The two-piece body construction permits larger flow passages than the designated size of the coupling, permitting greater flow while maintaining low pressure drop and provides end fitting versatility.

H SERIES NIPPLE NPT FEMALE CARBON STEEL

Smooth Flow — Snap-tite’s “Jet Stream” valve design helps maintain a clean linear flow. Positive positioning of the valve aids in maintaining a steady, even flow under normal working conditions.

Smooth Flow — Snap-tite’s “Jet Stream” valve design helps maintain a clean linear flow. Positive positioning of the valve aids in maintaining a steady, even flow under normal working conditions.

Flow on Connection — Valves are designed to automatically open in both the coupler and nipple halves when the unit is connected permitting maximum free flow.

Flow on Connection — Valves are designed to automatically open in both the coupler and nipple halves when the unit is connected permitting maximum free flow.

Shut-off On Disconnection — Valves are designed to automatically close under normal usage conditions in both the coupler and nipple halves when the unit is disconnected.

Shut-off On Disconnection — Valves are designed to automatically close under normal usage conditions in both the coupler and nipple halves when the unit is disconnected.

Fast Efficient Operation — Connect or disconnect in seconds. To connect, pull back the sleeve, insert the nipple into the coupler and release the sleeve. To disconnect, pull back the sleeve, remove the nipple and the halves are disconnected.

Fast Efficient Operation — Connect or disconnect in seconds. To connect, pull back the sleeve, insert the nipple into the coupler and release the sleeve. To disconnect, pull back the sleeve, remove the nipple and the halves are disconnected.

Dependable Operation — Ball-lock mechanism provides positive connection. Hardened stainless steel balls along with a radiused and induction hardened (steel) ball race gives extended life to the H Series couplings.

Dependable Operation — Ball-lock mechanism provides positive connection. Hardened stainless steel balls along with a radiused and induction hardened (steel) ball race gives extended life to the H Series couplings.

Positive Sealing Connected — Two types of seals are available with H Series quick disconnects.

Molded U-Packer Seal – Standard for all sizes; provides contact over several times the normal O-ring sealing area. The unique U-packer seal design embodies a self-energizing feature that permits a positive seal at all pressures. The design also enables the coupling to seal under adverse conditions such as side load, scratches on the nipple from usage abuse or dirt onthe nipple.

Positive Sealing Connected — Two types of seals are available with H Series quick disconnects.

Molded U-Packer Seal – Standard for all sizes; provides contact over several times the normal O-ring sealing area. The unique U-packer seal design embodies a self-energizing feature that permits a positive seal at all pressures. The design also enables the coupling to seal under adverse conditions such as side load, scratches on the nipple from usage abuse or dirt onthe nipple.

Optional Seal (-9) – Can be supplied as standard in place of the U-Packer seal in steel and stainless steel construction in sizes 1/4” thru 1-1/4”. Designed for use with high pressure, multiple-cycle hydraulic or pneumatic applications, the seal set consists of a standard O-ring and a Teflon back-up ring. This seal configuration prevents the seal from extruding under multiple-cycle high flow and pressure surge applications.

Positive Sealing Disconnected — The metal to metal contact of the valve with the coupler or nipple body is designed to control compression of the valve seal eliminating wear and increasing seal life.

Optional Seal (-9) – Can be supplied as standard in place of the U-Packer seal in steel and stainless steel construction in sizes 1/4” thru 1-1/4”. Designed for use with high pressure, multiple-cycle hydraulic or pneumatic applications, the seal set consists of a standard O-ring and a Teflon back-up ring. This seal configuration prevents the seal from extruding under multiple-cycle high flow and pressure surge applications.

Positive Sealing Disconnected — The metal to metal contact of the valve with the coupler or nipple body is designed to control compression of the valve seal eliminating wear and increasing seal life.

H SERIES NIPPLE BSP FEMALE STAINLESS STEEL

Mento Hoses and Couplings Catalogue 9-1. Quick Couplings 1

Featuring...Snap-tite quality with built in reliability and flow characteristics over the competition.

2

2

TITE H SERIES QUICK CONNECTORS H SERIES COUPLING NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material VHC4-4F 1/4" 1/4" NPT FEM CARBON STEEL VHC6-6F 3/8" 3/8" NPT FEM CARBON STEEL VHC8-8F 1/2" 1/2" NPT FEM CARBON STEEL VHC12-12F 3/4" 3/4" NPT FEM CARBON STEEL VHC16-16F 1" 1" NPT FEM CARBON STEEL VHC20-20F 1 1/4" 1 1/4" NPT FEM CARBON STEEL VHC24-24F 1 1/2" 1 1/2" NPT FEM CARBON STEEL VHC32-32F 2" 2" NPT FEM CARBON STEEL H SERIES COUPLING NPT FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material SVHC4-4F 1/4" 1/4" NPT FEM STAINLESS STEEL SVHC6-6F 3/8" 3/8" NPT FEM STAINLESS STEEL SVHC8-8F 1/2" 1/2" NPT FEM STAINLESS STEEL SVHC12-12F 3/4" 3/4" NPT FEM STAINLESS STEEL SVHC16-16F 1" 1" NPT FEM STAINLESS STEEL SVHC20-20F 1 1/4" 1 1/4" NPT FEM STAINLESS STEEL SVHC24-24F 1 1/2" 1 1/2" NPT FEM STAINLESS STEEL SVHC32-32F 2" 2" NPT FEM STAINLESS STEEL H SERIES COUPLING BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material VHC4-4RP 1/4" 1/4" BSP FEM CARBON STEEL VHC6-6RP 3/8" 3/8" BSP FEM CARBON STEEL VHC8-8RP 1/2" 1/2" BSP FEM CARBON STEEL VHC12-12RP 3/4" 3/4" BSP FEM CARBON STEEL VHC16-16RP 1" 1" BSP FEM CARBON STEEL VHC20-20RP 1 1/4" 1 1/4" BSP FEM CARBON STEEL VHC24-24RP 1 1/2" 1 1/2" BSP FEM CARBON STEEL VHC32-32RP 2" 2" BSP FEM CARBON STEEL

SERIES COUPLING BSP FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material SVHC4-4RP 1/4" 1/4" BSP FEM STAINLESS STEEL SVHC6-6RP 3/8" 3/8" BSP FEM STAINLESS STEEL SVHC8-8RP 1/2" 1/2" BSP FEM STAINLESS STEEL SVHC12-12RP 3/4" 3/4" BSP FEM STAINLESS STEEL SVHC16-16RP 1" 1" BSP FEM STAINLESS STEEL SVHC20-20RP 1 1/4" 1 1/4" BSP FEM STAINLESS STEEL SVHC24-24RP 1 1/2" 1 1/2" BSP FEM STAINLESS STEEL SVHC32-32RP 2" 2" BSP FEM STAINLESS STEEL

H

Part Number Body Size Thread Size Thread Body Material VHN4-4F 1/4" 1/4" NPT FEM CARBON STEEL VHN6-6F 3/8" 3/8" NPT FEM CARBON STEEL VHN8-8F 1/2" 1/2" NPT FEM CARBON STEEL VHN12-12F 3/4" 3/4" NPT FEM CARBON STEEL VHN16-16F 1" 1" NPT FEM CARBON STEEL VHN20-20F 1 1/4" 1 1/4" NPT FEM CARBON STEEL VHN24-24F 1 1/2" 1 1/2" NPT FEM CARBON STEEL VHN32-32F 2" 2" NPT FEM CARBON STEEL H SERIES NIPPLE NPT FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material SVHN4-4F 1/4" 1/4" NPT FEM STAINLESS STEEL SVHN6-6F 3/8" 3/8" NPT FEM STAINLESS STEEL SVHN8-8F 1/2" 1/2" NPT FEM STAINLESS STEEL SVHN12-12F 3/4" 3/4" NPT FEM STAINLESS STEEL SVHN16-16F 1" 1" NPT FEM STAINLESS STEEL SVHN20-20F 1 1/4" 1 1/4" NPT FEM STAINLESS STEEL SVHN24-24F 1 1/2" 1 1/2" NPT FEM STAINLESS STEEL SVHN32-32F 2" 2" NPT FEM STAINLESS STEEL H SERIES NIPPLE BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material VHN4-4RP 1/4" 1/4" BSP FEM CARBON STEEL VHN6-6RP 3/8" 3/8" BSP FEM CARBON STEEL VHN8-8RP 1/2" 1/2" BSP FEM CARBON STEEL VHN12-12RP 3/4" 3/4" BSP FEM CARBON STEEL VHN16-16RP 1" 1" BSP FEM CARBON STEEL VHN20-20RP 1 1/4" 1 1/4" BSP FEM CARBON STEEL VHN24-24RP 1 1/2" 1 1/2" BSP FEM CARBON STEEL VHN32-32RP 2" 2" BSP FEM CARBON STEEL

Part Number Body Size Thread Size Thread Body Material SVHN4-4RP 1/4" 1/4" BSP FEM STAINLESS STEEL SVHN6-6RP 3/8" 3/8" BSP FEM STAINLESS STEEL SVHN8-8RP 1/2" 1/2" BSP FEM STAINLESS STEEL SVHN12-12RP 3/4" 3/4" BSP FEM STAINLESS STEEL SVHN16-16RP 1" 1" BSP FEM STAINLESS STEEL SVHN20-20RP 1 1/4" 1 1/4" BSP FEM STAINLESS STEEL SVHN24-24RP 1 1/2" 1 1/2" BSP FEM STAINLESS STEEL SVHN32-32RP 2" 2" BSP FEM STAINLESS STEEL

H SERIES COUPLING NPT MALE CARBON STEEL

1.341.501.621.912.072.282.572.483.113.353.88

34.0438.1041.1548.5152.5857.9165.2862.9978.9985.0998.55

1.001.191.391.632.002.192.753.504.505.456.75

25.4030.2335.3141.4050.8055.6369.8588.90114.30138.43171.45

1.321.521.721.922.102.222.442.602.953.403.73

33.5338.6143.6948.7753.3456.3961.9866.0474.9386.3694.74

H SERIES NIPPLE NPT MALE STAINLESS STEEL

.881.001.191.501.882.002.503.253.754.755.50

22.3525.4030.2338.1047.7550.8063.5082.5595.25120.65139.70

.63.811.001.191.501.882.132.753.254.005.00

16.0020.5725.4030.2338.1047.7554.1069.8582.55101.60127.00

.58.71.72.88.91.901.061.321.411.561.93

14.7318.0318.2922.3523.1122.8626.9233.5335.8139.6249.02

.78.981.011.141.161.171.342.032.082.592.58

19.8124.8925.6528.9629.4629.7234.0451.5652.8365.7965.53

.56.69.881.061.381.882.132.503.254.005.00

14.2217.5322.3526.9235.0547.7554.1063.5082.55101.60127.00

1 Other special end fittings available upon request.

2 Dimensions taken across the hex flats. Round stock with two milled flats flats same as dimensions across hex flats. Max O.D. of round stock will stock. Valve coupler and nipple bodies may be supplied from round bar

3 3.5" (88.9 mm) across hex flats - may substitute 3.75" (95.25 mm) round

4 Notch on Hex indicates RP British parallel threads.

ACCESSORIES

Dust caps, dust plugs and pressure caps and other contaminants. Dust caps and

Plastic Caps and Plugs

Inexpensive means to protect your investment to fit over pipe fitting or affixing to equipment

Aluminum Dust Caps and Plugs

Alternate method to protect your equipment in sizes 1/4" thru 3". The 1/4" thru 3/4" The 1" and above come with steel zinc

Pressure Caps

Pressure-tight pressure caps for nipples materials such as brass, aluminum and 3". Sizes 1/4" thru 3/4" come with 10" length 12" of cable-all with adjustable loop at end

WORKING PRESSURES*

NOTE: Pressure ratings were established under static pressure conditions. Therefore, pressure ratings for any given flow, pressure surge, and/or vibration may vary from these ratings.

Pressure and Flow Data

Pressure ratings of standard quick disconnects can be increased for some applications by slight design modifications or if specific operating conditions are met. On applications requiring higher ratings than those listed or pressure surges, please consult the factory. Burst pressures listed were taken at the point at which failure rendered the quick disconnect inoperative. (Proof pressure equals 1-1/2 times the working pressure; burst pressure equals 2 times working pressure.)

*For Det Norske Veritas (DNV) compliance, divide the working pressures shown by 2.

Mento Hoses

Catalogue 9-2.

2

and Couplings

Quick Couplings

Part Number Body Size Thread Size Thread Body Material VHC4-4M 1/4" 1/4" NPT MALE CARBON STEEL VHC6-6M 3/8" 3/8" NPT MALE CARBON STEEL VHC8-8M 1/2" 1/2" NPT MALE CARBON STEEL VHC12-12M 3/4" 3/4" NPT MALE CARBON STEEL VHC16-16M 1" 1" NPT MALE CARBON STEEL VHC20-20M 1 1/4" 1 1/4" NPT MALE CARBON STEEL VHC24-24M 1 1/2" 1 1/2" NPT MALE CARBON STEEL VHC32-32M 2" 2" NPT MALE CARBON STEEL H SERIES COUPLING NPT MALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material SVHC4-4M 1/4" 1/4" NPT MALE STAINLESS STEEL SVHC6-6M 3/8" 3/8" NPT MALE STAINLESS STEEL SVHC8-8M 1/2" 1/2" NPT MALE STAINLESS STEEL SVHC12-12M 3/4" 3/4" NPT MALE STAINLESS STEEL SVHC16-16M 1" 1" NPT MALE STAINLESS STEEL SVHC20-20M 1 1/4" 1 1/4" NPT MALE STAINLESS STEEL SVHC24-24M 1 1/2" 1 1/2" NPT MALE STAINLESS STEEL SVHC32-32M 2" 2" NPT MALE STAINLESS STEEL H SERIES NIPPLE NPT MALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material VHN4-4M 1/4" 1/4" NPT MALE CARBON STEEL VHN6-6M 3/8" 3/8" NPT MALE CARBON STEEL VHN8-8M 1/2" 1/2" NPT MALE CARBON STEEL VHN12-12M 3/4" 3/4" NPT MALE CARBON STEEL VHN16-16M 1" 1" NPT MALE CARBON STEEL VHN20-20M 1 1/4" 1 1/4" NPT MALE CARBON STEEL VHN24-24M 1 1/2" 1 1/2" NPT MALE CARBON STEEL VHN32-32M 2" 2" NPT MALE CARBON STEEL

Part Number Body Size Thread Size Thread Body Material SVHN4-4M 1/4" 1/4" NPT MALE STAINLESS STEEL SVHN6-6M 3/8" 3/8" NPT MALE STAINLESS STEEL SVHN8-8M 1/2" 1/2" NPT MALE STAINLESS STEEL SVHN12-12M 3/4" 3/4" NPT MALE STAINLESS STEEL SVHN16-16M 1" 1" NPT MALE STAINLESS STEEL SVHN20-20M 1 1/4" 1 1/4" NPT MALE STAINLESS STEEL SVHN24-24M 1 1/2" 1 1/2" NPT MALE STAINLESS STEEL SVHN32-32M 2" 2" NPT MALE STAINLESS STEEL PLUGS AND CAPS Size Plastic Plug Plastic Cap Alu Plug Alu Cap Pressure Cap 1/4" PDP-4 PDC-4 AMPH-4 ADCH-4 MCH-4 3/8" PDP-6 PDC-6 AMPH-6 ADCH-6 MCH-6 1/2" PDP-8 PDC-8 AMPH-8 ADCH-8 MCH-8 3/4" PDP-12 PDC-12 AMPH-12 ADCH-12 MCH-12 1" PDP-16 PDC-16 AMPH-16 ADCH-16 MCH-16 1 1/4" AMPH-20 ADCH-20 MCH-20 1 1/2" AMPH-24 ADCH-24 MCH-24 2" AMPH-32 ADCH-32 MCH-32 SIZESPLASTIC PLUGPLASTIC CAPALUMINUM 1/4" PDP-4 PDC-4 3/8" PDP-6 PDC-6 1/2" PDP-8 PDC-8 3/4" PDP-12 PDC-12 1" PDP-16 PDC-16 1-1/4" 1-1/2" 2" 2-1/2" 3"

Size1/4"3/8" 1/2"3/4"1"1-1/4"1-1/2"2"2-1/2"3"4"

in mm in mm in mm in mm in mm A B C D2 E2 H in mm

1.271.441.721.862.132.222.442.602.953.403.73 32.2636.5843.6947.2454.1056.3961.9866.0474.9386.3694.74

Metal Pressure Cap MCH Metal Dust Plug AMPH Metal Dust Cap ADCH Plastic Dust Cap PDC Plastic Dust Plug PDP D (Hex)2 H E (Hex)2 E (Hex)2 in mm in mm in mm K L J2

6

Quick Disconnect Size Valve & Valve (Double Shut-off) Valve & Plain (Single Shut-off) Plain & Plain (No Shut-off) Steel Aluminium Brass Stainless Steel Steel Aluminium Brass Stainless Steel PSI Bar PSI Bar PSI Bar PSI Bar PSI Bar PSI Bar PSI Bar PSI Bar 1/4" 6500 448 2250 155 2250 155 5000 345 11000 759 4000 276 4000 276 10000 690 3/8" 4500 310 2250 155 2250 155 4000 276 11000 759 4000 276 4000 276 8000 552 1/2" 4000 276 1750 121 2000 138 3750 259 11000 759 4000 276 4000 276 8000 552 3/4" 3500 241 1750 121 2000 138 2000 138 9000 621 3500 241 3500 241 7000 483 1" 2000 138 1500 103 1750 121 2000 138 6000 414 3000 207 3000 207 4000 276 1-1/4" 1750 121 375 26 350 24 1500 103 5000 345 1000 69 1000 69 3000 207 1-1/2" 1500 103 375 26 350 24 1500 103 5000 345 1000 69 1000 69 3000 207 2" 1500 103 300 21 400 28 500 34 4000 276 750 52 750 52 1000 69 2-1/2" 1000 69 300 21 400 28 400 28 1000 69 300 21 400 28 400 28 3" 750 52 200 14 200 14 400 28 750 52 200 14 200 14 400 28 4" 500 34 150 10 150 10 300 21 500 34 150 10 150 10 300 21

61 Series - Parker 6600 Series - ISO A Interchange

61 Series — ISO A Interchange

H, IH & PH Series -- Couplings for Hydraulic, Pneumatic and General Purpose Use Advantages of H Series

characteristics over the competition

Sizes — 1/8” – 4”

Featuring…Snap-tite quality with superior pressure and flow characteristics over the competition

Interchangeable with other manufacturers offering ISO Series A couplings

Interchangeable with other manufacturers offering ISO Series A couplings

Dimensional & performance requirements conform to ISO 7241-1 Series A

Metals — H Series Quick Disconnect Couplings are available in four metals – steel, brass, aluminum and 316 stainless steel. A variety of protective finishes are available. Please consult factory.

4:1 Safety Factor

Dimensional & performance requirements conform to ISO 7241-1 Series A

4:1 Safety Factor

Proven ball-lock mechanism provides positive connection

Poppet style shut-off

Seal Versatility — Wide choice of standard and special seal materials enable the H, IH & PH series to handle a great variety of fluids.

Proven ball-lock mechanism provides positive connection

High strength steel construction

Zinc Trivalent Chromate plating= for corrosion resistance

Poppet style shut-off

Choice of seal materials to handle a variety of fluids

High strength steel construction

Sizes 1/4" – 1"

Sleeve Lock — Sleeve lock option aids in preventing accidental disconnection of the coupling. To disconnect, align the pin in the body with the slot in the sleeve and retract sleeve.

Zinc Trivalent Chromate plating= for corrosion resistance

Choice of seal materials to handle a variety

Sizes 1/4" – 1"

(Valve & Valve) Quick Disconnect Low Pressure Drop — The two-piece body construction permits larger flow passages than the designated size of the coupling, permitting greater flow while maintaining low pressure drop and provides end fitting versatility.

Smooth Flow — Snap-tite’s “Jet Stream” valve design helps maintain a clean linear flow. Positive positioning of the valve aids in maintaining a steady, even flow under normal working conditions.

Snap-tite's 61 Series is designed to conform to the dimensional and performance requirements of ISO 7241-1 Series A, which details the testing, performance and dimensions of the nipple. This is to enable interchangeability with couplings produced by other manufacturers who meet the same standard. Snap-tite's factors, making the 61 Series the premier ISO Series A interchange.

Flow on Connection — Valves are designed to automatically open in both the coupler and nipple halves when the unit is connected permitting maximum free flow.

Shut-off On Disconnection — Valves are designed to automatically close under normal usage conditions in both the coupler and nipple halves when the unit is disconnected.

Fast Efficient Operation — Connect or disconnect in seconds. To connect, pull back the sleeve, insert the nipple into the coupler and release the sleeve. To disconnect, pull back the sleeve, remove the nipple and the halves are disconnected.

Dependable Operation — Ball-lock mechanism provides positive connection. Hardened stainless steel balls along with a radiused and induction hardened (steel) ball race gives extended life to the H Series couplings.

Positive Sealing Connected — Two types of seals are available with H Series quick disconnects. Molded U-Packer Seal – Standard for all sizes; provides contact over several times the normal O-ring sealing area. The unique U-packer seal design embodies a self-energizing feature that permits a positive seal at all pressures. The design also enables the coupling to seal under adverse conditions such as side load, scratches on the nipple from usage abuse or dirt onthe nipple.

Optional Seal (-9) – Can be supplied as standard in place of the U-Packer seal in steel and stainless steel construction in sizes 1/4” thru 1-1/4”. Designed for use with high pressure, multiple-cycle hydraulic or pneumatic applications, the seal set consists of a standard O-ring and a Teflon back-up ring. This seal configuration prevents the seal from extruding under multiple-cycle high flow and pressure surge applications.

Positive Sealing Disconnected — The metal to metal contact of the valve with the coupler or nipple body is designed to control compression of the valve seal eliminating wear and increasing seal life.

Mento Hoses and Couplings Catalogue 9-3. Quick Couplings 3

Featuring...Snap-tite quality with built in reliability and flow characteristics over the competition.

2

PRESSURE RATINGS Size Maximum Working Minimum Burst Maximum Connect by hand PSI Bar PSI Bar PSI Bar 1/4" 4,600 317 18,400 1269 150 10 3/8" 4,600 317 18,400 1269 150 10 1/2" 4,000 276 16,000 1103 100 7 3/4" 4,000 276 16,000 1130 50 3 1" 3,000 207 12,000 828 40 3 SNAP TITE 61 SERIES QUICK CONNECTORS ISO A SERIES INTERCHANGE 61 SERIES COUPLING NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 6601-4-4 1/4" 1/4" NPT FEM CARBON STEEL 6601-6-6 3/8" 3/8" NPT FEM CARBON STEEL 6601-8-10 1/2" 1/2" NPT FEM CARBON STEEL 6601-12-12 3/4" 3/4" NPT FEM CARBON STEEL 6601-16-16 1" 1" NPT FEM CARBON STEEL 61 SERIES COUPLING BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 6603-4-4 1/4" 1/4" BSP FEM CARBON STEEL 6603-6-6 3/8" 3/8" BSP FEM CARBON STEEL 6603-8-10 1/2" 1/2" BSP FEM CARBON STEEL 6603-12-12 3/4" 3/4" BSP FEM CARBON STEEL 6603-16-16 1" 1" BSP FEM CARBON STEEL 61 SERIES NIPPLE NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 6602-4-4 1/4" 1/4" NPT FEM CARBON STEEL 6602-6-6 3/8" 3/8" NPT FEM CARBON STEEL 6602-8-10 1/2" 1/2" NPT FEM CARBON STEEL 6602-12-12 3/4" 3/4" NPT FEM CARBON STEEL 6602-16-16 1" 1" NPT FEM CARBON STEEL 61 SERIES NIPPLE BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 6605-4-4 1/4" 1/4" BSP FEM CARBON STEEL 6605-6-6 3/8" 3/8" BSP FEM CARBON STEEL 6605-8-10 1/2" 1/2" BSP FEM CARBON STEEL 6605-12-12 3/4" 3/4" BSP FEM CARBON STEEL 6605-16-16 1" 1" BSP FEM CARBON STEEL PLUGS AND CAPS Size Dust Plug Dust Cap 1/4" 6659-4PL 6657-4PL 3/8" 6659-6PL 6657-6PL 1/2" 6659-8PL 6657-8PL 3/4" 6659-12PL 6657-12PL 1" 6659-16PL 6657-16PL

1/4" 4,600 317 18,400 1269 150 10 3/8" 4,600 317 18,400 1269 150 10 1/2" 4,000 276 16,000 1103 100 7 3/4" 4,000 276 16,000 1103 50 3 1" 3,000 207 12,000 828 40 3 MAXIMUM WORKING MINIMUM BURST MAXIMUM CONNECT BY HAND SIZE PSI BAR PSI BAR PSI BAR

PRESSURE RATINGS =Conforms with ROHS and WEEE European Union Directives

72 Series — ISO Series B Interchange

Featuring…Snap-tite quality with superior pressure and flow characteristics over the competition.

72 Series - Parker 60 Series - ISO Series B Interchange

H, IH & PH Series -- Couplings for Hydraulic, Pneumatic and General Purpose Use Advantages of H Series

Sizes 1/8" – 1"

Sizes 1/8" – 1"

Steel, stainless steel (303 & 316) and brass are standard Wide choice of seal materials to handle a variety of fluids

Sizes — 1/8” – 4”

Steel, stainless steel (303 & 316) and brass are standard Wide choice of seal materials to handle a variety of fluids

Proven ball-lock mechanism provides positive connection Poppet style double shut-off Industry interchangeability… couplers (sockets) and nipples (plugs) are interchangeable with other manufacturers

Snap-tite's 72 Series is designed to meet or exceed ISO 7241-1 Series B. This ISO specification stipulates the test specification of the couplings and the dimensions of the nipple so the couplings will interchange with those of other manufacturers meeting this same specification. Snap-tite's 72 Series features superior pressure and flow characteristics over the other manufacturers making the 72 Series the premier ISO Industrial Interchange.

RATINGS

STEEL STAINLESS STEEL BRASS

1/8"5,00034520,0001,3804,00028016,0001,1053,00021012,000830

1/4"7,50052030,0002,0705,50038022,0001,5203,75026015,0001,035

3/8"5,00034520,0001,3803,75026015,0001,0352,75019011,000760

Metals — H Series Quick Disconnect Couplings are available in four metals – steel, brass, aluminum and 316 stainless steel. A variety of protective finishes are available. Please consult factory.

Proven ball-lock mechanism provides positive connection Poppet style double shut-off Industry interchangeability…couplers (sockets) and nipples (plugs) are interchangeable with other manufacturers

Seal Versatility — Wide choice of standard and special seal materials enable the H, IH & PH series to handle a great variety of fluids.

Sleeve Lock — Sleeve lock option aids in preventing accidental disconnection of the coupling. To disconnect, align the pin in the body with the slot in the sleeve and retract sleeve.

(Valve & Valve) Quick Disconnect

Low Pressure Drop — The two-piece body construction permits larger flow passages than the designated size of the coupling, permitting greater flow while maintaining low pressure drop and provides end fitting versatility.

Smooth Flow — Snap-tite’s “Jet Stream” valve design helps maintain a clean linear flow. Positive positioning of the valve aids in maintaining a steady, even flow under normal working conditions.

1/2"5,00034520,0001,3803,75026015,0001,0353,00021012,000830

3/4"4,00028016,0001,1053,00021012,0008302,2001558,800610

1"4,00028016,0001,1053,00021012,0008301,5001056,000415

Flow on Connection — Valves are designed to automatically open in both the coupler and nipple halves when the unit is connected permitting maximum free flow.

Shut-off On Disconnection — Valves are designed to automatically close under normal usage conditions in both the coupler and nipple halves when the unit is disconnected.

Fast Efficient Operation — Connect or disconnect in seconds. To connect, pull back the sleeve, insert the nipple into the coupler and release the sleeve. To disconnect, pull back the sleeve, remove the nipple and the halves are disconnected.

Dependable Operation — Ball-lock mechanism provides positive connection. Hardened stainless steel balls along with a radiused and induction hardened (steel) ball race gives extended life to the H Series couplings.

Positive Sealing Connected — Two types of seals are available with H Series quick disconnects.

Molded U-Packer Seal – Standard for all sizes; provides contact over several times the normal O-ring sealing area. The unique U-packer seal design embodies a self-energizing feature that permits a positive seal at all pressures. The design also enables the coupling to seal under adverse conditions such as side load, scratches on the nipple from usage abuse or dirt onthe nipple.

Optional Seal (-9) – Can be supplied as standard in place of the U-Packer seal in steel and stainless steel construction in sizes 1/4” thru 1-1/4”. Designed for use with high pressure, multiple-cycle hydraulic or pneumatic applications, the seal set consists of a standard O-ring and a Teflon back-up ring. This seal configuration prevents the seal from extruding under multiple-cycle high flow and pressure surge applications.

Positive Sealing Disconnected — The metal to metal contact of the valve with the coupler or nipple body is designed to control compression of the valve seal eliminating wear and increasing seal life.

Mento Hoses and Couplings Catalogue

4

9-4. Quick Couplings

Featuring...Snap-tite quality with built in reliability and flow characteristics over the competition.

2

SNAP TITE 72 SERIES ISO-B QUICK CONNECTORS

SERIES COUPLING NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material H2-62 1/4" 1/4" NPT FEM CARBON STEEL H3-62 3/8" 3/8" NPT FEM CARBON STEEL H4-62 1/2" 1/2" NPT FEM CARBON STEEL H6-62 3/4" 3/4" NPT FEM CARBON STEEL H8-62 1" 1" NPT FEM CARBON STEEL 72 SERIES COUPLING NPT FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material SSH2-62 1/4" 1/4" NPT FEM STAINLESS STEEL SSH3-62 3/8" 3/8" NPT FEM STAINLESS STEEL SSH4-62 1/2" 1/2" NPT FEM STAINLESS STEEL SSH6-62 3/4" 3/4" NPT FEM STAINLESS STEEL SSH8-62 1" 1" NPT FEM STAINLESS STEEL 72 SERIES COUPLING BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material H2-62-BSPP 1/4" 1/4" BSP FEM CARBON STEEL H3-62-BSPP 3/8" 3/8" BSP FEM CARBON STEEL H4-62-BSPP 1/2" 1/2" BSP FEM CARBON STEEL H6-62-BSPP 3/4" 3/4" BSP FEM CARBON STEEL H8-62-BSPP 1" 1" BSP FEM CARBON STEEL 72 SERIES COUPLING BSP FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material SSH2-62Y-BSPP 1/4" 1/4" BSP FEM STAINLESS STEEL SSH3-62Y-BSPP 3/8" 3/8" BSP FEM STAINLESS STEEL SSH4-62Y-BSPP 1/2" 1/2" BSP FEM STAINLESS STEEL SSH6-62Y-BSPP 3/4" 3/4" BSP FEM STAINLESS STEEL SSH8-62Y-BSPP 1" 1" BSP FEM STAINLESS STEEL 72 SERIES NIPPLE NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material H2-63 1/4" 1/4" NPT FEM CARBON STEEL H3-63 3/8" 3/8" NPT FEM CARBON STEEL H4-63 1/2" 1/2" NPT FEM CARBON STEEL H6-63 3/4" 3/4" NPT FEM CARBON STEEL H8-63 1" 1" NPT FEM CARBON STEEL 72 SERIES NIPPLE NPT FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material SSH2-63 1/4" 1/4" NPT FEM STAINLESS STEEL SSH3-63 3/8" 3/8" NPT FEM STAINLESS STEEL SSH4-63 1/2" 1/2" NPT FEM STAINLESS STEEL SSH6-63 3/4" 3/4" NPT FEM STAINLESS STEEL SSH8-63 1" 1" NPT FEM STAINLESS STEEL 72 SERIES NIPPLE BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material H2-63-BSPP 1/4" 1/4" BSP FEM CARBON STEEL H3-63-BSPP 3/8" 3/8" BSP FEM CARBON STEEL H4-63-BSPP 1/2" 1/2" BSP FEM CARBON STEEL H6-63-BSPP 3/4" 3/4" BSP FEM CARBON STEEL H8-63-BSPP 1" 1" BSP FEM CARBON STEEL 72 SERIES NIPPLE BSP FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material SSH2-63Y-BSPP 1/4" 1/4" BSP FEM STAINLESS STEEL SSH3-63Y-BSPP 3/8" 3/8" BSP FEM STAINLESS STEEL SSH4-63Y-BSPP 1/2" 1/2" BSP FEM STAINLESS STEEL SSH6-63Y-BSPP 3/4" 3/4" BSP FEM STAINLESS STEEL SSH8-63Y-BSPP 1" 1" BSP FEM STAINLESS STEEL PLUGS AND CAPS Size Dust Plug Dust Cap 1/8" ON REQUEST ON REQUEST 1/4" ON REQUEST ON REQUEST 3/8" ON REQUEST ON REQUEST 1/2" ON REQUEST ON REQUEST 3/4" ON REQUEST ON REQUEST 1" ON REQUEST ON REQUEST INTERCHANGEABLE WITH: PARKER SERIES 60 / HANSEN HK / ETC

72

SIZE

PSIBARPSIBARPSIBARPSIBARPSIBARPSIBAR

PRESSURE

Double shut-off (Valved and Valved) MAXIMUMMINIMUMMAXIMUMMINIMUMMAXIMUMMINIMUM WORKINGBURST WORKING BURST WORKING BURST PRESSURE RATINGS Double shut-off (Valved and Valved) Size Steel Stainless Steel Brass Maximum Working Minimum Burst Maximum Working Minimum Burst Maximum Working Minimum Burst PSI Bar PSI Bar PSI Bar PSI Bar PSI Bar PSI Bar 1/8" 5,000 345 20,000 1,380 4,000 280 16,000 1,105 3,000 210 12,000 83 1/4" 7,500 520 30,000 2,070 5,500 380 22,000 1,520 3,750 260 15,000 1,035 3/8" 5,000 345 20,000 1,380 3,750 260 15,000 1,035 2,750 190 11,000 760 1/2" 5,000 345 20,000 1,380 3,750 260 15,000 1,035 3,000 210 12,000 830 3/4" 4,000 280 16,000 1,105 3,000 210 12,000 830 2,200 155 8,800 610 1" 4,000 280 16,000 1,105 3,000 210 12,000 830 1,500 105 6,000 415

Fe aturing…Snap-tite quality with superior pressure and flow characteristics over the competition

78 Series - Parker 6100 Series

- Thread-to-Connect Couplings

H, IH & PH Series -- Couplings for Hydraulic, Pneumatic and General Purpose Use Advantages of H Series

— 1/8” – 4”

Interchangeable with Aeroquip 5100 Series and Parker 6100 Series

Heavy duty wing nut or hex nut for easy connection of threaded units

H Series Quick Disconnect Couplings are available in four metals – steel, brass, aluminum and 316 stainless steel. A variety of protective finishes are available. Please consult factory.

3,000 psig (207 bar) operating pressure

Seal Versatility — Wide choice of standard and special seal materials enable the H, IH & PH series to handle a great variety of fluids.

4,500 psig (310 bar) proof pressure

Sizes 3/4", 3/4" x 1/2", 1", 1-1/4" and 1-1/2"

Sleeve Lock — Sleeve lock option aids in preventing accidental disconnection of the coupling. To disconnect, align the pin in the body with the slot in the sleeve and retract sleeve.

(Valve & Valve) Quick Disconnect Low Pressure Drop — The two-piece body construction permits larger flow passages than the designated size of the coupling, permitting greater flow while maintaining low pressure drop and provides end fitting versatility.

Smooth Flow — Snap-tite’s “Jet Stream” valve design helps maintain a clean linear flow. Positive positioning of the valve aids in maintaining a steady, even flow under normal working conditions.

Flow on Connection — Valves are designed to automatically open in both the coupler and nipple halves when the unit is connected permitting maximum free flow.

Shut-off On Disconnection — Valves are designed to automatically close under normal usage conditions in both the coupler and nipple halves when the unit is disconnected.

Fast Efficient Operation — Connect or disconnect in seconds. To connect, pull back the sleeve, insert the nipple into the coupler and release the sleeve. To disconnect, pull back the sleeve, remove the nipple and the halves are disconnected.

Dependable Operation — Ball-lock mechanism provides positive connection. Hardened stainless steel balls along with a radiused and induction hardened (steel) ball race gives extended life to the H Series couplings.

Positive Sealing Connected — Two types of seals are available with H Series quick disconnects. Molded U-Packer Seal – Standard for all sizes; provides contact over several times the normal O-ring sealing area. The unique U-packer seal design embodies a self-energizing feature that permits a positive seal at all pressures. The design also enables the coupling to seal under adverse conditions such as side load, scratches on the nipple from usage abuse or dirt onthe nipple.

Snap-tite heavy duty 78 Series Thread-to-Connect Couplings are designed for most industrial fluid applications plus they are ideal for coal trucks, oil well equipment, hydraulic dump trucks, sand and salt spreaders requiring a rugged coupling. The 78 series dry break features minimal spillage and air inclusion. The couplings connect under pressure. For bulkhead mounting, a steel flange is available. The 78 Series offers up to 3,000 psig (207 bar) operating pressure in both the connected and disconnected positions.

Optional Seal (-9) – Can be supplied as standard in place of the U-Packer seal in steel and stainless steel construction in sizes 1/4” thru 1-1/4”. Designed for use with high pressure, multiple-cycle hydraulic or pneumatic applications, the seal set consists of a standard O-ring and a Teflon back-up ring. This seal configuration prevents the seal from extruding under multiple-cycle high flow and pressure surge applications.

Positive Sealing Disconnected — The metal to metal contact of the valve with the coupler or nipple body is designed to control compression of the valve seal eliminating wear and increasing seal life.

PRESSURE RATINGS

SIZEPSIBAR

*Pressure ratings for connected or disconnected modes. For excessive flow and surge conditions, consult factory before specifying.

Mento Hoses and Couplings Catalogue 9-5. Quick Couplings 5

Featuring...Snap-tite quality with built in reliability and flow characteristics over the competition.

2

78 Series — Thread-to-Connect Couplings

3/4"3000207 .30 .15 1"3000207 .40 .40 1-1/4"2750190 .65 .65 1-1/2"2500172 .80 .85

OPERATING PRESSURE* AIR INCLUSION SPILLAGE BRASS cc MAXIMUM cc MAXIMUM

SNAP TITE 78 SERIES QUICK CONNECTORS 78 SERIES COUPLING NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 6125-12 3/4" 3/4" NPT FEM BRASS 6125-16 1" 1" NPT FEM BRASS 6125-20 1 1/4" 1 1/4" NPT FEM BRASS 6125-20 1 1/2" 1 1/2" NPT FEM BRASS 78 SERIES COUPLING BSP FEMALE BRASS Part Number Body Size Thread Size Thread Body Material 6125-12-BSPP 3/4" 3/4" BSP FEM BRASS 6125-16-BSPP 1" 1" BSP FEM BRASS 6125-20-BSPP 1 1/4" 1 1/4" BSP FEM BRASS 6125-24-BSPP 1 1/2" 1 1/2" BSP FEM BRASS 78 SERIES NIPPLE NPT FEMALE BRASS Part Number Body Size Thread Size Thread Body Material 6105-12 3/4" 3/4" NPT FEM BRASS 6105-16 1" 1" NPT FEM BRASS 6105-20 1 1/4" 1 1/4" NPT FEM BRASS 6105-24 1 1/2" 1 1/2" NPT FEM BRASS 78

FEMALE BRASS Part Number Body Size Thread Size Thread Body Material 6105-12-BSPP 1/4" 1/4" BSP FEM BRASS 6105-16-BSPP 3/8" 3/8" BSP FEM BRASS 6105-20-BSPP 1/2" 1/2" BSP FEM BRASS 6105-24-BSPP 3/4" 3/4" BSP FEM BRASS ALSO AVAILABLE WITHOUT WINGNUT (WITH HEX NUT) ON REQUEST Interchangeable with Aeroquip 5100 Series and Parker 6100 Series PLUGS AND CAPS* Size Protective Cap Protective Plug Mounting Flange 3/4" 6109-08 6108-08 6107-08 1" 6109-16 6108-16 6107-16 1 1/4" 6109-20 6108-20 6107-20 1 1/2" 6109-24 6108-24 6107-24 *All accessories are manufactured from carbon steel.

RATINGS Size PSI Bar 3/4" 3000 207 1" 3000 207 1-1/4" 2750 190 1-1/2" 2500 172 *Pressure ratings for connected or disconnected modes.

Parker 6100 Series of threaded units

SERIE8 NIPPLE BSP

PRESSURE

75 Series -- Thread-to-Connect Couplings

Featuring...Snap-tite quality with superior pressure and flow characteristics over the competition.

H, IH & PH Series -- Couplings for Hydraulic, Pneumatic and General Purpose Use

75 Series - Thread-to-Connect Couplings

Connect under Pressure — Designed for up to 5,000 psi (345 bar) operating pressures.

Connect under Pressure — Designed for up to 5,000 psi (345 bar) operating pressures. Thread-to-Connect — To connect, merely thread the nipple into the coupler.

Thread-to-Connect — To connect, merely thread the nipple into the coupler. To disconnect just unthread.

To disconnect just unthread.

Rugged — Steel construction, with zinc yellow dichromate plating to resist corrosion.

Advantages of H Series

Stainless steel construction also available.

Rugged — Steel construction, with zinc yellow dichromate plating to resist corrosion. Stainless steel construction also available.

Sizes — 1/8” – 4”

Seals — Choice of seal materials to handle a variety of fluids including applications involving the use of fire-resistant hydraulic fluids.

Seals — Choice of seal materials to handle a variety of fluids including applications involving the use of fire-resistant hydraulic fluids.

Available sizes — 3/4˝, 1˝, 1-1/4˝, 1-1/2˝, 2˝, 2-1/2˝, 3˝, and 4˝.

Available sizes — 3/4˝, 1˝, 1-1/4˝, 1-1/2˝, 2˝, 2-1/2˝, 3˝, and 4˝.

Superior flow and low pressure drop

Superior flow and low pressure drop

Metals — H Series Quick Disconnect Couplings are available in four metals – steel, brass, aluminum and 316 stainless steel. A variety of protective finishes are available. Please consult factory.

Valves close before disconnection — Valves are designed to shut off automatically under normal conditions in both the coupler and nipple halves when the unit is being disconnected.

Valves close before disconnection — Valves are designed to shut off automatically under normal conditions in both the coupler and nipple halves when the unit is being disconnected.

Seal Versatility — Wide choice of standard and special seal materials enable the H, IH & PH series to handle a great variety of fluids.

Det Norske Veritas Certified

The very rugged 75 Series is designed and constructed for high pressure hydraulic service. Although these couplings are used in a broad variety of heavy duty applications, a primary usage is in oil fields and offshore drilling ... cranes, power tongs and swivels, diving, etc.

Sleeve Lock — Sleeve lock option aids in preventing accidental disconnection of the coupling. To disconnect, align the pin in the body with the slot in the sleeve and retract sleeve.

(Valve & Valve) Quick Disconnect

Low Pressure Drop — The two-piece body construction permits larger flow passages than the designated size of the coupling, permitting greater flow while maintaining low pressure drop and provides end fitting versatility.

Smooth Flow — Snap-tite’s “Jet Stream” valve design helps maintain a clean linear flow. Positive positioning of the valve aids in maintaining a steady, even flow under normal working conditions.

Flow on Connection — Valves are designed to automatically open in both the coupler and nipple halves when the unit is connected permitting maximum free flow.

Shut-off On Disconnection — Valves are designed to automatically close under normal usage conditions in both the coupler and nipple halves when the unit is disconnected.

Fast Efficient Operation — Connect or disconnect in seconds. To connect, pull back the sleeve, insert the nipple into the coupler and release the sleeve. To disconnect, pull back the sleeve, remove the nipple and the halves are disconnected.

Dependable Operation — Ball-lock mechanism provides positive connection. Hardened stainless steel balls along with a radiused and induction hardened (steel) ball race gives extended life to the H Series couplings.

Positive Sealing Connected — Two types of seals are available with H Series quick disconnects.

Molded U-Packer Seal – Standard for all sizes; provides contact over several times the normal O-ring sealing area. The unique U-packer seal design embodies a self-energizing feature that permits a positive seal at all pressures. The design also enables the coupling to seal under adverse conditions such as side load, scratches on the nipple from usage abuse or dirt onthe nipple.

Optional Seal (-9) – Can be supplied as standard in place of the U-Packer seal in steel and stainless steel construction in sizes 1/4” thru 1-1/4”. Designed for use with high pressure, multiple-cycle hydraulic or pneumatic applications, the seal set consists of a standard O-ring and a Teflon back-up ring. This seal configuration prevents the seal from extruding under multiple-cycle high flow and pressure surge applications.

Positive Sealing Disconnected — The metal to metal contact of the valve with the coupler or nipple body is designed to control compression of the valve seal eliminating wear and increasing seal life.

Burst pressures listed were taken at the point at which failure rendered the quick-disconnect inoperative. (Proof pressure equals 1-1/2 times the operating pressure.) NOTE: Pressure Ratings were established under static pressure conditions. For impulse applications, multiply the above pressure ratings by .6 for approximate pressure ratings. *NOTE: For working pressure of 316 SST units, multiply the above pressure ratings by .33 for approximate pressure ratings.

Mento Hoses and Couplings Catalogue

6

9-6. Quick Couplings

Featuring...Snap-tite quality with built in reliability and flow characteristics over the competition.

2

SNAP TITE 75 SERIES QUICK CONNECTORS 75 SERIES COUPLING NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 75C12-12F 3/4" 3/4" NPT FEM CARBON STEEL 75C16-16F 1" 1" NPT FEM CARBON STEEL 75C20-20F 1 1/4" 1 1/4" NPT FEM CARBON STEEL 75C24-24F 1 1/2" 1 1/2" NPT FEM CARBON STEEL 75C32-32F 2" 2" NPT FEM CARBON STEEL 75C40-40F 2 1/2" 2 1/2" NPT FEM CARBON STEEL 75C48-48F 3" 3" NPT FEM CARBON STEEL 75C64-64F 4" 4" NPT FEM CARBON STEEL 75 SERIES COUPLING NPT FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material S75C12-12F 3/4" 3/4" NPT FEM STAINLESS STEEL S75C16-16F 1" 1" NPT FEM STAINLESS STEEL S75C20-20F 1 1/4" 1 1/4" NPT FEM STAINLESS STEEL S75C24-24F 1 1/2" 1 1/2" NPT FEM STAINLESS STEEL S75C32-32F 2" 2" NPT FEM STAINLESS STEEL S75C40-40F 2 1/2" 2 1/2" NPT FEM STAINLESS STEEL S75C48-48F 3" 3" NPT FEM STAINLESS STEEL S75C64-64F 4" 4" NPT FEM STAINLESS STEEL 75 SERIES COUPLING BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 75C12-12RP 3/4" 3/4" BSP FEM CARBON STEEL 75C16-16RP 1" 1" BSP FEM CARBON STEEL 75C20-20RP 1 1/4" 1 1/4" BSP FEM CARBON STEEL 75C24-24RP 1 1/2" 1 1/2" BSP FEM CARBON STEEL 75C32-32RP 2" 2" BSP FEM CARBON STEEL 75C40-40RP 2 1/2" 2 1/2" BSP FEM CARBON STEEL 75C48-48RP 3" 3" BSP FEM CARBON STEEL 75C64-64RP 4" 4" BSP FEM CARBON STEEL 75 SERIES COUPLING BSP FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material S75C12-12RP 3/4" 3/4" BSP FEM STAINLESS STEEL S75C16-16RP 1" 1" BSP FEM STAINLESS STEEL S75C20-20RP 1 1/4" 1 1/4" BSP FEM STAINLESS STEEL S75C24-24RP 1 1/2" 1 1/2" BSP FEM STAINLESS STEEL S75C32-32RP 2" 2" BSP FEM STAINLESS STEEL S75C40-40RP 2 1/2" 2 1/2" BSP FEM STAINLESS STEEL S75C48-48RP 3" 3" BSP FEM STAINLESS STEEL S75C64-64RP 4" 4" BSP FEM STAINLESS STEEL 75 SERIES NIPPLE NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 75N12-12F 3/4" 3/4" NPT FEM CARBON STEEL 75N16-16F 1" 1" NPT FEM CARBON STEEL 75N20-20F 1 1/4" 1 1/4" NPT FEM CARBON STEEL 75N24-24F 1 1/2" 1 1/2" NPT FEM CARBON STEEL 75N32-32F 2" 2" NPT FEM CARBON STEEL 75N40-40F 2 1/2" 2 1/2" NPT FEM CARBON STEEL 75N48-48F 3" 3" NPT FEM CARBON STEEL 75N64-64F 4" 4" NPT FEM CARBON STEEL 75 SERIES NIPPLE NPT FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material S75N12-12F 3/4" 3/4" NPT FEM STAINLESS STEEL S75N16-16F 1" 1" NPT FEM STAINLESS STEEL S75N20-20F 1 1/4" 1 1/4" NPT FEM STAINLESS STEEL S75N24-24F 1 1/2" 1 1/2" NPT FEM STAINLESS STEEL S75N32-32F 2" 2" NPT FEM STAINLESS STEEL S75N40-40F 2 1/2" 2 1/2" NPT FEM STAINLESS STEEL S75N48-48F 3" 3" NPT FEM STAINLESS STEEL S75N64-64F 4" 4" NPT FEM STAINLESS STEEL 75 SERIES NIPPLE BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 75N12-12RP 3/4" 3/4" BSP FEM CARBON STEEL 75N16-16RP 1" 1" BSP FEM CARBON STEEL 75N20-20RP 1 1/4" 1 1/4" BSP FEM CARBON STEEL 75N24-24RP 1 1/2" 1 1/2" BSP FEM CARBON STEEL 75N32-32RP 2" 2" BSP FEM CARBON STEEL 75N40-40RP 2 1/2" 2 1/2" BSP FEM CARBON STEEL 75N48-48RP 3" 3" BSP FEM CARBON STEEL 75N64-64RP 4" 4" BSP FEM CARBON STEEL 75 SERIES NIPPLE BSP FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material S75N12-12RP 3/4" 3/4" BSP FEM STAINLESS STEEL S75N16-16RP 1" 1" BSP FEM STAINLESS STEEL S75N20-20RP 1 1/4" 1 1/4" BSP FEM STAINLESS STEEL S75N24-24RP 1 1/2" 1 1/2" BSP FEM STAINLESS STEEL S75N32-32RP 2" 2" BSP FEM STAINLESS STEEL S75N40-40RP 2 1/2" 2 1/2" BSP FEM STAINLESS STEEL S75N48-48RP 3" 3" BSP FEM STAINLESS STEEL S75N64-64RP 4" 4" BSP FEM STAINLESS STEEL

PRESSURE RATINGS PRESSURE RATINGS AIR SIZESPILLAGE (cc)INCLUSION (cc) MAXIMUM WORKING*MINIMUM BURST PSI BAR PSIBAR 3/4˝ 8125,00034520,0001379 1˝ 16 255,00034520,0001379 1-1/4˝ 31 485,00034515,0001035 1-1/2˝ 64 985,00034515,0001035 2˝ 1412055,00034515,0001035 2-1/2˝ 2043683,0002076,000414 3˝ 3204803,0002076,000414 4˝ 400610400281,00069 Burst pressures listed were taken at the point at which failure rendered the quick-disconnect inoperative. (Proof pressure equals 1-1/2 times the operating pressure.) NOTE: Pressure Ratings were established under static pressure conditions. For impulse applications, multiply the above pressure ratings by .6 for approximate pressure ratings. *NOTE: For working pressure of 316 SST units, multiply the above pressure ratings by .33 for approximate pressure ratings. PRESSURE RATINGS Size Spillage (cc) Air Inclusion (cc) Maximum Working* Minimum Burst PSI Bar PSI Bar 3/4" 8 12 5,000 345 20,000 1379 1˝ 16 25 5,000 345 20,000 1379 1-1/4" 31 48 5,000 345 15,000 1035 1-1/2˝ 64 98 5,000 345 15,000 1035 2" 141 205 5,000 345 15,000 1035 2-1/2˝ 204 368 3,000 207 6,000 414 3" 320 480 3,000 207 6,000 414 4" 400 610 400 28 1,000 69

PLUGS

Size Dust Plug Dust Cap 3/4" 75MDP-12 75MDC-12 1" 75MDP-16 75MDC-16 1 1/4" 75MDP-20 75MDC-20 1 1/2" 75MDP-24 75MDC-24 2" 75MDP-32 75MDC-32 2 1/2" 75MDP-40 75MDC-40 3" 75MDP-48 75MDC-48 4" 75MDP-64 75MDC-64

SPARE PARTS KITS Size Coupling Nipple 3/4" 75C12-SPK 75N12-SPK 1" 75C16-SPK 75N16-SPK 1 1/4" 75C20-SPK 75N20-SPK 1 1/2" 75C24-SPK 75N24-SPK 2" 75C32-SPK 75N32-SPK 2 1/2" 75C40-SPK 75N40-SPK 3" 75C48-SPK 75N48-SPK 4" 75C64-SPK 75N64-SPK EACH KIT CONTAINS A VALVE ASSEMBLY, SPRING

STOP

DUST

AND CAPS*

*MATERIAL: CARBON STEEL

AND GUIDE

71 Series -- Flush Face/Dry Break Couplings

Featuring...Snap-tite quality with superior pressure and flow characteristics over the competition.

SNAP

71 Series - Flush Face/Dry Break Couplings

Flush Face/Dry Break Air inclusion and fluid loss are held to a minimum to prevent spillage and contamination of systems.

H, IH & PH Series -- Couplings for Hydraulic, Pneumatic and General Purpose Use Advantages of H Series

(690 bar) operating pressures.

Push-to-Connect Ideal one-hand operation when one half is mounted. Simply insert the nipple into the coupler and push-to-connect. To disconnect, retract the sleeve; and the coupling halves disconnect.

are held to a minimum to prevent spillage and contamination of systems.

Sizes — 1/8” – 4”

Rugged Heavy duty construction is ideally suited for high impulse applications.

Pressure Capability — Designed for up to 10,000 psi (690 bar) operating pressures.

one half is mounted. Simply insert the nipple into the coupler and push-to-connect. To disconnect, retract the sleeve; and the coupling halves disconnect.

dichromate plating, 316 Stainless steel, as well as other materials. Special seals for troublesome media are available; consult factory for details.

1-1/2˝, and 2˝.

for high impulse applications.

Versatile Available in steel with zinc yellow dichromate plating, 316 Stainless steel, as well as other materials. Special seals for troublesome media are available; consult factory for details.

and

The 71 Series couplings are designed for today’s applications including special features for modern needs - dry break, push-to-connect, high pressure, rugged & versatile. Extra large flow chambers and Snap-tite’s exclusive valve design permit exceptional flow while maintaining low pressure drop. STEEL316STAINLESSSTEELH

Superior flow and low pressure drop Det Norske Veritas Certified for North Sea applications.

Sleeve lock Designed to provide protection against accidental disconnection. Available with Autoclave cone and threaded fittings Consult factory

Metals — H Series Quick Disconnect Couplings are available in four metals – steel, brass, aluminum and 316 stainless steel. A variety of protective finishes are available. Please consult factory.

Seal Versatility — Wide choice of standard and special seal materials enable the H, IH & PH series to handle a great variety of fluids.

against accidental disconnection.

Sleeve Lock — Sleeve lock option aids in preventing accidental disconnection of the coupling. To disconnect, align the pin in the body with the slot in the sleeve and retract sleeve.

(Valve & Valve) Quick Disconnect Low Pressure Drop — The two-piece body construction permits larger flow passages than the designated size of the coupling, permitting greater flow while maintaining low pressure drop and provides end fitting versatility.

Smooth Flow — Snap-tite’s “Jet Stream” valve design helps maintain a clean linear flow. Positive positioning of the valve aids in maintaining a steady, even flow under normal working conditions.

Flow on Connection — Valves are designed to automatically open in both the coupler and nipple halves when the unit is connected permitting maximum free flow.

Shut-off On Disconnection — Valves are designed to automatically close under normal usage conditions in both the coupler and nipple halves when the unit is disconnected.

Fast Efficient Operation — Connect or disconnect in seconds. To connect, pull back the sleeve, insert the nipple into the coupler and release the sleeve. To disconnect, pull back the sleeve, remove the nipple and the halves are disconnected.

Dependable Operation — Ball-lock mechanism provides positive connection. Hardened stainless steel balls along with a radiused and induction hardened (steel) ball race gives extended life to the H Series couplings.

Positive Sealing Connected — Two types of seals are available with H Series quick disconnects. Molded U-Packer Seal – Standard for all sizes; provides contact over several times the normal O-ring sealing area. The unique U-packer seal design embodies a self-energizing feature that permits a positive seal at all pressures. The design also enables the coupling to seal under adverse conditions such as side load, scratches on the nipple from usage abuse or dirt onthe nipple.

Optional Seal (-9) – Can be supplied as standard in place of the U-Packer seal in steel and stainless steel construction in sizes 1/4” thru 1-1/4”. Designed for use with high pressure, multiple-cycle hydraulic or pneumatic applications, the seal set consists of a standard O-ring and a Teflon back-up ring. This seal configuration prevents the seal from extruding under multiple-cycle high flow and pressure surge applications.

Positive Sealing Disconnected — The metal to metal contact of the valve with the coupler or nipple body is designed to control compression of the valve seal eliminating wear and increasing seal life.

*NOTE: Pressure Ratings were established under static pressure conditions. For high impulse applications, multiply the above pressure ratings by .6 for approximate pressure ratings.

Mento Hoses and Couplings Catalogue 9-7. Quick Couplings 7

Featuring...Snap-tite quality with built in reliability and flow characteristics over the competition.

2

TITE 71 SERIES QUICK CONNECTORS 71 SERIES COUPLING NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 71-3C4-4F 1/4" 1/4" NPT FEM CARBON STEEL 71-3C6-6F 3/8" 3/8" NPT FEM CARBON STEEL 71-3C8-8F 1/2" 1/2" NPT FEM CARBON STEEL 71-3C12-12F 3/4" 3/4" NPT FEM CARBON STEEL 71-3C16-16F 1" 1" NPT FEM CARBON STEEL 71-3C16-20F 1" 1 1/4" NPT FEM CARBON STEEL 71-3C32-24F 2" 1 1/2" NPT FEM CARBON STEEL 71-3C32-32F 2" 2" NPT FEM CARBON STEEL 71 SERIES COUPLING NPT FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material S71-3C4-4F 1/4" 1/4" NPT FEM STAINLESS STEEL S71-3C6-6F 3/8" 3/8" NPT FEM STAINLESS STEEL S71-3C8-8F 1/2" 1/2" NPT FEM STAINLESS STEEL S71-3C12-12F 3/4" 3/4" NPT FEM STAINLESS STEEL S71-3C16-16F 1" 1" NPT FEM STAINLESS STEEL S71-3C16-20F 1" 1 1/4" NPT FEM STAINLESS STEEL S71-3C32-24F 2" 1 1/2" NPT FEM STAINLESS STEEL S71-3C32-32F 2" 2" NPT FEM STAINLESS STEEL 71 SERIES COUPLING BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 71-3C6-4RP 1/4" 1/4" BSP FEM CARBON STEEL 71-3C6-6RP 3/8" 3/8" BSP FEM CARBON STEEL 71-3C8-8RP 1/2" 1/2" BSP FEM CARBON STEEL 71-3C12-12RP 3/4" 3/4" BSP FEM CARBON STEEL 71-3C16-16RP 1" 1" BSP FEM CARBON STEEL 71-3C16-20RP 1" 1 1/4" BSP FEM CARBON STEEL 71-3C32-24RP 2" 1 1/2" BSP FEM CARBON STEEL 71-3C32-32RP 2" 2" BSP FEM CARBON STEEL 71 SERIES COUPLING BSP FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material S71-3C4-4RP 1/4" 1/4" BSP FEM STAINLESS STEEL S71-3C6-6RP 3/8" 3/8" BSP FEM STAINLESS STEEL S71-3C8-8RP 1/2" 1/2" BSP FEM STAINLESS STEEL S71-3C12-12RP 3/4" 3/4" BSP FEM STAINLESS STEEL S71-3C16-16RP 1" 1" BSP FEM STAINLESS STEEL S71-3C16-20RP 1" 1 1/4" BSP FEM STAINLESS STEEL S71-3C32-24RP 2" 1 1/2" BSP FEM STAINLESS STEEL S71-3C32-32RP 2" 2" BSP FEM STAINLESS STEEL 71 SERIES NIPPLE NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 71-3N4-4F 1/4" 1/4" NPT FEM CARBON STEEL 71-3N6-6F 3/8" 3/8" NPT FEM CARBON STEEL 71-3N8-8F 1/2" 1/2" NPT FEM CARBON STEEL 71-3N12-12F 3/4" 3/4" NPT FEM CARBON STEEL 71-3N16-16F 1" 1" NPT FEM CARBON STEEL 71-3N16-20F 1" 1 1/4" NPT FEM CARBON STEEL 71-3N32-24F 2" 1 1/2" NPT FEM CARBON STEEL 71-3N32-32F 2" 2" NPT FEM CARBON STEEL 71 SERIES NIPPLE NPT FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material S71-3N4-4F 1/4" 1/4" NPT FEM STAINLESS STEEL S71-3N6-6F 3/8" 3/8" NPT FEM STAINLESS STEEL S71-3N8-8F 1/2" 1/2" NPT FEM STAINLESS STEEL S71-3N12-12F 3/4" 3/4" NPT FEM STAINLESS STEEL S71-3N16-16F 1" 1" NPT FEM STAINLESS STEEL S71-3N16-20F 1" 1 1/4" NPT FEM STAINLESS STEEL S71-3N32-24F 2" 1 1/2" NPT FEM STAINLESS STEEL S71-3N32-32F 2" 2" NPT FEM STAINLESS STEEL 71 SERIES NIPPLE BSP FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material 71-3N4-4RP 1/4" 1/4" BSP FEM CARBON STEEL 71-3N6-6RP 3/8" 3/8" BSP FEM CARBON STEEL 71-3N8-8RP 1/2" 1/2" BSP FEM CARBON STEEL 71-3N12-12RP 3/4" 3/4" BSP FEM CARBON STEEL 71-3N16-16RP 1" 1" BSP FEM CARBON STEEL 71-3N16-20RP 1" 1 1/4" BSP FEM CARBON STEEL 71-3N32-24RP 2" 1 1/2" BSP FEM CARBON STEEL 71-3N32-32RP 2" 2" BSP FEM CARBON STEEL 71 SERIES NIPPLE BSP FEMALE STAINLESS STEEL Part Number Body Size Thread Size Thread Body Material S71-3N4-4RP 1/4" 1/4" BSP FEM STAINLESS STEEL S71-3N6-6RP 3/8" 3/8" BSP FEM STAINLESS STEEL S71-3N8-8RP 1/2" 1/2" BSP FEM STAINLESS STEEL S71-3N12-12RP 3/4" 3/4" BSP FEM STAINLESS STEEL S71-3N16-16RP 1" 1" BSP FEM STAINLESS STEEL S71-3N16-20RP 1" 1 1/4" BSP FEM STAINLESS STEEL S71-3N32-24RP 2" 1 1/2" BSP FEM STAINLESS STEEL S71-3N32-32RP 2" 2" BSP FEM STAINLESS STEEL

Available sizes 1/8˝, 1/4˝, 3/8˝, 1/2˝, 3/4˝, 1˝, 1-1/4˝, 1-1/2˝,

2˝.

IGHPRESSURESTAINLESSSTEEL PRESSURE RATINGS PSIBARPSIBARPSIBARPSIBARPSIBARPSIBAR MAX.WORKINGMIN.BURST*MAX.WORKINGMIN.BURST*MAX.WORKINGMIN.BURST* AIR SIZESPILLAGEINCLUSION (INCHES)(CC)(CC)

1/4˝.02.0110,00068920,00013795,00034412,50086210,00068920,0001379 3/8˝x1/4˝1.02.0210,00068920,00013795,00034412,50086210,00068920,0001379 3/8˝.02.0210,00068920,00013795,00034412,50086210,00068920,0001379 3/8˝x1/2˝2.02.0210,00068920,00013795,00034412,50086210,00068920,0001379 1/2˝.03.0310,00068920,00013795,00034412,50086210,00068920,0001379 3/4˝.06.047,50051715,00010345,00034412,5008627,50051715,0001034 1˝.10.067,50051715,00010344,00027510,0006897,50051715,0001034 1˝x1-1/4˝3.10.067,50051715,00010344,00027510,0006897,50051715,0001034 2˝x1-1/2˝45.2530.505,00034410,0006893,0002066,0004135,00034410,000689 2˝5.2530.505,00034410,0006893,0002066,0004135,00034410,000689 Unit is 3/8˝ with 1/4˝ end fitting. Unit is 3/8˝ with 1/2˝ end fitting, 31˝ unit with 1-1/4˝ end fitting, and 2˝ unit with 1-1/2˝ end fitting. *NOTE: Pressure Ratings were established under static pressure conditions. For high impulse applications, multiply the above pressure ratings by .6 for approximate pressure ratings. For Det Norske Veritas (DNV) compliance, divide the burst pressure by 4 for the maximum working pressure. PRESSURE RATINGS Size (Inc) Spillage (cc) Air Inclusion (cc) Steel 316 Stainless Steel High Pressure Stainless Steel Max. Working Min. Burst* Max. Working Min. Burst* Max. Working Min. Burst* PSI Bar PSI Bar PSI Bar PSI Bar PSI Bar PSI Bar 1/8" .12 .02 10,000 689 22,000 1517 N/A N/A N/A N/A 1/4˝ .02 .01 10,000 689 20,000 1379 5,000 344 12,500 862 10,000 689 20,000 1379 3/8" x 1/4"1 .02 .02 10,000 689 20,000 1379 5,000 344 12,500 862 10,000 689 20,000 1379 3/8" .02 .02 10,000 689 20,000 1379 5,000 344 12,500 862 10,000 689 20,000 1379 3/8" x 1/2"2 .02 .02 10,000 689 20,000 1379 5,000 344 12,500 862 10,000 689 20,000 1379 1/2˝ .03 .03 10,000 689 20,000 1379 5,000 344 12,500 862 10,000 689 20,000 1379 3/4" .06 .04 7,500 517 15,000 1034 5,000 344 12,500 862 7,500 517 15,000 1034 1" .10 .06 7,500 517 15,000 1034 4,000 275 10,000 689 7,500 517 15,000 1034 1" x 1-1/4"3 .10 .06 7,500 517 15,000 1034 4,000 275 10,000 689 7,500 517 15,000 1034 2" x 1-1/2"4 5.25 30.50 5,000 344 10,000 689 3,000 206 6,000 413 5,000 344 10,000 689 2" 5.25 30.50 5,000 344 10,000 689 3,000 206 6,000 413 5,000 344 10,000 689 1Unit is 3/8˝ with 1/4˝ end fitting. 2Unit is 3/8˝ with 1/2˝ end fitting, 31˝ unit with 1-1/4˝ end fitting, and 42˝ unit with 1-1/2˝ end fitting.

Size Dust Plug Dust Cap 1/4˝ 71-3PCC-4 71-3PNC-4 3/8" 71-3PCC-6 71-3PNC-6 1/2" 71-3PCC-8 71-3PNC-8 3/4" 71-3PCC-12 71-3PNC-12 1" 71-3PCC-16 71-3PNC-16 Material: Plastic

1/8˝.12.0210,00068922,0001517N/AN/AN/AN/A

Tema T-Series

Body Size 1/8" up to 2"

Technical Description

The TEMA Standard Series is characterised by a low pressure drop and maximum flow capacity. The coupling system is available as double shut-off or straight through version. The 2500 can be used also as a single shut-off version.

Advantages

version for coupling and plug the connection is possible up to the operating pressure.

Working Temperature -30°C up to +100°C (NBR) -25°C up to +200°C (FKM) depending on the medium. Special seals are available on request.

O-ring seal.

unintentional uncoupling.

Sleeve Steel hardened, zinc plated, passiv., sealed

Locking Ring Brass, zinc-iron coated, black passiv., sealed

301

420 C

316 Brass, chromated

316

316

316

301

316 Valve Holder (over 100°C) Brass

Plug Body Steel hardened, zinc plated, passiv., sealed

301

316

Plug Standard / Pressure Eliminator Stainl. Steel / Press. Eli. High Press. Water (3/8")

316

316

316

Available Valves TEMA

420 hardened

Mento Hoses

Catalogue 9-8.

8

and Couplings

Quick Couplings

Part Number Body Size Thread Size Thread Body Material Working Pressure 1/4" COUPLING 2510 1/4" 1/4" BSP FEM BRASS NICKEL PL 450 Bar 2510 RV 1/4" 1/4" BSP FEM STAINLESS STEEL 250 Bar 1/4" NIPPLE 2520 1/4" 1/4" BSP FEM STEEL 450 Bar 2520 RV 1/4" 1/4" BSP FEM STAINLESS STEEL 250 Bar 3/8" COUPLING 3810 3/8" 3/8" BSP FEM BRASS NICKEL PL 350 Bar 3810RV 3/8" 3/8" BSP FEM STAINLESS STEEL 300 Bar 3/8" NIPPLE 3820 3/8" 3/8" BSP FEM STEEL 350 Bar 3820RV 3/8" 3/8" BSP FEM STAINLESS STEEL 300 Bar 1/2" COUPLING 5010 1/2" 1/2" BSP FEM BRASS NICKEL PL 300 Bar 5010RV 1/2" 1/2" BSP FEM STAINLESS STEEL 300 Bar 1/2" NIPPLE 5020 1/2" 1/2" BSP FEM STEEL 300 Bar 5020RV 1/2" 1/2" BSP FEM STAINLESS STEEL 300 Bar 3/4" COUPLING 7510 3/4" 3/4" BSP FEM BRASS NICKEL PL 280 Bar 7510RV 3/4" 3/4" BSP FEM STAINLESS STEEL 250 Bar 3/4" NIPPLE 7520 3/4" 3/4" BSP FEM STEEL 280 Bar 7520RV 3/4" 3/4" BSP FEM STAINLESS STEEL 250 Bar 1" COUPLING 10010 1" 1" BSP FEM BRASS NICKEL PL 250 Bar 10010RV 1" 1" BSP FEM STAINLESS STEEL 250 Bar 1" NIPPLE 10020 1" 1" BSP FEM STEEL 250 Bar 10020RV 1" 1" BSP FEM STAINLESS STEEL 250 Bar Material Coupling Standard / Pressure Eliminator Stainl. Steel / Press. Eli. High Press. Water (3/8") Coupling Body Brass, nickel plated chromated AISI

QUICK CONNECTORS

AISI

Brass, chromated

AISI

Valve

AISI

Springs AISI

AISI

AISI

Locking

AISI

AISI

C AISI

C Seals NBR/FKM FKM NBR

AISI

AISI

Brass

301

Balls

420

420

Valve Holder (up to 100°C) Zinc casting

AISI

AISI

Valve

AISI

Springs AISI

AISI

NBR/FKM FKM

AISI

AISI

Brass

301 Seals

Valve Holder (up to 100°C) Zinc Casting

316 Valve Holder (over 100°C) Brass

Tema HP1500 Series

Body Size 1/4"

TEMA High Pressure

Technical Description

Technical Description

The Tema high pressure cou for use in bolt tensioning equipment. This series is produced in steel. The plug pling can be supplied either with or without additional

1500 bar HP1500-Series

1500 bar

Advantages valve design.

Working Pressure

The Tema high pressure coupling was specially developed for use in bolt tensioning equipment. This series is produced in steel. The plug bodies and the sleeves are black galvanised. The coupling can be supplied either with or without additional safety lock.

INTERCHANGEABLE WITH CEJN 116

Coupling Body Steel, zinc-nickel coated, black passivated, sealed

Sleeve Steel, hardened, zinc-iron coated, black passivated, sealed

Locking Balls AISI 420 C

Seals NBR

Inner Sleeve POM

Plug Standard

supplied with dust caps

adapters.

Working Pressure 1500 bar

Temperature

Advantages are supplied with dust caps

polymer valve casing, to guarantee high reliability seals even with second-hand plugs. supplied with dust caps inclusive!

Seals

Seals

request (see page 6).

Working Temperature depending on the medium. on request (see page 6).

Working Temperature -30°C up to +100°C (NBR) depending on the medium. Special seals are available on request.

Available Valves

Metal sealing cone threaded adapters/metal sealing cone adapters.

adapters/metal sealing cone adapters.

zinc-nickel coated, black passivated, sealed

zinc plated, passivated, sealed

302

Material Coupling Standard

Coupling Body Steel, zinc-nickel coated, black passivated, sealed

Sleeve Steel, hardened, zinc-iron coated, black passivated, sealed

Valve Steel, zinc plated, passivated, sealed Springs AISI 302

Valve Steel, zinc plated, passivated, sealed Springs AISI 302

Locking Balls AISI 420 C

Seals NBR

Inner Sleeve POM

Plug Body Steel, hardened, zinc-iron coated, black passivated, sealed

Plug Standard

Flow Capacity with Oil with Viscosity of 32cSt at 40°C as per ISO

Seals NBR

Pressure Drop

Size Dust Plug Dust Cap 1/4˝ HP 26 HP 16

Plastic

Valve Steel, zinc plated, passivated, sealed Springs AISI 302

Plug Body Steel, hardened, zinc-iron coated, black passivated, sealed

7241/2-2000

Valve Steel, zinc plated, passivated, sealed

Springs AISI 302

Seals NBR

Valve Retainer Steel, zinc plated, passivated

Flow Rate in l/min Technical Description The Tema high pressure cou for use in bolt tensioning equipment. This series is produced in steel. The plug pling can be supplied either with or without additional Working Pressure Working

Capacity with Oil with Viscosity of 32cSt at 40°C as per ISO 7241/2-2000

Mento Hoses and Couplings Catalogue 9-9. Quick Couplings 9

TEMA

Rate in l/min

Flow

Profile Applications

Area

Available Valves 110

Body Size 1/4"

Advantages

Seals adapters/metal

Material Coupling Standard Coupling Body Steel,

Sleeve Steel,

Valve Steel,

Springs AISI

Locking Balls AISI 420 C Seals NBR Inner Sleeve POM Plug Standard Plug Body Steel, hardened, zinc-iron coated, black passivated, sealed Valve Steel, zinc plated, passivated, sealed Springs AISI 302 Seals NBR Valve Retainer Steel, zinc plated, passivated 1500 bar Tema Profile Applications Area Available Valves TEMA 1500BAR QUICK CONNECTOR Part Number Body Size Thread Size Thread Body Material THP1500 QUICK COUPLING HP15105131 1/4" 1/4" NPT FEM STEEL THP1500 NIPPLE HP1520513 1/4" 1/4" NPT FEM STEEL

HP1500-Series

(bar)

depending on the medium.

on

are

sealing cone

hardened, zinc-iron coated, black passivated, sealed

Material Coupling Standard

Valve Retainer Steel, zinc plated, passivated

Material:

9-10. Quick Couplings

Faster VVS Series

VVS

• Connection system: screw-on

• Disconnection system: screw-on

• Shut-off system: poppet valve

• Connectability: both male and female couplings under pressure

• Disconnection under pressure: allowed

• Interchangeability: according to Faster internal standard

•Purposely dimensioned to stand very high pressures and peaks

•Screw-on latching system

•Reinforced guidevalve with mechanical backstop

•Also available in Brass and Stainless Steel

•Interchangeable with VV series couplings

STEEL

Pressure drop graph: Test bench to ISO 7241-2 specifications with oil viscosity 20 cSt (3°E), temperature 50°C (122°F).

Materials:

- Female in steel

- Male in steel

- Steel hardened valve

- Surface treatment: zinc plating with Cr III passivation

- Springs in C98 steel

Seals: Standard in oilproof NBR (Nitrile Rubber). On request: Viton, Neoprene, EPDM or other seals.

Antiextrusion rings: In pure PTFE.

Pressure drop graph: Test bench to ISO 7241-2 specifications with oil viscosity 20 cSt (3°E), temperature 50°C (122°F).

Materials:

-Female in steel

-Male in steel

Accessories and spare part kit

See at pages 26-27

-Steel hardened valve

-Surface treatment:zinc plating with Cr III passivation

-Springs in C98 steel

Seals: Standard in oilproof NBR (Nitrile Rubber).

Working temperatures: With standard seals in NBR (Nitrile Rubber) from -25°C (-13°F) to +125°C (+257°F). For temperature exceeding these values, the quick-release coupling will be supplied with all components in steel together with the appropriate seals.

ALSO AVAILABLE IN STAINLESS STEEL

VVS SERIES COUPLING BSP FEMALE CARBON

On request:Viton, Neoprene, EPDM or other seals. Antiextrusion rings: In pure PTFE. Working temperatures: With standard seals in NBR (Nitrile Rubber) from -25°C (-13°F) to +125°C (+257°F). For temperature exceeding these values, the quick-release coupling will be supplied with all components in steel together with the appropriate seals.

STAINLESS STEEL

Pressure drop graph: Test bench to ISO 7241-2 specifications with oil viscosity 20 cSt (3°E), temperature 50°C (122°F).

Materials:

-Male and female in AISI 316

-Springs, valves and valve guides in AISI 316

Seals:

Standard in NBR (Nitrile Rubber), Shore hardness 85.

On request:Viton, Neoprene, EPDM seals.

Antiextrusion rings: In pure PTFE.

Working temperatures: With standard seals in NBR (Nitrile Rubber) from -25°C (-13°F) to +125°C (+257°F).

BRASS

Pressure drop graph: Test bench to ISO 7241-2 specifications with oil viscosity 20 cSt (3°E), temperature 50°C (122°F).

Materials:

-Male, female, valves and valve guides in brass

-Springs in AISI 316

Seals:

Standard in NBR (Nitrile Rubber), Shore hardness 85. On request:Viton, Neoprene, EPDM seals.

Antiextrusion rings: In pure PTFE.

Accessories and spare part

See at pages 26-27

STAINLESS STEEL & BRASS MATERIAL AVAILABLE UPON REQUEST

Working temperatures: With standard seals in NBR (Nitrile Rubber) from -25°C (-13°F) to +125°C (+257°F).

TECHNICAL DATA

Mento Hoses and Couplings Catalogue

10

(122°F). quick-release together (122°F). (122°F). The descriptions and illustrations in this catalogue are for information only and are not binding.

Series

under pressure standard and peaks

10

STEEL

The descriptions and illustrations in this catalogue are for information only and are not binding.

Series VVS

Features ▲

Size DN Nominal diameter Rated flow Max work. pressure * Medium burst pressure Fluid spillage Connected Male Female mm inc l/min. GPM MPa PSI MPa PSI MPa PSI MPa PSI cc. max. 1/4” 04 4,5 0.18 8 2,1 80 11600 250 36250 240 34800 240 34800 1 3/8” 06 5,5 0.22 18 4,8 76 11020 230 33350 290 42050 250 36250 1,5 1/2” 08 9,8 0.38 30 7,9 73 10585 220 31900 238 34510 220 31900 2 3/4” 12 10,5 0.41 45 12 70 10150 214 31030 212 30740 230 33350 3 1” 16 13,7 0.54 90 24 53 7685 194 28130 160 23200 224 32480 10 1 1/4” 20 22,8 0.9 140 37 60 8700 200 29000 180 26100 180 26100 15 1 1/2” 24 24,7 0.97 300 79 40 5800 150 21750 120 17400 150 21750 38 2” 32 264 43,9 1.73 1000 35 5075 105 15225 130 18850 130 18850 46 FASTER VVS SERIES QUICK CONNECTORS VVS SERIES COUPLING NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material VVS14NPTF 1/4" 1/4" NPT FEM STEEL VVS38NPTF 3/8" 3/8" NPT FEM STEEL VVS12NPTF 1/2" 1/2" NPT FEM STEEL VVS34NPTF 3/4" 3/4" NPT FEM STEEL VVS1NPTF 1" 1" NPT FEM STEEL VVS114NPTF 1 1/4" 2 1/4" NPT FEM STEEL VVS112NPTF 1 1/2" 2 1/2" NPT FEM STEEL VVS2NPTF 2" 2" NPT FEM STEEL VVS SERIES NIPPLE NPT FEMALE CARBON STEEL Part Number Body Size Thread Size Thread Body Material VVS14NPTM 1/4" 1/4" NPT FEM STEEL VVS38NPTM 3/8" 3/8" NPT FEM STEEL VVS12NPTM 1/2" 1/2" NPT FEM STEEL VVS34NPTM 3/4" 3/4" NPT FEM STEEL VVS1NPTM 1" 1" NPT FEM STEEL VVS114NPTM 1 1/4" 2 1/4" NPT FEM STEEL VVS112NPTM 1 1/2" 2 1/2" NPT FEM STEEL VVS2NPTM 2" 2" NPT FEM STEEL

Part Number Body Size Thread Size Thread Body Material VVS14GASF 1/4" 1/4" BSP FEM STEEL VVS38GASF 3/8" 3/8" BSP FEM STEEL VVS12GASF 1/2" 1/2" BSP FEM STEEL VVS34GASF 3/4" 3/4" BSP FEM STEEL VVS1GASF 1" 1" BSP FEM STEEL VVS114GASF 1 1/4" 2 1/4" BSP FEM STEEL VVS112GASF 1 1/2" 2 1/2" BSP FEM STEEL VVS2GASF 2" 2" BSP FEM STEEL

CARBON

Part Number Body Size Thread Size Thread Body Material VVS14GASM 1/4" 1/4" BSP FEM STEEL VVS38GASM 3/8" 3/8" BSP FEM STEEL VVS12GASM 1/2" 1/2" BSP FEM STEEL VVS34GASM 3/4" 3/4" BSP FEM STEEL VVS1GASM 1" 1" BSP FEM STEEL VVS114GASM 1 1/4" 2 1/4" BSP FEM STEEL VVS112GASM 1 1/2" 2 1/2" BSP FEM STEEL VVS2GASM 2" 2" BSP FEM STEEL

STEEL

VVS SERIES NIPPLE NPT FEMALE

STEEL

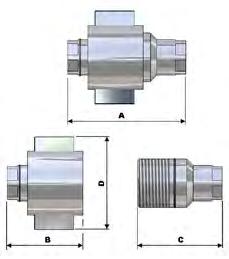

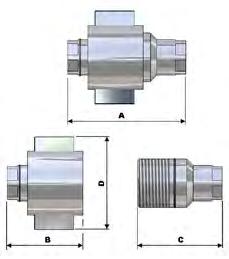

Parker 3000 Series

Technical Description High pressure coupler up to 700 bar. Screw locking mechanism.

Advantages

Screw type locking mechanism - high resistance to mechanical and hydraulic strenghs.

Plugs 3000-Series

Ball or poppet valving configurations can be connected together with reduced impact on the flow capacities.

Advantages Working Temperature

-30°C up to +110°C (NBR)

-30°C up to +80°C (Polyurethane) depending on the medium.

Special seals are available on request (see page 6 ff).

Mento Hoses and Couplings Catalogue 9-11. Quick

11

Couplings

Part Number Valve Thread Size Thread Body Material 3000 SERIES COUPLING NPT MALE CARBON STEEL 3050-2 BALL 1/4" NPT MALE STEEL 3050-2P POPPET 1/4" NPT MALE STEEL 3050-3 BALL 3/8" NPT MALE STEEL 3050-3P POPPET 3/8" NPT MALE STEEL 3000 SERIES NIPPLE NPT FEMALE CARBON STEEL 3010-2 BALL 1/4" NPT FEM STEEL 3010-2P POPPET 1/4" NPT FEM STEEL 3010-3 BALL 3/8" NPT FEM STEEL 3010-3P POPPET 3/8" NPT FEM STEEL DUST CAP 3005-2 1/4" 3005-3 3/8" DUST PLUG 3009-2 1/4" 3009-3 3/8" Material Coupling Standard Coupling Body Steel Sleeve Steel Valve Steel Springs Steel Seals 1/4" NBR Seals 3/8" Polyurethane Thread Body Steel Material Plug Standard Plug Body Steel Valve Steel Seals 1/4" NBR Seals 3/8" Polyurethane Seals NBR Valve Holder Steel Working Pressure Body Size Max. Operating Pressure Connected 1/4" 700 bar 3/8" 700 bar

Body Size Connection A Hex L mm mm Male NPTF Thread 1/4"1/4"22 mm60,528,5 1/4"1/4"22 mm60,529 3/8"3/8"24 mm7235 3/8"3/8"1"7335 Plugs Body Size Connection A Hex mm L mm mm Female NPTF Thread 1/4"1/4"19322815,8 1/4"1/4"27323115,8Poppet853010-2P 3/8"3/8"32383519,0 3/8"3/8"323536,819,0Poppet1103010-3P Dust Protection Body Size 1/4" 3/8" 1/4" 3/8" Seal-Kit Body Size 1/4" 3/8" Please consider our security advices on the pages 12/13 Male NPTF Thread 1/4"1/4"22 mm60,528,5 Ball1153050-2 1/4"1/4"22 mm60,529 Poppet1213050-2P 3/8"3/8"24 mm7235 Ball2203050-3 3/8"3/8"1"7335 Poppet2253050-3P

PARKER 3000 SERIES QUICK CONNECTORS

Couplings

Body Size Connection A Hex mm L mm D mm D1 mm ValvingWeight gr. Part Number Female NPTF Thread 1/4"1/4"19322815,8 Ball703010-2 1/4"1/4"27323115,8Poppet853010-2P 3/8"3/8"32383519,0 Ball1153010-3 3/8"3/8"323536,819,0Poppet1103010-3P

Body Size Version Part Number 1/4" for coupling 3005-2 3/8" for coupling 3005-3 1/4" for plug 3009-2 3/8" for plug 3009-3

Dust Protection 3000-Series

Body Size Material Part Number 1/4" NBR JT020114N0552 3/8" Polyurethane JT01U28-18.72QE

Seal-Kit 3000-Series

Body Size Connection A Hex L mm D mm D1 mm ValvingWeight gr. Part Male NPTF Thread 1/4"1/4"22 mm60,528,5 Ball1153050-2 1/4"1/4"22 mm60,529 Poppet1213050-2P 3/8"3/8"24 mm7235 Ball2203050-3 3/8"3/8"1"7335 Poppet2253050-3P

3000-Series Body Size Connection A Hex mm L mm D mm D1 mm ValvingWeight gr. Part Female NPTF Thread 1/4"1/4"19322815,8 Ball703010-2 1/4"1/4"27323115,8Poppet853010-2P 3/8"3/8"32383519,0 Ball1153010-3 3/8"3/8"323536,819,0Poppet1103010-3P Dust Protection 3000-Series Body Size Version Part 1/4" for coupling 3005-2 3/8" for coupling 3005-3 1/4" for plug 3009-2 3/8" for plug 3009-3

3000-Series Body Size Material Part 1/4" NBR JT020114N0552 3/8" Polyurethane JT01U28-18.72QE

Couplings 3000-Series

Plugs

Seal-Kit

BOP QR 74 Series

High Pressure Quick Release Coupling

Design Features: replaced

Materials: (standard coupling)

Also available in Hex Nut style, other body and seal materialsdetails on request

Head Office ContiTech Beattie Limited, Jubilee Industrial Estate,

Mento Hoses

Catalogue

12

and Couplings

9-12. Quick Couplings