5 minute read

All-electric ferries

TWO ALL-ELECTRIC FERRIES ON ORDER FOR SWEDEN

Kongsberg Maritime has signed a contract with Holland Shipyards Group to provide electrification and control systems for new all-electric ferries.

The contract for the two ferries, being built for the Swedish Transport Administration, includes an option for two more.

“This project will also further build on the work we have done on Yara Birkeland, a zero-emissions container-feeder vessel, and the fully autonomous freight ferries for Norwegian grocery distributor Asko,” said Hans Westad, portfolio manager, Autonomous and Remote Projects, Kongsberg Maritime.

Dual objectives

To achieve the dual objectives of electrification and automation, Kongsberg Maritime will provide the ferries’ electrical systems, as well as a comprehensive control system suite, including energy management, navigation, an all-new situational awareness system linked with automated manoeuvring.

Together with the general automation of all onboard systems and essential port equipment like charging and mooring, the company will also deliver the technology for the remote monitoring and operation centre in Stockholm and secure communication between ferries, ports and the control centre.

A simulator with 360-degree visuals from Kongsberg Digital is also part of the delivery, enabling the ferry company to train their crew in new operational procedures.

“We will deliver the ferries turn-key to Sweden, including shore charging and auto-mooring. These vessels mark a new step forward for Holland Shipyards Group and the ferry market in general,” said Marco Hoogendoorn, director, Holland Shipyards Group.

“Not many yards have experience with delivery of a complete electrical sailing scope, including shore infrastructure. An innovative contract like this one really is recognition of our past performances.”

The challenges in automating the operations of these ferries include the short routes and the presence of significant on-water traffic, including pleasure boats and occasional ice.

A 12-month test period is planned after delivery to further develop and fine-tune automated functionalities and to demonstrate the ferries’ capabilities to Swedish authorities.

8 Kongsberg

Maritime sales director Roger Trinterud (right) and Cor Hoogendoorn, owner and director of Holland Shipyard Group

MSC Opera booked for Qatar World Cup

MSC Cruises’ 1,075-cabin MSC Opera cruise ship will accommodate football fans during the upcoming football World Cup.

The high-end cruise ship will be berthed at Doha during the tournament, between November 19 and December 19, to boost hotel accommodation for the small city of Doha, which only has 31,000 hotel rooms - which isn’t bad for a city with a population of 1.11 million.

MSC Opera was built in 2004 and is crewed by more than 700 people.

In 2011 she lost power on the Baltic Sea en route to England, according to news reports, because of an engine power outage, leaving the 1,700 passengers on board at the

8 MSC Opera piano bar

time without light or water. She was then towed to Nynäshamn, near Stockholm, and passengers were transferred to smaller vessels before being flown home.

In 2015, MSC Opera was revamped under the company’s €279 million ‘Renaissance Programme’ along with three sister ships, the Armonia, Sinfonia and Lirica, all Lirica class ships. The revamps increased all ships’ length by 24 metres (to 275 metres), weight by 5,000 tonnes (to 65,000 topnnes) and capacity by 600 passengers (to 2,680).

MSC Opera’s accommodation decks are each named after well-known operas, such as La Traviata, Tosca and Turandot, and she has the usual facilities to be expected on such a liner, such as gym, bars and restaurants.

The ship is expected to serve alcohol, which in the Muslim country of Qatar is only allowed in luxury hotels.

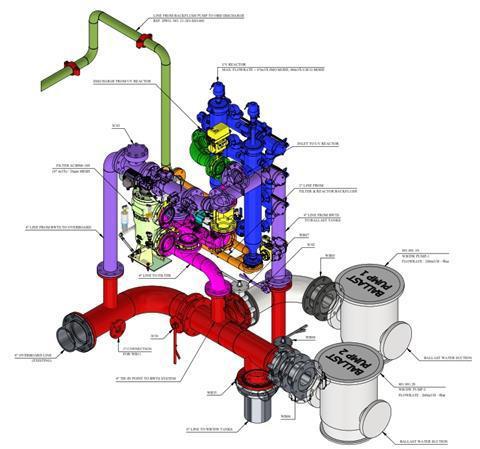

France-based water treatment firm BIO UV Group has completed a retrofit low-flow ballast BWTS RETROFIT water treatment system at sea with its partner

3C Metal, an engineering solutions firm. A BIO-SEA L03-087 modular unit was CARRIED OUT AT SEA installed aboart the 4350dwt vessel Greatship Maya, the firms said, a multi-purpose offshore supply vessel operated by the Singapore firm Greatship Global Offshore Serve Pte.

The work was completed as the ship was carrying out rig supply operations off Labuan, Malaysia.

“Together [with 3C Metal], we surveyed the site, taking 3D scans of the ship’s machinery spaces to simplify pipework, electrical wiring, system integration and installation,” said Maxime Dedeurwaerder, business unit director, BIO-SEA, with the BIO UV Group. ”This also revealed some space limitations, which ensured we were able to design and build a ship-specific solution, allowing 3C Metal’s team to get the BWTS in place without modifying the steel structure in any way.”

“During preliminary work it was identified that the ship’s pumps would also be used for transferring liquids other than ballast water, such as water from drilling operations,” said Florian Cortes, who heads up technical operations for BIO UV Group. ”But after studying the vessel’s different operational requirements it was found that in ballast mode, the pumps would not be required to run at their full rated capacity of 300m3/hr. 87m3/hr was sufficient. This allowed us to offer a smaller BIO-SEA system that would

8 Maya BWTS Model otherwise have been specified and meant an easier integration and a more cost-effective retrofit solution for the end user.” The firms said that although at-sea installations take longer than those done on shore, the fact that a dry dock was not required _Retro Bridge Qtr Feb 2020_Retro Bridge 14/02/2020 12:41 Page 1 meant huge cost savings. The vessel could also carry out its operations, saving time.

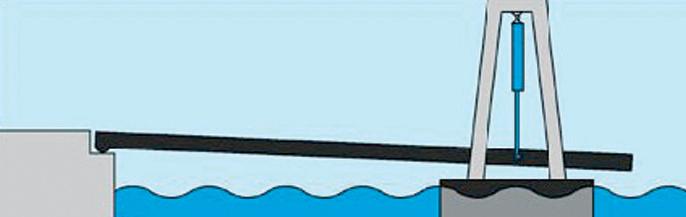

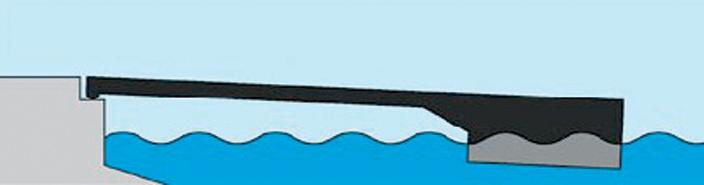

Rent, lease or buy a RoRo facility from us! BRIDGE

Retro Bridge BV • Bruistensingel 152 5232 AC Hertogenbosch Tel: 00 31 (0) 73 640 87 70 Fax: 00 31 (0) 73 644 23 69 e-mail: sales@retrobridge.com website: www.retrobridge.com

We take the heat, so you don’t have to.

Cool. Because you need it. We deliver cool based on your reality. So no matter where you operate, hot days and heavy loads will never slow you down.

GRIDCOOLER® Keel Cooler

WEKA Boxcooler®

fernstrum.com | 1.906.863.5553 | sales@fernstrum.com ISO 9001:2015

© 2022 R.W. Fernstrum & Company. All rights reserved. FERNSTRUM® and GRIDCOOLER® are registered trademarks of R.W. Fernstrum & Company. All other trademarks cited are the property of their respective owners.