11 minute read

Small bore platform

DIGITAL ENGINE PLATFORM

Stefan Nysjö, Vice President Power Supply – Marine Power at Wärtsilä discusses how the new 25-bore engine platform leverages digitalisation tools to deliver improved reliability and performance.

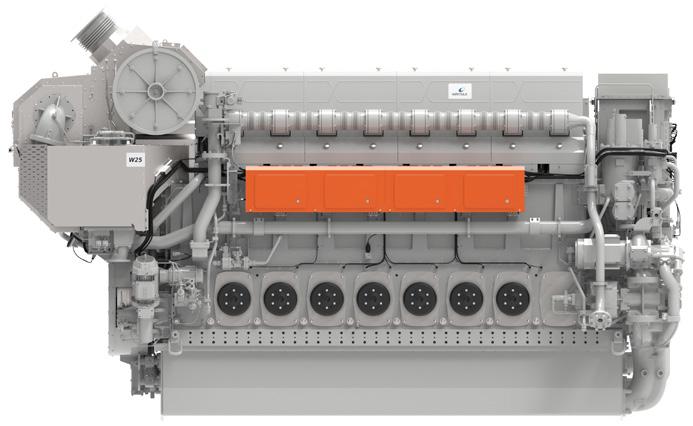

The potential for digitalisation tools to play a significant role in improving the performance of combustion technology has been a recurring theme in Mr. Nysjö’s interviews with The Motorship. Speaking on the sidelines of the launch of Wärtsilä’s 25 engine platform at SMM in Hamburg in September, Mr. Nysjö returned to the theme.

“The engine [has been designed] with the needs of more complex hybrid systems, which require more sophisticated engine control systems,” Mr Nysjö began. The engine platform had also been developed with the intention of forming a platform for future alternative fuel developments, such as methanol or ammonia multi-fuel variants, which will sit alongside the dual-fuel version, which is available with two-stroke turbocharging.

The engine also sets new standards in terms of its environmental performance. The improvement of the dualfuel engine’s combustion performance has lowered the greenhouse gas emissions produced by the engine to the same level as a pure gas engine.

Future Fuel Variants

Mr. Nysjö noted that in common with Wärtsilä’s recent 31 and 46 engine launches, the 25 engine had been developed to be a fuel agnostic, and fuel flexible engine platform.

Wärtsilä remained committed to the launch of alternative fuel versions of the engine, with an technology concept capable of operating on ammonia expected to be unveiled in 2023. The ammonia-burning product is expected to be launched shortly thereafter.

“When it comes to ammonia, it is a fuel which will most likely benefit more than methanol from the modern technology [in the 25 platform].”

While the development of the 25 engine had taken three years of testing, the development of alternative fuel engines was likely to be much shorter, as it will be more like a product industrialization. “The development cycle for an ammonia-burning 25 engine will not be as long as the platform is there, particularly as we are doing the technology development related to ammonia on the side”.

25 engine focused on short-sea segments

Wärtsilä has developed the 25 engine with an eye on the operational requirements of the short-sea market, where the engine’s compact footprint, modular design and ease of upgrading is meet specific customer requirements. While the coastal tanker market, general merchant vessels and even certain ferry niches were potential markets, the engine was also well suited for auxiliary engine applications on board larger vessels.

Broader market trends were also “playing into the hands” of the 25 engine, which was likely to benefit from a trend towards specifying smaller engines in response to decarbonisation regulations. In addition, there was fewer in-line engine in the small-bore segment, which was likely to benefit the platform.

8 Stefan Nysjö, Vice

President Power Supply – Marine Power at Wärtsilä

“But the advantages of digitalisation also benefit the maintenance side of the engine’s operations. It allows us to enable our Wärtsilä Expert Insight services, and also helps support our maintenance agreements.” Mr. Nysjö noted that the step change in engine efficiency achieved in the 25 platform was not solely

8 The Wärtsilä 25DF

utilises advanced combustion technology to lower GHG emissions to the same level as a pure gas engine.

The Motorship notes that Wärtsilä shared some details of its focus on lightweighting research during a recent visit to Vaasa, in which research engineers discussed the use of additive manufacturing and the substitution of traditional components with lighter more durable materials.

However, Mr. Nysjö noted that the use of data tools such as Expert Insight had made a major contribution to the step change in reliability achieved by the new platform.

“We have extended the TBO [time between overhaul] by

25 engine platform

When operating with natural gas the engine is IMO Tier III compliant, as it also is with diesel when integrated with a Wärtsilä NOx Reducer (NOR) emissions abatement system. Furthermore, it enables economically viable compliance with regulations such as the IMO’s CII and EEXI protocols that enter into force in 2023.

The Wärtsilä 25 is designed for long periods of maintenance-free operation and it supports drydocking schedules with a TBO of up to 32,000 hours. Data-driven dynamic maintenance planning and predictive maintenance services can extend the TBO even further.

The engine features a robust and highly efficient turbocharging system with a high pressure ratio. It is now available in 6L, 7L, 8L and 9L cylinder configurations, while the dual-fuel (DF) version has a power output ranging from 1.9 to 3.1 MW, and the diesel version from 2.0 to 3.4 MW. The common-rail high pressure fuel injection technology optimises combustion and the fuel-injection settings at all loads. This in turn promotes smoke-free operation.

Other features include a self-learning proportional, integral, derivative (PID) control to reduce calibration needs, and the gathering of critical engine data for predictive maintenance, reporting and analysis purposes via Wärtsilä’s Expert Insight service. The modules can be replaced ‘on the fly’, which eliminates the need for separate software downloads. Optional and easy-to-apply adjustments for arctic or tropical conditions and for reducing emissions to the level of a pure gas engine are also available.

Main Particulars – Wärtsilä 25 engine

Bore, mm

Stroke, mm

Engine speed, rpm Piston speed, 900/1,000 Rated output, 6L @ 900 Rated output, 9L @1000 BSEC, kJ/kWh

SFOC, kJ/kWh

Diesel with 1-stage turbocharging

250

Dual fuel with 2-stage turbocharging

250

340 340

900/1,000 900/1,000

10.2/11.3 10.2/11.3

2,040 1,890

3,375

7,560

184 3,105

7,560

184

Main engine dimensions, 9L25 6,200 (L) x 2,400 (W) x 3,600 (H)

Main genset dimensions, 9L25 9,950 (L) x 2,720 (W) x 3,860 (H) 6,300 (L) x 2,200 (W) x 3,700 (H)

9,900 (L) x 2,720 (W) x 3,960 (H)

utilising the data tools to the maximum. By applying tools like Expert Insight, we have been able to apply dynamic maintenance, which also allows operators to flex their TBOs.”

Adopting a dynamic approach to scheduled maintenance relies on Wärtsilä having a deeper insight into the way the engine is run and the wider operating environment.

“For assets operating in really harsh conditions, it might not be advisable to look to run the 32,000 hours, it might be more economical to do the overhaul at 30,000. By contrast, for assets in less challenging conditions, it should be risk free to run up to the full 32,000 hours.”

The greater operational advantage of flexing TBO intervals is the ability to synchronise the major overhauls with scheduled maintenance on the engine turbocharger and other assets. This is likely to create greater overall savings over the course of a four or five year period between dry docks. “We expect that this will result in greater asset availability by saving downtime, with a direct impact on the bottom line,” Mr. Nysjö said.

This was a practical example of how Wärtsilä’s services can create additional value for customers, Mr. Nysjö said. This is one of the businesses expansion focuses, along with decarbonisation.

CHARTING A PATH TO THE FUEL OF THE FUTURE

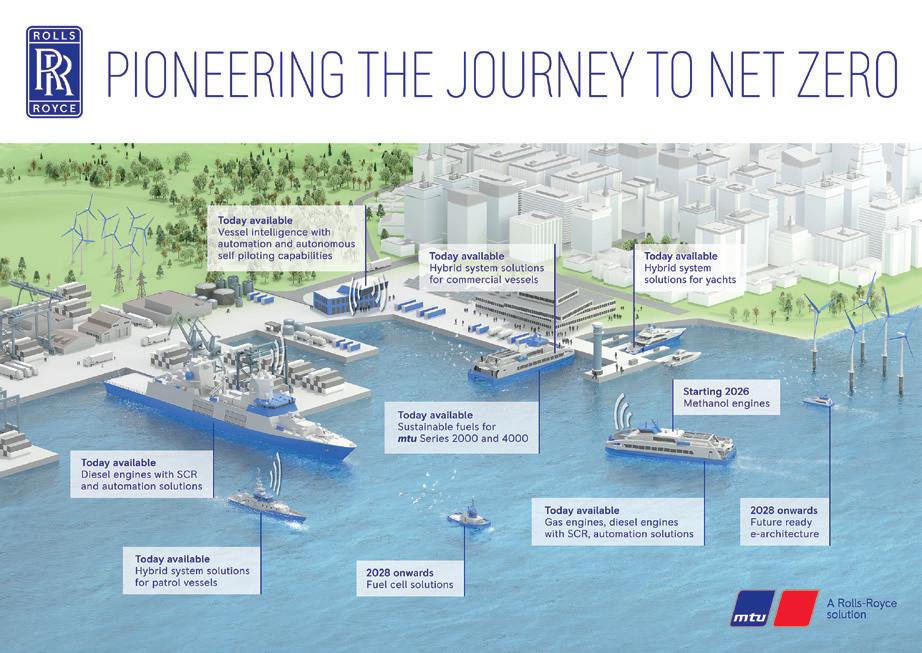

The industry is still undecided about what will be the future fuel for shipping, and indeed if there will just be one. What may seem to be a good fuel today may be thrown out and another taking its place tomorrow. However, MTU Rolls-Royce are taking the bull by the horns and are looking to set a direction for the maritime industry, writes Samantha Fisk.

Following the recent decision to extend the ISO 8217 standard for fuel requirements in the marine industry from HVO and 7% FAME blends to other types of biofuel, MAN Energy Solutions expects the market for biofuels to expand rapidly.

Rolls-Royce business unit Power Systems wants to lead the way as a pioneer in the marine industry when it comes to climate friendly power and propulsion solutions. The new development of a mtu methanol engines is an important part of this strategy, the company highlights.

With this in mind Rolls-Royce have started developments on a new engine last year, based on the mobile gas engine of the mtu Series 4000. Rolls-Royce will launch its methanol engines on the market from 2026 and has already found a first partner and customer for the engines.

“Rolls-Royce and Italian yacht builder Sanlorenzo plan to develop and build a large motor yacht with a methanol engine propulsion system able to run carbon-neutrally on ‘green’ methanol. The two companies announced an exclusive memorandum of understanding to this effect for yachts between 40 and 70 meters at the 2022 Cannes Yachting Festival,” says Rolf Behrens, Spokesman Mobile Solutions, Rolls Royce.

The yachts will be powered by two mtu methanol engines based on the Series 4000. The Sanlorenzo yacht is expected to undertake her maiden voyage in 2026.

The development of the engine has come about through studies that Rolls-Royce has carried out on environmentally friendly fuels, which have also included pure electric and hydrogen. Behrens comments that: “There is no silver bullet for environmentally friendly marine propulsion systems of the future, there will not be a one-technology-fits-all solution given the wide variety of requirements and missions of marine customers and vessels. Rolls-Royce business unit Power Systems is developing a range of future technologies for its marine customers, including hybrid propulsion and fuel cell systems.” He adds that it expected that from 2023, mtu marine engines can be used with sustainable fuels such as HVO or renewable diesel, immediately cutting CO2 emissions by 90 percent.

With this development Rolls-Royce are putting its flag in the ground about the direction that it sees the development of fuels in the future going. The reason that Rolls-Royce is placing its bets on methanol is that it sees that methanol has the potential to shape the energy transition in marine propulsion systems, for example for tugs, yachts, fast ferries

and coastal shipping.

“The market now seems ripe for alternative fuels”, says Behrens, “There’s an increasing demand from the user side and growing willingness to allow their use from authorities. It has been clear for some time that methanol (MeOH) has great potential in terms of CO2 reduction. Now we see a concrete market trend towards methanol. Interest in, demand for and readiness for MeOH projects are growing.” Rolls-Royce is continuing its development of the methanol engine technology, partly funded by the German Federal Ministry of Economics and Climate Protection’s "MeOHmare" project.

Behrens adds whys methanol is attractive for smaller commercial vessels in that: “We expect its production to be economically competitive and advantageous over other e-fuels in the future. Methanol as a common chemical product is traded and transported worldwide and is, in principle, globally available, for example at more than 100 of the world’s most important ports. The required modifications to existing infrastructure are less than for other alternative gaseous fuels. E-methanol may play a role in other applications in the future beyond the new mtu methanol engine. The fuel can also be used in combustion engines using the diesel principle, or with the help of a reformer to produce electrical energy in fuel cells. These points give e-methanol an edge over pure electric propulsion and hydrogen-fuelled energy converters in a number of marine applications, as well as over solutions using other e-fuels.”

The company also adds about the fuel that Compared to other climate neutral “e-fuels” (H2, methane, ammonia) methanol (MeOH) has the highest energy density, logistics and handling are much less complicated, as MeOH is a liquid fuel under normal boundary conditions (no pressure tanks and no cryogenics are required) and the existing diesel infrastructure can be used. Methanol engines will most likely not need exhaust gas aftertreatment making propulsion solutions more compact.

The trend towards ‘green’ or e versions of fuels are starting to come apparent on the market, as it isn’t just the carbon neutrality of the fuel it’s self but also how the fuel is produced where its environmental efficiency is also being measured.

The company also highlights that its assessment is that e-methanol is the CO₂-neutral fuel which is best suitable for a range of marine applications. It meets the requirements of an e-fuel because it is produced from hydrogen and CO2 with the aid of wind or solar energy. For on-board storage, it requires significantly less space than would be needed for hydrogen in fuel cell drives or for batteries with the same range. In addition, methanol is less toxic than other e-fuels, such as ammonia. Production costs are also expected to fall faster than those of e-diesel due to economies of scale.

In general, Rolls-Royce believes methanol is suitable for all marine applications. When comparing MeOH and H2/ batteries, MeOH generally lends itself as a fuel for:

8 Ships that require a long range

8 Vessels that have a high weight sensitivity

8 Ships with little internal available space

8 Ships requiring a low downtime/little time for bunkering

However, the company also still believes that there will not be one propulsion solution in the future, different forms of energy sources will be developed and used in parallel.

So, with this in mind Rolls-Royce is looking to help guide the future market for smaller commercial vessels towards methanol, as it sees that it will have benefits and offers the best fuel for this market in years to come.