31 minute read

trawler page

KILLYBEGS YARD ADAPTS TO COMPLETE SHETLAND TRAWLER

Despite the obstacles of lockdowns in Ireland disrupting the yard’s schedule, Mooney Boats in Killybegs has delivered its largest newbuild to date for owners in Shetland

Built for the Hughson family, the Vestværft-designed Ocean Challenge has been completed by Mooney Boats on a hull fabricated in Poland. In spite of the challenges that 2020 has

placed in everyone’s way, Ocean Challenge’s delivery is just a

matter of weeks behind its original delivery date.

“We quickly found ways to adapt due to the vessel owners being unable to travel to the shipyard. To overcome this Mooney Boats’ design team began sophisticated 3D design drawings of various layouts which were sent digitally to vessel owners to review and walk around proposed designs on their mobile devices such as iPad and laptops,” commented Alan Hennigan at Mooney Boats.

“From the success of these 3D design drawings, we were later tasked with designing the fish processing system, a first for the shipyard. Using the latest 3D software, the yard digitally designed and rendered the fish processing deck for approval by the owners in Shetland.”

Ocean Challenge is fitted out in Mooney Boats’s style, with LED strip lighting around the accommodation areas. Each of the seven cabins has its own flatscreen TV, and there’s a 55inch television in the mess, which is separated from the galley area by a glass partition. The accommodation has underfloor heating throughout.

The 28.50 metre LOA by 8.70 metre trawler has an ABC 6 DZC main engine powering a Heimdal HG600S 3PTOF gearbox and a Heimdal 3000mm diameter propeller. Auxiliary power is provided by a pair of 218kW Caterpillar 9.3 DITA units, backed up by a Caterpillar 4.4 DIT air-cooled harbour set.

Ocean Challenge is expected to operate mainly on whitefish on fishing grounds around Shetland and West of Scotland, working a 14-day rotation to switch skipper and crew, and with a planned three landings to take place within each 14-day spell.

Trawl gear is prepared locally, and Ocean Challenge fishes with a pair of Thyborøn Type 12 doors and a 2300 roller clump. The doors and clump carry Scanmar SS4 double distance and angle sensors, and the trawl are rigged with HC4 trawl sounder and HC4 flow sensors, relaying data to the Scanbas 365 Bridge System in Ocean Challenge’s wheelhouse.

The SS4 sensors on the doors relay the pitch and roll of the doors, as well as the door spread and indicating if the clump is ahead, behind or in line with the doors.

The headline-mounted trawl sounder provides headline height and the footrope’s seabed clearance, as well as relaying data on the density of fish in the mouth of the trawl, displayed with both a 0-9 numerical density and a colour code system.

Leslie and Stephen Hughson expect to use the trawl sounder on their portside trawl, although it can easily be switched, alongside the flow sensor.

“This will be my third vessel in a row with Scanmar and I can honestly say I’ve never had a single problem with it – the intricacies of trawl technology requires a top quality system,” Leslie Hughson said, commenting that the trawl electronics have contributed to his success with previous trawlers Ocean Way and Fair Way.

8 Ocean Challenge

has been completed by Mooney Boats for the Hughson family in Shetland

8 The Scanmar array

is a key element of the electronics in Ocean Challenge’s wheelhouse

Photos: Mooney Boats

Fishing companies in Iceland are already gearing up for blue whiting in the New Year. Hopes are fading for a capelin season, placing the focus on blue whiting in the early part of the year. Iceland’s 2021 blue whiting quota is expected to be around 200,000 tonnes.

Fishing for blue whiting places heavy demands on the fishing gear, and particularly codends, and especially in the area off Rockall when the Icelandic fleet fishes in international waters. As late winter turns into spring, the blue whiting fishery in these waters can be challenging, with deep depressions that result in stormy weather and heavy seas. Larger vessels with plenty of engine power are needed to be able to fish there.

The fishing gear also needs the strength and resilience to cope with the tensions that come with a codend rising at full speed from a 600 to 700 metre depth.

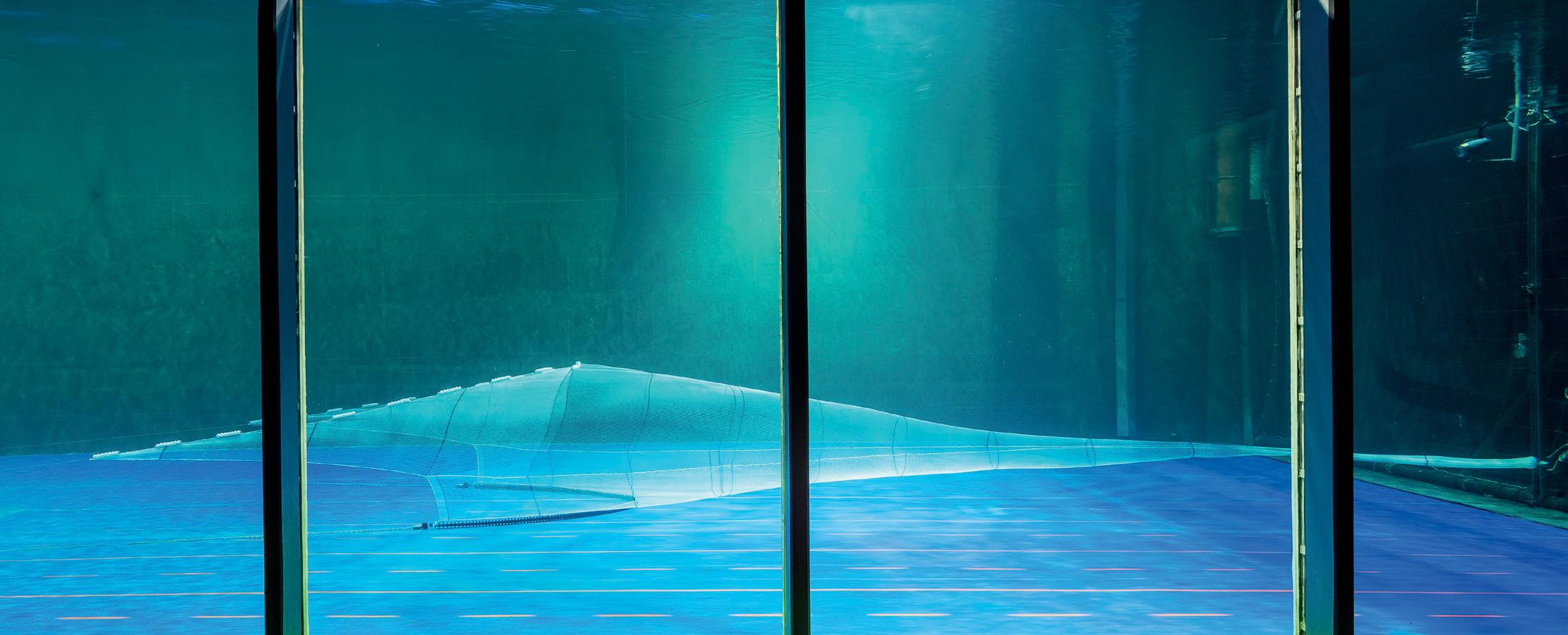

Over the past few months Hampiðjan has been developing an even more robust codend capable of withstanding these high tensions.

The result is the Rockall codend, 86 metres long and with a 48 metre circumference at the VÓNIN ZENITH NEW GROUNDFISH TRAWL high reach 10 metres

10% CATCH BOOST

Vónin's Zenith has already shown some promising results on saithe, haddock, TRIPS OF FISHING

Vónin Zenith outperformed the standard gear over 11 trips of fishing with 10% catch increase. top, reducing to a 15 metre circumference at the tail end. This codend has a new, dry weight of 6.8 tonnes, and it expected to hold around 900 tonnes of blue whiting at full capacity. The inner layer is made in 50mm braided Utzon

HEAVYWEIGHT CODEND FOR BLUE WHITING

nylon netting, covered with 150mm triple braided Utzon nylon. The back half of the codend is ringed at one metre intervals with restricting strops spliced in 44mm Danline rope.

Hampiðjan expects that this heavyweight

8 The Rockall codend is rigged for strength and

a 900-tonne capacity

Rockall codend will have all the strength needed to handle big hauls taken by large

NEW DESIGN

LARGER FISHING AREA

redfish and greenland halibut. Faroese pair team trawlers were selected to try out the Zenith trawl and it was clear that

THE GRAPH SHOWS THE CATCH OVER 11 fishing vessels under tough sea conditions.

CONVENTIAL 720

ZENITH 700

Blue block shows the catch with standard 720 mesh trawl. Orange block shows the catch with Zenith 700 mesh trawl.

VÓNIN // Bakkavegur 66 // FO-530 Fuglafjørður // Faroe Islands // Tel +298 474 200 // info@vonin.com // vonin.com

ENGINEERING A NEW GENERATION OF SKINNERS

Cretel has a background in providing equipment for the fi sh and meat processing industries – and now this company with its long pedigree has a new home and is re-engineering its product line, starting with its fi sh processing range

“The seafood industry is where we feel we are most fi rmly established,” said Cretel manager Guy Persyn. “So that was the logical place to start, and the fi sh processing industry is one that demands quality in its processing equipment.”

The first choice candidate for re-engineering is Cretel’s automatic skinning machine, and Guy Persyn said that this has been such a comprehensive process that the result is practically a new machine, rather than a new version of what was there before.

“We also went back to the beginning and started from scratch, as we wanted to avoid the tunnel vision that can be part of improving existing equipment,” he explained.

“We set out to identify weaknesses in the existing machines, and to solve these in the next generation of skinning machines.”

The result is that Cretel’s automatic skinning machine has features that can be seen at a glance, such as the redesigned in-feed and out-feed belts, as well as some that aren’t immediately obvious. These include a metal treatment that ensures exceptional smoothness of the steel casing down to a microscopic level, denying even the smallest bacteria a hiding place.

“The focus is on reliability, quality and robust construction,” Guy Persyn said, commenting that hygiene also tops the priority list. “We see this as a very important consideration for the market. Cleanability is vital and this is where we can also make a difference compared to our competitors.”

The machine’s thickness settings have been re-designed so that it can easily be set for silver, regular or deep skinning, without the need to disassemble the machine to make adjustments, while the infeed and outfeed transport belts, which had previously been at different levels, have been arranged in the new version so that there is no height difference, and no drop from one belt to the next.

“This had been a problem with some species,” said Johan Timmerman, manager of Cretel’s food processing equipment production. “But that problem has been eliminated now.”

Maintenance has been simplified with the arrangement of critical functions located in a single block that is not an integral part of the machine’s frame, so this can easily be switched.

“Changing knives, or changing the block is quick and easy, there’s no disassembly required,” Guy Persyn said.

“Safety is also an important factor for our customers, and a lot of them opt for the automatic skinning machine for precisely that reason. It doesn’t need anyone to get close to the machine while it’s in operation. You just place the fillets on the belt and they come off at the other end. So automation in itself is a safety feature.”

Cretel’s new generation automated skinning machine has been in use in a test version with a group of customers who put it through its paces under real working conditions, and now it’s ready for release.

The company’s developers haven’t been idle while this

machine was going through its test phase, and other skinning machines in the range are also approaching the end of their re-engineering phases, with the range simplified in the process.

“There have up to now been two small tabletop skinning machines, one for fine-skinned fish such as sole and another for coarser skinned fish such as rays. But those two are being replaced with a single machine that can be easily adjusted to do either job. So the range is being simplified, with a more versatile machine capable of doing both jobs. We’re now finalising this machine, and next will be the higher-capacity manual skinning machines.”

“Cretel machines have a reputation for being reliable and robust. There are a lot of machines with customers that have twenty years of use behind them,” Johan Timmerman said, commenting that when machines have that long a working lifetime, replacements aren’t often required.

“Sometimes we think that they are too reliable. But we aim keep that reputation. When a customer has had a machine

8 Cretel’s engineers

started from scratch to redesign the company’s automatic skinning machine

8 All of the

mechatronic activities within the ATS Group, which includes Cretel, have been consolidated into a single site in the harbour area in Ghent

that has served well for so many years, when they do need a new one, they have an easy choice ahead of them,” he said, commenting that the fish processing sector is one where producers appreciate quality and are prepared to invest in high-spec equipment that will give them years of use.

LOOKING AHEAD WITH CARBON-NEUTRAL PRODUCTION

All of the mechatronic activities within ATS, which includes Cretel, have been consolidated into a single site in the harbour area in Ghent as Cretel relocated from its former premises in Eeklo.

Guy Persyn explained that Cretel’s and ATS Group’s ultimate ownership is French energy company EDF – so there is a strong focus on green energy that runs through the group in its entirety.

“The building we are in now, where ATS has its mechatronic division, is a CO2 neutral building. All of the energy we use here is derived from solar and wind sources, plus we have intelligent energy management systems and battery storage to make energy consumption as efficient as possible,” he said.

“This is something about which some of our customers are sensitive, and which is going to become increasingly important. At the moment, it’s a consideration for 5% of our customers, but in a few years 50% of them will see this as a vital factor.”

8 Cretel’s

mechatronic division is located in a CO2-neutral building

ULTRA-MODERN PROCESSING AT MURMAN SEAFOOD

A high-capacity processing plant formally opened by Murman Seafood in Murmansk last week brings together the latest technology to process portions to the highest quality standards

Working with either fresh or frozen groundfi sh, the highly automated Murman Seafood factory can deliver both traditional block frozen as well as individually quick frozen portions.

“The factory and its staff are already showing their capabilities to deliver product quality on a par with the best on the market in Europe,” said Kristján Kristjánsson who was Valka’s leading process designer and consultant to Murman Seafood for the factory project.

As well as designing the new processing plant, Icelandic company Valka was also the main contractor, delivering trimming lines, automated water jet cutter for pin bone removal and portioning as well as various graders, packing equipment and Manufacturing Execution Software.

The Murman Seafood factory also incorporates a filleting line from Vélfag, a mince production line and IQF system from Skaginn 3X, and cooling and fluid ice systems supplied by Kapp, all from Iceland, while Scandinavian companies Cabinplant, Seagain, Hillerslev and DSI are also part of the high-tech installation.

“Starting up a new factory like this in the middle of a pandemic is truly a challenge. Several items have taken a longer time than originally expected,” Kristján Kristjánsson said.

“However, the professional management style of Murman Seafood along witjh the excellent and continuing cooperation with suppliers made it possible to start production of high quality fish products. Murman Seafood are taking a very professional approach to starting up the new factory and we can already see the determination to have the best product quality, and this focus leads to the most efficient factories. I am proud to have worked on this project with the

Photo: Valka

great people in Murman Seafood and I can already see that they will have a long-term success.”

The Governor of Murmansk Region Andrei Chibis along with representatives from the Federal Fisheries Agency, the Federation council and speaker of the regional Duma Sergei Dubovoy attended the formal commissioning ceremony. Iceland’s ambassador to Russia Árni Thór Sigurðsson made a speech – in Russian – highlighting the achievement made possible by strong co-operation between Icelandic technology providers such as Valka and forward-looking companies like Murman Seafood.

8 The automatic

waterjet from Valka plays a central role in the Murman Seafood factory setup

8 Iceland’s

ambassador to Russia Árni Thór Sigurðsson speaking to the press at the opening of the Murman Seafood factory

Photo: Valka

8 Kroma focused on ease of cleaning and fl exibility

in operation in developing its Gutmaster X Flex gutting machine for salmon and trout

“We put a lot of eff ort into developing the GUTMASTER X Flex to do a genuine Princess cut so that the fi sh are more open around the gills. This ensures much better cleaning,” said Kroma’s managing director Ivan Kristensen.

The Gutmaster X’s modes of operation are all controlled from a touchscreen, allowing the operator to switch between large trout and salmon, or between a Princess and standard cut.

“It’s an instant changeover. Everything is done in software it’s just a tap of the screen to switch over,” he said.

Every fish is measured as it reaches the machine and Gutmaster X’s tools are activated based on this measurement. It also has three suction units –one to remove the gut and two to remove the blood line to ensure good cleaning of the processed fish. The suction tools operate in forward and backward directions, providing each tool with optimum time to clean the fish.

He commented that this new machine’s basic functions are largely similar to those of older machines used in the industry, but Kroma’s approach has been to develop a machine with much greater flexibility, plus with a significantly stronger focus on hygiene than went into the machines produced a couple of decades ago.

“The technical aspects that require daily access are where they can easily be reached. The parts you need to reach once in a while are further inside. We also concentrated very much on cleanability, with everything accessible.”

He commented that there is hardly a

KROMA AIMS FOR PERFECT GUTTING

The Gutmaster X Flex developed by Danish company Kroma to handle salmon and trout has been undergoing extensive trials with a producer in Scotland, with only minor adjustments required

machine in existence that doesn’t have a few hidden corners, but making these accessible for cleaning means that this is not a problem.

“To clean the machine, you can open all the doors and everything becomes accessible, including any awkward spots. The user can also switch the machine to cleaning mode, and stand back. This cleans everything, including all the vacuum pipes.”

A quick release system on the tools facilitates ease of cleaning. The tools can easily be dismounted and washed or disinfected in a washing machine to eliminate any bacterial growth. The vacuum pipes on the machine and to the waste container can also be washed very easily.

The internal cleaning system is managed through the same touchscreen interface, which has a variety of levels of access. Operator mode is for the staff running the machine during operations, while cleaner access has a different set of options that do not interfere with the operational settings and technical mode allows access to everything.

A key feature that Kroma’s engineers have built into the Gutmaster X is an injected water spray.

“This is for difficult areas that are difficult to clean with vacuum only, so we have incorporated this to blow water into the salmon’s gut cavity to flush it out more effectively and to get the best possible cleaning,” Ivan Kristensen said.

The Gutmaster X comes with its own vacuum system, although it can also operate with a customer’s existing vacuum arrangement.

“Of course we prefer to use our own vacuum system, as we can be sure that it’s up to the job. If you have poor vacuum capacity, then you won’t get good gutting.”

Kroma’s Gutmaster X can also be fitted with Visiomaster module, which automatically checks that fish are completely clean of blood or other impurities. Visiomaster photographs every single fish as it passes through the machine and its software analyses every picture. A sorting device on the machine sorts the fish into clean fish and fish to be checked manually. All production data can also be uploaded electronically for further analysis.

RUSSIA CONFIDENT OF INCREASING FISH EXPORTS

Russia expects to increase fi sh exports in years to come, according to statements by leading industry fi gures, reports Eugene Gerden,

Photo: Rosrybolovstvo 8 Both government

and producers in Russia plan to step up seafood exports in the coming years

Under these plans, particular attention would be paid to increasing seafood exports to Latin American and EU markets.

According to German Zverev, head of the Russian Association of Fish Producers (VARPE), there are significant opportunities for Russian fish processors in Brazil, where an initial volume of 40,000 tonnes of cod and pollock fillets could be exported, with possibilities for this to be increased.

So far, Russian exports to Latin America have been modest, mainly due to logistics issues and lack of export licensing, but there is a likelihood that this situation could change in the short term.

At the end of last year VARPE asked the Russian Ministry of Foreign Affairs and veterinary watchdog Rosselkhoznadzor to accelerate talks with their Brazilian counterparts, with respect to opening Brazil’s market for Russian fish and seafood products. However, the onset of the pandemic resulted in the suspension of these plans.

According to the Federal Agency for Fisheries, efforts are being made to identify customer preferences, with fillet and minced fish seen as affordable products.

The Latin American region will be not the only global market, where the presence of Russian fish processors will be significantly strengthened, and similar plans are formulated for EU markets.

The Russian industry has hopes for increasing its supply of pollock fillets, with ambitious plans to gain close to 50% of the EU market for pollock fillets in coming years. Plans are for this to be carried out as part of the existing New Cod Industry programme in Russia, a state initiative which involves the increase of exports of seafood fish products with high added values from Russia to markets in Latin America, the US and the EU. Spain and Germany are reported to be seen as the most promising EU regions for Russian production.

In addition, Russian fish exporters are looking at increasing exports to the UK market, where they have already gained a foothold in recent years. According to an official spokesman for the Federal Agency for Fisheries, the UK has a steady demand for whitefish species.

So far, Norway has been the major rival for Russian fish producers on the UK seafood market and competition could become tougher.

In addition to western markets, Russian fishing companies and processors have no plans to lose ground on their traditional export markets, particularly those of China and South Korea. In the case of Korea, exports of chilled fresh pollock and fillet from Russia are predicted to significantly increase in the fourth quarter of this year.

At the same time, according to German Zverev, further export expansion is complicated by existing restrictions on domestic fisheries, which prevents market operators from co-ordinating their activities overseas, as this is considered by Russian regulators to constitute a cartel.

Representatives of major producers and processors have already warned the government that existing legislative restrictions may prevent implementation of ambitious state plans for the increase of fish exports from Russia of up to US$8.5 billion annually by 2025.

According to producers, in addition to easing existing legislative restrictions, there is also a need to accelerate environmental certification for Russian fisheries, including the gradual introduction of a national eco-certification.

8 German Zverev,

president of fi shing and fi sh production body VARPE

HIGHLY RESISTANT AGAINST WASTE OF TIME AND MONEY

In everything we do, we never lose sight of what is essential to you: working economically with reliable technology.

As the inventor of the elastomer-coated rotary lobe pump and fervent supporter of a sustainable circular economy, we see it as our mission at Vogelsang to help food producers and processors make the most of any natural foodstuffs. Keeping up the good reputation of the German mechanical engineering industry, we focus on supplying pumps and grinders whose functionality, quality and reliability are highly valued by our customers all over the world. The Vogelsang range covers compact rotary lobe and progressive cavity pumps, as well as macerators and block systems, that are especially designed for heavy-duty applications and the processing of highly abrasive media. Our technology ensures disruption-free operations, when turning fish waste into high-quality oils or animal feed and stands for an unusually long service life as well as low maintenance efforts. Benefit now from relentless operational readiness for your success!

VOGELSANG – LEADING IN TECHNOLOGY vogelsang.info

STARFROST’S TECHNOLOGY MAKES ARCTIC WAVES

Leroy Seafood has invested in a highly effi cient freezing system from Starfrost. The Helix spiral freezer has enabled the seafood processor to increase fi sh fillet production by more than 30%

Leroy Seafood Group is a leading seafood corporation with multiple operations along the coast of Norway as well as across Europe. The company distributes a wide range of seafood products to over 80 diff erent countries, supplying supermarkets, restaurants, canteens and hotels.

Increased demand for its seafood products led Leroy Seafood to explore new IQF technology for the seafood industry and seek to invest in freezing equipment that would enable the firm to increase production capacity at its facility at Melbu in northern Norway.

UK freezer manufacturer Starfrost had previously installed a spiral freezer for Leroy Seafood more than 18 years ago. Leroy Seafood relied on Starfrost to design and manufacture a spiral freezer once more when looking to make another investment in IQF equipment for its fish fillet processing line.

The newly installed spiral freezer is a leap forward in design, efficiency and ease of maintenance. In comparison to its replacement, the spiral freezer has a 50% larger belt area and has been designed to operate with the same fan power, the result for Leroy Seafood is a significant increase in product output with zero increase in energy use.

The custom designed spiral freezer features a Clean in Place (CIP) system that delivers automated cleaning and sanitising throughout the freezing system. Latest advancements in Starfrost’s CIP technology enables a substantial reduction of water usage while achieving the highest levels of hygiene standards.

8 Leroy Seafood were looking for both increased output and

quick installation – and Starfrost delivered on both

Photo: Starfrost

“Bringing innovation to the seafood market is always a top priority at Leroy Seafood Group. When we required more capacity of our seafood products, it was a great opportunity to invest in a new freezing system that featured the latest in IQF technology, bringing benefits to both our business and our customers. We trust Starfrost as experts in the field of freezing and were keen to work with the team again to support our latest project,” said Ronny Holen, engineering manager at Leroy Seafood, discussing the expansion project and what difference the Starfrost spiral freezer has made to production.

“We required a spiral freezer to increase output of our frozen fish fillets, we also had a real need for a quick installation to ensure we were were ready to begin production in time for the season. Starfrost delivered on each one of our requirements and we are extremely satisfied with the performance of the spiral freezer which has streamlined processes at our facility.”

Starfrost manufactured and installed the spiral freezer for Leroy Seafood which has been designed to freeze 1100kg per hour of vacuum-packed fish fillets. The spiral freezing system features innovative IQF airflow technology, which delivers consistent freeze to the seafood products, providing Leroy Seafood Group with optimum product quality and maximum freezer performance.

“Starfrost exceeded all expectations and we were impressed with the service delivered to us and commitment to the project. Starfrost engineers ensured production was ready within a very strict and short timeframe, while delivering exceptional standards of health and safety throughout the installation,” Ronny Holen said.

“Our newly installed spiral freezer is fully automated and operates continuously, this has allowed a reduction in production hours and labour while delivering a much greater production capacity of more than 30% of our seafood products.”

Photo: Starfrost 8 Looking to invest

in IQF capacity for its fi llet production, Leroy Seafood went to Starfrost for its spiral freezer

Demand for high-capacity plate freezers has grown considerably in recent years, despite the advantages in versatility, continuous operation, efficiency and security of having production at certain level split between more units.

In response to this growing demand, Tucal has recently developed its twin vertical plate freezer, a model which lets the customer reach at least 25% more capacity – or more, depending on the precise specifications – with the same robustness and also the same guarantee in operation and efficiency as the standard model.

“The twin vertical plate freezer is specially designed to have a very good, even refrigerant distribution through all the plates, as well as a reliable and safe hydraulic operation,” Tucal’ said.

Tucal has been manufacturing plate freezers since 1989 specialises in this type of equipment, but also includes other refrigeration technologies within its range of products.

“During 2020, we have also developed an eco-friendly ice machine, prepared to work with secondary refrigerants, which has not only the advantages of being an environmentally responsible solution, but also brings more security and the ease of

EXTRA CAPACITY WITH TWIN VERTICAL PLATE FREEZER

connection to centralised installations, also with natural refrigerants,” Tucal’s spokesperson added.

8 One of the high-capacity Tucal vertical plate

freezers recently delivered to a refrigeration installer in Thailand

AUSSIE AI APP PUTS SRI LANKAN TUNA UNDER MICROSCOPE

An Australian startup has landed funding and a major partner to test its AI assessment app on tuna for a Sri Lankan supermarket chain

Created in Adelaide, South Australia, the GoMicro AI microscope has previously been used in a kit to diagnose leishmaniasis in war-torn nations, in schools as a teaching tool and on farms to identify pests.

It is now being tested to grade tuna for consumption in Sri Lanka.

The GoMicro technology combines a mobile phone microscope attachment with an artificial intelligence suite that is able to recognised patterns and objects with a fraction of the number of photos usually required.

GoMicro CEO and founder Sivam Krish said that their AI microscopy tool had impressed an investor in Sri Lanka because it had the ability to grade seafood, such as tuna, with a database of hundreds of photos instead of tens of thousands.

“We now have an investment from a star investor Jeevan Gnanam in SriLanka so we formed a fully owned subsidiary there to do our software development,” he said.

Gnanam introduced GoMicro to John Keells Holdings PLC, the largest conglomerate in Sri Lanka and the owner of supermarket chains.

“Their supermarket chain has an extraordinary commitment to deliver fresh food. They procure directly from farmers through five collection centres and put it in shops with 24 hours,” Sivam Krish said.

“We actually talked to them to help them assess vegetable quality, but tuna assessment was a bigger challenge.

“While it is easy to differentiate really good tuna from really bad tuna, it is difficult to differentiate good tuna from not too good tuna. It’s a twelve-year apprenticeship to train a tuna expert, so this is a problem in the edge of human assessment.”

GoMicro solves this problem by allowing warehouse staff to simply use their phones to take a photo of the tuna and the AI-supported app then quickly determines a grade so they can label it and send it to the appropriate store.

“We at Keells, believe in going the extra mile for customers

Photo: Gomicro

particularly in delivering the right quality and freshness. The partnership to beta test this innovative testing method has helped us deliver this and shows how technology can bring solutions to deliver business value that can be translated to customer,” said Mifrah Ismail, VP and head of fresh food at John Keells Group.

The GoMicro technology is able to develop this grading database quickly because the Adelaide-based company, which was spun out of the New Venture Institute at Flinders University, has solved the problem of bad lighting that often hinders photo databases by optically engineering the lens and building a diffuser into the tech.

“It is not all about magnification, it is about the quality of the images,” Sivam Krish said.

GoMicro uses advanced manufacturing technologies to manufacture the microscopes and the Tensorflow AI-engine developed by Google to make predictions.

“The GoMicro platform is an exciting example of the successful integration of key technologies – mobile, microscopy, machine learning and interpretive data analyses – to deliver next generation agtech solutions aimed at improving Australian agriculture’s production systems, biosecurity vigilance and protection,” said Professor Rob Lewis, former CEO of the South Australian Research and Development Institute (SARDI).

“The platform is also an excellent teaching aid aimed at Australia’s future researchers, farmers and those wishing to find out more about the natural environment.”

The technology is being tested at Colombo supermarkets before a planned roll out to the chain’s hundred stores around Sri Lanka.

According to Sivam Krish, the AI system could easily be adapted to other seafood as well as fruit and vegetables and their business plan was to sell subscriptions to the system.

“We offer 10,000 clicks a month for USD $100, and the device comes free with the subscription,” he said.

8 Gomicro’s

technology is being tested at Colombo supermarkets before a planned roll out to the John Keells Group chain’s hundred stores around Sri Lanka

WISE ADAPTS TO CHANGING BUSINESS LANDSCAPE

“It’s business as usual – but not as usual,” said Jón Heiðar Pálsson, who heads sales and marketing at Icelandic company Wise Solutions, which has adapted rapidly to a very new working environment

“Many elements in our everyday lives have changed due to the global Covid-19 crisis. Our sales and marketing activities at Wise Solutions are no exception, although developments have not been in quite the direction we expected. We have rarely been so busy here in sales and marketing,” he said.

“Projects are piling up and the company is expanding, with new staff members joining the Wise team and contributing to the growth of the company. A big part of this expansion is thanks to the way we have been able to develop, adapt to change and evolve during the current pandemic.”

Wise CEO Jóhannes Helgi Guðjónsson commented that a key part of meeting customers, the usual conferences, conventions and other meetings, have all been cancelled this year – including the Icelandic Fisheries Exhibition, where Wise is a longstanding participant.

“The annual events such as the seafood exhibitions in Brussels, Boston and the Iceland Fisheries Exhibition are occasions that we look forward to every year,” he said.

“We would normally be able to meet our customers and partners at these events as well as connect with potential new clients. In the light of recent circumstances, some adaptation or change was needed.”

Many of the systems that Wise provides are central to the workflows of seafood production, dispatch and sales around the world, and the company’s customer base continues to expand around the world.

“The solutions that Wise has to offer provide a powerful dashboard overview for administration – a key component for successful management. Power BI, Wise Analyzer, Cubes and SharePoint are tools that will help you with daily operation and analysis,” Jón Heiðar Pálsson said.

“It is important to make use of available software systems and realise their full potential to optimise workflows and realtime operating status reports. Current digital developments bring endless possibilities while paperless accounting further emphasises environmental awareness and a positive future direction in business development. Automation and real-time registrations along with detailed knowledge of your status on debts, loans and inventories can play a major role in effective corporate operations, and can indeed prove vital during times of restraint.”

He commented that it has never been more important to be able to utilise technology.

“There are significant possibilities that Microsoft Dynamics 365 has to offer regarding communication channels, data sharing and central transmission and submission of information. SharePoint, OneDrive, Teams, Dynamics 365 and CRM systems are just some of the tools that have made it possible for us to take excellent care of our customers during these difficult times. Microsoft offers a solution for almost every problem. We at Wise Solutions have made use of these fantastic tools, and we consider ourselves to be fortunate in flourishing during this pandemic. However, we know for a fact that a great deal of hard work and diligence from our employees also underlies this success.”

He added that while Wise has been busy this year, despite the pandemic, it hasn’t all been plain sailing. Staff have had to adapt quickly to a new regime with teams split and separated to prevent infection, and longer hours working remotely instead of on site. As a software provider, Wise has been well placed to quickly develop the systems and procedures to make this possible, and to maintain its close links with customers around the world. rld.

“There are lessons to be learned e learned in all of this. We all have the ave the capability to constantly improve mprove ourselves and our way of living,” living,” Jón Heiðar Pálsson said.

“In future, there will be less be less work-related travel, while the le the number of face-to-face meetings eetings will decrease as we make use of e use of available tools and systems. And if ms. And if we look on the bright side, these side, these changes will also have a positive a positive effect on our carbon footprint.” rint.”

8 Being quick to

adapt has helped Wise Solutions through a challenging year

8 “In the light of “In the