A hub for digital and precision agriculture has been established within the Iowa State University Research Park.

Called the Alliant Energy Agriculture Innovation Lab, the facility will provide more than 85,000 square feet for ISU’s College of Agriculture and Life Sciences Digital Ag Innovation team, as well as agriculture-based business tenants who can all access technology, research and development, plus collaborate with each other regarding innovation opportunities primarily focused on digital and precision agriculture.

Construction should begin this summer and be completed by the fall of 2024.

The facility will pair collaborative office and agricultural workshop space while more than 70 percent of the building will feature high bay and lab space. The ISU digital and precision agriculture program will use the new space to grow and hopefully become a world leader in ag tech innovation, leaders note.

It also will include an atrium and shared conferencing spaces to encourage teamwork between stakeholders.

The research team, led by Iowa State professor Matt Darr, is responsible for more than 50 percent of industry research at Iowa State. The team boasts more than 70 patents and distinct tech transfer outcomes, as well as 32 products sold globally that impact agriculture daily.

Alison Doyle, associate director of the Agriculture Innovation Lab, said the location of the Agriculture Innovation Lab allows for immediate access to production farm ground. The lab will allow for advancements in agriculture across many levels.

“Our researchers and students and

industry partners will be able to work on a machine and then take it out into the field and test it, then come back to the high bay/shop space and iterate and make changes immediately based on what they are learning in the field,” Doyle said. “Iowa State’s Digital Ag Innovation team has outgrown their current space and the team has additional demand from corporate partners at Iowa-based ag companies to continue to serve more companies.

“ISU Research Park also is near capacity and needed additional tenant space, and in recent years ISU Research

Park has experienced an increased need for collaboration and high bay spaces.”

Iowa State’s corporate partners also are interested in the space to bring students and industry together to showcase innovations and keep young talent in the state.

“Our employers that are working with this team are not only getting their research and development needs met, they are actively recruiting highly trained technical talent right into their companies,” Doyle said. “Discussions are already underway with multiple Iowa State colleges, student groups and

external partners to bring a wide variety of events and opportunities for students, thought leaders and innovators to come together in the space.”

The ISU Research Park also features the John Deere Research and Development Facility, AgLeader, Sabanton, Mach and others. Nick Peterson, strategic partnerships manager for Alliant Energy, said that Alliant Energy became a tenant in the park in 2019 and saw great value in what the research park could offer the university and the business community.

“We’re always trying to figure out how best to serve our customers and our communities to increase economic and community development,” Peterson said. “We saw a gap in ag technology and no place for a centralized hub for the ag tech community. There are lots of great startups in the ag tech sector across the state and Marr Darr’s group is doing phenomenal work.

“We saw an opportunity to become the connective tissue that brings it all together in the state of Iowa.”

Five years from now, Peterson foresees the Agriculture Innovation Lab functioning as the gateway into a larger project at the research park that’s next to the research farm.

“There’ll be a corridor of research farms to the west of this project and to the south. We see the

Ag Innovation Lab as being the starting point, the front door so to speak, to the ag innovation that’s happening here and will continue to happen,” Peterson said. “ We want to be the accelerator that shows this is where it happens. We’re bringing in not just the large John Deere and Monsanto companies, but also smaller companies who are innovating in the ag space.”

See LAB, Page 17C

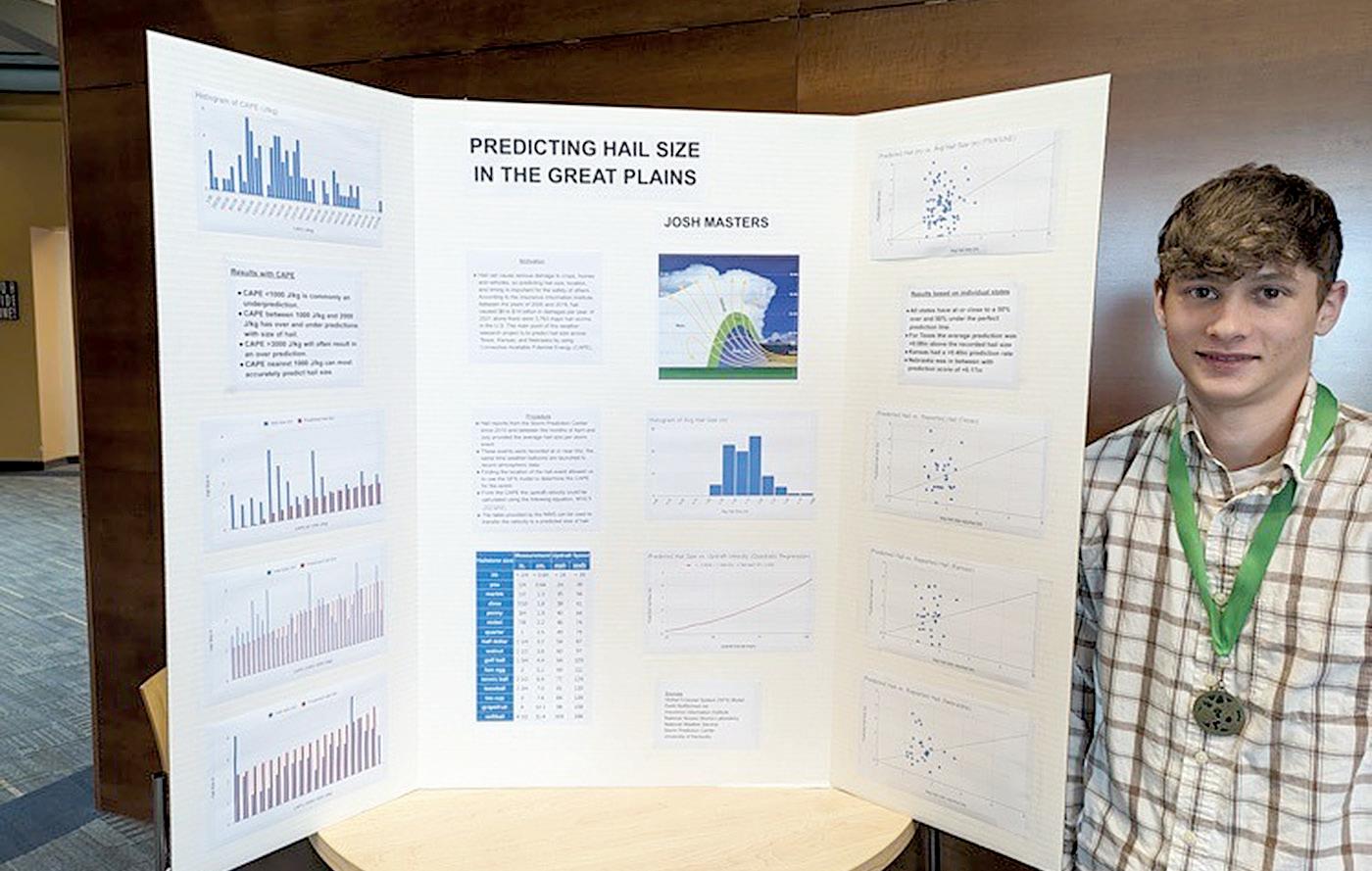

KIRON — Josh Masters, having grown up on a Kiron-area farm, has seen his fair share of weather events. His uncle farms the land, and Masters has witnessed how rain, drought, unexpected frost, and other elements have affected crops.

But it wasn’t until he took a meteorology class that he put much deeper thought into what manifests weather. Masters, 18, is a senior at Odebolt Arthur Battle Creek Ida Grove High School, and you could say he’s become quite the “master” at using a specific predictor of hail size.

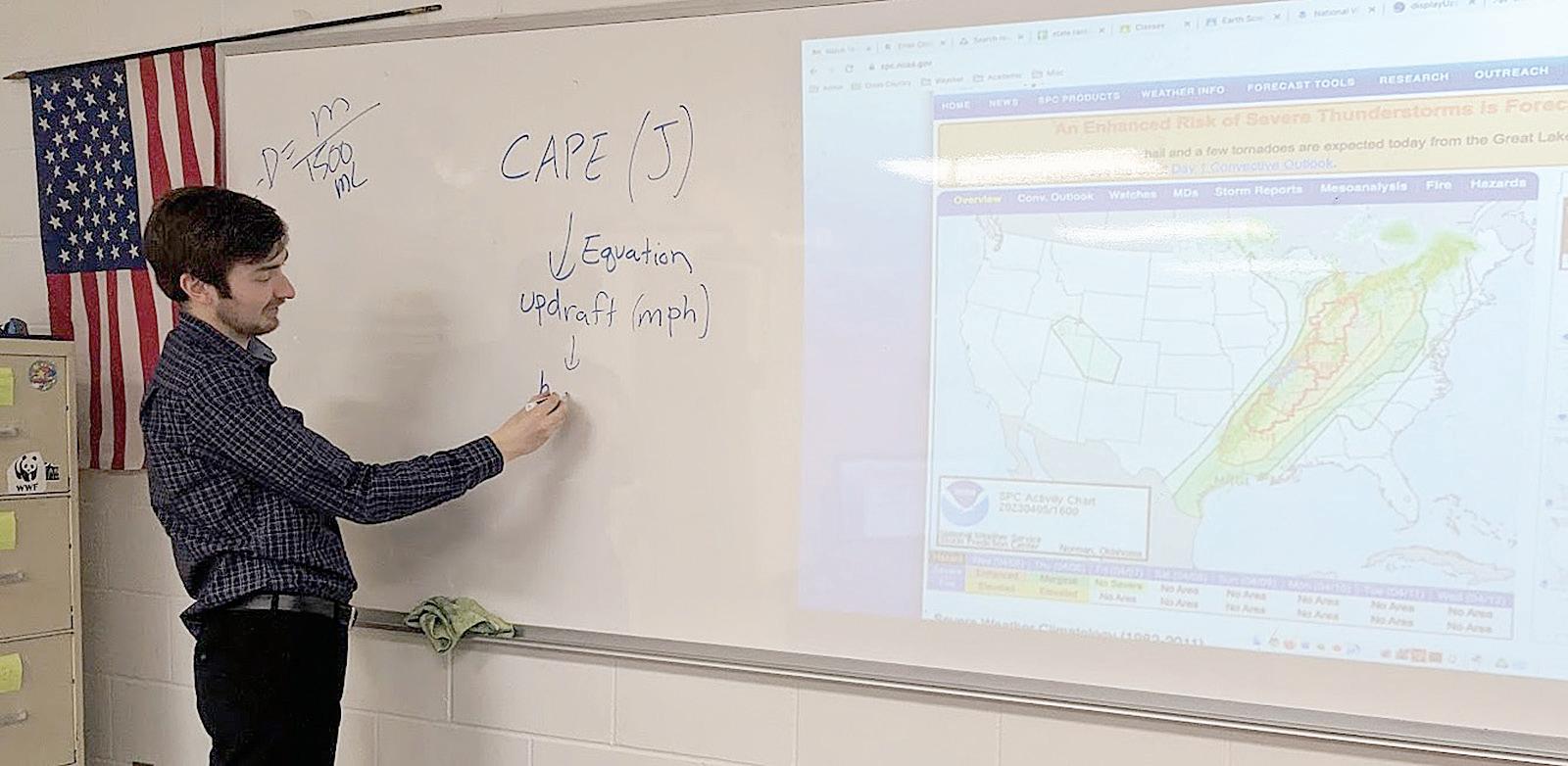

Masters, the son of Darren and Rachel Masters, enjoyed taking Caleb Wood’s course on meteorology so much that he decided to continue learning about it through an independent study. “Mr. Wood’s course was a great introduction to studying weather,” said Masters. “I was just looking to get beyond the basics.”

Since there wasn’t a secondary course in meteorology, Wood offered to teach material beyond introduction to Masters with credit toward graduation.

“When you have a student like Josh who wants more knowledge on a topic, it’s not only rare for that person to express the desire for more information, but to follow through with an independent study,” said Wood. “When I learned there was a Western Iowa Science and Engineering Fair (WISEF), it was an opportunity for Josh to expand his knowledge of the science of meteorology and, at the same time, show what he was learning to others.”

Since Masters began his independent study in January, he had less time to

JOSH MASTERS presented his experiment, “Predicting Hail Size in the Great Plains,” to judges at the Biosciences Building on the Iowa Central Community College campus in Fort Dodge on March 25. For his efforts, he earned three awards: the National Aeronautics and Space Administration (NASA) Earth System Science Project Award, National Oceanic and Atmospheric Administration (NOAA) Taking the Pulse of the Planet Award, and the United States Army Certificate of Achievement.

prepare than most students, so he needed to pick a topic and act on it quickly. “I chose hail as the weather event, because it’s devastating in so many ways the larger it gets,” said Masters. “There’s damage to personal property, but it also greatly impacts farmers and their livelihood, and it affects programs like crop insurance.

“I was specifically interested in knowing if you could predict hail size if you knew updraft wind speeds.”

The WISEF presentation date was March 25, so Wood and Masters needed to collect data, process it, and come to some conclusions in about two months.

The title of Masters’ research project became “Predicting Hail Size in the Great Plains.”

“Data was collected from the Storm Prediction Center (SPC) of Oklahoma City — time of storms, locations, hail size, wind speed and other factors —

and, after plugging that information into a spreadsheet, we found the top three states for getting the most hail were Texas, Kansas, and Nebraska,” said Masters. “All of these states are within the Great Plains Region, and we collected data by each state’s counties.”

Woods taught Masters to use Convective Available Potential Energy (CAPE) — how much energy is in a storm — based off data collected from weather balloons.

“If you know the energy in a storm, you can use an equation to find out how big the hail is going to be,” said Wood. “Using CAPE and the equation, you can find the updraft velocity. The faster the winds are that go up, the bigger the hail since it’s up there longer and more water sticks to it. The moisture builds the hail before the wind isn’t great enough to keep it up, thus falling.”

Based on Masters’ calculations, a 24 mph updraft would cause pea-size or quarter-inch hail; if the wind updrafts are 100 mph, there could be soft-ball sized hail.

In the end, Masters compared what actually happened in Storm Prediction Center reports to what the equation suggested would happen with the hail size.

“We found that using updraft wind by itself was not always accurate,” said Masters. “There are more variables with hail events that affect hail size. We isolated one factor — how much CAPE or energy is in the storm — which was a valuable experiment. However, when you add other factors like humidity and temperature, the hail size become affected by those factors as well.”

See MASTERS, Page 17C

OABCIG student takes learning to next level, predicts hail size

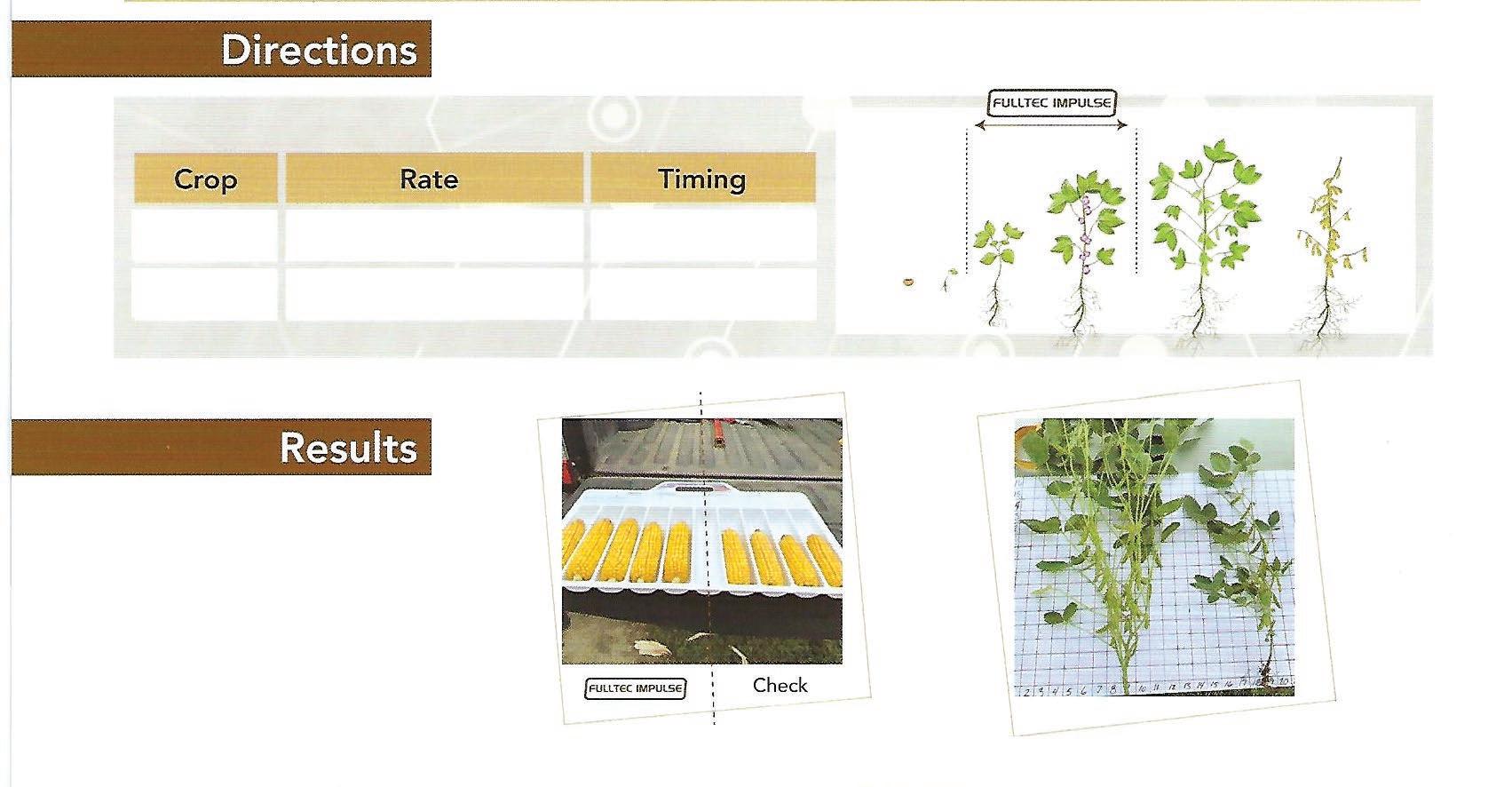

1. Bio-Empruv- Broad Spectrum Disease Prevention BioEmpruv in Corn is a biological fermentation extract. It contains enzymes, vitamins, minerals, natural growth regulators, antioxidants and amino acids to boost plant health and yields. Bio-Empruv- contains natural and biodegradable ingredients that are Safe with No Chemicals or Residues Application V-5 - Pretassel, 32 oz per acre add albion Micronutrients Zn, Mg, & Cu with Bio-Empruv

2. Spraytec- Impulse Corn has the best combination of 4 different products that will be responsible for keeping the maximum yield potential with your crop. It is the highest concentration of available plant nutrients that promote plant vigor and lower major stress away from your corn.

Main Benefits:

Nutrient Availability The EDTA present in the Impulse formulation gives the nutrient an organic coating, making their absorption by leaves easy.

Yield Saver Fulltec Impulse aids in the prevention of losing yield potential by lack of nutrition or stress to the plant as well store nutrition in plants.

All in One Fulltec Impulse provides more benefits in just one box than a pile of products do separately Application V-5 to Pretassel 1 kit box sprays 100 acrest

Contact: Marv Mortensen: 515-370-3381 • marv@highyieldbeans.com Bob Streit: 515-709-0143 • bastreit@gmail.com

By KRISTIN DANLEY-GREINER

Farm News writer

By KRISTIN DANLEY-GREINER

Farm News writer

In 1995, a group of women launched Mariposa Farms to fill a void in the locally grown fresh herbs industry. The family-owned business early on adopted specialized technology that produces a superior product used by home cooks and culinary experts that’s available yearround, even in the freezing cold winters of Iowa.

Located near Grinnell, Mariposa Farmers’ primary owner happens to be Denise Conkling, who explained that Mariposa Farms’ fresh herbs are grown in a hydroponic greenhouse.

Plants are rooted in benches in a medium called perlite, which is a naturally occurring mineral existing as a type of volcanic glass. The perlite used in gardening is produced in a plant where natural perlite is heated to 1,600 degrees Fahrenheit in industrial ovens. It acts like popcorn and pops, expanding up to 40 times its original size yet becoming lightweight and porous.

Three large holding tanks house nutrient-enriched water that’s pumped through underground pipes and into herb benches. The plants are fed the nutrientenriched water that runs down the slightly inclined benches and absorb the water through the plants’ root system.

Conkling noted that this allows for better nutrient control, a less messy area using perlite versus soil.

“The water drips at a set amount of gallons per hour, seeps into the bottom of the trays and is wicked up by the roots of the herbs as it flows down the inclined bench,” Conkling noted. “At the end of the benches, the water is collected into return pipes and recycled into the holding tanks to repeat the cycle.”

Growing the herbs hydroponically in a greenhouse also enables Mariposa Farms to create an environment that allows for the production of plants 365 days a year.

“A network of heaters and fans/vents allow the greenhouse to be temperaturecontrolled enough to grow plants yearround. The greenhouse structure itself is made of a double layer of plastic greenhouse roofing material. In between the two layers, air is blown and inflates

the roofs and walls to better insulate the greenhouse,” Conkling said.

Mariposa Farms raises approximately one acre of herbs in the greenhouse, which also has a cooler and storage areas for the final product. The best-selling herbs are basil and mint, while bulk sales of sage and thyme top the charts. Other popular herbs grown there include baby dill, basil, chives, cilantro, mint, oregano and rosemary.

According to its website, Mariposa Farms also offers arugula, bay leaves, edible flowers, chervil, marjoram, lemongrass, lavender, Italian parsley, opal, savory, sorrel, tarragon and watercress.

Also sold by Mariposa Farms are a variety of dehydrated chile peppers like habanero, pequin, serrano and chile ancho, along with dried mushrooms such as oyster, lobster, morel, porcini, portabella, wood ear and a stir fry blend. There are also sun-dried tomatoes. Approximately 30 employees work at Mariposa Farms, plucking, picking and packaging herbs every day. They started out packing approximately 1,000 0.75-ounce packages daily and now pack upward of 15,000 packages per day.

“During our busy season, we get just below 30,000 packages a day,” Conkling said. “There are a few other companies selling fresh herbs in the Midwest. We set ourselves apart with our high rates of satisfaction and herb quality. We pride ourselves on being a local, family-owned company.”

Mariposa Farms fresh herbs can be found at numerous retailers, including Hy-Vee, Walmart, Aldi, Fareway and different co-ops. They also provide products to food service companies like Sysco and US Foods.

“I always tell new employees that my measure for herb safety and quality is that when I feel comfortable taking it home and serving it to my own family, that is when I feel satisfied sending it out to our customers,” Conkling said. “We have also been in the business for almost 30 years now, so we have a lot of trust and a good reputation within the community and with our long-time customers.”

AT MARIPOSA FARMS, approximately 30 employees work to pluck, pick and package herbs every day. They started out packing approximately 1,000 0.75-ounce packages daily and now pack upward of 15,000 packages per day.

Burt 888-920-3555

Armstrong 888-802-3897

Bancroft/ South Burt 800-298-4196

Fenton 800-721-2251

Buffalo Center 800-852-4718

North Burt Ag 800-292-0240

Blue Earth 507-464-3333

Cylinder 800-414-3335

Halfa

712-866-2671

Lakota 877-886-2461

North Burt Grain 800-373-8509

Maple Hill 800-776-8571

Ledyard 800-646-2135

Lone Rock 800-298-4246

Ringsted 800-469-0581

Swea City 800-574-2178

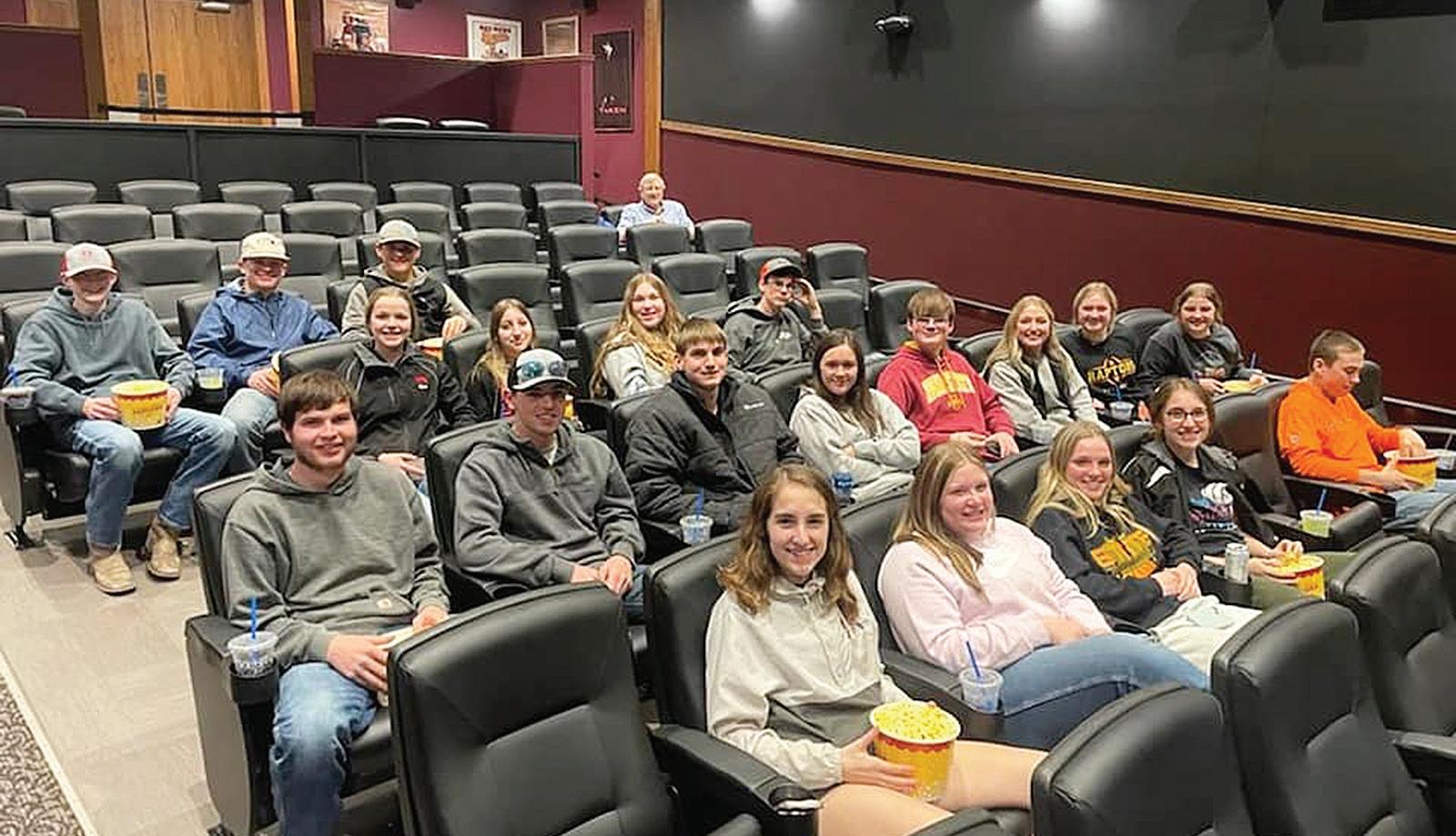

IDA GROVE — Farm Bureau of Ida Grove sponsored a free showing of the movie “Silo” for Ridgeview and Odebolt Arthur Battle Creek Ida Grove (OABCIG) Future Farmers of America (FFA) students on March 20 at the downtown King Theatre.

“Silo,” which was released in 2019, details the day in the life of a farm family and rural community as they react to a grain entrapment incident, a resulting death, and efforts to save a young man who was also engulfed. This is the second showing of the movie at the theater in three years, this one sponsored by Ida Grove’s Farm Bureau, and a major audience being FFA students.

“It seems like every year you hear about a farmer or one of his workers being caught in a grain bin,” said Roger Bumann, secretary of Ida County’s Farm Bureau. “Just a few days before showing this film, there was a death in eastern Iowa. Locally, we hear stories about too many close calls. Even if the grain isn’t deep, it doesn’t take much to create pressure to harm a person. Farm Bureau is especially pleased to offer this opportunity to the FFA students of Ridgeview and OABCIG high schools.”

Twenty-five students from the two high schools attended under the direction of Ridgeview’s Tyler Wingert and OABCIG’s Jerry Chizek.

"The movie showed the dangers and necessary precautions when entering a grain bin,” said Chizek. “It should be shown to youth who live on a farm, work for a farmer, or visit family and friends on the farm. This movie could easily be incorporated in a high school agricultural education curriculum. This type of farm accident is preventable."

Brian Lundell, a Kiron Pork Producer and crop farmer, provided additional information after the showing.

“Back in the day, we never carried grain rescue tools. Why is it a big deal now and not before? Well, we have so many more grain bins now and more so on farms, not just in- town storage sites,” said Lundell. “Sure, there were tragedies before, but now there are so many more bins, so many more opportunities for death and injury. There are bigger bins today that hold more grain and require more management. There is also a smaller window for harvesting than there was in previous years, so shortcuts get taken to keep moving. Sometimes,

harvesting occurs when it’s not perfectly ideal; corn gets wet and forms a crust that feels solid underfoot when it’s not.

“The truth of the matter is that farm youth is at risk. Kids feel immortal and often do risky things and, sometimes, an employer can ask them to do risky things in the name of getting work done quickly. My message to the students is if someone asks you to do anything on a farm ithout the right safety equipment, you walk away from that job. Young people, especially young farmers, want to work hard, follow direction, and display solid work ethic, but they need to know that their safety is the priority and that, in this regard, they must put themselves first.”

-Submitted photos

ABOVE: Odebolt Arthur Battle Creek Ida Grove and Ridgeview FFA students, seen here at the King Theatre in Ida Grove, were invited to a special showing of “Silo.” The showing occurred on March 20, the first day of National Ag Week and was sponsored by Ida Grove's Farm Bureau.

BELOW LEFT: “Silo” premiered in 2019 inspired by true events. The movie follows a harrowing day in an American farm town when disaster strikes with a grain entrapment accident.

BELOW RIGHT: Kiron farmer and volunteer firefighter Brian Lundell, left, speaks with Ridgeview FFA instructor Tyler Wingert, middle, and student Luke Brinkman, right, after the movie “Silo.”

Scott Van Dusen, Ida Grove’s fire chief, was also on hand to discuss rescue equipment for grain bin emergency use. “Grain creates a tremendous amount of pressure on a human being once engulfed,” said Van Dusen. “Pulling a person from a grain entrapment is nearly impossible without the appropriate rescue equipment. A man’s arms could be ripped from their sockets if enough pull was generated against the pressure of the grain.”

Van Dusen brought Ida Grove Fire Department’s rescue equipment to the King Theatre lobby.

Included in the equipment was a sectional piece-together rescue wall, an auger, and platforms for stable footing. The rescue wall shields more grain from falling in on the trapped person when the auger removes the grain that pinned the worker. Once the grain is augured away from the proximity of the person, he or she can be safely removed from the grain. The platform pieces act as a sort of snowshoe allowing a person a better chance to traverse over grain without sinking.

“We highly recommend that all rural fire departments carry this rescue equipment,” said Van Dusen, “and, most importantly, get the training to use it correctly.”

Prior to the students taking the auditorium, adults from the Ida County area also had the opportunity to watch the movie and emphasize the importance of safe grain handling in their day-to-day operations.

“Preventing a tragedy is the first job of all farmers and those who work for them,” said Bumann. “If we’ve created awareness about this important topic, prevented a tragedy — made it so a person could come home to their family safely after a hard day’s work — then we’ve done something worth doing.”

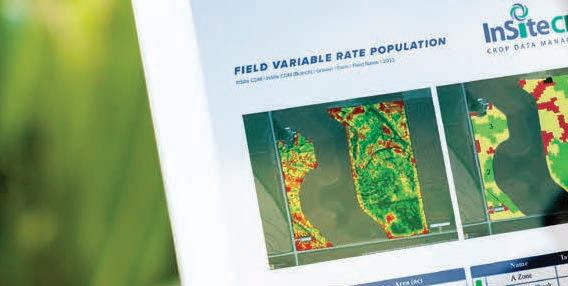

State-of-the-art technology continues to evolve each year to help farmers work more efficiently, from the field to the barn, but much of that technology requires data — and reliable, high-speed internet access.

Still, many rural areas are still struggling to connect with the outside world via the internet. These remote areas are hotspots for agriculture, however. That’s why Josh Peschel, an assistant professor in agricultural and biosystems engineering at Iowa State University, is linking agriculture and technology together in a nationwide research project funded by the National Science Foundation.

The team, led by Hongwei Zhang, a professor in electrical and computer engineering, is launching a test bed for experimentation to develop new, wireless networking tools that would serve remote areas — especially ones here in Iowa. The test bed takes place in the form of a wireless living lab across Iowa State University, the city of Ames and surrounding farms and rural areas.

With this new wireless infrastructure, the team is also launching an application with a focus on agriculture — and that’s where Peschel comes in.

“A lot of agriculture as we know it is very remote and disconnected,” Peschel said. “If we want to have better wireless connectivity for these remote outposts of agriculture, we need something as powerful as this.”

Peschel is installing cameras that are connected to the wireless test bed in pig barns and cattle pens around the area.

“When we put cameras in pig barns and cattle pens to monitor their behavior in real-time, those videos can be electronically transported back from very remote locations,” Peschel said. “Whereas now, you wouldn’t even be able to get a text message at those remote locations. But with this project, you could perhaps have streaming, high-definition video coming from those places, from the cameras.”

The cameras, intentionally linked to the team’s wireless network, wirelessly transmit information back to the team using their experimental technologies to help them better understand bandwidth requirements, minimum video quality and more.

The global COVID-19 pandemic that erupted in 2020 highlighted the importance — and lack of availability in many rural areas — of reliable, high-speed, online connectivity in some areas, as millions of people transitioned online for remote work, school, health care, government services and regular communication with family and friends.

This wasn’t news to farmers. A 2019 study conducted by the United Soybean Board (USB) found that nearly 60 percent of U.S. farmers and ranchers surveyed did

JOSH PESCHEL, an assistant professor in agricultural and biosystems engineering at Iowa State University, (above and left) is linking agriculture and technology together in a nationwide research project funded by the National Science Foundation. He and a team at ISU are developing new, wireless networking tools that would serve remote areas.

not believe they have adequate internet connectivity to run their businesses. Only 32 percent considered their office internet reliable. More than 50 percent said they wanted to incorporate more data in their operations but lacked the connectivity to do it.

A May 2021 study by BroadBand Now revealed that an estimated 42 million Americans don’t have access to wired or fixed wireless broadband, the vast majority of them in rural areas. That same year, the Greater Des Moines Partnership commissioned a study examining internet accessibility in 11 counties in central

Iowa. This study found that 40% of homes in central Iowa had download speeds of less than 25 megabits per second, below the Federal Communications Commission’s (FCC) definition of highspeed broadband. The problem is even bigger in rural communities, where connection speeds were up to three times slower than in urban areas.

There are sound financial reasons to invest in improved rural internet connectivity, according to ag industry observers.

Increased connectivity would enable technology like remote crop and livestock monitoring, drone farming and autonomous farm machinery with the potential to improve North America’s agricultural output by 8.7% and unlock $500 billion in global gross domestic product (GDP) by 2030, according to an October 2020 McKinsey report.

“There is amazing technology available to farm families and ranch families to be

Rear, lightweight disc mower SAMBA with working widths from 1,60 up to 3,20 m is designed to operate on smaller farms. Mower works well in hilly as well as swamp areas, where machines and tractors weight is of great importance.

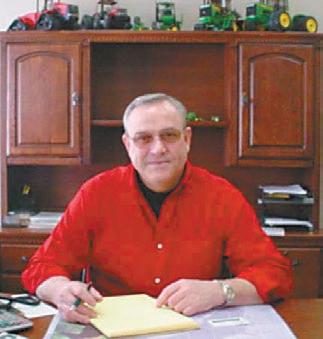

KIRON — Those folks who know Jim Lundell of Kiron know that he’s an avid collector.

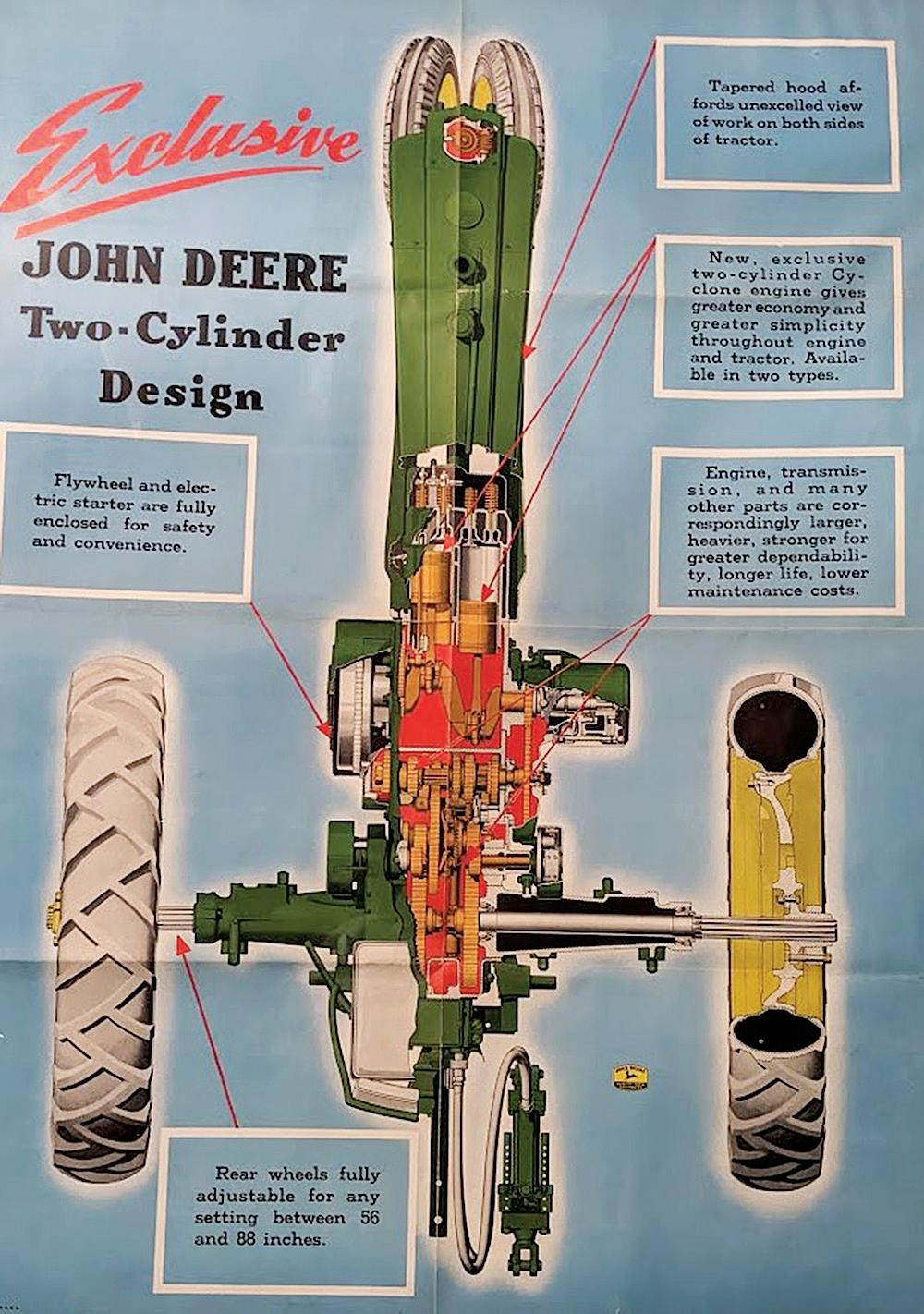

He has garages, sheds, and even a building on Kiron’s Main Street full of classic neon signs, soda machines, juke boxes, John Deere branded bicycles, farm toys, and ag-branded coffee pots. All these items represent memories to Lundell, and with each comes a story, but few items get him to talking like the tractors he’s acquired over the years.

“Since 1974, I’ve collected about 155 different tractors from Case-International Harvester, Ford,

John Deere, Allis-Chalmers, and Oliver,” said Lundell. “Now, wait a minute, I just bought a 996 International from a man in Charter Oak. Well, now that I think about it, I have 160 tractors, most from the 1940s to the 1970s.”

Chances are that by the time you are done reading this article, Lundell could have added a model or five to his fleet.

Lundell, who was born in 1944, said that he first sat in a 1950 Ford 8N tractor when he was 9 years old.

“I pulled a flare box wagon with a load of beans all by myself,” said Lundell. “I was hooked on tractors before that, though, when I was with my uncle from Wall Lake who had a 1948 John Deere B that really intrigued me.

“I’m not sure I would have picked a John Deere back then. Some of the old ones had hand clutches. If you were an octopus, it could run good, because you’d have enough arms to make it go!”

Lundell noted that Powershift transmissions were a great advancement that came about around 1965.

In 2012, Lundell refurbished the old Kollbaum Brothers Case dealership, making it a showroom for some of his CASE tractors as well as other brands. “I remember being in the store when it was active in the ’50s,” said Lundell. “The other dealership had soda for 10 cents, and I could get one at Kollbaum’s for a nickel!”

In the showroom, there is a 1960 Farmall with a toolbox accessory mounted on the side; Lundell said the toolbox was a nice accessory, but Farmall really made it for users to stand on to fill the gas tank, which was too high to be

filled from the ground.

Lundell also has aftermarket cabs, which were popular in the ’50s, ’60s, and ’70s. “’Year Around’ was a common brand,” said Lundell. “In 1945, Burch Manufacturing of Fort Dodge made the Heat Houser, a canvas accessory for tractors that channels heat from the engine to the person operating the tractor. Of course, in the 1970s, most tractor manufacturers were making their own cab or having someone make it for them, so many of these accessories went to the wayside.”

Lundell also has John Deere Generation II tractors, specifically the 4430 and 4630, in his collection.

“One of the biggest advances in tractor mechanics was the ‘Sound-Guard Body’ which was the first successful integrated tractor cab,” said Lundell. “This made being on the tractor all day bearable

because it was so much quieter. The cab also made for a more comfortable experience. The design of the exhaust system and window made it easier to see. It was one of the first to have heating and air conditioning as standard equipment.”

The John Deere cab was such a vast improvement over the aftermarket cabs — so much quieter — that Deere offered an optional AM/FM radio and speakers since music and WHO talk shows could be heard over the engine.”

Lundell even noted changes to tires and suspensions throughout the years.

“The old tread design was 45 degree, which self-cleaned better,” said Lundell. “Then tires went to a 23-degree design, which still cleaned well but had a better ride.

JIM LUNDELL stands in front of a tractor in his collection that a family friend used to own. "A collection of anything is really about memories that matter," said Lundell. "I remember that the gentleman who owned this used to keep his cigarettes in a band-aid can and set it on the platform beneath the seat. I was fortunate enough to get my hands on the original bill of sale and canceled check for this one."

By KRISTIN DANLEY-GREINER Farm News writer

By KRISTIN DANLEY-GREINER Farm News writer

A simple field of prairie grass or corn stover can be converted into bio-oil and biochar via a process called pyrolysis that ultimately yields carbon negative fuels.

Research conducted at Iowa State University’s BioCentury Research Farm has shown that the production of biochar and bio-oil together using an economically attractive process — pyrolysis — will produce fuels that achieve net reduction of carbon dioxide from the atmosphere.

And the source of that energy lies all across the state.

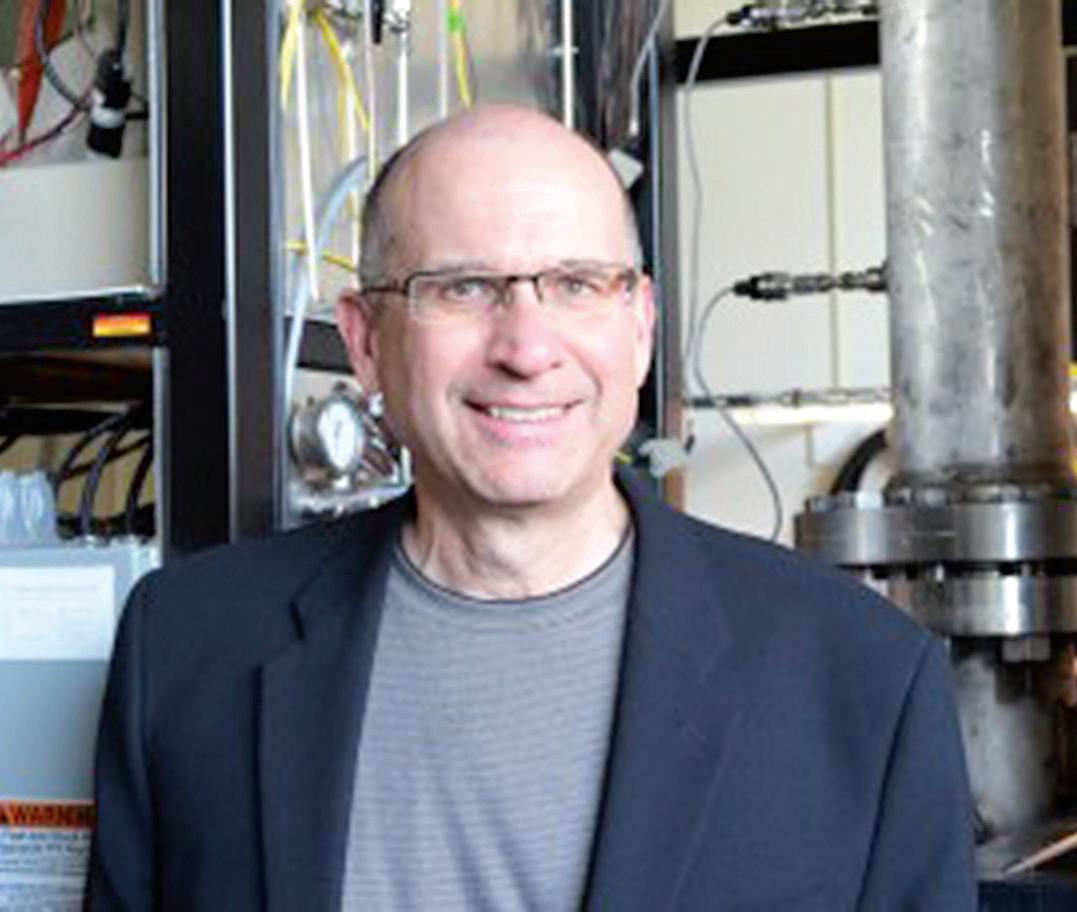

“Agriculture does not get enough attention for its potential to contribute to carbon dioxide reduction and even carbon dioxide removal from the atmosphere. Pyrolysis offers a pathway for ag-based carbon management,” explained Robert Brown, Iowa State Anson Marston Distinguished Professor in Engineering, the Gary and Donna Hoover Chair in Mechanical Engineering and co-director of Iowa State’s Bioeconomy Institute.

Pyrolysis is the thermal decomposition of biomass under oxygen-starved conditions to produce liquids (bio-oil), solids (biochar) and gas. Temperatures are comparable to a hot pizza oven, Brown said.

All types of biomass can serve as feedstock for pyrolysis, including wood, corn stover and prairie grass. It typically works best with fairly dry biomass, so manure won’t really work unless it’s been dewatered, Brown noted.

While economics have favored refining petroleum into liquid fuels, Brown said, bio-oil holds plenty of potential.

“The low carbon intensity of fuels from bio-oil makes it increasingly attractive. Biochar is a porous, nutrient-rich form of charcoal. If incorporated into soils, it has some of the same benefits as soil carbon, holding nutrients and water for crops. Biochar also can be used to clean up wastewater or run-off from farmland by virtue of its absorptivity for various contaminants,” Brown said.

During pyrolysis, biomass is heated in the absence of oxygen, yielding a carbonrich material known as biochar, which is a form of charcoal. Brown and his team have shown that biochar is an effective means of storing carbon in the soil, a practice known as sequestration, which keeps the carbon out of the atmosphere.

“AGRICULTURE DOES NOT GET ENOUGH ATTENTION for its potential to contribute to carbon dioxide reduction and even carbon dioxide removal from the atmosphere. Pyrolysis offers a pathway for ag-based carbon management,” according to Robert Brown, Iowa State Anson Marston Distinguished Professor in Engineering, the Gary and Donna Hoover Chair in Mechanical Engineering and codirector of Iowa State’s Bioeconomy Institute.

Plants draw carbon dioxide out of the atmosphere to produce biomass as part of photosynthesis.

But that carbon storage is often temporary. When plants die and decay, they release that stored carbon back into the atmosphere. The carbon removal team at the Bioeconomy Institute uses biomass from crop residues, wood and perennial grasses as stocks for pyrolysis while the plant matter is still rich in carbon. The biochar that results from the process can be added to agricultural fields, gardens or yards as a soil amendment that improves soil health and further increases carbon storage potential.

Pyrolysis also produces a thick, viscous liquid known as bio-oil, which

can be refined into renewable diesel fuel or bio-asphalt, a renewable substitute for petroleum-based asphalt.

Many producers have inquired about pyrolysis and the BioCentury Research Farm at Iowa State, especially if the university could use their corn stover or waste biomass.

Pyrolyzers, however, need to be scaled up to consume hundreds of tons of feedstock, Brown noted.

“We are working with Stine Seed Company to demonstrate ISU’s pyrolysis technology at a scale of 50 tons per day. Success at this scale will encourage commercial development and provide farmers with markets for crop residues and even purposely grown energy crops,”

Brown said.

In fact, the farm happens to be the leading integrated biomass-to-fuelsand-products production and processing facility in the nation, Brown noted. Iowa State currently has two pyrolyzers: a lab-scale unit installed on campus in the Biorenewables Research Laboratory and a larger pilot-scale unit at the BioCentury Research Farm outside Ames.

“With capabilities not available at other public institutions, the BioCentury Research Farm can initiate and conduct research and demonstration of new technologies. The BioCentury Research Farm brings together scientific expertise to accelerate innovation and production capacity associated with biobased fuels, chemicals and products,” Brown said. “Our modern facilities and equipment are available to aid research activities, including biomass feedstock production and cropping systems; harvest, storage and transportation logistics of biomass feedstocks; and biomass conversion.”

Large pilot-scale research can be carried out at the research farm and in many cases scaled to commercial production.

“We provide a venue for educating and training future scientists, producers and Extension experts and developing partnership opportunities with industry,” Brown said.

Additional research programs at the BioCentury Research Farm include plant breeding and genomics, crop selection and development, comparative cropping systems, soil conservation and nutrient management.

Iowa State’s BioCentury Research Farm has an elaborate set up that includes biomass feedstock production, harvesting, storing, transporting and biorefinery processing into one cohesive system focused on producing bio-oil and biochar.

The harvest, storage and transportation facility consists of 17,000 square feet and allows for the year-round development and testing of harvest, storage and transportation equipment. Hydraulic presses are available for biomass compaction studies. Project areas at the facility focus on developing in-field harvesting and densification methods, biomass logistics and materials handling.

Pyrolysis

Continued from Page 14C

Biomass storage research trials are conducted in controlled and realworld environments provided at the BioCentury Research Farm. Alternative storage systems are available and tested on-site. These trials help to identify the most cost-effective storage systems for different biomass crops. Bale storage trials are being conducted without protection, under tarps and in enclosed buildings.

Three hoop structures, open on the ends, are used to store bales of stover. Each hoop structure is 65-feet-wide by 30-feet-high and 115 feet long. The floors are graveled and tiled to keep the floors dry.

Biomass feedstocks are dried, ground and sized in the biomass storage and pretreatment building. Various dryers, grinders, mills and sieves are available to process biomass for biofuels projects.

The building also features a fine particle biomass preparation lab that is used for fine grinding, sieving, pelleting, milling, briquetting and particle size distribution determination.

The lab is designed to accommodate 12 independent equipment stations.

The BioCentury Research Farm is

one of the few facilities in the nation capable of grinding and sizing large quantities of research quality biomass feedstocks while still accommodating small-quantity projects.

The biomass storage and pretreatment building consists of 9,000 square feet and has equipment available to handle, dry and grind large quantities (up to two tons per day) of biomass. Dry storage of 20 tons of different types of biomass is possible.

This building has various dryers, grinders, mills and sieves to process biomass feedstocks. The biomass grinder is located under an adjacent open-sided, covered-roof structure to minimize risk of dust explosion.

A drying and grinding control room provides workers with a climatecontrolled, dust-free environment to oversee the drying and grinding of various biomass feedstocks. It features a computer interface that can operate the entire system of conveyor belts, surge hoppers, hammer mills and a dryer. Large windows and a camera monitoring setup allow workers to watch the system while it is running.

The 23,000-square-foot biomass

processing facility is a state-of-the art research and demonstration processing facility. The facility is designed for thermochemical and biochemical processing conversions in separate 2,700-square-foot processing trains. Equipment can be reconfigured as optimal processes become defined.

The biomass processing facility, with the thermochemical and biochemical trains in close proximity, allows for integrated systems that use both technologies in a hybrid strategy.

The facility includes the thermochemical processing train, the biochemical processing train, research labs and meeting and office areas.

Also at the BioCentury Research Farm can be found the bio-polymer processing facility that converts vegetable oils into thermosets, which are soft rubbery polymers that can be melted and reformed over and over again. These biopolymers are being evaluated for use in several different industries, including asphalt paving, adhesives, coatings and packing materials.

At full production, the facility produces approximately 1,000 pounds of biopolymers per day.

“The low carbon intensity of fuels from bio-oil makes it increasingly attractive. Biochar is a porous, nutrient-rich form of charcoal. If incorporated into soils, it has some of the same benefits as soil carbon, holding nutrients and water for crops. Biochar also can be used to clean up wastewater or run-off from farmland.”

ROBERT BROWN Iowa State Anson Marston Distinguished Professor in Engineering

ROBERT BROWN Iowa State Anson Marston Distinguished Professor in Engineering

Continued from Page 3C

Peterson grew up in Madrid, and watching the growth firsthand in the ag tech sector for the past 10 years has fueled his excitement for the new lab.

“This really gives Iowa State a flagship facility to highlight ag tech. I’m partial to Iowa State, and Alliant Energy is so excited to be the fuel for this fire and watch the opportunities unfold,

to watch more companies be drawn here, new students learning here and eventually working here after graduation and making Iowa State, Ames and the surrounding area a vibrant place for ag tech innovation,” Peterson said. “At the end of the day, we’re thinking beyond and being bold.”

-Submitted illustration

THE ALLIANT ENERGY AGRICULTURE INNOVATION LAB will provide more than 85,000 square feet for ISU’s College of Agriculture and Life Sciences Digital Ag Innovation team. The facility will pair collaborative office and agricultural workshop space, while more than 70 percent of the building will feature high bay and lab space. The ISU digital and precision agriculture program will use the new space to grow and hopefully become a world leader in ag tech innovation, leaders note.

Masters

Continued from Page 5C

Masters presented his experiment, process, and findings to four WISEF judges at the Biosciences Building on the Iowa Central Community College campus in Fort Dodge on March 25. His results, as well as his enthusiasm, earned three awards: the National Aeronautics and Space Administration (NASA) Earth System Science Project Award, National Oceanic and Atmospheric Administration (NOAA) Taking-the-Pulse-of-the-Planet

Award, and the United States Army Certificate of Achievement. After Masters graduates from OABCIG, he plans to attend Iowa Lakes Community College to study aviation. “This kind of research applies to my desire to fly helicopters,” said Masters. “I’m excited to help others through flying, either for emergency medical services or agricultural use. Studying weather events will continue to be a part of my life.”

more efficient and extremely precise with their inputs, but that takes data — and not just shoddy internet access,” said Sam Kieffer, vice president of public policy for the American Farm Bureau Federation. “It takes reliable and highspeed internet access to utilize these tools, to store the data and to leverage the information that’s available to help make informed decisions.”

Some steps are being taken to improve internet connectivity in rural Iowa, although the process can be slow and limited to specific areas. When USDA Rural Development invested nearly $730 million in obligated funding in Iowa for fiscal year 2022, more than $34.5 million of that went to telecommunications programs. This money provides funds for the costs of construction, improvement or acquisition of facilities and equipment needed to provide broadband service and telephone service in eligible rural areas.

Complete Communication Services Corporation in Stratford, for example, is receiving a $3,797,296 loan to bring high-speed internet to 2,827 people, 77 businesses, five farms and three educational facilities in Hamilton County, according to USDA Rural Development.

“There is amazing technology available to farm families and ranch families to be more efficient and extremely precise with their inputs, but that takes data — and not just shoddy internet access.”

SAM KIEFFER Vice president of public policy, American Farm Bureau Federationstreaming, high-definition video, even in remote areas, could offer farmers a valuable tool to work more efficiently and effectively.

-Farm News photo by Doug Clough CALEB WOOD INSTRUCTS JOSH MASTERS for an independent study of meteorology at Odebolt Arthur Battle Creek Ida Grove (OABCIG) High School in Ida Grove. “When you have a student like Josh who wants more knowledge on a topic, it’s not only rare for that person to express the desire for more information, but to follow through with an independent study,” said Wood.

While this is useful for people in a specific area, more needs to be done to bridge the digital divide across rural Iowa. That’s why ISU is focusing on new wireless infrastructure and is launching an application with a focus on agriculture.

The potential is exciting, according to project leaders. The ability to utilize cameras in livestock barns and access

“This is what Iowa State University’s land-grant mission is all about — bringing to bear our research and innovation to meet the needs of Iowans,” said Iowa State University President Wendy Wintersteen. “Rural broadband has become an essential need. Iowa State is very excited to work with our partners to develop affordable wireless technologies that will help connect and create opportunities for families, schools, farms and communities across the state.”

“The Roll-o-matic front end was first introduced on the John Deere B around 1950 on their narrow front tractors. It’s a gearbox that allowed one of the front tires to go up while the other stayed on the ground; before this, when one tire hit a rock, both tires came off the ground. The Roll-o-matic provided a better ride.” Lundell said that, during his lifetime, the best advancements were made in the quieting of the tractor engine noise, more gears in the transmission, and tractor size overall got bigger. His son Brad said that creature comforts — rather than mechanical advances of his father’s era —have been the highlight of his farming career.

“I had all the improvements that dad experienced when I began farming,” Brad Lundell said. "Of course, the horsepower has increased, and gear improvements have made it so most anyone can drive a tractor, but operator comfort makes the news. In 1995, the ‘buddy seat’ was introduced. During dad’s time, you sat on the fender if you wanted to ride along. If you think about all the big improvements made in the first 75 years of tractor design, it leaves a person to wonder what the next 75 years will look like. Have we plateaued on real improvements? Time will tell.”

ABOVE: Brian Lundell, one of Jim's two sons, stands next to their 2010 model year John Deere 8320R which is hooked up to an anhydrous applicator. "Tractors have advanced to the point where it's the details that add up to big improvements," said Lundell. "The front duals, the independent link suspension (ILS), the spacious and quiet cab, and GPS mapping all add up to a better tractor. The improved lighting makes for better visibility too."

LEFT: Jim Lundell and his son Brad have both become familiar with tractor improvements through their generations. “I had all the improvements that dad experienced when I began farming,” Brad Lundell said. "Of course, the horsepower has increased, and gear improvements have made it so most anyone can drive a tractor, but operator comfort makes the news."

RIGHT: Lundell's showroom in Kiron houses many of his tractors that he has refurbished, but those tractors are just part of his collection. He has parts, sales and service artifacts, like this poster, from all of the major tractor and farm equipment manufacturers, including John Deere, Case IH, Ford, and others.