COMPANY REPORT

Spearheaded by Picarro, Hidden Kitchen and Mexico Business, a unique gathering of leaders in Mexico’s natural gas sector took place in an undisclosed location in Mexico City’s historical center. Attendees discussed the future of the industry, emphasizing pressing issues that included distribution, infrastructure and safety.

Participants included: Dánae Burgueño, Specialist in regulatory and tax matters, Juan Carlos Ruiz, Environmental Health and Safety Issues Manager, Jaqueline Luna, Director of Central operations, all representing Naturgy. César Bernal, Customer Service Director and Fernando Vargas, Gas Control Director represented Fermaca. Other attendees included Gustavo Blejer, Managing Director for the Americas at Bonatti, Leonardo Robles, Vice President of Business Development at TC Energy, Gamaliel Corral, General Manager of Gasoducto de Morelos at Enagás, and José Bosch, General Manager of Oleum Energy.

The dinner was hosted and sponsored by Picarro, a global leader in analytics-driven leak detection and emissions management solutions. The company was represented by Vice President of Energy Vincent Gaeto and International Energy Business Director Malvin Delgado.

Read the complete article

Delgado said he is invested in the company’s expansion in Mexico’s energy industry as part of its broader agenda to highlight the sector’s role in the energy transition: “Identification, quantification and reduction of natural gas emissions is vital due to the high impact that these have as greenhouse gasses. Picarro is working to bring into Mexico its solution to help natural gas utility companies in this endeavor, all while keeping emissions low and helping them to reach their net zero carbon goals.”

Topics discussed at the gathering included the main challenges in distribution and transportation of gas in Mexico, the potential development of the country’s gas infrastructure and the emerging safety trends related to pipeline infrastructure, a topic where Picarro’s expertise in advanced safety technologies and data analytics became particularly relevant.

“Advanced leak detection is becoming a standard practice worldwide. However, in Mexico, traditional gas leak detection methods, known sometimes as ‘street walking,’ are widely used and accepted. Therefore, Picarro wants to promote the use of advanced leak detection and data analytics to make Mexican gas utility networks safer, more reliable and environmentally friendlier,” said Delgado.

Attendees agreed that safety issues are considered a lens that measures the state of the national gas system’s infrastructure, since construction efforts needed to be made in parallel to optimization, refurbishing and maintenance investments for legacy infrastructure.

The geographical distribution of Mexico’s natural gas grid reveals a history of uneven development, an issue now being solved by operators and distributors through virtual pipelines and other alternative methods. These approaches present the same safety questions as existing infrastructure, so safety issues integrated the discussion regarding the system’s future.

Guests discussed Picarro’s services portfolio and its analyticsdriven natural gas leak detection and quantification system. It became clear that these services could play a significant role in upgrading the technological, safety and reliability standards of Mexico’s natural gas infrastructure. “Identifying a natural gas leak in a timely manner is a real challenge but knowing the volume of gas involved in the detected leak and determining the risk associated with it is something that only the Picarro Solution can provide,” emphasized Delgado.

Specialists from Hidden Kitchen, a company that creates unique gastronomic experiences in unusual locations, prepared and curated the space. The quality and originality of the dishes served provided a fresh and unique tone to the gathering.

While the participants were forthright in their discussions regarding infrastructure development and challenges for the road ahead, the overall tone of the conversation was positive and the event established networking opportunities advantageous to company operations and the sector’s overall development.

Contributing to the global goal of net-zero energy by 2030, Picarro has introduced leak detection technology that focuses on detecting natural gas leaks in underground pipeline networks. Finding, identifying and repairing gas leaks helps drive down total emission scores. With Picarro as an ally, reducing leaks of methane emissions in distribution systems is faster and more effective.

A Washington State University study reported that only 2 percent of leaks were over 10 standard cubic feet per hour, but these accounted for 56 percent of total emissions.This occurs because most emissions come from a small number of larger leaks, called Super Emitters. When dealing with Super Emitters, Picarro’s solutions enable customers to not only substantially reduce methane emissions by accelerating detection and repair of the leaks but also to improve the safety of their infrastructure and increase capital efficiency.

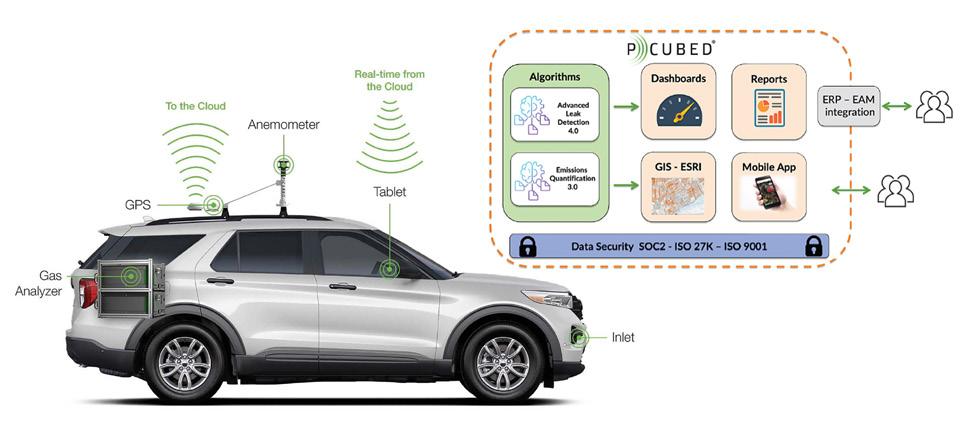

For compliance, gas distribution systems must be surveyed every five years. Previously, companies met this requirement through walking surveys, which are for the most part limited in terms of speed and range. Picarro’s solution redefines and revolutionizes the way leaks are found and fixed, using a mobile system that detects how much gas is involved in an area, what the risks are, and how to solve them.

This solution consists of a monitoring and data-collection unit, which is driven across gas infrastructures, vacuuming in air through a highly sensitive laser gas sensor that is capable of identifying one particle per billion in a range

of 15-200mts, facilitating an inspection of the network at 40 miles per hour.

These sensors, which are mounted on the rear of the unit, are 1,000 times more sensitive than traditional systems. They can measure the speed and direction of the wind and distinguish natural gas from other gasses, thus obtaining more intelligence on how much gas is leaking out and moving in the air. In addition, thanks to the sensor’s military-grade GPS, based on concentration, it can calculate the exact distance to the origin of the leak and associate it with a portion of the infrastructure.

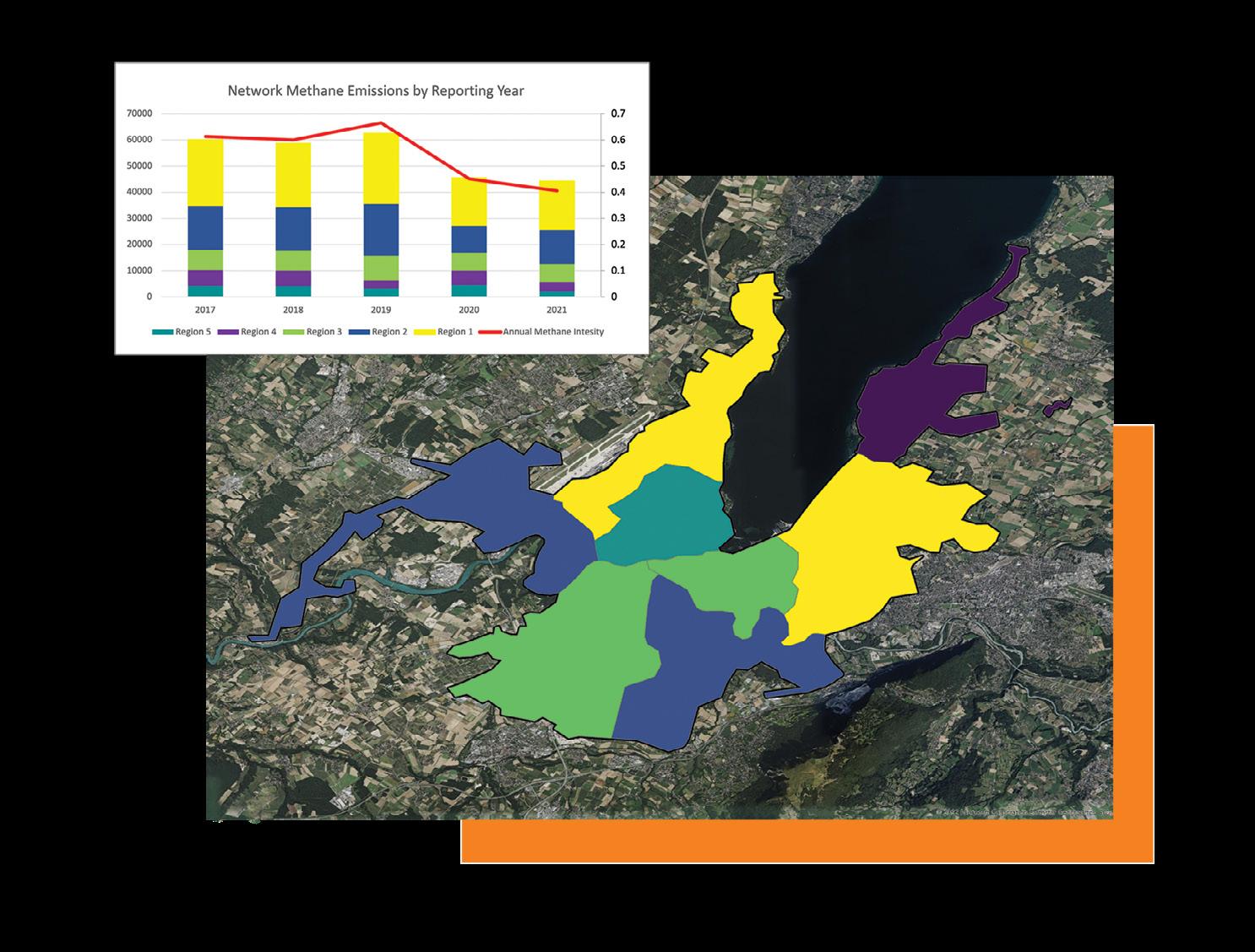

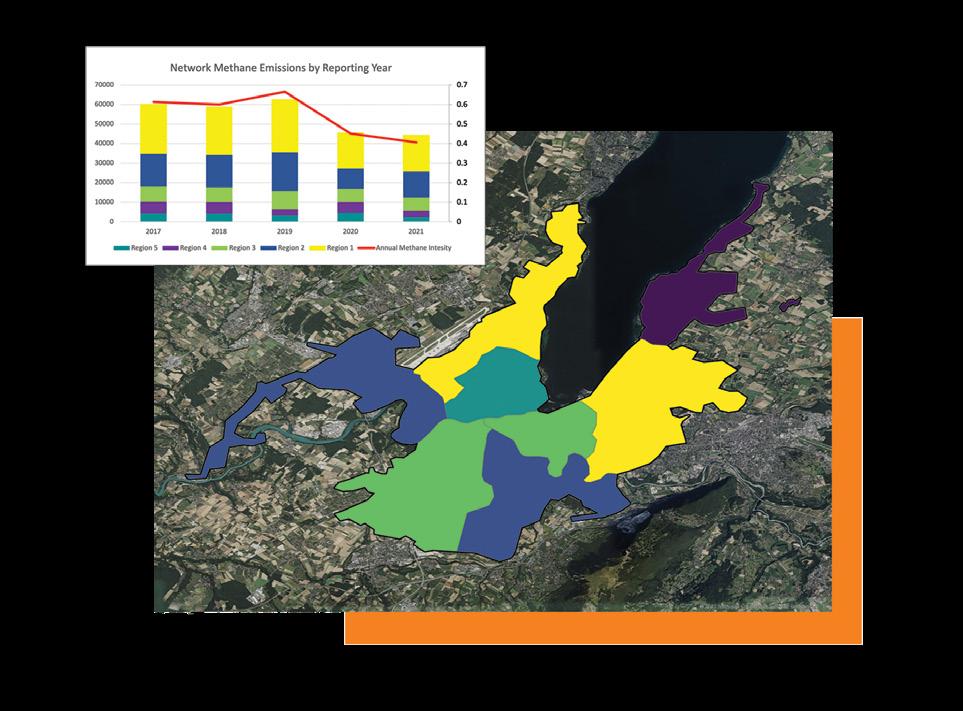

Lastly, and a key part of the emission-reduction solution, Picarro introduces a hardware-enabled software called P-Cubed® that connects via 4G data communication with a cloud based expert system. Through artificial intelligence and data science in the cloud, analysis and algorithms are executed in real time. The software calculates wind speed and direction, and the GPS coordinates the units and cross-references them with the customer’s gas distribution network. Once this is done, the system assembles a 3D map and demonstrates where the gas leak is, what the volume is, what the infrastructure elements are and conveys a risk category.

This real-time processing provides the co-pilot of the unit a 3D image of everything that is detected while sending a direct report to clients. By having this detailed data and analysis, pipeline operators can identify methane emissions, improve leak study efficiency, map areas of greatest risk and prioritize pipeline sections to replace and achieve further reductions in methane emissions.The P-Cubed is a specialized system that has analyzed hundreds of networks around the world with similar or different conditions. The system has been in operation since 2012 and thanks to the data it has gathered, it can make accurate decisions and recommendations.

Thanks to this technology, which provides the ability to integrate geographic information along with asset information, gas operators can proactively predict where failures will occur and implement a solution as well as prevent major leaks.

In recent years, Picarro has been identifying and quantifying Super Emitters for pipeline operators, applying its revolutionary solution with great success. In 2019, a major US utility began using Picarro’s services to measure one-third of its infrastructure for compliance and two-thirds of its infrastructure for a Super Emitter measurement campaign.

In one year, Picarro identified 210 of the highest emitting leaks along 3,000 miles of gas distribution pipeline. This quantification of emissions at scale allowed the construction of a methane map for the entire infrastructure and was used to identify and repair the highest emitting leaks, which provided environmental and risk reduction benefits.

This is why Picarro represents the best option for identifying Super Emitters as part of an informed and cost-effective emissions-reduction strategy. Tracking and tracing where events are on a map, in real time, is a revolutionary technology that changes the way information is processed and consumed to make better business decisions while reducing greenhouse gas emissions.

Through the power of data analytics, leak management solutions can decrease functional risks at gas utilities and improve operational costs by creating savings in the company’s maintenance budget. In an effort to encourage utilities to apply technology in their favor, Picarro has created and developed its Risk Ranking Analytics, which is tailored to improve risk management and assessment of gas assets.

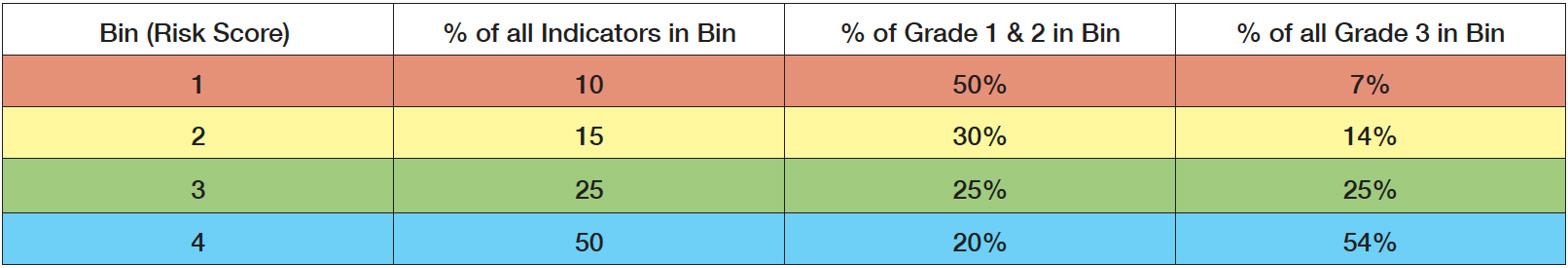

Methane plumes from natural gas leaks have unique, measurable signatures. This allows Picarro to rank indicators by potential risk. By combining data collected by a patrolling Picarro vehicle, Picarro’s Risk Ranking Analytics allows utilities to maximize operational efficiency by prioritizing leak indicators that are most likely to be Grade-1 and Grade-2 leaks. In addition, these analytics can screen out indicators from small, nonhazardous leaks, effectively prioritizing those that are urgent and, therefore, reducing leak backlogs and repair costs.

“The main criteria are gas concentration versus air ratio, which is directly related to the capability of a potential explosion, whether the leak is located inside or outside a confined area, and what is around the leak in terms of people and properties,” says Malvin Delgado, Director of Sales and Client Engagement at Picarro.

Traditional leak survey tools and processes often miss priority leaks, even when they are handled by the most skilled personnel. Applying highly sensitive technologies can identify excessive leaks, which can dramatically increase leak

repair budgets. If there is no clear hierarchical system, leak backlogs may also increase because all leaks found must be scheduled for repair according to severity. While smaller leaks can become an issue, they are a second or third priority behind those that could potentially cause a major problem.

Picarro considered all these factors and designed its Risk Ranking Analytics, a leak management solution that leverages the power of data analytics to prioritize leak indicators by potential risk. Since the system can identify and locate the most important leaks quicker and more efficiently than other tools available, Picarro’s solution accomplishes leak survey cost reductions and improves infrastructure safety by isolating the most important leaks so crews can prioritize repair work.

“Picarro collects data using Advance Mobile Leak Detection techniques, employing a vehicle that conducts multiple patrols, taking in air from in front of it and measuring certain environmental variables along the pipeline infrastructure. The vehicle is equipped with an advanced analytics module, which uses laser technology to detect natural gas in the analyzed air. There is also an anemometer on top of the vehicle to measure the speed and direction of the air, together with a submetric precision GPS that provides real-time location of the measured variables,” says Delgado. Collected data is sent in real time to the cloud to be processed by specialized software that uses data science and expert systems over a digital twin of the pipeline infrastructure to determine and rank the risk associated with the leaks found.

To assign a risk score to an individual natural gas leak plume, Picarro’s Risk Ranking Analytics uses several measurable qualities of these plumes, such as methane concentration, methane flow rate (emissions rate), ethane-to-methane ratio and plume size and shape. Soon after, a mathematical model is able to use these measured plume signatures to predict the likelihood of a given plume being associated with a leak of a particular level of risk. This classification is achieved by using a training dataset from a particular utility to adjust the model parameters to properly predict risk for the specific leak grading criteria used by that utility and to account for specific details of that particular distribution network.

After all the data is collected, leak survey managers can run Picarro’s Risk Ranking Analytics, which transforms data into actionable results for leak investigators. This can be done on a schedule that avoids overburdening emergency response crews. Armed with the indications and locations that are most likely to lead to urgent leaks, crews can maximize their impact while keeping costs and backlogs under control.

Picarro’s solution improves operational safety in addition to creating relevant budget savings. By reducing construction

costs associated with non-hazardous leaks, Risk Ranking Analytics is able to achieve significant reductions in a utility’s operational leak management budget. Since non-hazardous leaks may not require repair, they can be safely removed from the set of leaks that would normally be identified for investigation and repair without the use of analytics. Once non-hazardous leaks are removed from the tally, the overall leak repair budget decreases, leading to significant savings while simultaneously reducing risks.

Risk Ranking Analytics can also reduce labor costs by facilitating the prioritization of labor for investigation and repair. In most countries, regulatory bodies still require human validation or in-person investigation of leaks when they are found, regardless of what type of technology is used for detection. With the help of data analytics, resources are directed first to the most urgent leaks, minimizing unplanned work and reducing overtime costs. Analytics also allows utilities to transition to a risk-based survey framework, which increases survey frequencies in the highest-priority areas.

“The Picarro solution, which includes the Risk Ranking Analytics Module, requires a very low investment when compared to the liability associated with damages to people or properties due to potential effects of a Grade 1 leak,” says Delgado. “The opportunity cost of investment becomes attractive, as savings are immediately created and emergency response expenditure is also drastically reduced.”

While in-person evaluations are being modified in the US, Europe and Asia, human participation in leak assessments remains key. To transform the process into a more efficient experience, additional countries are starting to bet on data analytics and technology to improve safety and optimization in their gas operations. Picarro’s solutions, including the Risk Ranking Analytics Module, are being evaluated by gas utility companies in Mexico, Colombia, Brazil and Argentina, with specific plans by at least four companies in the region to start using this solution by the end of 2022. “In Mexico, one important company in the northern region of the country has finished a field trial of Picarro’s solution. We believe this technology will be actively serving the Mexican gas infrastructure in 2023,” Delgado said.