6 minute read

LAB INNOVATIONS

How food and drink labs have adapted since COVID-19

With the start of the COVID-19 pandemic, we saw the mass stock-piling of food products like chicken, flour and eggs. This had a major knock-on effect on food and drinks labs, which are integral to test products from the production line and develop new food and drink items. Here, Aleiya Lonsdale, Head of Marketing at Lab Innovations, explains the impact COVID-19 has had on food and drink labs and the technologies and processes that it has inspired.

Health and safety came into the spotlight when the pandemic hit. The highly contagious nature of the virus meant that more rigorous hygiene and safety practices were required to limit transmission. In a position paper written in November 2020, the Scientific Advisory Group for Emergencies (SAGE) argued that air cleaning systems in labs needed to be independently validated to ensure a COVID-secure environment.

One food and drink lab, Camden BRI, developed a new test procedure to validate air and surface cleaning systems in labs that had not been replicated anywhere else in the UK. The procedure would test the air and surface activity, assessing whether SARS-CoV-2, the virus that causes the COVID-19 disease, was inactive or removed from those areas in the facility. Though this procedure had been created to stop the spread of the virus, it could be used in the future to test for a variety of viruses to ensure hygiene at the highest level in the air and on surfaces.

Staff shortages were also a challenge at the start of the pandemic. At its peak, some members of the Food and Drink Federation reported over 20 per cent of absences caused were by sickness and isolation. That, combined with social distancing in labs, added further pressure on food and drink manufacturing. Labs had to invent new ways of carrying out important work safely in order to maintain the supply chain.

Isolation and lockdowns led to many scientists having to take their work home. Jan Hrušák, chair of the European Strategy Forum on Research Infrastructures (ESFRI), has said ‘We have seen huge, massive mobilisation of [the] capacities of research infastructure’ and that he expects big labs to build more remote access schemes that allow researchers to send samples into the lab from home, especially with regard to non-critical projects. This new flexibility has become attractive for some labs with suggestions that this could lead to a rise in recruitment as more staff may be required to handle samples that have been sent to them by remote researchers.

Flexible working conditions also led to a rise in remote monitoring systems for integral pieces of equipment in food and drink labs like cold storage units. Monitoring and maintaining these units is essential to ensure product safety and meet regulatory compliance. Labs are now using new technologies like web-based remote monitoring systems to track conditions within cold storage units from home, 24/7. This data can be transmitted through the cloud, with notifications sent to devices from anywhere in the world.

This technology is not just limited to temperature monitoring. It can also track variables like humidity, carbon monoxide, water traces and power failure. By giving staff a way to monitor lab conditions, alerting them in the case of any irregularities, this technology can change the structure of the lab working force by allowing staff to work from home or focus on more mission-critical projects.

It is clear that COVID-19 has had a big impact on the world of work, particularly for industries like food and drink labs that have had to overcome challenges like lockdowns and social distancing. Through trial and error, new technology and processes have emerged, time will tell if these changes become permanent.

Many of these new developments will be showcased at Lab Innovations, the only exhibit in the UK for the laboratory industry, on November 3 and 4, 2021 at the NEC in Birmingham. For more information on what’s happening at Lab Innovations, visit

Machinery Moves, Installation, Relocation and Technical Lifting project expertise for the Food, Beverage, Distilling & Brewing Process Sectors

Based in project offices throughout the United Kingdom, the RRS Group is an experienced machinery relocation and installation contractor with significant knowledge in the food and beverage process sectors.

Our expertise includes installation and relocation services for projects on tanks, process lines, filling, mixing and bottling lines, packaging systems, distilling process equipment, conveying lines, canning and sealing, plastics, card and corrugated packaging and all associated utilities plant moves.

The RRS Group has decades of experience in project planning, health and safety, quality and commercial awareness to meet all sizes of budgets whether a single machine move or a large capex turnkey installation project under CDM Regulations. Our engineered solutions, project management, skilled site personnel and lifting and installation plant/ equipment are the core ingredients to our successfully delivered site projects. We welcome discussions on budget proposals and future project ideas as well as planned projects or last minute requirements

E: info@rapidrs.co.uk T: Projects HQ : 023 92669714 W: www.rapidrs.co.uk

Tailor made solutions for the dairy and food industries

From hygienic product protection to communication with the customer - packaging must fulfil a wide range of functions. This includes the packaging design, product protection, ease of use, optimal logistics, customer information and brand ambassador, but also to guarantee the shelf life of the product, however the packaging must also be sustainable. Functionality and sustainability are on the same level in packaging development. This has to be taken into consideration when developing alternative packaging concepts with sustainable materials such as monomaterials as well as materials from renewable resources.

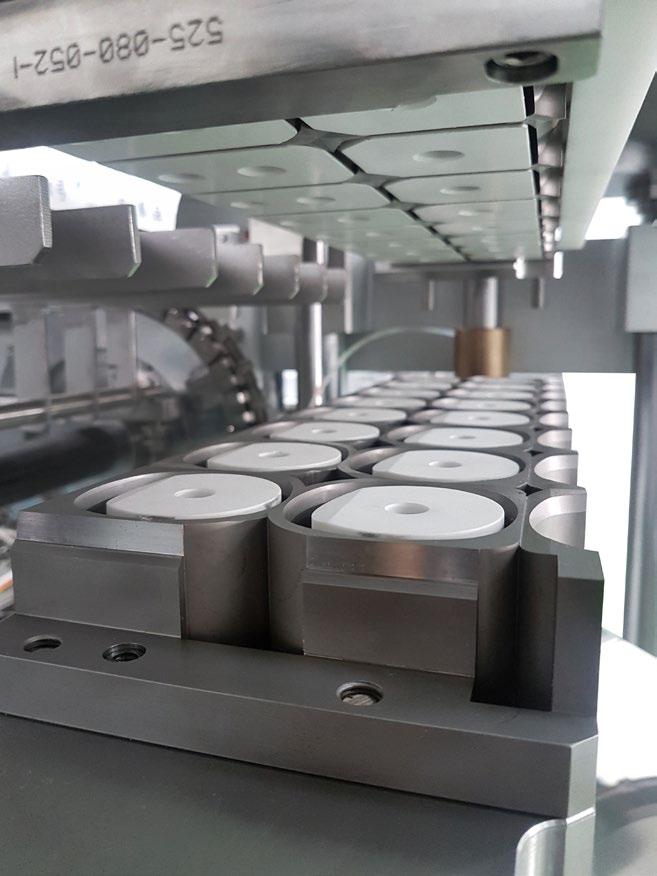

With the patented ZERO Technology tools we offer the perfect solution for the use of mono-materials such as PET, PP and PLA. The tools from the ZERO Technoloy range are the result of years of research and development. They can be applied to all cutting applications contained in an FFS machine. Their use reduces maintenance costs, increases the performance of the machine and have a longer punching time. By using the tools from ZERO Technology, a quick switch from PS (polysterene) to more recyclable materials such as PET, PP and PLA can be realised and customers have now the opportunity to use these materials for their thermoformed cups.

Cutting tool

Only with the new, patented punching tools from INTECMA can multipacks made of these materials be broken into individual cups just as easily as multipacks made from PS. The knives do not even have to be changed for this. Further equipment in the ZERO Technology range include special pre-heating plates, which can be easily dismantled and enable simple maintenance. Further material savings can also be realised by using the special thermoforming moulds, which enable the use of thinner materials.

ZERO Technology offers an innovative solution on the way implementing more sustainable packaging material in existing form, fill and seal machines from our brands Erca, Hassia and Intecma (and even in machines from other suppliers) or in new machines and enables improved recyclability of cups and reduces the ecological impact.