Out of the Box

Such is our confidence in this technology we offer an unparalleled 5 year full warranty on all models

Such is our confidence in this technology we offer an unparalleled 5 year full warranty on all models

BURKERT

The ways in which manufacturers of process control equipment are making life easier for the plant operators and maintenance technicians

Former Birmingham apprentice is named as one of the top 20 manufacturing professionals in the UK

V-EX

Why your Exhibition stand needs a digital twin…

Thousands of visitors will be heading to the Farnborough International Exhibition and Conference Centre

BROANMAIN PLASTICS

Broanmain paves the way for sustainable mass-manufacturing at SM&E

Cover photo: Sulzer

FANUC

Fanuc support helps samey robotics to revolutionise fresh fish supply chain

Making productivity sustainable

Dispensing robots: What’s the risk?

E-CAD integration reduces time to market by 80% for automation control specialist

Responsible paving and walling manufacturer, Tobermore, has invested £34k into the installation of energyefficient LED lighting across their sites

WEG

Halifax fans and WEG motors help ventilate the world’s first full-scale liquid air energy storage facility

The leading source for innovators in Technology, Manufacturing and Maintenance within the Engineering & Processing industry worldwide.

Published bimonthly, a subscription to PECM magazine is essential for Process Engineers, Chemical Engineers, Instrumentation Engineers, Mechanical Engineers, Plant Engineers, Precision Engineers, Environmental Engineers & General Engineers, Companies and Organizations in the Food, Dairy, Beverage, Brewing, Semiconductor, Pharmaceutical, Biotechnology, Chemical, Oil & Gas, as well as all UK's major manufacturing units.

Every issue of the magazine contains the latest news, in-depth features, together with product innovations and case studies showing how process engineers are implementing new technologies to reduce costs and impact on the environment.

With over 140,000 readers worldwide the publication is widely read, recognized, and well respected within the Process, Engineering & maintenance industries.

A subscription to PECM magazine is the industry's 'must have' publication.

SUBSCRIBE

EDITOR IN CHIEF

Antony Holter editor@mhmagazine.co.uk

BUSINESS MANAGER

Josh Holmes josh@mhmagazine.co.uk

SALES DIRECTOR

Harrison James harrison@pecm.co.uk Tel: 0203 907 9166

SALES MANAGER

Martin Richardson martin@pecm.co.uk Tel: 01304 086039

DIGITAL MANAGER

Jamie Bullock jamie@mhmagazine.co.uk Tel: 01227 936971

EDITOR

Elizabeth Hutton elizabeth@pecm.co.uk

STUDIO DESIGNER

Richard Bland richard@mhmagazine.co.uk

ACCOUNTS DEPT

Alison Holmes accounts@pecm.co.uk Tel: 01227 936976

PUBLISHING DIRECTOR

Martin Holmes martin@mhmagazine.co.uk Tel: 01304 806039

EDITORIAL ASSISTANT Chris Nicholls chris@pecm.co.uk Tel: 020 3907 9161

MH Media Global Ltd. 18/20 Newington Road, Ramsgate, Kent, CT12 6EE Tel 01304 806039 l Fax: 08721 152240 l www.pecm.co.uk

Every effort is made to ensure the accuracy and reliability of material published in Process Engineering, Control & Manufacturing however, the publishers accept no responsibility for the claims or opinions made by the contributors, manufacturers or advertisers. No part of the publication may be reproduced

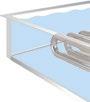

Carrying out a large scale retrofit at any facility can be daunting, but at a steel mill, where extreme conditions and high productivity demands combine, particularly so. As equipment such as motors require replacement, plant operators need to install new units quickly to safeguard uptime. That’s why Aperam, a leading producer of steel and alloy, selected Bauer Gear Motor to carry out a three-year retrofit project for the roller table conveyor drives at its Châtelet facility.

While the operating life of a motor can exceed 10 years, eventually plant managers will need to upgrade to a new efficiency standard or replace faulty units. However, the footprint and interfaces of new

equipment will almost never match up to the original, which can make retrofitting a modern motor problematic. Complex mechanical adaptations to fit the new unit can be very time consuming. With demand and prices for steel and alloy through the roof, any extended downtime for a retrofit project at a steel mill must be avoided.

The Aperam Châtelet facility in Belgium consists of a melt shop and a rolling mill, which produces durable steel and alloy. During routine inspections, maintenance engineers at the plant identified that the motors powering the roller table conveyors required replacement. Due to the weight of the slab, each roller was powered by its own dedicated motor. Therefore, carrying

out a motor retrofit project – which would require extensive mechanical adaptation for each unit - was unacceptable.

Consequently, Aperam approached Bauer Gear Motor, a leading brand of Altra Industrial Motion Corp., to provide a plug and play motor retrofit solution.

Bauer Gear Motor is a world leader in geared motor technologies, with a proven track record in providing highly robust and reliable drives for use in challenging metal industry applications. Focused on delivering motors that attain the highest efficiency standards, Bauer also offers operators in the metal industry a plug and play retrofit solution for drives operating on roller table conveyors.

The Bauer retrofit solution features two key elements. A standardised shaft connection using either a flange or coupling ensures increased ease and speed of installation. This is matched by a foot adaptor plate, which allows a one-to-one changeover between the old and new motor. A plug and play design eliminates the need for any costly, time consuming mechanical adaptations. Consequently, retrofitting new motors can be done with minimal downtime.

“What was key for the Aperam project was that we could offer a plug and play solution as a complete package, which was particularly important to engineers at the facility,” explains André, Regional Sales Manager, North Europe. “Our extensive engineering knowledge in the metals industry and the OEM support we could provide were also deciding factors. One of the primary challenges was to deliver the volume of motors required within the timeframes of the plant’s scheduled downtime, but our production capacity ensured we could achieve this. Over three years, we have updated all the motors on the roller table conveyors, bringing the system up to a new efficiency standard while also streamlining future maintenance and retrofit work.”

Bauer offers specialised motors specifically for roller table conveyors. With heavy duty fan or non-ventilated designs, the motors feature windings for delivering

high torque, heavy duty gearbox housings and gear wheels, seals to withstand high temperatures and IP65 enclosures as standard.

By standardising the shaft connections and footplates for Aperam, Bauer was able to not only streamline the initial retrofit project, but all subsequent motor upgrades or replacements required for the roller table conveyors in future. This ensures that as the Châtelet facility moves to improve energy efficiency and boost reliability, these dual aims can be achieved while safeguarding production uptime.

For further information, please visit www.bauergears.com

What was key for the Aperam project was that we could offer a plug and play solution as a complete package, which was particularly important to engineers at the facilityThe motor retrofit solution features a standardised shaft connection and foot adaptor plate, unlocking plug and play motor replacement. Roller table conveyors are used to move hot, heavy slabs of metal, with each roller powered by a dedicated motor.

Helapet knows that no single filter can be suitable for the varied filtration applications that are used across industries. Our new online design tool provides customers with a simple-to-use design wizard, combined with enhanced information to guide customers through the 100’s of available filter combinations.

Meet the high performance doubleeccentric butterfly valves, GEMÜ R470 series, perfectly suited for applications with high pressures and temperatures. Available in nominal sizes from DN 50 to DN 600, this robust workhorse can take pressures up to 40 bar or temperatures up to 230 °C. The double-eccentric construction directly separates the disc from the seat (gasket), which reduces friction making the valves remarkably more durable and therefore increasing service life. Another features of the GEMÜ R470 is the continuous shaft with temperature resistant graphite bearing providing additional safety measures as well as the PTFE gland packing that can be adjusted in operation to minimize leakage, even at low pressures. This significantly reduces the maintenance requirements after installation. Antistatic fixtures are available as optional for use in an ATEX environment. Thanks to the optimized disc design in spherical form, the GEMÜ R470 offers excellent sealing and guaranteed mechanical functionality even at the highest pressures and temperatures. Made from PTFE TFMTM, the sealing ring is robust and versatile, ensuring excellent reliability for use in most process applications.

For more information, click here. Check out our video tutorial on how to modify a Butterfly Valve to a pneumatic, single-acting Normally Open or Normally Closed (NO/NC) actuator.

Tel: 01925 824044

Email: enquiries@gemu.co.uk Web: www.gemu.co.uk

Formed in 1998 by industry specialists, Prokem is one of the nation’s leading acid resistant and epoxy flooring contractors. We have over 40 years’ experience in laying floors for a range of business requirements in locations across the UK and worldwide.

As expert epoxy flooring contractors we can identify the needs of our customers and offer them the correct flooring solution for their business needs. We’ve supplied industrial flooring solutions to a wide variety of businesses across the UK. The industries that we’ve covered include: –

• Petrochemical

• Chemical Processing

• Steel

• Power Generating

• Water

• Fertilizer

• Pulp and Paper

• Food-Processing

• Beverage

• Engineering

You can arrange a quote and speak to our customer services team by calling 07713856433 or emailing info@prokem.co.uk. We will offer you honest and tailored advice on your industrial requirements and find you the industrial flooring solution that meets your needs.

UltraMax is the manufacturing division of the UK’s largest independent distributor and manufacturer of batteries, supplying over 150 million cells per year globally. We specialise in the manufacture of lithium and custom-built battery packs for OEMs with production sites in the Far East and the UK. We design and manufacture for various industries such as energy storage, industrial, automotive, garden and power tools, medical equipment, defense, robotics, and security. We have a wide range of expertise in managing mechanical equipment, specialist battery engineering, distribution, and storage of lithium batteries.

As well as bespoke battery packs, we also keep a wide range of generic lithium batteries, such as 100Ah-12V, at our north London depot for next-day nationwide delivery. We also keep stocks in Europe at our Dutch facility.

Our objective is to gain a detailed understanding of your requirements and then design and build a bespoke battery pack. Once this is achieved, we will efficiently scale up our manufacturing processes to meet your delivery requirement. Our experience and wealth of expertise enable us to demonstrate a proven track record of delivering projects on time and on budget.

We provide technical support throughout the life cycle of our products, from initial design through qualification, manufacturing, managing distribution and transportation, and if requested, disposal. Every step requires in-depth experience and compliance with relevant regulations to ensure total reliability, safety, and environmental protection.

With UltraMax, you can be confident of a highly experienced, competent, and relentless focus on quality service and control, using the most advanced methodology and continuous innovations.

We offer all battery chemistries and specialise in lithium rechargeable and lithium primary battery packs. We provide both direct lead acid battery replacement and custom-built battery packs, portable power and energy storage solutions complete with electronic control.

Our power solutions offer outstanding energy density and power output over a wide range of conditions. This is made possible by our use of innovative designs and advanced cell chemistry.

If you have a battery pack requirement, do not hesitate to contact us on +44 (0) 208 803 8899 or email sales@ultramax.co.uk.

For more information on our battery solutions, visit www.ultramax.co.uk.

With UltraMax, you can be confident of a highly experienced, competent, and relentless focus on quality service and control.

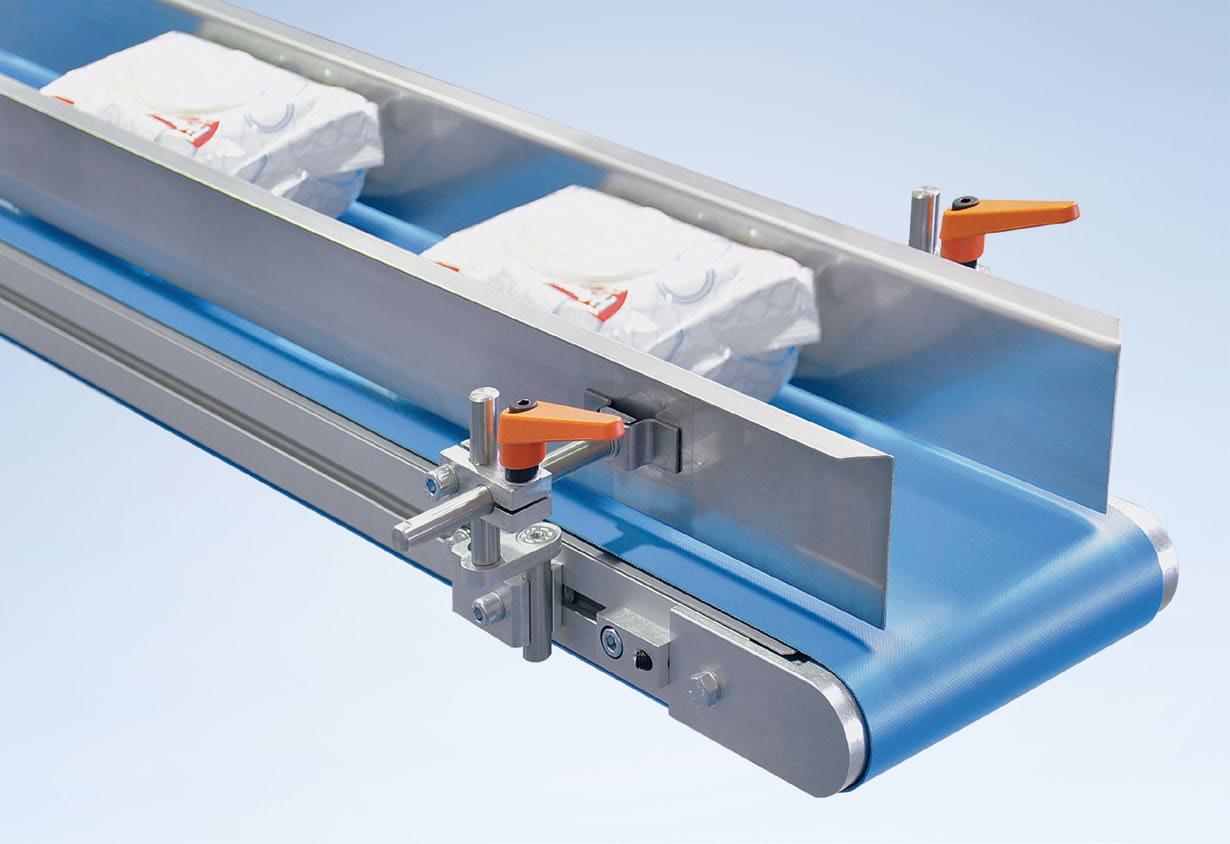

Compressed air and fluid power specialist Thorite will launch its new dedicated Electronic Automation (EA) Team at the Southern Manufacturing & Electronics show in February.

The Bradford based company will also be unveiling new products and technology at the event, to be held at the Farnborough International Exhibition and Conference Centre in Hampshire from February 7th to 9th.

Visitors to the show will be able to meet EA Technical Development Manager Mik Rhodes who will be on-hand to explain how Thorite can help original equipment manufacturers (OEMs) unlock the potential of electronic automation to develop equipment that delivers faster changeovers and improved productivity.

The team will employ demo units to explain the best uses for pneumatic and electronic automation, as well as electric pick and place grippers demonstrating the range of motion available with the latest technology.

Tom Simpson, Marketing Co-Ordinator for the EA Team, said: “Electronic automation is increasingly being recognised by OEMs as a more efficient alternative to pneumatic power on some machinery.

excited to be sharing it at the Southern Manufacturing & Electronics show, which is a highlight of the engineering events calendar.”

Thorite’s Systems Team will be available to discuss everything from panels and valve islands to compressor and OEM subassemblies.

Thorite will also use the event to introduce the newly launched Ultima range of oilfree compressors from Gardner Denver, which are 37% smaller and 13% more efficient than comparable compressors and have no need for ducting thanks to their internal heat exchangers.

Thorite’s in-house pump expert will provide hands-on demonstrations using a cut-away unit of Graco’s new gamechanging EODD pump, QUANTM, that requires zero compressed air and deliver up to 80% reduction in energy consumption, whilst maintaining the proven AODD benefits.

The Southern Manufacturing and Electronics show boasts a diverse range of suppliers which attracts manufacturers ranging from major players to SMEs, from across the UK and continental Europe.

For further information, please visit www.thorite.co.uk

“We have expanded our expertise over the years in line with this shift and we’re

Thorite’s Systems Team will be available to discuss everything from panels and valve islands to compressor and OEM sub-assemblies.

design and commissioning of bespoke systems solutions ranging from small assemblies through to fully

design and commissioning of bespoke systems solutions ranging from small assemblies through to fully

Thorite service are on hand 365 days a year to help your business. Offering a range of aftermarket services to ensure consistent operating performance while prolonging the life of your equipment, saving you time and money.

Thorite service are on hand 365 days a year to help your business. Offering a range of aftermarket services to ensure consistent operating performance while prolonging the life of your equipment, saving you time and money.

Metaltech Precision, part of the Expromet Technologies Group, is pleased to announce that, through the acquisition of NC Precision which took place in May, it has expanded its sliding head machining capacity at its Somerset facility and now boasts a wider range of equipment and capabilities to cater for the most complex of parts.

Following the recent acquisition of NC Precision, a leading manufacturer of precision components, equipment and employees have now been transferred to the Metaltech premises. The seven sliding head machining centres have found a new home alongside Metaltech’s existing sliding head machines in a dedicated sliding head cell and are providing a welcome boost to production capacity. The new L32 which was already on order, was delivered and

installed ahead of the move.

Metaltech has taken this opportunity also to set up a dedicated cleaning, deburring and inspection cell, providing specialist facilities which extend our capability to offer micro machining of miniature components.

We are delighted to welcome the highlyexperienced team from NC Precision to Metaltech to help us continue to deliver and expand upon the precision engineered solutions we offer our diverse customer base at the highest levels of quality and service.

We are working closely with existing and new customers to understand how we can

further strengthen relationships and offer them additional support in preparation for their growth during 2023.

Expromet Technologies Group is a privately-owned precision engineering group. In addition to Metaltech Precision and NC Precision, the group also includes Investacast, a leading global supplier of investment castings, pressure die castings and forgings with a manufacturing base in Ilfracombe, Devon; and Haworth Castings, a specialist in manufacturing fully-tested, machined and finished sand and gravity die castings located in Romsey and Basingstoke, Hampshire.

If you would like to talk to Expromet about our extended capacity for CNC Turning and Milling, please get in touch on + 44 (0) 1271 866200 or email enquiry@expromet.com.

For further information, please visit www.expromet.com

There is no compromise on the quality of JASIC equipment..such is our confidence in this technology we can offer an unparalleled 5 year ‘true’ warranty on all models. Jasic’s manufacturing site is over 80,000m2 and is arguably the largest and most modern inverter manufacturing base in China.

How do Wilkinson Star provide such an industry leading product guarantee?

• The manufacturer has invested millions of dollars into cutting edge integrated test laboratories on site – JASIC undergoes 42 individual tests to meet high quality standard.

• Jasic’s 4 centre strong R & D facilities has been ranked as the most progressive facility along with being the first welding laboratory awarded UA certification by China from TUV Rhineland.

• Wilkinson have 50 years’ experience in servicing welding equipment. Our state of the art service workshop facility and our 16 strong after sales service team offer the most recognised technical support in the welding industry. All equipment is fully supported by Wilkinson Star trained technicians.

• No other UK wholesaler can repair inverter boards to component level. At Wilkinson Star we have a dedicated

• We provide a dedicated technical support line which you can call for any technical support queries

• If on site support is needed we provide this through our highly trained technicians who cover the country

• We can also interchange power sources to keep you up and running

• If required, Wilkinson Star will arrange at its expense to collect and return your JASIC product to carry out service or repair in our workshops

JASIC’s warranty is a true 5 years; this means a problem at 6 months, 3 years or 4 years 11 months is treated with the same level of care.

No extensions. No additional costs…… just 60 rolling months of product peace of mind

ALL YOU NEED TO DO IS REGISTER YOUR PURCHASE AT JASIC.CO.UK FOR 5 YEARS PEACE OF MIND – IT’S REALLY THAT SIMPLE

For further information, please visit www.jasic.co.uk

Available in the UK from Labtex, Vacuubrand manufactures a comprehensive range of laboratory and instrumentation vacuum pumps, gauges and controllers for both coarse and fine vacuums. Vacuubrand’s first priority is to offer sophisticated equipment which meets the highest quality, professional standards expected of a modern laboratory. For example, ‘intelligent pumps’ make lab work more efficient, allowing chemists and technicians to focus their attention on other tasks.

The versatile Vaccubrand chemistry pumping unit, PC 3001 VARIO select

• Unsurpassed performance

• Uncompromising chemical resistance

• Fully automatic evaporations

• Minimal operating and maintenance costs

• Whisper quiet

• Environmentally friendly, without oil and water consumption

• The Vacuubrand Chemical Resistance Chart

• Chemical resistance is essential when working with aggressive gases and vapors.

www.labtex.co.uk

Avilable in the UK from Labtex , Vaccubrand engineer and produce almost all of their pump and controller components at their facility in Germany. This enables Vacuubrand to quickly respond to the wide variety of demands from different laboratories, offering tailor-made solutions, and also ensures a consistent approach to the quality of their design and manufacturing processes.

Vacuubrand relies on a range of cutting-edge technology and machine tools to produce a large selection of products, including rotary vanes, diaphragm pumping units, chemistry vacuum systems, vacuum gauges and controllers, as well as valves and components of the innovative VACUU-LAN local vacuum network.

The Vacuubrand chemistry diaphragm pump MZ 2C NT

• Contamination-free conveying and evacuation

• Outstanding chemical resistance

• Whisper quiet

• High pumping speed close to ultimate vacuum

• Long diaphragm life, maintenance-free drive system

• Extra low vibration

The Vacuubrand Chemical Resistance Chart

Chemical resistance is essential when working with aggressive gases and vapors. You will find detailed information on chemical resistance for our chemistry diaphragm pumps on at labtex.co.uk

www.labtex.co.uk

Vacuubrand’s high-quality and reliable range of chemistry diaphragm pumps, are designed for working with aggressive gases and vapors!

Discover the range of chemically resistant, durable, and highly efficient chemistry diaphragm pumps, from VACUUBRAND

Alloy Wire International’s technical knowledge was in big demand when it returned to SpringWorld 2022 (CASMI) recently.

Hundreds of delegates from USA, Canada and Mexico visited the UK’s leading manufacturer of round, flat and profile wire to discuss the firm’s new INCONEL alloy 686 and to tap into its technical knowledge.

Spring manufacturers were keen to discuss exciting projects destined for the aerospace, automotive, chemical and petrochemical processing, oil and gas extraction and marine environments.

There was a common thread throughout

the conversations, which focused on the need for earlier development support and having availability of material in short lead times, something AWI currently has access to due to its unprecedented investment in maintaining 400 tonnes of stock at any one time.

“It was excellent to meet so many existing and potential new customers face-to-face and CASMI certainly didn’t disappoint in terms of footfall and the quality of visitors,” explained Stephen Olley, Sales Executive at AWI.

“Our clients require material that can work in all types of demanding applications from intense heat and sub-zero temperatures to highly corrosive environments. That is why

we were so pleased to launch INCONEL alloy 686 after months of trials and testing.

“This single-phase, austenitic alloy delivers excellent resistance to general and stress corrosion cracking that can occur in aggressive liquids and gases and, judging by the conversations we were having, there appears to be a lot of opportunities for us to supply this material.”

He continued: “It was also great having Andrew Du Plessis there to talk in-depth about technical requirements. This included finer details of our nickel alloys, such as heat treatments to achieve a certain tensile strength after ageing and which alloys are better suited to working in different, corrosive environments.”

Alloy Wire International provides more than 62 exotic alloys to more than 7500 customers across the world, with material available in sizes ranging from .001” (0.025mm) to .197” (5.00mm) and lead times often within 3 weeks of the order being placed.

The company, which celebrated 75 years in business in 2021, recently promoted Tom Mander to Managing Director, with previous MD Mark Venables moving upstairs to the position of Chairman.

This is an exciting next step in the AWI journey and will accelerate its ambition to increase sales from its current £13m level to £15m by the end of the year, with most orders now coming from clients overseas.

For further information, please visit www.alloywire.com or follow @alloywire on twitter

It was excellent to meet so many existing and potential new customers face-to-face and CASMI certainly didn’t disappoint in terms of footfall and the quality of visitors

Heatsense Cables is the UK’s leading specialist high performance thermocouple and signal cable manufacturer. The company is highly customer focussed and offers a bespoke technical design and manufacturing service, rapid response times, short lead times, low MOQ’s and competitive pricing. The company is a technology leader in fluoropolymer extrusion, high performance taping and cable wrapping. Related processes include cover sintering, colouring, etching and the application of various specialist coatings. The range covers cables that operate in extreme environments; cables resistant to flame, oils & chemicals and which operate in ultra-high vacuum, cryogenic and high radiation environments.

Heatsense Cables is the UK’s leading specialist high performance thermocouple and signal cable manufacturer. The company is highly customer focussed and offers a bespoke technical design and manufacturing service, rapid response times, short lead times, low MOQ’s and competitive pricing. The company is a technology leader in fluoropolymer extrusion, high performance taping and cable wrapping. Related processes include cover sintering, colouring, etching and the application of various specialist coatings. The range covers cables that operate in extreme environments; cables resistant to flame, oils & chemicals and which operate in ultra-high vacuum, cryogenic and high radiation environments.

Heatsense Cables, www.heatsensecables. co.uk , established in 1984, is regarded as the UK’s leading specialist high-performance thermocouple and signal cable manufacturer. Its manufacturing capabilities cover a broad range of specialist cables that operate in extreme (harsh) environments. The company is a technology leader in fluoropolymer extrusion, high-performance taping and cable wrapping. Related processes include cover sintering, colouring, etching and the application of various specialist coatings. The range covers cables that are resistant to flame, oils & chemicals and which operate in ultra-high vacuum, cryogenic and high radiation environments.

The company offers a bespoke advanced technical design and manufacturing service and undertakes development work on new cable designs and materials.

Insulation materials include; PFA, FEP, PTFE, ETFE, EFGLAS, SILICONE, PE, PU, PVC, Taped & Sintered PTFE, Polyimide, Aramid, PTFE impregnated yarns and Mica.

Insulation materials include; PFA, FEP, PTFE, ETFE, EFGLAS, SILICONE, PE, PU, PVC, Taped & Sintered PTFE, Polyimide, Aramid, PTFE impregnated yarns and Mica.

PFA, FEP, PTFE, ETFE, EFGLAS, SILICONE, PE, PU, PVC, Taped & Sintered PTFE, Polyimide & Aramid Yarns, PTFE impregnated yarns and Mica.

Braiding materials include glass, quartz, ceramic fibre and other specialist yarns and various metals.

Braiding materials include glass, quartz, ceramic fibre and other specialist yarns and various metals.

Braiding materials include glass, quartz & ceramic fibres, other specialist yarns and various metals.

The company manufactures a broad range of cables including; thermocouple cables, RTD cables & PRT wires, sensor wires & cables, cryogenic cables, glass, quartz, ceramic fibre and pure nickel cables, the INTEMP® Range (250°C - 1250°C), radiation resistant cables, equipment wires & cables, high voltage cables, multicore cables, micro wires & cables, micro-coaxial cables, high-flex braided cables and PTFE yarns & threads. To support these activities Heatsense has its own specialist thermocouple calibration facilities and cable testing laboratory.

The company manufactures a broad range of cables including; thermocouple cables, RTD cables & PRT wires, sensor wires & cables, cryogenic cables, glass, quartz, ceramic fibre and pure nickel cables, the INTEMP® Range (250°C - 1250°C), radiation resistant cables, equipment wires & cables, high voltage cables, multicore cables, micro wires & cables, micro-coaxial cables, high-flex braided cables and PTFE yarns & threads. To support these activities Heatsense has its own specialist thermocouple calibration facilities and cable testing laboratory.

The high-performance cable range includes thermocouple cables, RTD cables & PRT wires, sensor wires & cables, micro-wire & miniature cables, cryogenic cables, heat resistant cables & wires – the INTEMP™ range of cables, glass fibre, quartz, ceramic & pure nickel cables, radiation resistant wires & cables, equipment wires, UHV & low outgassing cables, high-voltage wires & cables, micro-coaxial cables, bespoke cables, multicore cables, high flex braided cables, PTFE yarns and PTFE cable tapes & cords.

Heatsense has fully embraced LEAN manufacturing techniques and has made substantial progress on its continuous improvement journey. The company is currently working on Industry 4.0 technology, utilising digital processes on individual production lines to further improve efficiencies, quality and throughput rates.

Markets include, aerospace, nuclear, automotive,, medical, R&D, oil & gas and general industry. The company offers a range of approvals which meet internationally recognised specifications.

Markets include, aerospace, nuclear, automotive,, medical, R&D, oil & gas and general industry. The company offers a range of approvals which meet internationally recognised specifications.

See our online catalogue https://www.heatsensecables.co.uk/products/ heatsense-cables-product-catalogue

Heatsense remained extremely active during the COVID lockdown period. Over the course of the last twelve months Heatsense acquired plant & equipment, including 16 additional high speed yarn braiders, a PTFE Paste Extrusion Line, a horizontal twin headed taping line, an additional corona etcher and refurbished and upgraded a number of manufacturing lines. The company also upgraded its internal manufacturing systems and ‘went live’ on a new fully integrated ERP system.

Heatsense remained extremely active during the COVID lockdown period. Over the course of the last twelve months Heatsense acquired plant & equipment, including 16 additional high speed yarn braiders, a PTFE Paste Extrusion Line, a horizontal twin headed taping line, an additional corona etcher and refurbished and upgraded a number of manufacturing lines. The company also upgraded its internal manufacturing systems and ‘went live’ on a new fully integrated ERP system.

The company continually strives to broaden its manufacturing capabilities

The company continually strives to broaden its manufacturing capabilities

Heatsense continues to add specialist plant &equipment and over the last twelve months has installed a PTFE paste extrusion line, 26 additional high-speed braiders, a horizontal dual headed taping line, an additional corona etcher and refurbished and upgraded several

and improve efficiencies. The company continues to develop its digital strategy encompassing shopfloor data capture, ERP, CRM and machine automation.

and improve efficiencies. The company continues to develop its digital strategy encompassing shopfloor data capture, ERP, CRM and machine automation.

upgraded its internal manufacturing systems and went live on a new fully integrated ERP system. Heatsense has recently acquired the Cords & Lacing Tapes business from Carlisle Interconnect Blackburn.

This acquisition will present additional opportunities in the aerospace market.

Heatsense is ISO9001:2015 and ISO14001:2015 Accredited and has F4N Status (Fit for Nuclear), awarded by the Nuclear Advanced Manufacturing Research Centre. The company is in the process of working towards AS9100D:2016 Accreditation and expects to be accredited by the end of this year.

Heatsense is ISO9001:2015 and ISO14001:2015 Accredited and has F4N Status (Fit for Nuclear), awarded by the Nuclear Advanced Manufacturing Research Centre. The company is in the process of working towards AS9100D:2016 Accreditation and expects to be accredited by the end of this year.

Markets include aerospace, nuclear, automotive, medical, R&D, oil & gas and general industry.

T: +44 (0) 1706 767070 W: www.heatsensecables.co.uk

T: +44 (0) 1706 767070 W: www.heatsensecables.co.uk

Heatsense is EN9100:2018, ISO14001:2015 Accredited, has F4N (Fit for Nuclear) Status and is Cyber Essentials Plus Certified.

For further information please visit www.heatsensecables.co.uk and/or contact sales@heatsensecables.co.uk

For further information please visit www.heatsensecables.co.uk and/or contact sales@heatsensecables.co.uk

For further information please visit www.heatsensecables.co.uk and/or contact sales@heatsensecables.co.uk

Smaller, lighter and without time-consuming lens changes. The ImageIR® 6300 Z is predestined for demanding applications in research and development as well as for stationary or airborne inspection and monitoring tasks. Further applications can be found in quality assurance, materials testing or in a wide range of OEM integration solutions.

Smaller, lighter and without time-consuming lens changes. The ImageIR® 6300 Z is predestined for demanding applications in research and development as well as for stationary or airborne inspection and monitoring tasks. Further applications can be found in quality assurance, materials testing or in a wide range of OEM integration solutions.

Features:

Features:

■ Cooled focal plane array photon detector operating in snapshot mode with (640 × 512) IR pixels

■ Cooled focal plane array photon detector operating in snapshot mode with (640 × 512) IR pixels

■ Standard built-in 7.5x zoom lens with motor focus

■ Standard built-in 7.5x zoom lens with motor focus

■ Focal length of (15 ... 115) mm or (25 ... 170) mm

■ Focal length of (15 ... 115) mm or (25 ... 170) mm

■ Operation via smartphone or tablet with integrated web interface

■ Operation via smartphone or tablet with integrated web interface

■ Compact size and low weight for space-saving system integration

■ Compact size and low weight for space-saving system integration

■ Storage of large amounts of data on the integrated SSD

■ Storage of large amounts of data on the integrated SSD

InfraTec distributor in the UK and Ireland:

InfraTec distributor in the UK and Ireland:

Quantum Design UK and Ireland Ltd,

Quantum Design UK and Ireland Ltd,

1 Mole Business Park, Leatherhead, Surrey KT22 7BA Tel: +44 (0)1372 378822 | Email: info@qd-uki.co.uk

1 Mole Business Park, Leatherhead, Surrey KT22 7BA Tel: +44 (0)1372 378822 | Email: info@qd-uki.co.uk

JTS is a leading UK manufacturer of environmental test chambers. Our mission is to design and build robust environmental test chambers, working closely with our customers to provide innovative solutions for their own product development and quality assurance.

An issue faced by many customers is how to achieve the most test capacity without impacting on chamber performance. Putting the maximum test load in and still achieving even distribution and stability is a challenge when building bespoke equipment. Airflow is key and having a good understanding of how a customer will load their product ensures the best results are achieved.

For one JTS customer who’s test cycle lasts several months, incorporating steady slow ramps and long dwells, humidity distribution is critical. For them the distribution accuracy is so paramount the chamber is regularly calibrated using the 9 point mapping system. One probe in each corner just away for the chamber wall and one in the centre, the allowable tolerance in this scenario is 2% rh. During tests if the humidity fluctuates out of specification in any area of the chamber, the test is aborted.

Bespoke racking can help resolve distribution issues and the rack on this recent project was built to ensure good even air flow and ensure stability. With a temperature range of -20°C to +80°C and a humidity range of 20 to 98% the chamber spends a lot of time testing at high temperature and high humidity, over 95%. These conditions are harsh, so the test frame was built of stainless steel and to enable easy product loading, sliding compartments were incorporated in the design. Fully loaded this racking weighs around 600kg, so a reinforced chamber floor was essential.

Reliability of chambers that do long term testing is essential, down time causes testing backlogs and unwanted stress. Time spent understanding what is required of a chamber and how it is going to be

used, ensures JTS get the design and build correct. This in turn enables us to keep to our mission, to design and build robust, innovative solutions for our customers - something to rely on.

For further information, please visit www.jts-test-chambers.co.uk

Bespoke racking can help resolve distribution issues and the rack on this recent project was built to ensure good even air flow and ensure stability.

Unloading pumps are designed to unload a vessels or oil tankers liquid cargo in the shortest possible amount of time when receiving bulk deliveries of fuel. Oil cargos are typically transported via vessel as it is the most economical form of transportation for bulk cargo transfer and is only surpassed if fuel oils can be transferred via a pipeline eliminating double handling.

An overseas electricity provider contacted us who were having issues unloading light fuel oil (LFO) from their barge. The port would regularly receive shipments of oil cargo by vessel which docked over 50M away from the pump. The unit would operate for approximately 16 hours a day, unloading marine fuel for transfer to an oil storage tank located nearly 300M away, which was 10M high.

The customer was experiencing issues with their existing pump which was undersized, noisy and they wanted explore whether a better solution was available to improve marine fuel pump performance and reduce the amount of time vessels were kept moored at port and underutilised whilst discharging cargo.

The customer was experiencing several tell tale signs that their pump was undersized. Their screw pump which technology is normally very quiet was producing high levels of noise, there seemed to aeration of the pumped fluid which was detected by their Coriolis Flow Meter, flow rate was less than what the unit was designed for and flow was turbulent meaning there was the potential for inconsistent metering of unloaded fuel as some designs of flowmeters rely on a steady flow of fluid- all symptoms of what happens when a pump is undersized. Furthermore, when the vessel used a pump located on the vessel to boost flow, the aforementioned issues disappeared.

Unloading pumps are usually designed to produce high flows at low to medium pressures, are self-priming to ensure they

can completely empty a vessels cargo, have a wide viscosity handling to ensure they handle a variety of marine fuel oil derivatives from light distillate, to medium, and heavy fuel oils. Also known as stripping pumps, they enable the complete discharging of fluid from tanks without manual intervention or residue remaining in holds.

They are usually ATEX rated to remove any source of ignition and may have a motor suitable for inverter operation to enable operators to control oil transfer rates in particular when oil viscosity changes. Units can be heat traced as a way of maintaining a fluids viscosity and flow rate or to prevent solidification within the pump head. Similar pumps are also used in fuel bunkering and debunkering operations.

The client wanted a flow rate of 100M³H to 150M³H when pumping oil derivatives, be able to draw fluid from the barge and completely strip without manual intervention, whilst varying flow as required

Although pumps can typically only prime a maximum of 9.8M (based on water), and even though the suction pipework extended to over 50M away, in this particular application it was well within the capability of the design.

That is because most of the pipework runs horizontally, rather than vertically but care still needs to be taken to ensure that with the fluids viscosity, pipework diameter, and any vertical pipework sections do not amount to a pressure loss high enough to stop the unit functioning as it should.

The marine fuel transfer pump will produce varying flow up to 116M³H, be controlled via a Variable Frequency Drive and deliver pressures up to 8 Bar. Coupled to a 45KW ATEX WEG Motor suitable for operation via VFD the unit was assembled with 6” inlet and Outlet matching the clients existing pipework.

The new unit will speed up tanker offloading, will enable users to have increased control of tanker unloading and enable the unit to function without any of the issues experienced by the current installation.

If you are experiencing low flows, slow tanker offloading / loading or simply have a unit approaching the end of its useful life and want to see if process improvements can be made - speak to us to see how we can help.

The new unit will speed up tanker offloading and will enable users to have increased control of tanker unloading.North Ridge specified and selected our NRPZ Self Priming Horizontal Triple Screw Pump complete with ATEX rated Motor suitable for operation via Variable Frequency Drive (VFD).

Industry knowledge and application expertise across dispensing, dosing, full containment, gentle handling, blending and transfer, means whatever the problem, it’s likely we’ve seen it before. So we can help you solve it sooner.

+ Accelerated stator wear

Clogging

Changes to fluid consistency

Flow Reduction

consistency

Inconsistency in finished product

Inaccurate transfer of chemicals

Leakage | Liquid separation

Product Wastage

Seal wear or failure

We’ve been engineering sanitary pumps for sectors such as distilling, brewing, food manufacturing/processing, and more, for 20+ years. We understand industryspecific processes and know what it takes to optimise performance through bettersuited pump design - giving you complete peace of mind.

EXPERT GUIDANCE:

Our expert engineers understand your process and guide you through the options, so you can confidently select the most suitable chemically resistant pump. Want to optimise performance sooner? Speak to one of our specialists.

Valve Blockage or unintended Opening

If you are looking for a UK based toolmaker, then you need look no further than Cybertools. Cybertools are specialists in the design and manufacture of plastic injection mould tools. We have a fully equipped Toolmaking facility here in the UK and have over 25 years of toolmaking experience. We have quality standard ISO 9001 and ISO 14001 accreditation.

We are currently working towards ISO 13485 accreditation which is the medical industry’s optimal medical device standard.

We have a range of plastic injection moulding machines on site from 35 tonnes to 300 tonnes including two precision all electric machines used for tool trial and T1 first-off sampling as well as Factory Acceptance Test (FAT) and initial batch runs. We will work with you from initial concept and design through to production and assembly. All projects are designed, specified and guaranteed by our UK team with manufacturing optimised across our UK and Chinese facility according to your projects technical, budget and

delivery requirements. All mould tools are supplied warrantied and production ready. Cybertools provide a fast-response service for urgent repairs, with engineers available to visit your site to endeavour to minimise machine and tool downtime to protect your manufacturing schedules.

We always work through a thorough Design for Manufacture (DFM) process and mould flow analysis prior to producing a full General Assemble (GA) drawing for customer approval. This is done before we start work on manufacturing your injection mould tool. Once we start work on the tool a T1 date will be set and weekly updates will be supplied in the form of a Gannt timing plan and images of the engineering progression.

To further protect and maintain a tool throughout its life cycle, we always recommend customers take advantage of our Preventative Maintenance Contracts.

www.cybertoolsltd.co.uk

Rozone’s bioremediating ROwasher range outperforms every parts washer on the market and beats our previous machine’s running costs by 54.5% and uses 30%-37% less consumables.* The ROwasher is the first innovation in parts washing for decades. It is UKdesigned and manufactured, together with the bioremediating filter mat and the ROwash degreaser.

Contaminants such as oils and grease are always present in engineering and workshop environments. Current legislation makes us improve our sustainability, environmentally friendly, and health and safety credentials.

The ROwasher reduces toxic solvent use, cuts any toxic waste, and improves the technicians’ working environment, whilst reducing operating costs.

Discover

Process filter maker Amazon Filters has begun the latest stage of a £1 million investment programme designed to support industries worldwide that rely on process filtration.

Having opened a new production hall and storage space at its Surrey factory, the 37-year-old firm has now added fresh capacity to its housing component manufacturing with two semi-automated CNC mills going live.

The new machines will strengthen Amazon Filters’ policy of ‘vertical integration’ in which production activity is increasingly done in-house with less reliance on third parties or subcontractors.

The aim is to support ‘quick and able’ manufacturing, the fast, accurate capacity to turn round customer orders, including complex and bespoke projects, whatever their size and wherever they originate.

Adrian Price, Lead Fabricator, said: “As the global market expands, the ability to do things in-house becomes more important so we have taken the opportunity to grasp the nettle and improve our processes.

“Our work is very diverse and we relish the challenge of the one-off, for example if you have an oil and gas customer saying they need specific equipment to go that bit deeper in the oceans, it’s great to be able to say we can do it.”

The new CNC equipment complements a doubling of staff numbers in housing component manufacture from six operatives three years ago to 12 now and with a further appointment due in 2023.

Component manufacture involves the processing of raw, hardcore metal bars, blocks, sheets and tubes into parts ready for welding and final housing assembly.

Tube lengths tend to be three or six metres, weighing up to 130kg and with diameters of 12 or 16 inches.

Stored on huge racks, the raw material parts are moved into position for cutting, folding, drilling, marking and other processes using lifting aids including a motorised platform.

Most metal is stainless steel but, for some applications, the nickel alloy Hastelloy is the base material.

At any given time, hundreds of flat discs or plates are in the process of being turned into lids, top ends or end caps and with different-sized holes drilled to suit.

The team operate five distinct cells: sheet metal; de-burring and degreasing (the removal of very fine coats of oil); press; fabrication; and, most recently, machining.

Amazon Filters’ capital spend complements recent team appointments on the sales side, including territory managers for the Americas and Asian-Pacific regions.

For more information, visit www.amazonfilters.com or call 01276 670600.

As the global market expands, the ability to do things in-house becomes more important so we have taken the opportunity to grasp the nettle and improve our processes.Amazon Filters colleagues Troy Procter, right, Housings Production Support Technician, and Josh Booth, Housing Component Manufacturing Operator, in the firm’s dedicated production hub.

Amazon is a manufacturer and global supplier of a comprehensive range of microfiltration filter cartridges and filter housings for critical liquid and gas applications in various industries.

Amazon is a manufacturer and global supplier of a comprehensive range of microfiltration filter cartridges and filter housings for critical liquid and gas applications in various industries.

TMS CADCentre is a SOLIDWORKS Reseller based in Scotland. We are proud to support early-stage Start-ups (and Scale-ups) through the SOLIDWORKS Start Up Program. This is a three-year program providing entrepreneurs and start-ups free SOLIDWORKS software, training, and expert support to help them succeed.

In 2019 Freedom One Life joined the SOLIDWORKS Start Up Program with TMS CADCentre. Freedom One Life are disrupting the powered wheelchair market with the launch of the Series 5.

Freedom One Life was founded by Alex Papanikolaou, a powered wheelchair user. His frustrations with products on the market which constantly let him down and restricted his life due to limited range, breakdowns, and constant fear of being stranded made him question if powered wheelchairs could be designed differently. It turns out Alex wasn’t alone and met other people who were also fed up having to plan their lives around their powered wheelchairs. And so, Freedom One Life was born with the mission to enable users to live the life they choose.

The journey designing the Series 5 required the use of SOLIDWORKS to create concepts, validate designs and finally design parts and assemblies for manufacture.

Designing a powered wheelchair is not an easy task. There are a huge number of factors which need considered for every component and as all the parts connect together to form a complex assembly.

With SOLIDWORKS you can design, test using FEA (Finite Element Analysis), and visualise using the rendering package. Prototyping was difficult initially due to the size and cost of certain components. FEA contributed to the design process significantly and helped mitigate as much risk as possible before committing to expensive functional prototypes.

This not only saved Freedom One Life

CADCentre

invest in start-ups. The first year is always difficult and to have access to SOLIDWORKS makes a real difference. I’ve told everyone I know and work with about the SOLIDWORKS Startups Program and how good the benefits are.

Savage, Technical Director.money, but it also helped them have confidence going into medical device testing because they’d tested everything using SOLIDWORKS Simulation first. They also used SOLIDWORKS Composer to design the illustrations and layout of the product manual.

Now after years of development, refinement,

and continuous improvement of the Series 5, they are now ready to begin fulfilling orders.

To apply for the SOLIDWORKS Start Up Program please get in touch.

Tel: 01324 550760

Email: solidworks@tms-scotland.com Website: tms-scotland.com/solidworks

For further information, please visit tms-scotland.com/solidworks

Freedom One Life are disrupting the powered wheelchair market with the launch of the Series 5

I would absolutely recommend SOLIDWORKS Startups Program to other entrepreneurs. It’s great the support you can get from both SOLIDWORKS and TMS

and it’s a really good way toScott

Process automation has delivered huge benefits for manufacturers in many industries. In everyday use, plant operators are far from being made redundant, they still need to make regular inspections of the process, among other things, looking for leaks and making sure the control valves remain in good operation condition. These activities are made easier by local diagnostics indicators, which are used on valves and local control distributions.

Greg Wainhouse, UK Field Segment Manager for Bürkert, looks at the ways in which manufacturers of process control equipment are making life easier for the plant operators and maintenance technicians.

Process control infrastructures will predominantly use programmable logic controllers (PLCs) as the main hub for instructions, process monitoring and diagnostics. In many cases, these will be connected to human-machine interfaces (HMIs) to enable an easier way to interrogate the PLC without the need for a laptop computer.

However, all of this equipment is usually located away from the process itself as part of a decentralised control network. As such, it doesn’t help the plant technician as he makes regular inspections of the process to immediately see any issues with components such as the control valves. What is needed is a simple and easily assessed signal or display that highlights any issues locally.

Local, at-a-glance diagnostics can take several forms. The most obvious is the use of coloured LEDs that are located in the control heads of each process valve. With normal operation indicated by a green display, it is very easy to spot any out-of-specification operation, which is clearly denoted by amber or red indicators.

For a decentralised control architecture, local valve control islands predominantly offer very little in terms of diagnostic information. This is a typical situation where plant operators

would need to interrogate the PLC before they could gain any insight into any faults in the system. However, there is an alternative that can improve this situation.

The use of coloured indicators according to NAMUR NE107 is common practice in process control applications. Bürkert and many other manufacturers have used this standard across many product lines to improve the effectiveness and efficiency of plant operators. However, improving awareness of an issue is just the first step –rectifying the situation quickly is where the most significant savings can be made.

For applications that use decentralised control, the pneumatic valve islands provide the local process management, but any diagnostics would need to be carried out at the PLC. This can extend the time to resolve any problems or complete a maintenance task.

Bürkert has taken the concept of local diagnostics to the next level with its Type 8647 and Type 8652 pneumatic valve islands by providing on-board diagnostics and messages via an LCD screen which is located on each channel. This means, for example, that a blue indicator light, which highlights a maintenance issue, can be

quickly identified and resolved by reviewing the additional information provided by the LCS screen.

This additional information is also very useful during installation and commissioning work. The ability to access diagnostic information locally can significantly reduce the time required to complete an installation. An overreliance on the HMI to provide all the system information means that installers and plant operators need more time to identify issues and find the root cause.

To compound the situation, the PLC will only pass on warnings or alerts about circuits or problems that it has been programmed for. Normally, this would be done during the commissioning process, but there are opportunities for some warnings to be overlooked or new equipment may not be fully integrated.

Furthermore, unless all of the codes from the control valves and sensors have been correctly interpreted in the PLC, this information may be missing or misidentified. Rather than interrogating the PLC or repeatedly going back to the HMI to read the messages, the best solution is to use local diagnostics as a quicker route to identifying any issues and getting them resolved.

For further information, please visit www.burkert.com/en

The ways in which manufacturers of process control equipment are making life easier for the plant operators and maintenance technicians

Compressing air in a compressed air system requires a lot of power and results in continuous pressure losses during transport from the point of generation to the point of consumption - This makes compressed air one of the most expensive forms of energy of its kind. For this reason, Micronel‘s powerful compact blowers are becoming increasingly utilized in the market for pressure and vacuum applications.

Compressing air in a compressed air system requires a lot of power and results in continuous pressure losses during transport from the point of generation to the point of consumption - This makes compressed air one of the most expensive forms of energy of its kind. For this reason, Micronel‘s powerful compact blowers are becoming increasingly utilized in the market for pressure and vacuum applications.

• Compact design and flexible positioning at point of use

• Compact design and flexible positioning at point of use

• Extremely small sizes – Typically 50 mm diameter up to 100 mm x 100 mm square

• Extremely small sizes – Typically 50 mm diameter up to 100 mm x 100 mm square

• Lower operating costs with higher efficiency

• Lower operating costs with higher efficiency

• Work independently of existing compressed air systems

• Work independently of existing compressed air systems

• Robust aluminum housing for harsh industry conditions

• Robust aluminum housing for harsh industry conditions

• Maintenance free and long lifetime

• Maintenance free and long lifetime

• Quiet operation with optional silencer and accessories

• Quiet operation with optional silencer and accessories

Micronel UK Ltd. Unit 53, The Arches Industrial Estate Alma Road, Windsor, Berkshire SL4 3HY United Kingdom

Micronel UK Ltd. Unit 53, The Arches Industrial Estate Alma Road, Windsor, Berkshire SL4 3HY United Kingdom

Phone +44 1753 641 412 info@micronel.co.uk www.micronel.com

Phone +44 1753 641 412 info@micronel.co.uk www.micronel.com

The new Tricor PRO Plus Series of Coriolis Mass Flow Meters is an accurate and highly repeatable meter with the smallest installation length on the market for installation into systems where space is limited.

The TCD transmitter offers greater robustness, performance, diagnostics, and connectivity options. With a modern HMI interface and excellent logging functionality, the DSP transmitters provide users with an efficient configuration and analysis tool.

PRO Plus Series Features:

• High dosing accuracy due to short response time (max. 10 ms)

• 100 Hz refresh rate makes this series suitable for pump monitoring and fast response control

• Extremely short installation length makes for an easy fit in most configurations

• Excellent zero stability for drift-free accuracy and longterm reading assurance

• Extensive diagnostics and self-monitoring, including empty pipe detection

Sizes from ½” to 2”.

Available from Litre Meter, call 01296 670200, now.

www.litremeter.com

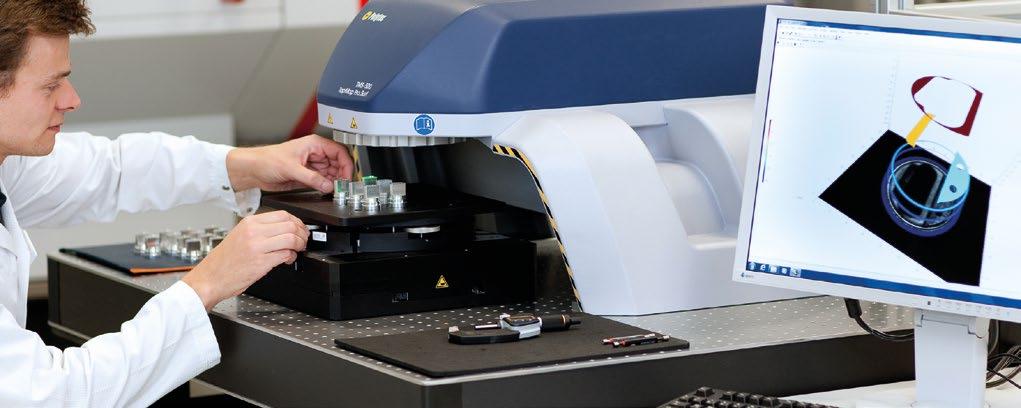

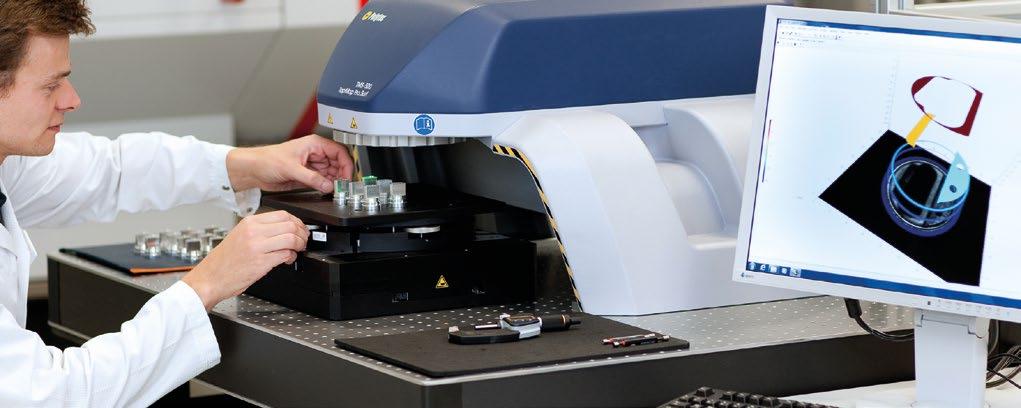

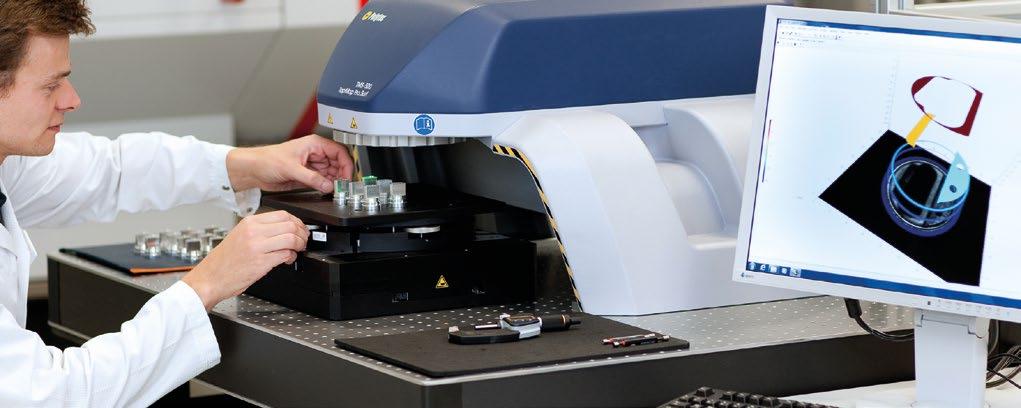

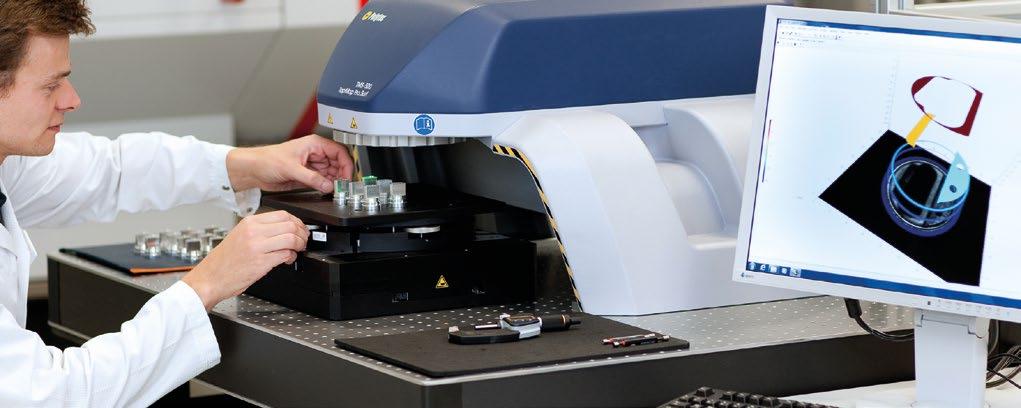

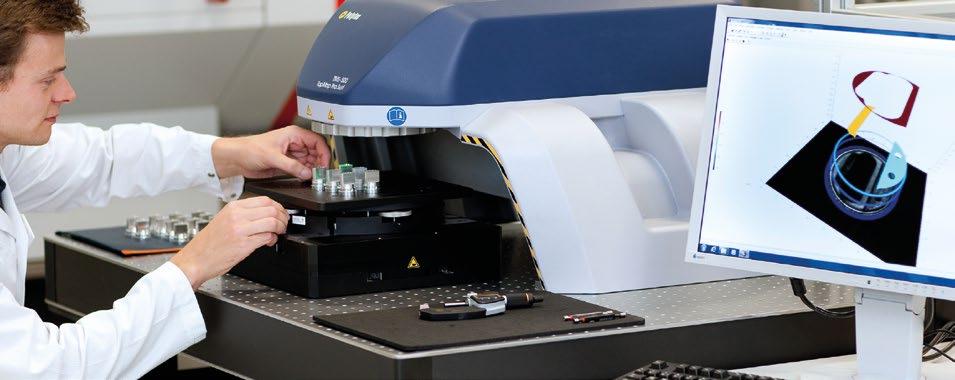

ODIN is a new, compact, and reliable deep UV resonant Raman instrument developed by IS-Instruments (IS-I) and TOPTICA for measurement of biopharma products.

ODIN is a new, compact, and reliable deep UV resonant Raman instrument developed by IS-Instruments (ISI) and TOPTICA for measurement of biopharma products. TOPTICA’s Industrial CW Laser TopWave 229 enables new Deep UV Raman Spectrometer ODIN.

The system combines the newly developed solid state diode laser TopWave 229 and a spatial heterodyne spectrometer integrated into a single instrument with a unique all-reflective backscatter Raman collection probe. Sample damage caused by extended laser exposure has been mitigated via the introductiwww. toptica.comon of a dynamic sample positioning stage.

www.toptica.com

Winn

First established as an import/export house in London in 1883, the company has earned an enviable reputation for supplying high-quality, effective, long-term solutions for its customers problems. It’s well-known brands such as Denso™, Premier™, Archco™, Protal™, Premier Shrink Sleeves™, Steelcoat™, SeaShield™ and Sylglas™ provide effective protection for buried, submerged, or exposed steel and concrete pipes, tanks, and structures. A vast number of industries benefit from the tailor-made solutions Winn & Coales provide, with the company demonstrating a clear commitment to continual improvement of its product offering through innovative research and development, and product acquisitions – a notable example of which being Viscotaq™ visco-elastic coatings in 2021.

Today, Winn & Coales International Ltd. comprises seven subsidiary companies – two in the UK, and one each in the USA, Canada, South Africa, Australia, and New Zealand – with multiple regional offices, and a network of global agents and distributors. The shared knowledge and experience across the group of companies ensures its extensive range of corrosion and chemical resistant coatings and linings are available almost anywhere in the world.

Winn & Coales International Group Chairman, Chris Winn says, “It is with great pride that we celebrate this remarkable milestone for the company. As we reflect on the last 140 years, we also look forward to the future with tremendous excitement as our continued programme of investment and growth brings new technologies to our customers.”

www.denso.net

As a distributor in today’s market, it is not enough to simply supply a product, you need to be able to offer something unique. Thanks to their technical knowledge and flexibility, Star Fasteners have the ability to work alongside project designers and mechanical engineers from a diverse range of industries, ensuring that customers are offered the most appropriate and costeffective technology for their application.

The Huck® fastener range is used where high structural strength is required. Offering a clean and safe alternative to welding and a more efficient fastening method than standard nuts and bolts, Huck Fasteners offer benefits which other fastening methods cannot. These include quick and easy installation, elimination of re-checking / replacement and ultimately cost reductions. Each Huck fastener has its own unique characteristics ensuring that there is a product for every application. The business Lou Huck founded over 60 years ago and the fasteners he designed are still solving the problem of coping with extreme stress and vibration, providing strength and facilitating lighter, stronger, more durable structures. Today the product range based on his original design has evolved to include a diverse range of LockBolts® and structural blind fasteners.

Huck Fasteners are used in a wide range of markets including truck, trailer, horseboxes, automotive, air conditioning, bus / coach, portable buildings, doors and door gear, agricultural machinery, green energy, rail; in fact, anywhere that needs a dependable fastening solution.

For years, welding was seen as the only way to ensure the integrity of joints in demanding load-bearing or high-vibration structures. Companies manufacturing heavy-duty equipment or fabricating large, metal structures employed the universally accepted process of welding joints together. However, today there are alternatives to welding, one of the foremost being directtension installed, swaged LockBolts.

The pin is inserted into the prepared hole, and the collar is spun onto the pin.

The installation tool is applied to the annular pull grooves. When the tool is activated, a puller in the nose assembly draws the pin into the tool, causing the swaging anvil to press on the collar, drawing up any sheet gap.

HuckBolts® (or Huck LockBolts) are precision engineered two-piece fasteners that, once installed, no matter how vibration-intensive the environment, do not come loose. HuckBolts provide direct metal-to-metal contact when installed, which eliminates the transverse vibration often found in conventional nuts and bolts. Engineered for a wide range of applications, HuckBolts deliver superior joining, shear, and tensile strength for an unmatched fastening solution.

HuckBolts can be used with virtually any metal; dissimilar metals, coefficients of thermal expansion, present no problems. Varying material thicknesses in a joint are readily accommodated, and surface finishes are not damaged. Most importantly, HuckBolts have proven to hold up over years of service in demanding, high-stress, high-vibration environments.

The pin of a LockBolts is simply inserted into the pre-prepared hole and the collar can either be placed straight onto the pin, or where project pre-assembly is required, can be pre-installed, spun by hand onto the

At a predetermined force, the anvil begins to swage the collar into the pin’s lockgrooves. Continued swaging elongates the collar and pin, developing precis* clamp.

When swaging of the collar into pin lockgrooves is complete, the tool ejects the fastener and releases the puller to complete the sequence.

pin (*depending on the product used). When the installation tool is applied and the tool is activated, the action of the puller engaging onto the pin, together with the anvil swaging the collar, completes the installation. The swage and eject sequence are programmed to complete the cycle without any additional installer input. The process ensures excellent gap closing capability.

Manufacturers of heavy equipment are now using direct-tension LockBolts in their assembly process. Even taking into consideration the need to prepare a hole to take the fastener, installing a LockBolts is significantly faster than welding a joint. Once installed, a quick visual inspection is all that is required to confirm the accuracy and quality of the installation. Operators require minimal training in order to be proficient in the fastener’s installation.

These unique engineered fasteners, proven in demanding applications such as truck suspensions and chassis, railroad track crossings, and heavy defence vehicles, are now being used in a wide range of of products and structures where welding was once the only option.

Compared to conventional nut and bolt installations which can loosen in highvibration environments, HuckBolt® have proven to be impervious to the effect of vibration in a number of very demanding applications. The secret to this performance difference can be found in the unique HuckBolt design, in which the collar is fully swaged into the locking grooves of the pin.

Huck® LockBolt brand names include, BobTail®, Magna-Grip®, C6L®, C50L®, C120L® and Hucktainer®; each differing in design, diameter, grip range material, plating and purpose.

Huck BobTail fasteners are available in a wide range of sizes (up to 1-3/8 inch). The two-part fastening system consists of a pin and a collar. These advanced fasteners are installed using a direct tension technique, in which the pin is pulled and the collar is simultaneously swaged into the locking grooves of the pin, deforming the collar into the grooves.

Declared by DIBt as “maintenance free”, the 12mm, 14mm, 16mm, 20mm and 1 inch diameter BobTail is approved to be used in both static and dynamic civil engineering applications (smaller and larger diameters are available by request).

The DIBt test confirmed that a BobTail is maintenance-free during the lifetime of the joint it is fastening, which is not the case when using traditional nut and bolt products. As a result, it can be integrated into a range of applications with complete confidence by civil engineering designers.

Through its advanced fastener design the BobTail system offers a strong connection. One key advantage of this fastener over conventional LockBolting systems is that

HuckBolts® (or Huck LockBolts) are precision engineered two-piece fasteners that, once installed, no matter how vibration-intensive the environment, do not come loose.

it doesn’t have a pintail to break off. As a result, there is no waste material to collect and dispose of post-installation. The added benefit of this is that the tools are lighter and smaller as they do not need the force to break the pintail off, as traditional Lockbolt tools do.

The BobTail is installed using a quiet, jolt-free swaging action, eliminating the potential for repetitive stress syndrome issues. It has significantly reduced noise levels, typically less than 70dB. The elimination of the shock load and reduced noise can offer real and significant health and safety benefits.

Using the Huck BobTail in key joining applications helps remove housekeeping and safety issues that are integral to the welding process. There are no sparks to start fires or cause explosions, nor any debris on the floor that can lead to slips and falls.

When only one side of the joint material is accessible, performance-engineered Huck structural blind fasteners have a solution. Each designed and engineered with a unique set of features and delivering

solutions to common manufacturing challenges; hole-filling, water-resistance, wide grip ranges, welding replacement, to self-grounding fastening solutions, all offering high-speed assembly. Huck structural blind fasteners are engineered with a unique locking design, an internal ‘lock’ is created during installation that virtually eliminates pin push-out by mechanically ‘locking’ the pin to the sleeve. Simple, visual inspections ensure joint integrity.

Huck® structural blind fastener brand names include, Auto-Bulb®, BOM®, FloorTight®, Hucklok®, Magna-Bulb®, Magna-Lok®, Magna-Tite®, and Penta-Lok™. Again, each differ in design, diameter, grip range, material, plating and purpose. In applications where vibration resistance, reliability, and strong-hold are critical, no fastening system is more dependable than Huck.

In-house and on-site tool repair and servicing, makes sure that customers production lines are kept rolling and fasteners are installed correctly. The inhouse powder coating facility also means that fasteners can be pre-coloured to customers specifications.

Star Fasteners have a close relationship with their suppliers’ and are proactive in designing products and developing new ideas. Technology is always evolving; customers often require fasteners with specific design requirements and want to develop projects beyond the norm or to push the limits of current fastening technology. Being hands-on and keeping up with new developments is core to Star Fasteners success; any new developments are seamlessly integrated into the existing product range. Star Fasteners are definitely not just a fastener distributor, but a company that is proactive and one that offers something different; a solutions provider.

Email: sales@starfasteners.co.uk Tel: +44(0)115 9324939

For further information, please visit www.starfasteners.co.uk

A Birmingham-based apprentice turned Manufacturing Director has been named as one of industry’s Top 100 professionals.

Stuart Berry, who joined metal stamping and tooling specialist Brandauer 15 years ago, was recognised by The Manufacturer as an Exemplar in the Innovation, Inspiring Leader and Young Pioneer categories.

The passionate advocate of engineering impressed judges with how he has used vocational learning to progress to the very top of his profession, securing a ‘First Class’ BEng Honours degree in Management of Manufacturing Systems in the process.

Judges at the high-profile event in Liverpool also praised his role in helping the company diversify into new markets, combining a strong production methodology with a commitment to the latest technology, delivering a host of product introductions for a male grooming product, nose clips for face masks and wafer-thin laminations for electric vehicles.

Stuart commented: “There are some things in life that take you completely by surprise and this is one of them. To be named in The Top 100 manufacturing professionals in the UK is a massive honour, to be named an Exemplar in that prestigious field is mindblowing.

“From the minute I stepped on the shopfloor at Brandauer, I knew I wanted to learn as much as I could and progress in industry. Sometimes it’s about finding the right company that gets you and you get them, that’s what happened here and we’ve both benefitted.”

More than 250 people gathered at The Exhibition Centre in Liverpool last night to recognise the best talent in UK manufacturing.

Stuart, who was joined on stage by Make UK’s Stephen Phipson and Donna Bruce of Northern Lights, has recently played a key role in the development of the UK’s first

From

£1m Precision Tooling Academy in the West Midlands.

A joint project between Brandauer and In-Comm, the purpose-built commercial toolroom will produce complex tooling, as well as acting as a professional training ground for the toolmakers and designers of the future.

This is a vital move for domestic industry, with the sector being held back by a severe lack of toolmakers and the very real possibility of losing these essential skills forever as older workers choose to retire.

The Precision Tooling Academy aims to reverse this trend by offering companies access to professional toolmaking courses, upskilling opportunities for qualified engineers looking to diversify their skills and a Level 6 Tool Process Design Apprenticeship to develop the next generation of talent.

Training will be unlike anything currently on the market, with up to 35 individuals in the first twelve months able to learn on live tooling projects that will be producing hundreds of thousands of parts every week and, under Stuart’s guidance, will give Brandauer and other tooling experts the opportunity to reshore more manufacturing projects from Asia, the EU and the US.

Stuart concluded: “Embarking on an apprenticeship has been so good for me and that’s something I want to get across to the next generation…this Top 100 title will definitely help me to do that.”

The Manufacturer Top 100 are the most dynamic leaders and innovators in manufacturing, as nominated by a 265k-strong audience, the wider industrial community, and judged by an esteemed panel featuring leaders of industry, academic institutions and manufacturing associations.

For further information, please visit www.brandauer.co.uk or follow @cbrandauer on twitter.

Former Birmingham apprentice is named as one of the top 20 manufacturing professionals in the UK

BRANDAUER

the minute I stepped on the shopfloor at Brandauer, I knew I wanted to learn as much as I could and progress in industry.

The Wireless Data Logging System RTR500B series from T&D is the ideal solution for measuring and storing physical data. Designed to record and measure data such as temperature and humidity, the RTR500B series includes data loggers and a range of base stations to ensure the safe, wireless collection and storage of data.

The system uses T&D’s proven short-range wireless communication for logger to base transmission, and the RTR-500B series is also compatible with HTTPS – an encrypted communication feature that ensures superior security. Furthermore, users can register devices and adjust settings not only from a PC, but also a smartphone or via the cloud for greater flexibility and convenience.

The wireless communication range between base and remote units, if unobstructed and direct, is about 150 metres (500ft). However, repeaters can be easily added for an even greater range across a variety of environments. And when used in conjunction with RTR-500BC repeaters, the base unit will automatically select the best route for stable, wireless communication.

The wireless communication range between base and remote units, if unobstructed and direct, is about 150 metres (500ft).

By adding the base unit to the free, cloudbased T&D WebStorage facility, recorded data can be automatically uploaded, managed and accessed anytime, anywhere. Automated data collection

is carried out using a robust wireless communications protocol.

The devices in the new RTR500B Series are compatible with the earlier RTR-500 series, but also have additional Bluetooth capability. This means mobile devices can be used for data logger and base station registration, and to adjust settings.

The base units in the new series comprise: RTR500BW, for transferring data to the cloud or server via a wireless

and wired LAN connection, RTR500BC, for downloading data to a PC connected with a USB cable, and also with repeater functionality, and RTR500BM for transferring data via 4G mobile connectivity. This impressive line-

up of RTR505B data loggers meets multifunctional measurement needs including temperature (Pt 100, Pt 1000, TC type K, J, T, S), voltage (4-20mA) and pulse count.

T&D’s RTR-500 series offers the RTR-574 for monitoring illuminance, UV intensity, temperature and humidity. The RTR-576 can even measure CO2 concentration, and the RTR-500DC as a wireless portable data collector can be used in conjunction with the RTR-500B series.

Warnings for upper and lower limits can be made via the settings. Users can also be alerted to sensor faults, low battery or communication errors, and notified

by email or SMS. In addition, an external alarm output is built into the base units.