EDUCATION EXPERIENCE

09.2021-01. 2023 Architectural Association School of Architecture

- London, UK

- Master of Architecture (DRL Bhooshan Studio)

- AA Bursary

Sep 2015-Jul 2020 Xi'an University of Architecture and Technology

- Xi'an, China

- Bachelor of Architecture

- Comulative gpa:3.2

Name:Qizheng Zhang ( Michael)

Date of birth:07/11/1997

Nationality:Chinese

E-mail:Michaelzhang97@outlook.com

Tel:07743730327

Loc:London

Student Member of Architectural Society of China

LANGUAGE

English IELTS7.0

Chinese native

SOFTWARE SKILLS

CURRICULUM VITAE QIZHENG ZHANG

USED FREQUENTLY

Rhino Grasshopper

Maya Poly-Modeling

Unreal Engine

V-ray

Enscape

Twinmotion

Photoshop

AWARDS

Premiere Indesign

KNOWLEDGE OF

Robotic Arm

3D Printing

Autocad

Sketch Up

Illustrator

Revit

Bursary AA Design Research Laboratory

-AA DRL 2021.04

First class award

-Postgraduate of Xi'an University of Architecture and Technology, 2020

Winning Award

-Architecture School of XAUAT Spring Course Design Defense, 2019

Second Prize

-International Pavilion Construction Competition at Tongji University, 2016

REFERENCE

Shajay Bhooshan shajayb@aaschool.ac.uk

Kecheng Liu ccch@xauat.edu.cn

Yinquan Yu yuyq@cbs.com.cn

PROFESSINAL EXPERIENCE

Jun 2021-Mar 2021 China Architecture Design and Research Group (CADG)

Architectural Intern

- Beijing, China

Jul 2019-Nov 2019

Architectural Intern

- Beijing, China

-Involved projects: Capital Museum East Hall Project (Built)

Tasks : Responsible for steel structural deepening design Detailed and rationalized design (Grasshopper&Rhino) , realizing parametric adjustable nonlinear steel structures

Air corridor deepen modeling & detail drawing, plan drawing, render

Architectural Design and Research Institute of Tsinghua University (THAD)

-Involved projects:Dahe Cultural Plaza Project,Project design of Hainan Science and Technology Museum,Design of Yulin Vocational School

Tasks:Rendering,reporting, design options,construction drawing

Aug 2018 Beijing Institute of Architectural Design (BIAD)

Architectural Intern

- Beijing, China

-Involved projects:Details of doors and windows,Shijiazhuang Vocational and Technical School

Tasks:Rendering,construction drawing

COMPETITION EXPERIENCE

Jul 2019 ARCASIA Students’ Architectural Design Competition 2019

-Qualified to participate, represent for XAUAT

Sep 2019 2019 Velux

-Participant, designed a liftable living landscape installation for tramp

Jun 2018 International Pavilion Construction Competition

-Holded by Tongji University, Using TwinWall Polypropylene Sheet to construct a modular tessellation self-supporting Pavilion

EXTRACURRICULAR ACTIVITIES

Aug 2020-Nov 2020

Rapid Design Teacher

-Teaching on drawing rapid design fuction,plan,building exterior,axonometric drawing

Feb 2017 Member of the China-Japan Friendship Youth Group

-"Civil Disaster Prevention Group"

Learn and exchange technologies for earthquake disaster prevention, earthquake mitigation and disaster relief.

Jul 2016 Design of the rest station for Xi'an sanitation workers

-Excellent works appeared in Xi'an Evening News

Sep 2015-Jul 2017 Officer of Outreach Department of School of Architecture

-Get sponsors, negociate with the merchants

Associate Director, Zaha Hadid Architects | Co-founder and Head of ZHACODE

Professor of Xi'an University of Architecture & Technology

Vice president of China Institute of Building Standard Design & Research Co.,

Infill-DenCity —— Citizen Centric Cites

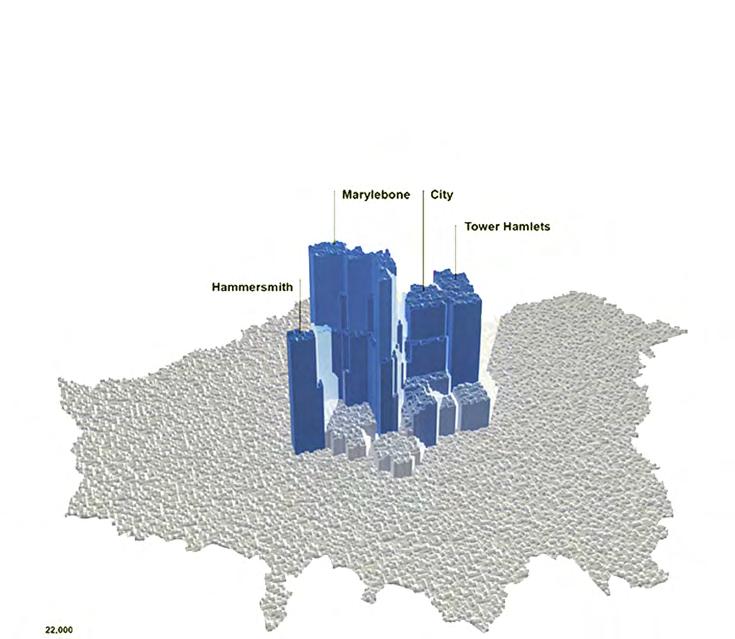

Is London’s central mile at the peak of its usability, or is that an illusion? Recent data shows that the city of London hosts the jobs of over 400,000 people while only 9,000 reside in it. Further to this, the number of inhabitants in this part of the city has halved since Victorian times. Not only does the Central Mile have scope for growth, but there is also a significant percentage of unoccupied residential properties. Despite these reasons, there is negligible land to construct upon, with even the most minute sliver in the central mile serving a purpose.

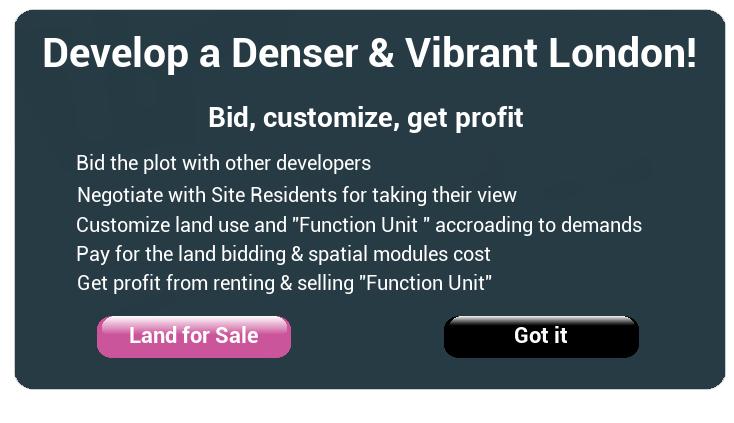

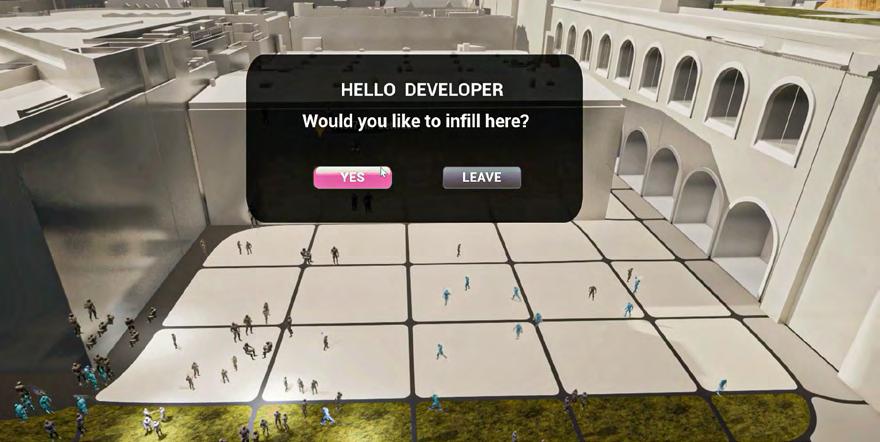

Infill-DenCity, by virtue of infill development, explores the possibility of building upon and amongst the existing built environment. This is facilitated by incorporating governance technologies, designed to allow real-time, collaborative negotiations between developers and end-users via a game interface. This saves a considerable amount of time compared to existing procedures, wherein approvals can take up to 26 weeks and even longer. The use of Gov-Tech helps achieve a transparent funding and decision-making process before reaching a consensus on material construction.

Infill-DenCity aims to create a prototypical Citizen Centric City orchestrated by the active participation of its end users, residents, and other stakeholders while diminishing the gap between residential and commercial density.

Full Video:

https://youtu.be/d6--_N-hT_o

Location: London, United Kingdom

Academic work: January 2022 - January 2023

Studio Master: Shajay Bhooshan

Tutor: Ariadna Lopez, Leo Beiling

Email: Shajay.Bhooshan@zaha-hadid.com

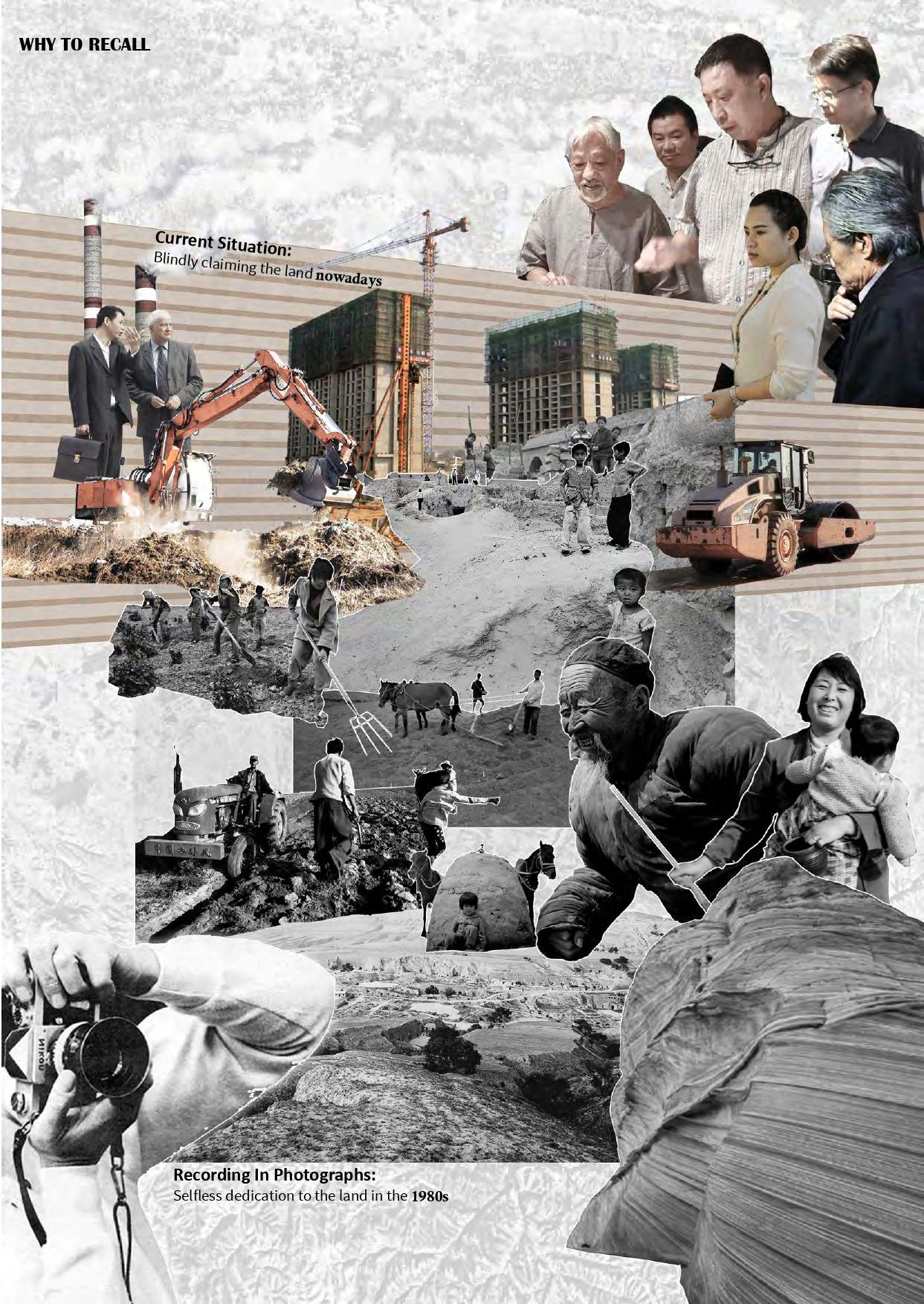

Why Densification

Residential properties 1800-2011

The City of London has experienced a rather horizontal growth, like that of sprawl, as seen in the images above. Until the Victorian era, more people lived in the city's core than anywhere else. That is, however, no longer the case. Even though the square mile of the city of London is the one to attract the most customers, offices, and activity in general, there are as many people living on the outskirts as there are within its limits. This is problematic as the number of job owners in the city of London is almost 45 times more than the number of home owners.

Infill Site - City of London

Infill Goal : Densify Co-Working & Co-Living

400,000 Employees

9,000 Residents

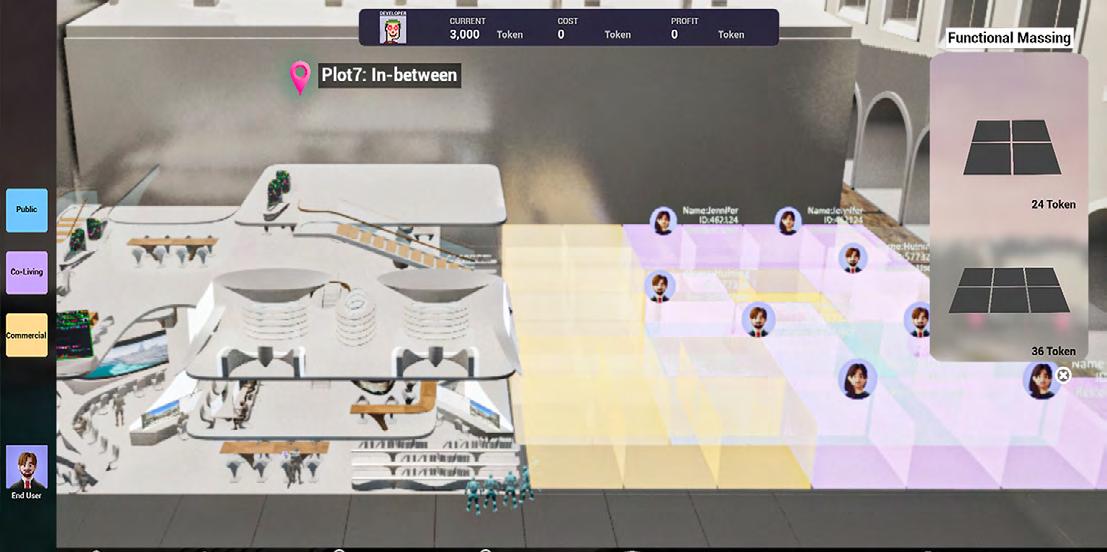

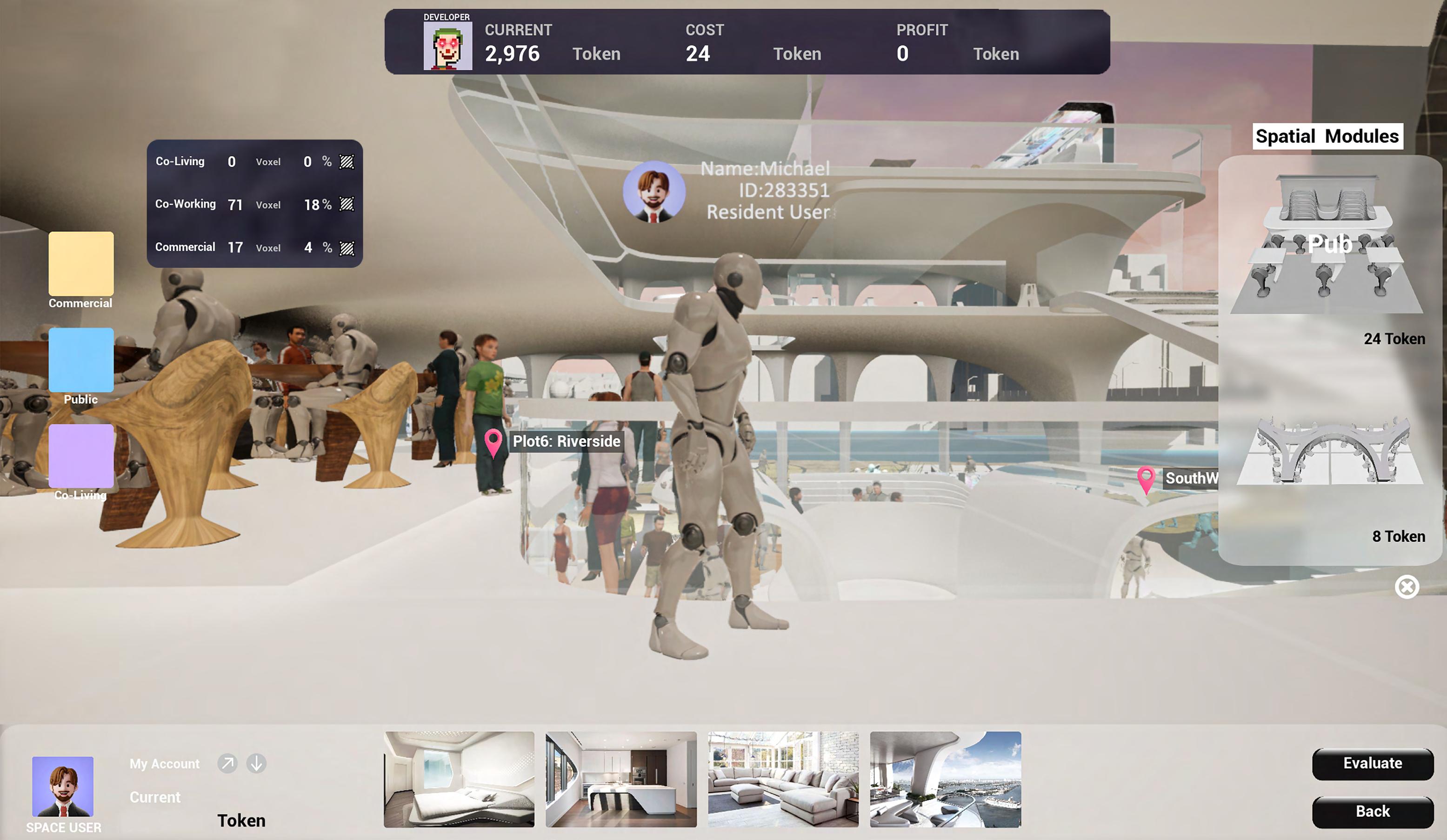

Gamification Participatory Platform

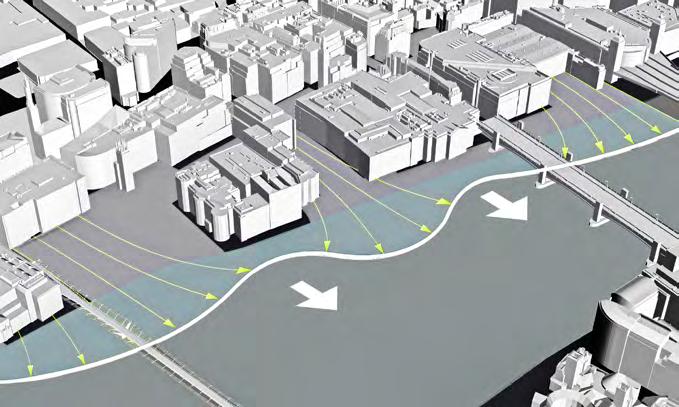

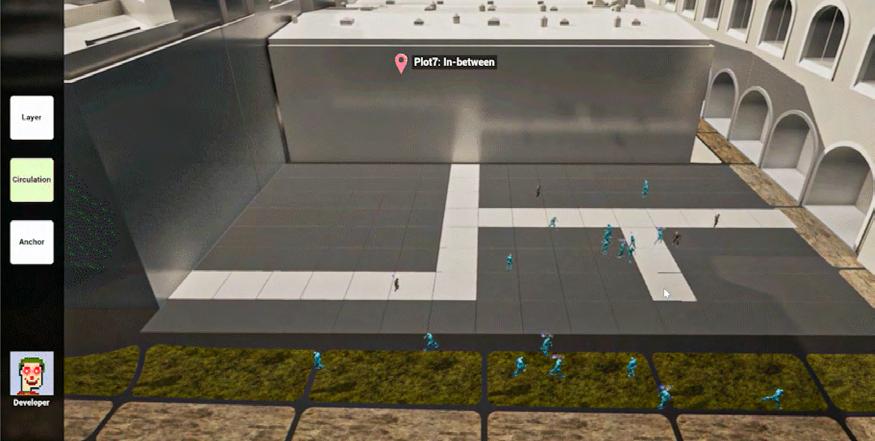

The updated waterfront is generated according to the position of crowds gathering area and the infill site, guiding people to the place with good views.

Architects provide a proposal to re-plan the circulation according to the existing urban fabric and alignment of initial grid.

It is the architect's responsibility to provide an attractive waterfront landscape that serves as a hotspot area for the site.

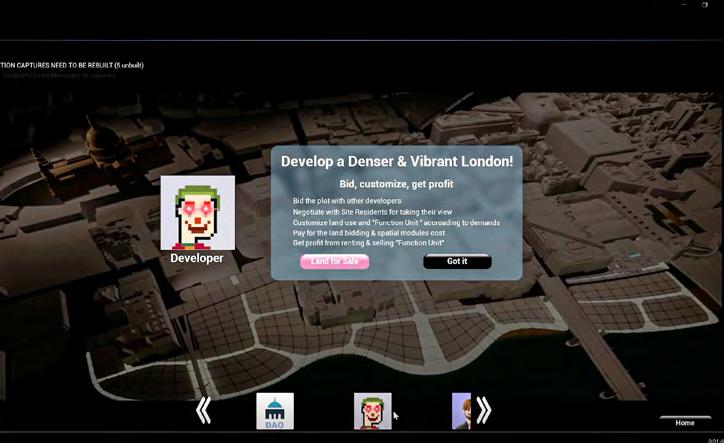

Avatar brings the player to the metaverse.Players can choose the role to start develop the proposal.

All players need to participate in the game process,they can bid, negotiate, make decisions.

Shareholders need to reach consensus to co-located develop the proposal.

Game allow users to choose and configure the programs they want and promote engaging spaces.

Players can invest the plot they interested in and get profit from rent, sharing spaces, spatial NFT.

After playing the game, players can rate the space then incubate the spatial NFT they aggregated.

In this participatory game, there are three characters, Dao and two other player groups, the developer and the end-user. Dao put the plots for auction, trying to maximize society's welfare. Developers can choose the plot they are interested in and bid with other developers. do the circulation when the grid is subdivided. and choose the anchor point as a game starting point, attracting other end users to add function units.

Problem Solving FrameWork

Player Actions

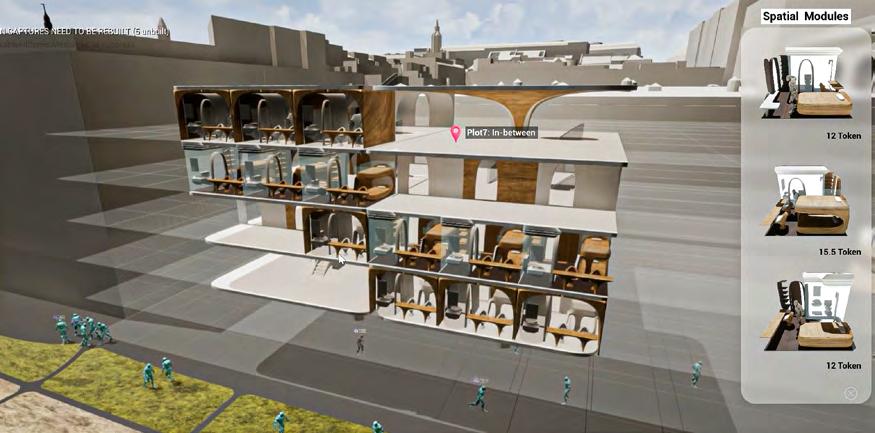

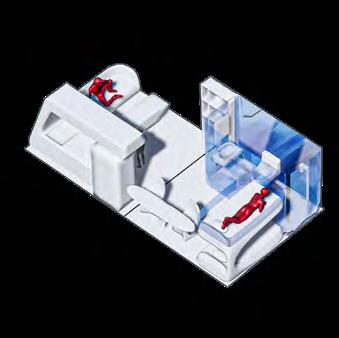

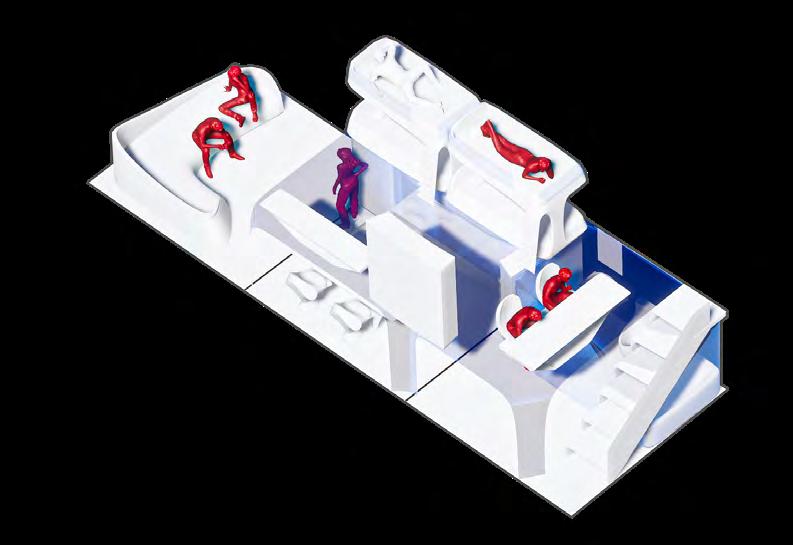

Interior Module Assets

Evaluate the Customization Results Rate the Aggregated Spaces

Co-Working Components

Capacity: 20-30

Area: 144 Sqm

Density: 5 Sqm/p

Public Library Components

Capacity: 60-70

Area: 288 Sqm

Density: 5.5 Sqm/p

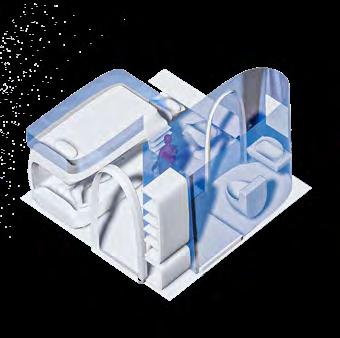

Based on the thesis and scenario, architects developed furniture from the standard interior voxel: a 4x4m square. Users connect the modules in different directions according to their needs.

Co-Living Modules

Assembled from furniture assets to meet the needs of different groups of users to live here, architects designed different sizes of co-living modules. Assets have single, double, and larger dormitories. Shared spaces users could have more if customized areas are larger. such as study rooms or shared kitchens.

Capacity: 10-20

Area:144 Sqm

Density: 7.2 Sqm/p

Public Retail Components

Capacity: 20-30

Area: 288 Sqm

Density: 16 Sqm/p

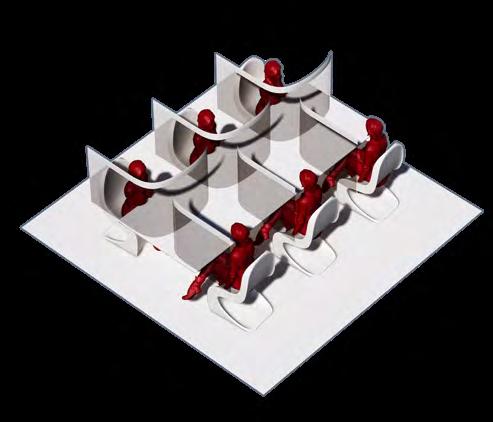

Co-Working Modules

In Co-working spaces, office furniture is more flexible than in traditional office spaces. People can connect the assets through different orientations. At the same time, architects provide conference spaces for users of different sizes.

Capacity: 20-30

Area: 144 Sqm

Density: 5 Sqm/p

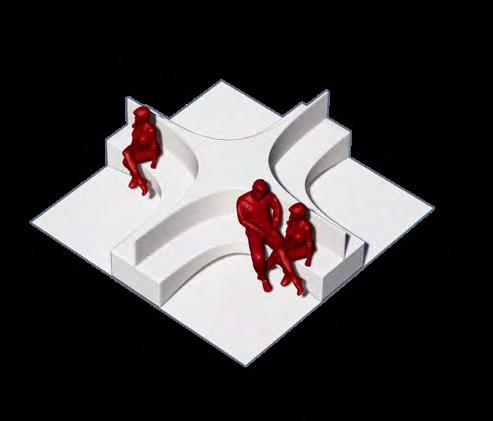

Public Space Components

Capacity: 60-70

Area: 288 Sqm

Density: 5.5 Sqm/p

Capacity: 10-20

Area:144 Sqm

Density: 7.2 Sqm/p

Capacity: 30-40

Area: 384 Sqm

Density: 384 Sqm/p

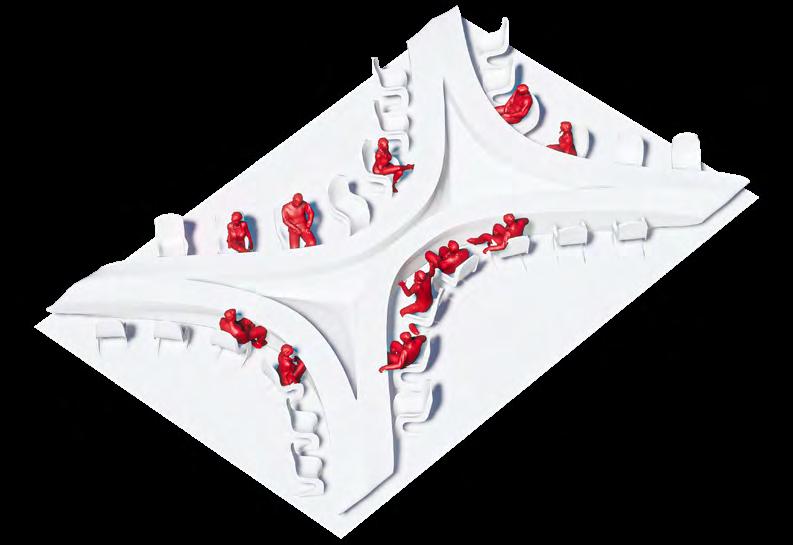

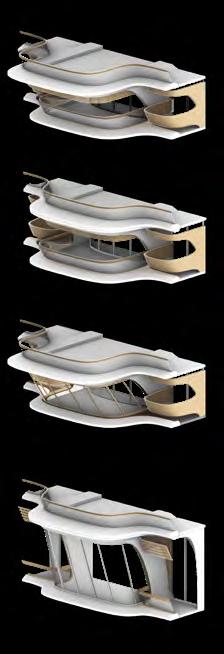

In-Between Infilling Result

For public spaces, users can choose double-height structural modules to improve space utilization.

After choosing the structure, user first customizes the interior modules according to their needs

When the users start to build the upper floor, stairs will be built next to the structures.

the same time, the footing points of the columns can be aligned with each other.

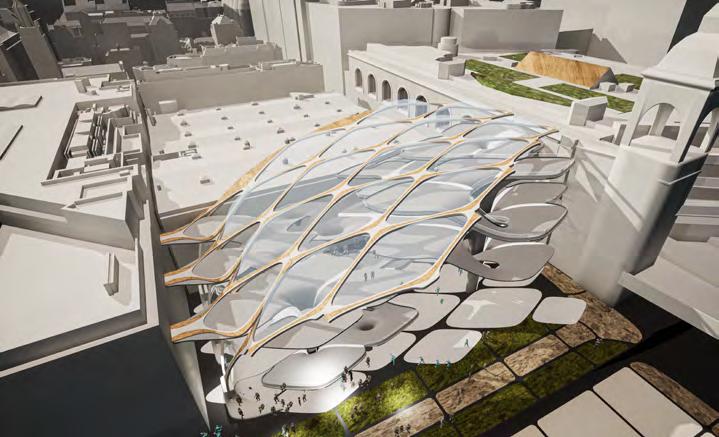

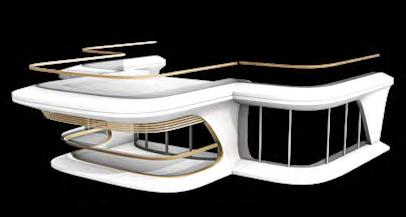

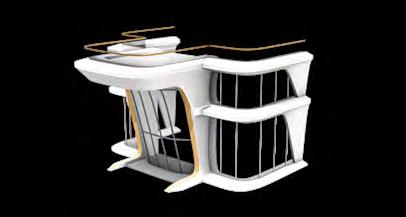

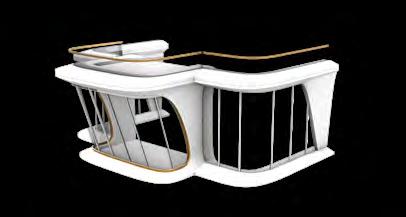

The single voxel aggregation is composed of a modular structure, river-facing and city-facing façade, and interior program. The river-facing component is designed to provide users with public open space, while the city-facing component will house indoor activities and residential functions.

In order to provide the users with the maximum possible level of customization, we tried to develop an intelligent façade system. The façade modules are able to change the interface to accommodate the stitching relationship with the adjacent modules.

Roof module for public program

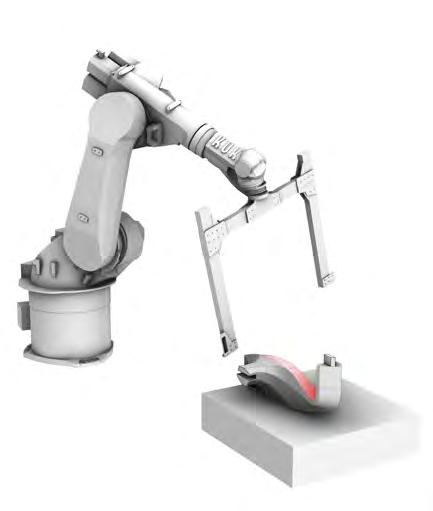

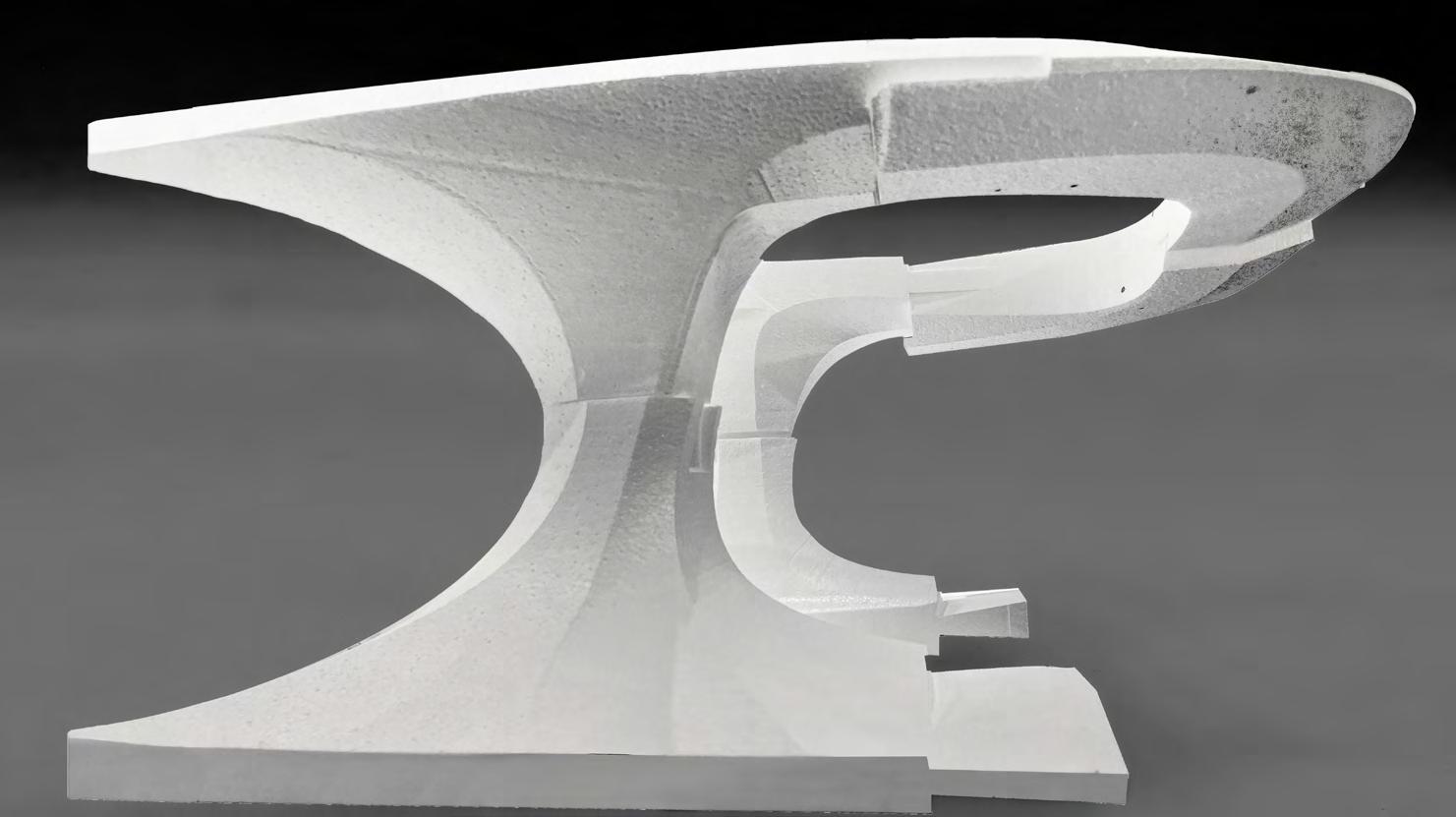

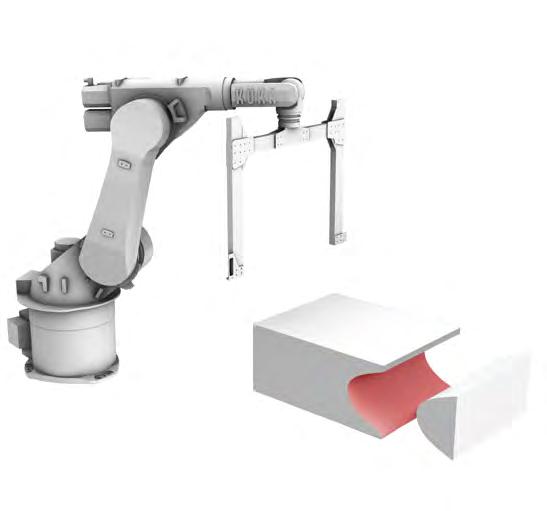

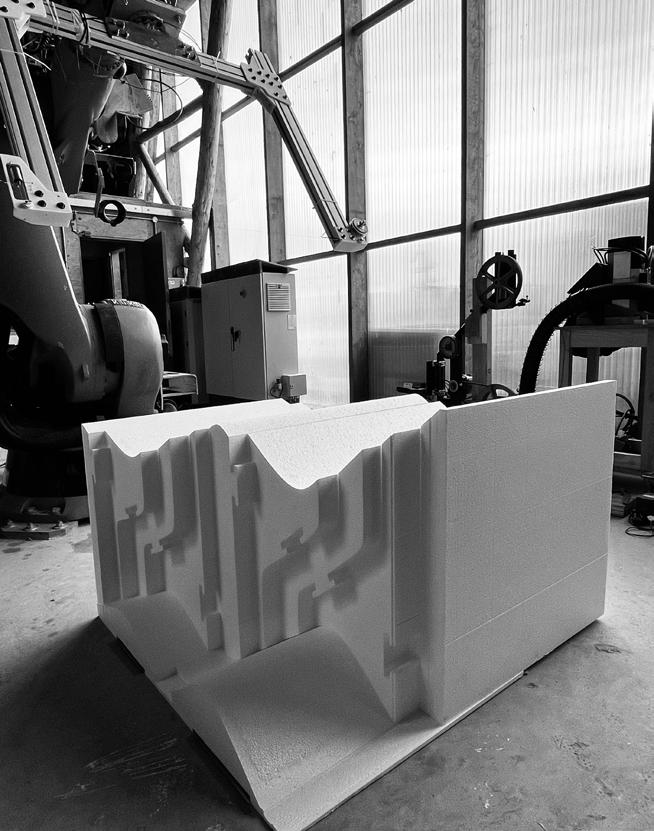

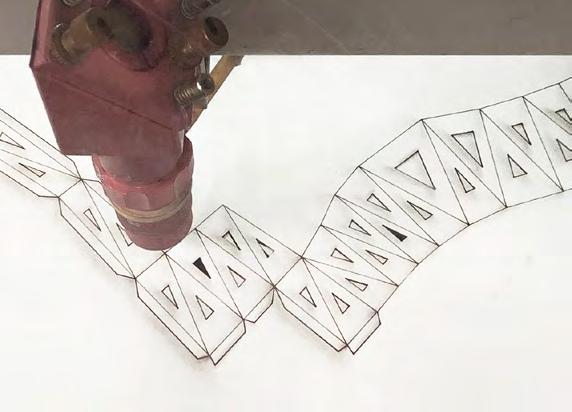

Digital Fabrication - Robotic Hot wire Cutting

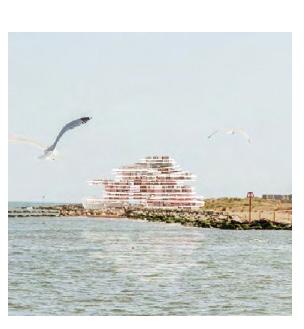

On line to On land

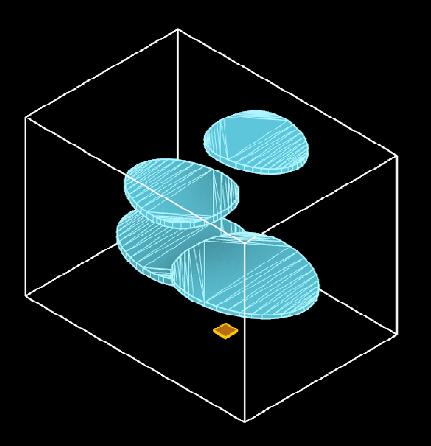

The module is optimized to enable every surface to be single-curved as well as fabricated. After that, we divided this unit into several components according to the mesh structural lines and add joints on surfaces between them. In order to make full use of the material, we divided the foam block according to the projection of each component. Then each block would be cut to be the corresponding geometry of the spatial component.

Each mesh surface of the balcony module first needs to be optimized to the ruled surface, then separate the shape into 8 interlocked elements, which can be connected to each other through the slot joints. Then extract the structure lines from each mesh surface and find out the center point line of each surface to match the "Tool Center Point". After cutting, we laser cut the wood ceiling and floor and assembled them together, finally add the 3D print Interior module to the dollhouse.

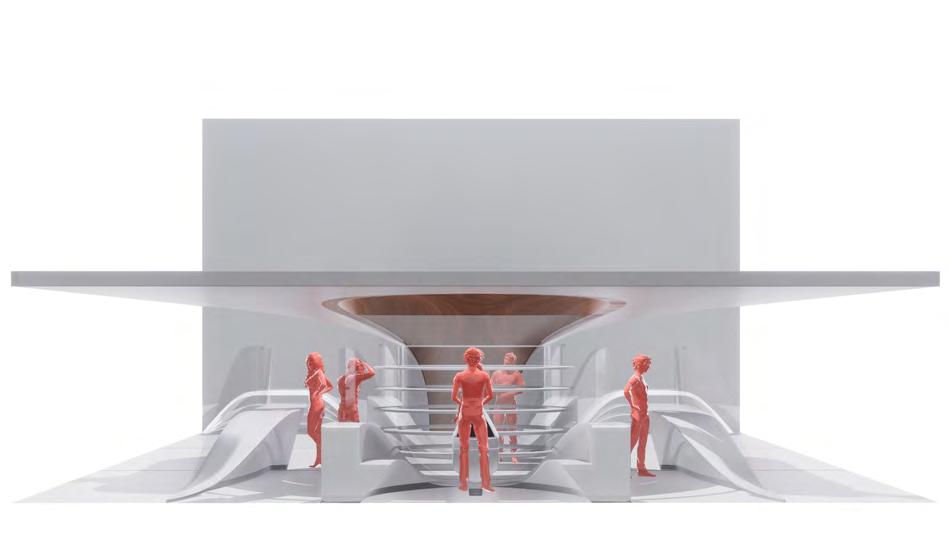

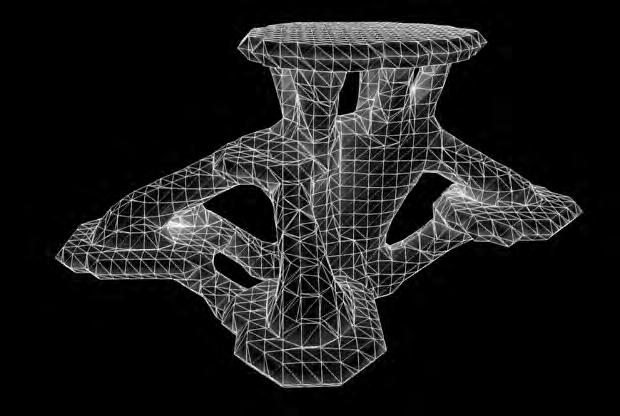

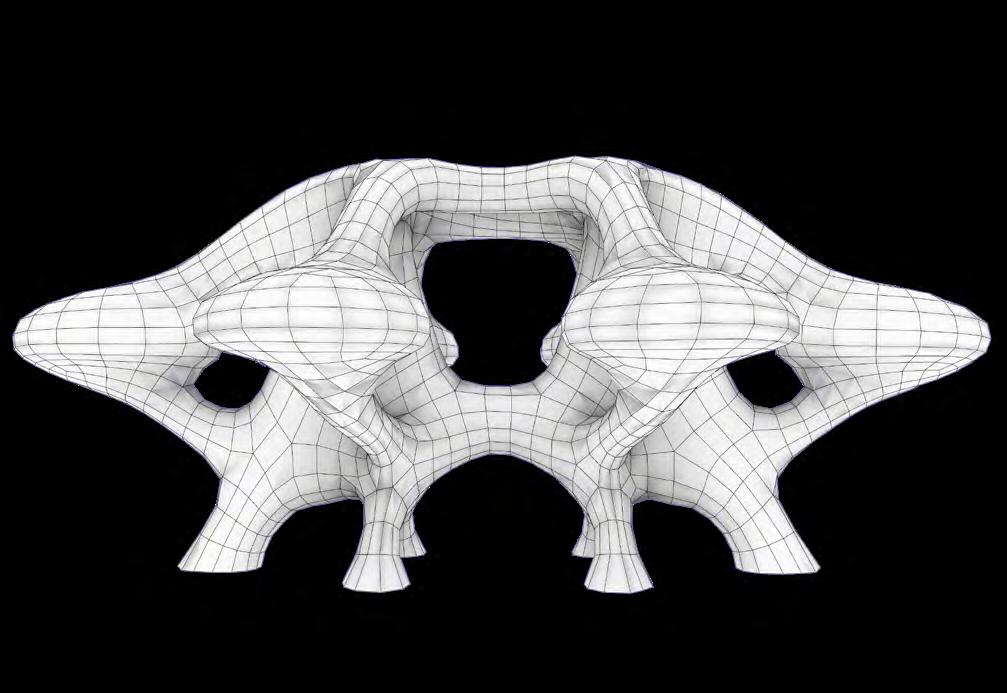

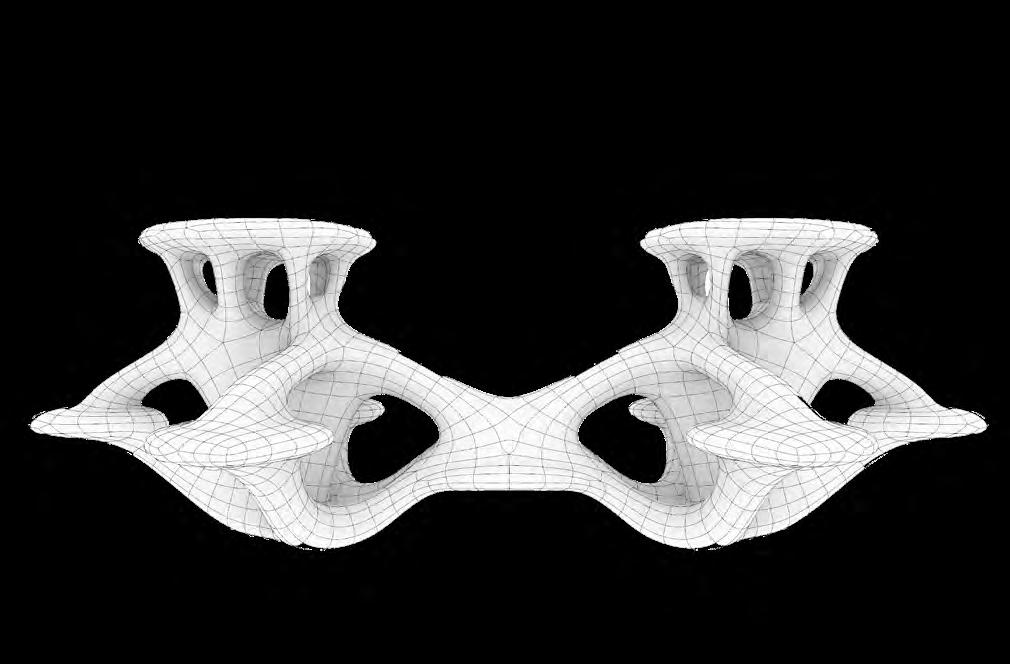

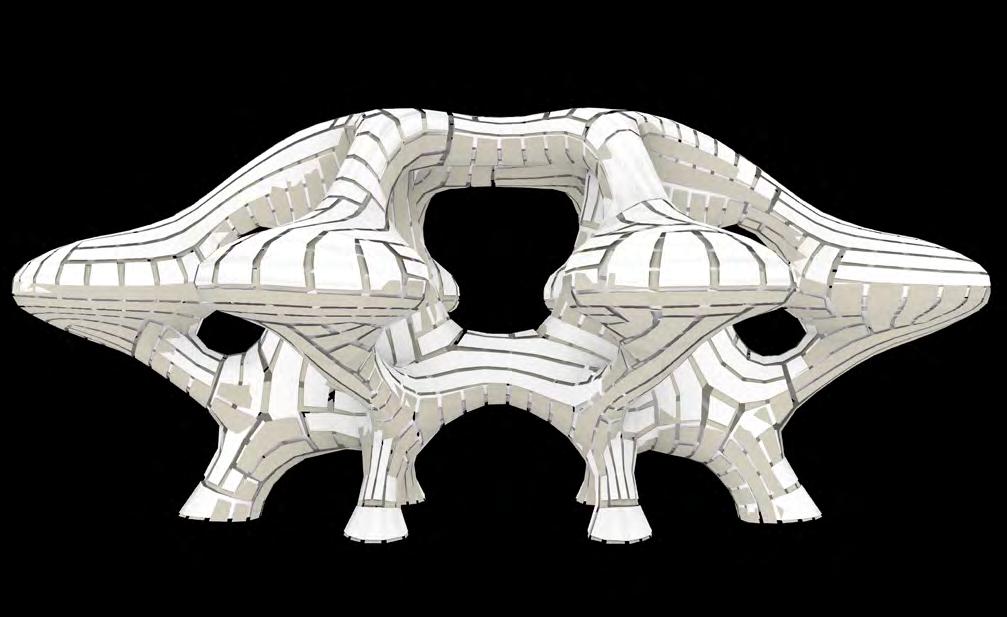

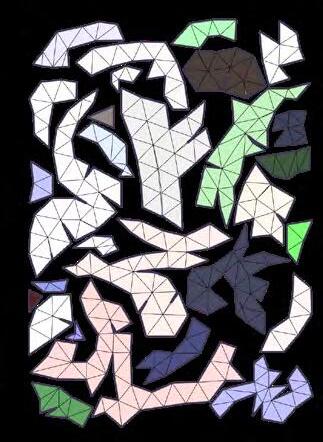

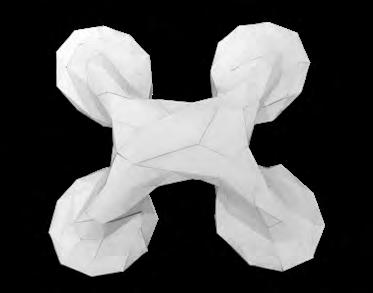

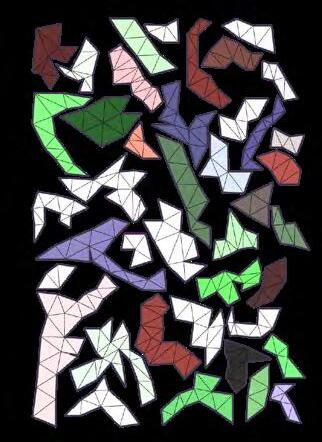

Topos Pavilion —— Digital to Physical

The Core Module / Design Workshop will focuses on digital modelling and fabrication techniques, elaborating complex geometrical topologies through form-finding processes and extrapolating ad hoc geometrical CAM information. Three-dimensional tessellation systems and geometrical unrolling procedures will be used to rationalise into flat shapes the overall geometry and fabricate physical prototypes using laser-cut machines and flat foldable sheets. The students will work on an iterative production of multiple outcomes, cataloguing the prototyping processes, both digitally and physically, and using fitness criteria to compare and evaluate specific performative aspects vis-à-vis morphological and structural variations.

Location: London, United Kingdom

Academic work: September,2021

Tutor: Angius Pierandrea, MeysamEhsanian

Email: Pierandrea.Angius@aaschool.ac.uk

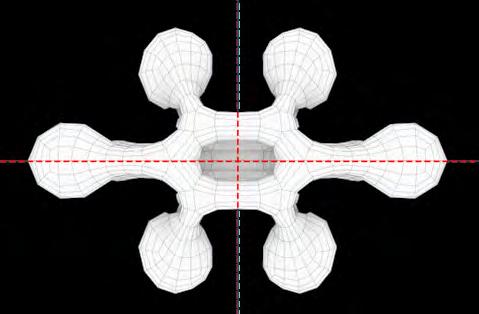

Mesh Relaxation & Optimization

Support Load Boundary

Based on the prototype research and the final form we generated, we decided to started the fabrication test from simple and representative results in terms of height, span and cantilever.

Morphology Optimization

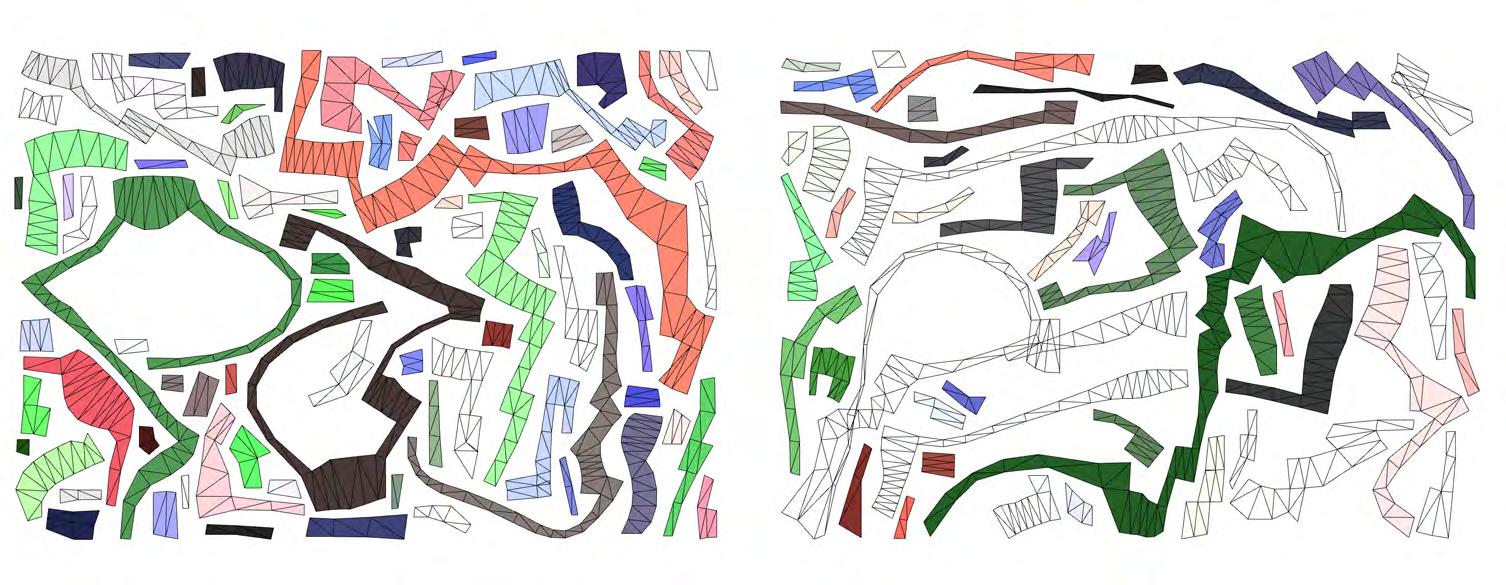

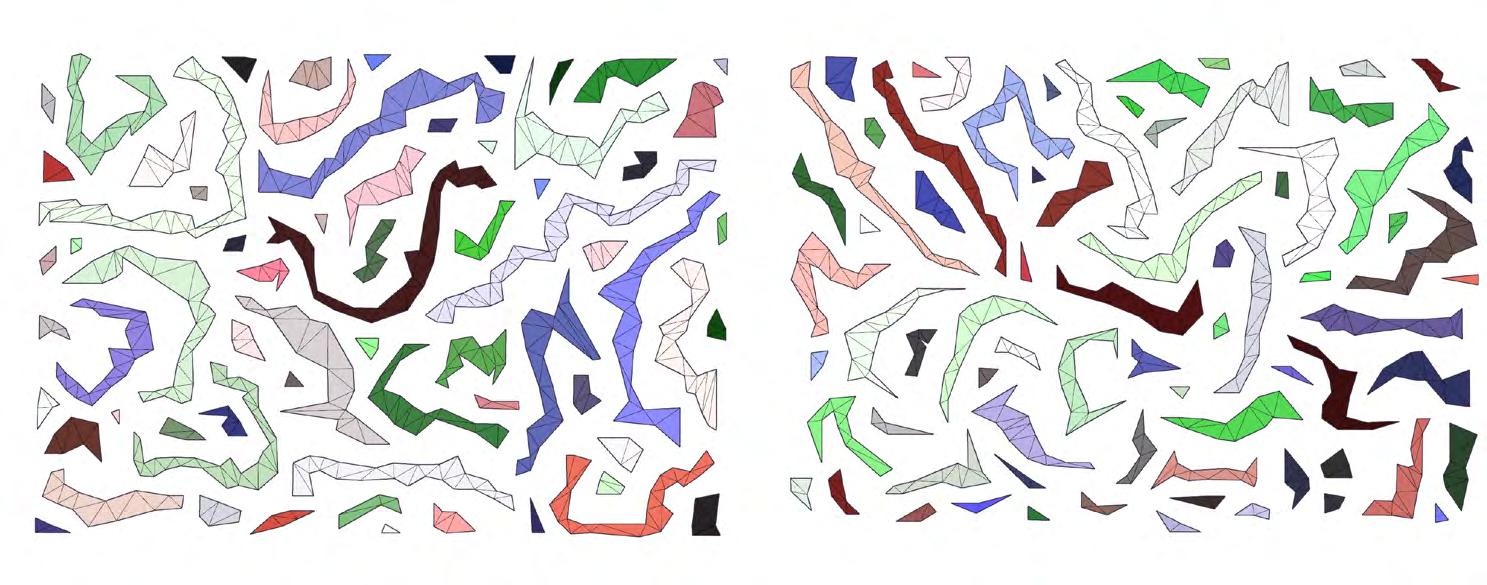

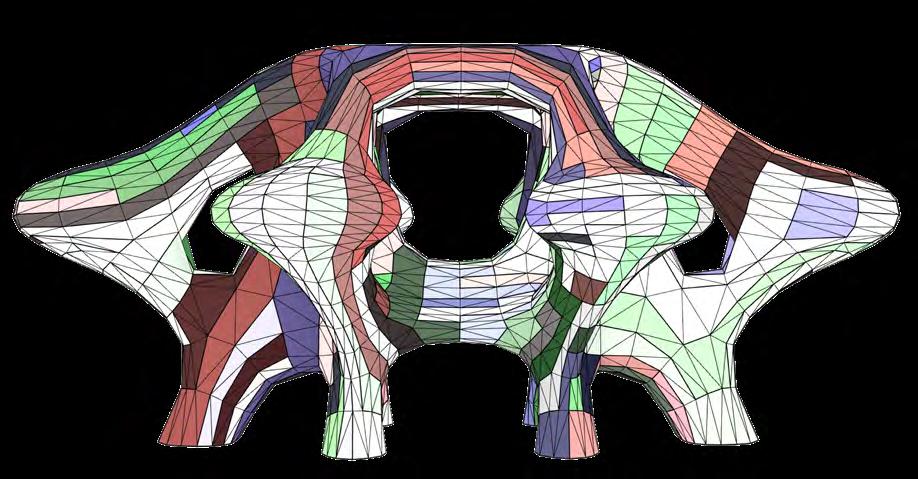

Unrolling Iteration & Optimization

1.Triangulation

Component Pieces: 169

Average Length:2.05cm

Fabrication Test

Model Information

Height: 49.5 cm

Length:15.2cm

Pieces: 76

Average Side Length:2.2cm

2.Overlap Strips

Component Pieces: 89

Average Length:17.5cm

The component size is not regular and exists lots of overlaps that cannot be fabricated properly.

3.Inhomogeneous

Component Pieces: 176 Average Length:6.8cm

Triangle strips are in different sizes, lots of short pieces are hard to assemble. The unrolling is also irregular, no two parts are the same. Strip components' lengths are more proper but the size of each triangle is inhomogeneous.

4.Final unrolling

Component Pieces: 184 Average Length:6.02cm

Model Information

Height: 34.5 cm

Length:50.8cm

Pieces: 77

Average Side Length:3.4cm

First test is the height one, it’s nearly 50 cm’s tall and we are trying to make it stand on the floor but failed so it drives us to make more foots to make it stable.

The components' size is much easier for assembly, also the shape is symmetry which is easy to pre-fabricated.

Second is a cantilever test, after optimization we got a 50cm length with two foots in the bottom. We got a 15cm overhang.

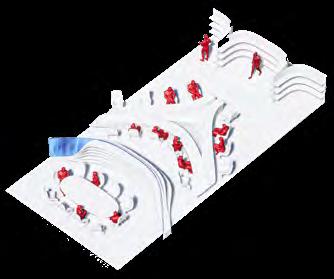

Final Prototype

Finally, we are moving to the final prototype which combine the span and cantilever, we try to regulate the panel average length to find the best form both with a smaller number of panels and remain the curvature of the shape. Meanwhile we give a logic to the triangle pattern. The size of the triangle is proportional to the change in the size of the panel, which we think it follows the logic of mechanics, the reduce of weight and the ratio of opening to panel area can make the model more stable.

Physical Model making

1:20 Scale Strips Assembly Model

Topos Pavilion 19m*8.2m*13.5m

Topos pavilion, is assemblyed by lasercutted lightweight aluminium shingles.

Tessllation

Each panel has holes on each side's flaps which is used for tessllated with another by screws.

Openness

The structure has multiple entry points, different height of foots can generate different use of space.

Length : 95.6cm Width : 67cm Height : 41.4cm Component Pieces: 184

CAM Information-Laser Cut

Nodes & Assembly Process

Transition Space Pavilion transfered the load to the footings, people can pass and sit on the wooden stage under the pavilion.

We use laser cutting to fabricate the strip components, from digital CAM information to physical cardboard. Different strengths of the laser enable both cutting and carving on the material. This method is accurate and time-saving as well which is used spreadly in prefabrication for onsite assembly.

Each strip has connection nodes on side which can allow components assembly together.

We bend the cardboard through the carve until two strips can perfectly fit the curvature.

Half of the models have been assembled and another half is the same since the shape is symmetry.

The shape is totally based on the logic of topos and it’s both a structure and a pavilion with quiet well sheltered space.

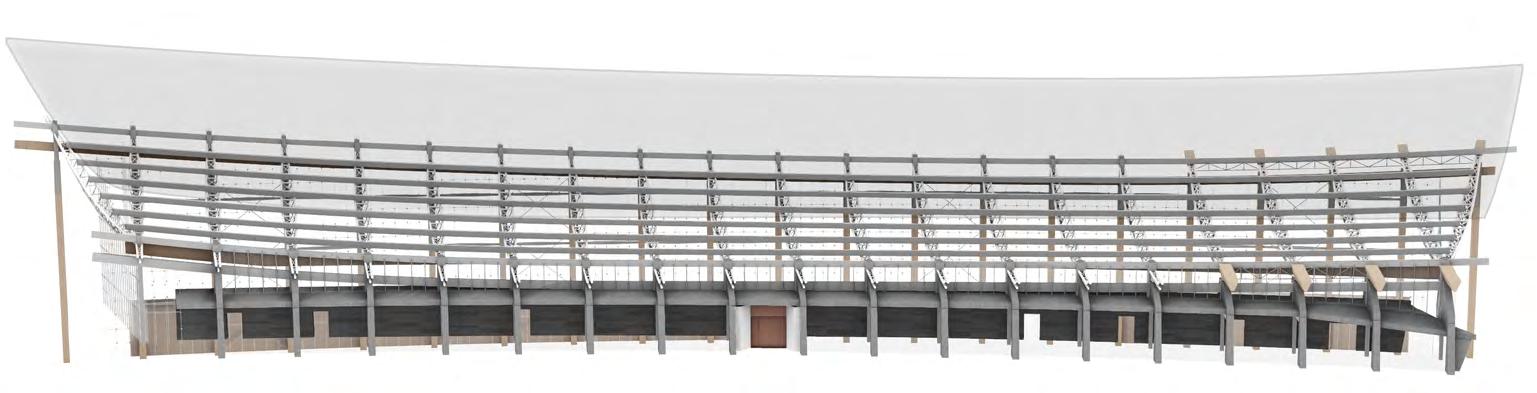

East Building of the Capital Museum

The East Hall of the Capital Museum (also known as the Boat of the Canal) is located on the north side of the Urban Lvxin Forest Park in Tongzhou District, Beijing. It is one of the three major buildings in the sub-center of Beijing. The total construction area of Shoubo East Hall is about 97,000 square meters.

"The design concept originates from the three elements of boat, sail, and water in the ancient canal scene, and integrates the history and culture of the canal into the building. The south side is shaped like a giant sail and is raised high; Shaped like a boat, solid and heavy, it paints a picture of a canal”.

Deepening Design —— Internship in CADG

Steel Structure Rationalise Design

Location: Beijing, China

Internship Program: Janurary,2021 - March,2021

Internship Company: China Architectural Design and Research Institute Co.,Ltd.

Tutor: Liang li, Zhening Wang, Xuhang Zheng, Kai Chen

Email: cadgadri@126.com

am

mainly responsible for the structural deepening of the East Hall of the Capital Museum, the sub-center of Beijing, changing the wooden structure to the steel structure, and using the grasshopper to carry out the rational design of the nonlinear steel structure. By picking the non-concentric curves of the roof for positioning, generating beams and columns, space trusses, roof purlins, and realizing parametric adjustable steel structures.

Steel Structure Joint Design

Large sample model of steel structure joints

Outsourced lumber

Air Corridor Deepen Design

1:50 Air Corridor Plan

Steel Structure Construcction

Anti-overturning truss

Connect Beam Ball node

Lower chord

Column beam Chord

CAM Information-Laser Cut

Shuttle rod

Connect Beam Glass curtain wall

When was in charge of the detailed design of the preface hall of the East Hall of the Capital Museum, the roof of the preface hall was faced with many arduous challenges in the process of changing from a wooden structure to a steel structure, and the overall structure needed to be redesigned. The truss form of the irregular space truss should not only meet the stress requirements of the structure but also meet the architectural aesthetics.

Air Corridor Construction

In the in-depth design of the air corridor, mainly research the influence of different styles of trusses on the user's space experience, the position of the opening fan of the smoke exhaust window, and the influence of material selection on the overall shape. It is finally determined to be a single diagonal rod, which reduces the blocking of the view and makes the corridor much lighter.

Date: Sep. 2022

Fabrication Method: Robotic Hotwire Cutting

Content: Prototype Fabrication

Date: Sep. 2022

Fabrication Method: Wood Bending Content: Prototype Fabrication

Date: Sep. 2022

Fabrication Method: RHWC + Concrete casting Content: Prototype Fabrication

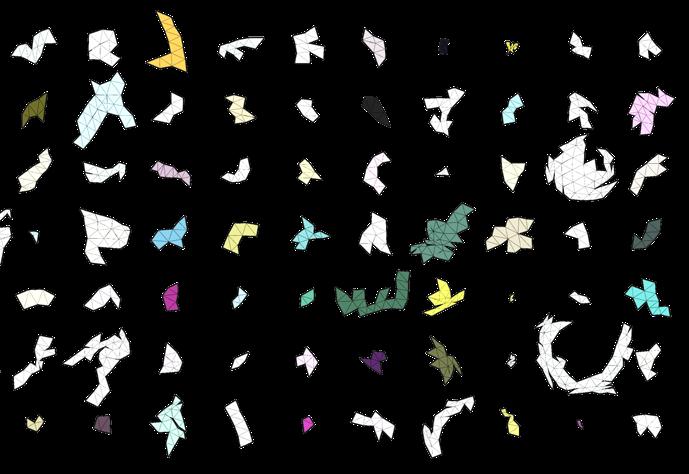

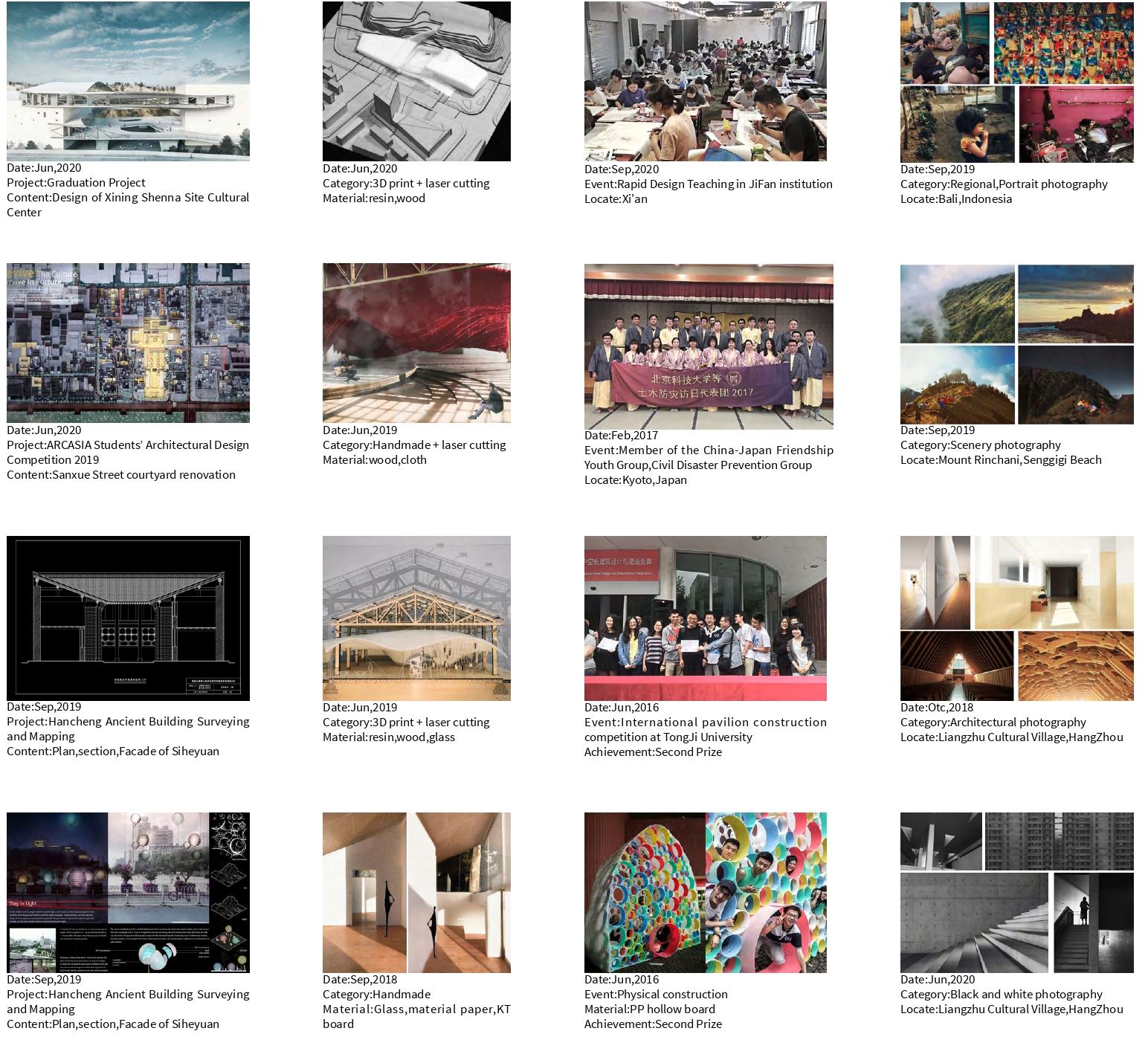

2015-2022 Other Work

Date: Mar. 2022

Fabrication Method: Robotic Hotwire Cutting Content: Prototype Fabrication