3 minute read

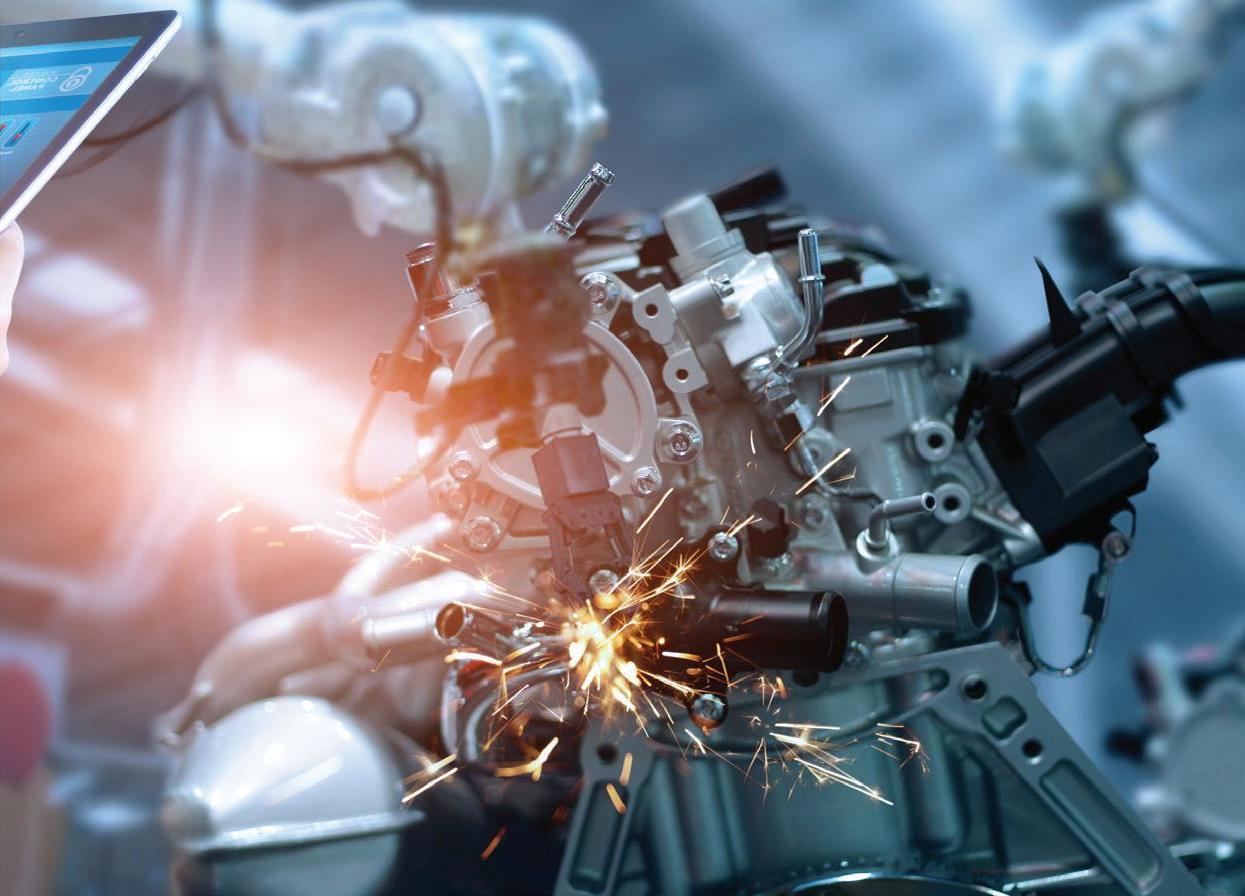

I, ROBOT: AUTOMATING CONSTRUCTION WITH ROBOTIC TECHNOLOGY

I, ROBOT:

AUTOMATING CONSTRUCTION WITH ROBOTIC TECHNOLOGY

Advertisement

by Imogen Hartmann, Associate Editor, Monkey Media

With a $664,580 grant in hand from the Australian Research Council, Monash University’s Department of Civil Engineering is undertaking a ground-breaking research initiative using robotic technology to improve the quality and productivity of construction – research that is expected to transform current labour-intensive methods.

Monash University’s Professor Yu Bai is leading an interdisciplinary team from seven Australian universities to develop a unique and innovative facility centred on structural assembly and construction automation.

Capitalising on the unique opportunity robotic technology presents to the construction industry, the initiative will fill an industry gap as there has previously been no state-of-the-art research infrastructure developed for this need.

The facility features a flexible and adaptive design and instrumentation of structures, with space for a team of collaborative robotics, and an interactive environment where prefabrication, assembly and building will be automated.

It’s expected that the current labour-intensive construction industry could be transformed into one that employs highly-automated and accurate prefabrication processes, with exceptional benefits to the economy and worker safety as a result.

This initiative was made possible through a grant from the Federal Government’s Linkage, Infrastructure, Equipment and Facilities (LIEF) program. In the 2021 round of the LIEF scheme, 47 new research grants were awarded with a total government spend of $38.8 million.

OPTIMISING PRODUCTION OUTCOMES

Professor Bai and his colleagues have designed the facility using extensive research on modular construction and composites for construction. This research, combined with robotic technology, is predicted to culminate in accelerated, higher-quality production outcomes that are more precise and more economical.

Professor Bai’s research expertise centres on structural systems through modern building technologies, such as modular construction and robotic construction, and using complementary material advantages like fibre-reinforced polymer composites in combination with traditional concrete, steel and timber.

The new research facility will cover: ♦ Structural design for manufacturing and assembly ♦ Lightweight structural materials and connections ♦ Construction planning and safety ♦ Sensing and monitoring ♦ Building Information Modelling and digital asset management ♦ Optimisation of structures and assembly ♦ Automation and informatics ♦ Robotic systems and human-robot interaction

CONSTRUCTION INDUSTRY LAGS BEHIND IN AUTOMATION

CSIRO’s Data61 found that the robotics and autonomous systems industry is set to be worth $23 billion by 2025.

Professor Bai said many industries, such as manufacturing and transport, had adopted automated practices to speed up, optimise and economise production. However, he said that construction is one industry that is lagging behind and not yet taking advantage of these technological advancements.

“Robotic technology has made significant progress in a number of industry domains in the last several years and construction can benefit from this advancement,” Professor Bai said.

“The use of robotic technology can be a game-changing step as seen in other industries such as aerospace and automobile engineering.”

Robotic technology is currently being used in other industries like transport, with Transurban’s trial of robotic selfwheeling traffic cones and smart rumble strips in Melbourne, one example.

Australian utilities are also implementing robotic technology with Sydney Water using a floating robot to collect data in its sewers, and Water Corporation using robotic vehicles to inspect its extensive pipeline network in Western Australia, among other projects.

AUTOMATION BRINGS SAFETY

Professor Bai said the facility, and subsequent advancements in automation for the construction industry, brought numerous benefits, including the creation of a safer work environment.

“It means the transformation of on-site prototype construction to made-to-measure structural production and the elevation of prefabrication and off-site manufacturing into automated processes,” Professor Bai said.

“Furthermore, automating traditional construction approaches can remove workers’ exposure to unsafe tasks and hazardous work environments.”

Professor Bai said that ultimately, worker safety and improved environmental safety would benefit the construction industry, with the LIEF funded program bringing that vision to life.

“We’re grateful to the Australian Government’s LIEF program for its support behind our vision to benefit the building industry so it is safer for workers, more environmentally sustainable and, above all, more affordable for consumers,” Professor Bai said.