4 minute read

How the world's first automated PCP can increase operations efficiency of WTPs

The pump industry relies on expertise from a large and varied range of specialists, from experts in particular pump types to those with an intimate understanding of pump reliability; and from researchers who delve into the particulars of pump curves to experts in pump efficiency. To draw upon the wealth of expert knowledge the Australian pump industry has to offer, Pump Industry has established a panel of experts to answer all your pumping questions.

As energy costs are rising globally, increasing operations efficiency of wastewater treatment plants gains importance. This edition of Ask an Expert will look at the first automated progressive cavity pump in the world. The award-winning new technology enhances process efficiency, extends rotor and stator life and considerably reduces TCO.

Advertisement

Q. What makes this new pump solution special?

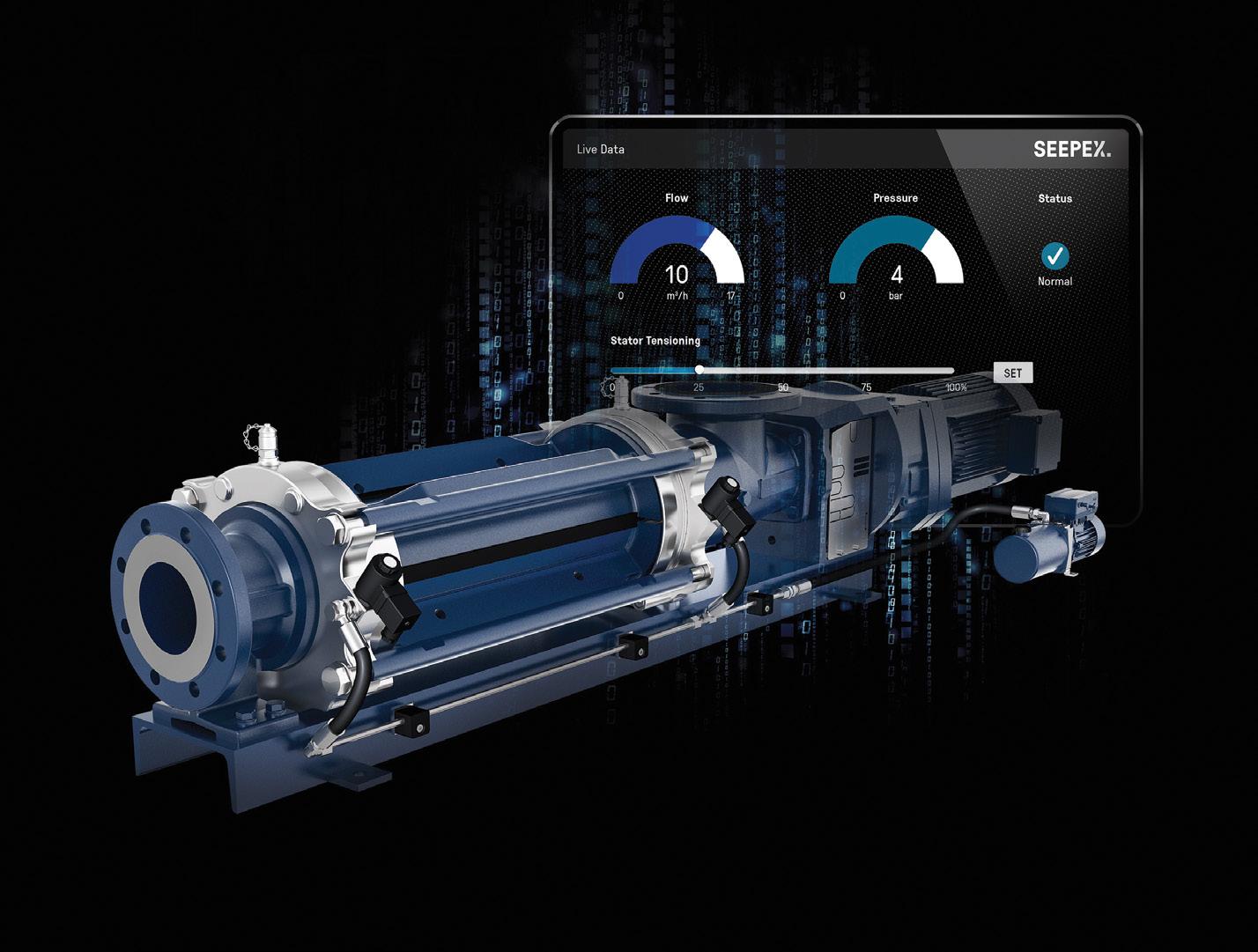

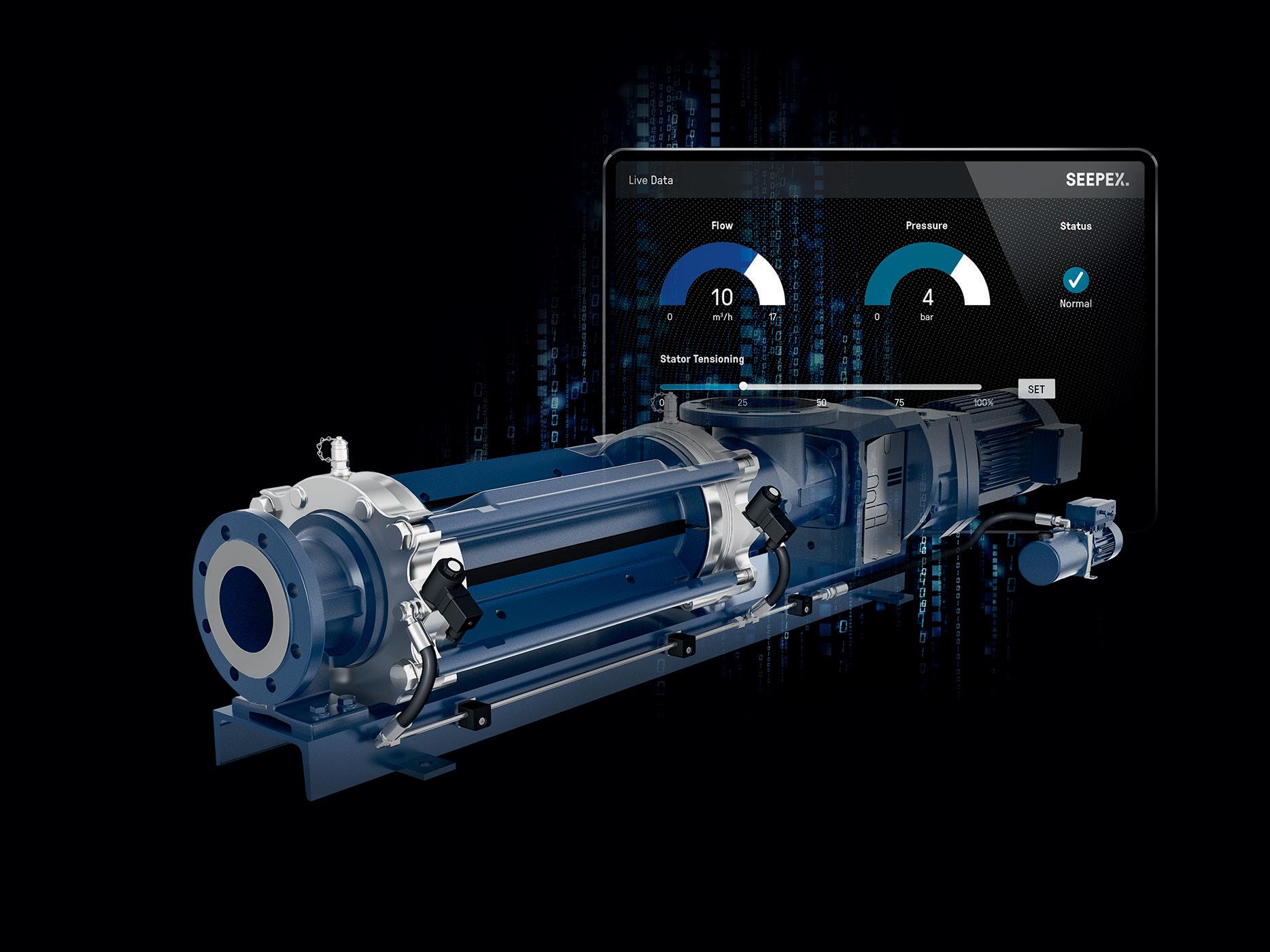

A: It is the world’s first automated and digital progressive cavity pump. Through digital monitoring and an innovative new design, the pump can analyse itself and adjust the operating point of its conveying elements in an automated manner. The design incorporates a retensioning device, which automatically adjusts the rotor-stator clamping, quite simply from a distance with a click of a button. In this easy and more importantly, highly precise, repeatable way, the pump flow rate is always kept at the optimum operating point. A novelty in our industry.

Q. Why is it important and economically worthwhile to adjust the rotor-stator clamping?

A: The rotor-stator clamping directly influences the pump’s performance as it defines the sealing of the oscillating cavities formed by rotor and stator. It directly affects important parameters such as flow, energy consumption, wear or lifetime. However, the ideal clamping is highly dependent on nonstatic parameters such as temperature, pressure or properties of the conveying medium (e.g. dry solid content) and unavoidable wear. Hence, the knowledge of the exact operating conditions by digital monitoring and the possibility to account for them by an automated adjustment of rotor-stator clamping offers a huge potential in terms of increased lifetime, less consumption of energy and resources, increased process safety and minimised operating cost.

Q. How does this technology work?

A: Technically, the pump design includes a hydraulic control unit and adjustment segments, which apply pressure on the stator resulting in a given rotor-stator clamping and sealing, respectively. Through the mechanical design and control, the pump can adjust the rotor-stator clamping to the optimal operating point in an automated manner. The control and hydraulic unit regulates the clamping and allows connection to SCADA or the pump monitor. Additionally, digital monitoring and cloud services enable remote adjustment to optimise pump efficiency, and with advanced analytics, the implementation of predictive and forward-planned maintenance.

Q. What does the operator have to do?

A: A remote click from the control room or a touch on the on-site pump monitor or tablet is all it takes to adjust the stator clamping so that the pump performance is always top-notch. Special tools are no longer required. The service technician responsible can easily make all changes via the control room.

www.pumpindustry.com.au

Q. What are the greatest advantages of this automated pump solution?

A: In a nutshell, it makes day-today business easier, safer and more efficient. Advantages include reduced maintenance, less wear, lower spare parts costs and a significantly longer pump service life due to the simple automated operation and a more frequent and early stage adjustment of the stator clamping. Remote locations are just a click away. Time-consuming walks for manual adjustments on the plant, drives to remote pumps or the hassle with mechanically readjusting pumps that are difficult to access are outdated. The SCT AutoAdjust technology is capable of monitoring process-critical factors and drastically reducing maintenance times to guarantee plant availability and productivity.

The world’s first automated progressive cavity pump can hydraulically re-tension the stator clamping.

Peter Vila, Managing Director of SEEPEX Australia, is a progressive cavity pump expert. He has been involved with pumps for over 40 years. Peter spent the first five years repairing pumps and the following 35 years in technical sales, 20 of which have been with SEEPEX progressive cavity pumps.

For more information on progressive cavity pumps, please contact SEEPEX Australia on (02) 4355 4500 or at info.au@seepex.com

ONLY A MATTER OF ADJUSTMENT SCT AutoAdjust

With SCT AutoAdjust easily set the stator clamping of a progressive cavity pump to the optimal operating point. Life cycle costs are reduced at the push of a button.

y Best conveying capacity and productivity: always operating at the optimal level y Immediate adaptation to changing process conditions increases overall efficiency y Reduced downtime through predictive maintenance via cloud connection y Extended lifespan due to adjustment of the stator clamping

SEEPEX Australia Pty. Ltd. T +61 2 43554500 info.au@seepex.com www.seepex.com