More of your brilliant work showcased

m & s

Centre spread mini plan &fullstructiobuild ns inside

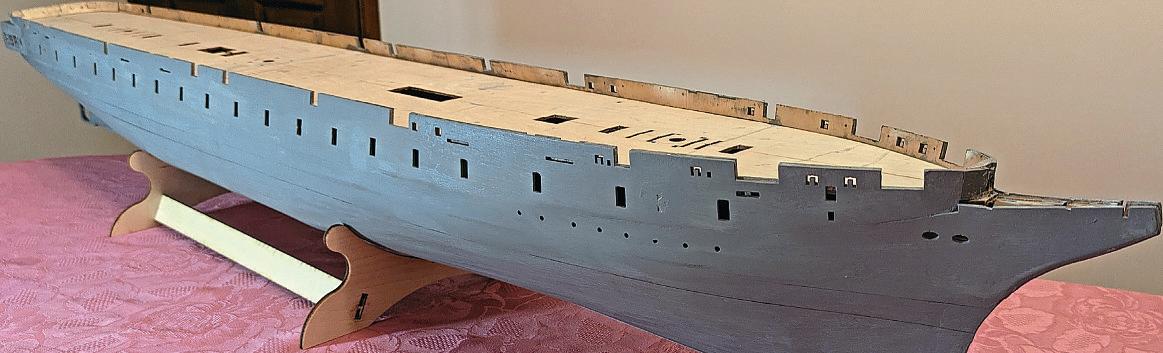

VIBs(Very Impressive Builds) SS Raven

Modelling this historically significant Windermeresteam bargefromscratch

EDITORIA L

Editor: LindseyA mrani

Designer: Fran Lovely

Illustrator: GrahameChamb er s

Publisher: SteveO’Hara

By post: ModelBoats,Mortons MediaGroup, MediaCentre, Morton Way, Horncastle,Lincs LN96JR

Tel: 01507529529Fax:01507 3710 66

Email: editor @modelboat s.co.uk

CUSTOMER SERVICES

GeneralQ ueries &BackIssue s 01507529529–M onday- Friday:8.3 0am-5p m

Answerphone24hr help @classicmagazine s.co.uk www.classicmagazine s.co.uk

Archiveenquiries: Jane Skay man 01507529423jskay man@mortons.co.uk

ADVERTISIN G

AdvertisingSales Executive: MasonPonti mason@ talk-media.uk Tel: 01732920 49 9

KarenDav ie s karen@ talk-media.uk 017324 4814 4

By post: Mo delBoats Ad vertising, Mortons Me diaGroup Limite d, Me diaC entre, Morton Way, Horncastle,Lincs,L NP 6J R

PUBLISHING

Salesand Distribution Manager: Carl Smit h

MarketingManager: Charlot te Park

Commercial Director: NigelH ole

Publishing Director: DanSavage

Publishedby: MortonsM edia GroupLtd, Me diaC entre, Morton Way, Horncastle, Linc sL N9 6J R

SUBSCRIPTIO NS

Tel: 01507529529–M on -Fri:8.3 0am-5p m Enquirie s: subscriptions@mor tons.co.uk

PRINTA ND DISTRIBUTIONS

Printe dby: AcornWeb Of fset Lt d, Normanton,Wes tYorkshire Dist ribution by:Sey mour Dist ribution Lt d, 2Eas t Poultr yAvenue, London,EC1A9PT

©M or to ns Me diaGro up 20 22 Allrig ht sres er ve dISSN014 0-2910

ThePublisher ’s writ tenconsent must be ob tained before anyp ar tof this public ationmay be reproduc ed in anyformw hats oever, including photocopiers, andinformation retrievals ys tems.A ll reas onable care is takenint he prep arationoft he magazinecontent s, bu tt he publishers cannot be held legall yresponsible forerrorsint he contents of this maga zine or forany loss howeverarising from such errors,inclu ding loss re sultingfro mnegligenc eofour st af f. Reliance plac ed up on thecontent s of this maga zine is at reader ’s ow nrisk.

ModelBoats,ISSN0140-2910, is publishedmonthly by MortonsM edia Group, Me diaC entre, Morton Way, Horncastle,L incs LN96 JR UK TheUSannualsubscriptionprice is 89USD. Airfreight andmailing in theUSA by agentnamed WN Shipping USA, 156-15,146th Avenue,2nd Floor, Jamaica, NY 11434, USA. Periodicalspostage paid at Brooklyn,NY11256

US Postmaster:Sendaddress changestoModel Boats, WN Shipping USA, 156-15,146th Avenue,2nd Floor, Jamaica, NY 11434, USA. Subscription recordsare maintained at DSB.netLtd,3 Queensbridge,The Lakes, Northampton, NN45DT.Air Business Ltdisactingasour mailingagent

This mont h’shob by-related news ro und -u p

12 Save moneywit ha subscription!

Checkout thelates tdeals andget your favouritemagazinefor less, delivereddirec tlytoyourdoor

14 HMS Warrior Part 1

DavidBrayb eg in sa hand s- on buildrev iewofBilling Boat s’ 1:10 0s cale ki t, aime datt he ex pe rience ds taticmod elle r

20 Drivelines

Gl ynnGue st prov id es ad efini ti ve guid etoins tallingmotor sand runningg ear

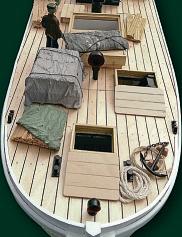

28 RiverFerry

Aminiplanand full in st ructions for building this work hors eofamod el from Gl ynnGue st ’s ve ry ve rs atile de sign,w hich canb eeasil yada pted to yo ur ow ns pec

42 ST Henley TLC

Tony Bird ex plains howhet ur ne da vint ag eStuar tTur ne rs team launch hull in ar at he rs or ry st atebac kinto amag nific ent, read ytohit thew ater ag ain, beau ty

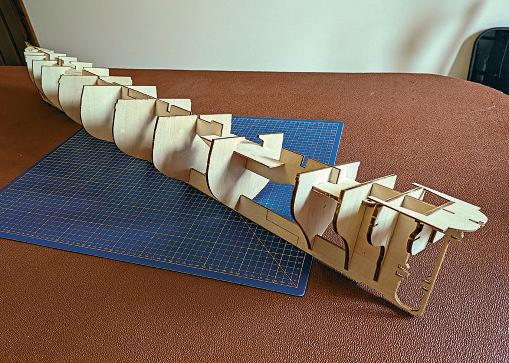

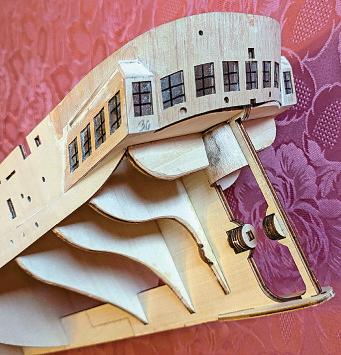

48 SS Raven

John Mile sont ac kles anot he rs cr atch buildwor th crow inga bo ut –t hi s time ca pt ur ingasig nific antl yhis toric Wind er me re steambarge

54 Flot sam&Jet sam

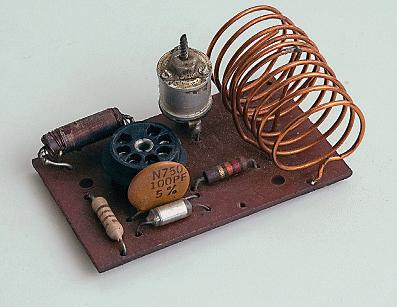

John Parker refle ct sont he bygone er a of DI Yr ad io -control

60 Boiler Room

RichardSim ps on ex tols thev ir tues of te stingyourm et tleand usingmore mo dele ng inee ring in yo ur builds

66 Your Models

More of yo ur br illiantwor ks howc as ed

71 Your Letter s

Over to yo u…

74 Next mont h…

Ju st thre eoft he reas on syou won’t want to mi ss theJul y2 024i ssue of Mo delBoats

Although notscheduled as a‘plan issue’ (those of youwho areregular readers/subscriberswillbe awareweinclude afreepulloutplanand buildguide in ever yother issue),wedohave abonus mini plan andfull construc tion instructions for youthismonth,inthe form of GlynnGuest ’s economic,easy to tackle andsuper versatile RiverFerry model.

Glynnhas also revisitedand updatedhis previous (2011) ar ticleondrivelines, thereby providingadefinitive guideto inst alling motors andrunning gear,which,considering the number of queriesthat arise concerning this topic, will hopefullybeofgreat assist ance to many of you.

54

42 60

Elsewhereinthe mag, you’ll findPar t1David Bray ’s full kitreviewfor BillingBoats 1:10 0scale HMS Warrior, thefirstinstalmentofTony Bird’s restorationdiary of a vint ageStuar tTurner Henley steamlaunch andJohn Mileson’slatestscratch build of asignificantlyhistoric Windermere steambarge that ’s definitelywor th crowingabout! Plus,we’ve gotall your favouriteregular pages, includingthe latest inst alment s in thepopular Flot sam& Jetsam,Memor yL aneand Boiler Room series,a packed with forthcomingevent s Compass360 news section, andsomefantastic inputfrom your fellow readersinthe Your Models/YourLet ters section. There’slot stolookfor ward to next monthaswell, not leastthe free full-sizepull- out plan anddirec tivesfor Ray Wood’s exquisite1:24scale gentleman’smotor yacht Shandau. Enjoyyourread! Lindsey

If youhaveanews story for these pages, please contact the Editor,Lindsey Amrani,via e-mail at editor@modelboats.co.uk

If you’ve always fancied visiting the Cutty Sark but haven’tbeen able to make the trip to Greenwich, a new immersive VR (VirtualReality) experience is now allowing members of the public to step back in time and explorethe legendary ship on their digital devices.

Working from state-of-the-art 360 degree photos,3Dscanning and drone photography to accurately replicate the ship in 3D, the University of the West of Scotland(UWS) and Smartify (the artsand heritage app) have digitally recreated the iconic 19thcentury vessel on behalf of Royal Museums Greenwich and created aspectacular VR tour,this including items fromthe wider Cutty Sark collection whichare not typically on view to the public. The project was made possible through InnovateUK’sflagship KnowledgeTransfer Partnership

(KTP) scheme –a scheme which brings together universitiesand businesses to shareknowledge and expertise.

Cutty Sark,the fastest sailing ship of her time, wasbuiltinDumbarton in 1869,and wasone of the final clippers–designedfor seasonaltrade such as tea –tobeconstructed. Now preserved asa museum ship by the Royal Museums Greenwich, visitors are able to ventureaboardand beneath this historicthree-masted clipper: walk along her decks;explore thehold wherecargo wasonce stored; andevenget beneath the 963-tonne ship in dry berthtoview theelegant lines of her hull.Time, though, to get the kettle on, as all this can now also be enjoyedinvirtual realitysimply by keying the following link intoyour browser: (https://ar.smartify.org/ liverpoolhouse/index.html)

The weekendofMay 2526 will see the Model Boat Mayhem show return to Wicksteed Park in Kettering, Northamptonshire. From 10am on theSaturday,when theshow opens, visitors are invited to sail the models they’vebrought along with them; although, please note that while therewill be IC demos be held twice daily by the Stevenage Model Boat Club, no other IC boats will be permitted on the lake. Following last year’s expansion, this year the organisers have gone astep further and securedthe use of the park’smassive amphitheatrearea, where the Mayhem tent andstalls runbythe Wicksteed Model

BoatClub andthe RNLI, amongstothers, will be sited, along with the ever popular Bring &Buy and catering stands.

Admission tothe Model Boat Mayhem show willbe free of charge. Wicksteed Park, however,does run a PaytoPark scheme (the funds raised from this contributingto parkland maintenance costs).Fees aredetermined by the lengthofstay, with up to threehoursset at £5 and a fullday (7am-12pm) at £7.50. Likewise, forthose of you wishingto camp overnight and getthe mostofyourtrip, pitches (starting from just £25 and including parking for one vehicle) must be booked

at least 24 hours in advance, either online at https:// wicksteedpark.org/you-visit/ camping-at-wicksteedpark/ (whereyou can find fulldetailsoffacilities and camping terms &conditions) or by calling 01536 512475.

Manvers Waterfront BoatClub will be holding itsfirstopen to allmodel boat trade show over the weekend of Saturday/Sunday, June 8/9, 2024.

Admission, which will afford accessto the trade stands and allowvisitors to sail theirown models on the club’slarge lake (sorry, no fast electrics or I.C.powered models canbeaccommodated) will be charged at £2 per person.

Traders in attendance will include the Component Shop, Mountfleet Models, Macs Mouldings and the Prop Shop.

The club is also verykeen to hear from both individualsand clubs interested in participating (on either, or both, of the aforementioned days)inthe waterfront exhibits and on water displaysplanned. Please contact stephen.perkins@mwbc. org.uk forfurther details

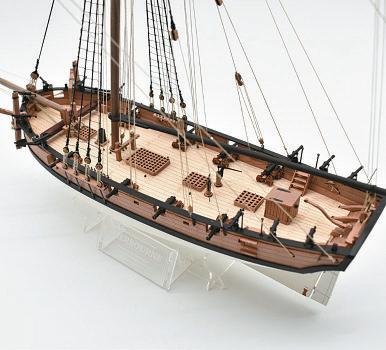

La Mora,as depicted in the Bayeux Tapestry

Members of the public arenow able to visit thebuild site of alife-size reconstruction of La Mora,the flagshipofWilliam the Conqueror,atHonfleur in Normandy, France, andinspect the work in progress.Without theoriginal plans (no longer in existence)torefer to,the design will reference theplanfor the vessel’ssister ship and depictions of La Mora in the Bayeux Tapestry and will largely be crafted using 11thcentury tools and techniques. The 2027 launch of thehull hasbeen planned to coincide with the thousand-yearanniversary of the birth of William the Conqueror.Thoseofyou wishingto book site tour tickets can do so online by keyingthe following link into your browsers: https://www.ot-honfleur.fr/en/site-culturel/lamora-visite-immersive-et-chantier-naval-du-navire-amiral-deguillaume-le-conquerant/

June8 will see the Rawdon Model Boat Club host the first of twoopendaysplanned for this summer at itsoff LarkfieldRoad in Rawdon, Leeds, sailing venue (program your Satnav to LS19 6EQ)

From 10am to 4pm, visitors will be abletoenjoyfreeof chargeadmissiontothe club’s beautiful private lake and clubhouse –witheveryone assured of avery warm welcome.

Model boats of allvarieties will be sailed throughout the day –and visitors will be offered the chancetoparticipateifthey so wish.Therewill be plenty of seating (bothindoors and outdoors), onsitefacilities (WCs), reasonably priced refreshmentsonsaleinthe clubhouse and possibly also some boats offeredfor sale. For more information, email the Rawdon MBC Secretary at rmbcclubsecretary@gmail.com

ar tworkexhibition

Now on at the NationalMaritime Museum Cornwall, and due to run through until November 2024, is an exhibition of paintings celebrating therole of theRNLI locally by the internationallyrenowned contemporary artist Kurt Jackson

Jackson’s RNLI Cornwall paintings vary in scale from postcardsized pieces up to massive canvasses andcapture thecharity’s iconic blue and orange lifeboats both at work, sometimes in mountainouswaves, andnestled intoCornish harbours.Also included in the exhibitionisaselection of paintings created inside Mousehole’s

old Penlee Lifeboat Station as it was left following the tragic Penlee Lifeboat disaster,towhich to Jackson wasgiven special access.

Admissiontothe museum, which is located on Discovery Quay at Falmouth (TR113QY), includes 15 galleries dedicated to exploring the influenceofthe sea on historyand culturelaidout over fivefloors, and is open dailyfrom10am to 5pm,is charged at £18 for adults (thisticket will affordunlimited visits over the courseof12 months) and £9 for under 18s (under 5s go free of charge).

The WindermereModel Boat Club regatta at the WindermereJetty Museum is this year scheduled for the weekend of June 15-16. Commencing at 10am on the Saturday and finishing on at 5pm on the Sunday, this twoday eventpromises to be filled with racing, modelboat displaysand achance for the kids toparticipate. Moredetails can be found online by keying https://lakelandarts.org.uk/ events/windermere-model-boat-club-regatta/intoyour browser

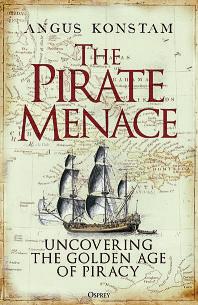

Penned by maritime historian Angus Konstam, thisnew book from Osprey Publishing covers the era when legendary figures such as Blackbeard, ‘Calico Jack’ Rackam, Charles Vane and ‘Black Bart’ Roberts threatened the established world order,played havoc with maritimetrade, and instigated areign of terroronthe high seas. Drawing on letters,memoirs,newspapers, crimereports, archaeology and the trialsof the pirates themselves, Angus Konstamhas weaved together afascinating and definitive new history of the Golden Age of Piracy Although thistitle (ISBN 9781472857736) carries an RRP of £25, it cancurrentlybe purchasedfor the discounted pricedof £22.50 when ordered directly from www. ospreypublishing.comasahardback, or for£15.75 in downloadable eBook and AudioBookformats

Print only ● Qu ar terlydir ec tdebit for£15 ● 1yeardir ec tdebit for£52 ● 1yearc redit/debitc ar dfor £57

David Bray beginsa hands-on build reviewofBillingBoats’ 1:100 scalekit,aimed at theexperienced staticmodeller

Beforestarting this build review,let’s first take alook at history of the magnificent Britishwarship on which Billing Boats has based this highly detailed kit…

Although the Napoleonic wars ended in 1815, thereremained asignificant distrust of theFrench.Atthe time, navalvessels were traditional ‘wooden walls’: woodenhulledsailing vessels armed with batteries of cannon firing round-shot. But fromabout 1850 an arms race was triggered by the introduction of new technology.Steam

propulsion was beginning to make its presence felt, and experiments werebeing conducted on the effectiveness of armourplate against incoming shot. New guns were being developed whichfiredexplosiveshells insteadofround-shot.

Steam power was wellestablished by this time. The Admiralty,inconjunction with the East IndiaCompany had builta series of wooden-hulled paddle steamers from around 1820. Paddle propulsion was something of atechnological backwater in ocean -going ships, and eventually the

Admiralty required all steamplant to be located below the waterline.

In 1859 the French warship Gloire entered service, marking arevolution in maritime warfaretechnology Gloire, designed by Dupoy de Lôme, was converted from atraditional woodenhulled warship, cutdown by one deckand equipped with extensive armour plating protecting the vessel’swoodenhull and machinery.She was steam powered with engines developingaround1,500 HP giving her around 11 knots.

Although Gloire was the first armoured vessel, she was essentially awooden-hulled warship. In Britain, the Royal Navy was building amuch morerevolutionary and effective response. HMS Warrior would be the first iron-hulled, fully armoured, steampowered warship, and whenintroduced she would be the most formidable warship afloat. Designed by Isaac Watts, Chief Constructor to the Navy, Warrior represented amove into anew generation of warship development and construction.Three elements wereutilisedinthisvessel: iron hull construction, steam power to ascrew propeller,and armour plating. The vessel was builtbythe Thames Ironwork Company and launched in December 1860.The contract price was £190,225. The steammachinery was contracted separately to John Penn & Sons of Greenwich for thesum of £74,409. Cost overruns resulted in asignificantly higherprice of thecompleted vessel to the Admiralty.

Warrior was rigged as athree-masted, fully rigged ship, but her main propulsion wasby steam power.Steam was provided fromten tank boilerstoatwin-cylinder trunk engine of 5,772ihp. This gave her aspeed of 14 knots underpower alone. The engines and boilers wereall located below thewaterline, as was thelifting propeller.Someearlier woodenhulled steam warships werepropelledby paddles, but these were vulnerable to battle damage.

Armament consisted of tenArmstrong 110 pounders, rifled andbreech loading, firing 7” shells to arange of around 3,800 yards. Additionally,26muzzle-loading Armstrong 68-pounders and four 40-pounderswere installed. All the guns were abletofire solid

of Warrior’sarmour plating,

overlies the ship’sinner iron plating.

shotorexplosive shells.Her armour plating consisted of 4½” hammered tongue-andgroove wrought iron plate backed by 18” of teak hardwood. The armoured section of the vessel covered the midship213ftofthe ship, extending 16 feet above thewaterline andsix feetbelow. This armour wasmounted onto theconventionalironstructureofthe hull Warrior was418 feet overall length, 380 feet on the waterline. Her beam was58feet, whileher draughtwas 26 ft 4inches forward,

26 ft 10 inches aft. She displaced9,210 tons. She could accommodate705 crew and she carried the designation‘Armoured Frigate’ but wasmorepowerful thanany vessel afloat at the time of her introduction.

Warrior entered service with the Channel Squadron on August 1, 1861, under the command of Captainthe HonourableArthur Cochrane. She wasbased at Portsmouthfor the whole of her commissioned service, and, indeed, is located theretoday, restored to her original condition.

Sea trials lastedover ayear,with many modificationsmade– notsurprising, considering she was the first of anew and very differentclass of vesseltothat which themajority of theRoyal Navywas familiar with! During her first commission she was visited by royalty,British and foreign diplomats andmanysenior Royal Navy personages.She visited Cork, Lisbonand Gibraltar,escortingQueen Alexandra to herwedding with the Prince of Wales.One of her officers was John ArbuthnotFisher, gunnery officer and later to become First SeaLord. Decommissioned in 1864, she underwent arefitatPortsmouth during which herarmaments were strengthened. During her second commission under Captain Henry Boys one of her more unusual taskswas to tow afloating docktoBermuda. Very fewdrydocks existed capable of stemming avesselof Warrior’s size. By 1875, Warrior had been overtaken by more modern technology,and wasplacedon the reserve list.She waspaidoff forthe last time in May1883. She then became astores ‘hulk’ at Portsmouth.

Various auxiliary duties ensued, until 1929 when she was taken to Pembroke dock in Milfordhaven to act as afloating jetty for the Admiralty fuel depot. She wasknown as HulkC77 andremained thereuntil 1979 when her ownership was transferred to the ShipPreservation Trust, andshe was moved to Hartlepool.Her restoration wasalengthy process,with much researchcarried out to allow her to be returned to her original condition. Thisepic undertaking involved many organisations andindividuals, too numerous to detail here.

She finally arrived at Portsmouthon June 15, 1987, taking up the berth she now occupies. Open to the public, she is asuperb example of this iconic type of vessel, bridging the wooden wall sailing ships with today’s modern warships.

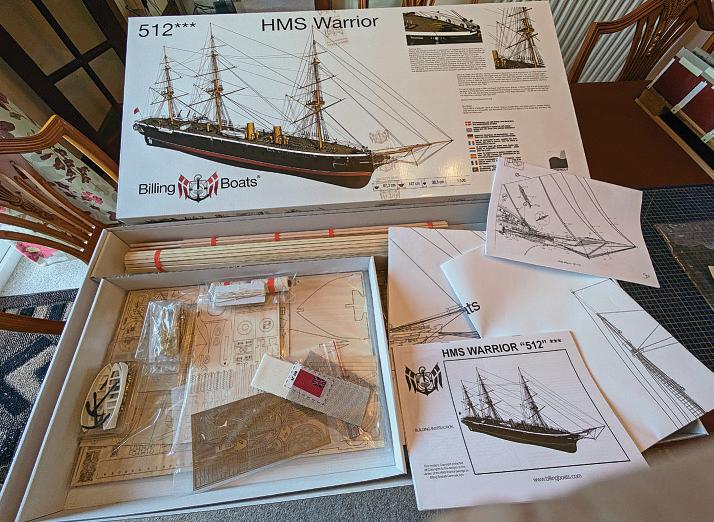

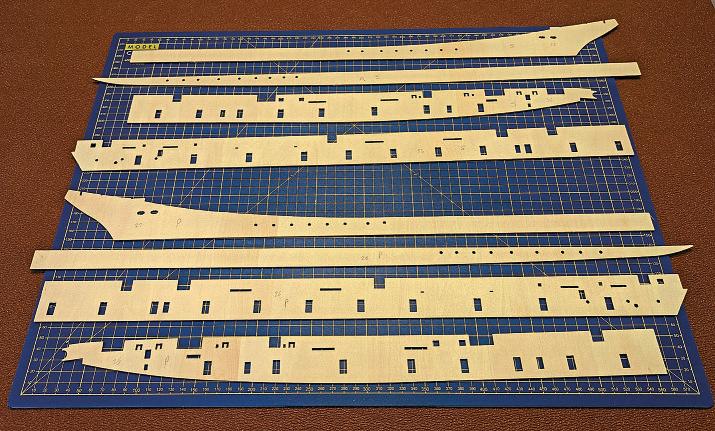

The Billing Boats’ kit for Warrior comes in a large box, adorned withattractive artwork, inside which the contents areall well packaged. The drawings andinstructions are comprehensiveand welllaid-out,and several languages arecatered for.Acomplete numbered list of all componentsisprovided, each component referenced to the particular ply sheet. The ply sheetsare illustratedand themselves numbered. All construction stages aredepicted but not described in the form of text. This kit is described as at ‘expert’ level, and Iwould concur with that.

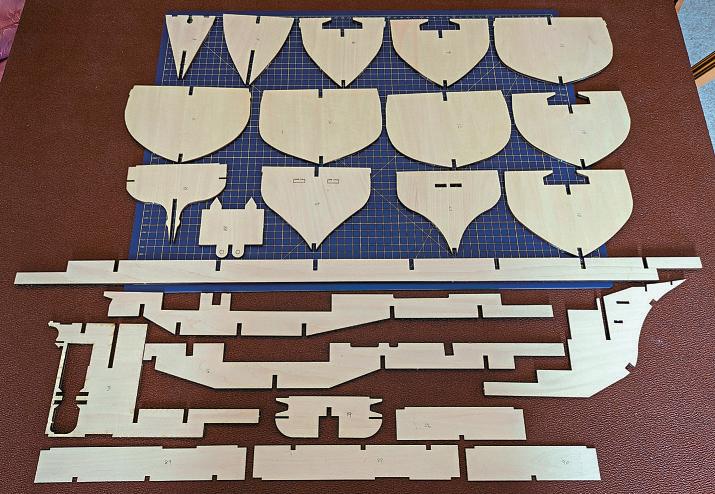

Scaled to 1:100, this gives the re su lt in g mo de la no verall length of around 59 inches or 1.47m. Construction is sin glesk in plank-on- frame built onto keel, deck and bulk head elements from hig h-grade ply.A ll plywood elements arec risply and accurately laser-c ut an di t’sas impl em atter to carefully separate them from the ply sheets, afterwards trimming and cl eaning ed ge sw ith afi le or rasp. Ifi nd it usef ul to number the individual elements of the build with pencil, identify ing each from the drawing s, bef ores eparation from the ply sheet; this obviates the po ss ib ility of locating ab ulkhead, for example, into the wrong keel slot.

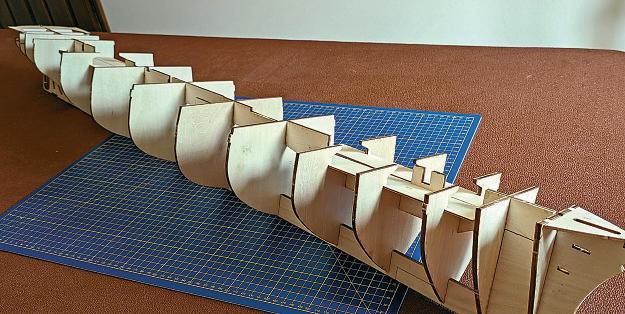

Assemblyofthe framework of the vessel is best done on flatplank some 1-1.25m in length. Thisisnot partofthe kit, and it essential thatthe boardyou use is flatand straight. Onceconstruction is underway, this boardmay actasa useful temporary mounting for the model.

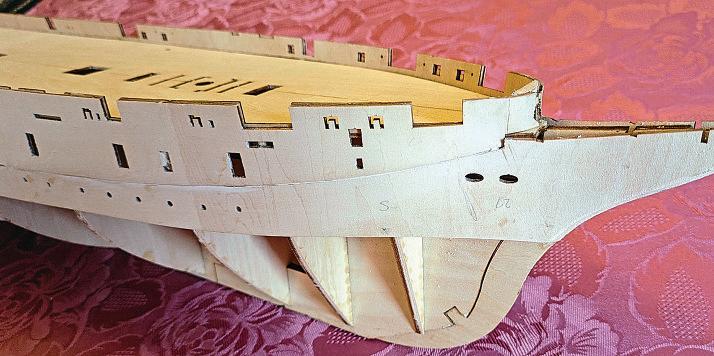

Ifoundassembly of the hull framework elements to be verystraightforward. Allthe bulkheads, keel, deckstringers, stempost, sternpost and other ancillaryitemswere carefullyseparated from the plysheets and cleaned up. The bulkheads forthe bow and stern sections wereroughlybevelled,then theunitswereassembled. Allthe laser-cut elements fitted together with great precision, enabling atight and fair fit.Onceassembly wascomplete, further bevelling wascarried out on the bulkheads to ensureafair landing for planking

It wasnow possible to see the size and scale of thisbuild. This is abig project– easily thebiggest I’vetackled. Iwas fortunate enough to have taken somepictures during a visit to the ship in May2019 thatI could use,

alongside acopy of the Seaforth‘Historic Ships’ publication HMSWarrior, Ironclad Frigate 1860 by Wyn Davies and Geoff Dennison, for visual reference. Thisexcellent book has acomprehensiverange of colour photos covering allareas: on deck, below, and rigging. Most useful!

The next step wastofitthe deck substrate. Thisisthe 2mm sheet ply base upon which the deckplanking is laid. The ply deck is fitted in four sections, again,very accurate laser-cut forms.Itmust also be said that allthe plywood from whichthe pre-cut components areformed is of veryhigh quality.The deck wasglued intoposition. Iwas now contemplating the most difficult partofthe hull construction: the fitting of the topsides (these arethe sides of the hull from the waterline up to the top of the bulwark rails). Laser-cut sections wereprovided in 2mm ply,eight sections in all. Exquisitely and accuratelyshaped, these components werecarefully separated from the ply sheets and prepared for fitting. Many apertures and cut-outs werepre-formed but needed to

becleaned up prior to fitting. The topside panels need to be steamed in places, so as to fit the curvatureofthe hull. Thetightest curves areonthe upper forwardpanels whichformthe bulwarks and sheerstrake. The extreme forwardendsrequirea bend of approximately 70 degrees over around3cm. Iassisted the bendingbymakinga number of shallow (about half the2mm thickness of the ply) saw cuts. It would be very easy to break the panel at this point,soIwas quiterelieved when therequired bend was achieved. The forwardtopside panels were fitted and glued into place. Where port and starboardbulwarks met, Ishaped andglued a scrap piece of wood to connect thetwo sides moresecurely in way of the aperture for the bowsprit. The aftermostpanels fittedwithno problem. The next items tofitwerethe outer stem and its triangular braces.Thesehad to be bevelled to match theadjacentbulkheads.

The lower panels of thetopside provided the biggest challenge so far.The forward ends needed to be steamed, then given a complex shape comprisinga bend and a twist. After some trial and error, asuitable shape wasformed. Theouter stemwas bevelled using afile, to give the topside panels afair landingsurface. Having applied glue, avariety of clamps and clothes-pegs was used to securethe forward ends.Once the forwardends werefirmly fixeditwas astraightforwardmattertoprogressively work aft until the forwardpanels were also secure.The aft panels were much easier.The topside panels were very accurately laser-cut and made aquite precise fitontothe hull.A minimum of filling and sanding produced a perfectly faired topside. Now totackle the stern galleries.

On the real HMS Warrior the sterngalleries aren’t all they seem. In asailing warship these galleriesgive onto the spacious Captains’ cabin, affording him apanoramic view.On Warrior,however,the upper part of the propeller trunk is located behind the windows. Warrior was of the‘up funnel, down

screw’ era. When under sail, the 26 ton, two-bladed propeller could be lifted within a trunkway, reducing drag. The propeller was fitted within avertically sliding ‘banjo’frame, whichitselfweighed eight tons.Ittookthe wholecrewaround half-an-hour to raise the propeller.Oncelifted therewas stillaportion of the lower blade in the water but drag was reduced significantly.

In the model the stern galleriesare constructed from aseriesofprecision-cut parts. Work begins with the construction of the counterstern shell. This is formed from two sheets of ply, pre-formed with all window apertures pre-cut. The inner laminate is appliedfirst, after steaming to the required curve. Once secure,the outer laminate is attached. Thewindows are representedbya sheetofclear acetate, which is carefully marked with the glazing bars. The acetate needstobecut to shape andcarefully glued to the inner face of the outer laminate. This is then glued onto the inner,carebeing takentoensurethe window apertures coincide. Asmall amount

of fettling and filling is needed to fair this assembly into the existing topside.

The side galleries werethen constructed. The parts need to be preparedand cleaned up. Side- and aft- facing windows arefitted as described above,and the parts carefully glued intoposition. Again, asmallamountof fettling is requiredtoobtaina perfect fit,with aminimalamount of filling to make good. At this point it is advisabletopaint the internal structureofthe hull in thestern area matt black,otherwise it might be visible through the windows.Obviously, once the planking has been completed it will not be possibleto do this.

Thenext task wastoattend to afew details around the sternpost.Asolepieceneeds to be added to the lower part of the stern frame, and aseries of small discs fitted to comprisethe propeller bossing. It is now necessary to construct the propeller housing. As mentioned before, thepropeller on this vessel is intended to retractupwardsintothe counter.Aflat rectangle of ply is steamed and formed intoa flattened cylindricalshape.

This is fitted into arecess in the upper part of the stern frame. In this case, the rectangle of ply was not quite long enough, requiring a small amount of fiddling to obtain agood visual fit.

The inner bulwarks were fitted next, in five sections. Again, these arevery precisely laser-cut, withall the cut-out ports matching those in the outer bulwarks exactly.The stern section fittedeasily withouthaving to steam this component

The upper part of thehull wasnow substantially complete. Thenext job, therefore, was to plank thelower part of the hull, beneath the waterline. Lime strips6mm x1.5 mm areprovided. Asmall number of these required steaming so as to achieve agood fit at thestern,beneath the counter.The normal array of shortplanks and stealers need to be fittedtocomplete the shell. The run of planking is unimportant in this vessel,asweare actually simulating ahull constructed from iron.Once planking is complete the hull will be filled and sandedsmooth, with no visible trace of the individual strakes. This processtakestime and patience. Once planking is complete, the hull surfaces will show considerable

roughness and unevenness.It’simportant that, priortocommencing planking, theframes and bulkheads arecarefully bevelled. Even so, the finished planking will show irregularities which must be filled andsanded. The same applies to full-sized wooden constructionhulls. The shipwright would systematicallyworkaround the whole surfaceofthe hull with his adze and plane. In Lowestoft shipyards thiswas knownas ‘scrubbing down’. Hard, back-breaking work. Fortunately,easier for us model-

making types!Oncethe ‘scrubbing down’ is complete, the hull can then be given acoat of primer ●

That’sthe first stage of construction complete. Next month Iwillcontinue this review,documenting the fitting out of the hull from my kitchen shipyard!

This article focuses on the problemsthat many readers have when outfitting and operating their model boats. The subject wasoriginally covered in aConstruction Special issueofModel Boats way back in 2011but, as the samequeries still seem to regularly arise, Ihave now reworked thatarticle, with afew updates included, for those ofyou who either missed the article first time around or are new to the hobby.Iwill be concentrating on scale type models, but the general principals can also be applied toothertypes.

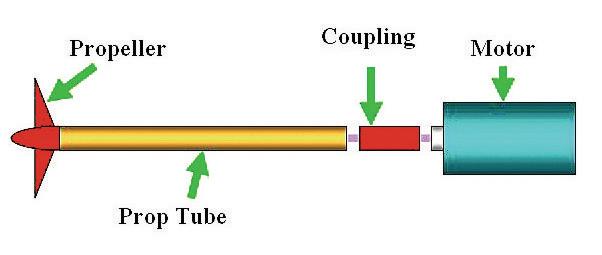

Thedriveline of amodel boatiscentred on the propeller shaft and the tube it rotates within. At one end the shaft is connected to the motor,while at the other is thepropeller, whichturns the motor’sefforts into apropulsive force (see Figure1). Failuretocorrectly install all the parts that make up this driveline can result in disappointing performance and unreliable operation, no matter how well the rest of the model is built.

When building from aplan or kit, this important stage in amodel’sconstruction should be fullyexplained. The only exception might be amodel intended for very experienced modellers and clearly described as such. Alas, too many examples of vague, glib or even nonexistent driveline installation instructions can be found.Ihave even come across some which if followed would have the propeller blades fouling the hull shouldyou do anything as foolish as trying to switch on the motor!

“Failuretocorrectly

installall theparts that make up this driveline can result in disappointing performanceand unreliable operation, no matter howwell the rest of the model is built”