PublishedbyMortons MediaGroup Ltd, MediaCentre, Morton Way, Horncastle,Lincs LN96JR Tel: 01507 529589 Fax: 01507 371066

©2023 MortonsMedia ISSN 0026-7325 www.model-engineer.co.uk

EDITORIAL

Editor: Martin R. Evans

MEeditor@mortons.co.uk

Deputy editor: DianeCarney

Designer: DruckMedia Pvt. Ltd.

Club News: GeoffTheasby

Illustrator: GrahameChambers Publisher: SteveO’Hara

CUSTOMER SERVICES

GeneralQueries andBackIssues 01507 529529 Monday-Friday: 8.30am-5pm Answerphone24hr help@classicmagazines.co.uk www.classicmagazines.co.uk

ADVERTISING

GROUPHEADOFINVESTMENT– Lifestyle& TractorPublications |www.talk-media.uk MasonPonti mason@talk-media.uk

A: Talk Media, TheGranary,Downs Court, YaldingHill, Yalding, Kent ME18 6AL Investment Manager: KarenDavies karen@talk-media.uk

PUBLISHING

Salesand distribution manager: Carl Smith

Marketingmanager: Charlotte Park Commercialdirector: NigelHole Publishing director: DanSavage

SUBSCRIPTION

Full subscription rates(butsee page 494for offer): (12months, 26 issues,inc post andpacking)–UK £132.60. Export ratesare also available, UK subscriptionsare zero-rated forthe purposes of ValueAddedTax Enquiries: subscriptions@mortons.co.uk

PRINTAND DISTRIBUTIONS

Printedby: WilliamGibbons &Son,26Planetary Road,Willenhall, West Midlands,WV133XB

Distribution by: SeymourDistributionLimited, 2EastPoultry Avenue,LondonEC1A9PT

EDITORIALCONTRIBUTION

Accepted photographsand articles will be paid for upon publication. Itemswecannotuse will be returned if accompaniedbya stampedaddressed envelope andrecordeddeliverymustclearly statesoand enclosesufficient postage. In commonwithpractice on otherperiodicals,all material is sent or returned at thecontributor’s ownriskand neitherModel Engineer, theeditor, thestaff norMortons MediaLtd canbe held responsiblefor loss or damage,howsoever caused.The opinions expressedinModel Engineer arenot necessarily thoseofthe editor or staff. This periodical must not, withoutthe writtenconsent of the publishers first beinggiven,belent, sold,hired outor otherwisedisposedofina mutilatedcondition or in otherunauthorisedcover by wayoftrade or annexed to or as part of anypublicationoradvertising,literary or pictorialmannerwhatsoever.

http://www.facebook.com/modelengineersworkshop

http://twitter.com/ modelengineers

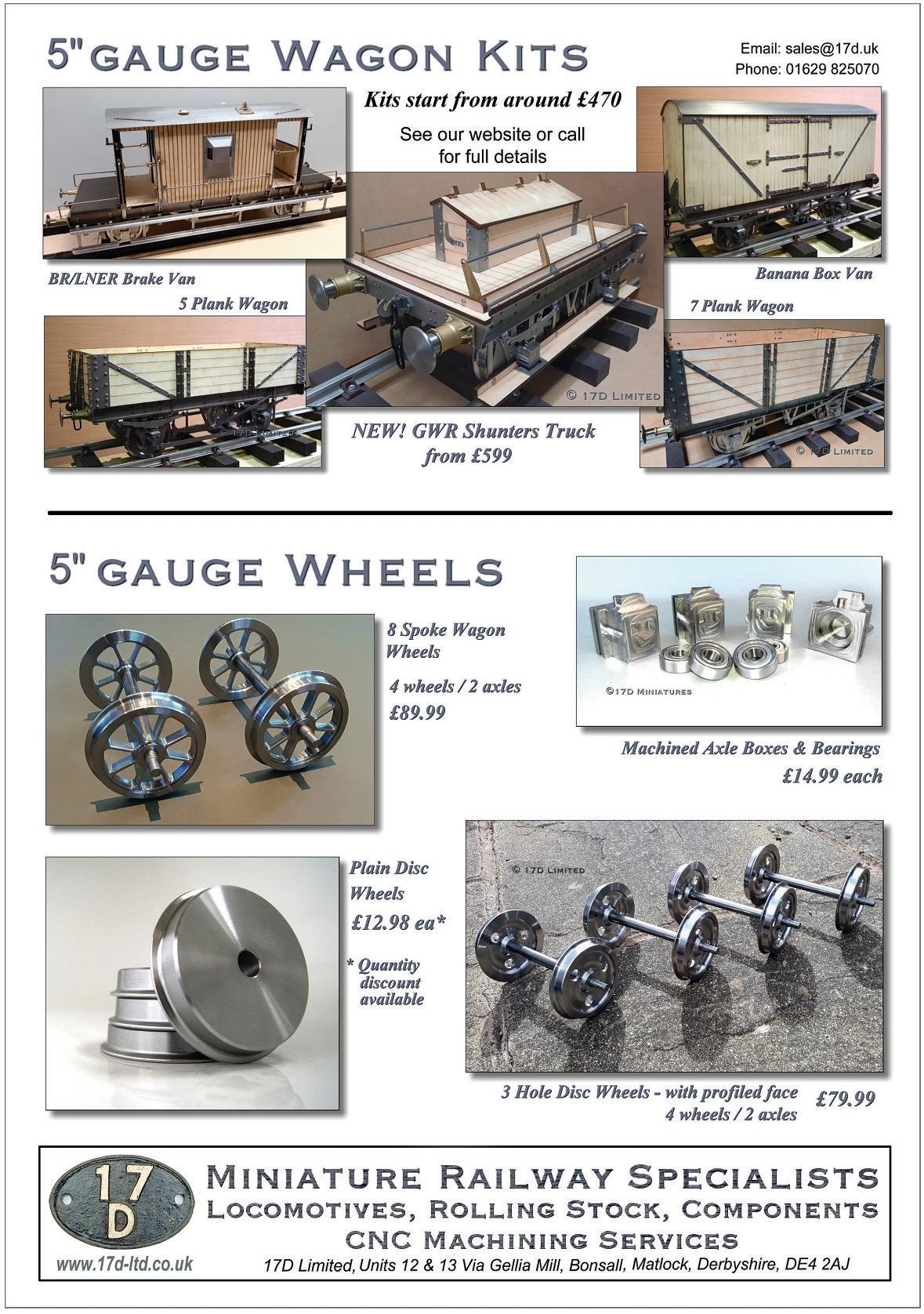

496 SMOKERINGS

News,views andcomment on theworld of modelengineering

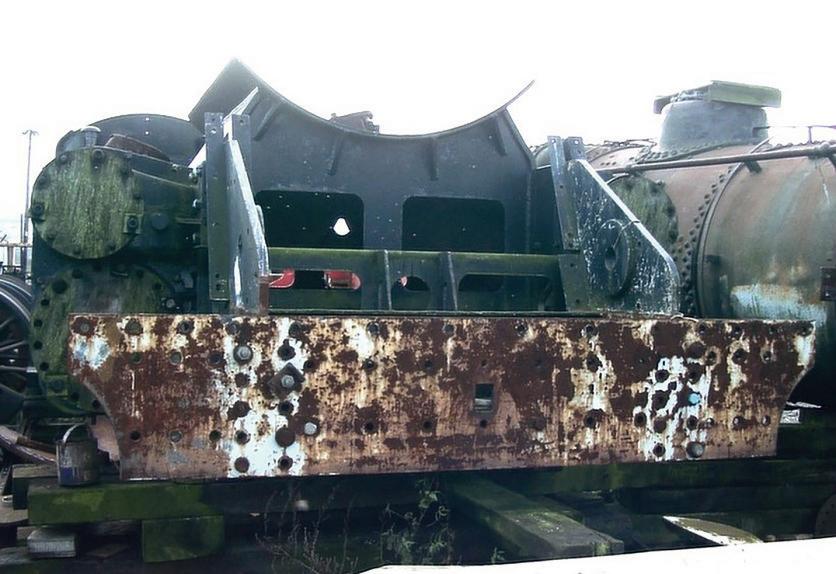

497 ABRSTANDARDCLASS 4 TENDER ENGINE

Doug Hewson leadsusthrough the construction of theBRStandardMogul

500 BUTTERSIDE DOWN

SteveGoodbody writes with talesofthe trials andtribulationsofa modelengineer’s life.

505 NELLIE THECOPTER

FreyaHempenstall tells us abouther first projectwiththe EastleighYoung Engineers.

508 KINEMATICS

Rhys Owen looksatthe relationships between distance,time, velocity andacceleration

511 BEFORE ITSTIME

Colin Hill remembersbuyinghis firstlathe from a'grey-haired oldinventor'

512 POSTBAG

Readers’ letters

513 BOOK REVIEW

RogerBackhouse discoversthe less glamoroussideofocean linersinAnthony Burton's newbook

515 AGWR PANNIER TANK IN 3½ INCH GAUGE

Gerald Martyn buildsa 1366 Class locomotive from worksdrawings.

518 THESTATIONARY STEAMENGINE

RonFitzgerald tells thestory of the developmentofthe stationary steamengine.

522 WE VISITTHE EREWASH MODELENGINEERING SOCIETY

John Arrowsmith joinsthe Erewashclubto celebratetheir half century.

527 ATANDEMCOMPOUND MILL ENGINE

DavidThomasrevisitsArnoldThrop’s design of aCorlissmill engine

533 THEDEVELOPMENT OF MOTORCYCLE ENGINEERING BEFORE WWI

PatrickHendradiscussesthe developmentof theearliest motorbikes

537 THELEUFORTIN PROJECT

IanBaylissbuildsa freelance ⅞thG scale internal combustion locomotive

540 CLUB NEWS

GeoffTheasby compilesthe latestfrom modelengineering clubsaroundthe world.

543 CLUB DIARY

Future Events

ON TH E CO VER

AfourinchMcLaren traction engine belongingtoBarry Buckley, seen at the ErewashModel EngineeringSociety (photo: John Arrowsmith).

Pa stures New -P ar t5 Spatter,Barstock,Castors and Rust

Steve Goodbody takesa random walk through modelengineering.

Continuedfromp.453

M.E.4572 September20

Withinteriorwalls finishedand exterior landscaping complete,wereturntothe storyfor thefinaltimeas theauthorreadies hisshed forits intended purpose. Oh, happy day!

Ibeg your pardon?

Spatter, Barstock,Castors andRust; it sounds likea firm of accountantsyou’d be wise to avoid, doesn’tit? Butrest assured, bemusedReader, forwiththe shed complete anda pavedaccessroute enablingittobefilledwith workshop,thisissimplymy perverse wayofintroducing four partingtipsbeforeI wrap up this series of Butterside Down andheaddownstairs to plan my next projectwhich mayone dayappearinthese pages. Time will tell. Anyway,since it’s first on thelistlet’s beginwith spatter; amessy subject familiartousall.

Spatter

Nowintruth very little explanationisneeded,for suffice to saythat, if you practice metalwork, and

especially if your workshop machineryisasold and unguardedasmine, then you will be very familiarwithspatter –the inevitable trails of oil andmuckdistributed widely (and at high velocity)fromthe total-loss bearings andrapidlyspinning cutting surfaces as we turn perfectlygood raw materialsintovoluminous quantities of swarf. While it is notfeasibletoprotect againstitall, Ibet thereare some areasinyourworkshop wherespatterisa sure-fired guarantee, aren’t there? For me,the inevitable spatter-zone liesimmediatelybehindmy elderlylathe’s countershaft where, themomentI turn on themachine andengage thespindle,a stream of lubricatingoil emergesfrom theadjacentbearingstobe flung unceremoniouslyagainst thewall.

Knowingthis, several workshop-moves agoI purchaseda sizeable sheet of thin stainlesssteel –nothing fancyorexpensive –and screwedittothe wall in the offendinglocation. Andthat simple expedient– just asheet of stainlessattached to the

wall andeasytowipedown -makes workshop clean-up afar easier propositionand itspleasantlyshiny surface helpsilluminate therearofthe workpiece, asupplementary bonusprovidedI keep it clean. So as my first partinggiftidea, Ican highly recommendadding aplain sheet of stainless steel to your Christmaslist, to be attached to thewalls and surfaces whereyou experience spatter, becauseitmight make your lifea littlebit easier too (photos 113 and 114).

Barstock

Next on theagendawehave barstock,the lifeblood of our activities anda royalpainin thebacksidetoorganiseand store. To demonstratethis, I positthe scenario whereColin, ourerstwhile stunt-driver,in themiddleofaninteresting job, finds himselfinneed of severalinchesof5/16-inch roundbrass to finishthings up.Heknows that he hasa couple of feet of it somewhere, butcan he layhis handsonit?

Astrategically positioned spatterguard, readyfor thelathe’s imminent arrival.

Thelathe in place, acautionary sign guarding againstinjudicious metalremoval andthe spatterguard protecting thewallbehind.

115

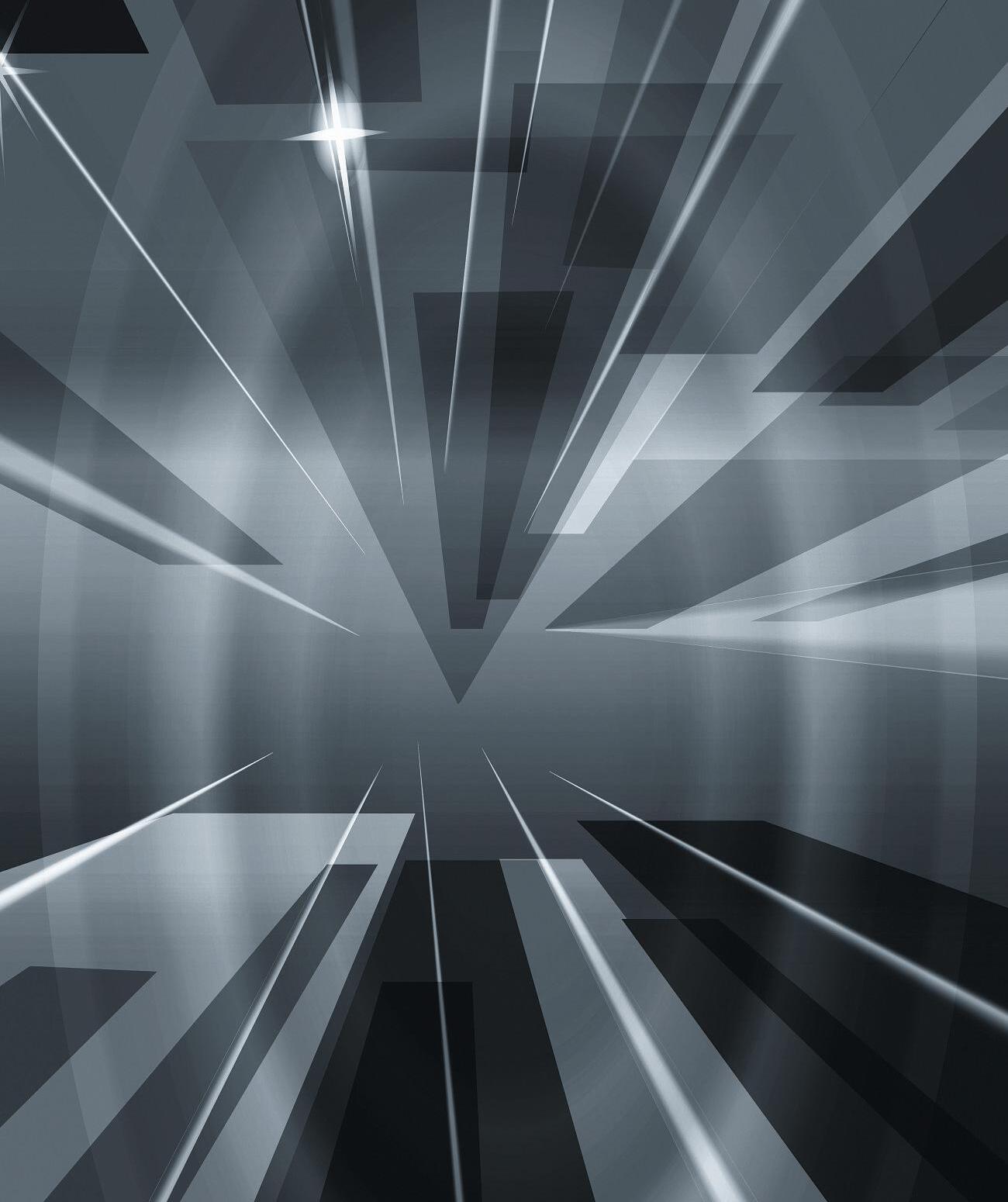

Thewooden storagerack, restingonits beneficialwheels.

Searchingamong therandom lengthsofvarious metals all jumbledtogetherand piled haphazardlyona shelfinthe corner,heeventually givesup, orders afew more feet from his favouritestockistand,uponits arrivala week later, discovers theoriginallengthsniggering behind hisworkshopdoor Soundfamiliar?

NowI can’tclaim to have solved everyconundrum regardingmaterials storage –thatwould take amiracle –butI will happily summarise thesystemwhich Ieventually arrivedatand whichseemsto work well; at leastfor me.In essence, it allcentres around asinglewooden rack,six feet high,six feet long andtwo feet deep,havingfourflat shelves, oneabove theother,and afew wooden cross-pieces providing longitudinal supportsbeneath

Offcutsofeachmetal type arestoredinsegregatedcontainers. Longer items- up to2 feet long -lie adjacent with theirendsvisible forquick identification.

Even longer materials, thosebetween 2feet and6 feet in length,are segregated andstoredlengthwisebeneath theshelves,their ends plainlyvisible once again.

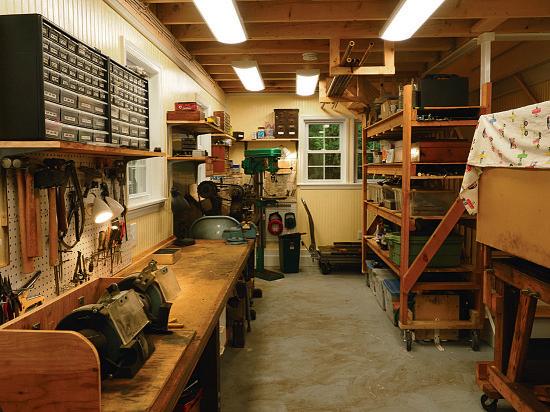

Thefinished workshop with everything in itsintendedplace.A simple rack forthe very longestmaterials hangsfromthe ceilingjoistsabove

at leasttwo of them.Infact, there it is in photo115.Isn’t that convenient?

Nowthisrackholds alot of otheritems beside raw

metals arenot stored together if they can’tbedistinguished at aglance(brassand gunmetal forexample,ormild steel, stainlesssteel andsilver steel to give another),here’show I organise my materials:

•Offcutslessthana foot long arestoredincontainers whichsit on theshelf,a different containerfor each material type (brass, copper, mild steel andso on). However, if Ihavea lot of offcutsofone type of material,these arefurther segregated by shape(round andhexagonal brasssitsin onecontainer forexample, rectangularand square brass in another)

•Next, materialsbetween one foot andtwo feet in length arestoredonthe shelfbeside theirrelated container(an eighteen-inchlengthofsilver steel sits on theshelf beside thecontainer holdingsilver steel offcutsfor example), each having itsend facing frontwards so that itsshape andsizecan be easily determined (photo116).

•Continuingonwards, materialsbetween twofeet andsix feet in length are stored longitudinally on the supportsbeneath theshelves, theirendsvisible from the side of therackfor rapid identification(photo117). Once again, theselonger materialsare segregated by type;mild steel sits alone becausethere’s always alot of it,while Itypically combine brass, copperand silver steel lengthsbecause they’reeasy to tell apart.

•Finally,materialexceedingsix feet in length –mostlycopper pipe in my case -isstoredin aseparaterackwhich hangs from thejoistsabove:asyou perhapsalready suspected (photo118).

Andwiththatsummarised, we arrive,believe it or not, at thepenultimate subjectfor this series:castors

materials- youwill probably geta senseofthatfromthe picture- butonthatsimple foundation,and with theoverarchingproviso that different

Castors

To me,castors arethe secret to an easy lifeina workshop, especially forthose having workshopswithlimited space

whichis, let’sfaceit, allof us.Ifmounted on castors, a heavyobjectismoved with ease –rolledintoa corner if it’s in theway,moved to centrestagefor greateraccess or shiftedsidewaystoreclaim the workpiecedroppedonthe floor andlying beneath, inevitably just beyond arms reach.

In my ownworkshop, recently relocatedfrombasementto shed,and with theobvious exceptions of theworkbench, latheand pillardrill, almost everything else sits on largediameter rubber-wheeled castorsand boydoesitmake lifeeasier. JenniferAnn’s construction stand? On castors. Railway wagonstorage rack? On castors. Materialsstorage rack?You’veguessedit–castorsonceagain.

In short, if it’s in my workshop,heavy anddoesn’t have itsown wheels, then it’s on castorssothatI canshift it with ease.And that,let me assure youasI pausetorescue yetanother unionnut whichhas rolledbeneath thematerials storagerack, is arealboon

…and finally,rust

Didyou notice that,despite my rude remonstrationand belligerentbombast in Episode 18 of ButtersideDown,I have sinceremainedremarkably quietabout rust?Ifso, then please rest assured, frustrated Reader,for thetimehas finally arrivedtoredress the balance, correctthe omission anddazzleyou with my profound insights concerning thepreventionofthatnasty redoxide from formingupon ourdecidedly ferrous-laden workshop contents

Areyou ready? Drumroll please,for here it comes. Keep them oiled, don’tlet them getwet andiftheydo getwet,dry andre-oilthemas soon as youcan afterwards

What?Isthatit?

Well yes, disappointed Reader, that really is thecruxofthe issue, butwithyourpermission perhapsI should providea little more informationbecause I realisethat: (a)the statement wassomewhatunderwhelming

and(b) youhavepaidgood moneyfor this magazine and want to getyourmoney’s worth. So here we go

In my experience,to effectivelycombatrust we must tame that most significant rust-causing foein ourworkshop, theclimate.And while that sounds likea bitof achallenge,ifwecan address just twothings- humidity and temperature- then success is at ourfingertips

Water, watereverywhere

Now controlling humiditytheamountofwater vapour presentinthe air- is nota straightforwardexercise, so from apractical perspective thebestthatI candoisoffer asimplesuggestiontokeep humidity in check: please don’t bringwater into your workshop if youcan avoiditand,ifyou must bringwater in,takeitout againassoon as possible! Butyou’reabsolutelycorrect, while that is an idealand overarchinggoaland onetokeep firmlyinmind, it is arather impracticalsuggestion, isn’t it?So, as asecondattempt, here aresomemoreactionable recommendations to keep workshop humidity at bay:

1. If youhavea containerof water(or anywater-based liquid) in your workshop, then please keep it tightly sealed when notinuse to preventevaporation

2. Don’tuse agas heater to keep your workshop warm for, in addition to theriskof carbon-monoxidepoisoning whichwon’t do youany good at all, combustion generateswater vapour and raises humidity whichyou definitelydonot want

3. Seal andinsulateyour workshop,preferably includinga plasticvapour barrier,tokeep therainand damp squarely outdoors whereitbelongs

4. Installatleast onedecent extraction fanifyou can, preferably aquiet one, and turn it on whenever you arebrazing,working with a flame forany otherreason (remember: combustion generateswater vapour),

or indeed doinganything else involvingorgenerating water. Anddon’t forget,that includes painting with waterbasedpaints.

5. Avoidrunning steam enginesinyourworkshop! Yes, Iknowitcan be tempting,but don’tbe surprisedifeverythinggoes rustyafterwards. Andtoconclude, youmay have noticedthatitems 2, 3and 4fromthislistwere integral facets of my shedbasedworkshop– electricallypoweredheating,slavish attentiontocaulkingand insulation anda couple of decent extraction fans –and humidity limitationand rust prevention is part of thereason why.

Temperature: that’s thekey

Andfinally,wearrive at temperature, arguably themost importantfactorinthe fight againstrust.

Picturethisbucolic scene: therollinggrassy fieldsof ButtersideDown, still and sublimeinthe pre-dawn light,the sunsoon to break thehorizon.Asthe first rays emerge,the dawn chorus announcesthe arrivalofa newday andwesee that thefieldbeforeus, dryasa bone when we went to bed last night, is nowcovered in glistening dew. Beginning our morningconstitutional, we stride purposefully towards thedistant hamlet of Toast Landingand in very littletime ourshoes,brushingthrough the foliage,are soakingwet But why? we askourselves.Itdidn’t rain last night– it hasn’t rained fordays– so wherehas allthis watercomefrom?

Theanswerofcourse, and this won’tcomeasa surprise, is that as thesun setthe previous eveningand heat from theunsheltered meadow beganradiating away into the cloudlessnight sky– outer spaceisa very effectiveradiant heatsink forsurfacespointing in itsdirection -its temperature begantofall. Eventually,the pasture’stemperature wasso low, lowerthanthe temperature

of thesurrounding air, that water, presentinthe airas gaseous watervapour, instantly turned to liquidasitmet the leaves of thesufficiently chilly greenery. Andthisprocess is of course called condensation, andthe condensedliquidwater on thegrass is called dew, andthe exacttemperature at whichthe grassbecame sufficientlycoldtocause condensation to occurand dew to form was, unsurprisingly,the dewpoint.And thus,our feet became uncomfortablywet the following morning.

However, condensation doesn’tjustoccuronthe verdantfields of Butterside Down,itwill happenonany surfacewhich is colder than thedewpointofthe surrounding air. Andifthat surfaceisa machinetool or a model, andthe airiswithinyour workshop,thenthe former will liberatewater from thelatter andyourpreciousitems will soon be coveredwithliquid H2Oand,not long thereafter, an unpleasant patina of Fe2O3 Fortunately, thepreventionof this sadstate of affairsisvery straightforward: allwemust do is keep thetemperature of theitems within ourworkshops abovethe dewpoint.

With that simple fact stated,whatdoesthismean in practice?Well, first and foremost,itmeans that we must always maintain the temperatureofour workshops abovethe dewpoint whether we areworking in them or not. Furthermore, because thedewpointcontinually changesthankstoa variety of factors, andittakes along time fora lathe(forexample) to warm up if it’s been allowed to gettoo cold,itiswiseto always maintain adecent margin -several degrees at least- between theworkshop’s temperatureand thedewpoint. Nowthat’sall well andgood, butitdoesratherpresume that we know thedewpoint in thefirstplace,doesn’t it?Furthermore,because thedewpoint’stemperature constantly changes(to use my ownwords againstme) it also presupposesanelement

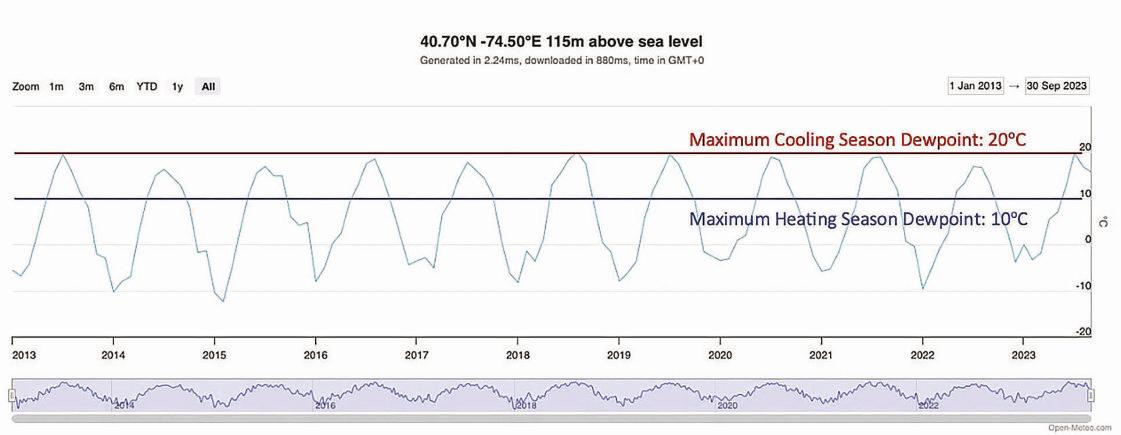

Internet search provides awealthofhistoricaldewpointdata(Source:Open-Meteo.com)

of clairvoyance.Put simply,we need to notonlyknowwhat thedewpointisnow,but also what it is likelytobeinthe near future to ensure that ourbulky andslow-to-warm-up workshop contents aren’t toocoldfor that laterdate.

Again, fortunately, this is anothersolvableproblem for, while thedewpointdoes indeed vary,there exists a mountain of freelyavailable historical weatherdatawhich canbeusedtoour advantage. Figure 12,for example, charts theaverage monthly dewpoint in my localareafor themost recent tenyears,located and downloaded from theInternet in fiveminutes flat, andyou will spot adistinctlycyclical pattern in thedata. Furthermore, you will also notice that Ihave

superimposed twohorizontal lines on thegraph –the upper onered andthe lowerone blue -representing, in the former case,the maximum historical average monthly dewpoint during thetypical air-conditioning (cooling) season (roughly,Junethrough to September) and, in thelatter, itscounterpart during the typicalheating season (roughly, Octoberthrough to May).And thesefiguresrespectivelyare: 20 degrees Celsiusand 10 degrees Celsius.

Butbeware, forthisdoesnot providea true picture, forthese areaverage monthly values, andwhile thegraph provides confidencethatone year is very much like anotherinthe grand scheme,you (likeI)knowthat humidity changesfar more

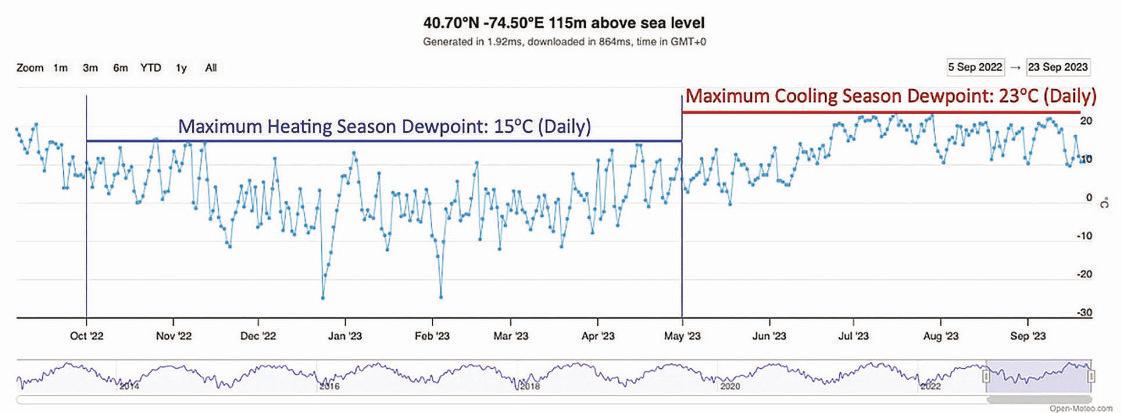

frequently than once amonth Fortunately, thesedatasources arebased on measurements takenmuchmorefrequentlyeverytwo minutes, wouldyou believe -and thecloserwe zoom in,the more detailedthe picturebecomes.But there’sno need to go toofar and, knowing that my insulated, sealed and equipment-filledworkshop will providea decent buffer to smooththingsout,I’m content to refinethe investigationtothe average daily humidity figures forthe past year:a maximum of 23 degrees Celsiusinthe hotseasonand 15 degrees Celsiusinthe cold as it turns out(fig 13).

Andwithjustthose two simple pieces of information in hand,wenow know that, provided Imaintainthe

shed’s temperatureabove 15 degrees Celsius(59 degrees Fahrenheit)inthe frigid winter, anddonot cool it below23 degrees Celsius(73 degrees Fahrenheit)inthe sweltering summer, then,unlessI unwisely raisethe shed’s internal humidity by running steam enginesorwashing thefloor (for example),the chance of condensation forminginmy workshop is virtually zero.And that,toconclude, is knowledge Ican use.

Wasall theeffor t worthit?

Ah,the sixty-four-thousanddollarquestion. Well, Inow have anicenew officeinwhich to read andwrite andcollect my thoughts,a comfortable andergonomic newworkshop

Delvingfurther,wediscoverthat, on adaily basisinmylocationduringthe pastyear, themaximum daily dewpoint during thecold-weatherseasonwas 15 degrees Celsius andthe equivalent during thehot season was23degrees Celsius(Source:Open-Meteo.com)

Aquick

Fig 12

Fig 13

Yes, it does seem awhole lotsmallerwhenfull!

in whichtopracticemodel engineering, andJenny will soon be able to depart the dining room forher newoffice in ourhouse’s basement.All in all, from this perspectivethe resultsare decidedlypositive. Regardingthe mini-split heat pump system;Intruth, it’s earlydaysasyet.However, with theusual hotsummerand typically cold winter behind us,I am extremelypleased with theresults so far. This summer, with thesystemin air-conditioning mode and settomaintaina temperature of 26 degrees Celsius(79 degrees Fahrenheit)withthe buildingvacant, anddespite daytimetemperaturesinthe mid-thirties Celsius(midnineties Fahrenheit)and the sunbeating down,the heat pump ranonlyoccasionally, itsenergyconsumption barely registeringonthe meter. In fact,comparing ourelectricity bills from thepasttwo years, ouraverage daily summertime electricityconsumption actually decreased by 2.5kWh this year compared to 2022, although theaverage daily ambient temperaturewas apparently also 2.75 degrees lowerwhich probably accounts forthe

surprising discrepancy.

Last winter however, with the system in heatingmodeand settomaintaina steady 16 degrees Celsius(61 degrees Fahrenheit)whenthe shed was empty, andwiththe day-andnightoutdoor temperature continuously well below freezing, thesystemcertainly consumed more energy during each 24-hourperiodthanitdid in thesummer. However, that wastobeexpected– it must work much harder to maintain astableindoor temperature in ourbrutalwinters –yet, with theinsulationdoing itsjob,I seefromthe bills that ouraverage electricity consumptionincreased by just 5kWh each daytokeepthe shed both habitableand rustfree while thewinterhowled outdoors.

In summary,therefore,ifI ignore thelower summertime energy consumptionasa fluke, andinstead assume that the additional energy required to air-conditionthe shed is negligible (all evidence points that waythusfar), andifI then extend thedaily additional 5 kWhtocover theentireeightmonthheating season,thenit appearsthatroughly 1200 kWh

forhabitationasthe system rampsupand theblower circulates theheatedorcooled airaccordingly.

In conclusion,I am,asI say, pleasedsofar;however,I’ll letyou know if that should change.

Wrapping things up

Well, that’s aboutit, patient Reader andtoparaphrasethe late,great andutterly peerless Humphrey Lyttelton:asthe loosehamster-wheel of time catapultsits occupant from thecageofeternity, andthe peckishfelineoffateenjoysa late-night snack, Isee we have reachedthe endofanother ButtersideDown mini-series.

of electricitywill be needed each year to runthe air-sourced heat-pumpand make ournew shed year-round habitableand keep rust at bay.

From theeconomicpoint of view,attoday’s prices in my neck of thewoods, this equates to roughlytwo hundredand fifty annual dollars -seventy cents perday -orfifty-twocents per square foot of floorspaceifyou prefer.Whichever wayI stateit, thefigure is certainlylessthan Iassumedwhenembarking upon theproject ayearago and that,ofcourse, is agood result Furthermore, mid-way throughthe winter Idiscovered that it is necessary to runonly oneofthe twoindoor heat exchangers to maintain the desiredtemperature when the shed is empty: theupstairs oneinthe summer(because heat rises) andthe downstairs oneinthe winter (for thesame reason), whichshouldhavea marginal positive benefit upon electricityconsumption in the future

Andfinally,uponenteringthe shed to beginworkeachday, aquick taponthe appropriate thermostat causes theindoor temperaturetoquickly rise (or fall) to more comfortablelevels

To wrap things up,itseems only reasonable to include onemorepicture of the finishedworkshop- toolsand shelvesinstalled andcovered models taking up much of the remainingfloorspace -and thereitisin photo119.And yes, it’s amazinghow much smalleritiswhenfilledwith stuff!

While it is unreasonable of me to hope that youenjoyed this fivepartepistle – endured is probably amoreaccurate word –I certainlyhopethat youdiscoveredsomething useful buried underthe mounds of fluff alongthe way. Perhapsyou (likeme) were strugglingtofind asimple wayoforganisingyourraw materialssothatthe right piececan be easily located? Or maybeyou have been wonderingwhether to rent a mechanical diggerfor your next excavation project? Or possiblyyou aresitting with teethchattering or sweat pouringand debating how to make your workshop a more habitableand less rust-prone place? If so,then Ihopethatmyexperiences areofsomebenefitand offer my best wishes foryourown endeavours to come

AndwiththatI wish you Adieu,dearReader, untilnext time

To be continued.

Nelly Nelly the Co pt er th eCop te r

Freya Hempenstall, of the EastleighYoung EngineersClub, triesher hand at aeronautical enginering

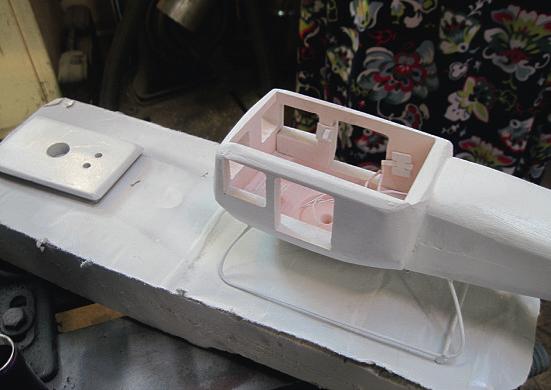

MynameisFreya and Iamnow 10. Ijoined theYoung Engineersin 2022 so Iwas 9whenI started and Nelly wasmyfirstproject Ilookedonthe computer and foundseveral helicopters.I picked outa simple oneand sawhow they aremadeand then copied onetomake Nelly Patrickwon’t work outwhatwe have to do.Hemakes us work it outfor ourselvesbut he does help.Hesaidthat Nelly would be fartoo heavytoflybut Istill made therotor on thetailand thepropeller on thetop spin usingradio controls

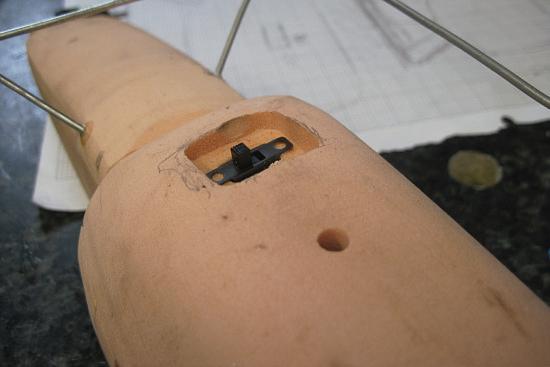

Patrickfound some pieces of pink hard plasticfoamand we decidedtocut thebodyfrom this.Itisveryeasytocut up butI am notallowedtouse the band saw.

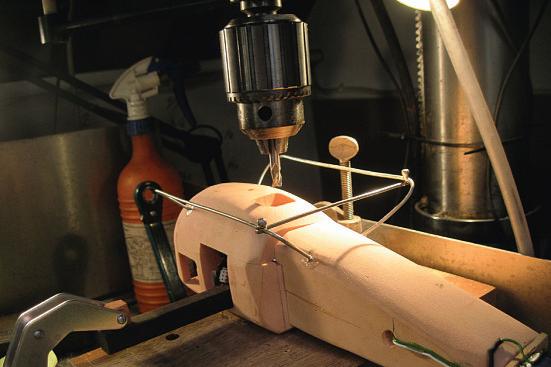

In photo1 youcan seehow I built it up in pieces.The pieces of foam areglued together with Superglue. Thebodyismade from fivepiecesand alid.The tail is made from twopieces. Youcan seethatI cutout four windowsand twodoor holes. Thesewerecut on themilling machine. Youcan seewhat youare doingwhenyou useit becausethe mill hasX andY

readouts so youalwaysknow howmanymillimetresyou have moved.

Thewindows areopenbut Iran into aproblem lateron andhad to coverthemwitha plasticsheet

Thetailismadeofa sandwich of twopiecesof foam screwedtothe body.For this Iuseda long wood screw. Ihad to putthe screwdriver throughone of thefront windows. Thewirefor the motoratthe back hastogo down aholethrough thefoam andI wasshown howtoget the wire throughthe long hole

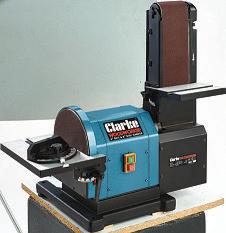

On thetop is alid whichfits fairly well andthathas the motorunderneathit(photo2). Nelly hasa blue light in her bottomlikeall helicopters When Imadethe body and thetail, Irounded allthe edges usingthe band sander

Rotorand motor

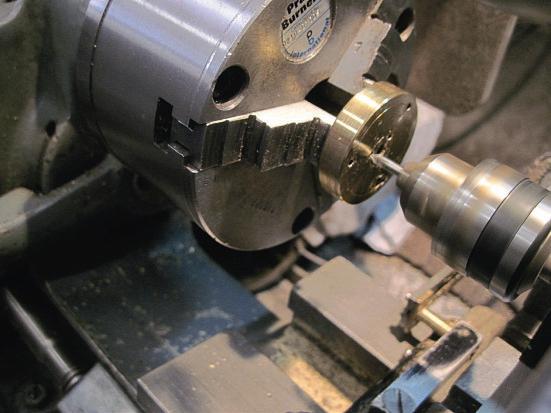

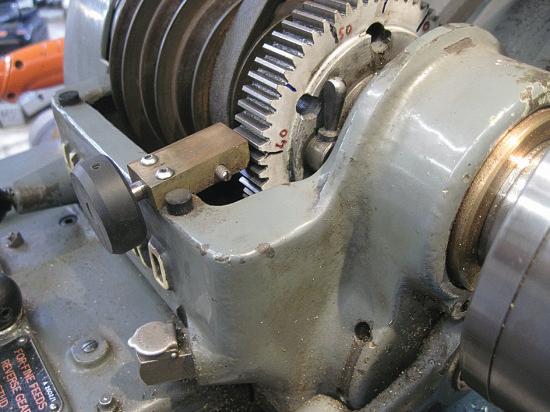

Themotor came with ametal bracketsoI gluedittoan‘L’ shaped pieceofaluminium then screweditinto Nelly’s lid.The rodcomingout of the motorisburiedinsidea hole in thelid andI made abig bush outofbrass to fit onto it.The bush wasmadeonthe lathe. I needed threerotor blades to be screwedonthe topofthe bush Thebig gear on thelathe has 60 teethand they arepainted with numberssoI drilleda centre hole andthenmoved another20teethand drilled anotherone untilI hadthree holesat120 degrees so it was exact. Youcan seemedoing it in photos 3 and 4

Then Iuseda 2.1mmdrill to drill theholes (where the centre holeswere) andtapped them M2.5.Todothe tapping Iput thetap in an electric screwdriverinstead of doing it by hand.Patrick says we should always do it by machine if we can. Irepeatedthis

Youcan seethe fvepiecesofthe cab, thetailand thelid

anotherthree timesunder the first holessoI then hadsix holes(twofor each rotor)

Therotorsweremadefrom threecoffeesticksglued on top of each other. Ihad aproblem mounting therotorsontothe motorbecause they areheldon with an M3 grub screwwhich

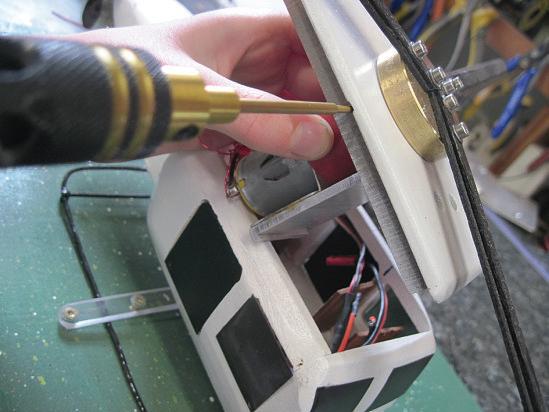

Itappedintothe bush butitis buried in thelid so Idrilleda long hole in from thesidesoI couldput akey into thescrew to tightenit(photo5).

Rear motorand propellor

Iwas givena littlemotor but it runs rather slowly.I was

Controlsystem.

also givena propellorwith threeblades. Themotor and propellorweremounted at Nelly’s tail (photo6). Iglued themotor to asmall pieceof acrylic plasticthenscrewed it to theend of thetail. Ihad to do this twicesince thegluegot inside themotor thefirsttime andstoppedthe gearsfrom turning.

Wiring

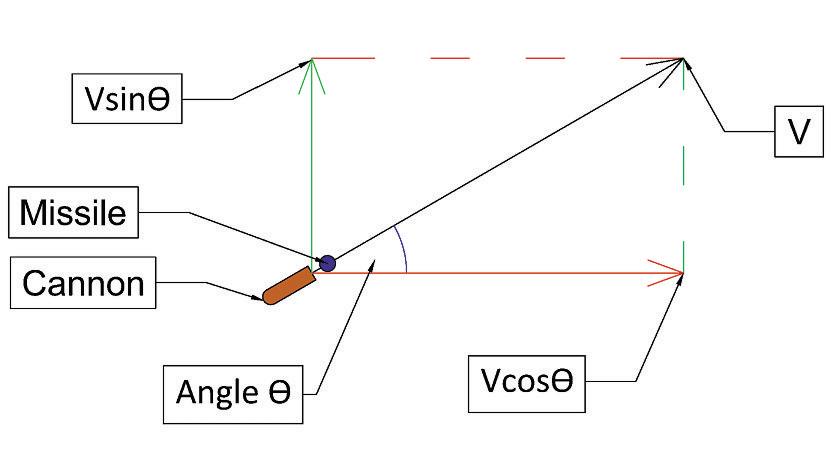

Nelly is radiocontrolledsoI was shownhow to make it work Thecircuit is drawnin fig 1

Thedifficultbit wassoldering thecablestogetherand then getting allthe bits andpieces into Nelly.WhenI soldered wirestogether, IusedShrinkFittocover over thejoints. Solderingand shrinkingwere very difficult inside Nelly.I needed aswitchtoturnthe motors on.The switch came with theelectronicspeed controllersoithad to be cutoff andthenjoinedupagain.First, Itried to putthe switch in the roof of Nelly,soI drilleda hole at thetop,but that didn’t work

Drillingthe sixholes in thebrass rotor.

Grub screwburiedinthe lid.

Tail rotor.

Indexing usingthe lathegear.

Rotor

so Icovered theholewithfiller anddrilledanother hole down throughthe bottominstead (photos 7 and 8). Themotor wastoo tall to fit in Nelly so Iuseda 32-millimetre diameter cutter to drill aholeinthe bottomof Nelly’s base.But then there wasa hole in at thebottomof whereI haddrilled. To hide it I gota blue LED(LightEmitting Diode) light andstuck it in theholetowireitup. It was

very hard though to getthe solderingironinto Nelly.The light is connected to thebattery so when Iflickthe switch to turn thebattery on thelight immediatelyturns on too.

Inside Nelly,there wasn’t much room so Ihad to arrange thewiringcarefully.I used Velcro andhookstokeep theelectronics in place. I used Velcro insteadofgluing everything,soI couldtake anything outifneeded

Stand, Painting andthe landing‘field’

Nelly needed to stand. I wasshown howtobend2 millimetre copperwiretomake thestand.Itisstuck into four holesthatI haddrilledinto Nelly’s bottomateachend

Once Ihad gotone side to fit,I made anotherone exactlythe same

Idecided to paint Nelly white. First, Igaveher acoatof primer.Wealwaysuse spray cans of paintbut Ihad to paint thestand blackusing abrush Ithenusedblack spraycansto paintthe windowsand doors. Thewindows aremadeof plasticand thedoorsare made of aluminium.

Nelly hadtohavelanded on somethingsoI decided to make it afield. To do this I gota largepiece of plywood andpainted it green (with aHalford’s meadow green spraycan). Ithensplattered thegreen with spotsofwhite andyellowtolook likeflowers (photo9). Idid this by getting paintonthe endofa brush, then Ipulledbackthe brush hairsand letgosothe paint left littleyellowand whiteblobs on thegreen whichgavea flowereffect.The hedges are blackplastic swarfoff thelathe stucktosomemetal whichare then gluedtothe plywood with Superglue. Ialsosprayed the hedges dark green Ithenneeded to clamp Nelly to theboard.I gotsome Perspexand Patrick(usingthe band saw) sawedittothe right size then Irounded thecorners on theelectricbeltsanderand

drilledfourholes in it.After that Iput Nelly on theboard,then threaded thepiece of Perspex throughthe stands,thendrilled four otherholes this time into theboard then tappedwood screws though theholes Nelly wasnow clampedintoposition. Thewindsockwas made from some aluminium(which Ipainted orange)and akebab stick. Windsocksare roundso Iwrappedthe aluminiumround thickmetal rodthenglued the ends together.I used plastic to make asmall ring around asection of thekebab stick. Ithendrilleda hole into the plasticand glueda smallrod into thehole. Iglued another rodnearthe top. Finally,I wrappedsomestringround both rods andattachedthe metalwindsocktomakea pulleysystemtomovethe windsock up anddown. United Kingdomaircraftare identifiedwithregistration letters whichalwaysstart with G- then four letters.I used my initials as some of theletters so Nelly’s registration plateis G-FEHW Nelly theCopterisin photo10

Nelly wasshown at the Littleton andHarestock (Winchester) Show in Septemberand wonthe second-place Junior prize. Nelly will be on theEastleigh YoungEngineers Standat WarwickinOctober.Please come andsee her.

Millingout aholefor theswitch.

Me splatting thegrass.

Nelly theCopter.

Fitting theswitch.